c3ccda69d5dc62b1d33a52423ba81765.ppt

- Количество слайдов: 16

Subsea Standardization

Brief History • SPE ATW on Subsea Standardization held Dec 2008 – Form workgroup for further review – The purpose of the workgroup would be to: • Identify potential areas of industry standardization • Obtain cross section of industry input on standardization issues • Present API SC 17 with recommendation for moving forward at Summer Meeting in June 2009.

Prep for API 2009 Summer Conf Performed rationalization of potential areas of standardization • Materials • Welding • Quality Management

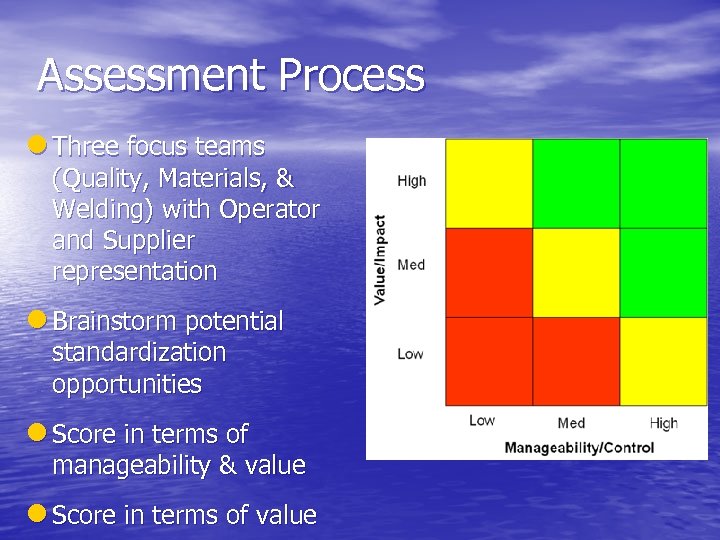

Assessment Process l Three focus teams (Quality, Materials, & Welding) with Operator and Supplier representation l Brainstorm potential standardization opportunities l Score in terms of manageability & value l Score in terms of value

Summary • Industry standards have surpassed standard API 6 A requirements • Specific requirements have been identified to pursue possible • codification Specific Areas of Opportunity are: – Quality Management l Standardize manufacturing record book contents and requirements l Standardize positive metal identification (PMI) requirements l Standardize traceability requirements for critical elements l l l Standardize nonconformance reporting and processes necessary to proceed with the work Align API 17 series specifications and RPs with QMS concepts and terms of API Q 1, ISO/TS 29001 and ISO 9001 Apply API “data sheet” concept to all API 17 series specs and RPs to communicate requirements

Summary (Cont’d) Materials l l l Assign varying requirements according to the difficulty in making a given forging, the difficulty in obtaining the required properties in a given forging (taking into account engineering requirements, hardenability of the alloy, and section size of the forging) , and the consequences of a forging failure Imposing API RP 6 HT as a mandatory requirement for large forgings Allowing the current API 6 A options for QTC’s (separately forged test bar, prolongation, or sacrificial forging). If separately forged test bars are used, the manufacturer must provide technical justification for end user approval l Mandatory normalizing for large low alloy steel forgings l Preheat treat machining requirements (as necessary)

Summary (Cont’d) Welding l l l Group similar materials & grades (US vs Europe) to eliminate requirement for individual weld qualifications Adopt “Weld Criticality” ratings. Match welding / NDE requirements to criticality Join forces with other welding standardization committees already working the problem (i. e. API RP 582 and others)

Actions from API 2009 Summer Conference It was recommended that the SPE group continue their efforts to address the suggested optimization in Materials, Quality and Welding and generate a draft specification document.

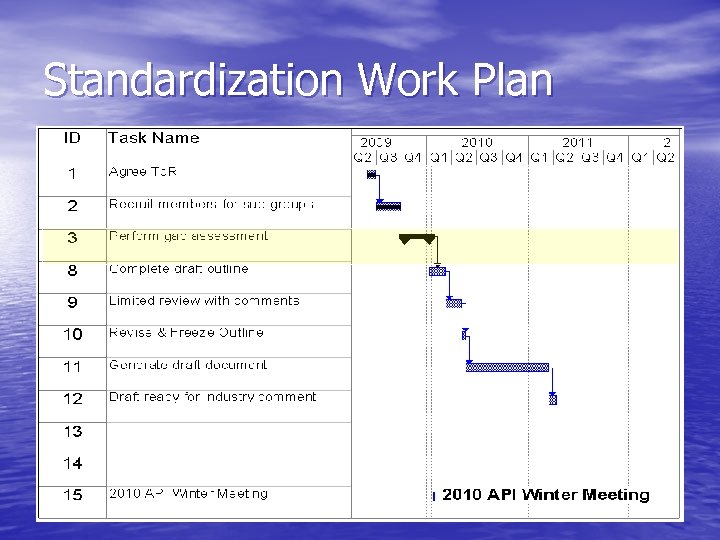

Standardization Work Plan

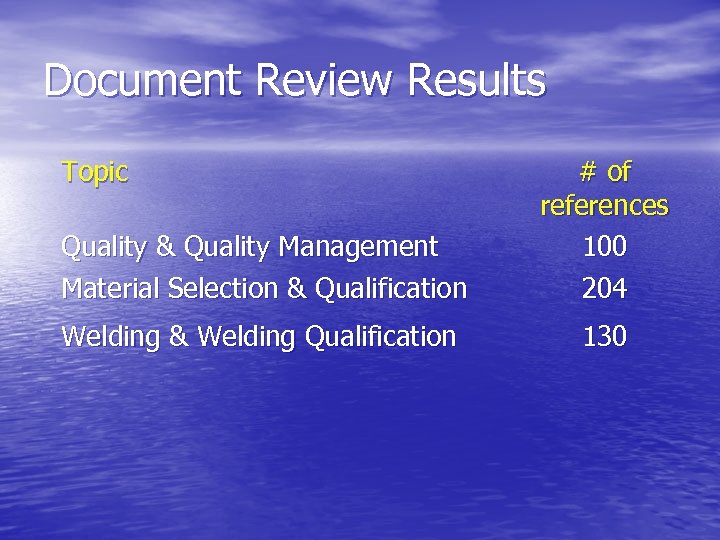

Recorded These References • Document Type • Document No. • Name & Rev • Quality and Quality Management • Material Selection and Qualification • Welding and Welding Requirements

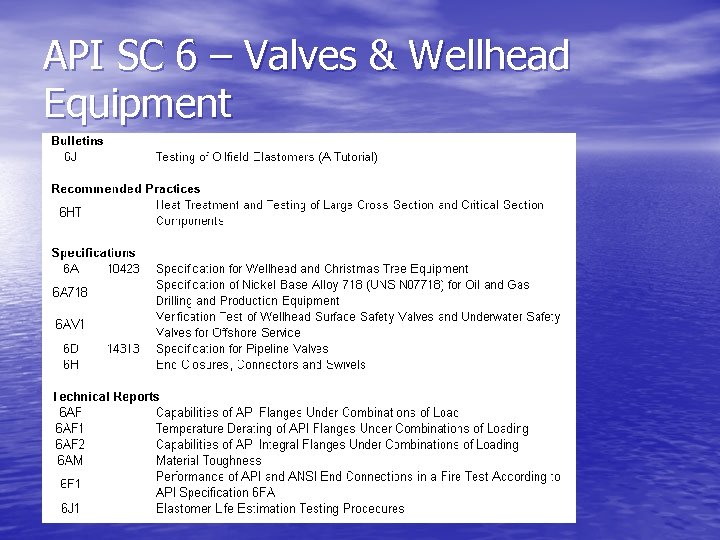

API SC 6 – Valves & Wellhead Equipment

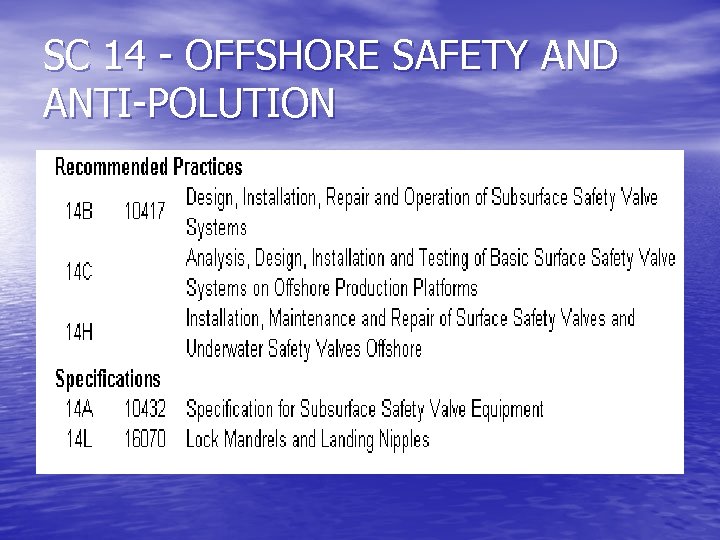

SC 14 - OFFSHORE SAFETY AND ANTI-POLUTION

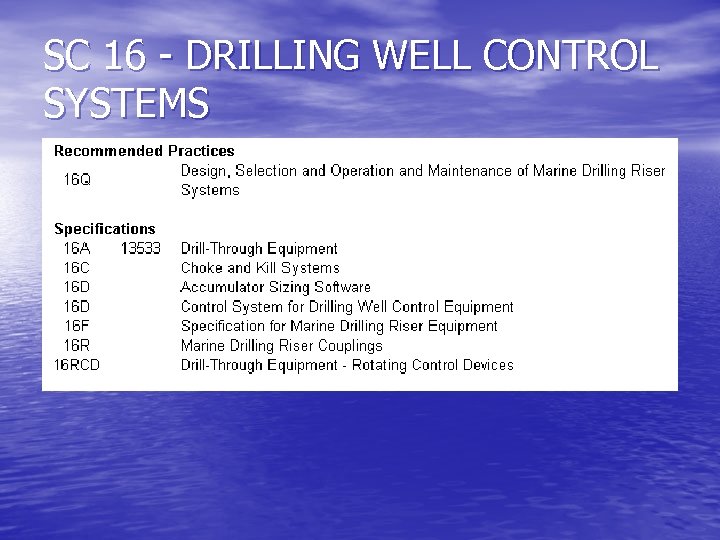

SC 16 - DRILLING WELL CONTROL SYSTEMS

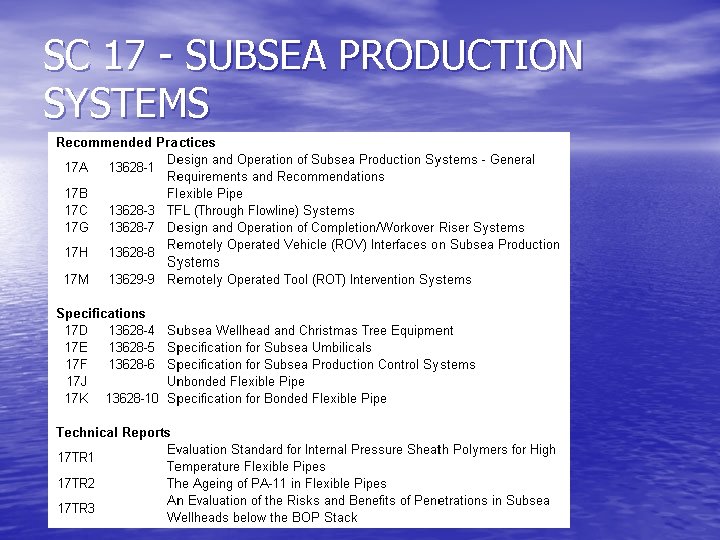

SC 17 - SUBSEA PRODUCTION SYSTEMS

Document Review Results Topic Quality & Quality Management Material Selection & Qualification # of references 100 204 Welding & Welding Qualification 130

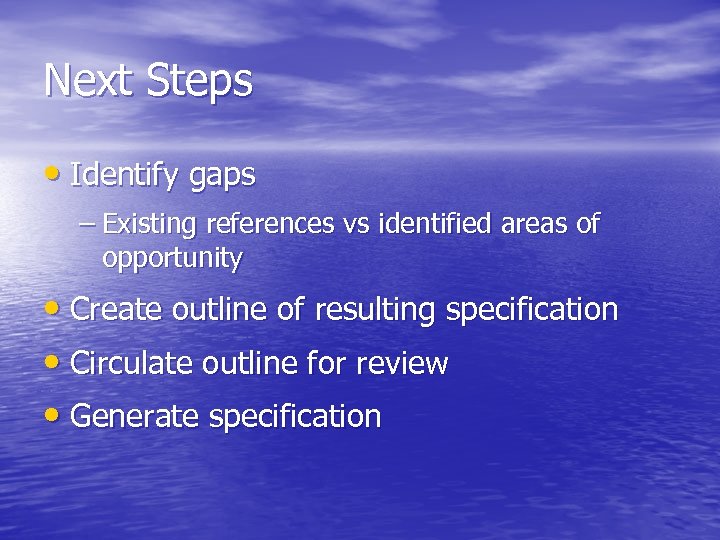

Next Steps • Identify gaps – Existing references vs identified areas of opportunity • Create outline of resulting specification • Circulate outline for review • Generate specification

c3ccda69d5dc62b1d33a52423ba81765.ppt