b1a5ce66a0da0283a2631dd7af5f57d1.ppt

- Количество слайдов: 92

SUBGRADE STABILITY and LIME TREATMENT APPLICATIONS at OMP Marshall Thompson, P. E. Professor Emeritus – CE University of IL @ U-C

SUBGRADE SOIL PROPERTIES * STRENGTH (CBR/QU) * MODULUS * RUTTING RESISTANCE

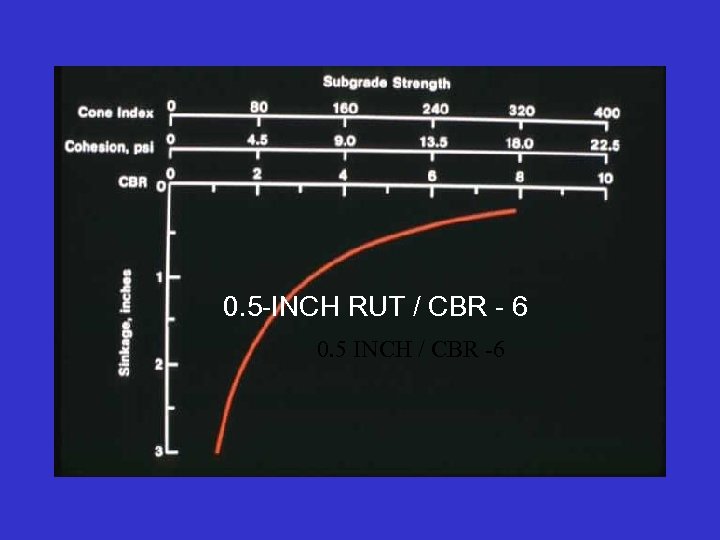

0. 5 -INCH RUT / CBR - 6 0. 5 INCH / CBR -6

SOIL COMPACTION

MATERIAL COMPACTION

MATERIAL COMPACTION

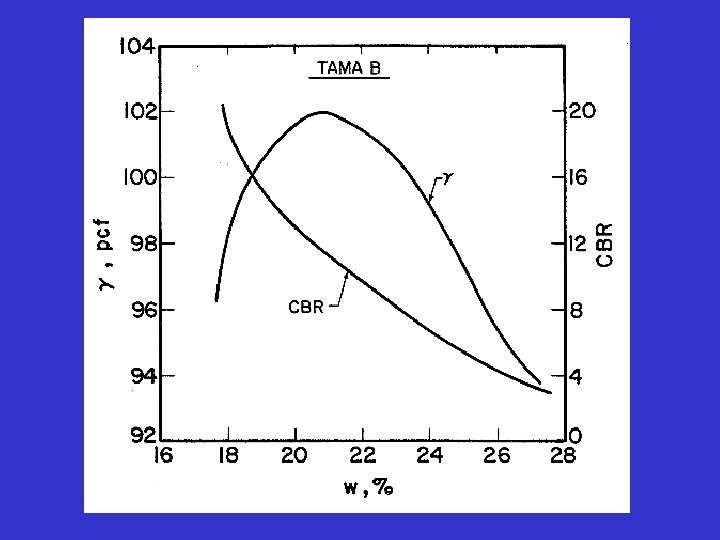

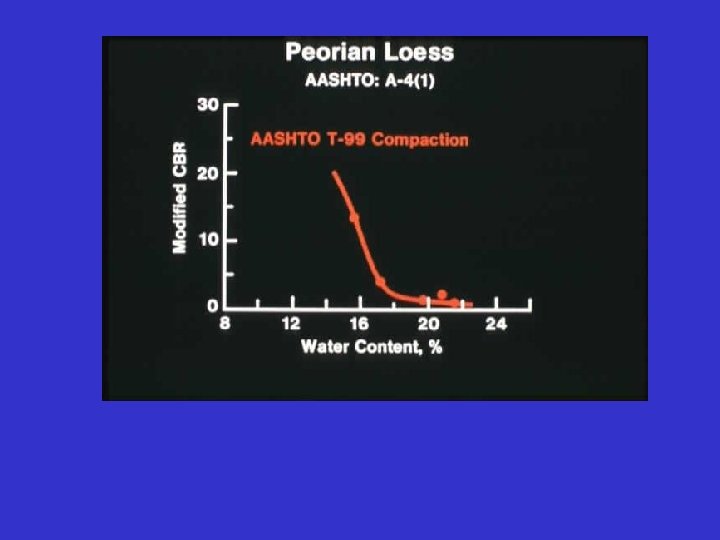

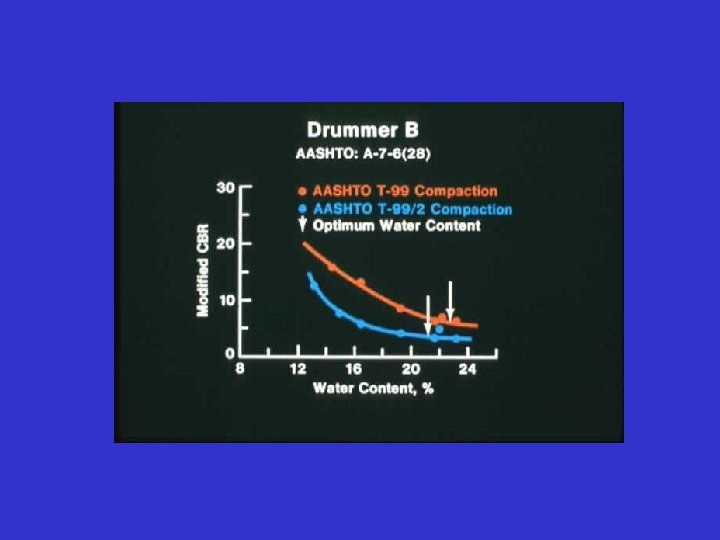

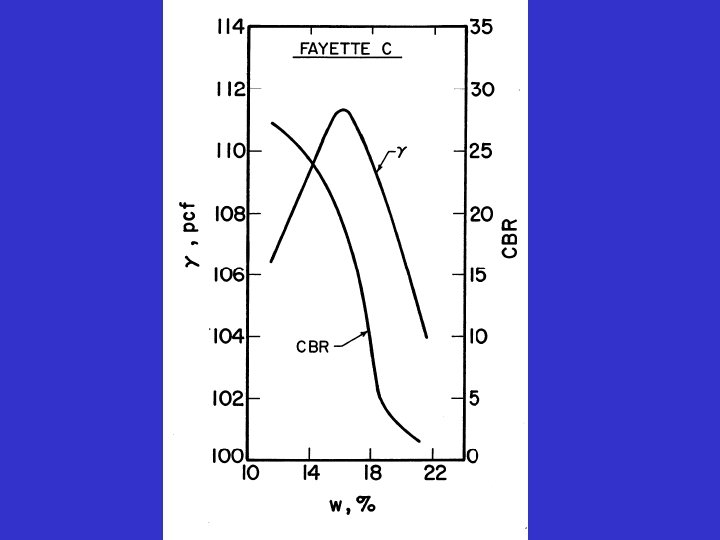

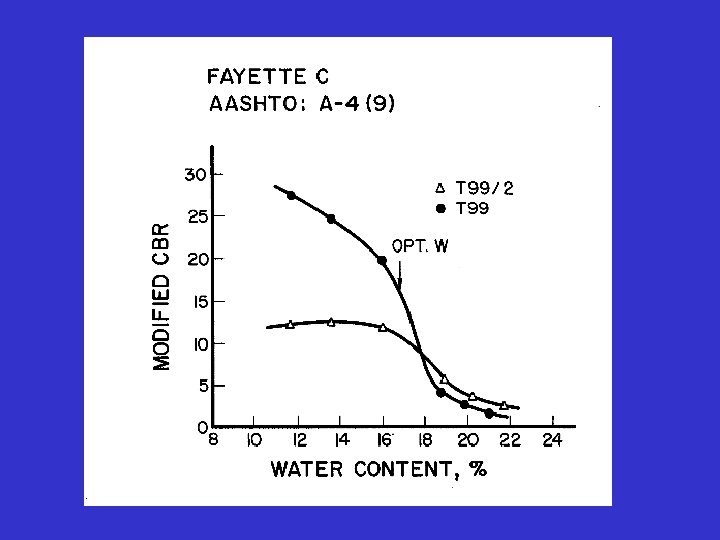

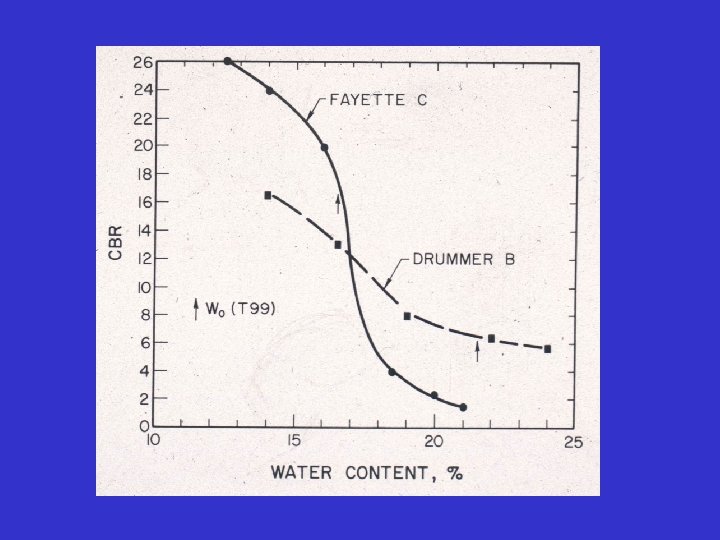

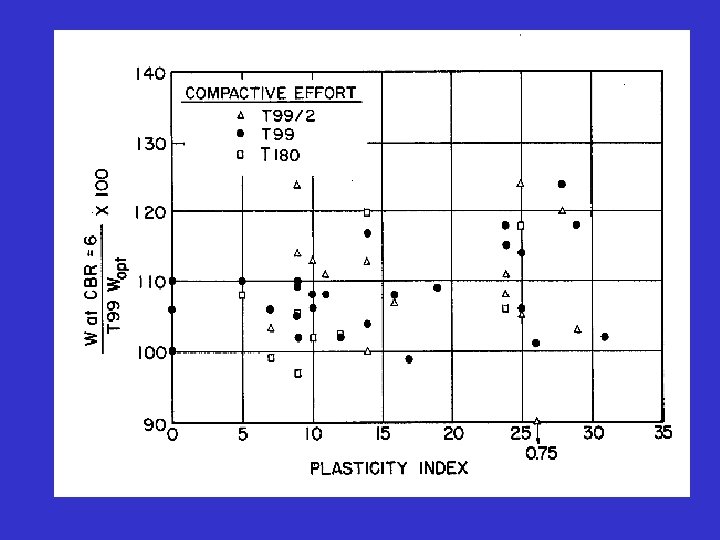

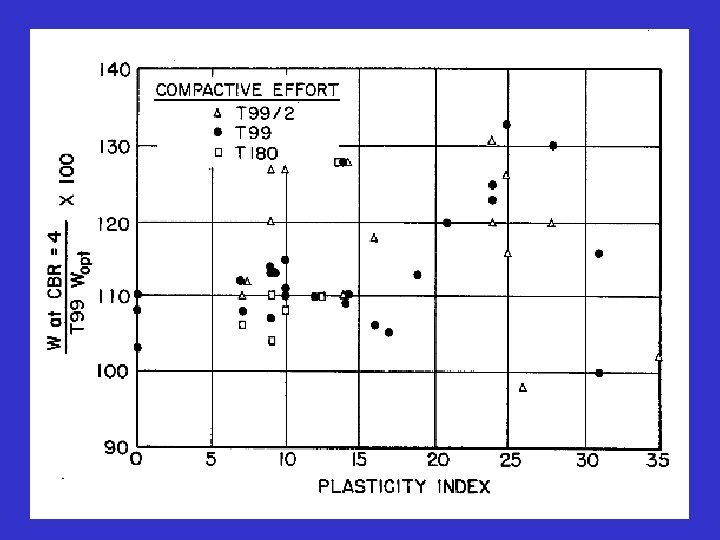

MOISTURE – DENSITY - CBR • Uof. IL / IDOT PROCEDURE • COMPACT MOLD • CBR ON “FINISHED” MOLD

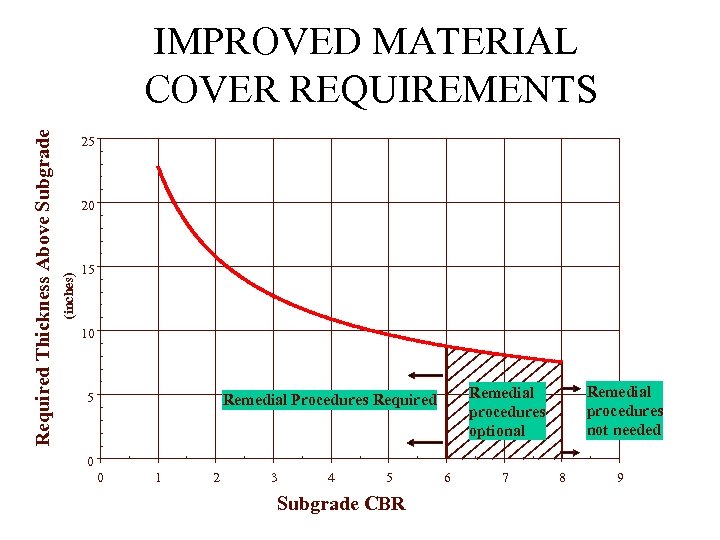

25 20 (inches) Required Thickness Above Subgrade IMPROVED MATERIAL COVER REQUIREMENTS 15 10 5 Remedial procedures not needed Remedial procedures optional Remedial Procedures Required 0 0 1 2 3 4 5 Subgrade CBR 6 7 8 9

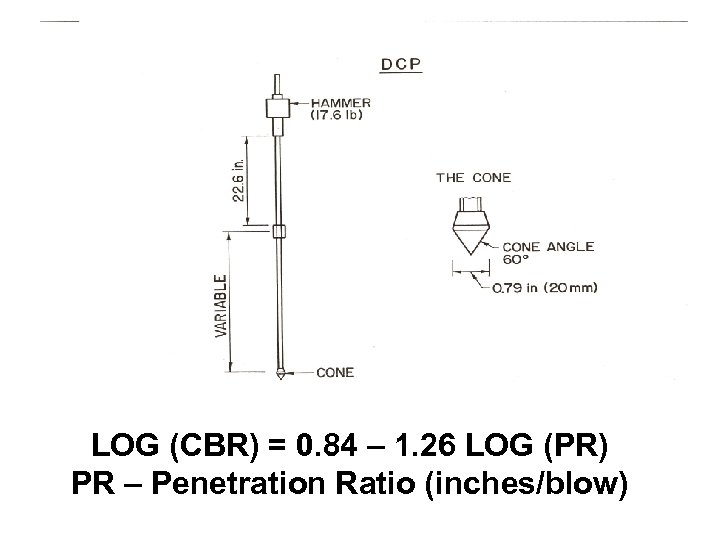

CE CONE PENETROMETER

CBR = CI / 40

LOG (CBR) = 0. 84 – 1. 26 LOG (PR) PR – Penetration Ratio (inches/blow)

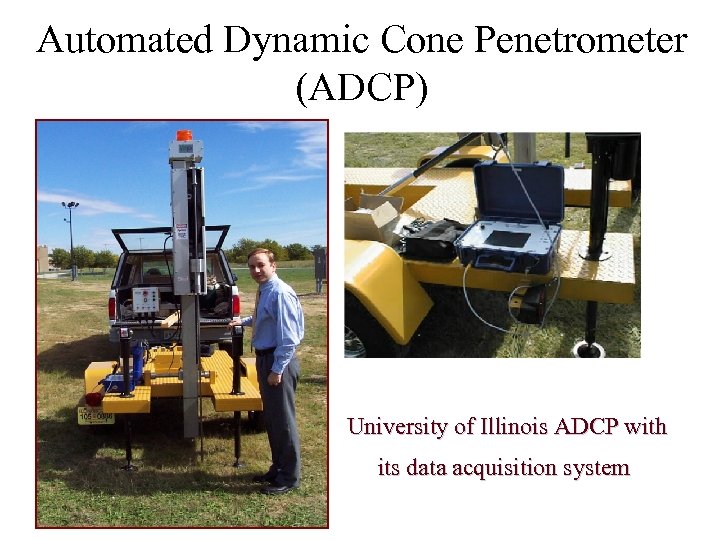

Automated Dynamic Cone Penetrometer (ADCP) University of Illinois ADCP with its data acquisition system

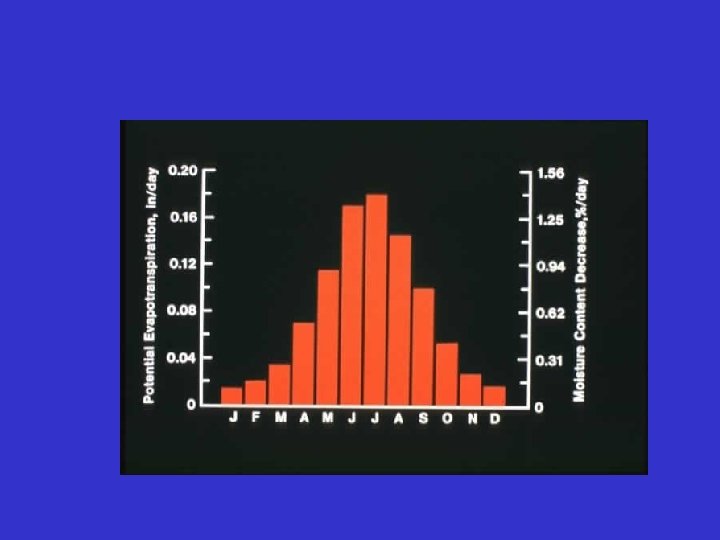

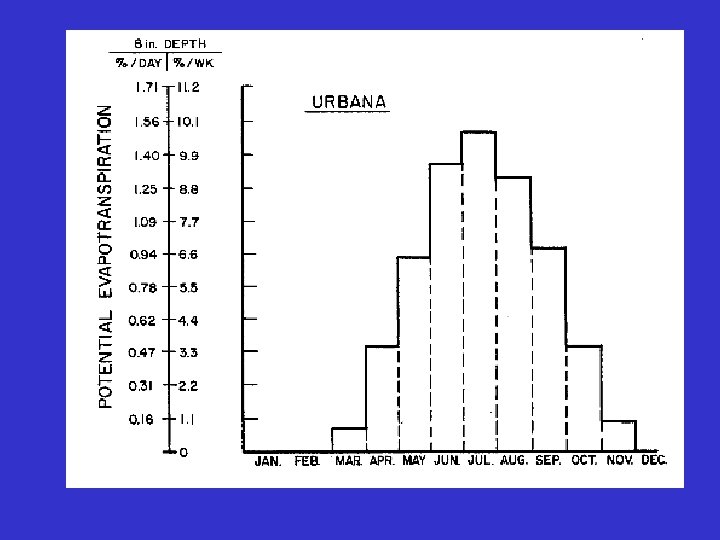

MOISTURE – DENSITY CONTROL DIFFICULTIES • DRYING EFFORTS = ? ? ? • DRYING DAY = ? ? ? (TEMP / ET) • # DRYING DAYS ? ?

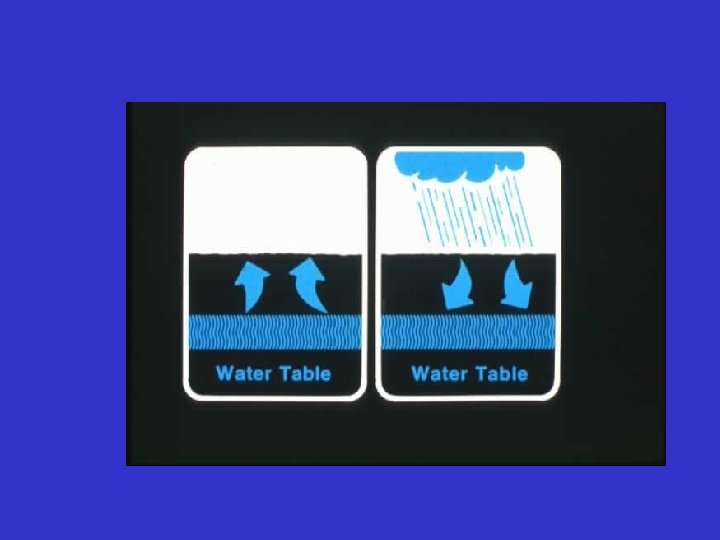

MOISTURE CONTROL IS TEMPORARY SOLUTION!!!!!

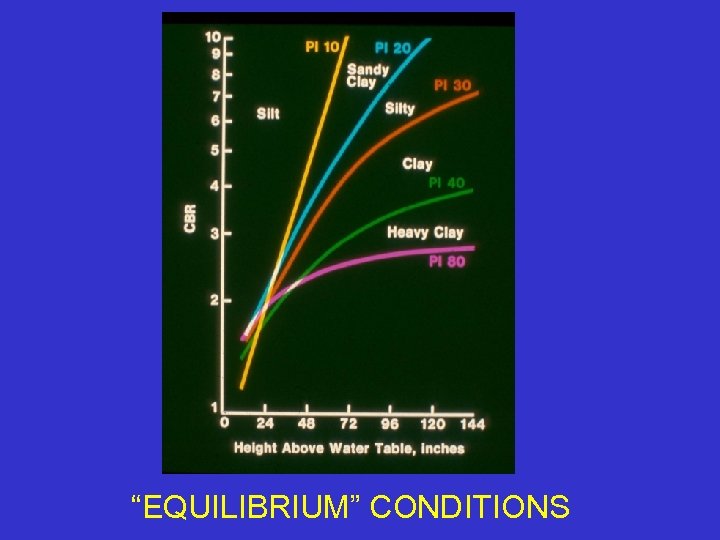

“EQUILIBRIUM” CONDITIONS

LIME PRODUCTS

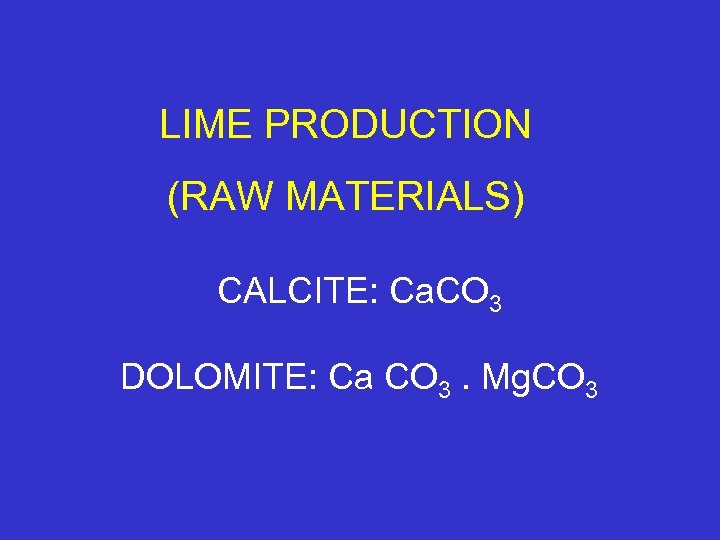

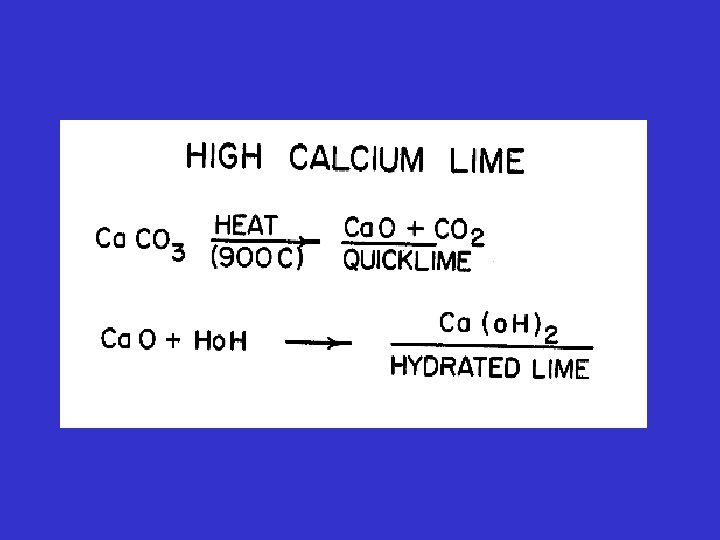

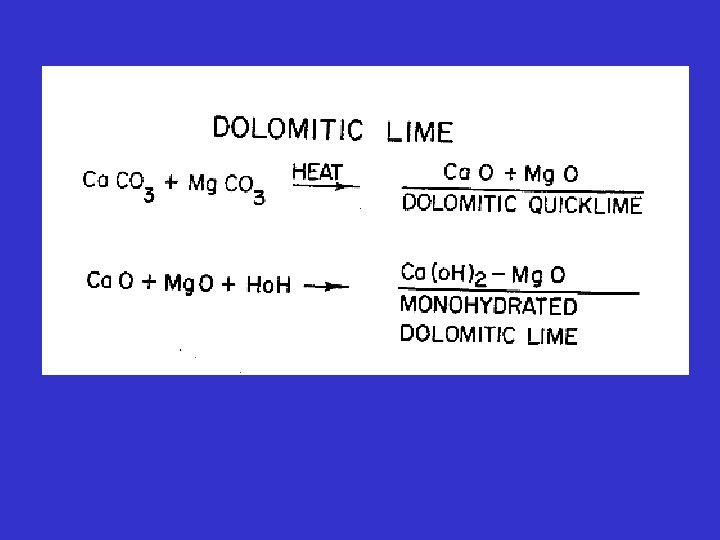

LIME PRODUCTION (RAW MATERIALS) CALCITE: Ca. CO 3 DOLOMITE: Ca CO 3. Mg. CO 3

QUICKLIME (QL) FINES SOME QL PARTICLE SIZES ARE << SMALL FOR HYDRATION PRODUCT = QL FINES

LIME KILN DUST (LKD) FINELY-DIVIDED “DUST” FROM THE KILN STACKS

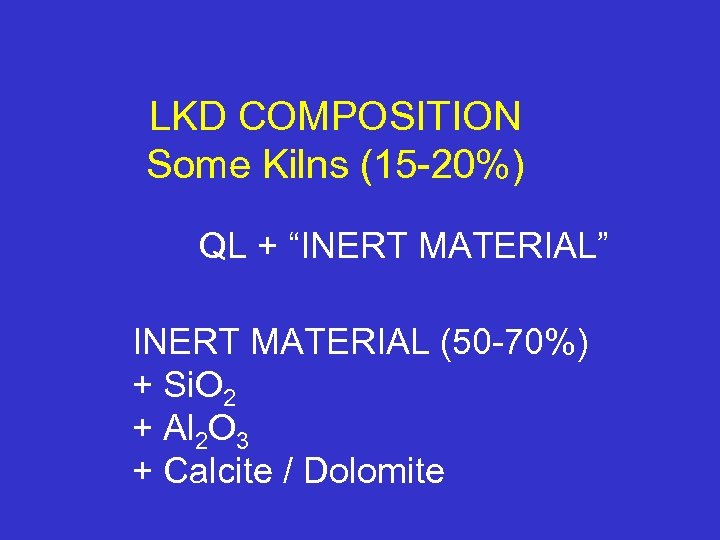

LKD COMPOSITION Some Kilns (15 -20%) QL + “INERT MATERIAL” INERT MATERIAL (50 -70%) + Si. O 2 + Al 2 O 3 + Calcite / Dolomite

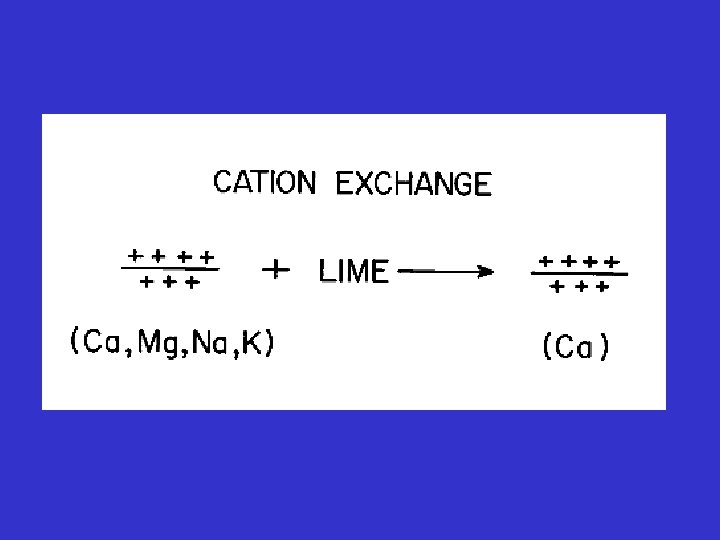

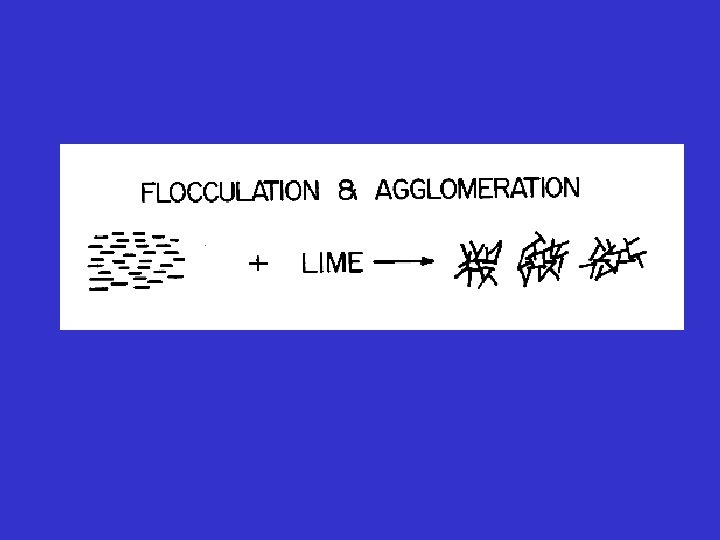

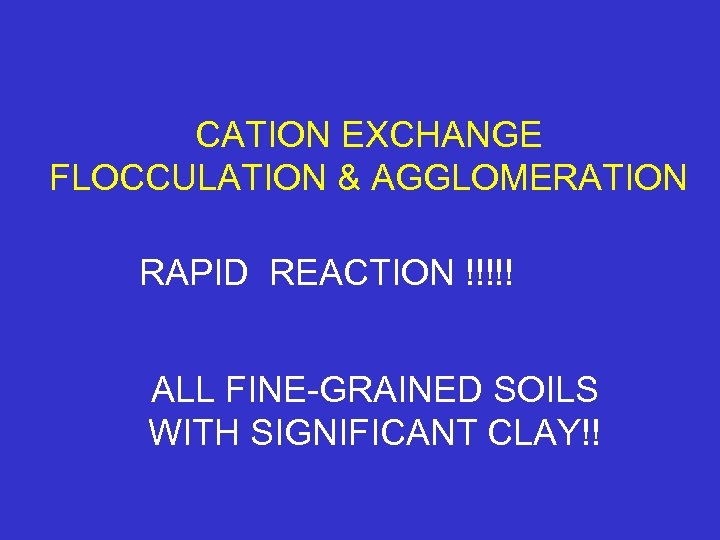

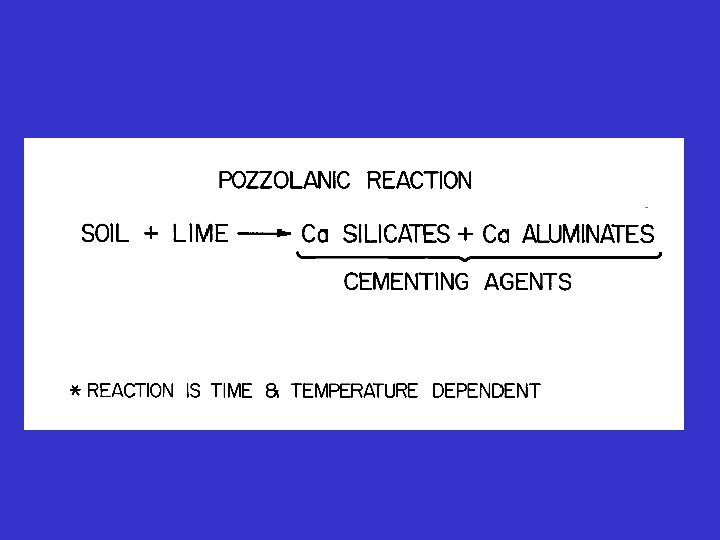

CATION EXCHANGE FLOCCULATION & AGGLOMERATION RAPID REACTION !!!!! ALL FINE-GRAINED SOILS WITH SIGNIFICANT CLAY!!

NOT ALL FINE-GRAINED SOILS ARE “LIME REACTIVE” !!!!

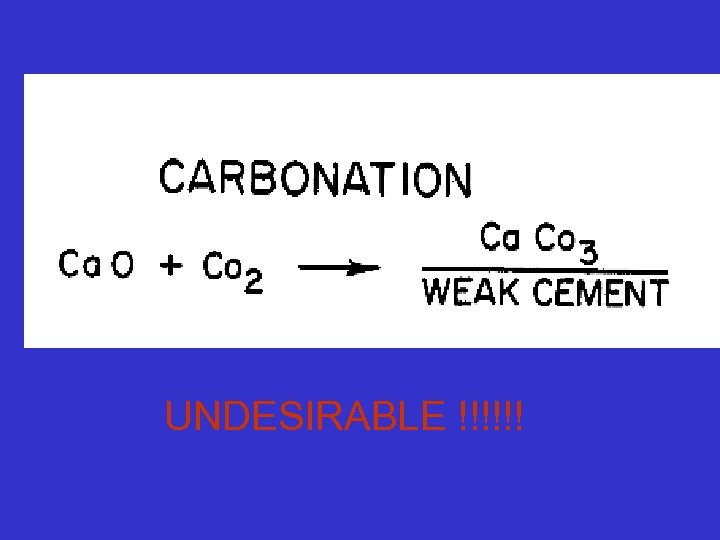

UNDESIRABLE !!!!!!

IMMEDIATE EFFECTS

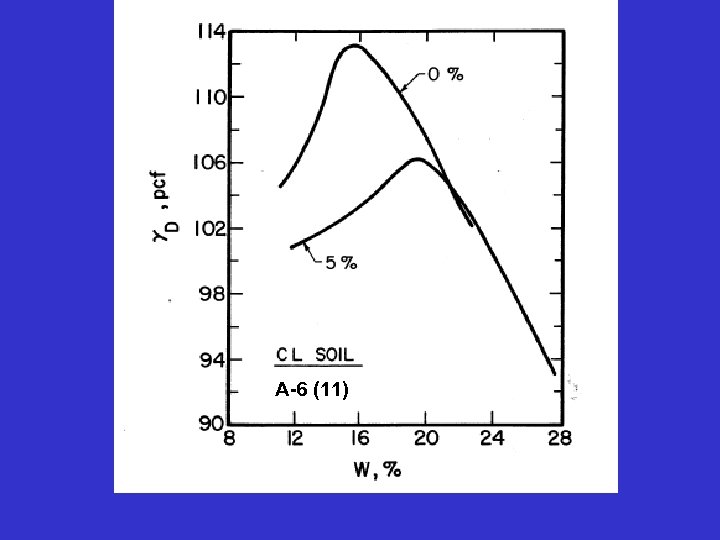

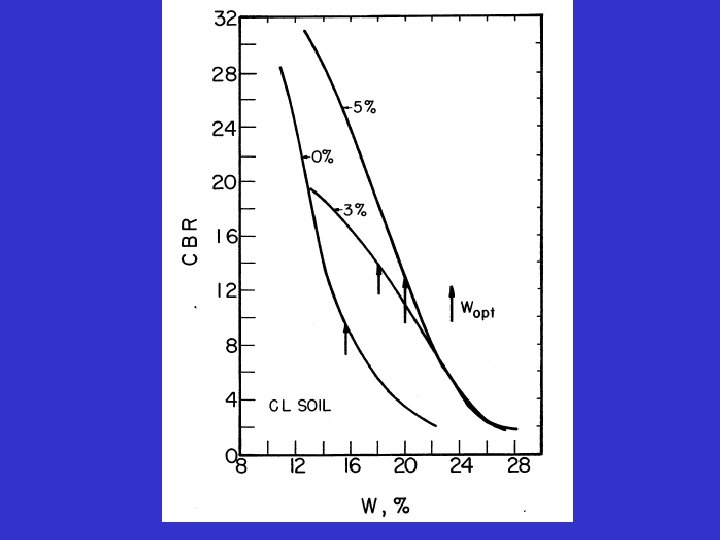

A-6 (11)

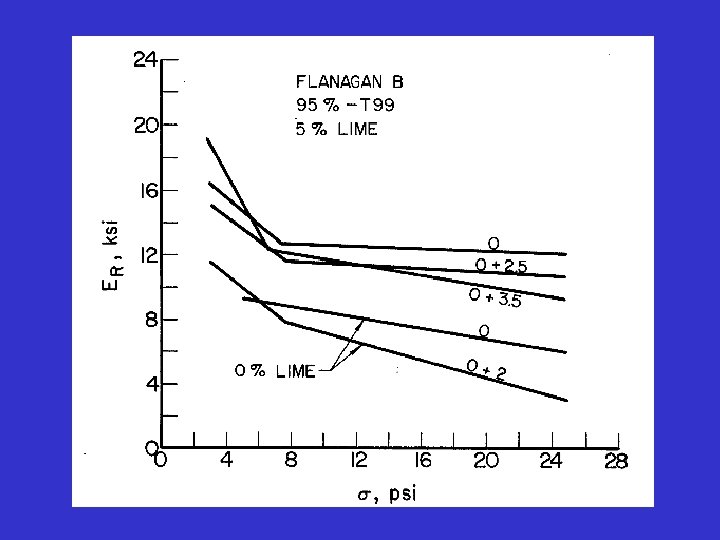

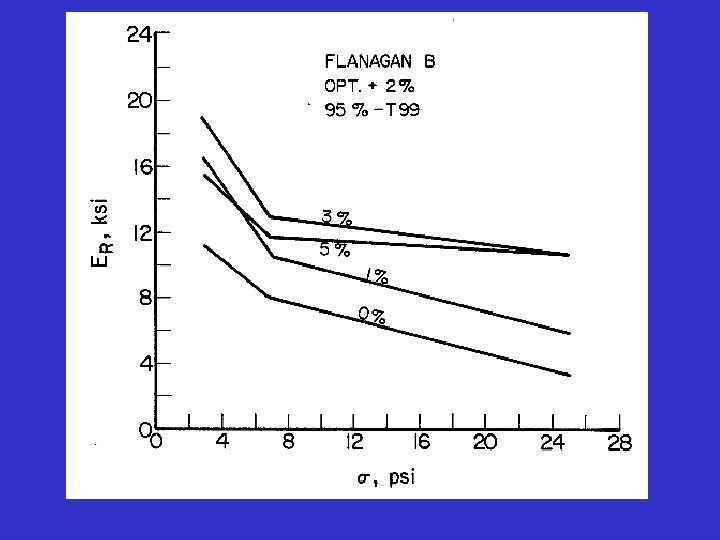

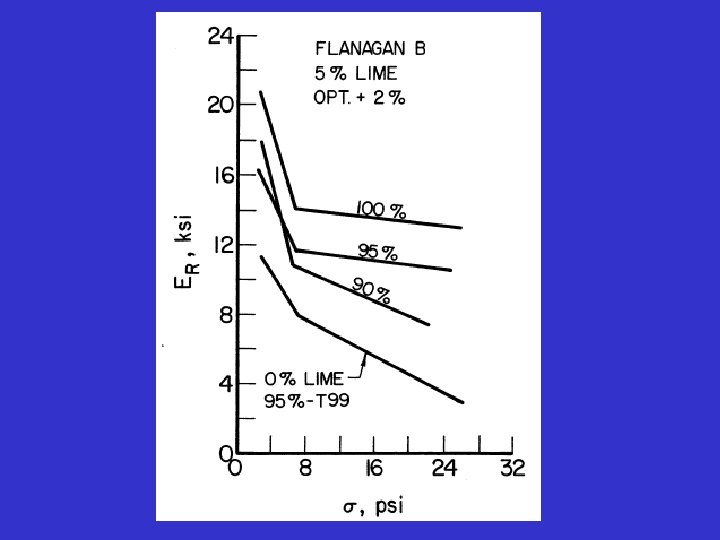

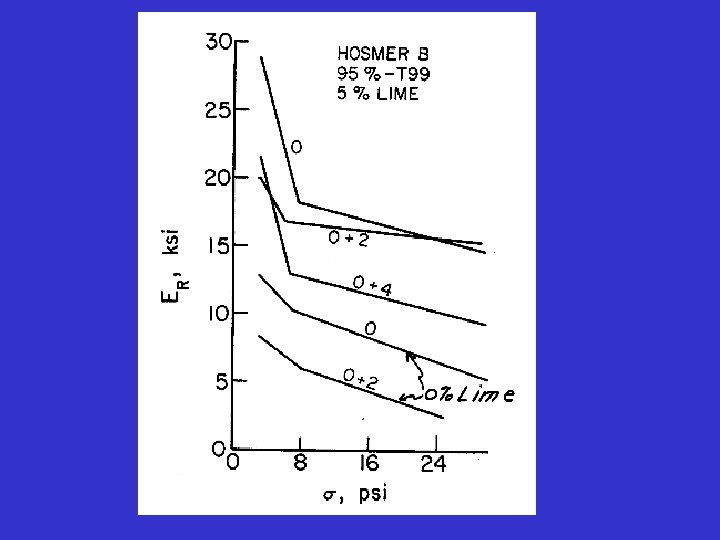

FLANAGAN-B 36% CLAY PI – 21 HOSMER-B 30% CLAY PI-22

CURING EFFECTS

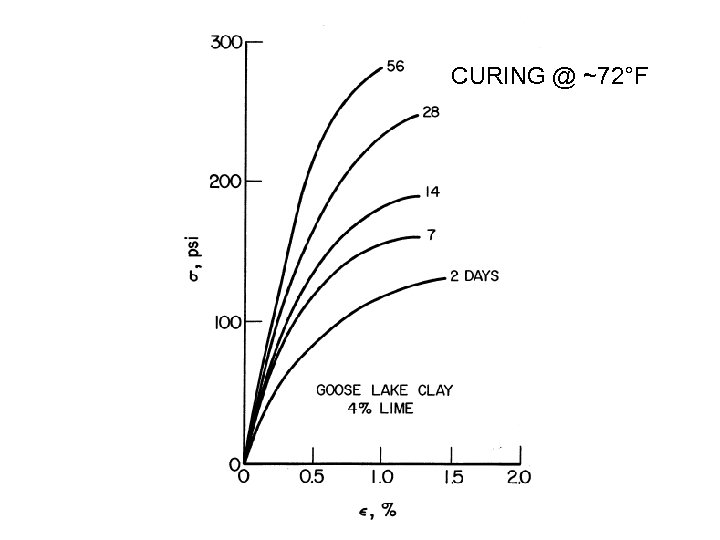

CURING @ ~72°F

CHECK MT. CARMEL SAND & GRAVEL VIDEO (CONSTRUCTION PROCESS)

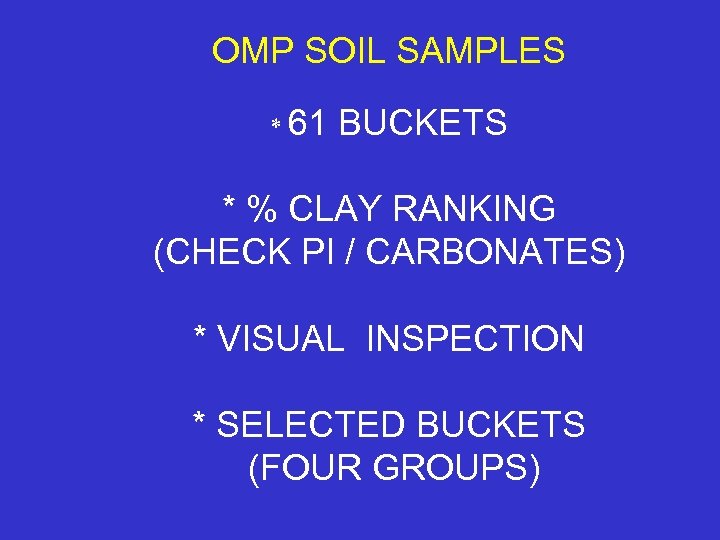

OMP SOIL SAMPLES * 61 BUCKETS * % CLAY RANKING (CHECK PI / CARBONATES) * VISUAL INSPECTION * SELECTED BUCKETS (FOUR GROUPS)

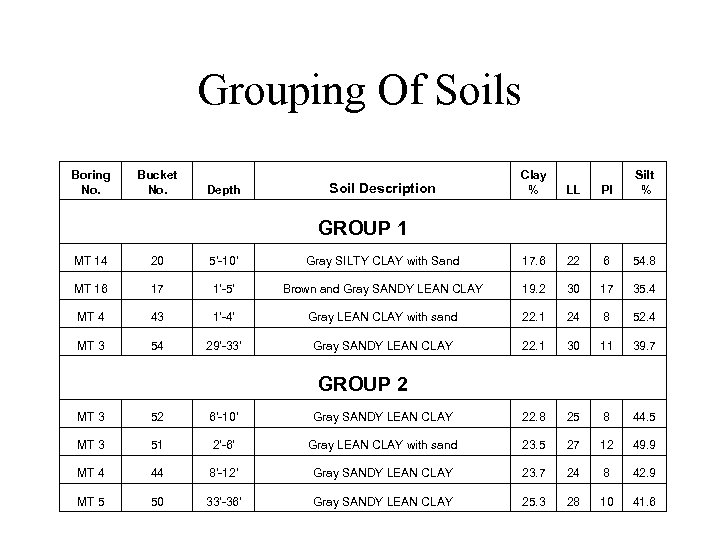

Grouping Of Soils Boring No. Bucket No. Depth Soil Description Clay % LL PI Silt % GROUP 1 MT 14 20 5'-10' Gray SILTY CLAY with Sand 17. 6 22 6 54. 8 MT 16 17 1'-5' Brown and Gray SANDY LEAN CLAY 19. 2 30 17 35. 4 MT 4 43 1'-4' Gray LEAN CLAY with sand 22. 1 24 8 52. 4 MT 3 54 29'-33' Gray SANDY LEAN CLAY 22. 1 30 11 39. 7 GROUP 2 MT 3 52 6'-10' Gray SANDY LEAN CLAY 22. 8 25 8 44. 5 MT 3 51 2'-6' Gray LEAN CLAY with sand 23. 5 27 12 49. 9 MT 4 44 8'-12' Gray SANDY LEAN CLAY 23. 7 24 8 42. 9 MT 5 50 33'-36' Gray SANDY LEAN CLAY 25. 3 28 10 41. 6

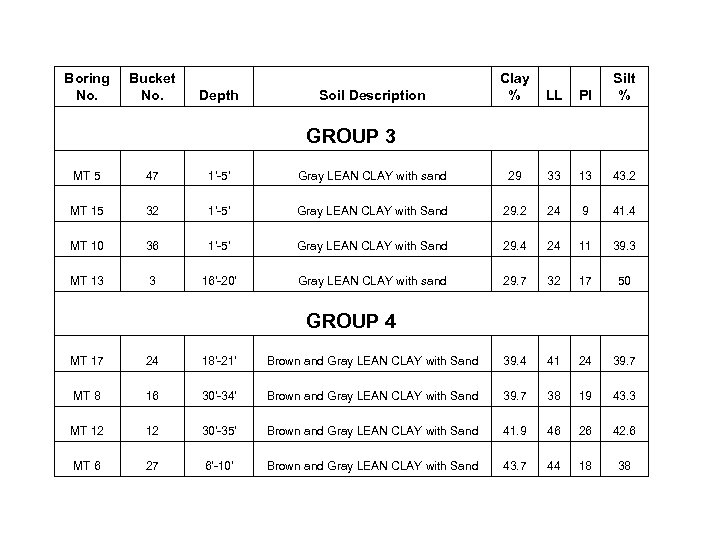

Boring No. Bucket No. Depth Soil Description Clay % LL PI Silt % GROUP 3 MT 5 47 1'-5' Gray LEAN CLAY with sand 29 33 13 43. 2 MT 15 32 1'-5' Gray LEAN CLAY with Sand 29. 2 24 9 41. 4 MT 10 36 1'-5' Gray LEAN CLAY with Sand 29. 4 24 11 39. 3 MT 13 3 16'-20' Gray LEAN CLAY with sand 29. 7 32 17 50 GROUP 4 MT 17 24 18'-21' Brown and Gray LEAN CLAY with Sand 39. 4 41 24 39. 7 MT 8 16 30'-34' Brown and Gray LEAN CLAY with Sand 39. 7 38 19 43. 3 MT 12 12 30'-35' Brown and Gray LEAN CLAY with Sand 41. 9 46 26 42. 6 MT 6 27 6'-10' Brown and Gray LEAN CLAY with Sand 43. 7 44 18 38

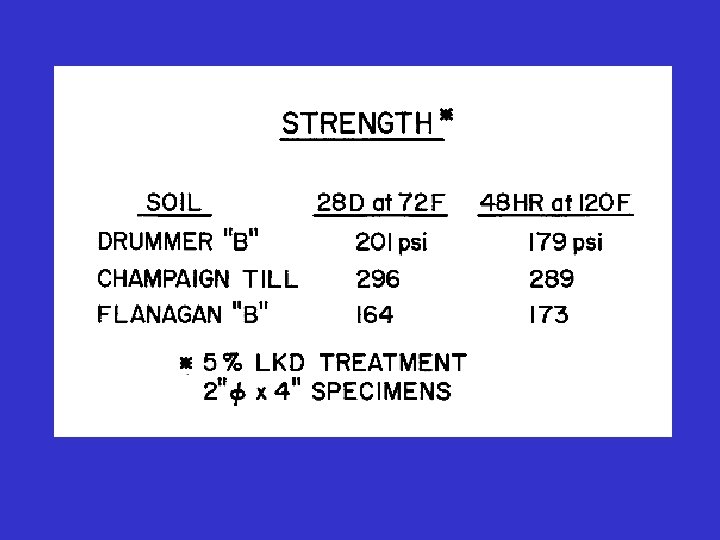

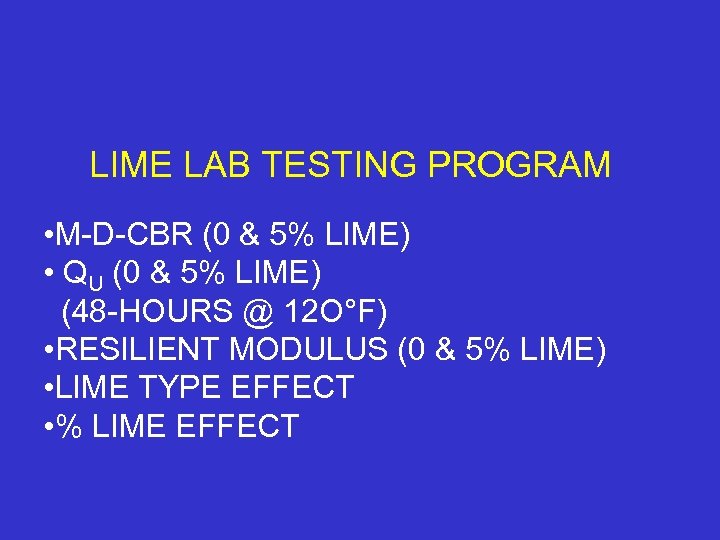

LIME LAB TESTING PROGRAM • M-D-CBR (0 & 5% LIME) • QU (0 & 5% LIME) (48 -HOURS @ 12 O°F) • RESILIENT MODULUS (0 & 5% LIME) • LIME TYPE EFFECT • % LIME EFFECT

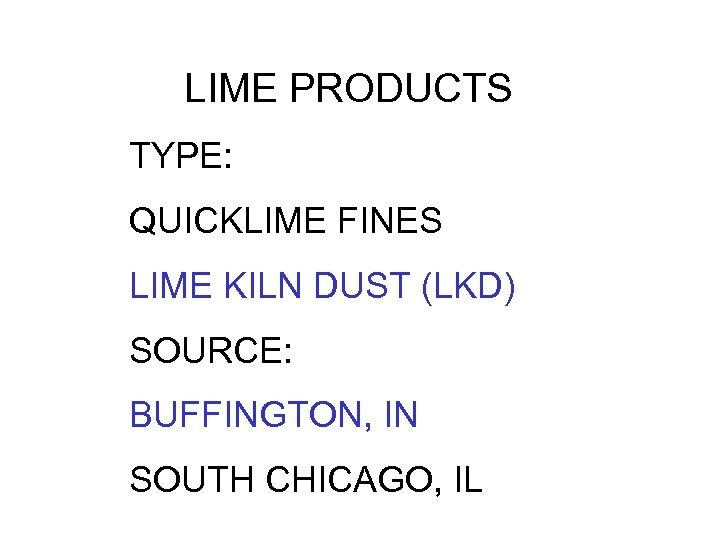

LIME PRODUCTS TYPE: QUICKLIME FINES LIME KILN DUST (LKD) SOURCE: BUFFINGTON, IN SOUTH CHICAGO, IL

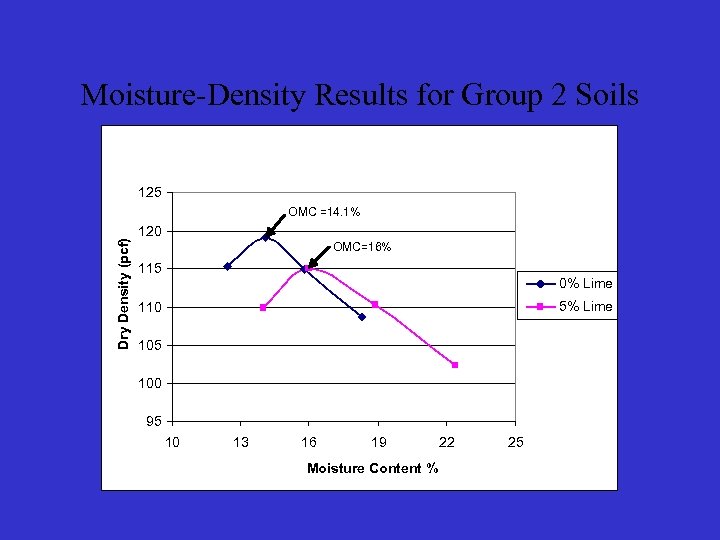

Moisture-Density Results for Group 2 Soils 125 Dry Density (pcf) OMC =14. 1% 120 OMC=16% 115 0% Lime 5% Lime 110 105 100 95 10 13 16 19 Moisture Content % 22 25

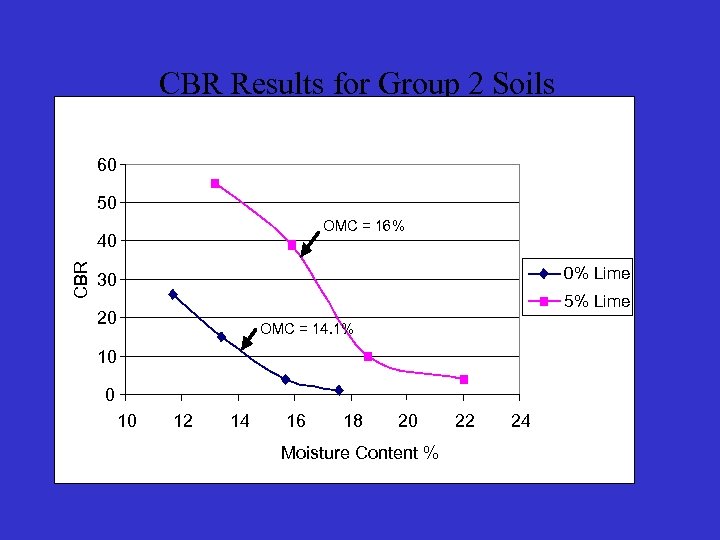

CBR Results for Group 2 Soils 60 50 OMC = 16% CBR 40 0% Lime 30 5% Lime 20 OMC = 14. 1% 10 0 10 12 14 16 18 20 Moisture Content % 22 24

BEST OPTION LIME TREATMENT

b1a5ce66a0da0283a2631dd7af5f57d1.ppt