99019465b62a84a5d2ae9c137c487142.ppt

- Количество слайдов: 60

Stirling Biopower Introduction to the Product and Markets

Agenda n 회사와 제품, 역사 n 스터링사이클 엔진 개발 하이라이트 n Stirling engine 의작동원리 n 열원과 maintenance and service requirements n Markets n 시장 경쟁력 n 스털링사이클 엔진 발전기의 장점 © 2008 Stirling Biopower, Inc. 2

Stirling Biopower Defined n 벤처회사로 회사설립 30년의 연구 개발하였으며 현재는New privately-held company로 멕시칸 회사와 독일회사에서 인수하여 2008년 10월부터 제품생산. Stirling engine technology 는 세계에서 유일한 회사(상업용 43 kw 발전기). n Stirling engine 을 구동으로 하는 발전기 설계, 제작, 판매 n 신 재생에너지(태양광, 메탄, Hot Gas)를 연료로 사용하는 Power Unit. n 39 U. S. patents, 2 pending; 28 Rest of World patents, 7 pending; 1 disclosure n Located in Ann Arbor, MI, USA. Two buildings, including manufacturing © 2008 Stirling Biopower, Inc. 3

Company, Technology and Product Evolution n 1977 – 2000 – 벤처회사 설립Small team 으로 Stirling engine 연구 개발. – Single-unit 제작, various fuels 이용 테스트: • Dish solar • Hybrid car and bus • Biomass © 2008 Stirling Biopower, Inc. 4

Technology and Product Evolution n 2000 – 2004 – Gaseous 연료와 Hot Air를 이용 25 k. W power generator 제작. – Alpha and Beta 제품테스트 거처 새로운제품으로 탄생. – Over 40, 000 시간 현장 테스트. © 2008 Stirling Biopower, Inc. 5

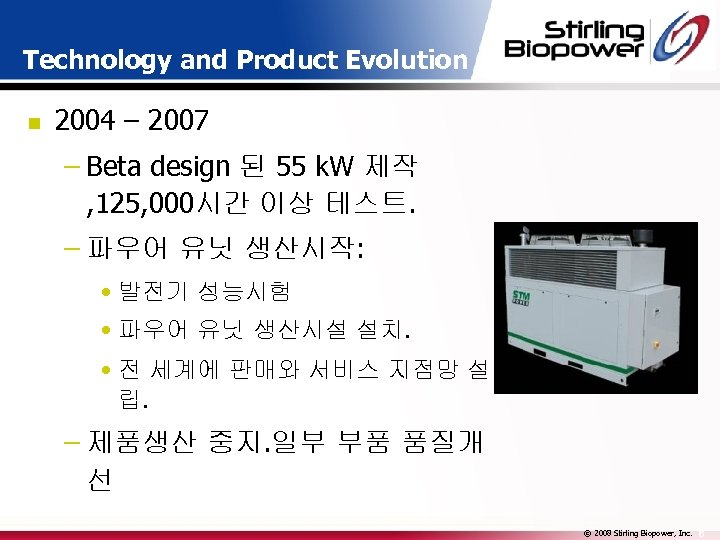

Technology and Product Evolution n 2004 – 2007 – Beta design 된 55 k. W 제작 , 125, 000시간 이상 테스트. – 파우어 유닛 생산시작: • 발전기 성능시험 • 파우어 유닛 생산시설 설치. • 전 세계에 판매와 서비스 지점망 설 립. – 제품생산 중지. 일부 부품 품질개 선 © 2008 Stirling Biopower, Inc. 6

Technology and Product Evolution n 2007 - current – 43 k. W 파우어 유닛 생산 준비. – 2008년 10월 파우어 유닛 생산 판매. © 2008 Stirling Biopower, Inc. 7

Sales and Distribution n Power. Units 는Independent distributors를 통해서 판매와 서비스. n Distributors are channel partners로서 상생 협력체제구축. n n Distributors provide balance of plant engineering, procurement, installation, support, coordination of permitting, testing, etc. Ideal partners have all or most of these attributes: – – – Well defined market space (clientele in targeted market segments) Established sales and service infrastructure Technical expertise Strong local brand presence Established relationships with complementary equipment vendors and project financing – Financing capability or Buy/Own/Operate business model n Stirling Biopower는 sales training, 영업자료제공과 application engineering support 한다. © 2008 Stirling Biopower, Inc. 8

After Sales Product Support n n n 5 -day factory training for distributor technicians Distributor has complete factory service tool sets and local parts inventory for quick response, accurate diagnosis and limited down time Web-based service publications, such as service, owner, commission and installation manuals n 24시간 Hotline 운영으로 현장애로사항 지원. n 빠른 서비스를 하기 위하여 지역별 Field Service Technicians 조직 구성. © 2008 Stirling Biopower, Inc. 9

Distributed Generation § Distributed generation (DG) is the use of small scale power generation located close to the loads being served – Generate on-site power to offset plant consumption – Reduces cost and need to transmit power, including associated line losses – Increases reliability – Enables the use of the waste heat produced in the power generation process to be used on site (combined heat and power, “CHP”) § Distributed generation is the conversion of local energy sources to power – Allows the utilization of energy sources which would not be economical to transport or dispose of © 2008 Stirling Biopower, Inc. 10

Historical Highlights of the Stirling Engine

Major Stirling Development Efforts n Robert Stirling (1800 s) n Phillips (1930 s to 1970 s) n United Stirling of Sweden (1960 s to present) n MTI NASA Lewis (1980 s) n STM Power (1977 – 2007) n Stirling Biopower (2007 – present) © 2008 Stirling Biopower, Inc. 12

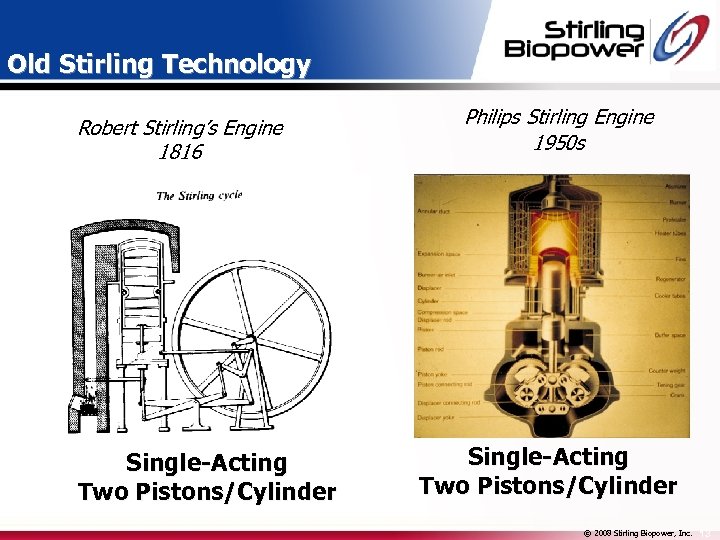

Old Stirling Technology Robert Stirling’s Engine 1816 Single-Acting Two Pistons/Cylinder Philips Stirling Engine 1950 s Single-Acting Two Pistons/Cylinder © 2008 Stirling Biopower, Inc. 13

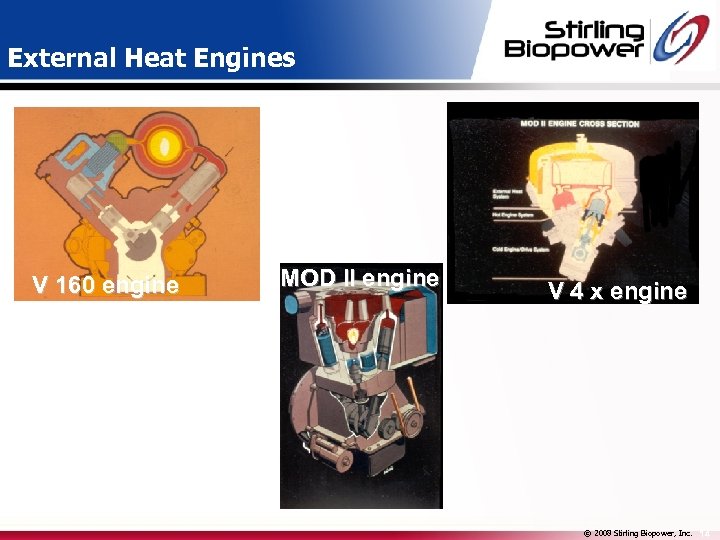

External Heat Engines V 160 engine MOD II engine V 4 x engine © 2008 Stirling Biopower, Inc. 14

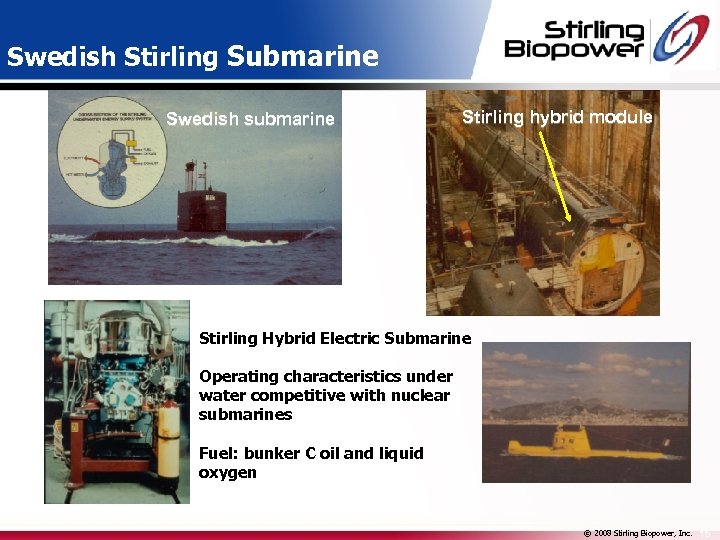

Swedish Stirling Submarine Swedish submarine Stirling hybrid module Stirling Hybrid Electric Submarine Operating characteristics under water competitive with nuclear submarines Fuel: bunker C oil and liquid oxygen © 2008 Stirling Biopower, Inc. 15

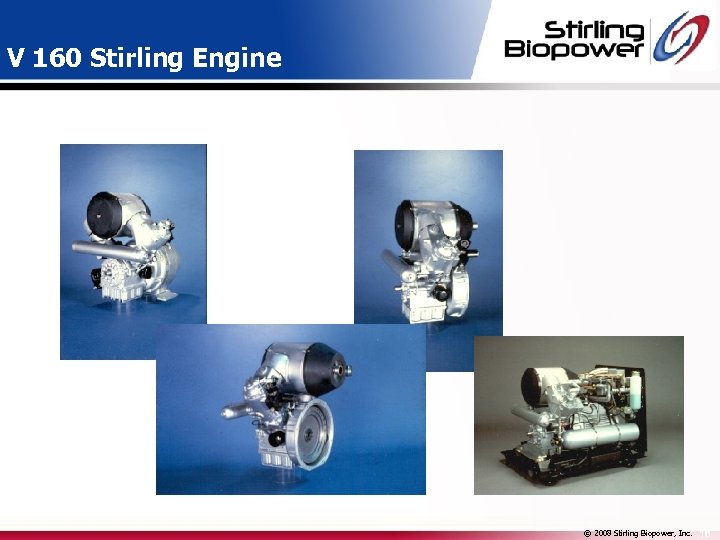

V 160 Stirling Engine © 2008 Stirling Biopower, Inc. 16

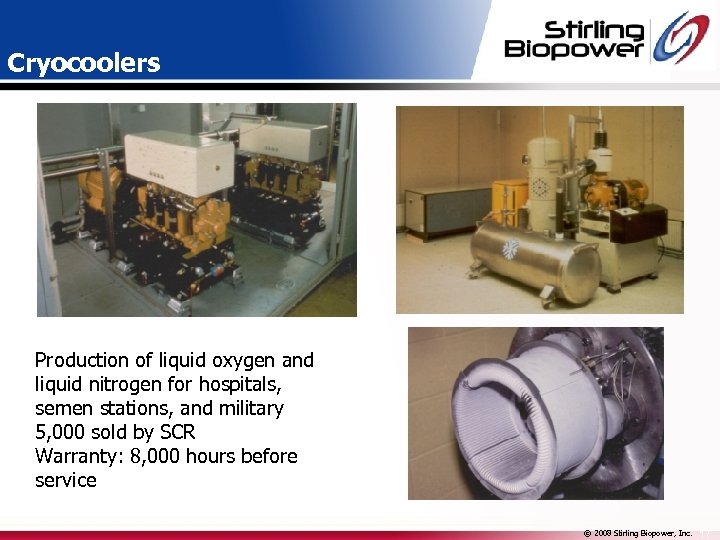

Cryocoolers Production of liquid oxygen and liquid nitrogen for hospitals, semen stations, and military 5, 000 sold by SCR Warranty: 8, 000 hours before service © 2008 Stirling Biopower, Inc. 17

Stirling Biopower Operating Principles of the Stirling Engine

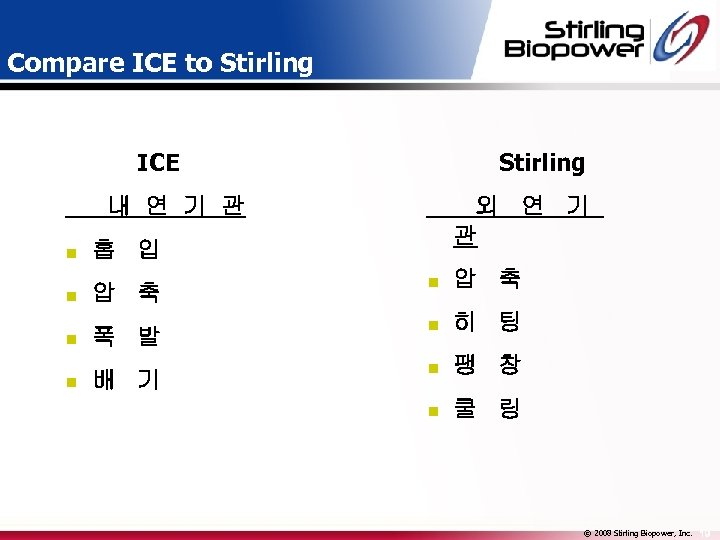

Compare ICE to Stirling ICE Stirling 내 연 기 관 n n 외 연 기 관 흡 입 압 축 폭 발 배 기 n 압 축 n 히 팅 n 팽 창 n 쿨 링 © 2008 Stirling Biopower, Inc. 19

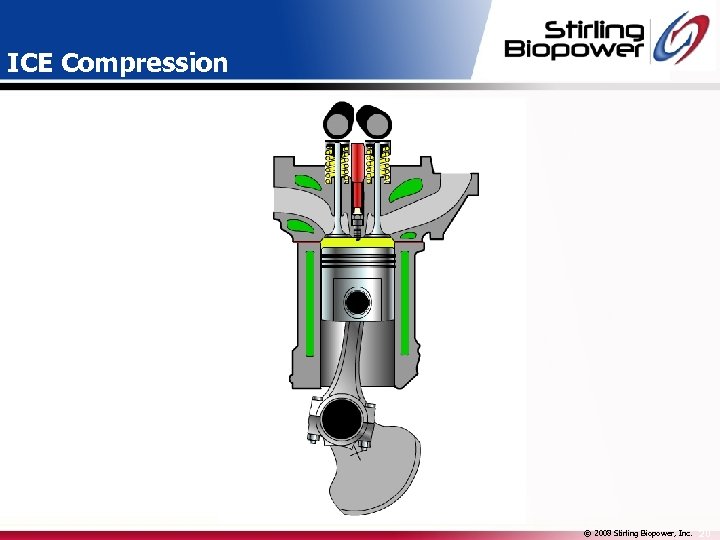

ICE Compression © 2008 Stirling Biopower, Inc. 20

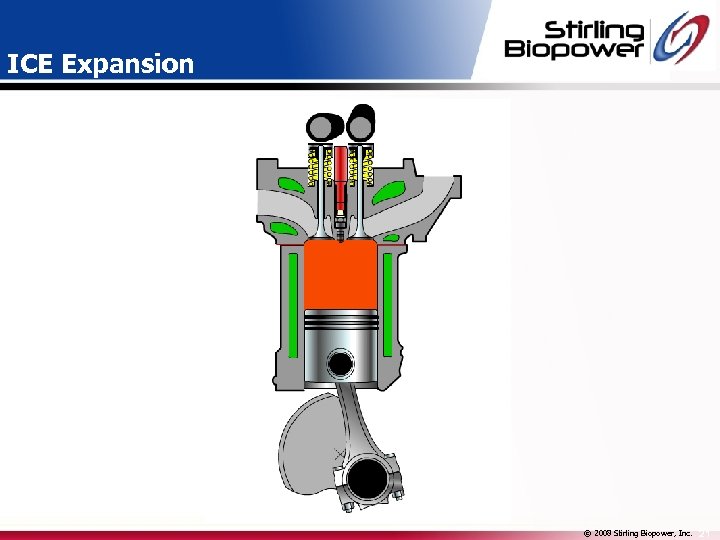

ICE Expansion © 2008 Stirling Biopower, Inc. 21

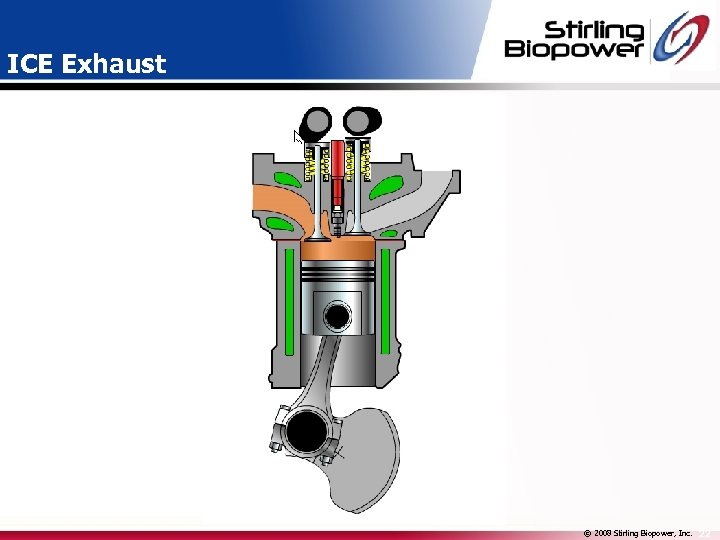

ICE Exhaust © 2008 Stirling Biopower, Inc. 22

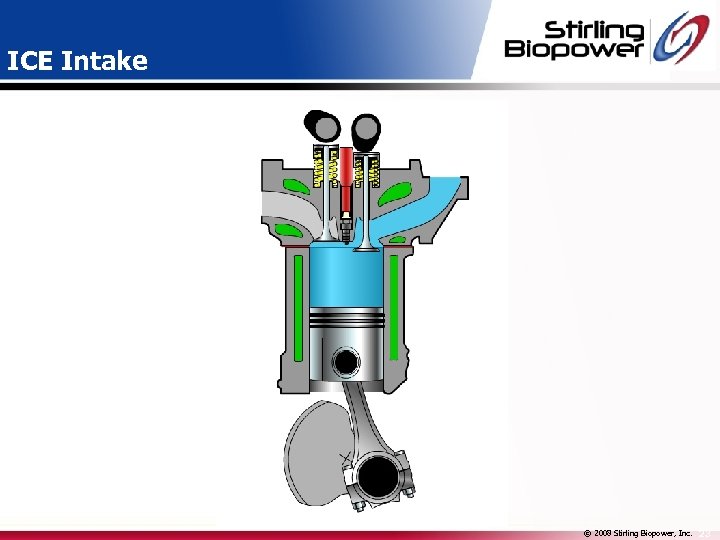

ICE Intake © 2008 Stirling Biopower, Inc. 23

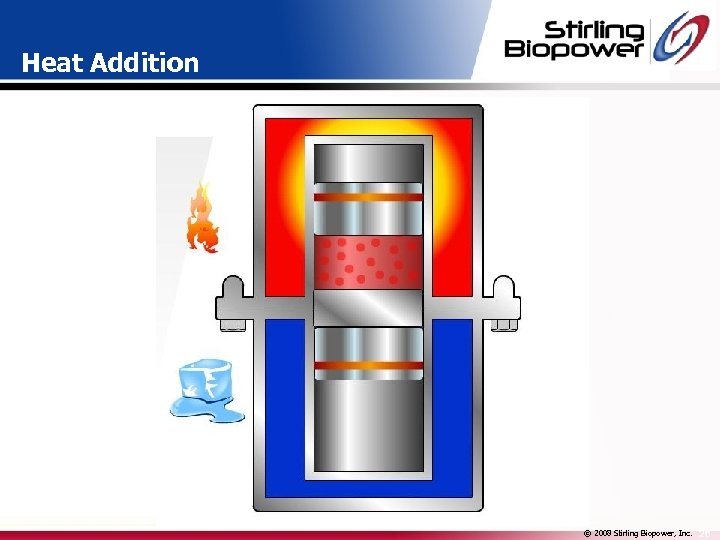

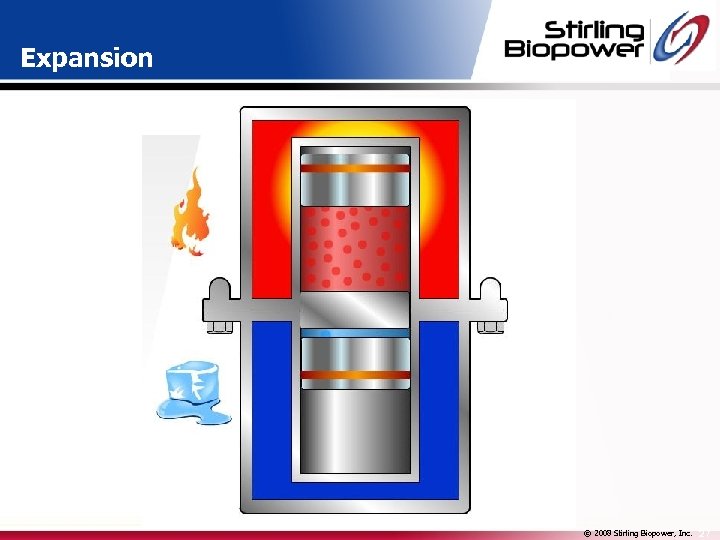

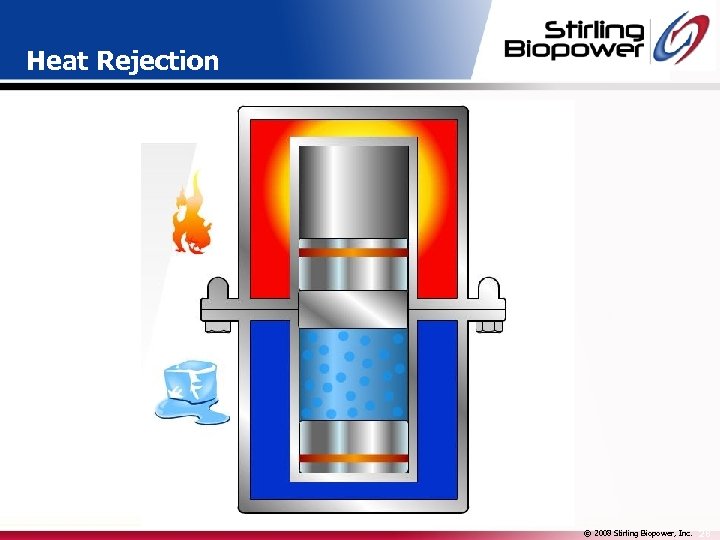

Four Phases of the Stirling Engine n 압 축(Compression) n 히 팅(Heat Addition) n 팽 창(Expansion) n 쿨 링(Heat Rejection) © 2008 Stirling Biopower, Inc. 24

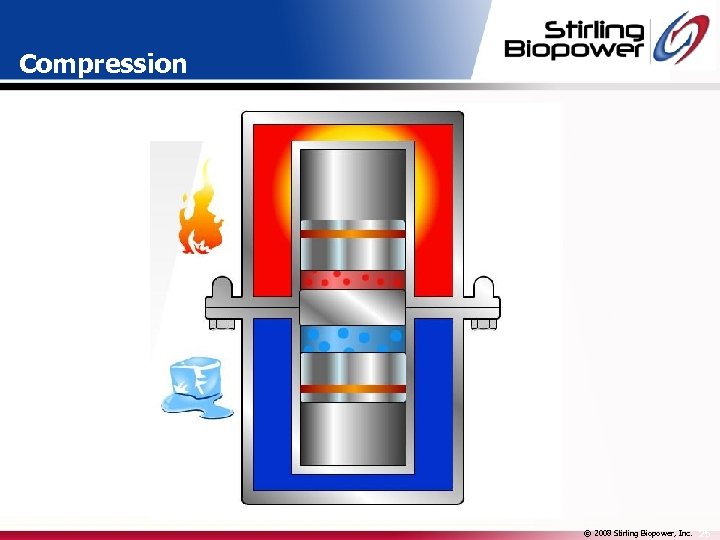

Compression © 2008 Stirling Biopower, Inc. 25

Heat Addition © 2008 Stirling Biopower, Inc. 26

Expansion © 2008 Stirling Biopower, Inc. 27

Heat Rejection © 2008 Stirling Biopower, Inc. 28

Stirling Biopower Engine Design

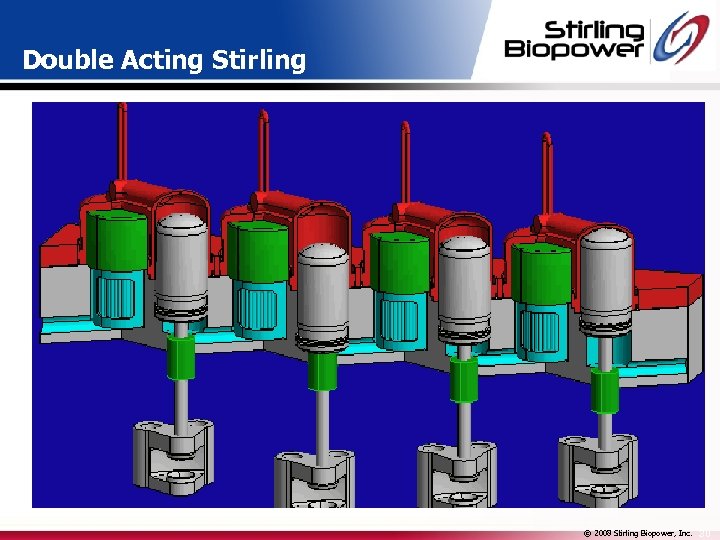

Double Acting Stirling © 2008 Stirling Biopower, Inc. 30

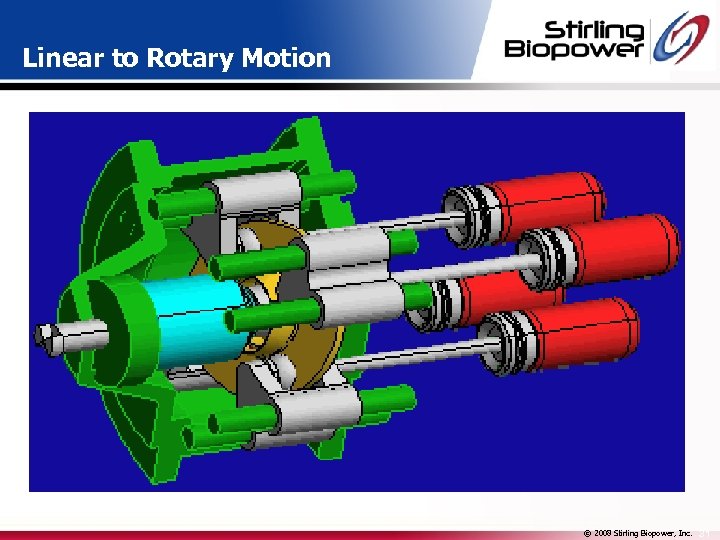

Linear to Rotary Motion © 2008 Stirling Biopower, Inc. 31

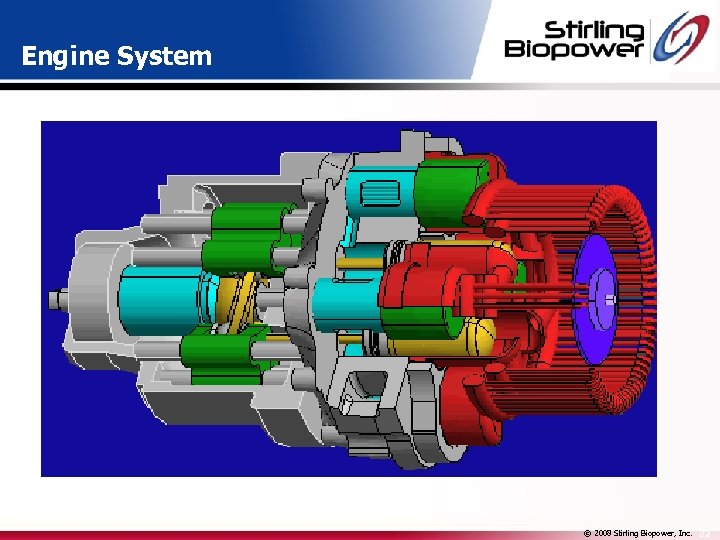

Engine System © 2008 Stirling Biopower, Inc. 32

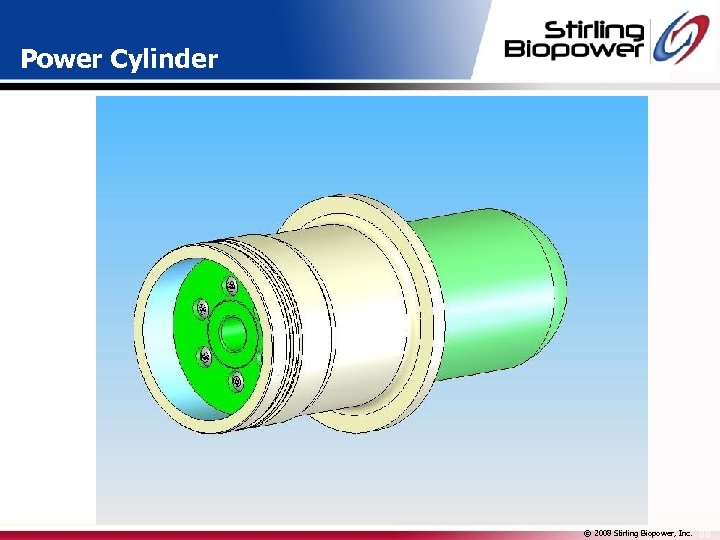

Power Cylinder © 2008 Stirling Biopower, Inc. 33

Rod Seal Assembly © 2008 Stirling Biopower, Inc. 34

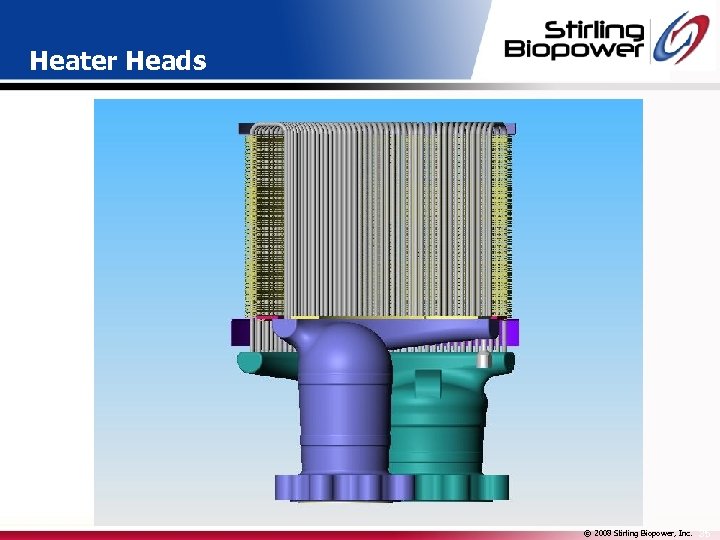

Heater Heads © 2008 Stirling Biopower, Inc. 35

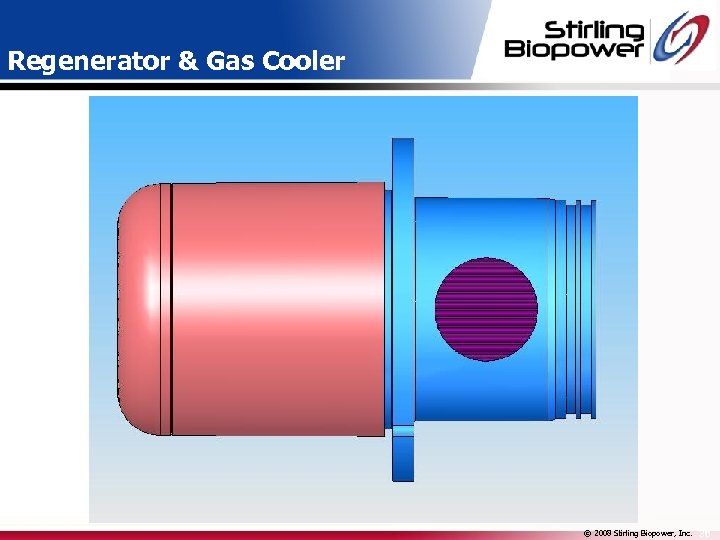

Regenerator & Gas Cooler © 2008 Stirling Biopower, Inc. 36

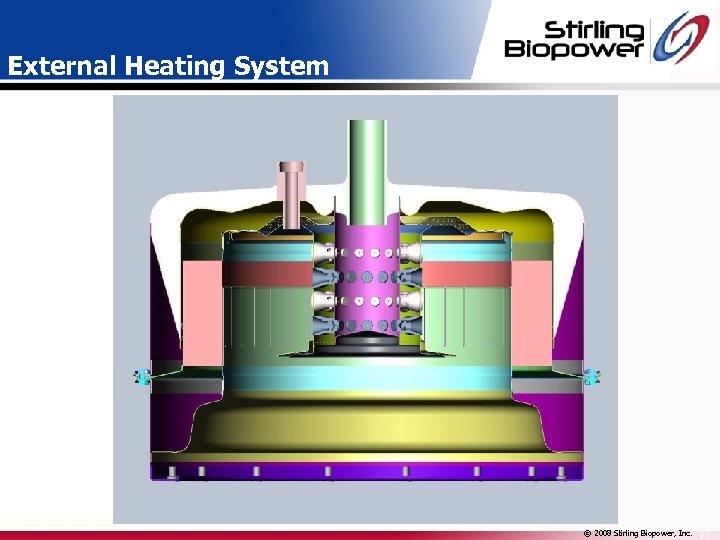

External Heating System © 2008 Stirling Biopower, Inc. 37

The End of Engine Design

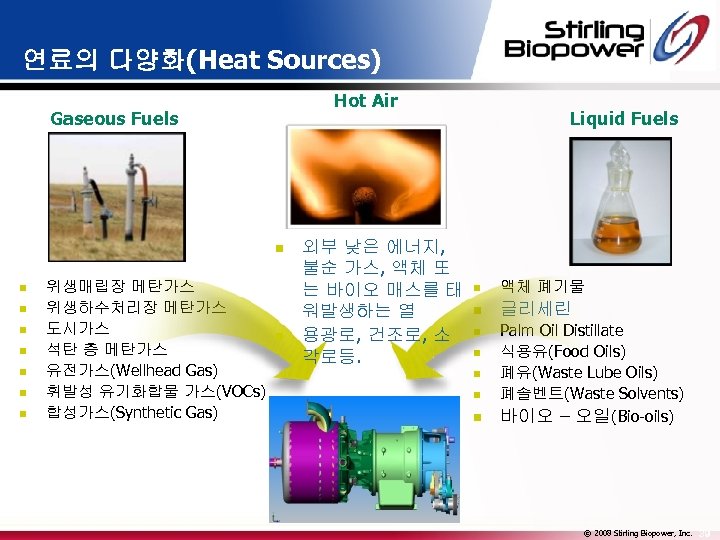

연료의 다양화(Heat Sources) Hot Air Gaseous Fuels n n n n 위생매립장 메탄가스 위생하수처리장 메탄가스 도시가스 석탄 층 메탄가스 유전가스(Wellhead Gas) 휘발성 유기화합물 가스(VOCs) 합성가스(Synthetic Gas) n 외부 낮은 에너지, 불순 가스, 액체 또 는 바이오 매스를 태 워발생하는 열 용광로, 건조로, 소 각로등. Liquid Fuels n 액체 폐기물 n 글리세린 n n n Palm Oil Distillate 식용유(Food Oils) 폐유(Waste Lube Oils) 폐솔벤트(Waste Solvents) 바이오 – 오일(Bio-oils) © 2008 Stirling Biopower, Inc. 39

Biogas Sources and Customers Primary biogas sources: n 하수, 폐수 처리장 -시, 농업 및 산업 매립지( Municipal, Agricultural and Industrial) n 쓰레기 매립장(Landfills) Biogas customers want technology that: n 낮은 비용으로 "버려지는 낭비 가스, 메탄 가스에서 전기와 온수를 생산 할수있다 n 버려지는 가스 경제성은(Is scalable to meet the gas available) n Can utilize low pressure gas that fluctuates in energy content n Is tolerant of gas impurities such as siloxanes and H 2 S n 유지 보수 및 운영 비용이 낮은지(Has low maintenance and operating costs) n Offsets expensive retail electricity purchase from the utility n Emits low levels of NOx and is easier to get permitted n Does not de-rate with low BTU gases © 2008 Stirling Biopower, Inc. 40

Digester Gas – Municipal WWTP § § § Typical gas composition from a municipal wastewater treatment plant: – Methane: 50 -65% – CO 2: 30 -38% – H 2 S: 2 -2000 ppm – Octamethyl-siloxane: 25 ppmv – BTEX: 65 ppmv Gas content is proportional to organic content in wastewater Average wastewater plant in US has 2 mgd flow rate (138 k. W) A city of 100, 000 produces enough gas for 1, 165 k. W Wastewater flow rate is proportional to urban population US – 219 million, OECD – 715 million © 2008 Stirling Biopower, Inc. 41

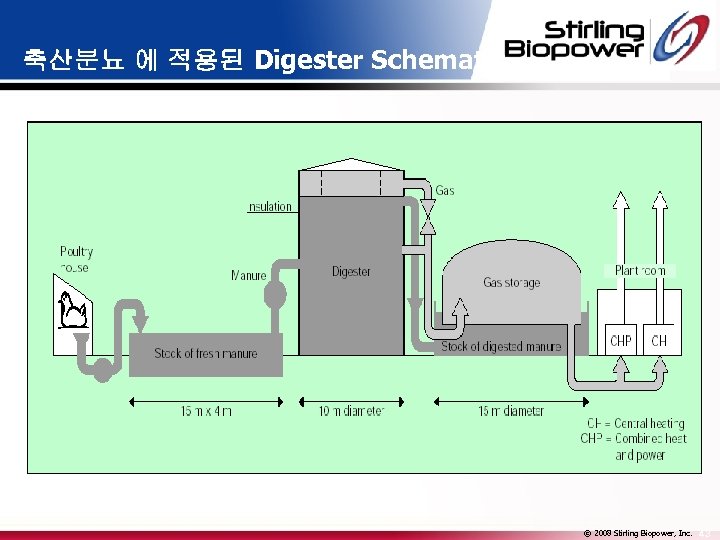

Digester Gas – Agricultural and Industrial n n 축산분뇨 자원화 시설적용 – 소 약 600두 = One Power Unit – 되지 약 7, 000 hogs = One Power Unit Many industrial companies have biodegradable waste that can be digested and turned into a valuable commodity © 2008 Stirling Biopower, Inc. 42

축산분뇨 에 적용된 Digester Schematic © 2008 Stirling Biopower, Inc. 43

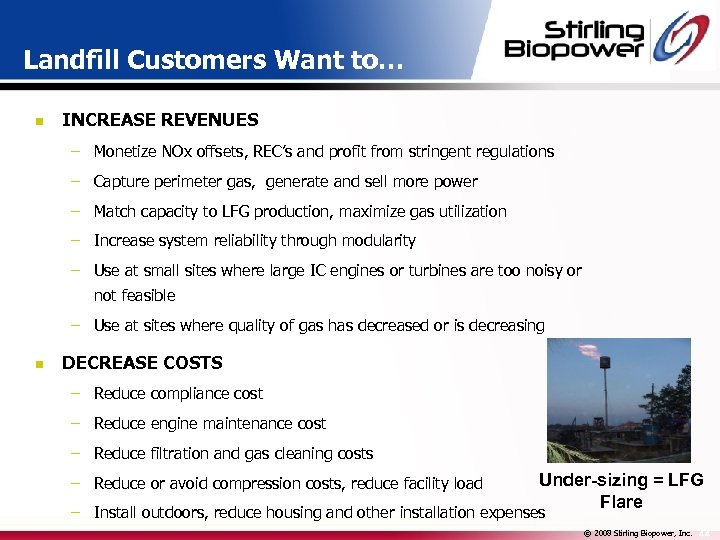

Landfill Customers Want to… n INCREASE REVENUES – Monetize NOx offsets, REC’s and profit from stringent regulations – Capture perimeter gas, generate and sell more power – Match capacity to LFG production, maximize gas utilization – Increase system reliability through modularity – Use at small sites where large IC engines or turbines are too noisy or not feasible – Use at sites where quality of gas has decreased or is decreasing n DECREASE COSTS – Reduce compliance cost – Reduce engine maintenance cost – Reduce filtration and gas cleaning costs – Reduce or avoid compression costs, reduce facility load Under-sizing = LFG Flare – Install outdoors, reduce housing and other installation expenses © 2008 Stirling Biopower, Inc. 44

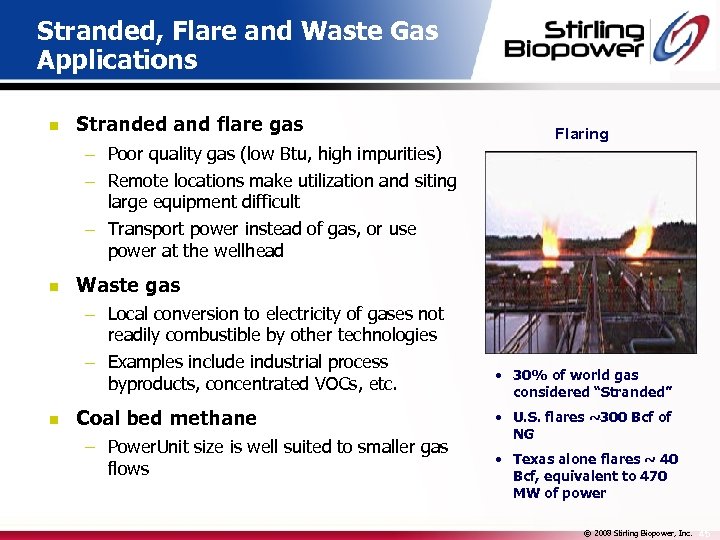

Stranded, Flare and Waste Gas Applications n Stranded and flare gas - Poor quality gas (low Btu, high impurities) - Remote locations make utilization and siting large equipment difficult - Transport power instead of gas, or use power at the wellhead n Waste gas - Local conversion to electricity of gases not readily combustible by other technologies - Examples include industrial process byproducts, concentrated VOCs, etc. n Flaring Coal bed methane – Power. Unit size is well suited to smaller gas flows • 30% of world gas considered “Stranded” • U. S. flares ~300 Bcf of NG • Texas alone flares ~ 40 Bcf, equivalent to 470 MW of power © 2008 Stirling Biopower, Inc. 45

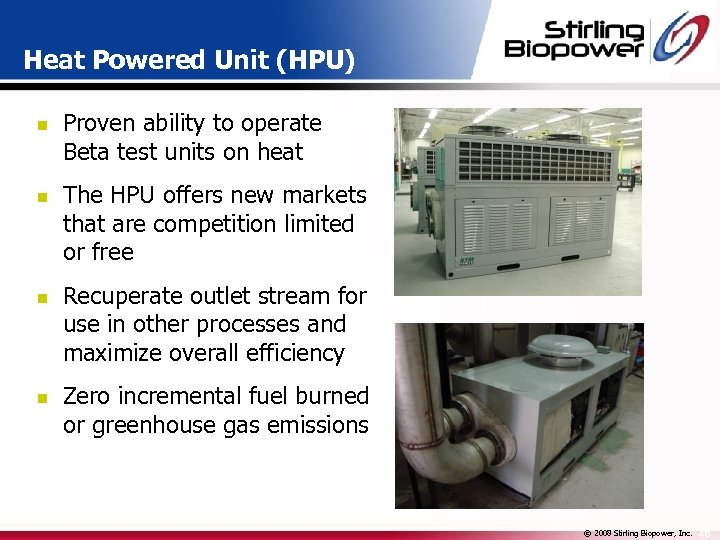

Heat Powered Unit (HPU) n n Proven ability to operate Beta test units on heat The HPU offers new markets that are competition limited or free Recuperate outlet stream for use in other processes and maximize overall efficiency Zero incremental fuel burned or greenhouse gas emissions © 2008 Stirling Biopower, Inc. 46

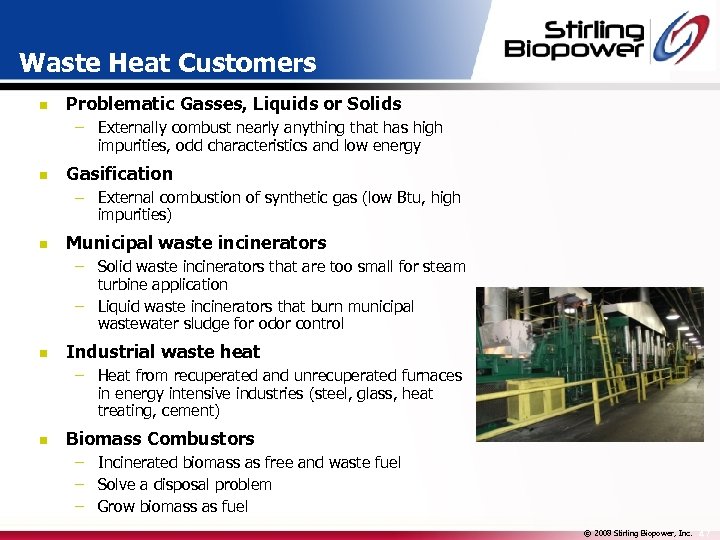

Waste Heat Customers n Problematic Gasses, Liquids or Solids – Externally combust nearly anything that has high impurities, odd characteristics and low energy n Gasification - External combustion of synthetic gas (low Btu, high impurities) n Municipal waste incinerators – Solid waste incinerators that are too small for steam turbine application – Liquid waste incinerators that burn municipal wastewater sludge for odor control n Industrial waste heat – Heat from recuperated and unrecuperated furnaces in energy intensive industries (steel, glass, heat treating, cement) n Biomass Combustors – Incinerated biomass as free and waste fuel – Solve a disposal problem – Grow biomass as fuel © 2008 Stirling Biopower, Inc. 47

Liquid Fuels n Able to consume liquids that are problematic, have storage or transportation issues or unable to be used in conventional technologies. n Can consume locally and offset electrical load n Potential liquid fuels: – – – n n Glycerin Food oils Waste solvents Bio oils Successful alpha test of (7) liquid fuel Power. Units on palm oil in 2006 Commercial liquid fuel Power. Unit in development now, ready for sale in 2009. © 2008 Stirling Biopower, Inc. 48

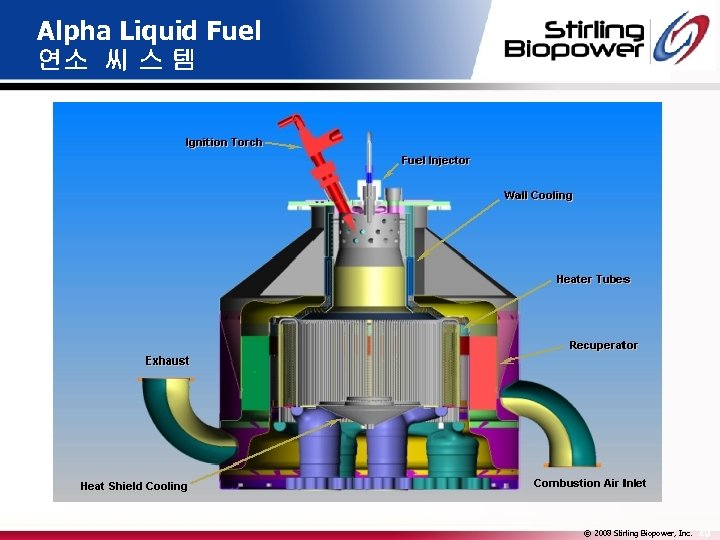

Alpha Liquid Fuel 연소 씨 스 템 © 2008 Stirling Biopower, Inc. 49

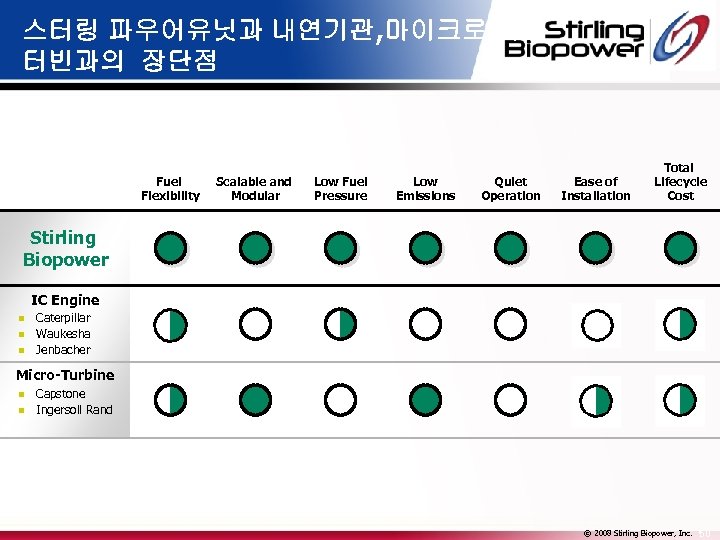

스터링 파우어유닛과 내연기관, 마이크로 가스 터빈과의 장단점 Fuel Flexibility Scalable and Modular Low Fuel Pressure Low Emissions Quiet Operation Ease of Installation Total Lifecycle Cost Stirling Biopower IC Engine n n n Caterpillar Waukesha Jenbacher Micro-Turbine n n Capstone Ingersoll Rand © 2008 Stirling Biopower, Inc. 50

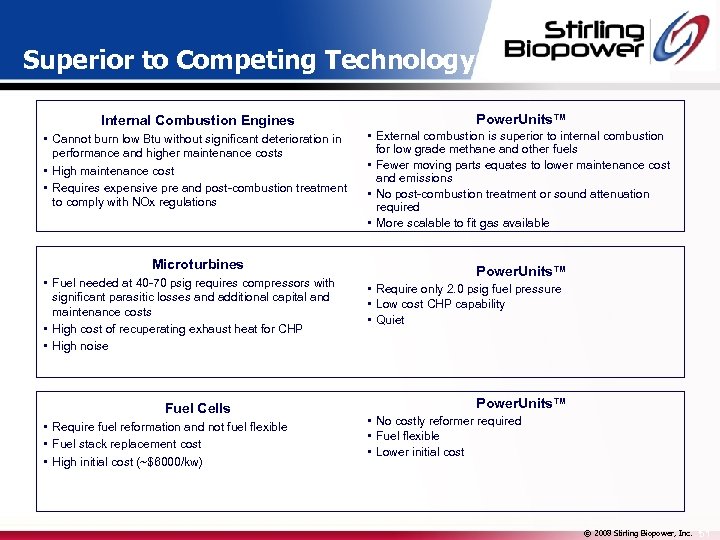

Superior to Competing Technology Internal Combustion Engines Power. Units™ • Cannot burn low Btu without significant deterioration in performance and higher maintenance costs • High maintenance cost • Requires expensive pre and post-combustion treatment to comply with NOx regulations • External combustion is superior to internal combustion for low grade methane and other fuels • Fewer moving parts equates to lower maintenance cost and emissions • No post-combustion treatment or sound attenuation required • More scalable to fit gas available Microturbines • Fuel needed at 40 -70 psig requires compressors with significant parasitic losses and additional capital and maintenance costs • High cost of recuperating exhaust heat for CHP • High noise Fuel Cells • Require fuel reformation and not fuel flexible • Fuel stack replacement cost • High initial cost (~$6000/kw) Power. Units™ • Require only 2. 0 psig fuel pressure • Low cost CHP capability • Quiet Power. Units™ • No costly reformer required • Fuel flexible • Lower initial cost © 2008 Stirling Biopower, Inc. 51

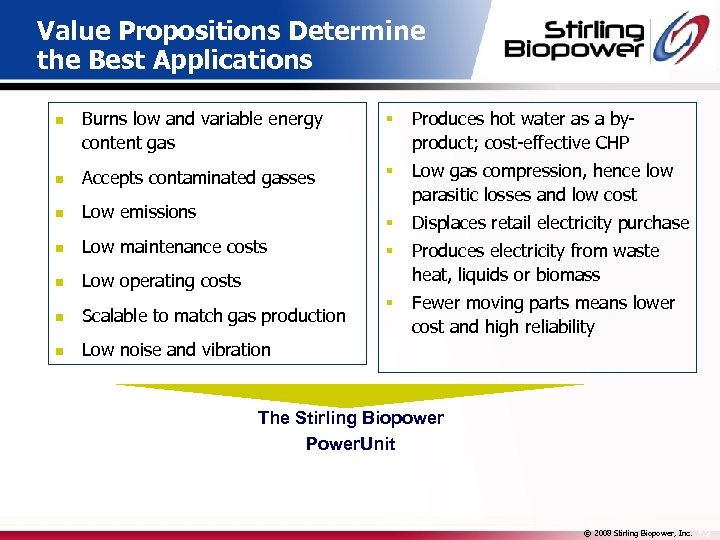

Value Propositions Determine the Best Applications Burns low and variable energy content gas § Produces hot water as a byproduct; cost-effective CHP n Accepts contaminated gasses § n Low emissions Low gas compression, hence low parasitic losses and low cost § Displaces retail electricity purchase n Low maintenance costs § n Low operating costs Produces electricity from waste heat, liquids or biomass n Scalable to match gas production § Fewer moving parts means lower cost and high reliability n Low noise and vibration n The Stirling Biopower Power. Unit © 2008 Stirling Biopower, Inc. 52

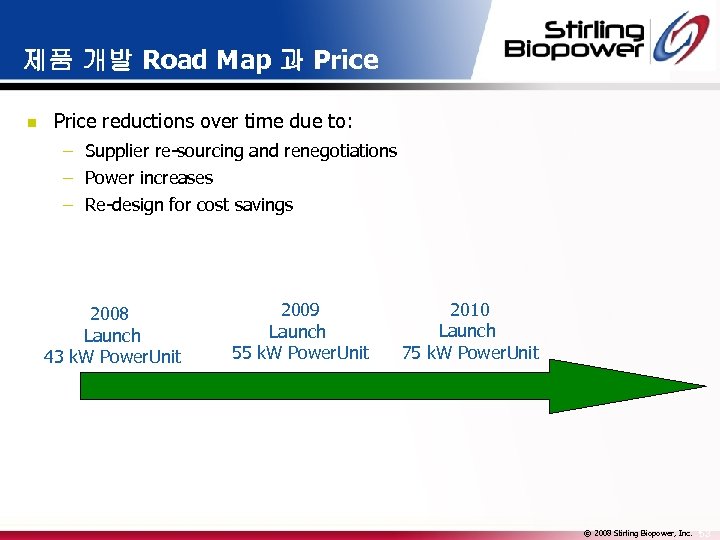

제품 개발 Road Map 과 Price n Price reductions over time due to: – Supplier re-sourcing and renegotiations – Power increases – Re-design for cost savings 2008 Launch 43 k. W Power. Unit 2009 Launch 55 k. W Power. Unit 2010 Launch 75 k. W Power. Unit © 2008 Stirling Biopower, Inc. 53

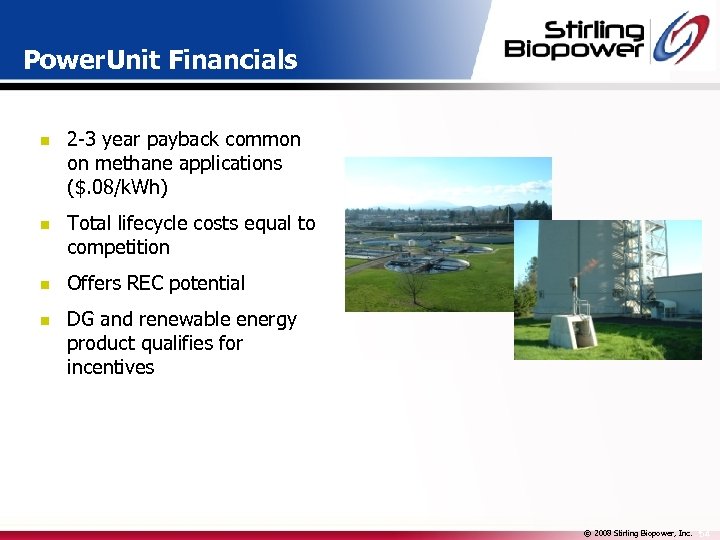

Power. Unit Financials n n 2 -3 year payback common on methane applications ($. 08/k. Wh) Total lifecycle costs equal to competition Offers REC potential DG and renewable energy product qualifies for incentives © 2008 Stirling Biopower, Inc. 54

Our Focus Offer Innovative Technology That Customers Need Alternative and off -specification fuels Green solution Distributed Generation © 2008 Stirling Biopower, Inc. 55

Global Drivers of Alternative Energy Security Demand for New Sources of Clean, Safe, Low-Cost Energy Economic Environmental © 2008 Stirling Biopower, Inc. 56

A Market Gap Increasing Demand for Safe, Green, Low-Cost, Fully Dispatchable Power from Alternative Fuels Growing Need for Electrical Power © 2008 Stirling Biopower, Inc. 57

SB’s Technology Bridges the Gap Stirling Biopower Unit은 외 연기관 입니다. Increasing Demand Multi-Fuel Capability from Stirling Cycle for Safe, Green, Technology Growing Need for Low-Cost, Fully Electrical Power Dispatchable Power from Alternative Fuels © 2008 Stirling Biopower, Inc. 58

SB – A Leader in Alternative Power Generation Enormous Demand for Power Generation from Alternative Fuels Unique Transformative Product Poised for Commercial Launch © 2008 Stirling Biopower, Inc. 59

The Clean Energy Choice Thank you! Contact us at : Shinil ENG Co. Power. Unit™ Shin D. B Phone: 82 -17 -581 -2380 Email : dongbs @ hanmail. net

99019465b62a84a5d2ae9c137c487142.ppt