94598a795081ee90a1ab9ec20375d5ea.ppt

- Количество слайдов: 23

Structural Health Monitoring of Steel Bridges Pradipta Banerji Professor of Civil Engineering, IIT Bombay CE 152 LECTURE

Overview n Why Structural Health Monitoring? n How Structural Health Monitoring? n Investigation for an Example Steel Bridge n Outcomes from the Investigation

Why SHM? n Health Assessment for Increased Service Loads n Condition Assessment for Aged Structures n Life Extension Beyond Design Life n Experimental Verification of Design Procedure

How SHM? n Measure Sensitive Structural Responses to Loads Use Mathematical Model of Structure n Optimize Information and Sensor Requirements n Determine Critical Sensor Locations n Determine Sensor and DAQ Requirements

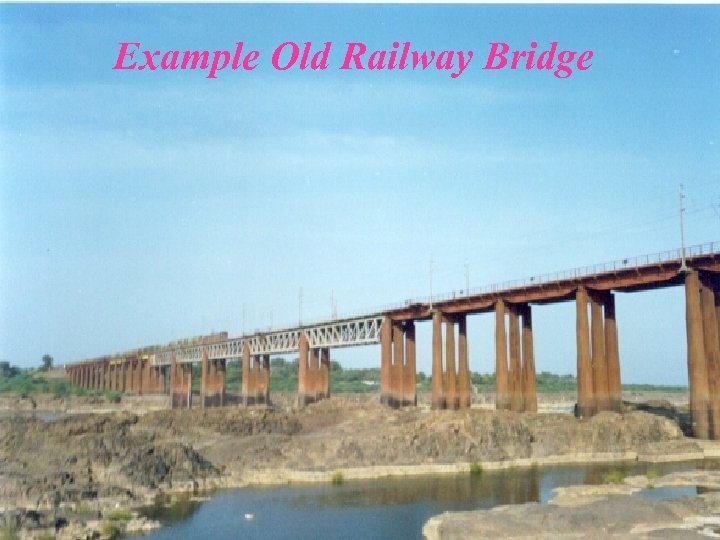

Example Old Railway Bridge

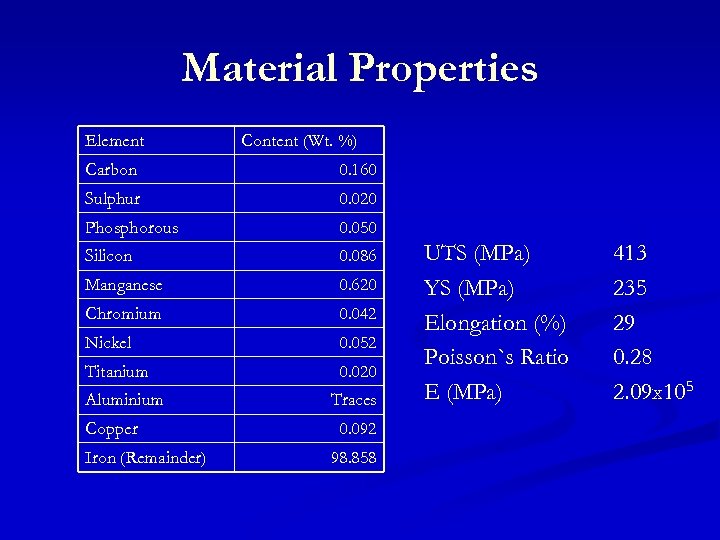

Material Properties Element Content (Wt. %) Carbon 0. 160 Sulphur 0. 020 Phosphorous 0. 050 Silicon 0. 086 Manganese 0. 620 Chromium 0. 042 Nickel 0. 052 Titanium 0. 020 Aluminium Copper Iron (Remainder) Traces 0. 092 98. 858 UTS (MPa) YS (MPa) Elongation (%) Poisson`s Ratio E (MPa) 413 235 29 0. 28 2. 09 x 105

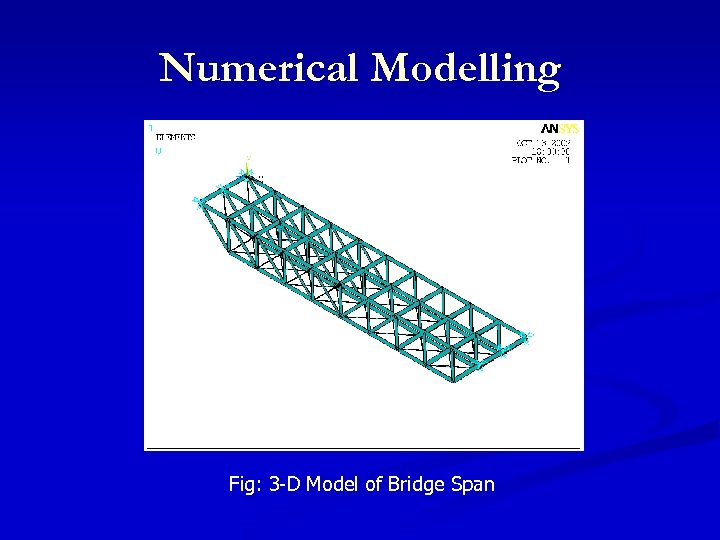

Numerical Modelling Fig: 3 -D Model of Bridge Span

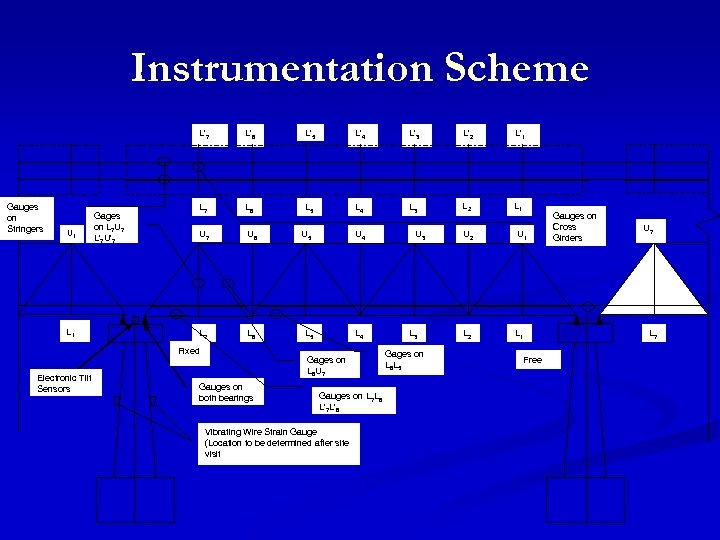

Instrumentation Scheme L'7 Gauges on Stringers U 1 L 1 Gages on L 7 U 7 L'7 U'7 L'6 L'5 L'4 L'3 L'2 L'1 L 7 L 6 L 5 L 4 L 3 L 2 L 1 U 7 U 6 U 5 U 4 U 2 U 1 L 7 L 6 L 5 L 4 L 2 L 1 Fixed Electronic Tilt Sensors Gages on L 6 U 7 Gauges on both bearings Gauges on L 7 L 8 L'7 L'8 Vibrating Wire Strain Gauge (Location to be determined after site visit U 3 L 3 Gages on L 6 L 5 Gauges on Cross Girders U 7 L 7 Free

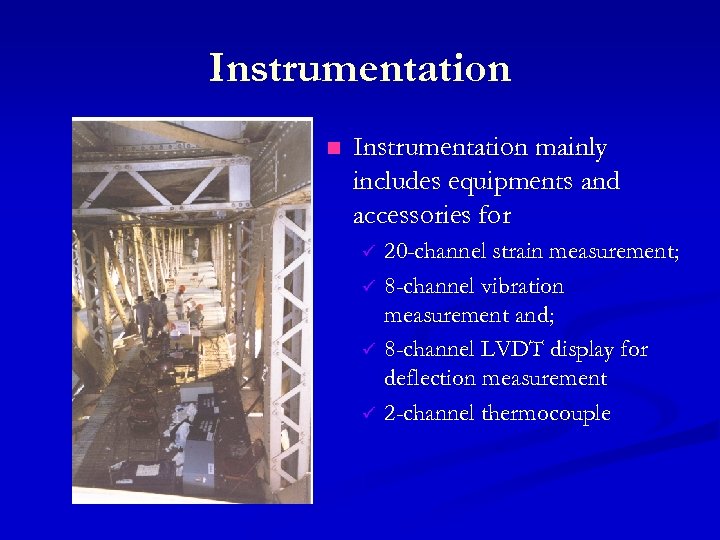

Instrumentation n Instrumentation mainly includes equipments and accessories for ü ü 20 -channel strain measurement; 8 -channel vibration measurement and; 8 -channel LVDT display for deflection measurement 2 -channel thermocouple

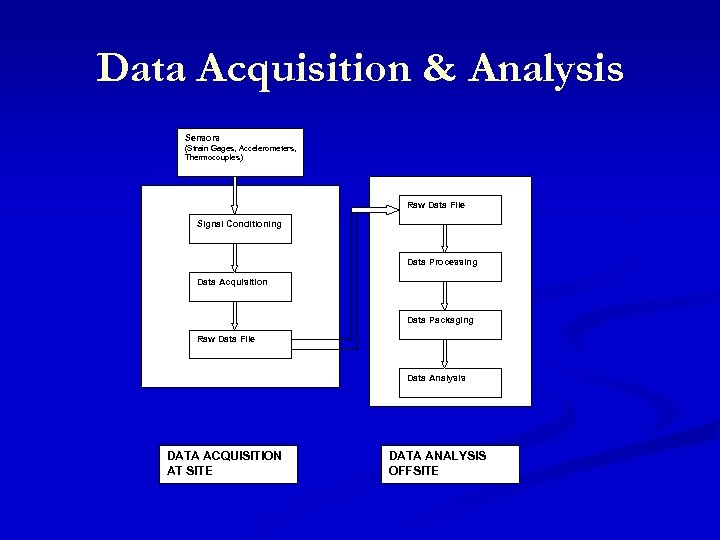

Data Acquisition & Analysis Sensors (Strain Gages, Accelerometers, Thermocouples) Raw Data File Signal Conditioning Data Processing Data Acquisition Data Packaging Raw Data File Data Analysis DATA ACQUISITION AT SITE DATA ANALYSIS OFFSITE

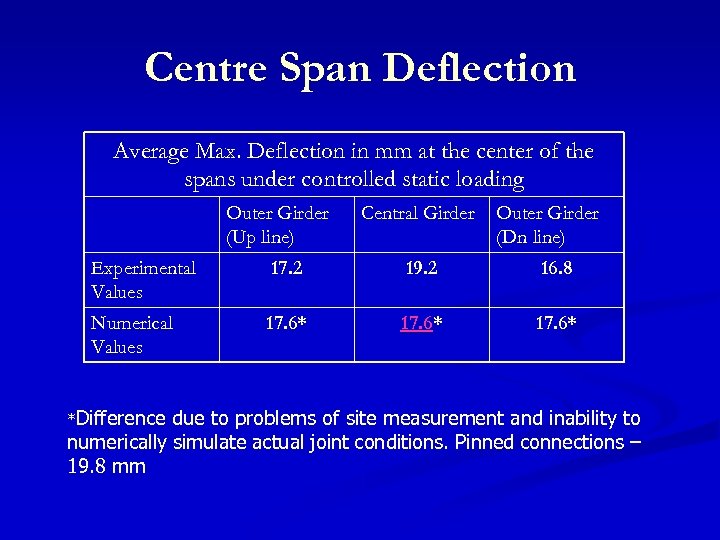

Centre Span Deflection Average Max. Deflection in mm at the center of the spans under controlled static loading Outer Girder (Up line) Central Girder Outer Girder (Dn line) Experimental Values 17. 2 19. 2 16. 8 Numerical Values 17. 6* *Difference due to problems of site measurement and inability to numerically simulate actual joint conditions. Pinned connections – 19. 8 mm

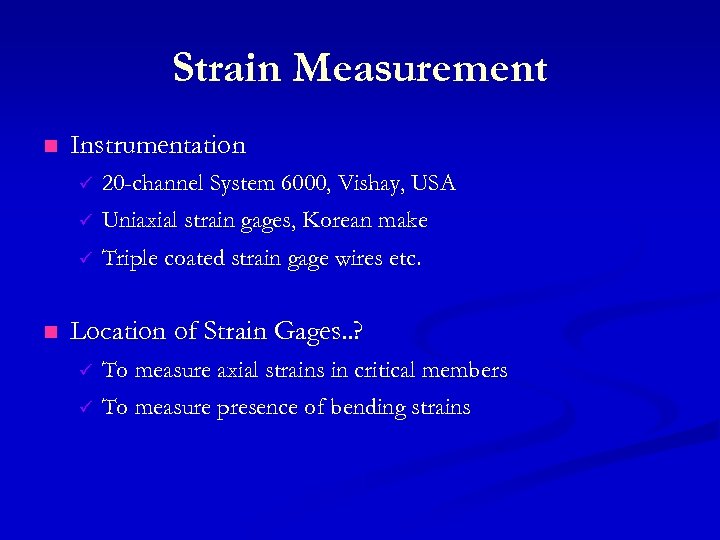

Strain Measurement n Instrumentation ü ü Uniaxial strain gages, Korean make ü n 20 -channel System 6000, Vishay, USA Triple coated strain gage wires etc. Location of Strain Gages. . ? ü To measure axial strains in critical members ü To measure presence of bending strains

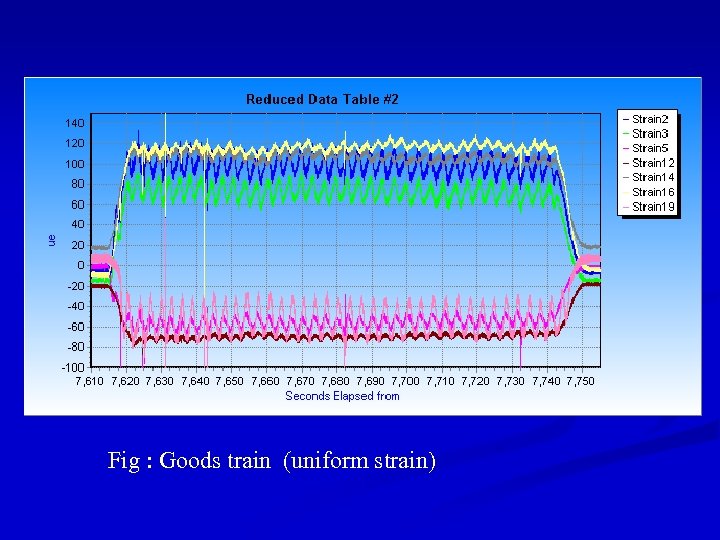

Fig : Goods train (uniform strain)

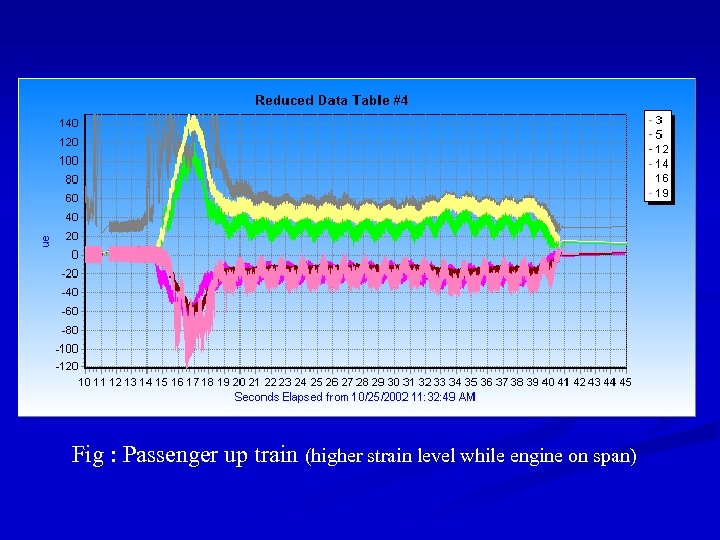

Fig : Passenger up train (higher strain level while engine on span)

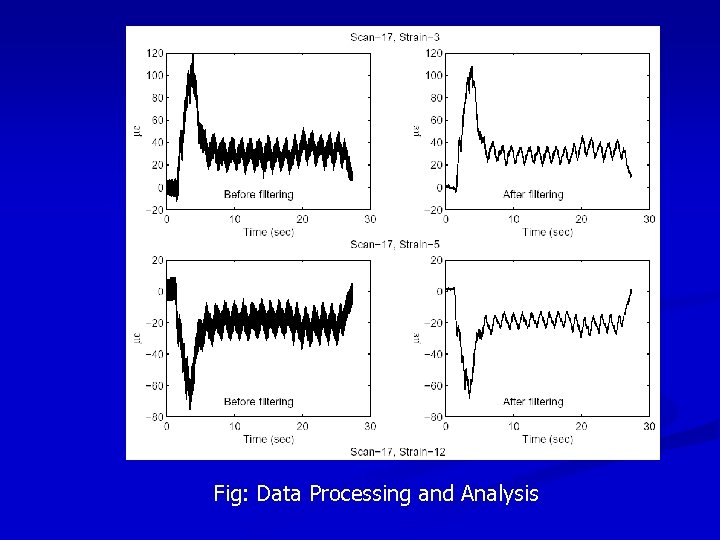

Fig: Data Processing and Analysis

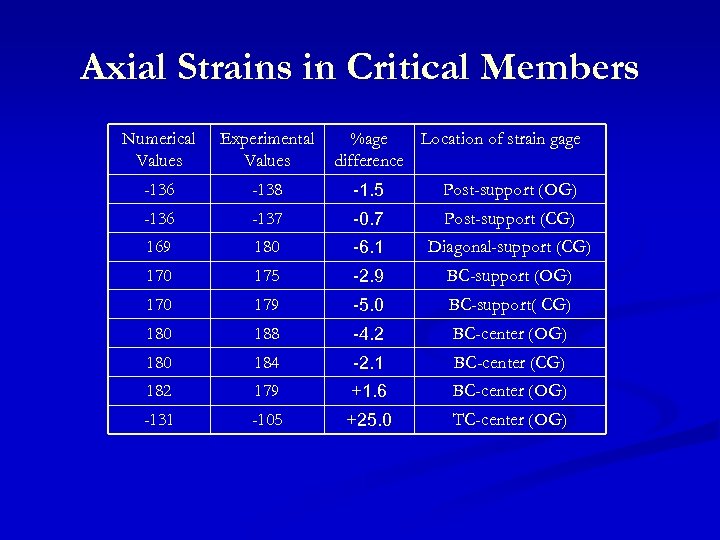

Axial Strains in Critical Members Numerical Values Experimental Values %age Location of strain gage difference -136 -138 -1. 5 Post-support (OG) -136 -137 -0. 7 Post-support (CG) 169 180 -6. 1 Diagonal-support (CG) 170 175 -2. 9 BC-support (OG) 170 179 -5. 0 BC-support( CG) 180 188 -4. 2 BC-center (OG) 180 184 -2. 1 BC-center (CG) 182 179 +1. 6 BC-center (OG) -131 -105 +25. 0 TC-center (OG)

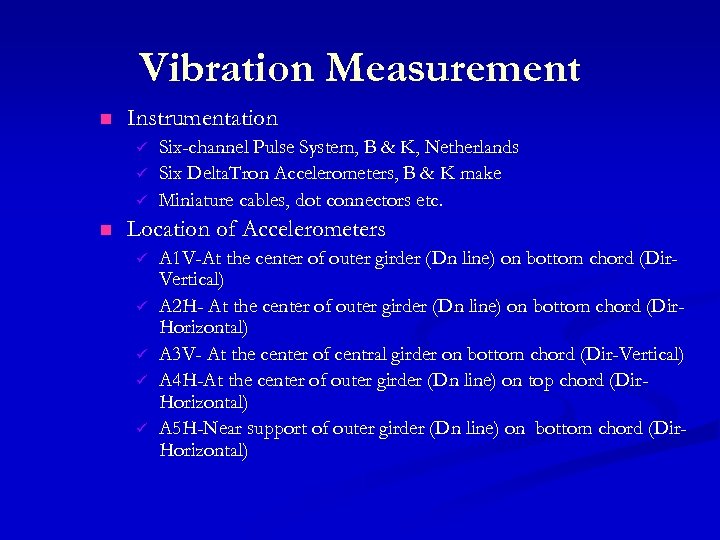

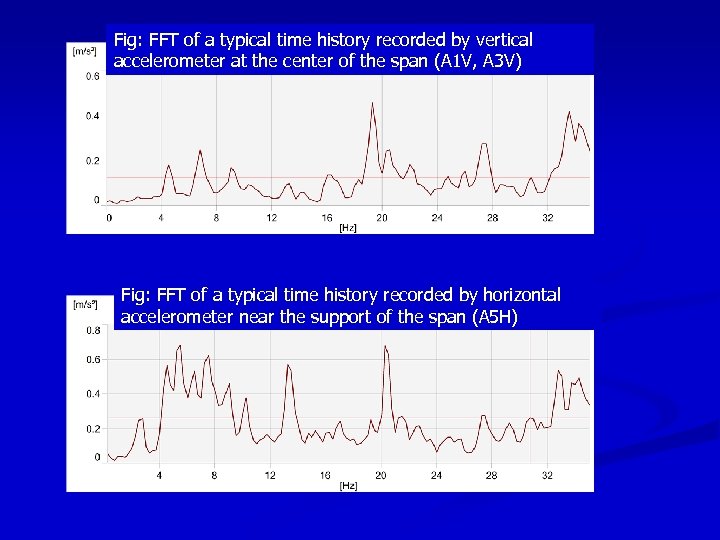

Vibration Measurement n Instrumentation ü ü ü n Six-channel Pulse System, B & K, Netherlands Six Delta. Tron Accelerometers, B & K make Miniature cables, dot connectors etc. Location of Accelerometers ü ü ü A 1 V-At the center of outer girder (Dn line) on bottom chord (Dir. Vertical) A 2 H- At the center of outer girder (Dn line) on bottom chord (Dir. Horizontal) A 3 V- At the center of central girder on bottom chord (Dir-Vertical) A 4 H-At the center of outer girder (Dn line) on top chord (Dir. Horizontal) A 5 H-Near support of outer girder (Dn line) on bottom chord (Dir. Horizontal)

Fig: FFT of a typical time history recorded by vertical accelerometer at the center of the span (A 1 V, A 3 V) Fig: FFT of a typical time history recorded by horizontal accelerometer near the support of the span (A 5 H)

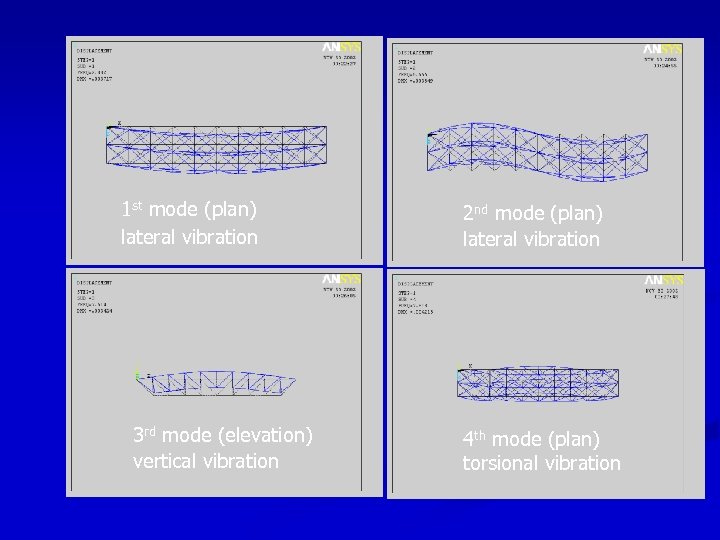

1 st mode (plan) lateral vibration 3 rd mode (elevation) vertical vibration 2 nd mode (plan) lateral vibration 4 th mode (plan) torsional vibration

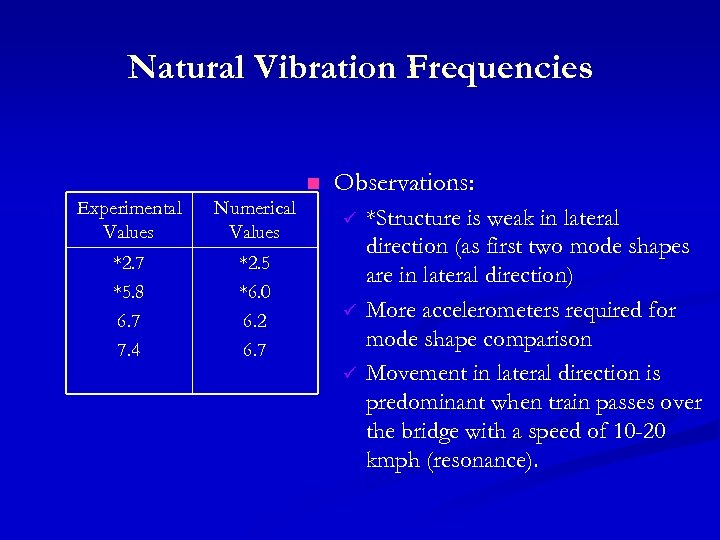

Natural Vibration Frequencies n Experimental Values Numerical Values *2. 7 *5. 8 6. 7 7. 4 *2. 5 *6. 0 6. 2 6. 7 Observations: ü ü ü *Structure is weak in lateral direction (as first two mode shapes are in lateral direction) More accelerometers required for mode shape comparison Movement in lateral direction is predominant when train passes over the bridge with a speed of 10 -20 kmph (resonance).

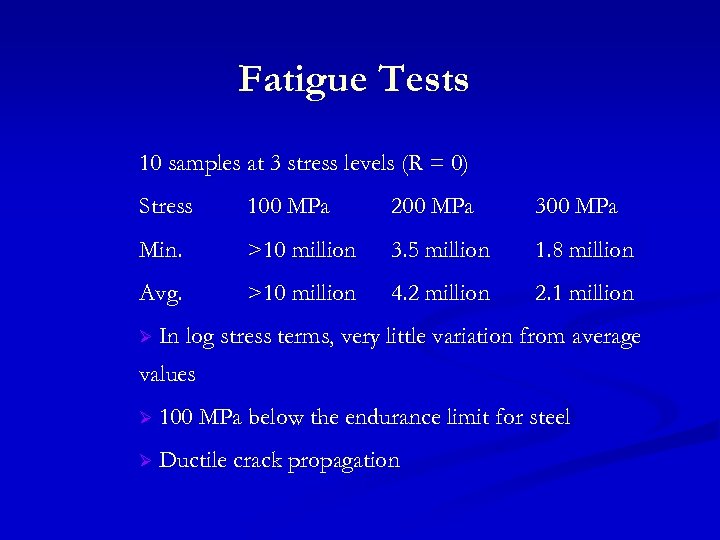

Fatigue Tests 10 samples at 3 stress levels (R = 0) Stress 100 MPa 200 MPa 300 MPa Min. >10 million 3. 5 million 1. 8 million Avg. >10 million 4. 2 million 2. 1 million Ø In log stress terms, very little variation from average values Ø 100 MPa below the endurance limit for steel Ø Ductile crack propagation

Remaining Life Assessment n n n Use Miner’s Rule for estimating remaining life Use rainfall counting procedures to estimate stress histograms Maximum dynamic stress (incl. DL) Chords 150 MPa Bracings (5 million cycles) 80 MPa (below endurance limit) n Estimate of traffic over last 95 years = 900, 000 n Remaining life at current traffic - 45 years

Conclusions Objective of SHM has to be clear n Comprehensive procedure for condition and remaining life assessment is illustrated n Metallurgy, physical and fatigue test show the ductile crack propagation phenomenon n Experimentally validated numerical model used to determine current condition and estimate remaining life based on current traffic conditions n

94598a795081ee90a1ab9ec20375d5ea.ppt