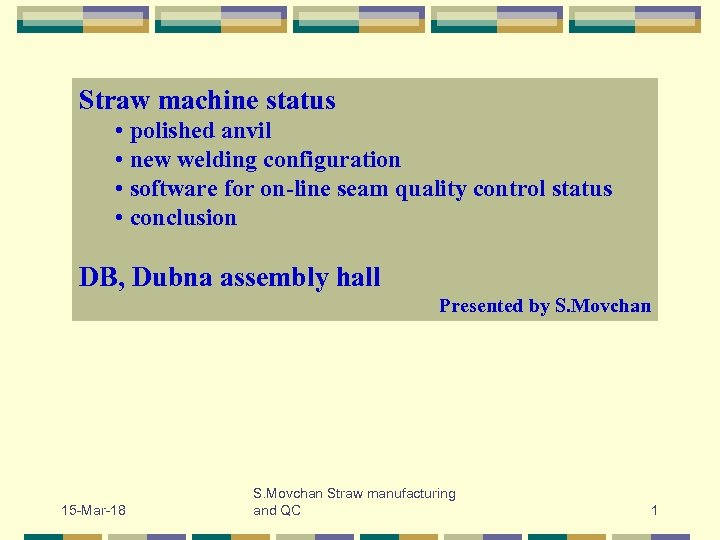

Straw machine status • polished anvil • new welding configuration • software for on-line seam quality control status • conclusion DB, Dubna assembly hall Presented by S. Movchan 15 -Mar-18 S. Movchan Straw manufacturing and QC 1

Straw machine status • polished anvil • new welding configuration • software for on-line seam quality control status • conclusion DB, Dubna assembly hall Presented by S. Movchan 15 -Mar-18 S. Movchan Straw manufacturing and QC 1

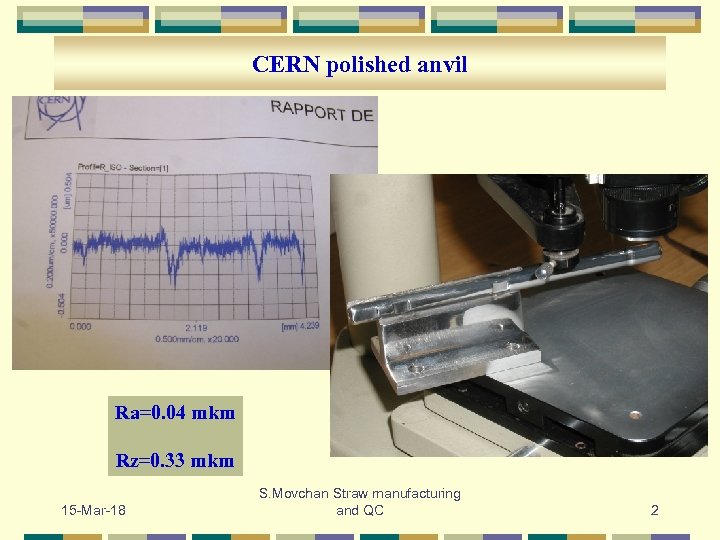

CERN polished anvil Ra=0. 04 mkm Rz=0. 33 mkm 15 -Mar-18 S. Movchan Straw manufacturing and QC 2

CERN polished anvil Ra=0. 04 mkm Rz=0. 33 mkm 15 -Mar-18 S. Movchan Straw manufacturing and QC 2

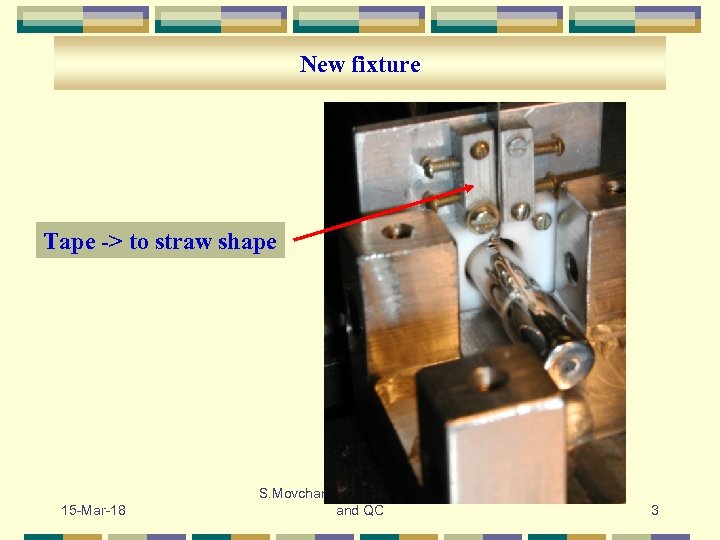

New fixture Tape -> to straw shape 15 -Mar-18 S. Movchan Straw manufacturing and QC 3

New fixture Tape -> to straw shape 15 -Mar-18 S. Movchan Straw manufacturing and QC 3

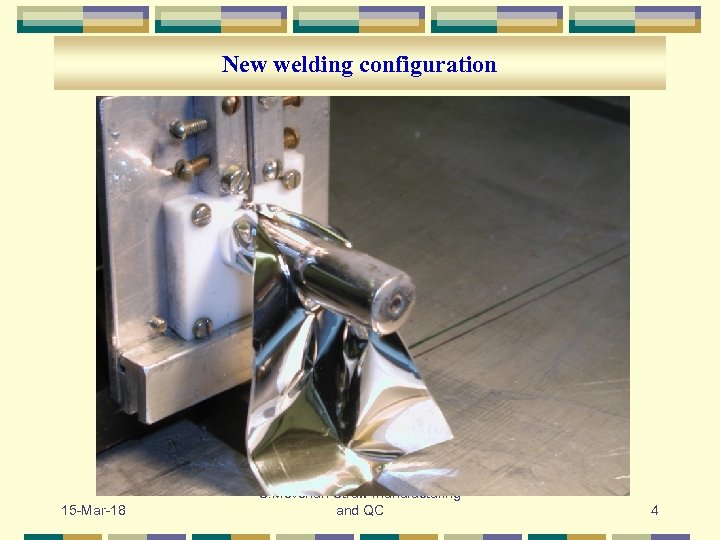

New welding configuration 15 -Mar-18 S. Movchan Straw manufacturing and QC 4

New welding configuration 15 -Mar-18 S. Movchan Straw manufacturing and QC 4

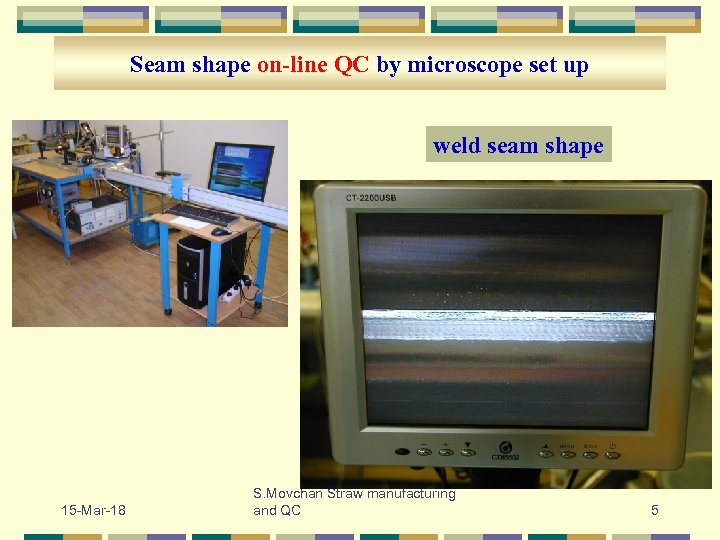

Seam shape on-line QC by microscope set up weld seam shape 15 -Mar-18 S. Movchan Straw manufacturing and QC 5

Seam shape on-line QC by microscope set up weld seam shape 15 -Mar-18 S. Movchan Straw manufacturing and QC 5

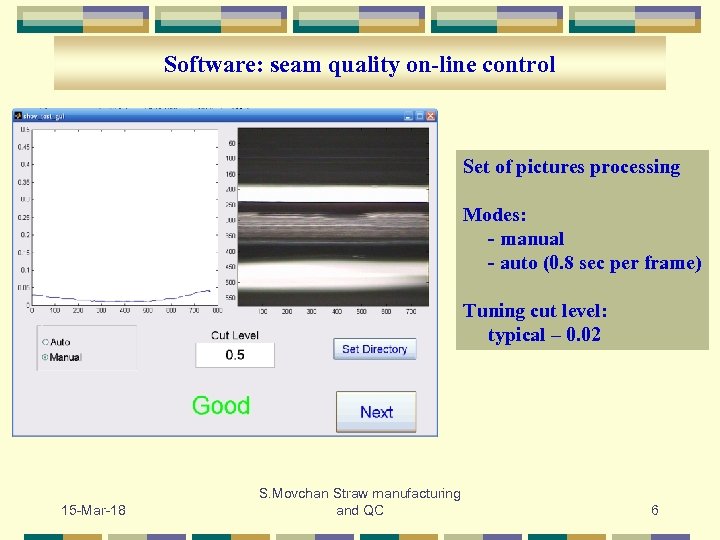

Software: seam quality on-line control Set of pictures processing Modes: - manual - auto (0. 8 sec per frame) Tuning cut level: typical – 0. 02 15 -Mar-18 S. Movchan Straw manufacturing and QC 6

Software: seam quality on-line control Set of pictures processing Modes: - manual - auto (0. 8 sec per frame) Tuning cut level: typical – 0. 02 15 -Mar-18 S. Movchan Straw manufacturing and QC 6

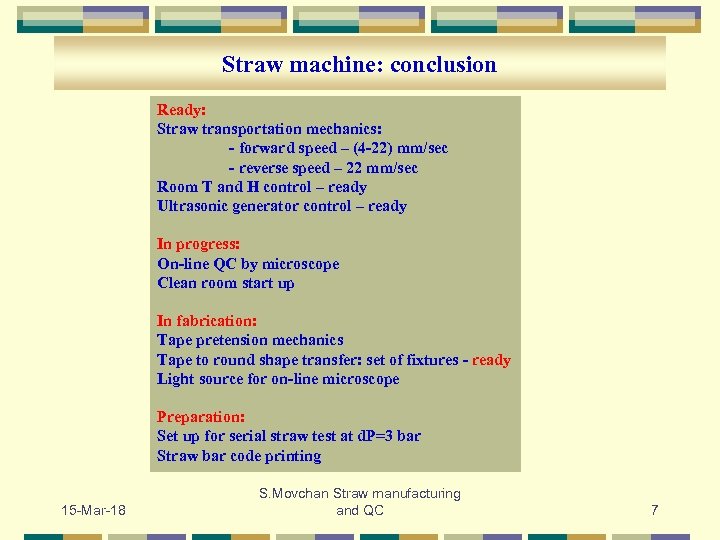

Straw machine: conclusion Ready: Straw transportation mechanics: - forward speed – (4 -22) mm/sec - reverse speed – 22 mm/sec Room T and H control – ready Ultrasonic generator control – ready In progress: On-line QC by microscope Clean room start up In fabrication: Tape pretension mechanics Tape to round shape transfer: set of fixtures - ready Light source for on-line microscope Preparation: Set up for serial straw test at d. P=3 bar Straw bar code printing 15 -Mar-18 S. Movchan Straw manufacturing and QC 7

Straw machine: conclusion Ready: Straw transportation mechanics: - forward speed – (4 -22) mm/sec - reverse speed – 22 mm/sec Room T and H control – ready Ultrasonic generator control – ready In progress: On-line QC by microscope Clean room start up In fabrication: Tape pretension mechanics Tape to round shape transfer: set of fixtures - ready Light source for on-line microscope Preparation: Set up for serial straw test at d. P=3 bar Straw bar code printing 15 -Mar-18 S. Movchan Straw manufacturing and QC 7

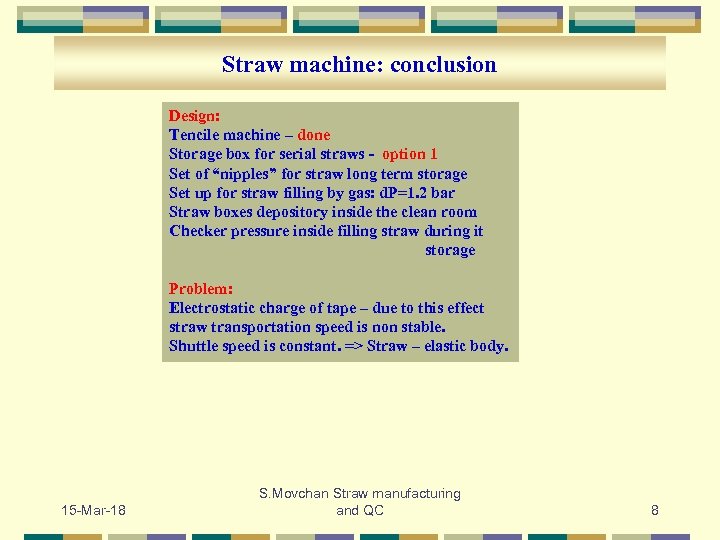

Straw machine: conclusion Design: Tencile machine – done Storage box for serial straws - option 1 Set of “nipples” for straw long term storage Set up for straw filling by gas: d. P=1. 2 bar Straw boxes depository inside the clean room Checker pressure inside filling straw during it storage Problem: Electrostatic charge of tape – due to this effect straw transportation speed is non stable. Shuttle speed is constant. => Straw – elastic body. 15 -Mar-18 S. Movchan Straw manufacturing and QC 8

Straw machine: conclusion Design: Tencile machine – done Storage box for serial straws - option 1 Set of “nipples” for straw long term storage Set up for straw filling by gas: d. P=1. 2 bar Straw boxes depository inside the clean room Checker pressure inside filling straw during it storage Problem: Electrostatic charge of tape – due to this effect straw transportation speed is non stable. Shuttle speed is constant. => Straw – elastic body. 15 -Mar-18 S. Movchan Straw manufacturing and QC 8

Spare 15 -Mar-18 S. Movchan Straw manufacturing and QC 9

Spare 15 -Mar-18 S. Movchan Straw manufacturing and QC 9

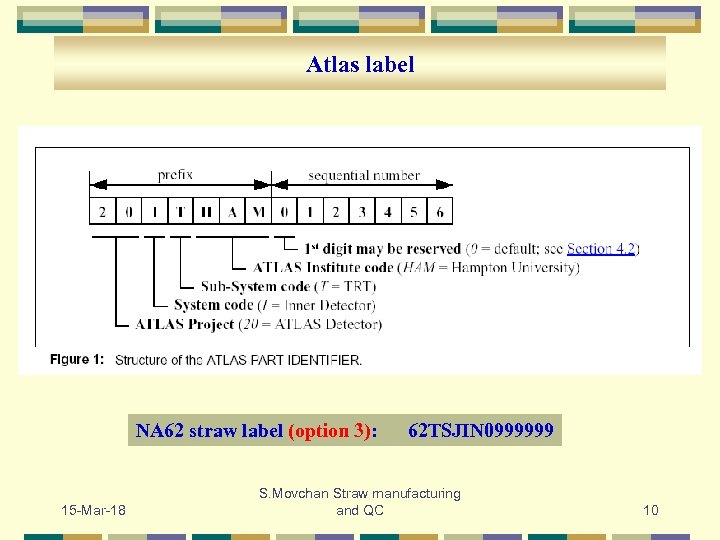

Atlas label NA 62 straw label (option 3): 15 -Mar-18 62 TSJIN 0999999 S. Movchan Straw manufacturing and QC 10

Atlas label NA 62 straw label (option 3): 15 -Mar-18 62 TSJIN 0999999 S. Movchan Straw manufacturing and QC 10

Straw labeling: label glue to straw 15 -Mar-18 S. Movchan Straw manufacturing and QC 11

Straw labeling: label glue to straw 15 -Mar-18 S. Movchan Straw manufacturing and QC 11

Straw labeling: conclusion Straw labeling procedure is proposed: - label code - 62 TSJIN 0999999 (14 digits) - label size – 10 x 30 mm - print labels by “label printer” - 2 the same labels will be glued on both straw ends (for robustness) - before straw gluing into module straw label will be read out and cut out - straw # (label) will be replaced by hole # in the “Module holes numbering DB” Label reader and DB (based on Excel table) exist at Dubna 15 -Mar-18 S. Movchan Straw manufacturing and QC 12

Straw labeling: conclusion Straw labeling procedure is proposed: - label code - 62 TSJIN 0999999 (14 digits) - label size – 10 x 30 mm - print labels by “label printer” - 2 the same labels will be glued on both straw ends (for robustness) - before straw gluing into module straw label will be read out and cut out - straw # (label) will be replaced by hole # in the “Module holes numbering DB” Label reader and DB (based on Excel table) exist at Dubna 15 -Mar-18 S. Movchan Straw manufacturing and QC 12