b5ac3cb8a993a8c41f246722de400e51.ppt

- Количество слайдов: 56

Subgrade Soil Support and Stabilization O’HARE Airport Modernization Research Project Research Progress Presentation – July 20, 2006 Co-PIs: RA: Erol Tutumluer Marshall R. Thompson H. S. Brar

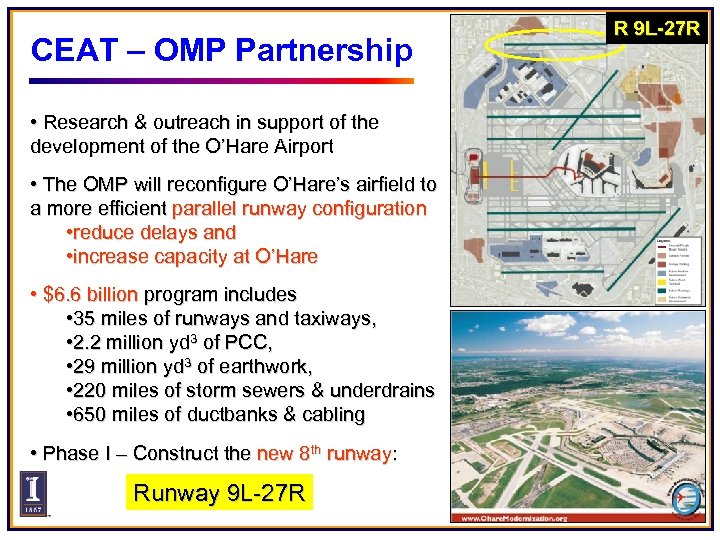

CEAT – OMP Partnership • Research & outreach in support of the development of the O’Hare Airport • The OMP will reconfigure O’Hare’s airfield to a more efficient parallel runway configuration • reduce delays and • increase capacity at O’Hare • $6. 6 billion program includes • 35 miles of runways and taxiways, • 2. 2 million yd 3 of PCC, • 29 million yd 3 of earthwork, • 220 miles of storm sewers & underdrains • 650 miles of ductbanks & cabling • Phase I – Construct the new 8 th runway: Runway 9 L-27 R R 9 L-27 R

Introduction ü The strength and performance of an airport pavement related to the structural design and the subgrade soil characteristics ü This project provides testing and analysis to establish subgrade support and stabilization requirements for O’Hare airport pavements

Introduction (cont’d) ü The preliminary concrete pavement design for the Runway 9 L-27 R: • Design modulus of subgrade reaction, k = 150 pci • • • 15 – 17 inches of PCC Surface 6 -inch Hot Mix Asphalt Base 6 -inch Asphalt Treated Permeable Base (!? ) “Stabilized” Subgrade Zone (SSZ) Prepared Subgrade ü North Runway (9 L-27 R, 7, 500 ft) paving was scheduled first for the Spring 2006 • Stockpiles of local soil in and around runway & taxiways Primarily fill and cut areas

Research Objectives ü Consider/Establish subgrade support and stabilization requirements with respect to: • Need for subgrade stabilization • Selection of lime and other suitable admixture stabilization considerations • Stabilization depth ü Estimate “subgrade support” for various combinations of subgrade stabilization treatments and prepared subgrade conditions

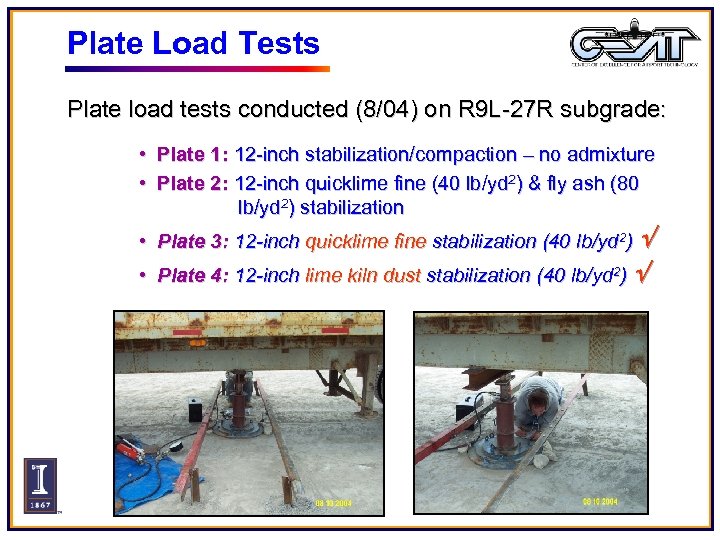

Plate Load Tests Plate load tests conducted (8/04) on R 9 L-27 R subgrade: • Plate 1: 12 -inch stabilization/compaction – no admixture • Plate 2: 12 -inch quicklime fine (40 lb/yd 2) & fly ash (80 lb/yd 2) stabilization • Plate 3: 12 -inch quicklime fine stabilization (40 lb/yd 2) • Plate 4: 12 -inch lime kiln dust stabilization (40 lb/yd 2)

Progress Made In 2004 -05 ü Sampling of the R 9 L-27 R stockpiled soils • Grain size distribution (including hydrometer) • Atterberg limits (LL and PL for PI) • PH value & carbonate content ü Selecting & identifying representative soil samples ü Characterizing the representative soil samples by conducting tests at the UIUC ATREL for • Moisture-Density-CBR • Resilient Modulus • Unconfined Compressive Strength • Lime Treatment Effectiveness

Progress Made In 2004 -05 ü June 2005 technical report prepared on the Laboratory Soil Test Program presented preliminary results of the virgin and lime-treated soil testing efforts at ATREL focused on determining moisturedensity-CBR relationships, unconfined compressive strengths, and resilient modulus properties ü The need for soil stabilization was established from these preliminary test results ü A 5 % Lime Kin Dust (LKD) treatment was considered a feasible stabilization choice for increasing the strength/ modulus of the North Runway 9 L-27 R subgrade soils

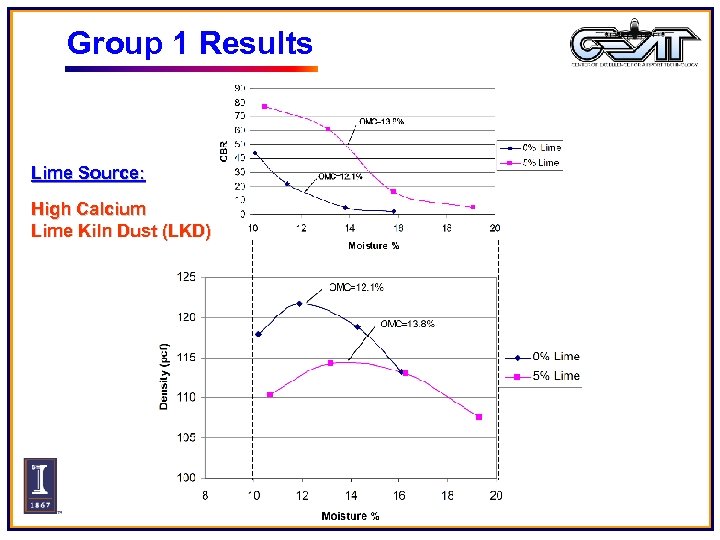

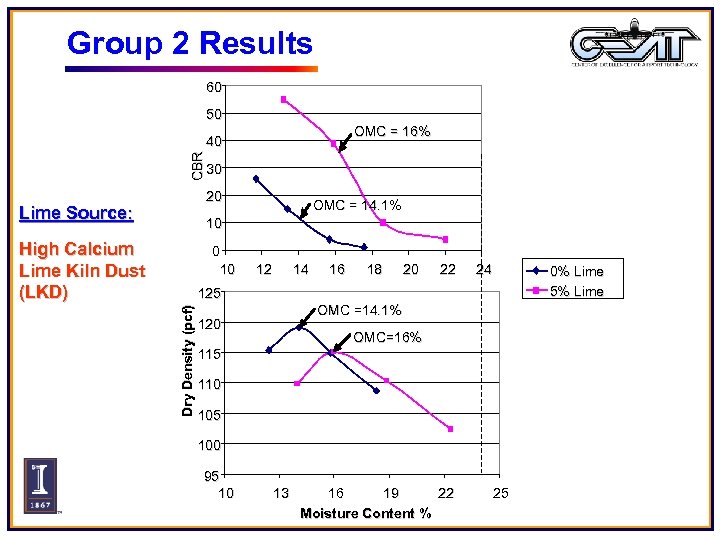

Summary of 2004 -05 Findings (1) Moisture Density CBR Tests: ü Optimum moisture contents of the natural soils were always lower those of the same soils treated with 5% lime kiln dust (LKD) ü Similarly, maximum dry densities were always higher for the natural soils without lime treatment ü The unsoaked CBR values obtained from testing the compacted specimens tend to drop sharply after the optimum moisture contents for the soils without lime ü The treated soils with 5% lime always gave much higher unsoaked CBR values than the natural soils with no lime

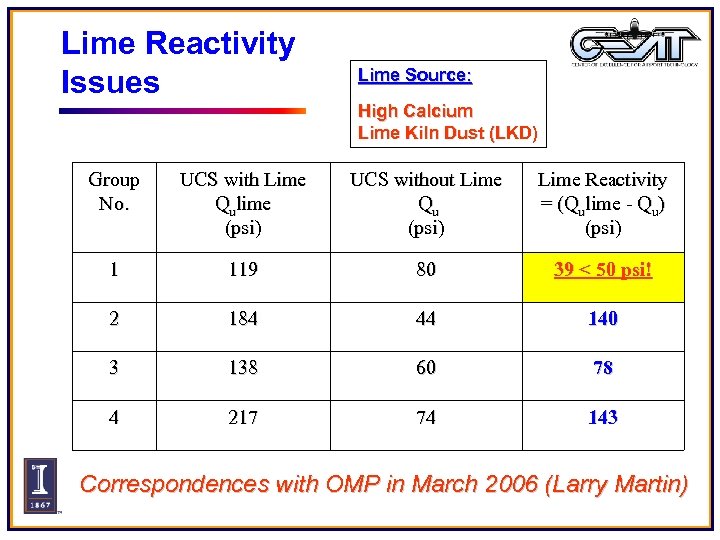

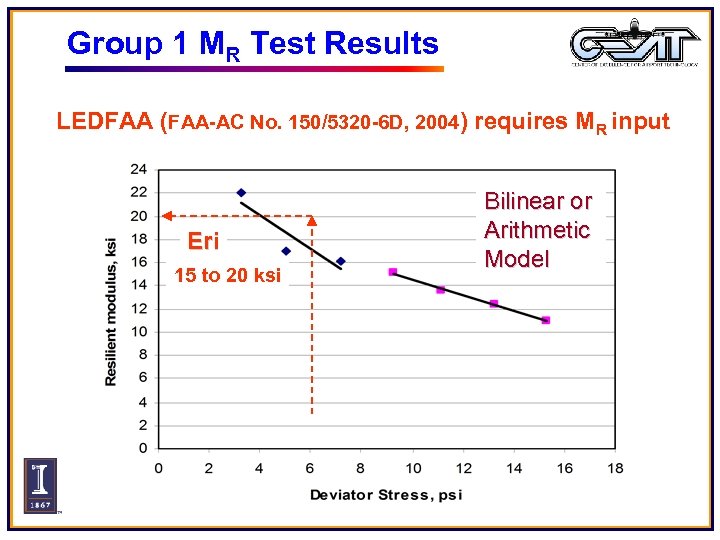

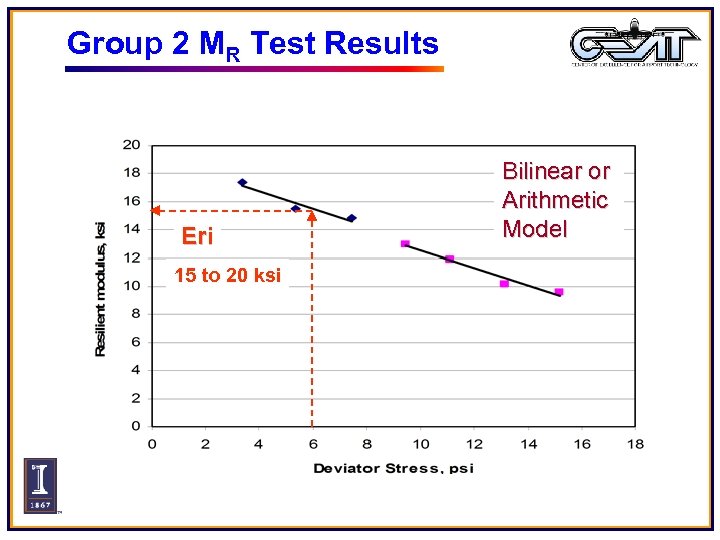

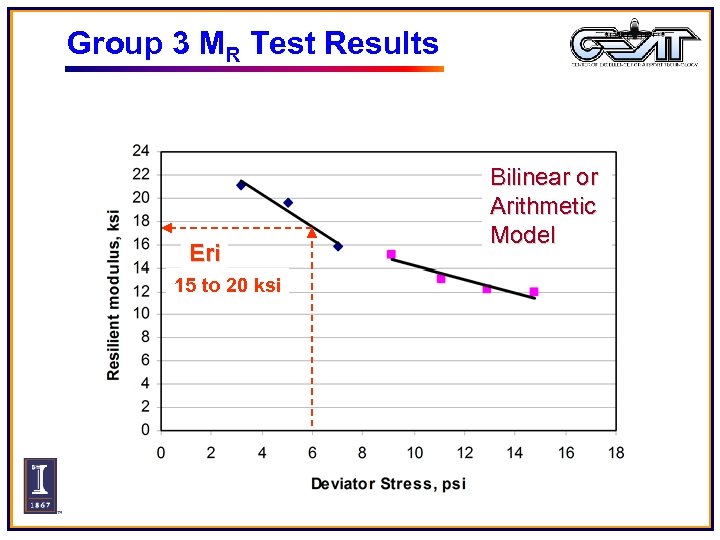

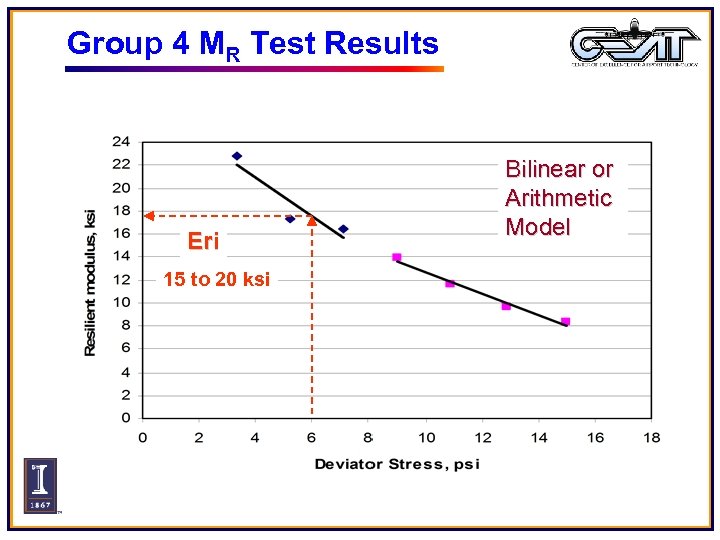

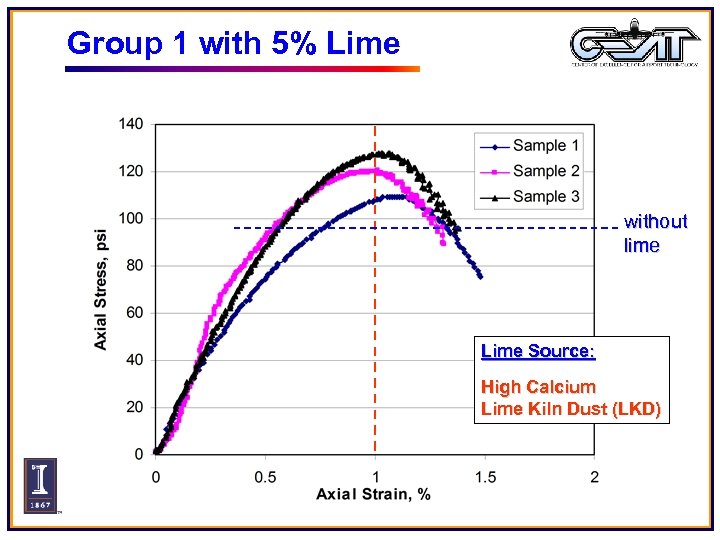

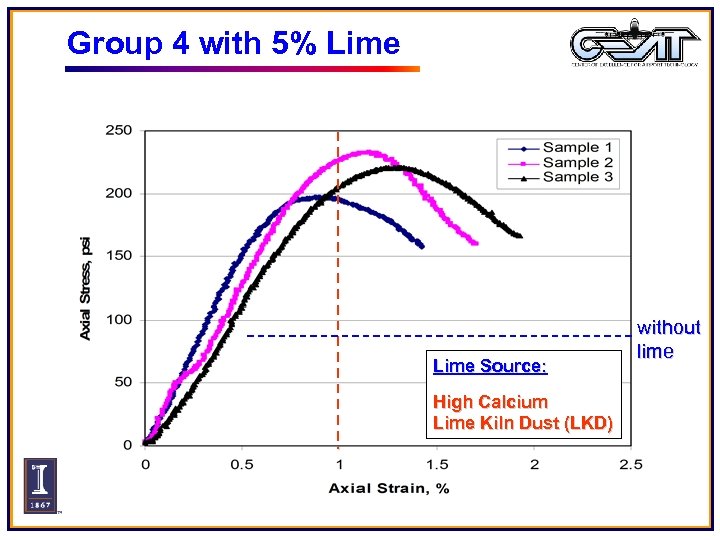

Summary of 2004 -05 Findings (2) Resilient Modulus (MR) Tests: ü MR decreased with increasing applied deviator stresses; typical stress-softening fine grained soil behavior ü All soil groups tested at the OMC gave high MR values at 6 psi deviator stress, in the range of Eri = 15 -20 ksi Unconfined Compressive Strength Tests: ü Large increases in unconfined compressive strengths observed for all groups when 5% lime was added ü Lime reactivity (Qu lime treated - Qu natural) is greater than 50 psi for all the groups except for Group 1 ü Minimum lime treated Qu = 119 psi was recorded for Group 1 soils with the lowest clay contents & the least reactivity with lime

2004 -05 End of Year 1 Recommendation The results to date indicate that even the 5% high calcium lime kiln dust (BLKD) is adequate and cost effective for improving moisture-density-CBR and cured compressive strengths of the subgrade soils at the new North Runway 9 L -27 R of O’Hare International Airport. ü seems to be working quite well in increasing the soil strengths ü the improvements are sufficient to serve as a stabilized subgrade zone and alleviate wet soil conditions

Progress Made In 2005 -06 ü Conducted additional soil-lime testing in the laboratory for soil samples with different ü lime percentages ü lime sources ü curing times ü Established subgrade support for various combinations of subgrade stabilization treatments and prepared subgrade conditions

Admixture Types / Sources ü Carmeuse (potential supplier) ü South Chicago (dolomitic lime) ü Buffington, IN (high calcium lime) Buffington is the primary source and primarily worked with in year 1 ü Lime types ü Lime Kiln Dust (LKD) ü Quicklime fines

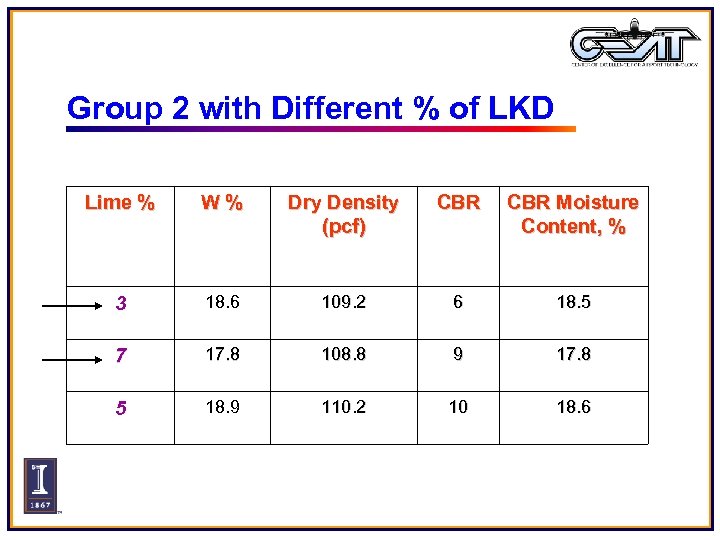

Group 2 with Different % of LKD Lime % W% Dry Density (pcf) CBR Moisture Content, % 3 18. 6 109. 2 6 18. 5 7 17. 8 108. 8 9 17. 8 5 18. 9 110. 2 10 18. 6

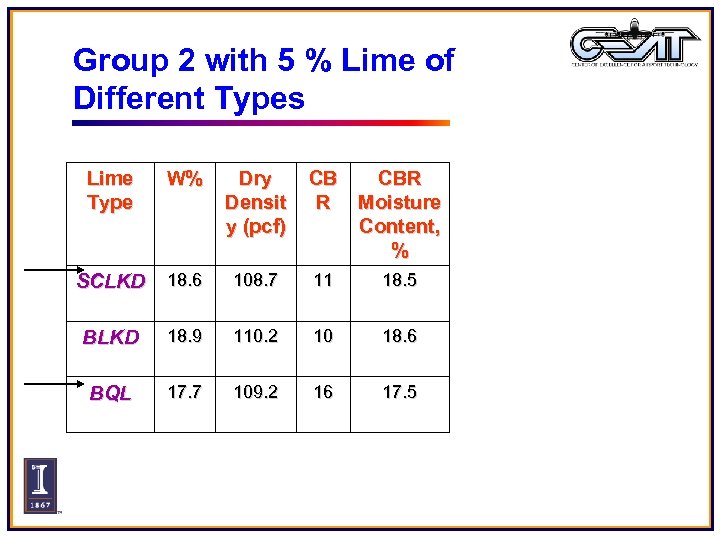

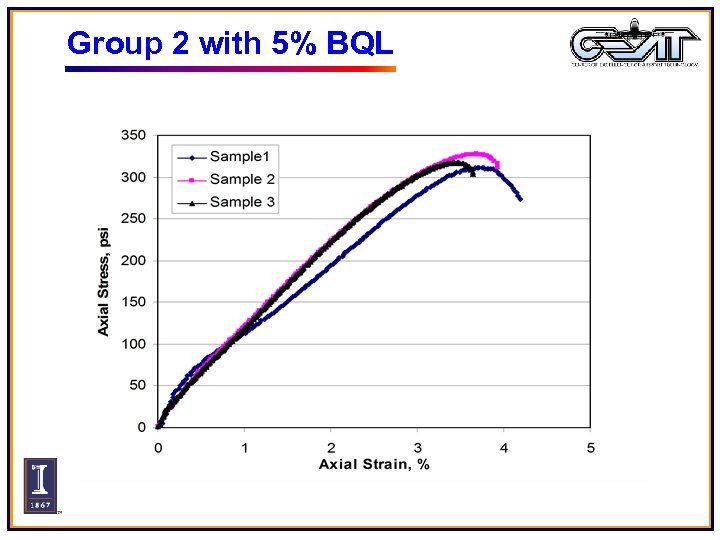

Group 2 with 5 % Lime of Different Types Lime Type W% Dry Densit y (pcf) CB CBR R Moisture Content, % SCLKD 18. 6 108. 7 11 18. 5 BLKD 18. 9 110. 2 10 18. 6 BQL 17. 7 109. 2 16 17. 5

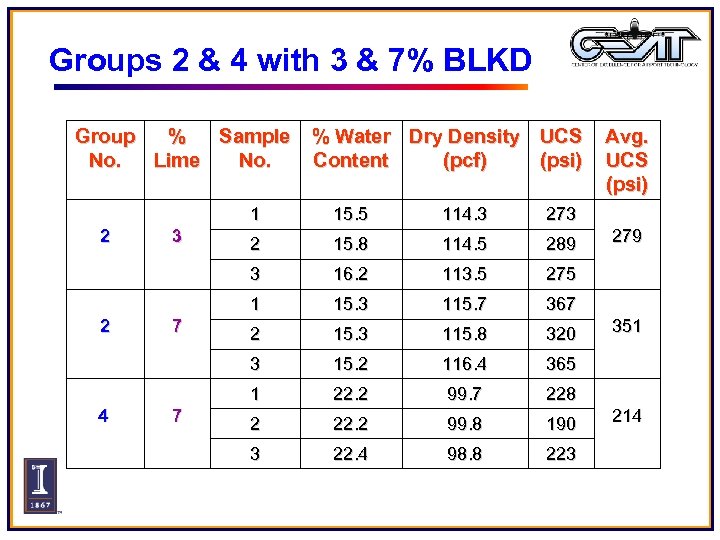

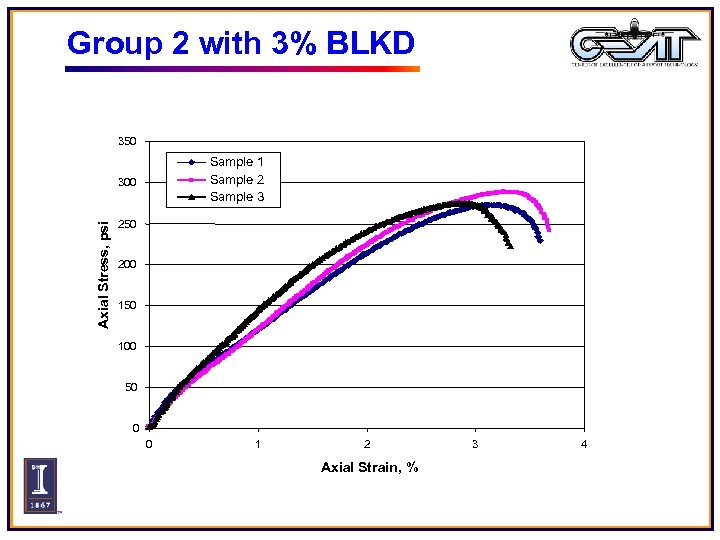

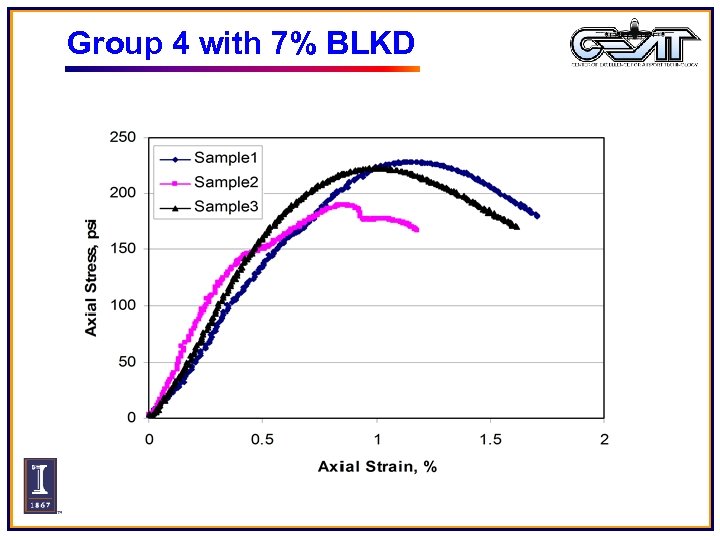

Groups 2 & 4 with 3 & 7% BLKD Group % Sample No. Lime No. % Water Dry Density UCS Content (pcf) (psi) 1 4 7 15. 8 114. 5 289 16. 2 113. 5 275 15. 3 115. 7 367 2 15. 3 115. 8 320 15. 2 116. 4 365 1 7 2 3 2 273 1 3 114. 3 3 2 15. 5 22. 2 99. 7 228 2 22. 2 99. 8 190 3 22. 4 98. 8 223 Avg. UCS (psi) 279 351 214

Group 2 with 3% BLKD 350 Sample 1 Sample 2 Sample 3 Axial Stress, psi 300 250 200 150 100 50 0 0 1 2 Axial Strain, % 3 4

Group 4 with 7% BLKD

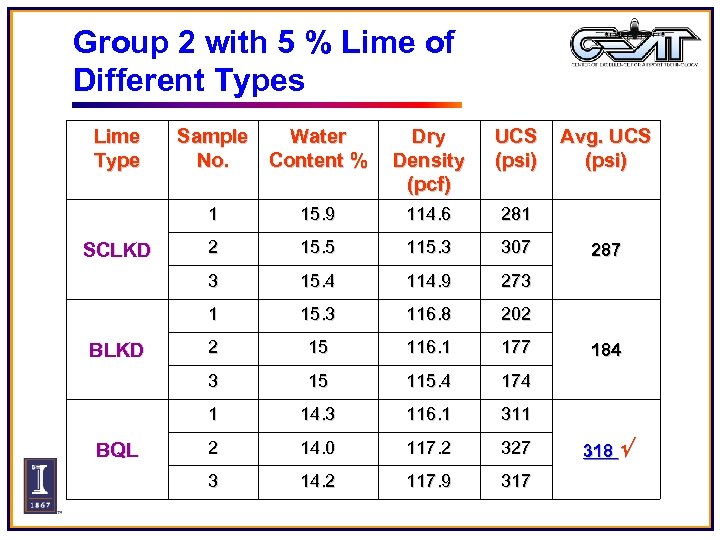

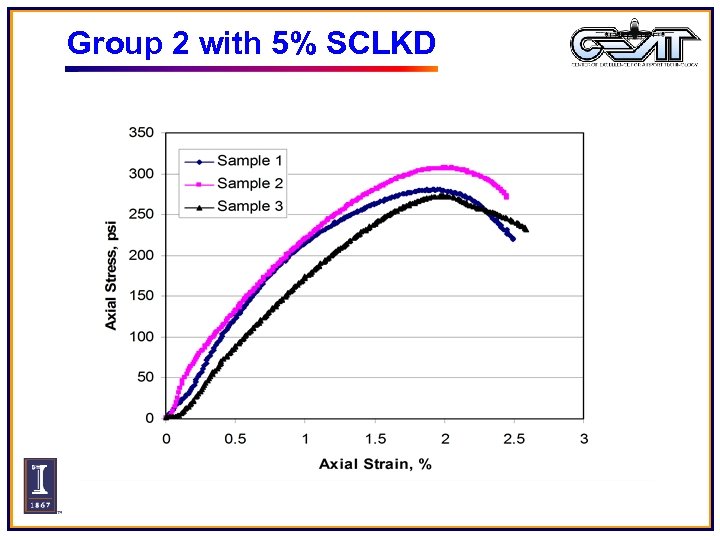

Group 2 with 5 % Lime of Different Types Lime Type Sample Water No. Content % Dry Density (pcf) UCS (psi) 1 2 15. 5 115. 3 307 15. 4 114. 9 273 15. 3 116. 8 202 2 15 116. 1 177 3 15 115. 4 174 1 BQL 281 1 BLKD 114. 6 3 SCLKD 15. 9 14. 3 116. 1 311 2 14. 0 117. 2 327 3 14. 2 117. 9 317 Avg. UCS (psi) 287 184 318

Group 2 with 5% SCLKD

Group 2 with 5% BQL

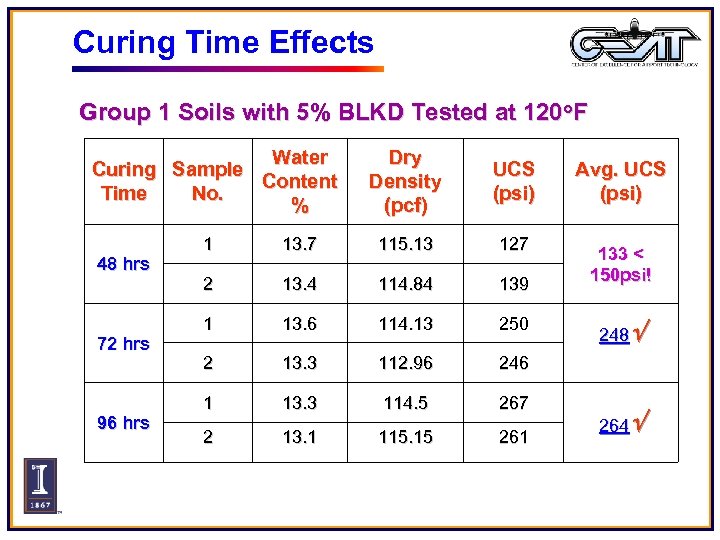

Curing Time Effects Group 1 Soils with 5% BLKD Tested at 120 o. F Water Curing Sample Content Time No. % 48 hrs 72 hrs 96 hrs Dry Density (pcf) UCS (psi) 1 13. 7 115. 13 127 2 13. 4 114. 84 139 1 13. 6 114. 13 250 2 13. 3 112. 96 246 1 13. 3 114. 5 267 2 13. 1 115. 15 261 Avg. UCS (psi) 133 < 150 psi! 248 264

Progress Made In 2004 -06 Technical Notes have been prepared and submitted to the OMP throughout the project duration to: ü Establish the Best Demonstrated Available Technology (BDAT) for subgrade soil evaluation and stabilization ü Communicate specific findings and recommendations to OMP engineers • TN 5: K-150 Considerations for RW 9 -27 • TN 6: Subgrade Strength/Stiffness Evaluation • TN 7: “Working Platform” Requirements for Pavement Construction • TN 8: Subgrade Stability Manual (IDOT) • TM 13: Moisture Limitations for Lime Stabilization • TN 14: Admixture Stabilization (Lime Treatment of Subgrades) • TN 19: Progress Report on Laboratory Soil Test Results (March 2006)

Progress Made In 2005 -06 ü A project research paper was presented at the 2006 ASCE Airfield and Highway Pavement Specialty Conference, Atlanta, GA, April 30 – May 3, 2006 ü Published in the Proceedings book Airfield and Highway Pavements, edited by I. L. Al-Qadi “Characterizing Subgrade Soils and Establishing Treatment Needs for a New Runway at the Chicago’s O’Hare Airport” by H. S. Brar, E. Tutumluer, M. R. Thompson, Gosain, and R. Anderson L.

Progress Made In 2005 -06

Progress Made In 2005 -06 ü On April 5 th, 2006, the Co-PIs joined a teleconference meeting with the OMP concerning the project findings on subgrade stabilization and additional frost action effects ü Both North Runway 9 L-27 R and South Airfield subgrade soil support and stabilization needs were discussed: ü effectiveness of lime stabilization on primarily silty soils with low clay contents (less than 20%), ü adequate strength gain requirements, ü poor workmanship and inadequate construction quality control, ü construction cut off dates for lime treatment effectiveness, ü frost penetration effects, and ü Cement treatment as an option to include in the construction specifications (and use in certain project locations in case lime treatment becomes unsatisfactory for the primarily silty, low clay contents soils to be encountered during subgrade preparation)

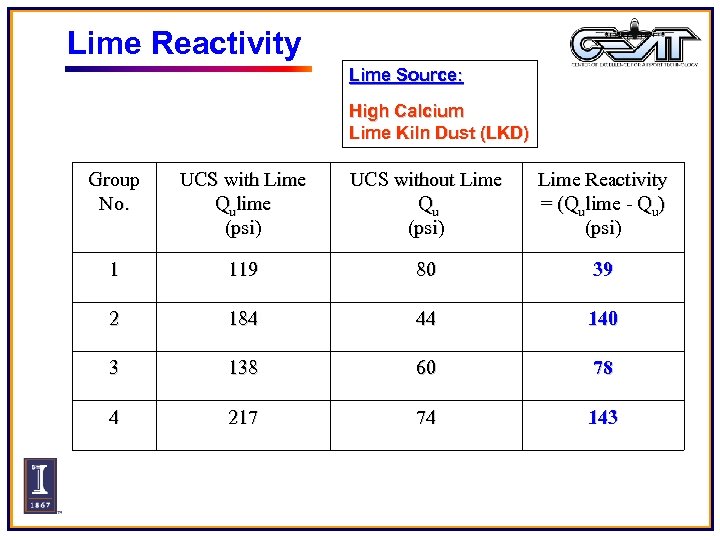

Lime Reactivity Issues Lime Source: High Calcium Lime Kiln Dust (LKD) Group No. UCS with Lime Qulime (psi) UCS without Lime Qu (psi) Lime Reactivity = (Qulime - Qu) (psi) 1 119 80 39 < 50 psi! 2 184 44 140 3 138 60 78 4 217 74 143 Correspondences with OMP in March 2006 (Larry Martin)

Progress Made In 2005 -06 ü Based on climatic data from 1997 until 2001, recently acquired and studied at the University of Illinois, Professor Barry Dempsey, an expert on climatic effects at UIUC, indicated that a typical frost penetration depth of 39 inches was predicted for the North Runway 9 L-27 R pavement designs. ü accordingly, frost penetration and related heave should not be a problem for these pavements ü Marshall Thompson traveled to the OMP office on April 11 th and participated in a conference at ORD with OMP staff concerning ü soil stabilization (lime/cement) ü frost action effects, and ü use of fly ash as a stabilization admixture

FY 07 Year 3 Project Tasks Task 1: Conduct additional soil-lime testing in the laboratory for soil samples with different curing conditions ü Temperature conditions to affect curing and strength gain to investigate potential problems if lime stabilization is applied in colder weather ? ! ü to what extent? ü what is the minimum strength? ü what is the cut off date?

FY 07 Year 3 Project Tasks Task 2: Cooperate with OMP in the reviewing (and modifying if appropriate) Section P-152 (Excavation and Embankment) and Section P-159 (Lime Modified Soils) ü Experiences (problems/successes) from the current 9 -27 contract should be considered ü The “modified” versions should be included in future contracts

FY 07 Year 3 Project Tasks Task 3: Cooperate with OMP in the reviewing and modifying Section P-158 (Lime Stabilized Subgrade) for inclusion in the upcoming paving contract ü Current version cites “latest edition” of IDOT Specs. Should reference the IDOT 2002 version. ü Modify Spec. (as needed) to include cement as a possible admixture ü Consider frost action and freeze-thaw potentials. Dempsey’s study will provide important inputs. ü Will construction be permitted outside the current April 15 – Sept 15 window ? ü Other issues? ?

FY 07 Year 3 Project Tasks Task 4: Evaluate the 9 L-27 R runway/taxiway soil lime stabilization and modification for meeting the subgrade support (k-value) requirements ü The research team will support the activities of OMP in the evaluation of completed lime stabilization ü Project Staff will cooperate with the OMP Project – Field Validation of Constructed Subgrade and Pavement Layers in this effort

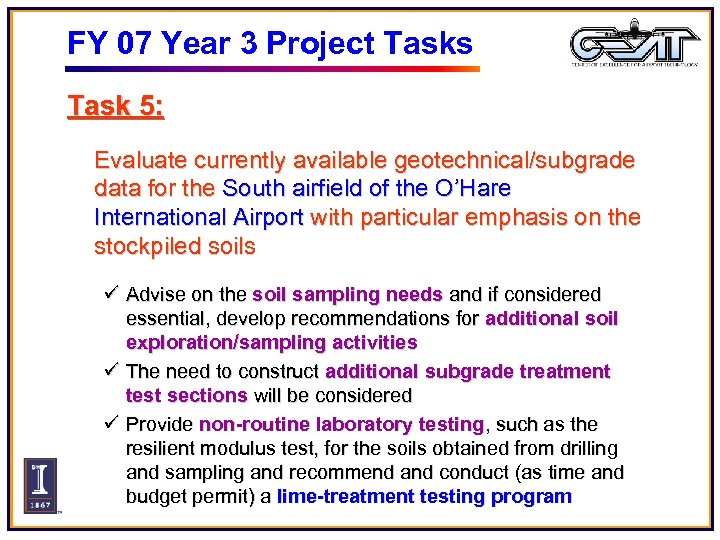

FY 07 Year 3 Project Tasks Task 5: Evaluate currently available geotechnical/subgrade data for the South airfield of the O’Hare International Airport with particular emphasis on the stockpiled soils ü Advise on the soil sampling needs and if considered essential, develop recommendations for additional soil exploration/sampling activities ü The need to construct additional subgrade treatment test sections will be considered ü Provide non-routine laboratory testing, such as the resilient modulus test, for the soils obtained from drilling and sampling and recommend and conduct (as time and budget permit) a lime-treatment testing program

Project Schedule & Deliverables ü Technical Notes will be prepared and submitted to the OMP throughout the duration of this project to communicate specific findings and recommendations to OMP engineers as needed ü Several of the Project Tasks are already pursued simultaneously, and the specific delivery of results will be contingent upon availability of OMP data and other factors that depend on coordination with OMP ü Continue to work with OMP on current and future subgrade soil support and stabilization needs for all O’Hare runways/taxiways. This will be in the form of sustained support for working with OMP on subgrade soil support issues

Any Questions?

University of Illinois Laboratory Testing Program at ATREL Advanced Transportation Research & Engineering Laboratory (ATREL)

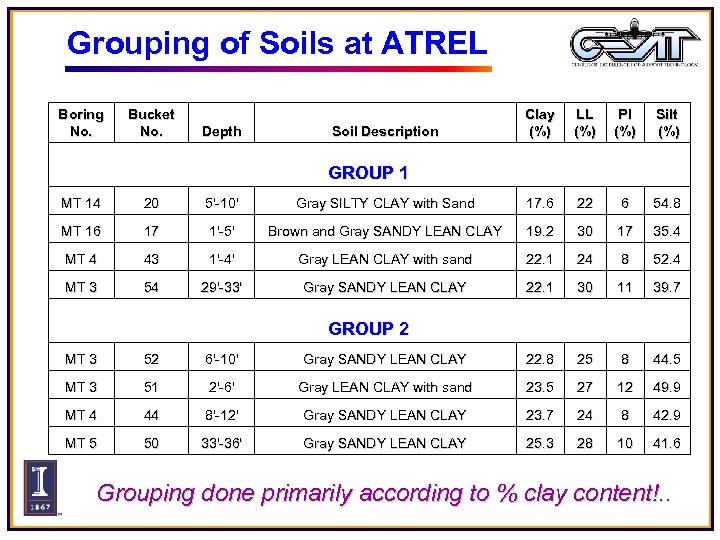

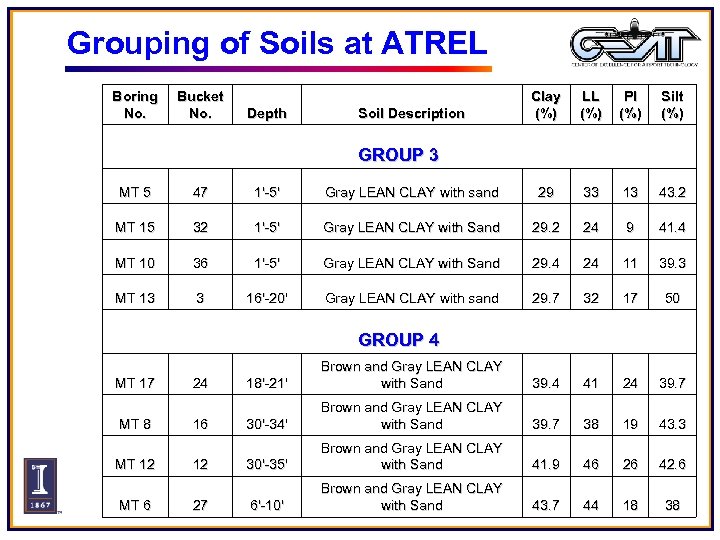

Grouping of Soils at ATREL Boring No. Bucket No. Depth Soil Description Clay (%) LL (%) PI (%) Silt (%) GROUP 1 MT 14 20 5'-10' Gray SILTY CLAY with Sand 17. 6 22 6 54. 8 MT 16 17 1'-5' Brown and Gray SANDY LEAN CLAY 19. 2 30 17 35. 4 MT 4 43 1'-4' Gray LEAN CLAY with sand 22. 1 24 8 52. 4 MT 3 54 29'-33' Gray SANDY LEAN CLAY 22. 1 30 11 39. 7 GROUP 2 MT 3 52 6'-10' Gray SANDY LEAN CLAY 22. 8 25 8 44. 5 MT 3 51 2'-6' Gray LEAN CLAY with sand 23. 5 27 12 49. 9 MT 4 44 8'-12' Gray SANDY LEAN CLAY 23. 7 24 8 42. 9 MT 5 50 33'-36' Gray SANDY LEAN CLAY 25. 3 28 10 41. 6 Grouping done primarily according to % clay content!. .

Grouping of Soils at ATREL Boring No. Bucket No. Depth Soil Description Clay (%) LL (%) PI (%) Silt (%) GROUP 3 MT 5 47 1'-5' Gray LEAN CLAY with sand 29 33 13 43. 2 MT 15 32 1'-5' Gray LEAN CLAY with Sand 29. 2 24 9 41. 4 MT 10 36 1'-5' Gray LEAN CLAY with Sand 29. 4 24 11 39. 3 MT 13 3 16'-20' Gray LEAN CLAY with sand 29. 7 32 17 50 18'-21' Brown and Gray LEAN CLAY with Sand 39. 4 41 24 39. 7 30'-34' Brown and Gray LEAN CLAY with Sand 39. 7 38 19 43. 3 30'-35' Brown and Gray LEAN CLAY with Sand 41. 9 46 26 42. 6 6'-10' Brown and Gray LEAN CLAY with Sand 43. 7 44 18 38 GROUP 4 MT 17 MT 8 MT 12 MT 6 24 16 12 27

Test Specimen Preparation Air Drying Pulverizing Mixing

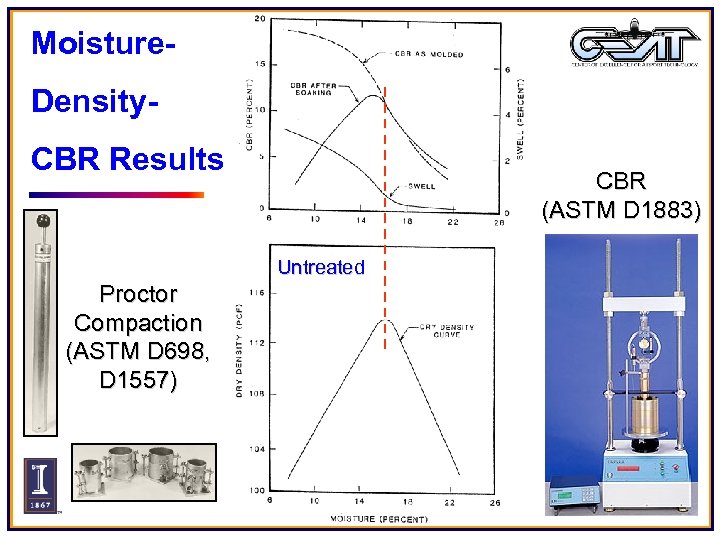

Moisture. Density. CBR Results CBR (ASTM D 1883) Untreated Proctor Compaction (ASTM D 698, D 1557)

Group 1 Results Lime Source: High Calcium Lime Kiln Dust (LKD)

Group 2 Results 60 50 OMC = 16% CBR 40 30 20 Lime Source: OMC = 14. 1% 10 High Calcium Lime Kiln Dust (LKD) 0 10 12 14 16 18 20 22 24 0% Lime 5% Lime Dry Density (pcf) 125 OMC =14. 1% 120 OMC=16% 115 110 105 100 95 10 13 16 19 22 Moisture Content % 25

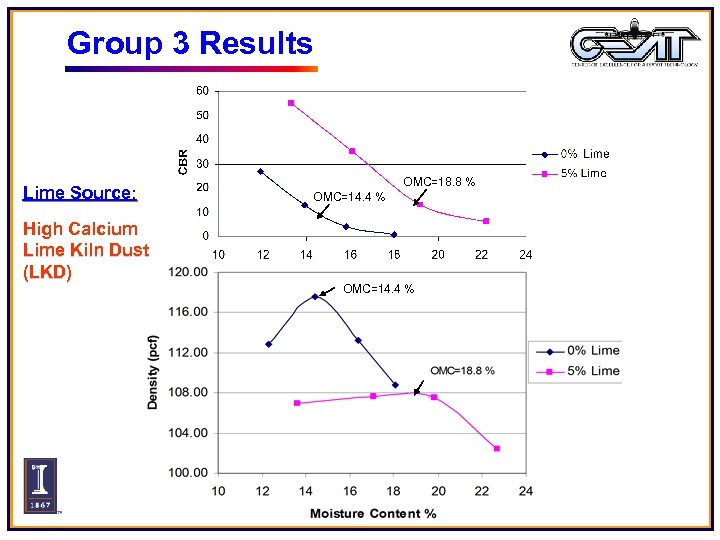

Group 3 Results Lime Source: High Calcium Lime Kiln Dust (LKD) OMC=18. 8 % OMC=14. 4 %

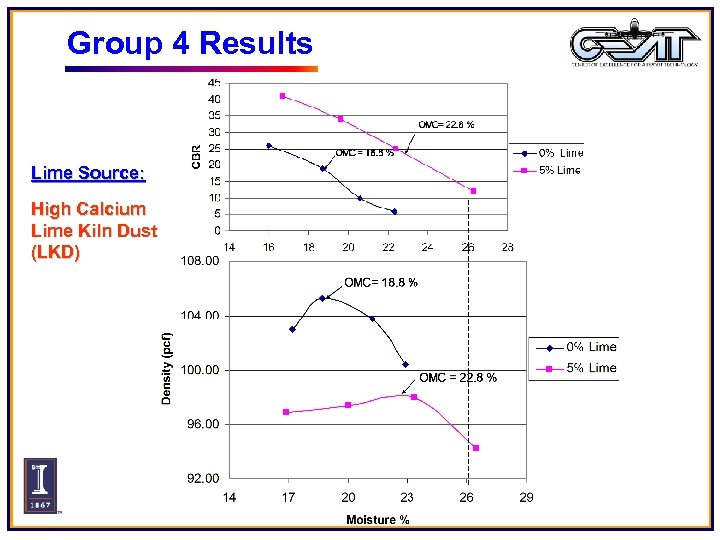

Group 4 Results Lime Source: High Calcium Lime Kiln Dust (LKD)

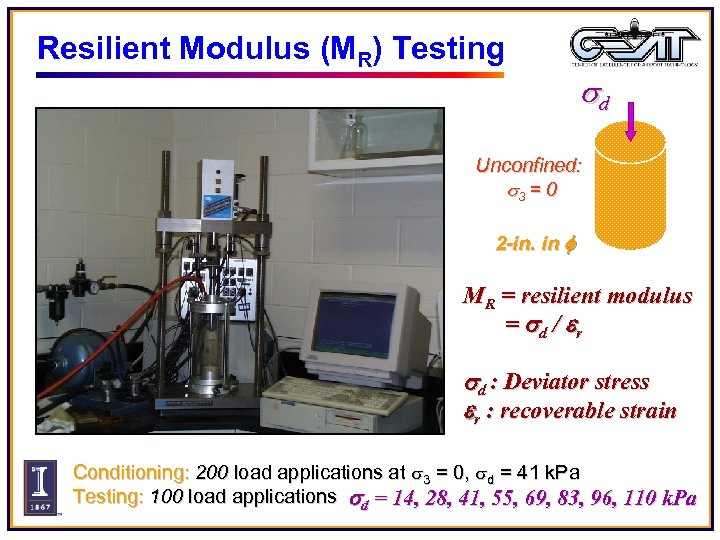

Resilient Modulus (MR) Testing sd Unconfined: s 3 = 0 2 -in. in f MR = resilient modulus = sd / e r sd : Deviator stress er : recoverable strain Conditioning: 200 load applications at s 3 = 0, sd = 41 k. Pa Testing: 100 load applications sd = 14, 28, 41, 55, 69, 83, 96, 110 k. Pa

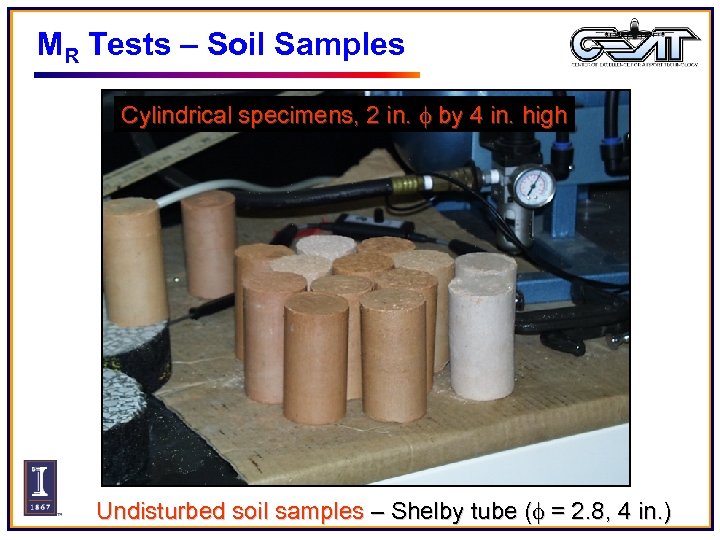

MR Tests – Soil Samples Cylindrical specimens, 2 in. f by 4 in. high Undisturbed soil samples – Shelby tube (f = 2. 8, 4 in. )

Group 1 MR Test Results LEDFAA (FAA-AC No. 150/5320 -6 D, 2004) requires MR input Eri 15 to 20 ksi Bilinear or Arithmetic Model

Group 2 MR Test Results Eri 15 to 20 ksi Bilinear or Arithmetic Model

Group 3 MR Test Results Eri 15 to 20 ksi Bilinear or Arithmetic Model

Group 4 MR Test Results Eri 15 to 20 ksi Bilinear or Arithmetic Model

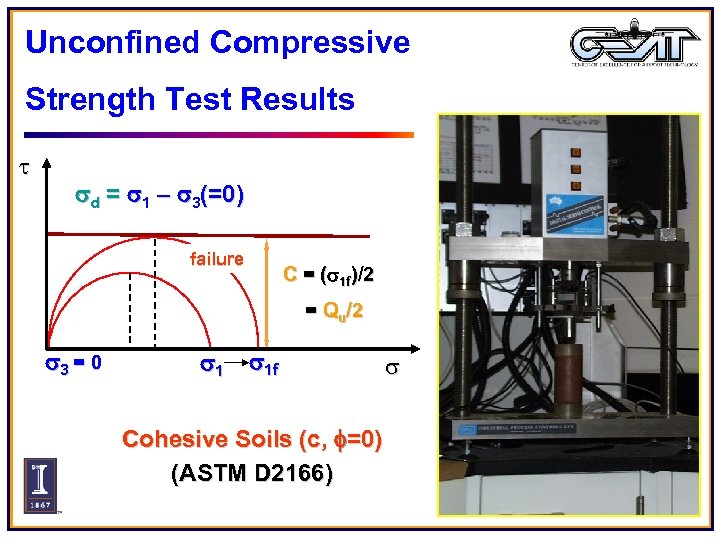

Unconfined Compressive Strength Test Results t sd = s 1 – s 3(=0) failure C = (s 1 f)/2 = Qu/2 s 3 = 0 s 1 f Cohesive Soils (c, f=0) (ASTM D 2166) s

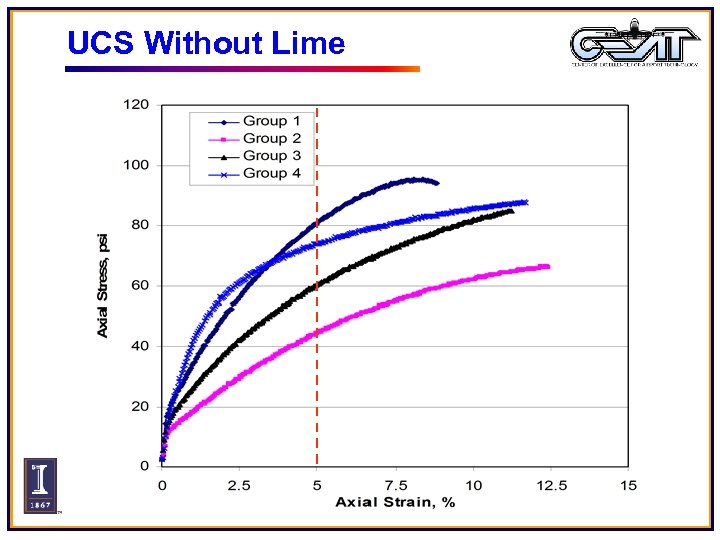

UCS Without Lime

Group 1 with 5% Lime without lime Lime Source: High Calcium Lime Kiln Dust (LKD)

Group 4 with 5% Lime Source: High Calcium Lime Kiln Dust (LKD) without lime

Lime Reactivity Lime Source: High Calcium Lime Kiln Dust (LKD) Group No. UCS with Lime Qulime (psi) UCS without Lime Qu (psi) Lime Reactivity = (Qulime - Qu) (psi) 1 119 80 39 2 184 44 140 3 138 60 78 4 217 74 143

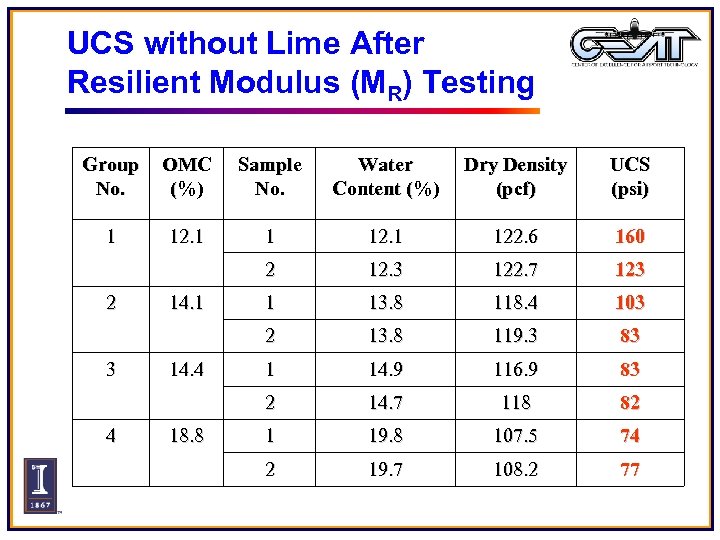

UCS without Lime After Resilient Modulus (MR) Testing Group No. OMC (%) Sample No. Water Content (%) Dry Density (pcf) UCS (psi) 1 122. 6 160 2 12. 3 122. 7 123 1 13. 8 118. 4 103 2 13. 8 119. 3 83 1 14. 9 116. 9 83 2 14. 7 118 82 1 19. 8 107. 5 74 2 19. 7 108. 2 77 2 3 4 14. 1 14. 4 18. 8

b5ac3cb8a993a8c41f246722de400e51.ppt