22c6b6524db66d2d43715faec6cd8703.ppt

- Количество слайдов: 89

STRENGTHENING STRUCTURES USING FRP COMPOSITE MATERIALS DAMIAN I. KACHLAKEV, Ph. D. , P. E. California Polytechnic State University San Luis Obispo

STRENGTHENING STRUCTURES USING FRP COMPOSITE MATERIALS DAMIAN I. KACHLAKEV, Ph. D. , P. E. California Polytechnic State University San Luis Obispo

WHY COMPOSITES? • ADVANTAGES OVER TRADITIONAL MATERIALS • CORROSION RESISTANCE • HIGH STRENGTH TO WEIGHT RATIO • LOW MAINTENANCE • EXTENDED SERVICE LIFE • DESIGN FLEXIBILITY

WHY COMPOSITES? • ADVANTAGES OVER TRADITIONAL MATERIALS • CORROSION RESISTANCE • HIGH STRENGTH TO WEIGHT RATIO • LOW MAINTENANCE • EXTENDED SERVICE LIFE • DESIGN FLEXIBILITY

COMPOSITES DEFINITION • A combination of two or more materials (reinforcement, resin, filler, etc. ), differing in form or composition on a macroscale. The constituents retain their identities, i. e. . , they do not dissolve or merge into each other, although they act in concert. Normally, the components can be physically identified and exhibit an interface between each other.

COMPOSITES DEFINITION • A combination of two or more materials (reinforcement, resin, filler, etc. ), differing in form or composition on a macroscale. The constituents retain their identities, i. e. . , they do not dissolve or merge into each other, although they act in concert. Normally, the components can be physically identified and exhibit an interface between each other.

DEFINITION Fiber Reinforced Polymer (FRP) Composites are defined as: “A matrix of polymeric material that is reinforced by fibers or other reinforcing material”

DEFINITION Fiber Reinforced Polymer (FRP) Composites are defined as: “A matrix of polymeric material that is reinforced by fibers or other reinforcing material”

COMPOSITES MARKETS • • TRANSPORTATION CONSTRUCTION MARINE CORROSION-RESISTANT CONSUMER ELECTRICAL/ELECTRONIC APPLIANCES/BUSINESS AIRCRAFT/DEFENSE

COMPOSITES MARKETS • • TRANSPORTATION CONSTRUCTION MARINE CORROSION-RESISTANT CONSUMER ELECTRICAL/ELECTRONIC APPLIANCES/BUSINESS AIRCRAFT/DEFENSE

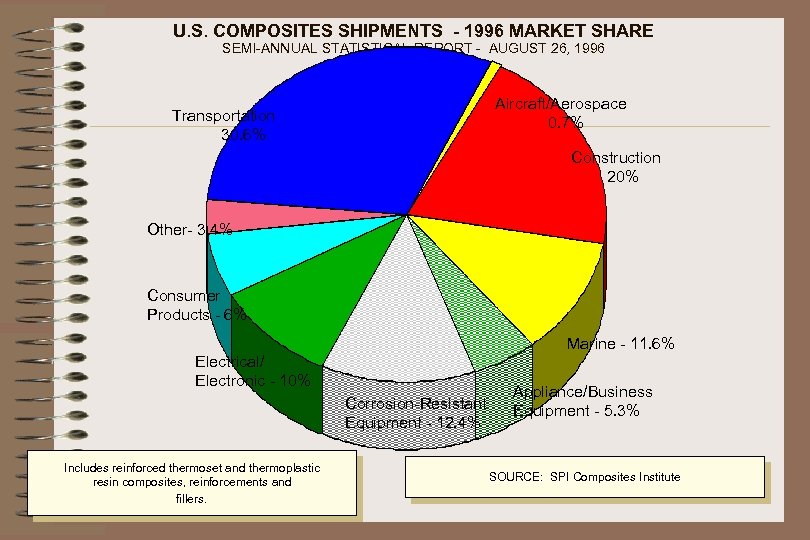

U. S. COMPOSITES SHIPMENTS - 1996 MARKET SHARE SEMI-ANNUAL STATISTICAL REPORT - AUGUST 26, 1996 Aircraft/Aerospace 0. 7% Transportation 30. 6% Construction 20% Other- 3. 4% Consumer Products - 6% Marine - 11. 6% Electrical/ Electronic - 10% Corrosion-Resistant Equipment - 12. 4% Includes reinforced thermoset and thermoplastic resin composites, reinforcements and fillers. Appliance/Business Equipment - 5. 3% SOURCE: SPI Composites Institute

U. S. COMPOSITES SHIPMENTS - 1996 MARKET SHARE SEMI-ANNUAL STATISTICAL REPORT - AUGUST 26, 1996 Aircraft/Aerospace 0. 7% Transportation 30. 6% Construction 20% Other- 3. 4% Consumer Products - 6% Marine - 11. 6% Electrical/ Electronic - 10% Corrosion-Resistant Equipment - 12. 4% Includes reinforced thermoset and thermoplastic resin composites, reinforcements and fillers. Appliance/Business Equipment - 5. 3% SOURCE: SPI Composites Institute

Infrastructure Benefits • • • HIGH STRENGTH/WEIGHT RATIO ORIENTATED STRENGTH DESIGN FLEXIBILITY LIGHTWEIGHT CORROSION RESISTANCE LOW MAINTENANCE/LONG-TERM DURABILITY LARGE PART SIZE POSSIBLE TAILORED AESTHETIC APPEARANCE DIMENSIONAL STABILITY LOW THERMAL CONDUCTIVITY LOW INSTALLED COSTS

Infrastructure Benefits • • • HIGH STRENGTH/WEIGHT RATIO ORIENTATED STRENGTH DESIGN FLEXIBILITY LIGHTWEIGHT CORROSION RESISTANCE LOW MAINTENANCE/LONG-TERM DURABILITY LARGE PART SIZE POSSIBLE TAILORED AESTHETIC APPEARANCE DIMENSIONAL STABILITY LOW THERMAL CONDUCTIVITY LOW INSTALLED COSTS

FRP COMPOSITE CONSTITUENTS • RESINS (POLYMERS) • REINFORCEMENTS • FILLERS • ADDITIVES

FRP COMPOSITE CONSTITUENTS • RESINS (POLYMERS) • REINFORCEMENTS • FILLERS • ADDITIVES

MATERIALS: RESINS • PRIMARY FUNCTION: “TO TRANSFER STRESS BETWEEN REINFORCING FIBERS AND TO PROTECT THEM FROM MECHANICAL AND ENVIRONMENTAL DAMAGE” • TYPES: – THERMOSET – THERMOPLASTIC

MATERIALS: RESINS • PRIMARY FUNCTION: “TO TRANSFER STRESS BETWEEN REINFORCING FIBERS AND TO PROTECT THEM FROM MECHANICAL AND ENVIRONMENTAL DAMAGE” • TYPES: – THERMOSET – THERMOPLASTIC

RESINS • THERMOSET – POLYESTER – VINYL ESTER – EPOXY – PHENOLIC – POLYURETHANE

RESINS • THERMOSET – POLYESTER – VINYL ESTER – EPOXY – PHENOLIC – POLYURETHANE

RESINS • THERMOPLASTIC – ACETAL – ACRYRONITRILE BUTADIENE STYRENE (ABS) – NYLON – POLYETHYLENE (PE) – POLYPROPYLENE (PP) – POLYETHYLENE TEREPHTHALATE (PET)

RESINS • THERMOPLASTIC – ACETAL – ACRYRONITRILE BUTADIENE STYRENE (ABS) – NYLON – POLYETHYLENE (PE) – POLYPROPYLENE (PP) – POLYETHYLENE TEREPHTHALATE (PET)

RESINS • THERMOSET ADVANTAGES – THERMAL STABILITY – CHEMICAL RESISTANCE – REDUCED CREEP AND STRESS RELAXATION – LOW VISCOSITY- EXCELLENT FOR FIBER ORIENTATION – COMMON MATERIAL WITH FABRICATORS

RESINS • THERMOSET ADVANTAGES – THERMAL STABILITY – CHEMICAL RESISTANCE – REDUCED CREEP AND STRESS RELAXATION – LOW VISCOSITY- EXCELLENT FOR FIBER ORIENTATION – COMMON MATERIAL WITH FABRICATORS

RESINS • THERMOPLASTIC ADVANTAGES – ROOM TEMPERATURE MATERIAL STORAGE – RAPID, LOW COST FORMING – REFORMABLE – FORMING PRESSURES AND TEMPERATURES

RESINS • THERMOPLASTIC ADVANTAGES – ROOM TEMPERATURE MATERIAL STORAGE – RAPID, LOW COST FORMING – REFORMABLE – FORMING PRESSURES AND TEMPERATURES

POLYESTERS • • LOW COST EXTREME PROCESSING VERSATILITY LONG HISTORY OF PERFORMANCE MAJOR USES: – Transportation – Construction – Marine

POLYESTERS • • LOW COST EXTREME PROCESSING VERSATILITY LONG HISTORY OF PERFORMANCE MAJOR USES: – Transportation – Construction – Marine

VINYL ESTER • SIMILAR TO POLYESTER • EXCELLENT MECHANICAL & FATIGUE PROPERTIES • EXCELLENT CHEMICAL RESISTANCE • MAJOR USES: – Corrosion Applications - Pipes, Tanks, & Ducts

VINYL ESTER • SIMILAR TO POLYESTER • EXCELLENT MECHANICAL & FATIGUE PROPERTIES • EXCELLENT CHEMICAL RESISTANCE • MAJOR USES: – Corrosion Applications - Pipes, Tanks, & Ducts

EPOXY • • • EXCELLENT MECHANICAL PROPERTIES GOOD FATIGUE RESISTANCE LOW SHRINKAGE GOOD HEAT AND CHEMICAL RESISTANCE MAJOR USES: – FRP Strengthening Systems – FRP Rebars – FRP Stay-in-Place Forms

EPOXY • • • EXCELLENT MECHANICAL PROPERTIES GOOD FATIGUE RESISTANCE LOW SHRINKAGE GOOD HEAT AND CHEMICAL RESISTANCE MAJOR USES: – FRP Strengthening Systems – FRP Rebars – FRP Stay-in-Place Forms

PHENOLICS • • EXCELLENT FIRE RETARDANCE LOW SMOKE & TOXICITY EMISSIONS HIGH STRENGTH AT HIGH TEMPERATURES MAJOR USES: – Mass Transit - Fire Resistance & High Temperature – Ducting

PHENOLICS • • EXCELLENT FIRE RETARDANCE LOW SMOKE & TOXICITY EMISSIONS HIGH STRENGTH AT HIGH TEMPERATURES MAJOR USES: – Mass Transit - Fire Resistance & High Temperature – Ducting

POLYURETHANE • TOUGH • GOOD IMPACT RESISTANCE • GOOD SURFACE QUALITY • MAJOR USES: – Bumper Beams, Automotive Panels

POLYURETHANE • TOUGH • GOOD IMPACT RESISTANCE • GOOD SURFACE QUALITY • MAJOR USES: – Bumper Beams, Automotive Panels

SUMMARY: POLYMERS • WIDE VARIETY AVAILABLE • SELECTION BASED ON: – PHYSICAL AND MECHANICAL PROPERTIES OF PRODUCT – FABRICATION PROCESS REQUIREMENTS

SUMMARY: POLYMERS • WIDE VARIETY AVAILABLE • SELECTION BASED ON: – PHYSICAL AND MECHANICAL PROPERTIES OF PRODUCT – FABRICATION PROCESS REQUIREMENTS

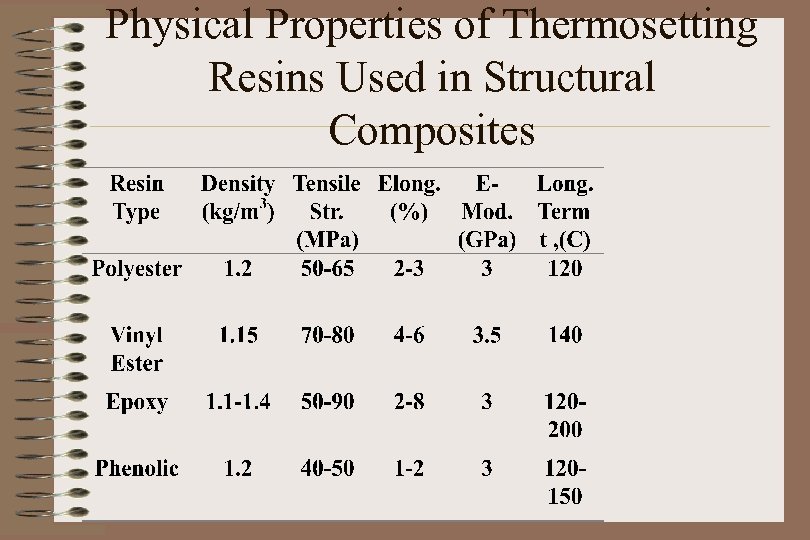

Physical Properties of Thermosetting Resins Used in Structural Composites

Physical Properties of Thermosetting Resins Used in Structural Composites

MATERIAL: FIBER REINFORCEMENTS • PRIMARY FUNCTION: “CARRY LOAD ALONG THE LENGTH OF THE FIBER, PROVIDES STRENGTH AND OR STIFFNESS IN ONE DIRECTION” • CAN BE ORIENTED TO PROVIDE PROPERTIES IN DIRECTIONS OF PRIMARY LOADS

MATERIAL: FIBER REINFORCEMENTS • PRIMARY FUNCTION: “CARRY LOAD ALONG THE LENGTH OF THE FIBER, PROVIDES STRENGTH AND OR STIFFNESS IN ONE DIRECTION” • CAN BE ORIENTED TO PROVIDE PROPERTIES IN DIRECTIONS OF PRIMARY LOADS

REINFORCEMENTS • NATURAL • MAN-MADE • MANY VARIETIES COMMERCIALLY AVAILABLE

REINFORCEMENTS • NATURAL • MAN-MADE • MANY VARIETIES COMMERCIALLY AVAILABLE

MAN-MADE FIBERS • • ARAMID BORON CARBON/GRAPHITE GLASS NYLON POLYESTER POLYETHYLENE POLYPROPYLENE

MAN-MADE FIBERS • • ARAMID BORON CARBON/GRAPHITE GLASS NYLON POLYESTER POLYETHYLENE POLYPROPYLENE

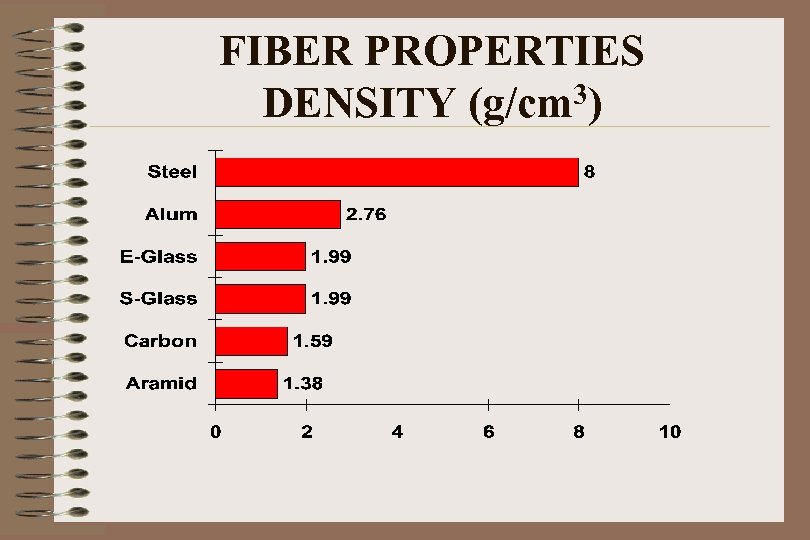

FIBER PROPERTIES DENSITY (g/cm 3)

FIBER PROPERTIES DENSITY (g/cm 3)

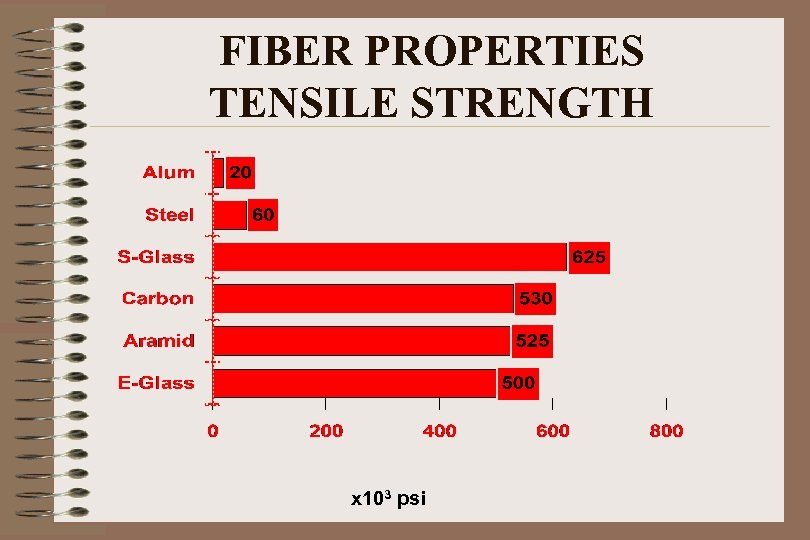

FIBER PROPERTIES TENSILE STRENGTH x 103 psi

FIBER PROPERTIES TENSILE STRENGTH x 103 psi

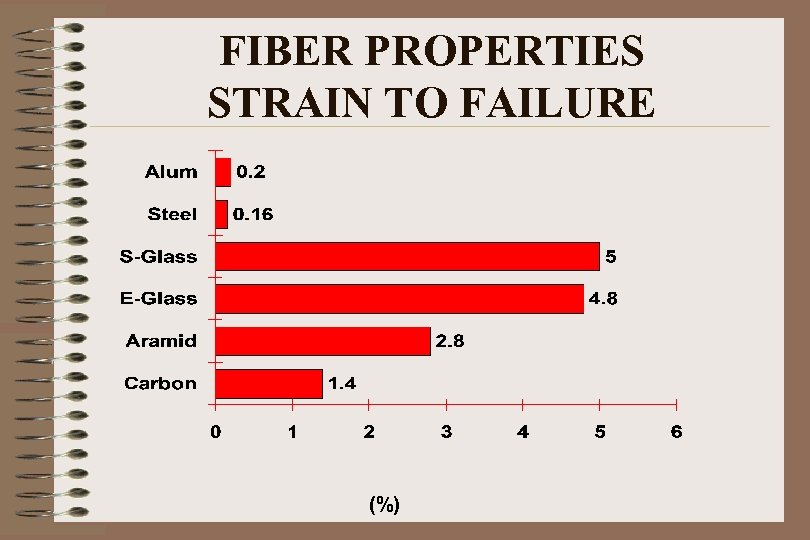

FIBER PROPERTIES STRAIN TO FAILURE (%)

FIBER PROPERTIES STRAIN TO FAILURE (%)

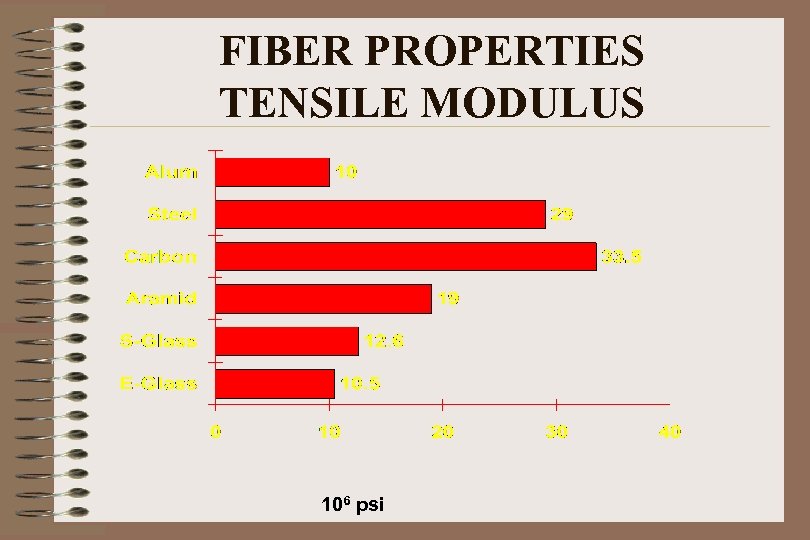

FIBER PROPERTIES TENSILE MODULUS 106 psi

FIBER PROPERTIES TENSILE MODULUS 106 psi

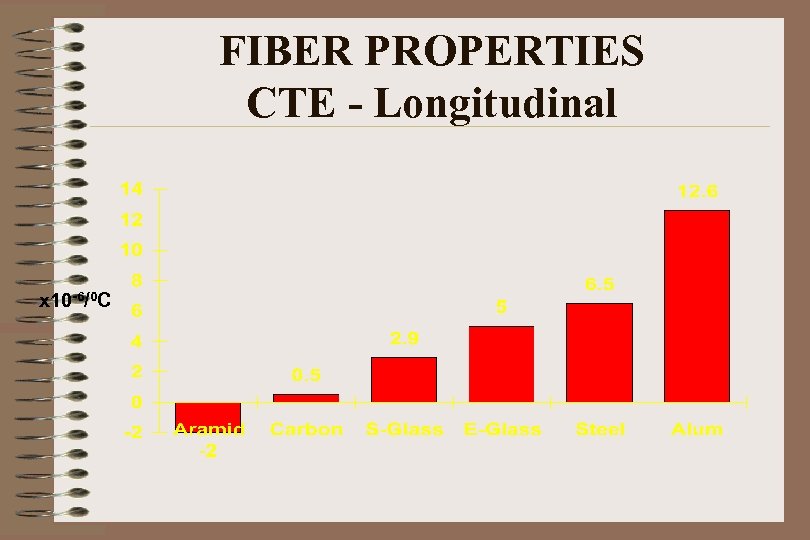

FIBER PROPERTIES CTE - Longitudinal x 10 -6/0 C

FIBER PROPERTIES CTE - Longitudinal x 10 -6/0 C

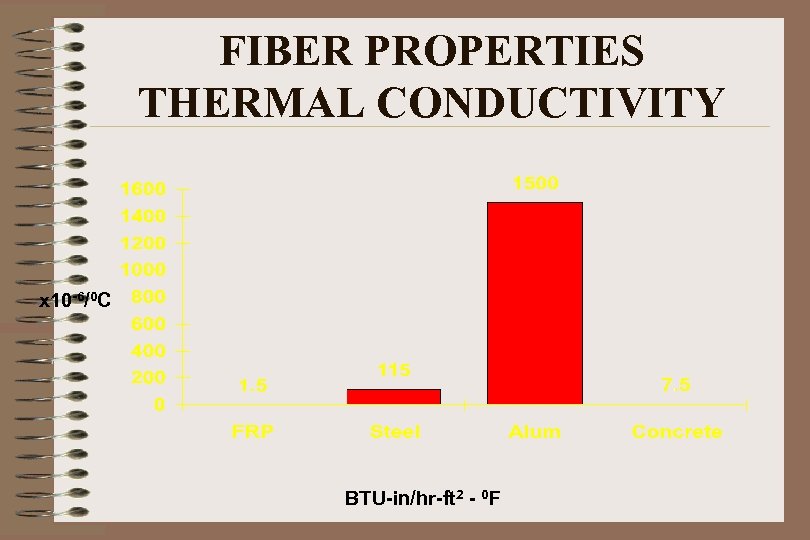

FIBER PROPERTIES THERMAL CONDUCTIVITY x 10 -6/0 C BTU-in/hr-ft 2 - 0 F

FIBER PROPERTIES THERMAL CONDUCTIVITY x 10 -6/0 C BTU-in/hr-ft 2 - 0 F

FIBER REINFORCEMENT • GLASS (E-GLASS) – MOST COMMON FIBER USED – HIGH STRENGTH – GOOD WATER RESISTANCE – GOOD ELECTRIC INSULATING PROPERTIES – LOW STIFFNESS

FIBER REINFORCEMENT • GLASS (E-GLASS) – MOST COMMON FIBER USED – HIGH STRENGTH – GOOD WATER RESISTANCE – GOOD ELECTRIC INSULATING PROPERTIES – LOW STIFFNESS

GLASS TYPES • • • E-GLASS S-GLASS C-GLASS ECR-GLASS AR-GLASS

GLASS TYPES • • • E-GLASS S-GLASS C-GLASS ECR-GLASS AR-GLASS

FIBER REINFORCEMENT • ARAMID (KEVLAR) – SUPERIOR RESISTANCE TO DAMAGE (ENERGY ABSORBER) – GOOD IN TENSION APPLICATIONS (CABLES, TENDONS) – MODERATE STIFFNESS – MORE EXPENSIVE THAN GLASS

FIBER REINFORCEMENT • ARAMID (KEVLAR) – SUPERIOR RESISTANCE TO DAMAGE (ENERGY ABSORBER) – GOOD IN TENSION APPLICATIONS (CABLES, TENDONS) – MODERATE STIFFNESS – MORE EXPENSIVE THAN GLASS

FIBER REINFORCEMENT • CARBON – GOOD MODULUS AT HIGH TEMPERATURES – EXCELLENT STIFFNESS – MORE EXPENSIVE THAN GLASS – BRITTLE – LOW ELECTRIC INSULATING PROPERTIES

FIBER REINFORCEMENT • CARBON – GOOD MODULUS AT HIGH TEMPERATURES – EXCELLENT STIFFNESS – MORE EXPENSIVE THAN GLASS – BRITTLE – LOW ELECTRIC INSULATING PROPERTIES

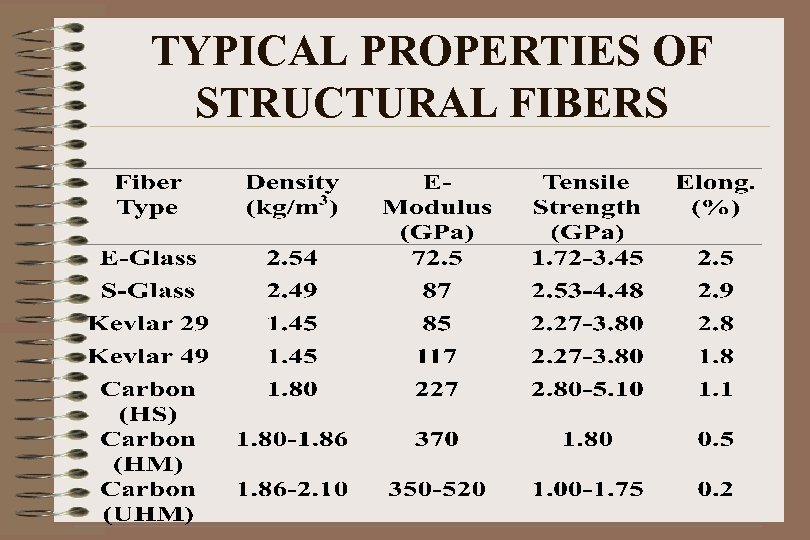

TYPICAL PROPERTIES OF STRUCTURAL FIBERS

TYPICAL PROPERTIES OF STRUCTURAL FIBERS

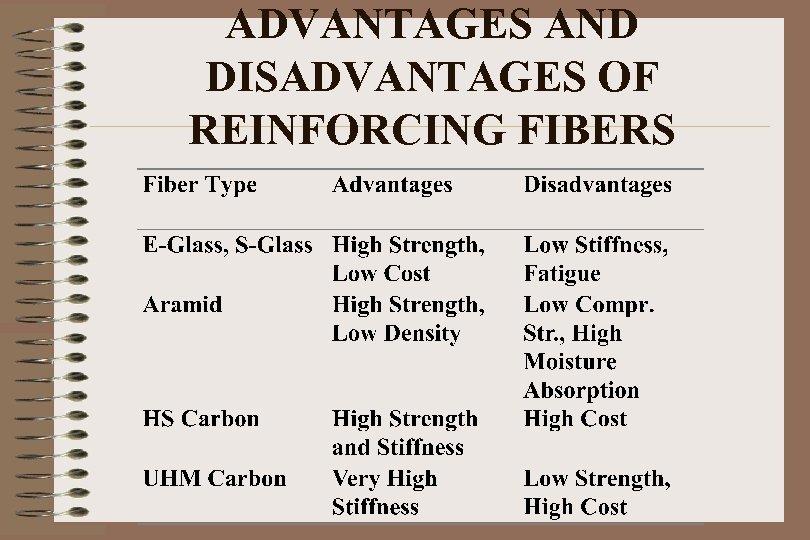

ADVANTAGES AND DISADVANTAGES OF REINFORCING FIBERS

ADVANTAGES AND DISADVANTAGES OF REINFORCING FIBERS

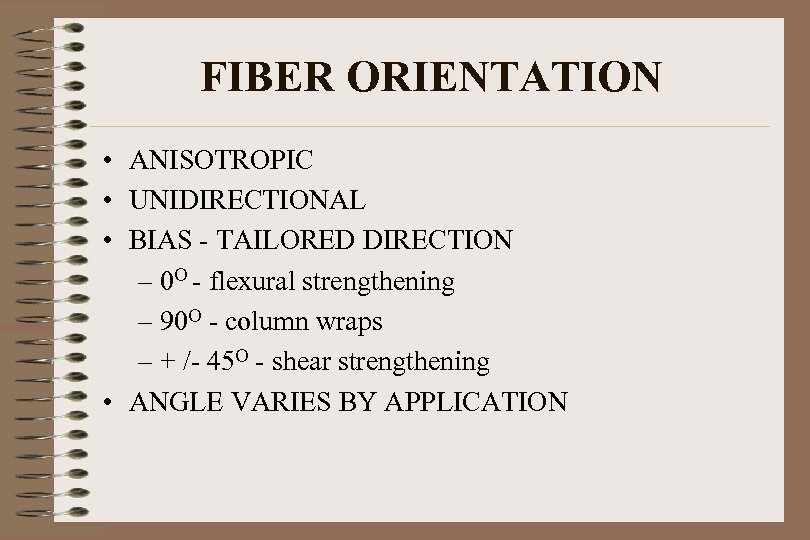

FIBER ORIENTATION • ANISOTROPIC • UNIDIRECTIONAL • BIAS - TAILORED DIRECTION – 0 O - flexural strengthening – 90 O - column wraps – + /- 45 O - shear strengthening • ANGLE VARIES BY APPLICATION

FIBER ORIENTATION • ANISOTROPIC • UNIDIRECTIONAL • BIAS - TAILORED DIRECTION – 0 O - flexural strengthening – 90 O - column wraps – + /- 45 O - shear strengthening • ANGLE VARIES BY APPLICATION

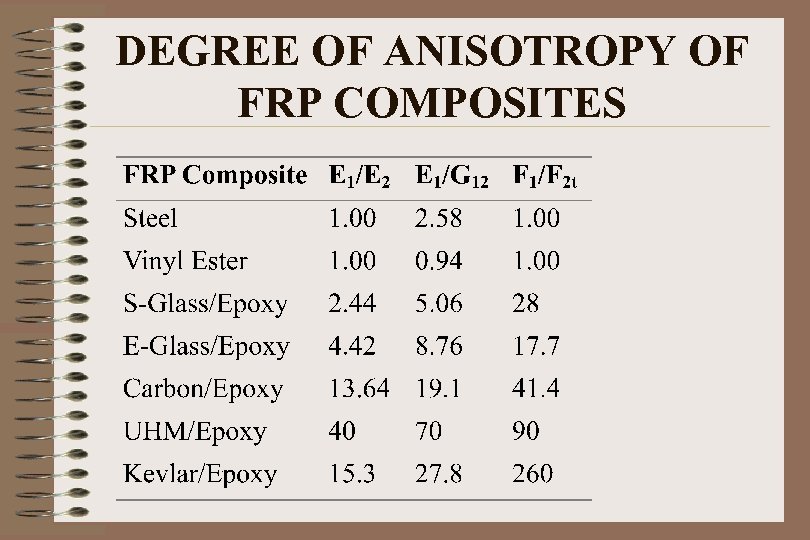

DEGREE OF ANISOTROPY OF FRP COMPOSITES

DEGREE OF ANISOTROPY OF FRP COMPOSITES

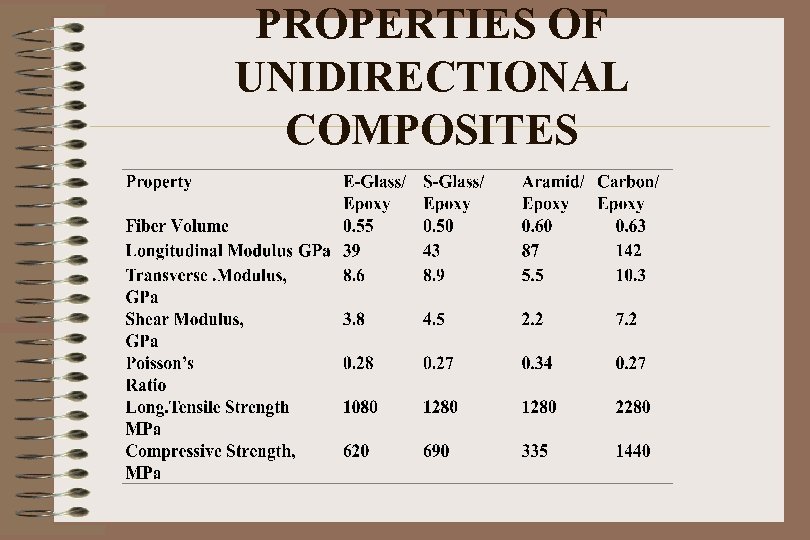

PROPERTIES OF UNIDIRECTIONAL COMPOSITES

PROPERTIES OF UNIDIRECTIONAL COMPOSITES

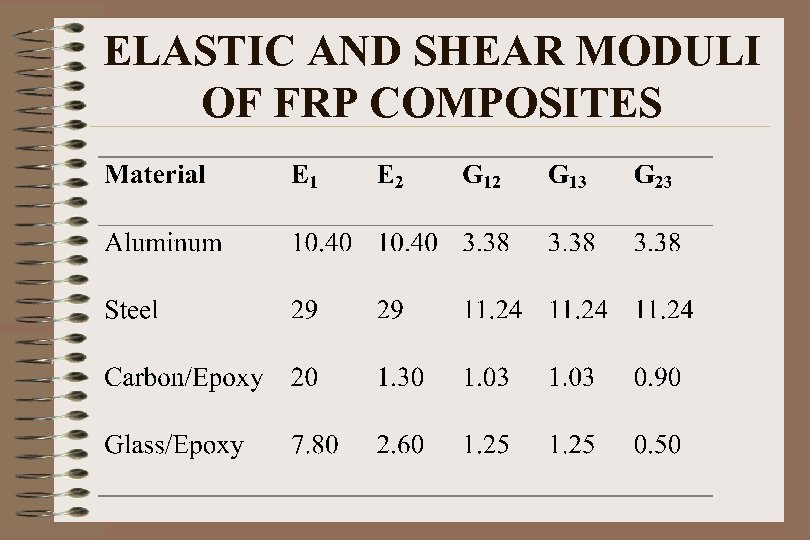

ELASTIC AND SHEAR MODULI OF FRP COMPOSITES

ELASTIC AND SHEAR MODULI OF FRP COMPOSITES

REINFORCEMENTS SUMMARY • TAILORING MECHANICAL PROPERTIES – TYPE OF FIBER – PERCENTAGE OF FIBER – ORIENTATION OF FIBER

REINFORCEMENTS SUMMARY • TAILORING MECHANICAL PROPERTIES – TYPE OF FIBER – PERCENTAGE OF FIBER – ORIENTATION OF FIBER

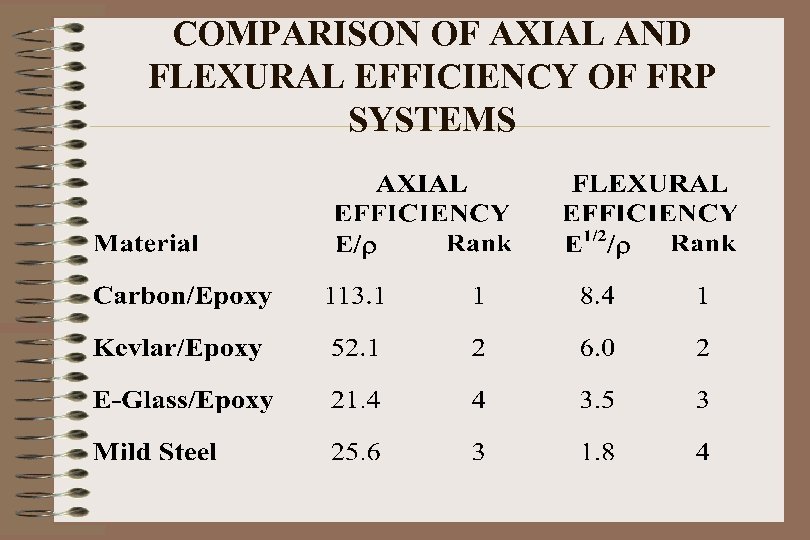

COMPARISON OF AXIAL AND FLEXURAL EFFICIENCY OF FRP SYSTEMS

COMPARISON OF AXIAL AND FLEXURAL EFFICIENCY OF FRP SYSTEMS

DESIGN VARIABLES FOR COMPOSITES • TYPE OF FIBER • PERCENTAGE OF FIBER or FIBER VOLUME • ORIENTATION OF FIBER – 0 o, 90 o, +45 o, -45 o • TYPE OF POLYMER (RESIN) • COST • VOLUME OF PRODUCT - MANUFACTURING METHOD

DESIGN VARIABLES FOR COMPOSITES • TYPE OF FIBER • PERCENTAGE OF FIBER or FIBER VOLUME • ORIENTATION OF FIBER – 0 o, 90 o, +45 o, -45 o • TYPE OF POLYMER (RESIN) • COST • VOLUME OF PRODUCT - MANUFACTURING METHOD

DESIGN VARIABLES FOR COMPOSITES • PHYSICAL: – tensile strength – compression strength – stiffness – weight, etc. • ENVIRONMENTAL: – Fire – UV – Corrosion Resistance

DESIGN VARIABLES FOR COMPOSITES • PHYSICAL: – tensile strength – compression strength – stiffness – weight, etc. • ENVIRONMENTAL: – Fire – UV – Corrosion Resistance

TAILORING COMPOSITE PROPERTIES • MAJOR FEATURE • PLACE MATERIALS WHERE NEEDED ORIENTED STRENGTH – LONGITUDINAL – TRANSVERSE – or between • STRENGTH • STIFFNESS • FIRE RETARDANCY

TAILORING COMPOSITE PROPERTIES • MAJOR FEATURE • PLACE MATERIALS WHERE NEEDED ORIENTED STRENGTH – LONGITUDINAL – TRANSVERSE – or between • STRENGTH • STIFFNESS • FIRE RETARDANCY

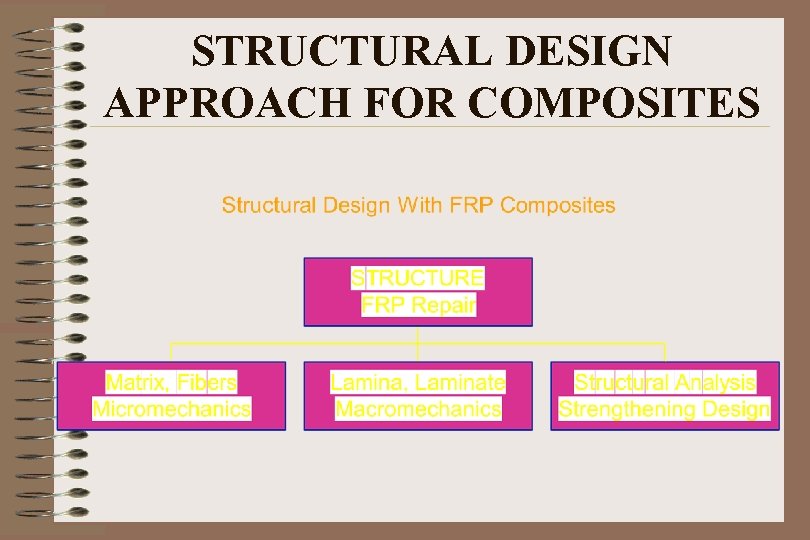

STRUCTURAL DESIGN APPROACH FOR COMPOSITES

STRUCTURAL DESIGN APPROACH FOR COMPOSITES

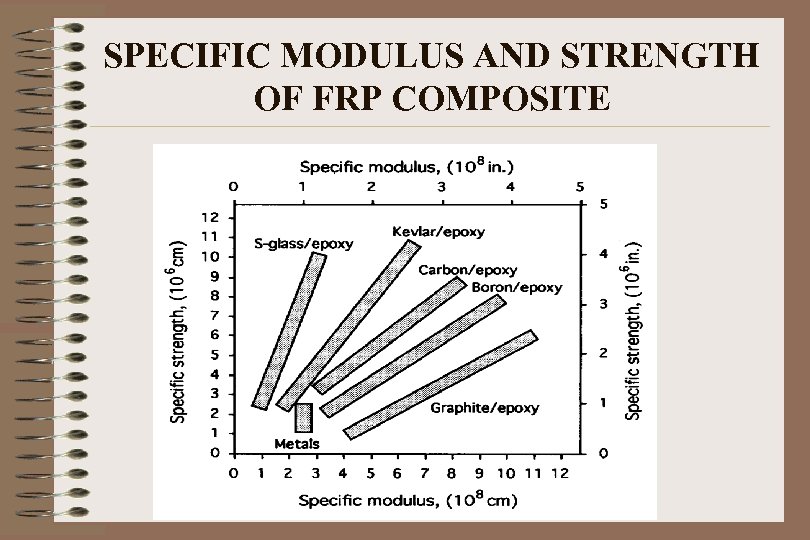

SPECIFIC MODULUS AND STRENGTH OF FRP COMPOSITE

SPECIFIC MODULUS AND STRENGTH OF FRP COMPOSITE

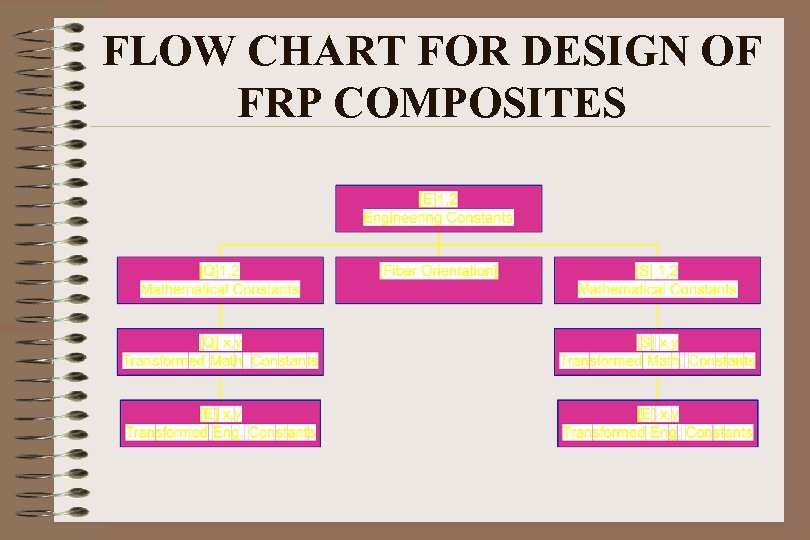

FLOW CHART FOR DESIGN OF FRP COMPOSITES

FLOW CHART FOR DESIGN OF FRP COMPOSITES

MANUFACTURING PROCESSES • • • Hand Lay-up/Spray-up Resin Transfer Molding (RTM) Compression Molding Injection Molding Reinforced Reaction Injection Molding (RRIM) Pultrusion Filament Winding Vacuum Assisted RTM (Va-RTM) Centrifugal Casting

MANUFACTURING PROCESSES • • • Hand Lay-up/Spray-up Resin Transfer Molding (RTM) Compression Molding Injection Molding Reinforced Reaction Injection Molding (RRIM) Pultrusion Filament Winding Vacuum Assisted RTM (Va-RTM) Centrifugal Casting

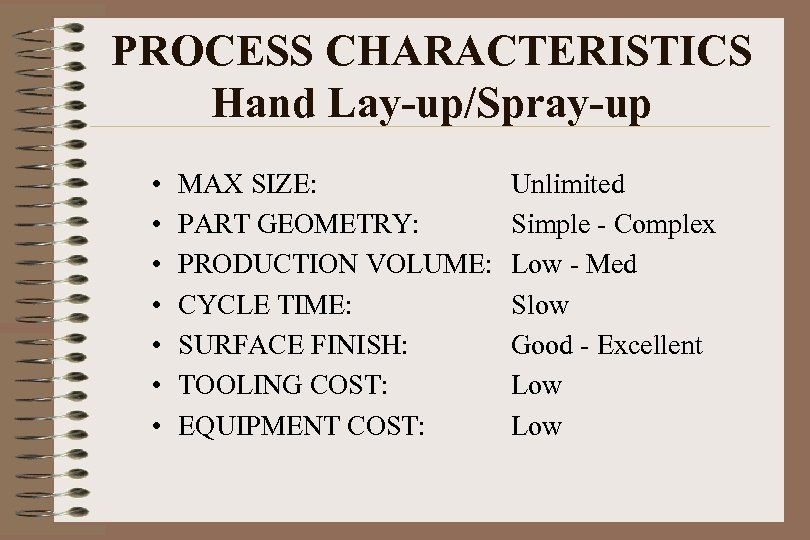

PROCESS CHARACTERISTICS Hand Lay-up/Spray-up • • MAX SIZE: PART GEOMETRY: PRODUCTION VOLUME: CYCLE TIME: SURFACE FINISH: TOOLING COST: EQUIPMENT COST: Unlimited Simple - Complex Low - Med Slow Good - Excellent Low

PROCESS CHARACTERISTICS Hand Lay-up/Spray-up • • MAX SIZE: PART GEOMETRY: PRODUCTION VOLUME: CYCLE TIME: SURFACE FINISH: TOOLING COST: EQUIPMENT COST: Unlimited Simple - Complex Low - Med Slow Good - Excellent Low

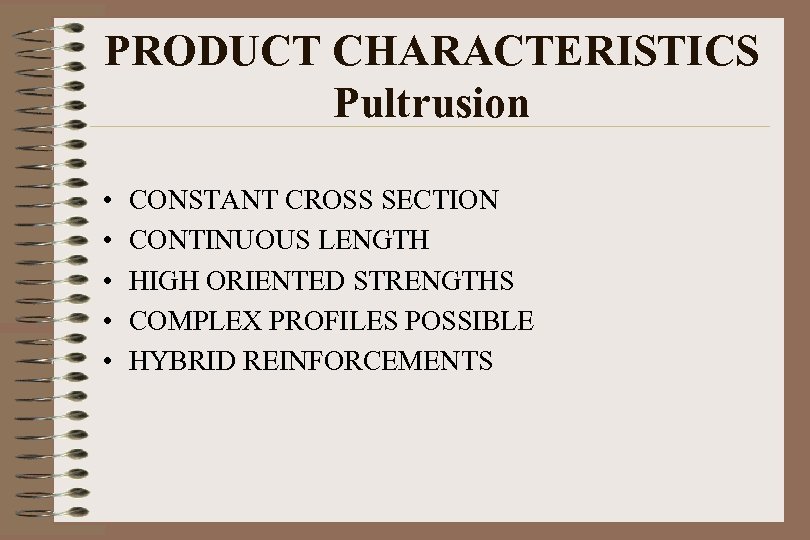

PRODUCT CHARACTERISTICS Pultrusion • • • CONSTANT CROSS SECTION CONTINUOUS LENGTH HIGH ORIENTED STRENGTHS COMPLEX PROFILES POSSIBLE HYBRID REINFORCEMENTS

PRODUCT CHARACTERISTICS Pultrusion • • • CONSTANT CROSS SECTION CONTINUOUS LENGTH HIGH ORIENTED STRENGTHS COMPLEX PROFILES POSSIBLE HYBRID REINFORCEMENTS

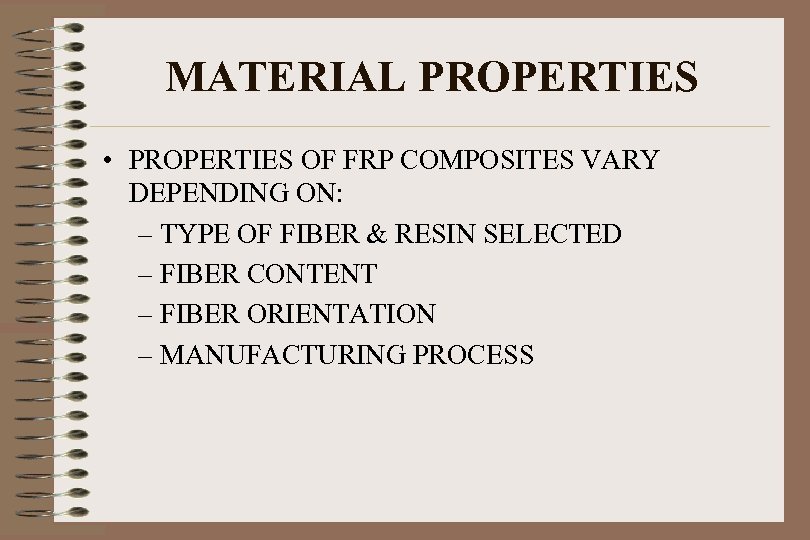

MATERIAL PROPERTIES • PROPERTIES OF FRP COMPOSITES VARY DEPENDING ON: – TYPE OF FIBER & RESIN SELECTED – FIBER CONTENT – FIBER ORIENTATION – MANUFACTURING PROCESS

MATERIAL PROPERTIES • PROPERTIES OF FRP COMPOSITES VARY DEPENDING ON: – TYPE OF FIBER & RESIN SELECTED – FIBER CONTENT – FIBER ORIENTATION – MANUFACTURING PROCESS

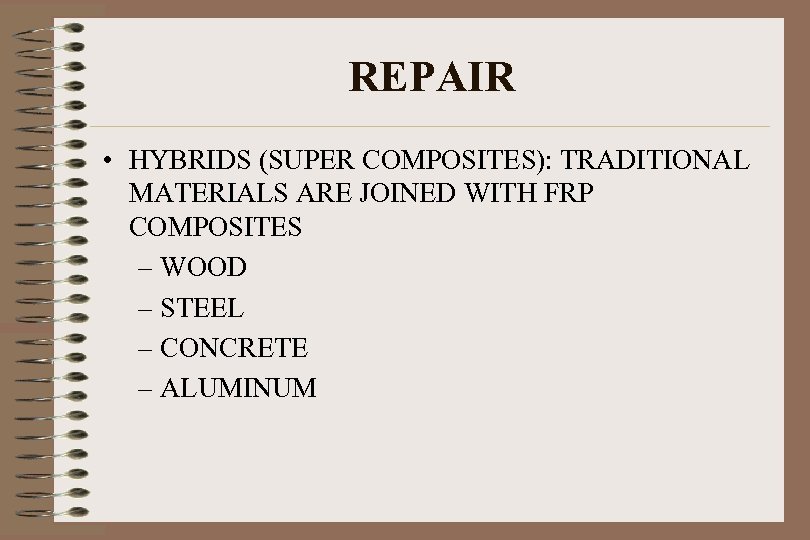

REPAIR • HYBRIDS (SUPER COMPOSITES): TRADITIONAL MATERIALS ARE JOINED WITH FRP COMPOSITES – WOOD – STEEL – CONCRETE – ALUMINUM

REPAIR • HYBRIDS (SUPER COMPOSITES): TRADITIONAL MATERIALS ARE JOINED WITH FRP COMPOSITES – WOOD – STEEL – CONCRETE – ALUMINUM

BENEFITS - SUMMARY • • • LIGHT WEIGHT HIGH STRENGTH to WEIGHT RATIO COMPLEX PART GEOMETRY COMPOUND SURFACE SHAPE PARTS CONSOLIDATION DESIGN FLEXIBILITY LOW SPECIFIC GRAVITY LOW THERMAL CONDUCTIVITY HIGH DIELECTRIC STRENGTH

BENEFITS - SUMMARY • • • LIGHT WEIGHT HIGH STRENGTH to WEIGHT RATIO COMPLEX PART GEOMETRY COMPOUND SURFACE SHAPE PARTS CONSOLIDATION DESIGN FLEXIBILITY LOW SPECIFIC GRAVITY LOW THERMAL CONDUCTIVITY HIGH DIELECTRIC STRENGTH

LIFE CYCLE ECONOMICS • PLANNING/DESIGN/DEVELOPMENT COST • PURCHASE COST • INSTALLATION COST • MAINTENANCE COST • LOSS/WEAR COST • LIABILITY/INSURANCE COSTS • DOWNTIME/LOST BUSINESS COST • REPLACEMENT/DISPOSAL/RECYCLING COST

LIFE CYCLE ECONOMICS • PLANNING/DESIGN/DEVELOPMENT COST • PURCHASE COST • INSTALLATION COST • MAINTENANCE COST • LOSS/WEAR COST • LIABILITY/INSURANCE COSTS • DOWNTIME/LOST BUSINESS COST • REPLACEMENT/DISPOSAL/RECYCLING COST

LIFE CYCLE ECONOMICS (Examples) • IBACH BRIDGE (SWITZERLAND) – CFRP LAMINATES- 50 TIMES MORE EXPENSIVE THAN STEEL PER KILOGRAM – CFRP LAMINATES- 9 TIMES MORE EXPENSIVE THAN STEEL BY VOLUME – REPAIR WORK REQUIREMENTS-175 KG STEEL OR 6. 2 KG CFRP – MATERIAL COST-20 % OF THE TOTAL PROJECT COST

LIFE CYCLE ECONOMICS (Examples) • IBACH BRIDGE (SWITZERLAND) – CFRP LAMINATES- 50 TIMES MORE EXPENSIVE THAN STEEL PER KILOGRAM – CFRP LAMINATES- 9 TIMES MORE EXPENSIVE THAN STEEL BY VOLUME – REPAIR WORK REQUIREMENTS-175 KG STEEL OR 6. 2 KG CFRP – MATERIAL COST-20 % OF THE TOTAL PROJECT COST

LIFE CYCLE ECONOMICS (Examples) • HORSETAIL CREEK BRIDGE (OREGON) – CONVENTIONAL REPAIR (SHEAR ONLY-ONE BEAM)-$69, 000 – FRP REPAIR (GFRP SHEAR ONLY-ONE BEAM)$1850 – FRP REPAIR [SHEAR (GFRP)+ FLEXURE(CFRP), ONE BEAM]- $9850

LIFE CYCLE ECONOMICS (Examples) • HORSETAIL CREEK BRIDGE (OREGON) – CONVENTIONAL REPAIR (SHEAR ONLY-ONE BEAM)-$69, 000 – FRP REPAIR (GFRP SHEAR ONLY-ONE BEAM)$1850 – FRP REPAIR [SHEAR (GFRP)+ FLEXURE(CFRP), ONE BEAM]- $9850

CONCLUSIONS • ECONOMICS ARE MORE THAN THE BASIC ELEMENTS OF MATERIALS, LABOR, EQUIPMENT, OVERHEAD, ETC. • ENTIRE LIFE CYCLE ECONOMICS MUST BE CONSIDERED AND COMPARED TO THAT OF TRADITIONAL MATERIALS TO DETERMINE THE BENEFITS OF COMPOSITES IN A GIVEN APPLICATION

CONCLUSIONS • ECONOMICS ARE MORE THAN THE BASIC ELEMENTS OF MATERIALS, LABOR, EQUIPMENT, OVERHEAD, ETC. • ENTIRE LIFE CYCLE ECONOMICS MUST BE CONSIDERED AND COMPARED TO THAT OF TRADITIONAL MATERIALS TO DETERMINE THE BENEFITS OF COMPOSITES IN A GIVEN APPLICATION

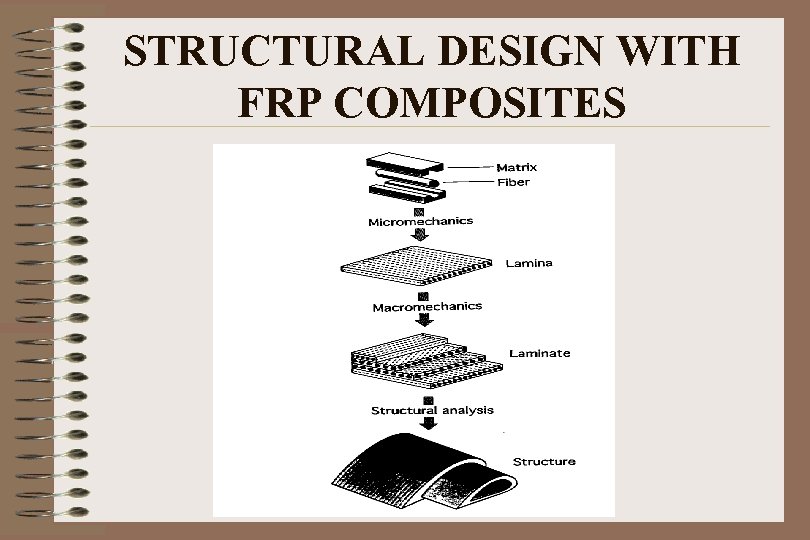

STRUCTURAL DESIGN WITH FRP COMPOSITES

STRUCTURAL DESIGN WITH FRP COMPOSITES

EXTERNAL REINFORCEMENT OF RC BEAMS USING FRP • BACKGROUND • DESIGN MODELS – – LACK OF DUCTILITY FLEXURAL STRENGTHENING SHEAR STRENGTHENING PRESTRESSED FRP APPLICATION • DESIGN METHODOLOGY AND ANALYSIS • OTHER ISSUES – FATIGUE, CREEP, LOW TEMPERATURE FRP PERFORMANCE • DESIGN EXAMPLES

EXTERNAL REINFORCEMENT OF RC BEAMS USING FRP • BACKGROUND • DESIGN MODELS – – LACK OF DUCTILITY FLEXURAL STRENGTHENING SHEAR STRENGTHENING PRESTRESSED FRP APPLICATION • DESIGN METHODOLOGY AND ANALYSIS • OTHER ISSUES – FATIGUE, CREEP, LOW TEMPERATURE FRP PERFORMANCE • DESIGN EXAMPLES

FRP STRENGTHENED BEAMS BACKGROUND • FRP VS. EXTERNALLY STEEL BONDED PLATES – CORROSION AT THE EPOXY-STEEL INTERFACE – STEEL PLATES DO NOT INCREASE STRENGTH, JUST STIFFNESS – HIGH TEMPERATURES PERFORMANCE DIFFICULTIES DUE TO HEAVY WEIGHT OF THE STEEL PLATES – STRENGTHENING DESIGN BASED ON MATERIAL WEIGHT, NOT STRUCTURAL NEEDS – CONSTRUCTION DIFFICULTIES – TIME CONSUMING, HEAVY EQUIPMENT NEEDED

FRP STRENGTHENED BEAMS BACKGROUND • FRP VS. EXTERNALLY STEEL BONDED PLATES – CORROSION AT THE EPOXY-STEEL INTERFACE – STEEL PLATES DO NOT INCREASE STRENGTH, JUST STIFFNESS – HIGH TEMPERATURES PERFORMANCE DIFFICULTIES DUE TO HEAVY WEIGHT OF THE STEEL PLATES – STRENGTHENING DESIGN BASED ON MATERIAL WEIGHT, NOT STRUCTURAL NEEDS – CONSTRUCTION DIFFICULTIES – TIME CONSUMING, HEAVY EQUIPMENT NEEDED

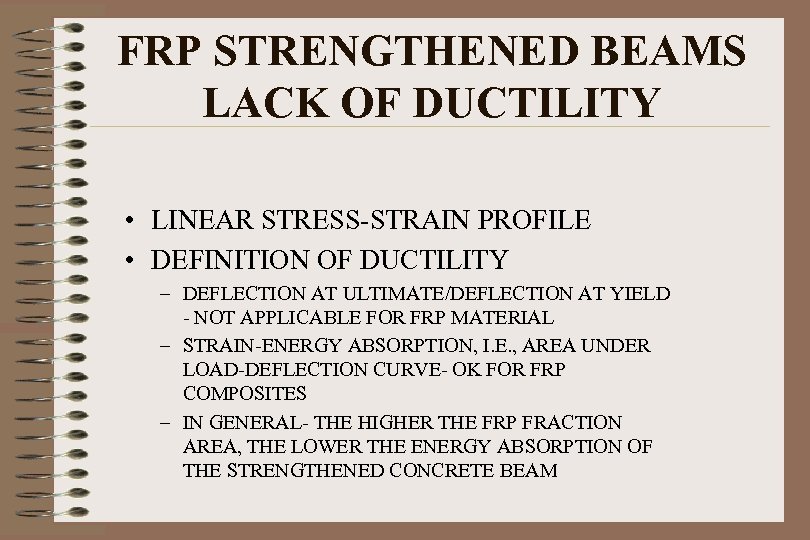

FRP STRENGTHENED BEAMS LACK OF DUCTILITY • LINEAR STRESS-STRAIN PROFILE • DEFINITION OF DUCTILITY – DEFLECTION AT ULTIMATE/DEFLECTION AT YIELD - NOT APPLICABLE FOR FRP MATERIAL – STRAIN-ENERGY ABSORPTION, I. E. , AREA UNDER LOAD-DEFLECTION CURVE- OK FOR FRP COMPOSITES – IN GENERAL- THE HIGHER THE FRP FRACTION AREA, THE LOWER THE ENERGY ABSORPTION OF THE STRENGTHENED CONCRETE BEAM

FRP STRENGTHENED BEAMS LACK OF DUCTILITY • LINEAR STRESS-STRAIN PROFILE • DEFINITION OF DUCTILITY – DEFLECTION AT ULTIMATE/DEFLECTION AT YIELD - NOT APPLICABLE FOR FRP MATERIAL – STRAIN-ENERGY ABSORPTION, I. E. , AREA UNDER LOAD-DEFLECTION CURVE- OK FOR FRP COMPOSITES – IN GENERAL- THE HIGHER THE FRP FRACTION AREA, THE LOWER THE ENERGY ABSORPTION OF THE STRENGTHENED CONCRETE BEAM

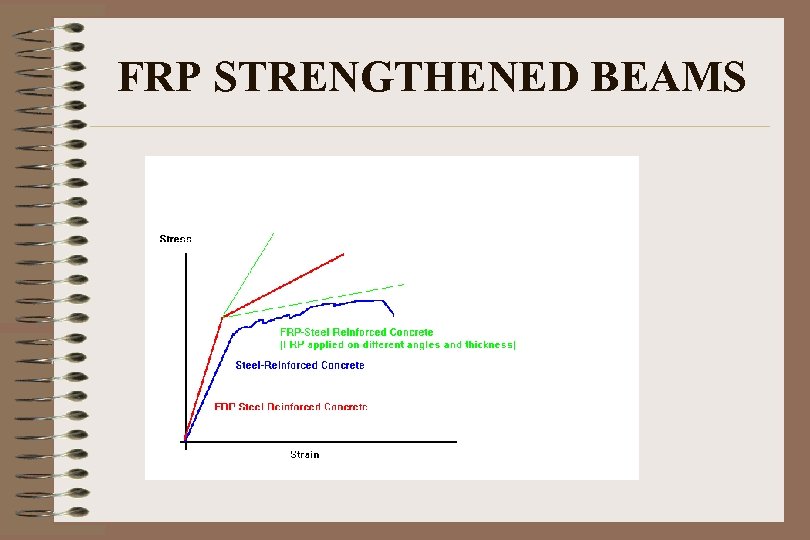

FRP STRENGTHENED BEAMS

FRP STRENGTHENED BEAMS

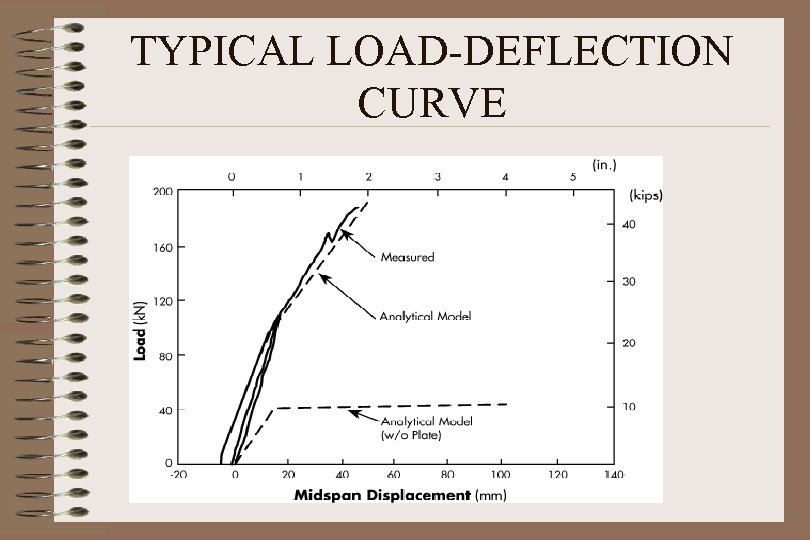

TYPICAL LOAD-DEFLECTION CURVE

TYPICAL LOAD-DEFLECTION CURVE

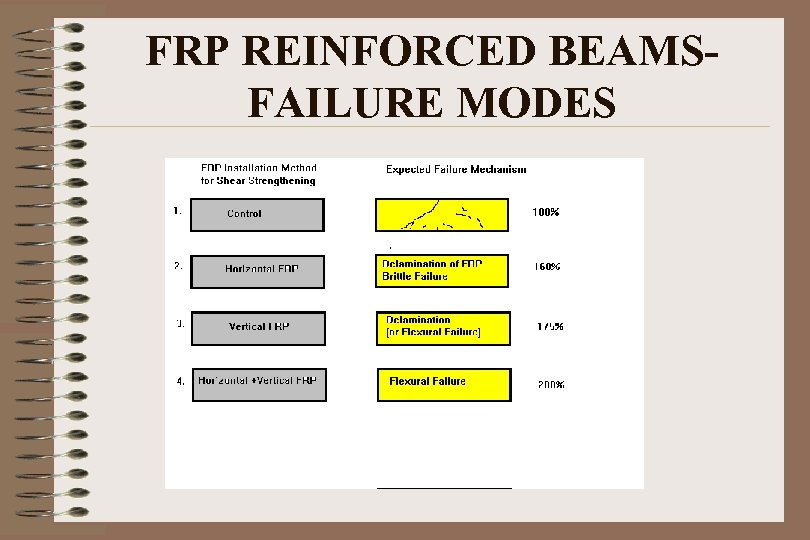

FRP REINFORCED BEAMSFAILURE MODES

FRP REINFORCED BEAMSFAILURE MODES

FRP REINFORCEMENT OF RC COLUMNS • Advantages of Strengthening Columns with FRP Jackets – Increased Ductility – Increased Strength – Low Dead Weight – Reduced Construction Time – Low Maintenance

FRP REINFORCEMENT OF RC COLUMNS • Advantages of Strengthening Columns with FRP Jackets – Increased Ductility – Increased Strength – Low Dead Weight – Reduced Construction Time – Low Maintenance

FRP REINFORCEMENT OF RC COLUMNS • Factors Influencing the Behavior of FRPRetrofitted Columns – Column composition – Column geometry – Current condition – Type of loading – Environmental conditions

FRP REINFORCEMENT OF RC COLUMNS • Factors Influencing the Behavior of FRPRetrofitted Columns – Column composition – Column geometry – Current condition – Type of loading – Environmental conditions

DESIGN OF FRP RETROFIT OF RC COLUMNS • Shear Strengthening • Flexural Hinge Confinement • Lap Splice Clamping

DESIGN OF FRP RETROFIT OF RC COLUMNS • Shear Strengthening • Flexural Hinge Confinement • Lap Splice Clamping

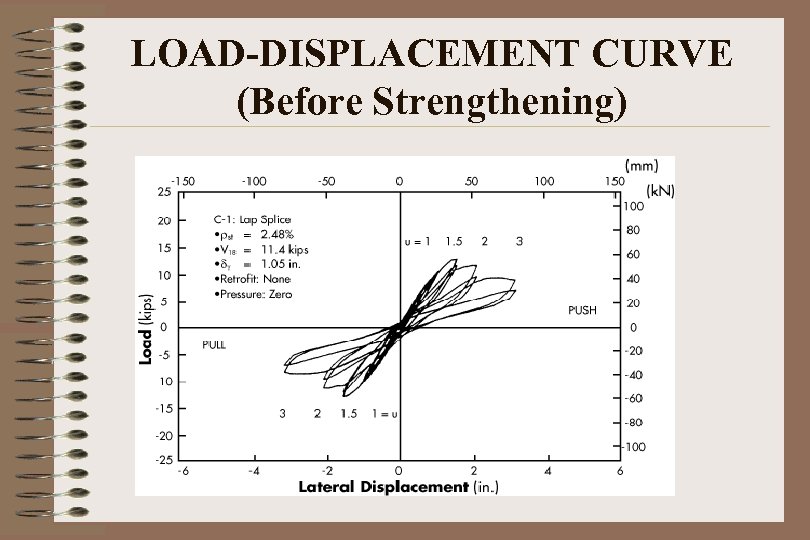

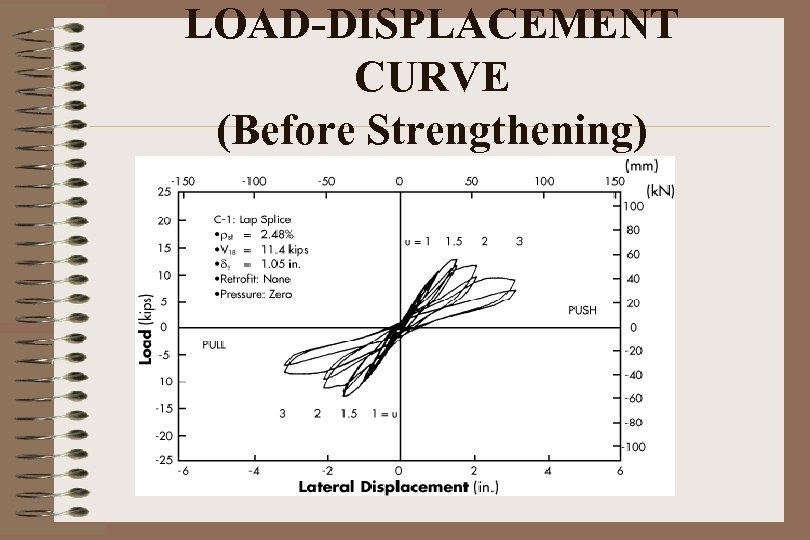

LOAD-DISPLACEMENT CURVE (Before Strengthening)

LOAD-DISPLACEMENT CURVE (Before Strengthening)

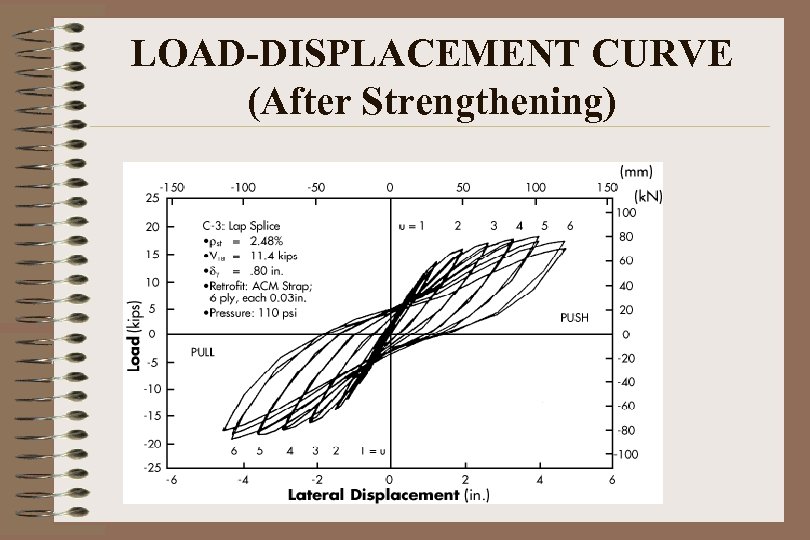

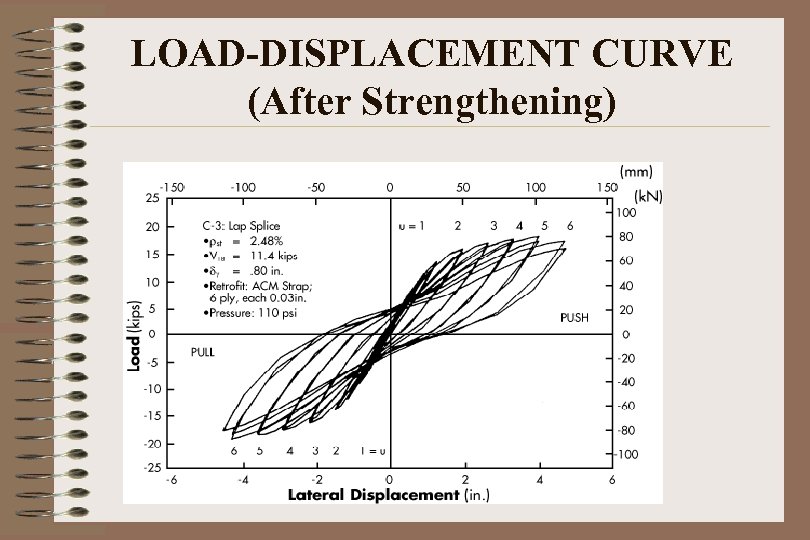

LOAD-DISPLACEMENT CURVE (After Strengthening)

LOAD-DISPLACEMENT CURVE (After Strengthening)

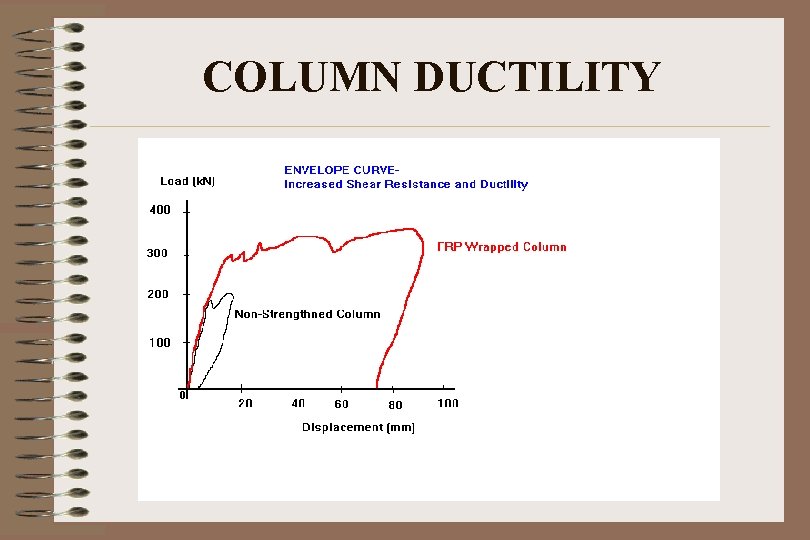

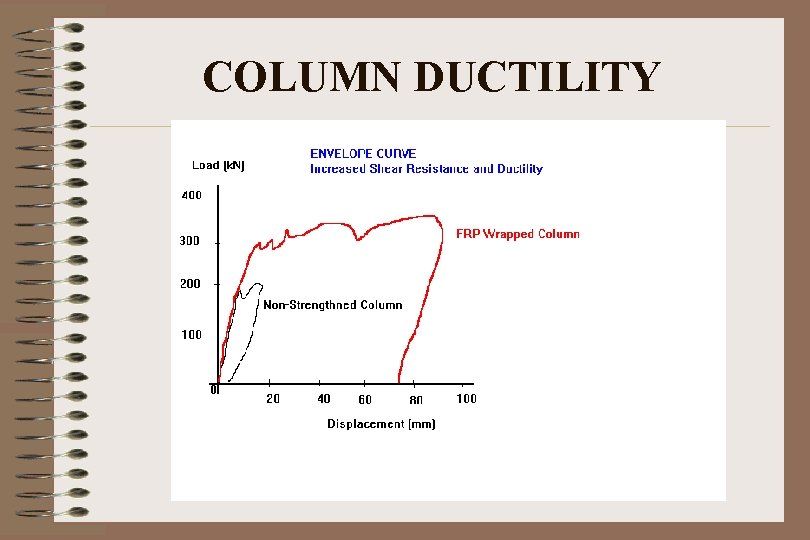

COLUMN DUCTILITY

COLUMN DUCTILITY

FRP REINFORCEMENT OF RC COLUMNS • Advantages of Strengthening Columns with FRP Jackets – Increased Ductility – Increased Strength – Low Dead Weight – Reduced Construction Time – Low Maintenance

FRP REINFORCEMENT OF RC COLUMNS • Advantages of Strengthening Columns with FRP Jackets – Increased Ductility – Increased Strength – Low Dead Weight – Reduced Construction Time – Low Maintenance

FRP REINFORCEMENT OF RC COLUMNS • Factors Influencing the Behavior of FRPRetrofitted Columns – Column composition – Column geometry – Current condition – Type of loading – Environmental conditions

FRP REINFORCEMENT OF RC COLUMNS • Factors Influencing the Behavior of FRPRetrofitted Columns – Column composition – Column geometry – Current condition – Type of loading – Environmental conditions

LOAD-DISPLACEMENT CURVE (Before Strengthening)

LOAD-DISPLACEMENT CURVE (Before Strengthening)

LOAD-DISPLACEMENT CURVE (After Strengthening)

LOAD-DISPLACEMENT CURVE (After Strengthening)

COLUMN DUCTILITY

COLUMN DUCTILITY

CONSTRUCTION PROCESS • • Preparation of the Concrete Surface Mixing Epoxy, Putty, etc. Preparation of the FRP Composite System Application of the FRP Strengthening System Anchorage (if recommended) Curing the FRP Material Application of Finish System

CONSTRUCTION PROCESS • • Preparation of the Concrete Surface Mixing Epoxy, Putty, etc. Preparation of the FRP Composite System Application of the FRP Strengthening System Anchorage (if recommended) Curing the FRP Material Application of Finish System

CONCRETE SURFACE PREPARATION • Repair of the existing concrete in accordance to: – ACI 546 R-96 “Concrete Repair Guide” – ICRI Guideline No. 03370 “Guide for Surface Preparation for the Repair of Deteriorated Concrete. . . ” • Bond Between Concrete and FRP Materials – Should satisfy ICRI “Guide for Selecting and Specifying Materials for Repair of Concrete Surfaces”

CONCRETE SURFACE PREPARATION • Repair of the existing concrete in accordance to: – ACI 546 R-96 “Concrete Repair Guide” – ICRI Guideline No. 03370 “Guide for Surface Preparation for the Repair of Deteriorated Concrete. . . ” • Bond Between Concrete and FRP Materials – Should satisfy ICRI “Guide for Selecting and Specifying Materials for Repair of Concrete Surfaces”

CONCRETE SURFACE PREPARATION • Repair Cracks 0. 010 inches or Wider – Epoxy pressure injected – To satisfy Section 3. 2 of the ACI 224. 1 R-93 “Causes, Evaluation and Repair of Cracks…” • Concrete Surface Unevenness to be Less than 1 mm • Concrete Corners- Minimum Radius of 30 mm

CONCRETE SURFACE PREPARATION • Repair Cracks 0. 010 inches or Wider – Epoxy pressure injected – To satisfy Section 3. 2 of the ACI 224. 1 R-93 “Causes, Evaluation and Repair of Cracks…” • Concrete Surface Unevenness to be Less than 1 mm • Concrete Corners- Minimum Radius of 30 mm

APPLICATION OF THE FRP COMPOSITE • In Accordance to Manufacturer’s and Designer's Specifications – Priming – Putty Application – Under-coating with Epoxy Resin – Application of the FRP Laminate/ FRP Fiber Sheet – Over-coating with Epoxy Resin

APPLICATION OF THE FRP COMPOSITE • In Accordance to Manufacturer’s and Designer's Specifications – Priming – Putty Application – Under-coating with Epoxy Resin – Application of the FRP Laminate/ FRP Fiber Sheet – Over-coating with Epoxy Resin

CURING OF THE FRP COMPOSITES • In Accordance to Manufacturer’s Specifications – Temperature ranges and Curing Time- varies from few hours to 15 days for different FRP systems • Cured FRP Composite – Uniform thickness and density – Lack of porosity

CURING OF THE FRP COMPOSITES • In Accordance to Manufacturer’s Specifications – Temperature ranges and Curing Time- varies from few hours to 15 days for different FRP systems • Cured FRP Composite – Uniform thickness and density – Lack of porosity

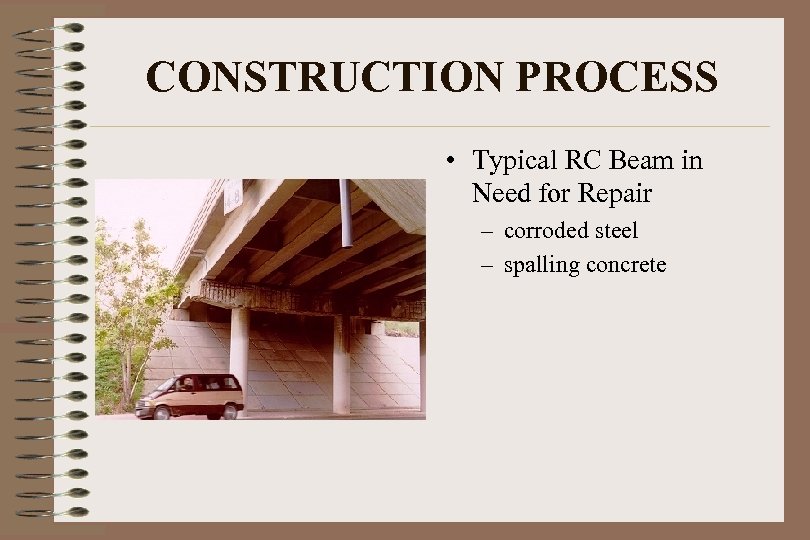

CONSTRUCTION PROCESS • Typical RC Beam in Need for Repair – corroded steel – spalling concrete

CONSTRUCTION PROCESS • Typical RC Beam in Need for Repair – corroded steel – spalling concrete

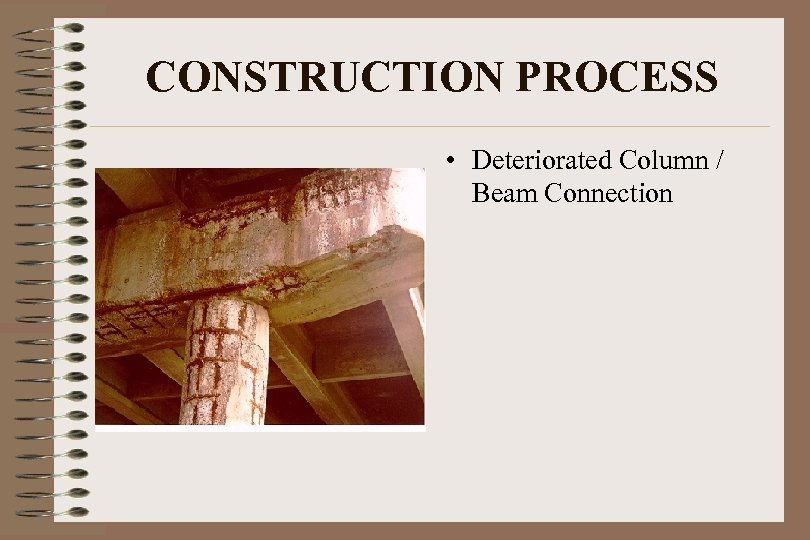

CONSTRUCTION PROCESS • Deteriorated Column / Beam Connection

CONSTRUCTION PROCESS • Deteriorated Column / Beam Connection

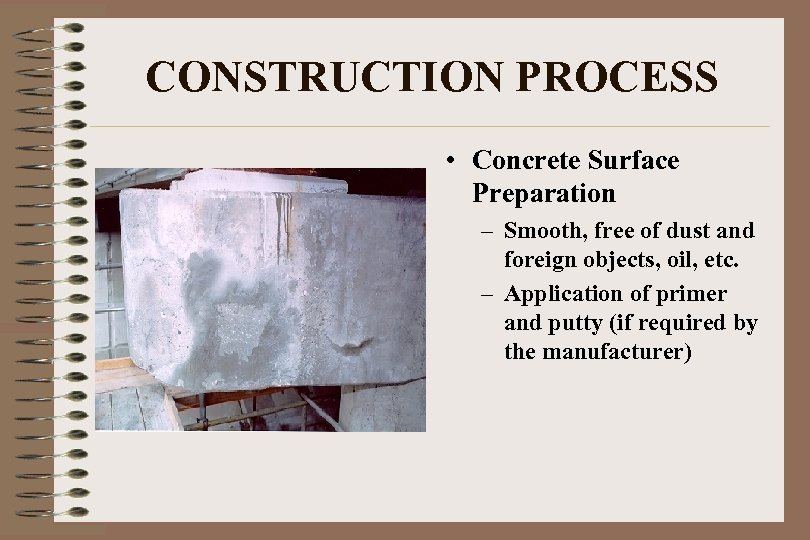

CONSTRUCTION PROCESS • Concrete Surface Preparation – Smooth, free of dust and foreign objects, oil, etc. – Application of primer and putty (if required by the manufacturer)

CONSTRUCTION PROCESS • Concrete Surface Preparation – Smooth, free of dust and foreign objects, oil, etc. – Application of primer and putty (if required by the manufacturer)

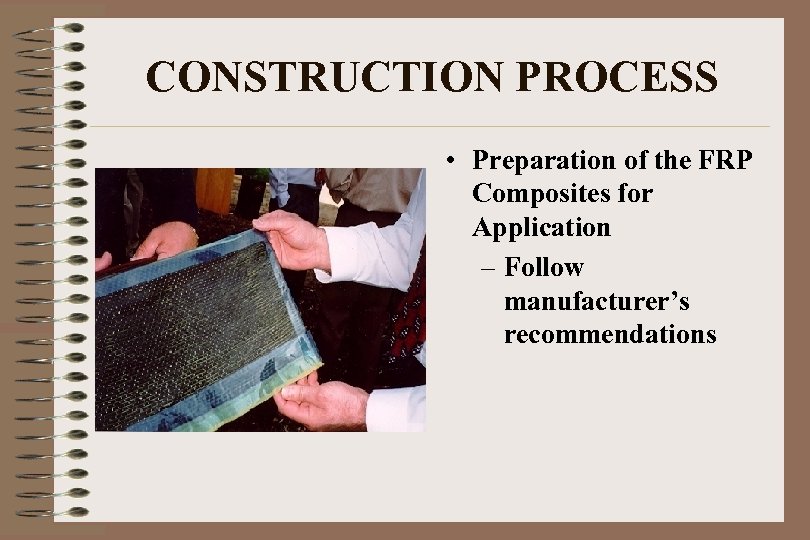

CONSTRUCTION PROCESS • Preparation of the FRP Composites for Application – Follow manufacturer’s recommendations

CONSTRUCTION PROCESS • Preparation of the FRP Composites for Application – Follow manufacturer’s recommendations

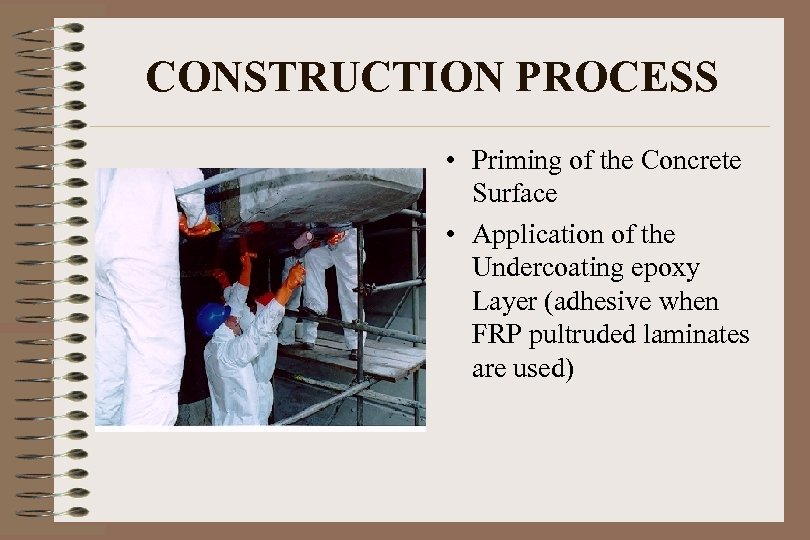

CONSTRUCTION PROCESS • Priming of the Concrete Surface • Application of the Undercoating epoxy Layer (adhesive when FRP pultruded laminates are used)

CONSTRUCTION PROCESS • Priming of the Concrete Surface • Application of the Undercoating epoxy Layer (adhesive when FRP pultruded laminates are used)

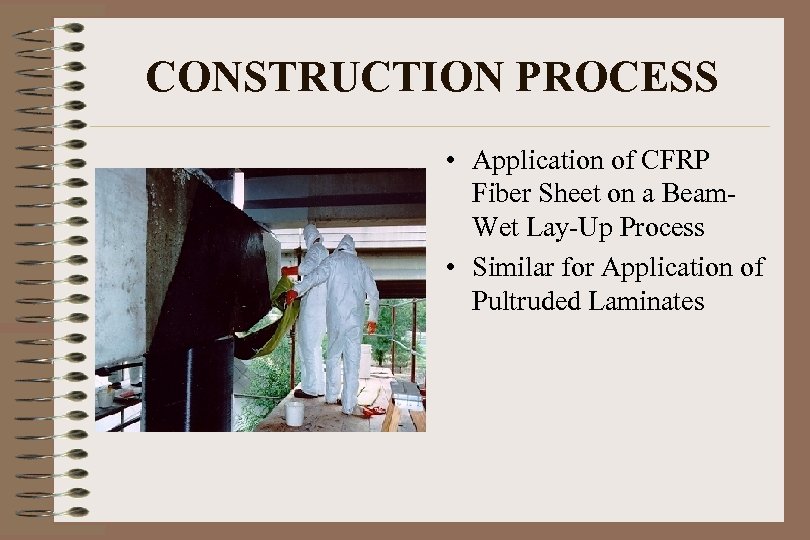

CONSTRUCTION PROCESS • Application of CFRP Fiber Sheet on a Beam. Wet Lay-Up Process • Similar for Application of Pultruded Laminates

CONSTRUCTION PROCESS • Application of CFRP Fiber Sheet on a Beam. Wet Lay-Up Process • Similar for Application of Pultruded Laminates

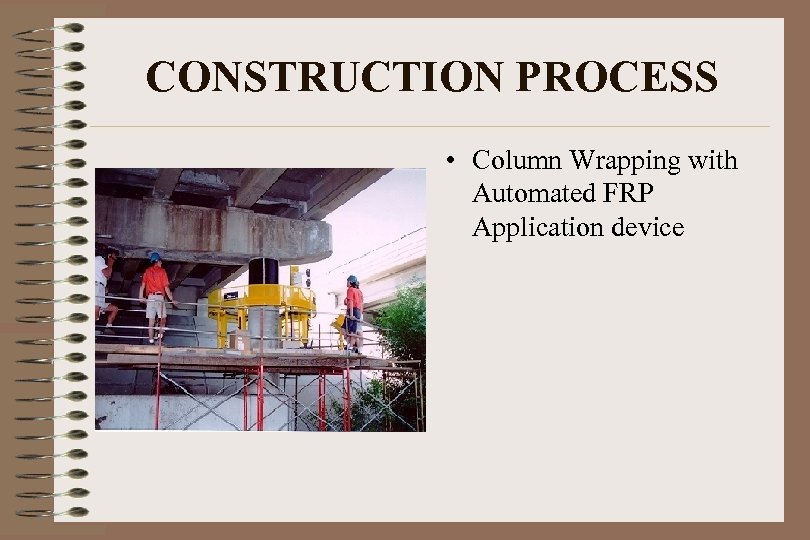

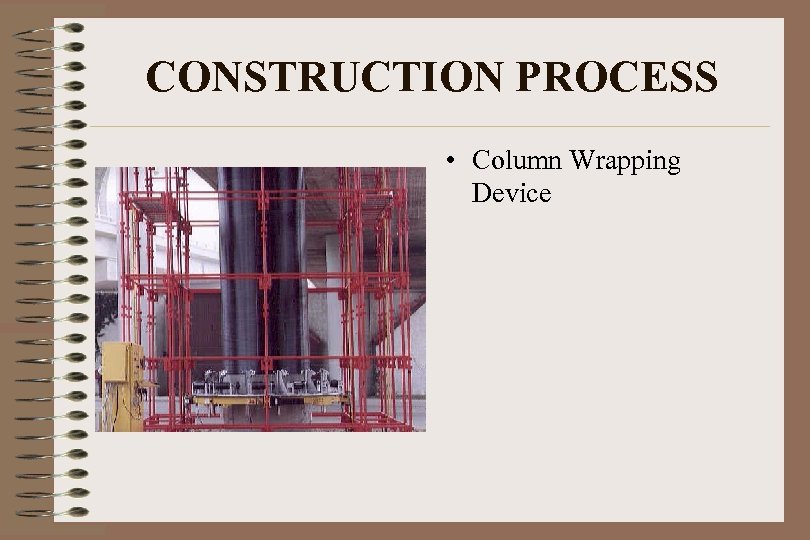

CONSTRUCTION PROCESS • Column Wrapping with Automated FRP Application device

CONSTRUCTION PROCESS • Column Wrapping with Automated FRP Application device

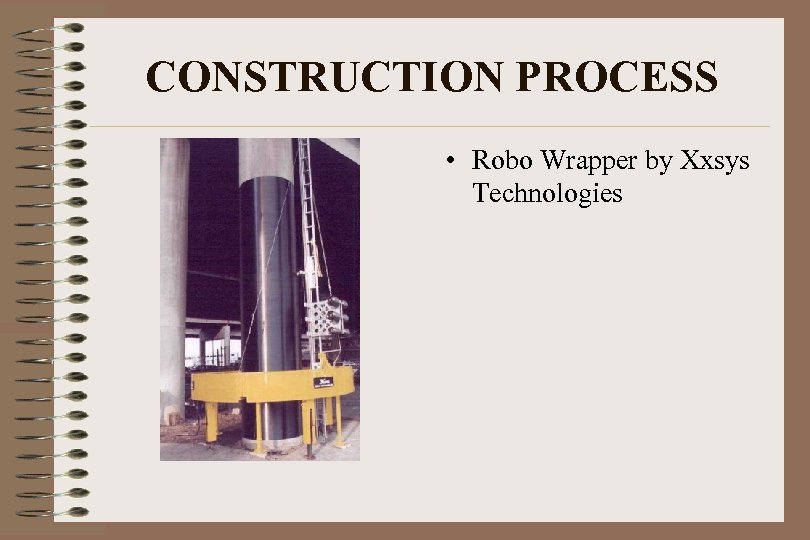

CONSTRUCTION PROCESS • Robo Wrapper by Xxsys Technologies

CONSTRUCTION PROCESS • Robo Wrapper by Xxsys Technologies

CONSTRUCTION PROCESS • Column Wrapping Device

CONSTRUCTION PROCESS • Column Wrapping Device