7c9ded85e2602807d1917b8f45456bc2.ppt

- Количество слайдов: 35

Subdirección General Técnica Gerencia de Ingeniería y Normas Técnicas “Desalination plants in Mexico, Operation, Issues and Regulation”. Ing. Mario López Pérez

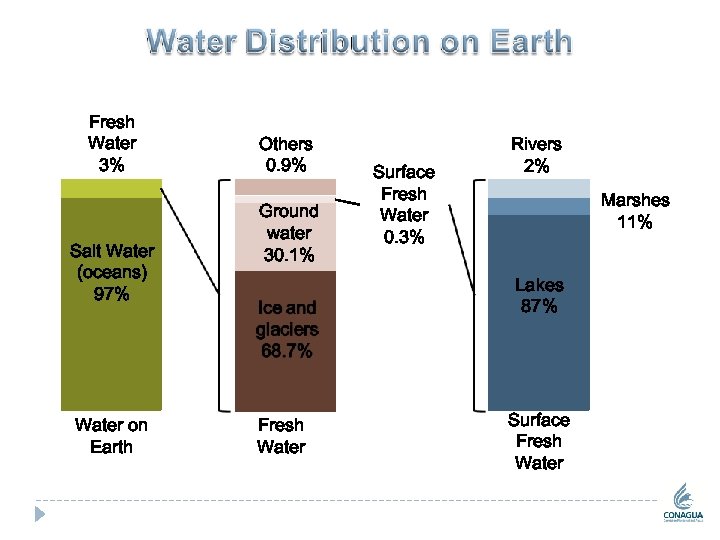

Fresh Water 3% Salt Water (oceans) 97% Water on Earth Others 0. 9% Ground water 30. 1% Surface Fresh Water 0. 3% Rivers 2% Marshes 11% Lakes 87% Fresh Water Surface Fresh Water

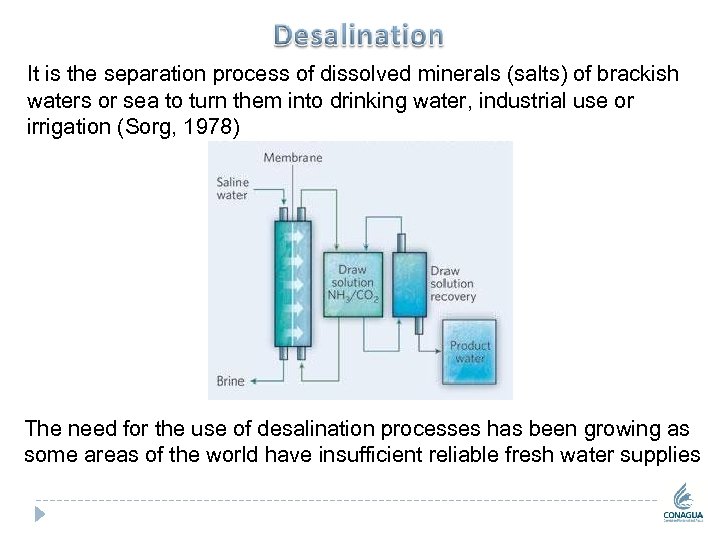

It is the separation process of dissolved minerals (salts) of brackish waters or sea to turn them into drinking water, industrial use or irrigation (Sorg, 1978) The need for the use of desalination processes has been growing as some areas of the world have insufficient reliable fresh water supplies

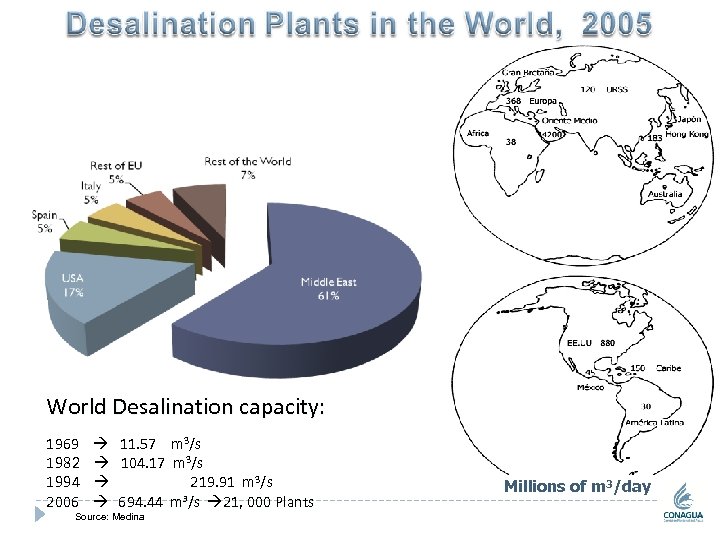

World Desalination capacity: 1969 1982 1994 2006 11. 57 m 3/s 104. 17 m 3/s 219. 91 m 3/s 694. 44 m 3/s 21, 000 Plants Source: Medina Millions of m 3/day

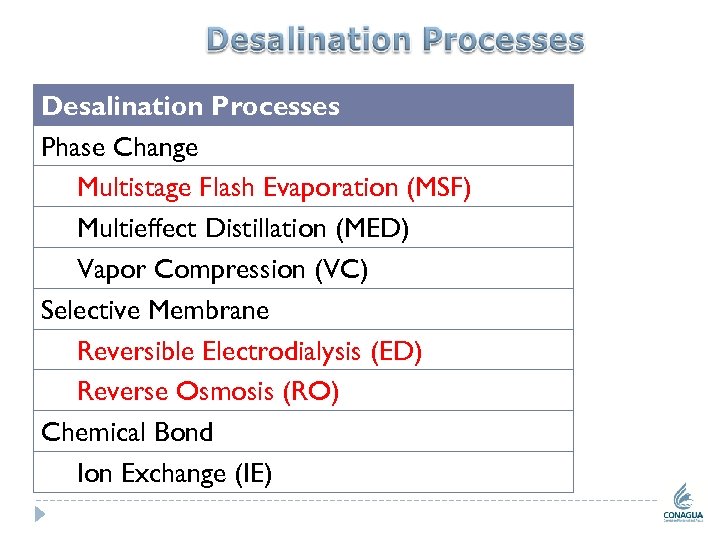

Desalination Processes Phase Change Multistage Flash Evaporation (MSF) Multieffect Distillation (MED) Vapor Compression (VC) Selective Membrane Reversible Electrodialysis (ED) Reverse Osmosis (RO) Chemical Bond Ion Exchange (IE)

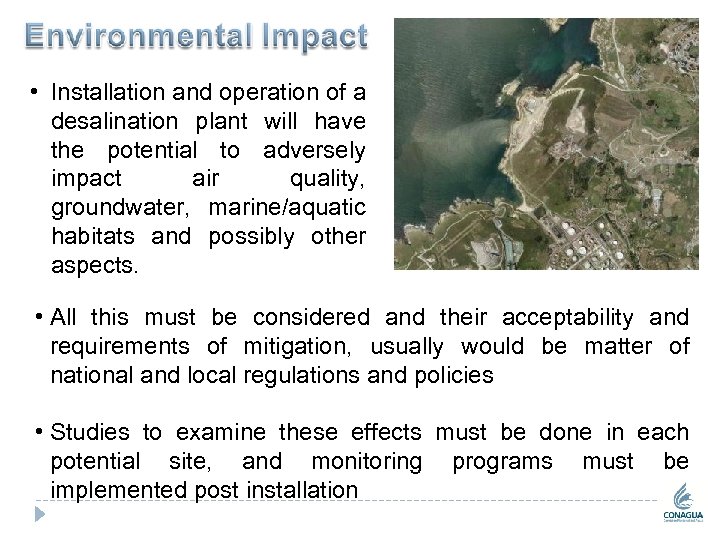

• Installation and operation of a desalination plant will have the potential to adversely impact air quality, groundwater, marine/aquatic habitats and possibly other aspects. • All this must be considered and their acceptability and requirements of mitigation, usually would be matter of national and local regulations and policies • Studies to examine these effects must be done in each potential site, and monitoring programs must be implemented post installation

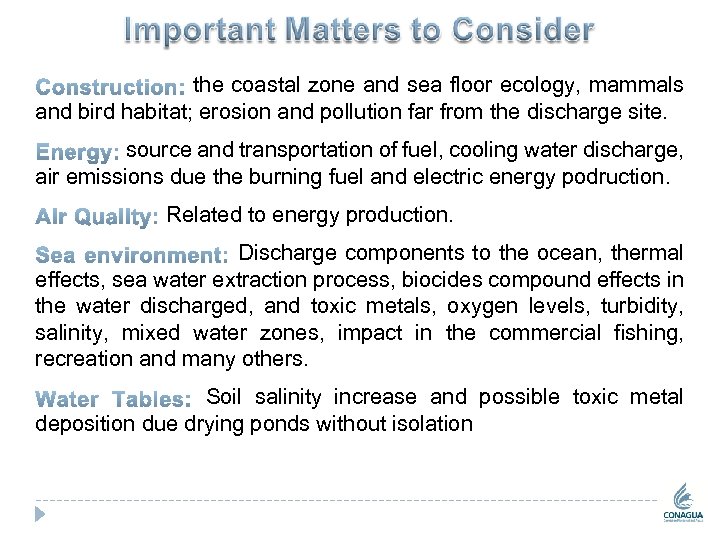

the coastal zone and sea floor ecology, mammals and bird habitat; erosion and pollution far from the discharge site. source and transportation of fuel, cooling water discharge, air emissions due the burning fuel and electric energy podruction. Related to energy production. Discharge components to the ocean, thermal effects, sea water extraction process, biocides compound effects in the water discharged, and toxic metals, oxygen levels, turbidity, salinity, mixed water zones, impact in the commercial fishing, recreation and many others. Soil salinity increase and possible toxic metal deposition due drying ponds without isolation

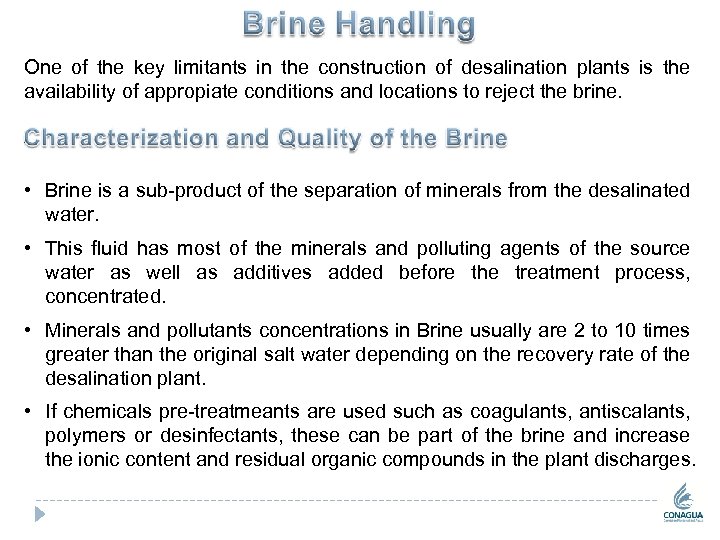

One of the key limitants in the construction of desalination plants is the availability of appropiate conditions and locations to reject the brine. • Brine is a sub-product of the separation of minerals from the desalinated water. • This fluid has most of the minerals and polluting agents of the source water as well as additives added before the treatment process, concentrated. • Minerals and pollutants concentrations in Brine usually are 2 to 10 times greater than the original salt water depending on the recovery rate of the desalination plant. • If chemicals pre-treatmeants are used such as coagulants, antiscalants, polymers or desinfectants, these can be part of the brine and increase the ionic content and residual organic compounds in the plant discharges.

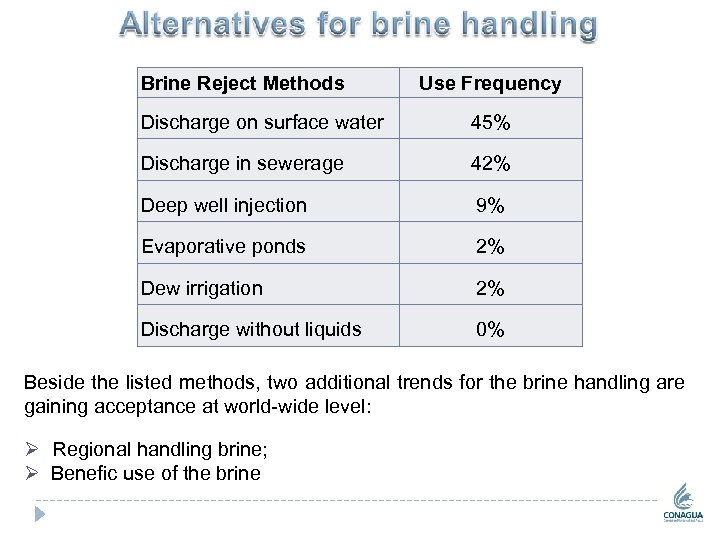

Brine Reject Methods Use Frequency Discharge on surface water 45% Discharge in sewerage 42% Deep well injection 9% Evaporative ponds 2% Dew irrigation 2% Discharge without liquids 0% Beside the listed methods, two additional trends for the brine handling are gaining acceptance at world-wide level: Ø Regional handling brine; Ø Benefic use of the brine

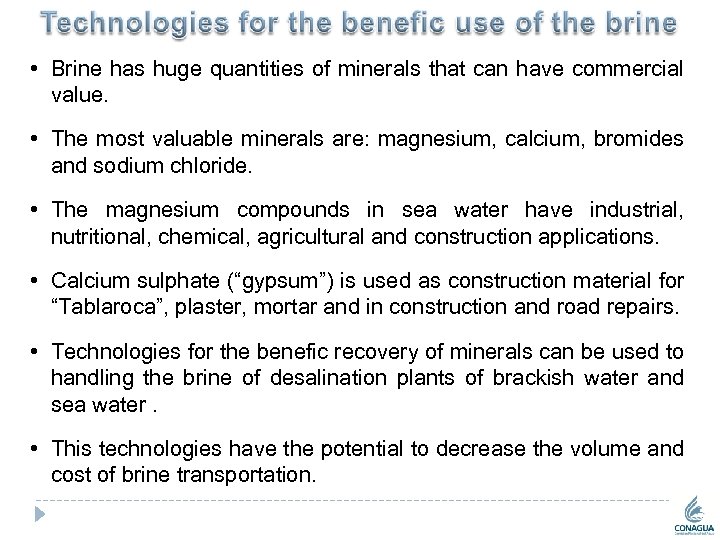

• Brine has huge quantities of minerals that can have commercial value. • The most valuable minerals are: magnesium, calcium, bromides and sodium chloride. • The magnesium compounds in sea water have industrial, nutritional, chemical, agricultural and construction applications. • Calcium sulphate (“gypsum”) is used as construction material for “Tablaroca”, plaster, mortar and in construction and road repairs. • Technologies for the benefic recovery of minerals can be used to handling the brine of desalination plants of brackish water and sea water. • This technologies have the potential to decrease the volume and cost of brine transportation.

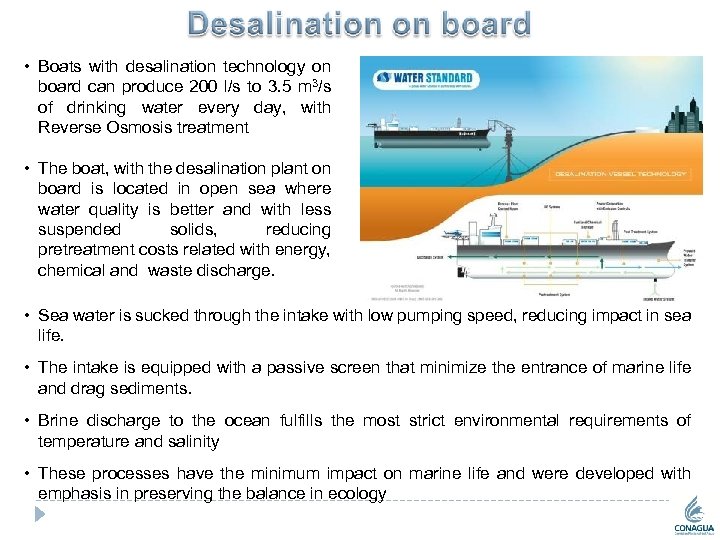

• Boats with desalination technology on board can produce 200 l/s to 3. 5 m 3/s of drinking water every day, with Reverse Osmosis treatment • The boat, with the desalination plant on board is located in open sea where water quality is better and with less suspended solids, reducing pretreatment costs related with energy, chemical and waste discharge. • Sea water is sucked through the intake with low pumping speed, reducing impact in sea life. • The intake is equipped with a passive screen that minimize the entrance of marine life and drag sediments. • Brine discharge to the ocean fulfills the most strict environmental requirements of temperature and salinity • These processes have the minimum impact on marine life and were developed with emphasis in preserving the balance in ecology

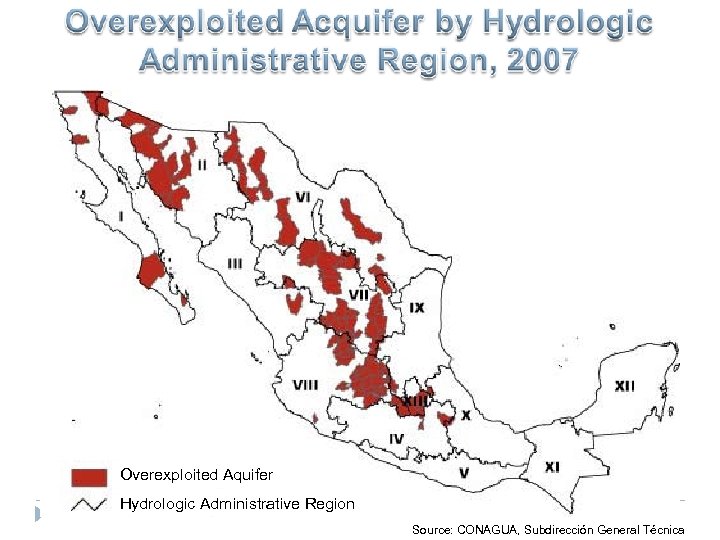

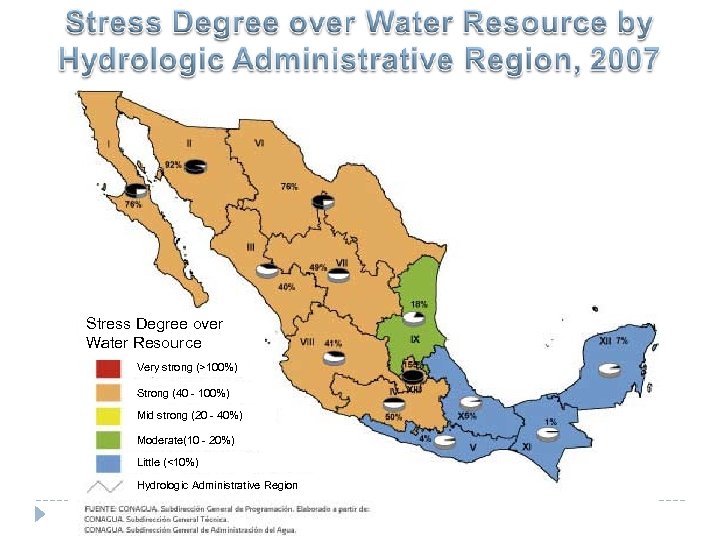

Overexploited Aquifer Hydrologic Administrative Region Source: CONAGUA, Subdirección General Técnica

Stress Degree over Water Resource Very strong (>100%) Strong (40 - 100%) Mid strong (20 - 40%) Moderate(10 - 20%) Little (<10%) Hydrologic Administrative Region

• According with statistics, our country has low availability of fresh water (between 1, 000 and 5, 000 liters annuals person, approximately 3 to 15 liters daily), for that reason, knowledge and implementation of sea water desalination techniques are very important • In some zones of the country, in short term, the only available supplies of water to population centers, industries and hotels will be sea and brackish water, which makes impossible to use them in its natural conditions, that’s why is necessary to process them to take them out the excess of salts and to supply drinking water, as well as to prevent reject water discharges pollution.

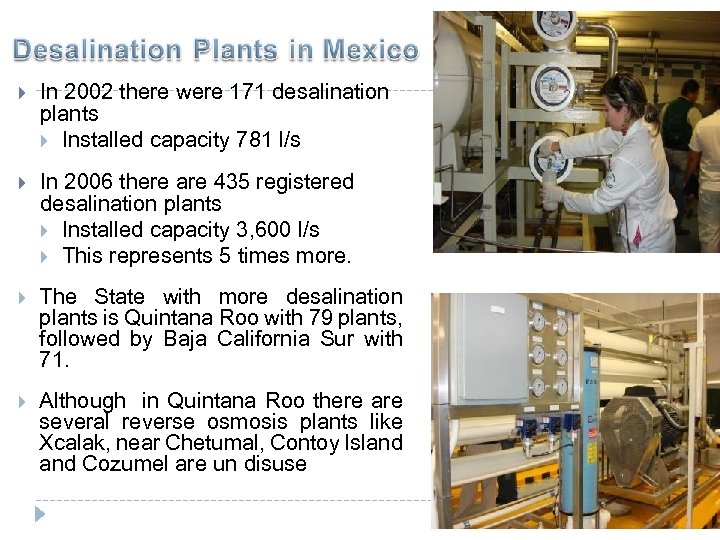

In 2002 there were 171 desalination plants Installed capacity 781 l/s In 2006 there are 435 registered desalination plants Installed capacity 3, 600 l/s This represents 5 times more. The State with more desalination plants is Quintana Roo with 79 plants, followed by Baja California Sur with 71. Although in Quintana Roo there are several reverse osmosis plants like Xcalak, near Chetumal, Contoy Island Cozumel are un disuse

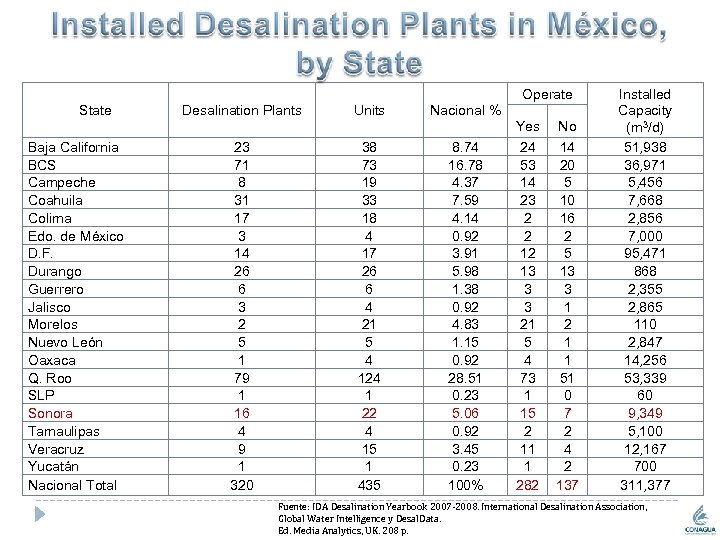

Operate State Baja California BCS Campeche Coahuila Colima Edo. de México D. F. Durango Guerrero Jalisco Morelos Nuevo León Oaxaca Q. Roo SLP Sonora Tamaulipas Veracruz Yucatán Nacional Total Desalination Plants 23 71 8 31 17 3 14 26 6 3 2 5 1 79 1 16 4 9 1 320 Units 38 73 19 33 18 4 17 26 6 4 21 5 4 124 1 22 4 15 1 435 Nacional % 8. 74 16. 78 4. 37 7. 59 4. 14 0. 92 3. 91 5. 98 1. 38 0. 92 4. 83 1. 15 0. 92 28. 51 0. 23 5. 06 0. 92 3. 45 0. 23 100% Yes 24 53 14 23 2 2 12 13 3 3 21 5 4 73 1 15 2 11 1 282 No 14 20 5 10 16 2 5 13 3 1 2 1 1 51 0 7 2 4 2 137 Installed Capacity (m 3/d) 51, 938 36, 971 5, 456 7, 668 2, 856 7, 000 95, 471 868 2, 355 2, 865 110 2, 847 14, 256 53, 339 60 9, 349 5, 100 12, 167 700 311, 377 Fuente: IDA Desalination Yearbook 2007 -2008. International Desalination Association, Global Water Intelligence y Desal. Data. Ed. Media Analytics, UK. 208 p.

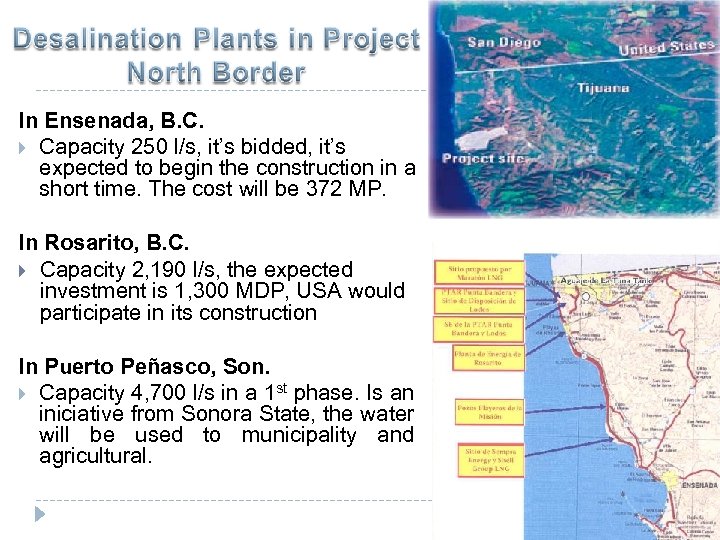

In Ensenada, B. C. Capacity 250 l/s, it’s bidded, it’s expected to begin the construction in a short time. The cost will be 372 MP. In Rosarito, B. C. Capacity 2, 190 l/s, the expected investment is 1, 300 MDP, USA would participate in its construction In Puerto Peñasco, Son. Capacity 4, 700 l/s in a 1 st phase. Is an iniciative from Sonora State, the water will be used to municipality and agricultural.

• Bad qualification. • Lack of consultation of the supplier. • Response time of the qualified personnel. Insufficiency in: • Specialized tools stock • Membranes Stock • Electronic and electric equipment Reserve pumps

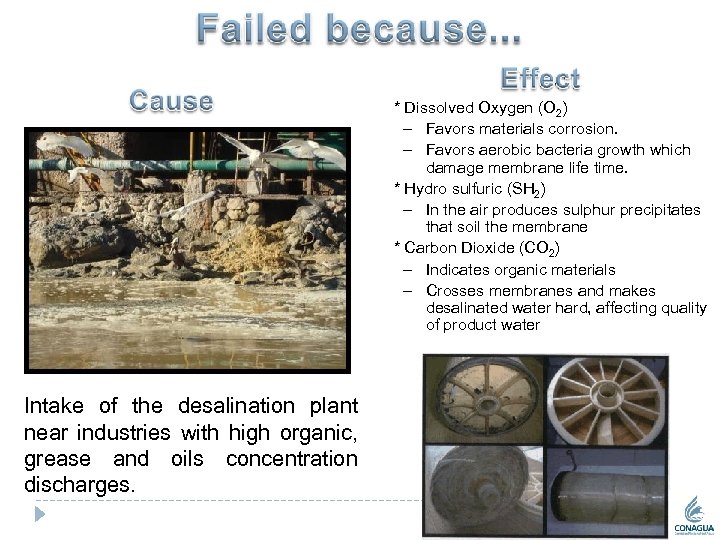

* Dissolved Oxygen (O 2) – Favors materials corrosion. – Favors aerobic bacteria growth which damage membrane life time. * Hydro sulfuric (SH 2) – In the air produces sulphur precipitates that soil the membrane * Carbon Dioxide (CO 2) – Indicates organic materials – Crosses membranes and makes desalinated water hard, affecting quality of product water Intake of the desalination plant near industries with high organic, grease and oils concentration discharges.

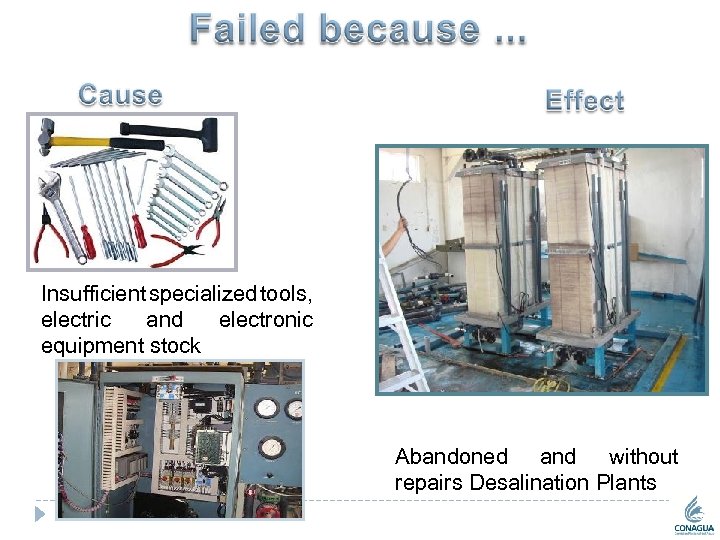

Insufficient specialized tools, electric and electronic equipment stock Abandoned and without repairs Desalination Plants

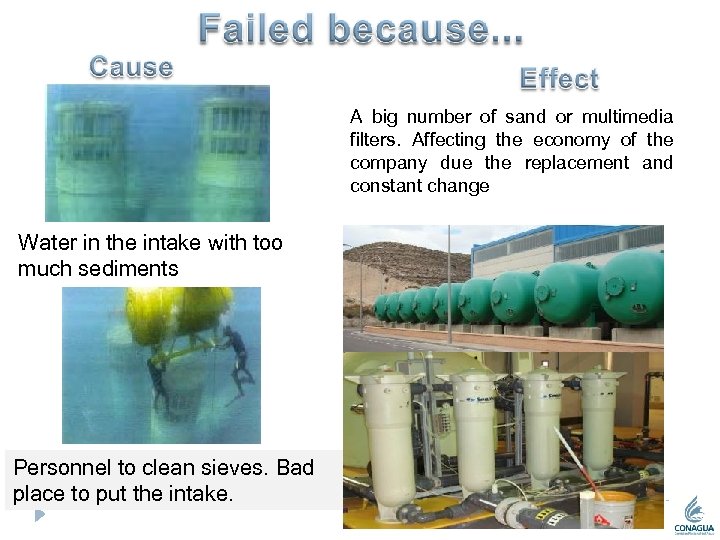

A big number of sand or multimedia filters. Affecting the economy of the company due the replacement and constant change Water in the intake with too much sediments Personnel to clean sieves. Bad place to put the intake.

• Sea water intake with organic materials • Poor knowledge on desalination • Personnel in charge with low education level • Intake without previous filtration • Bad application of anti-scalants • Non suitable acid circuits neither time nor concentration • Non suitable membranes to water quality in the intake • Damages the heart of membranes frame of reverse osmosis

Qualified personnel and a good and suitable administration, with knowledge and faith in desalination success.

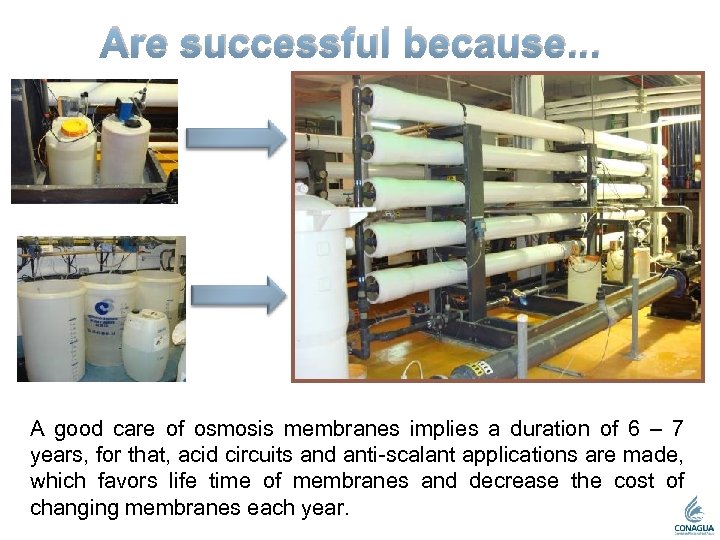

Are successful because. . . A good care of osmosis membranes implies a duration of 6 – 7 years, for that, acid circuits and anti-scalant applications are made, which favors life time of membranes and decrease the cost of changing membranes each year.

Are successful because. . . Investment in high definition electronic equipment, assuring correct operation of desalination plant, avoiding productions stops and with that decrease in tanks levels and dead times which means costs to the company

Before the pressure that will be exerted by the implementation of water desalination processes in our country due shortage of freshwater, is essential to have clear rules, of handling and management of this facilities, and the quality products, subproducts and wastes must fulfill, with the intention of fulfill two basic objectives, increasing water supply and not to contaminate.

• The National Water Law defines concession like the Title that is granted through CONAGUA or the River Basin Organization that correspond, according to its respective competitions, for the extraction or use of national waters, and their inherent public assets, to persons or companies, public or private, except allocation titles. (Artt. 15 Fracc. III) • And refers that concession for the inner sea water or territorial sea extraction or use won’t be required, except for those to be desalinated, which will be object of concession. (Art. 17) • In addition, indicates like public works, concerning to Federation, through CONAGUA, those that allows supply, purification and desalination which construction affects two or more states (Art. 96 BIS 2, Fracc. IV)

NOM-000 -CNA-0000, Drinking Water (Project) – To establish specifications to be fulfilled by sea and brackish water desalination plants for consumption and human use, as well as wastewater discharges. The established specifications would be mandatory for all public or private facilities whose purpose is sea or brackish water desalination , whatever the procedure used for this purpose, are also bound water thus obtained, which are integrated – in the case of sea water desalination - in the hydrologic cycle, along with freshwater and renewable groundwater.

Administrative • Administrative authorization for grant and permit of discharge, to conduct sea or brackish water desalination. • Product water is considered national water when incorporates to national assets. And are responsible of the urban public system when are discharged to sewerage. • Desalination plants whose construction affects two or more states, are considered necessary public works, that concern to CONAGUA. Product water quality and wastes The options for handling and disposal of brine are not specifically about the effects on human health and ecosystems. Discharges of brine must be placed in areas with a good enough hydrodynamics to facilitate salt dispersion. It should propose a pilot project to identify and test the operation conditions of the plant before the construction of the real project.

Monitoring • Responsible of the discharge will submit the monitoring report and parameters analysis with the frequency required on its discharge permit. • In situations that a major control is required, CONAGUA could adjust the frequency of analysis and reports.

Conclusions • The use of techniques for obtaining non-renewable resources such as water desalination should be considered after considering all possible forms of savings in all sectors of water. • Quality of water obtained by desalination processes is suitable for any type of human consumption, supply and irrigation. • Only some very specific industrial processes require special treatment. • Currently, in some countries, desalination is one of the mail source of water, with a large number of desalination plants with a fully satisfactory performance. • In Mexico, the most commonly used for water desalination is reverse osmosis, with 76% of the plants according to the inventory, and most of them in the hotel industry.

Conclusions • The desalination plant in Los Cabos is the first installed in Mexico, to supply water to a community of 40 thousand inhabitants, which has made desalination in Mexico one of the options to reduce water shortage • It’s expected that in the medium term, desalination would be an option to apply to different uses of human consumption, such as irrigation of high value crops in greenhouses. • Should not be denied the environmental impact related to desalination plants, the most important are brine discharge, chemical and generation of CO 2 y Nox caused by energy consumption. • Given this, and finally, appropriate legislation (to the gradual introduction of these plants) can minimize these impacts (of dynamic nature), as opposed to the permanent environmental impact arising from these large hydraulic works

Subdirección General Técnica Gerencia de Ingeniería y Normas Técnicas Ing. Mario López Pérez mario. lopezperez@conagua. gob. mx

7c9ded85e2602807d1917b8f45456bc2.ppt