311573d9d5703c56b5d43834d80ee08b.ppt

- Количество слайдов: 34

STEP from a Life Cycle Point of View - The PLCS Initiative NASA STEP for Aerospace Workshop JPL Pasadena, 17 January 2001 Presented by: Howard Mason, BAE SYSTEMS Position: Chairman of the Board, PLCS Inc. Chairman, ISO TC 184 SC 4

STEP from a Life Cycle Point of View - The PLCS Initiative NASA STEP for Aerospace Workshop JPL Pasadena, 17 January 2001 Presented by: Howard Mason, BAE SYSTEMS Position: Chairman of the Board, PLCS Inc. Chairman, ISO TC 184 SC 4

Agenda Key Business Drivers Impact of the Internet - B 2 B exchanges Overview of Current Standards About the PLCS initiative The PLCS Technical Approach Questions

Agenda Key Business Drivers Impact of the Internet - B 2 B exchanges Overview of Current Standards About the PLCS initiative The PLCS Technical Approach Questions

Key Business Drivers l l International Collaboration demands product data exchange and sharing across many organisations Defence and Airline customers and major aerospace companies want a single way to exchange digital product data Suppliers want a unified approach from prime contractors Worldwide operation demands a worldwide standard

Key Business Drivers l l International Collaboration demands product data exchange and sharing across many organisations Defence and Airline customers and major aerospace companies want a single way to exchange digital product data Suppliers want a unified approach from prime contractors Worldwide operation demands a worldwide standard

Key Business Drivers l Shared or Integrated Digital Environments demand accurate information on product configuration, which is: v v l Achieved on delivery Maintained through the lifecycle Communicated between customer and supplier Communicated along the supply chain Integrated software needs configuration management v v v Product software is a key element of the platform Need closer control of product structure than ever before Need to integrate and maintain information from multiple sources and systems

Key Business Drivers l Shared or Integrated Digital Environments demand accurate information on product configuration, which is: v v l Achieved on delivery Maintained through the lifecycle Communicated between customer and supplier Communicated along the supply chain Integrated software needs configuration management v v v Product software is a key element of the platform Need closer control of product structure than ever before Need to integrate and maintain information from multiple sources and systems

The Internet changes everything. . . “The emergence of the internet and the associated opportunities has sounded a wake-up call to all product development organisations across the world to change and adapt the way they do business or risk being run over” Gartner. Group, Strategic Analysis Report “How you gather, manage and use information will determine whether you win or lose” Bill Gates, Microsoft Corporation “The internet is driving business change and technology change and it lets you use the open standards to run your business” Oracle Corporation

The Internet changes everything. . . “The emergence of the internet and the associated opportunities has sounded a wake-up call to all product development organisations across the world to change and adapt the way they do business or risk being run over” Gartner. Group, Strategic Analysis Report “How you gather, manage and use information will determine whether you win or lose” Bill Gates, Microsoft Corporation “The internet is driving business change and technology change and it lets you use the open standards to run your business” Oracle Corporation

Which industries are likely to embrace B 2 B solutions? “e-Business growth over the next few years will be primarily comprised of business to business (B 2 B) transactions and will be driven by manufacturing and supply-chain related industries” Source: Forrester Research Group Financial Times, 10 Feb 2000 “ We conclude that industries that are B 2 B inclined exhibit certain key characteristics. Some of these characteristics include the following: v v v The supply chain is highly diffuse Techno-innovators dominate the culture Process represents more than 20% of total costs Products exhibit complex configurations Expense pressure is intense” www. goldmansachs. com/hightech/research/b 2 b

Which industries are likely to embrace B 2 B solutions? “e-Business growth over the next few years will be primarily comprised of business to business (B 2 B) transactions and will be driven by manufacturing and supply-chain related industries” Source: Forrester Research Group Financial Times, 10 Feb 2000 “ We conclude that industries that are B 2 B inclined exhibit certain key characteristics. Some of these characteristics include the following: v v v The supply chain is highly diffuse Techno-innovators dominate the culture Process represents more than 20% of total costs Products exhibit complex configurations Expense pressure is intense” www. goldmansachs. com/hightech/research/b 2 b

“Opportunity of a lifetime” or “Business as usual” ? “by 2004 the aerospace sector will have the largest proportion of internet-based Business to Business (B 2 B) sales, 35%…” B 2 B: 2 b or not 2 B? , Goldman Sachs, 11/99 but today… “only 3% of all transactions involving sales of aviation parts are conducted on line” Shop Talk: Parts. Planes and B 2 B exchanges, Red Herring, 24 Feb 2000 Exostar addresses three distinct needs in the aerospace and defense industry: (Non-production procurement ( Designing and building aerospace and defense products (Spares and maintenance for airlines, aviation operators and defense businesses

“Opportunity of a lifetime” or “Business as usual” ? “by 2004 the aerospace sector will have the largest proportion of internet-based Business to Business (B 2 B) sales, 35%…” B 2 B: 2 b or not 2 B? , Goldman Sachs, 11/99 but today… “only 3% of all transactions involving sales of aviation parts are conducted on line” Shop Talk: Parts. Planes and B 2 B exchanges, Red Herring, 24 Feb 2000 Exostar addresses three distinct needs in the aerospace and defense industry: (Non-production procurement ( Designing and building aerospace and defense products (Spares and maintenance for airlines, aviation operators and defense businesses

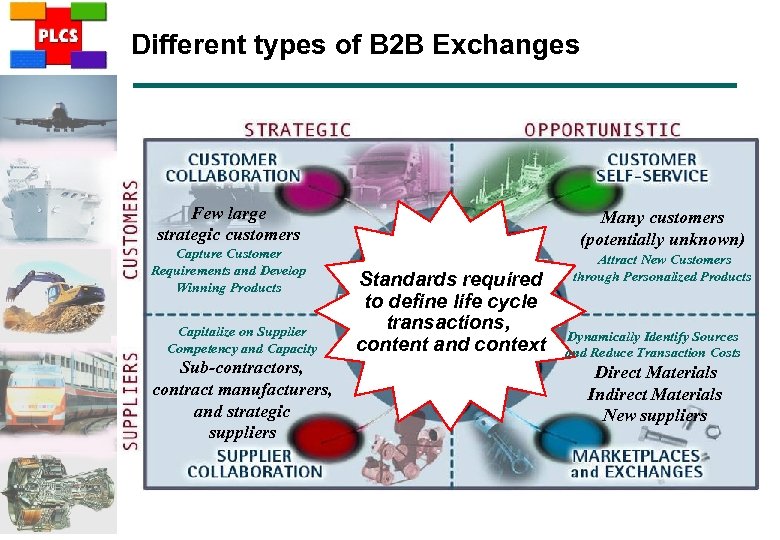

Different types of B 2 B Exchanges Few large strategic customers Capture Customer Requirements and Develop Winning Products Capitalize on Supplier Competency and Capacity Sub-contractors, contract manufacturers, and strategic suppliers Many customers (potentially unknown) Standards required to define life cycle transactions, content and context Attract New Customers through Personalized Products Dynamically Identify Sources and Reduce Transaction Costs Direct Materials Indirect Materials New suppliers

Different types of B 2 B Exchanges Few large strategic customers Capture Customer Requirements and Develop Winning Products Capitalize on Supplier Competency and Capacity Sub-contractors, contract manufacturers, and strategic suppliers Many customers (potentially unknown) Standards required to define life cycle transactions, content and context Attract New Customers through Personalized Products Dynamically Identify Sources and Reduce Transaction Costs Direct Materials Indirect Materials New suppliers

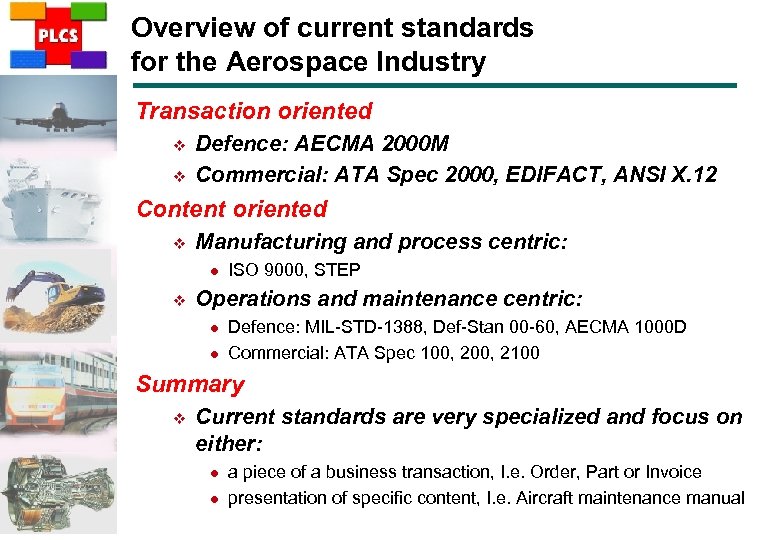

Overview of current standards for the Aerospace Industry Transaction oriented v v Defence: AECMA 2000 M Commercial: ATA Spec 2000, EDIFACT, ANSI X. 12 Content oriented v Manufacturing and process centric: l v ISO 9000, STEP Operations and maintenance centric: l l Defence: MIL-STD-1388, Def-Stan 00 -60, AECMA 1000 D Commercial: ATA Spec 100, 2100 Summary v Current standards are very specialized and focus on either: l l a piece of a business transaction, I. e. Order, Part or Invoice presentation of specific content, I. e. Aircraft maintenance manual

Overview of current standards for the Aerospace Industry Transaction oriented v v Defence: AECMA 2000 M Commercial: ATA Spec 2000, EDIFACT, ANSI X. 12 Content oriented v Manufacturing and process centric: l v ISO 9000, STEP Operations and maintenance centric: l l Defence: MIL-STD-1388, Def-Stan 00 -60, AECMA 1000 D Commercial: ATA Spec 100, 2100 Summary v Current standards are very specialized and focus on either: l l a piece of a business transaction, I. e. Order, Part or Invoice presentation of specific content, I. e. Aircraft maintenance manual

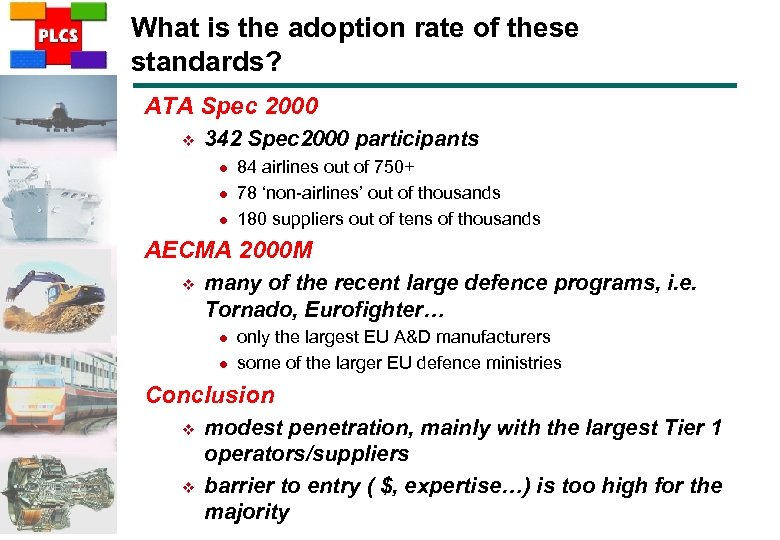

What is the adoption rate of these standards? ATA Spec 2000 v 342 Spec 2000 participants l l l 84 airlines out of 750+ 78 ‘non-airlines’ out of thousands 180 suppliers out of tens of thousands AECMA 2000 M v many of the recent large defence programs, i. e. Tornado, Eurofighter… l l only the largest EU A&D manufacturers some of the larger EU defence ministries Conclusion v v modest penetration, mainly with the largest Tier 1 operators/suppliers barrier to entry ( $, expertise…) is too high for the majority

What is the adoption rate of these standards? ATA Spec 2000 v 342 Spec 2000 participants l l l 84 airlines out of 750+ 78 ‘non-airlines’ out of thousands 180 suppliers out of tens of thousands AECMA 2000 M v many of the recent large defence programs, i. e. Tornado, Eurofighter… l l only the largest EU A&D manufacturers some of the larger EU defence ministries Conclusion v v modest penetration, mainly with the largest Tier 1 operators/suppliers barrier to entry ( $, expertise…) is too high for the majority

So what is missing? v v v Available standards do not address product support requirements Major problems keeping technical information in line with the changing physical product through life Major problems linking support information to relevant product information Software applications use proprietary data standards and are often difficult to integrate Inconsistent data definitions Existing standards are insufficient to support the forecasted growth in e-business

So what is missing? v v v Available standards do not address product support requirements Major problems keeping technical information in line with the changing physical product through life Major problems linking support information to relevant product information Software applications use proprietary data standards and are often difficult to integrate Inconsistent data definitions Existing standards are insufficient to support the forecasted growth in e-business

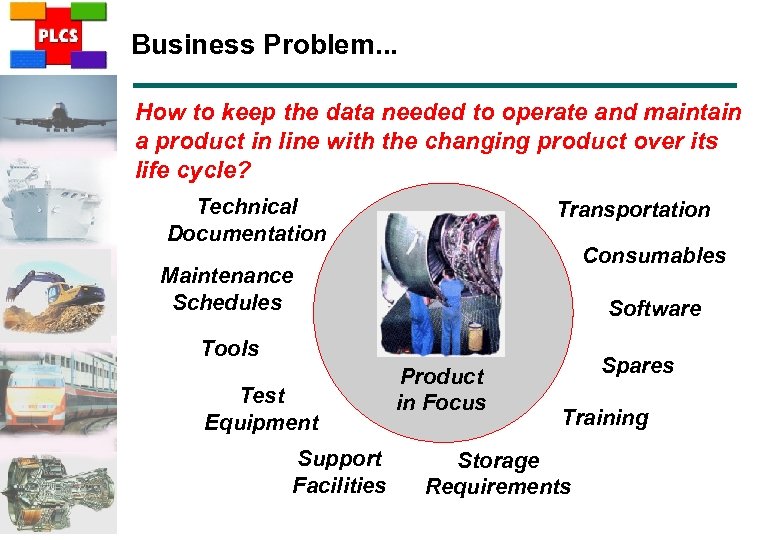

Business Problem. . . How to keep the data needed to operate and maintain a product in line with the changing product over its life cycle? Technical Documentation Transportation Consumables Maintenance Schedules Software Tools Test Equipment Support Facilities Product in Focus Spares Training Storage Requirements

Business Problem. . . How to keep the data needed to operate and maintain a product in line with the changing product over its life cycle? Technical Documentation Transportation Consumables Maintenance Schedules Software Tools Test Equipment Support Facilities Product in Focus Spares Training Storage Requirements

The Product Life Cycle Support (PLCS) initiative About PLCS v A joint industry and government initiative to accelerate development of new standards for product support information v An international project, managed within the ISO framework, to produce draft standard(s) within 3 years. v PLCS utilizes ISO 10303 STEP - the STandard for Exchange of Product model data v PLCS Inc. established in 1999 by 14 leading private and public sector organisations

The Product Life Cycle Support (PLCS) initiative About PLCS v A joint industry and government initiative to accelerate development of new standards for product support information v An international project, managed within the ISO framework, to produce draft standard(s) within 3 years. v PLCS utilizes ISO 10303 STEP - the STandard for Exchange of Product model data v PLCS Inc. established in 1999 by 14 leading private and public sector organisations

PLCS Launch Members Finnish Defence Forces information services

PLCS Launch Members Finnish Defence Forces information services

Goals of PLCS v v v Improve product availability Reduce operating, support and maintenance costs Improve quality and accessibility of Product Life Cycle Support information Accelerate technical development of the ISO standards Encourage early implementation commercial software vendors Encourage early industry participation in the development and testing of the standard

Goals of PLCS v v v Improve product availability Reduce operating, support and maintenance costs Improve quality and accessibility of Product Life Cycle Support information Accelerate technical development of the ISO standards Encourage early implementation commercial software vendors Encourage early industry participation in the development and testing of the standard

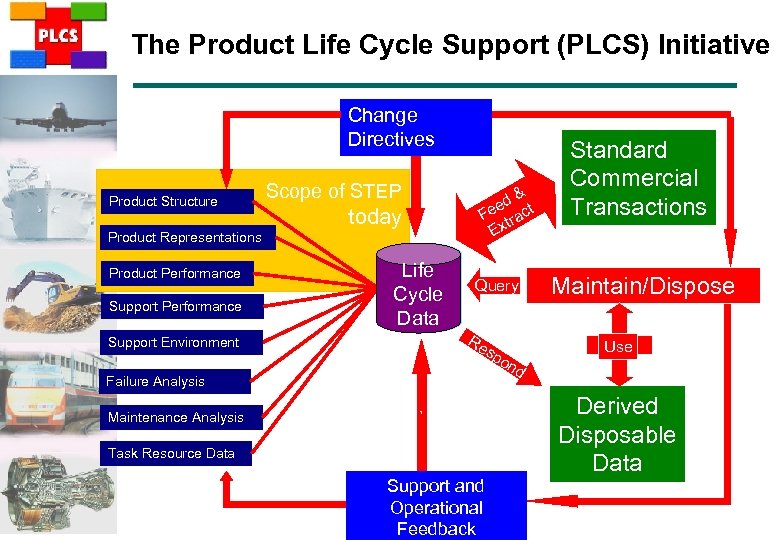

The Product Life Cycle Support (PLCS) Initiative Change Directives Product Structure Scope of STEP d& ee act F tr Ex today Product Representations Product Performance Support Environment Life Cycle Shared Data Query Re s Maintain/Dispose Use po n d Failure Analysis Maintenance Analysis Standard Commercial Transactions ` Task Resource Data Support and Operational Feedback Derived Disposable Data

The Product Life Cycle Support (PLCS) Initiative Change Directives Product Structure Scope of STEP d& ee act F tr Ex today Product Representations Product Performance Support Environment Life Cycle Shared Data Query Re s Maintain/Dispose Use po n d Failure Analysis Maintenance Analysis Standard Commercial Transactions ` Task Resource Data Support and Operational Feedback Derived Disposable Data

Key Deliverables v v v New capability for support, based on simplified and integrated process components Interface standards defined to support enterprise integration Integrated data models using common terminology Cost drivers and performance metrics identified generic and industry specific Information available for education and awareness programmes ISO standard for the exchange of product life cycle support data

Key Deliverables v v v New capability for support, based on simplified and integrated process components Interface standards defined to support enterprise integration Integrated data models using common terminology Cost drivers and performance metrics identified generic and industry specific Information available for education and awareness programmes ISO standard for the exchange of product life cycle support data

The PLCS Technical Approach l l l Organisation Links to ISO Activity Modelling Data Modelling Testing

The PLCS Technical Approach l l l Organisation Links to ISO Activity Modelling Data Modelling Testing

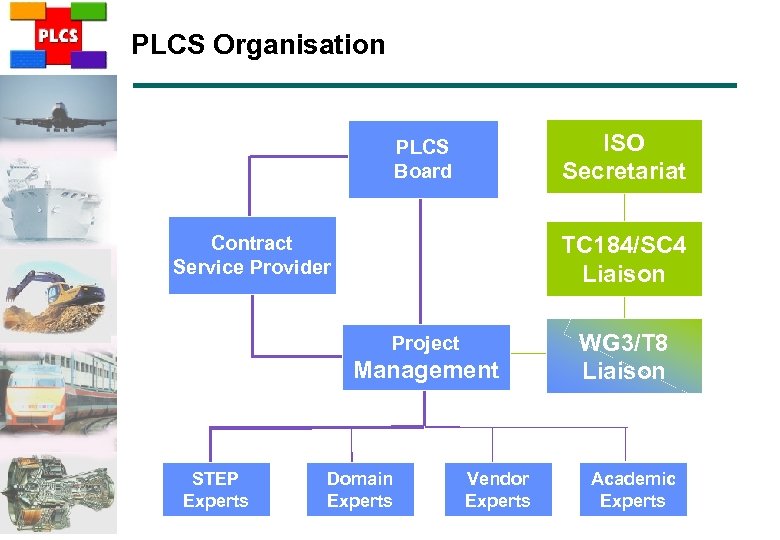

PLCS Organisation ISO Secretariat PLCS Board TC 184/SC 4 Liaison Contract Service Provider Project Management STEP Experts Domain Experts Vendor Experts WG 3/T 8 Liaison Academic Experts

PLCS Organisation ISO Secretariat PLCS Board TC 184/SC 4 Liaison Contract Service Provider Project Management STEP Experts Domain Experts Vendor Experts WG 3/T 8 Liaison Academic Experts

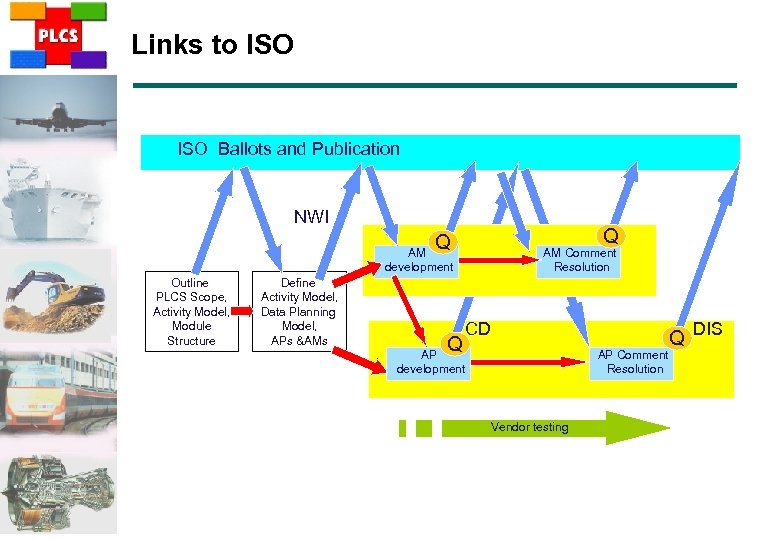

Links to ISO Ballots and Publication NWI Draft for ballot TS Q Q AM development Outline PLCS Scope, Activity Model, Module Structure Define Activity Model, Data Planning Model, APs &AMs Q AM Comment Resolution CD AP development AP Comment Resolution Vendor testing Q DIS

Links to ISO Ballots and Publication NWI Draft for ballot TS Q Q AM development Outline PLCS Scope, Activity Model, Module Structure Define Activity Model, Data Planning Model, APs &AMs Q AM Comment Resolution CD AP development AP Comment Resolution Vendor testing Q DIS

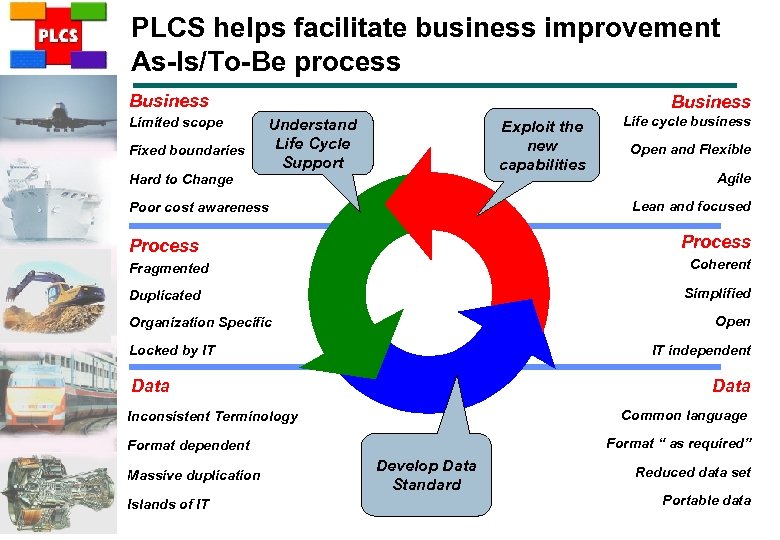

PLCS helps facilitate business improvement As-Is/To-Be process Business Limited scope Fixed boundaries Hard to Change Business Understand Life Cycle Support Exploit the new capabilities Agile Process Coherent Fragmented Simplified Duplicated Open Organization Specific Locked by IT IT independent Data Common language Inconsistent Terminology Format “ as required” Format dependent Islands of IT Open and Flexible Lean and focused Poor cost awareness Massive duplication Life cycle business Develop Data Standard Reduced data set Portable data

PLCS helps facilitate business improvement As-Is/To-Be process Business Limited scope Fixed boundaries Hard to Change Business Understand Life Cycle Support Exploit the new capabilities Agile Process Coherent Fragmented Simplified Duplicated Open Organization Specific Locked by IT IT independent Data Common language Inconsistent Terminology Format “ as required” Format dependent Islands of IT Open and Flexible Lean and focused Poor cost awareness Massive duplication Life cycle business Develop Data Standard Reduced data set Portable data

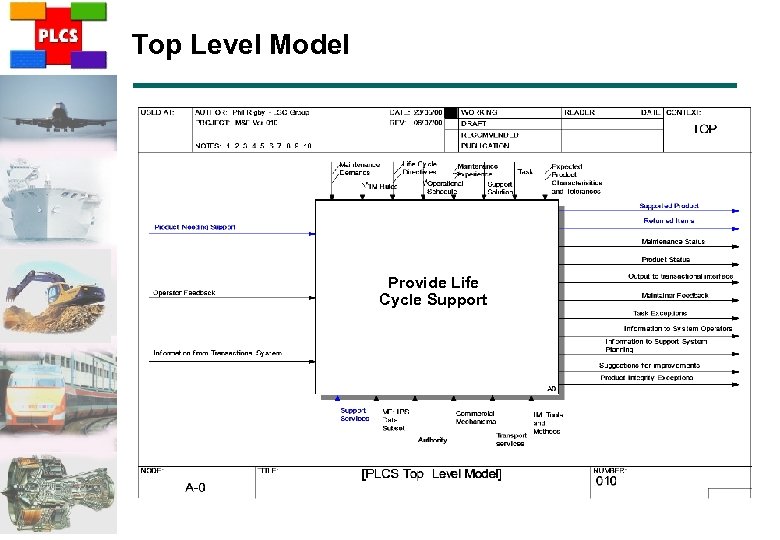

Top Level Model Provide Life Cycle Support

Top Level Model Provide Life Cycle Support

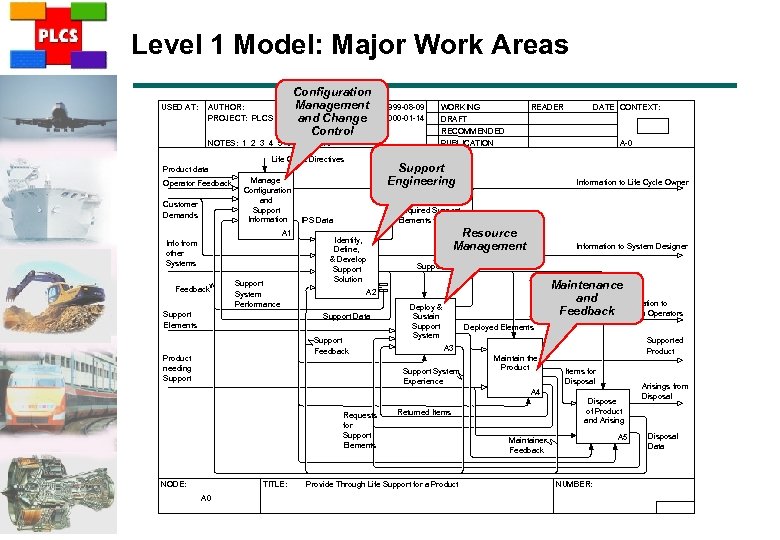

Level 1 Model: Major Work Areas Configuration USED AT: Management 1999 -08 -09 AUTHOR: DATE: PROJECT: PLCS AAM v 2. idd Change REV: 2000 -01 -14 and Control NOTES: 1 2 3 4 5 6 7 8 9 10 Life Cycle Directives Customer Demands Manage Configuration and Support Information A 1 Info from other Systems Feedback Support System Performance Support Elements Identify, Define, & Develop Support Solution A-0 Orders for Support Elements Resource Management Information to System Designer Support Plans Maintenance and Information to Feedback System Operators A 2 Support Feedback DATE CONTEXT: Information to Life Cycle Owner Required Support Elements IPS Data Support Data Product needing Support READER Support Engineering Product data Operator Feedback WORKING DRAFT RECOMMENDED PUBLICATION Deploy & Sustain Support System Deployed Elements Supported Product A 3 Support System Experience Maintain the Product Items for Disposal A 4 Requests for Support Elements NODE: TITLE: A 0 Dispose of Product and Arising Returned Items Provide Through Life Support for a Product A 5 Maintainer Feedback NUMBER: Arisings from Disposal Data

Level 1 Model: Major Work Areas Configuration USED AT: Management 1999 -08 -09 AUTHOR: DATE: PROJECT: PLCS AAM v 2. idd Change REV: 2000 -01 -14 and Control NOTES: 1 2 3 4 5 6 7 8 9 10 Life Cycle Directives Customer Demands Manage Configuration and Support Information A 1 Info from other Systems Feedback Support System Performance Support Elements Identify, Define, & Develop Support Solution A-0 Orders for Support Elements Resource Management Information to System Designer Support Plans Maintenance and Information to Feedback System Operators A 2 Support Feedback DATE CONTEXT: Information to Life Cycle Owner Required Support Elements IPS Data Support Data Product needing Support READER Support Engineering Product data Operator Feedback WORKING DRAFT RECOMMENDED PUBLICATION Deploy & Sustain Support System Deployed Elements Supported Product A 3 Support System Experience Maintain the Product Items for Disposal A 4 Requests for Support Elements NODE: TITLE: A 0 Dispose of Product and Arising Returned Items Provide Through Life Support for a Product A 5 Maintainer Feedback NUMBER: Arisings from Disposal Data

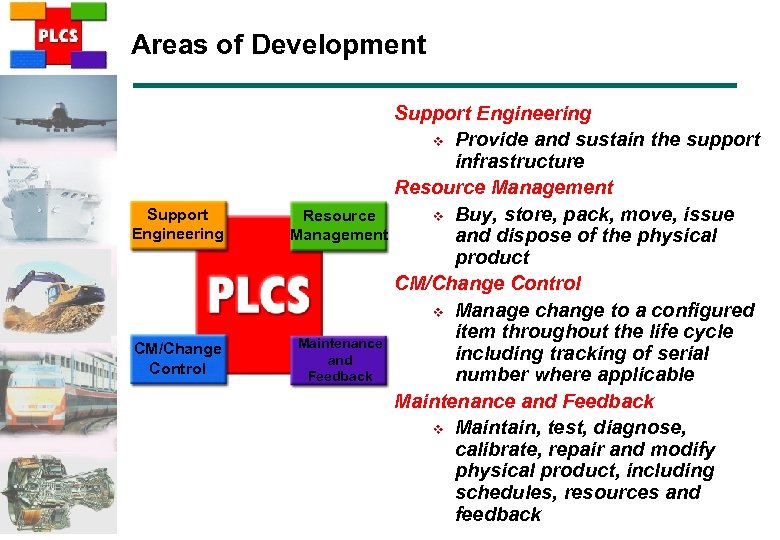

Areas of Development Support Engineering Resource Management CM/Change Control Maintenance and Feedback Support Engineering v Provide and sustain the support infrastructure Resource Management v Buy, store, pack, move, issue and dispose of the physical product CM/Change Control v Manage change to a configured item throughout the life cycle including tracking of serial number where applicable Maintenance and Feedback v Maintain, test, diagnose, calibrate, repair and modify physical product, including schedules, resources and feedback

Areas of Development Support Engineering Resource Management CM/Change Control Maintenance and Feedback Support Engineering v Provide and sustain the support infrastructure Resource Management v Buy, store, pack, move, issue and dispose of the physical product CM/Change Control v Manage change to a configured item throughout the life cycle including tracking of serial number where applicable Maintenance and Feedback v Maintain, test, diagnose, calibrate, repair and modify physical product, including schedules, resources and feedback

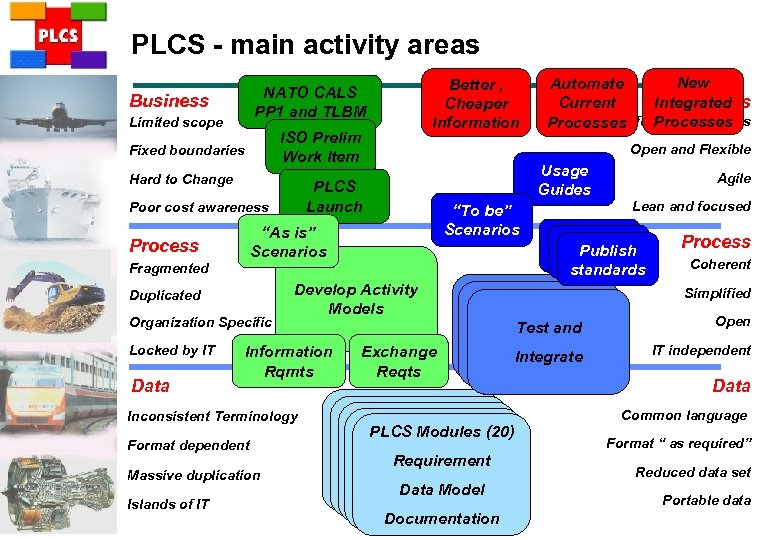

PLCS - main activity areas Better , Cheaper Information NATO CALS PP 1 and TLBM Business Limited scope ISO Prelim Work Item Fixed boundaries Hard to Change Open and Flexible Usage Guides PLCS Launch Poor cost awareness “To be” Scenarios “As is” Scenarios Process Fragmented Duplicated Organization Specific Locked by IT Data Develop Activity Models Information Rqmts Inconsistent Terminology Format dependent Massive duplication Islands of IT New Automate Integrated Business Current Life cycle business Processes Exchange Reqts Agile Lean and focused Published Publish standards Process Coherent Simplified Test and Integrate Open IT independent Data Common language PLCS Modules (20) Requirement Data Model Documentation Format “ as required” Reduced data set Portable data

PLCS - main activity areas Better , Cheaper Information NATO CALS PP 1 and TLBM Business Limited scope ISO Prelim Work Item Fixed boundaries Hard to Change Open and Flexible Usage Guides PLCS Launch Poor cost awareness “To be” Scenarios “As is” Scenarios Process Fragmented Duplicated Organization Specific Locked by IT Data Develop Activity Models Information Rqmts Inconsistent Terminology Format dependent Massive duplication Islands of IT New Automate Integrated Business Current Life cycle business Processes Exchange Reqts Agile Lean and focused Published Publish standards Process Coherent Simplified Test and Integrate Open IT independent Data Common language PLCS Modules (20) Requirement Data Model Documentation Format “ as required” Reduced data set Portable data

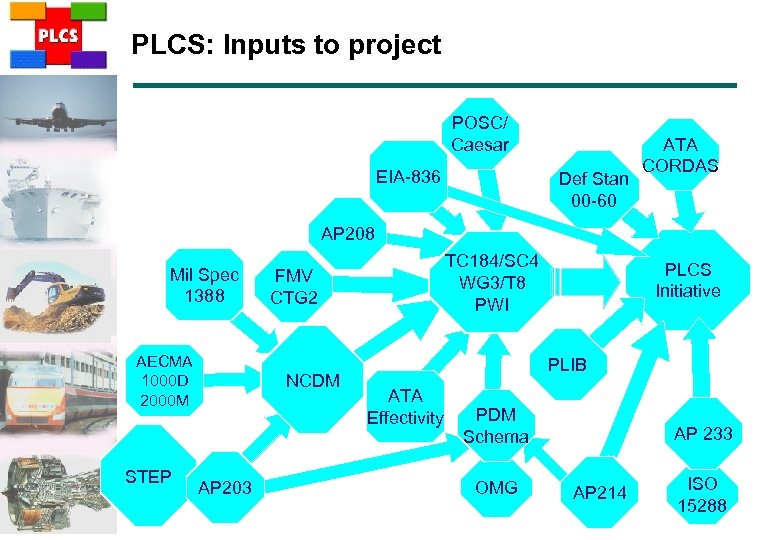

PLCS: Inputs to project POSC/ Caesar Mil Spec EIA-836 2549 Def Stan 00 -60 ATA CORDAS AP 208 Mil Spec 1388 STEP FMV CTG 2 NATO Pilot NCDM Project #1 AECMA 1000 D 2000 M AP 203 TC 184/SC 4 WG 3/T 8 PWI PLCS Initiative PLIB ATA Effectivity PDM Schema OMG AP 233 AP 214 ISO 15288

PLCS: Inputs to project POSC/ Caesar Mil Spec EIA-836 2549 Def Stan 00 -60 ATA CORDAS AP 208 Mil Spec 1388 STEP FMV CTG 2 NATO Pilot NCDM Project #1 AECMA 1000 D 2000 M AP 203 TC 184/SC 4 WG 3/T 8 PWI PLCS Initiative PLIB ATA Effectivity PDM Schema OMG AP 233 AP 214 ISO 15288

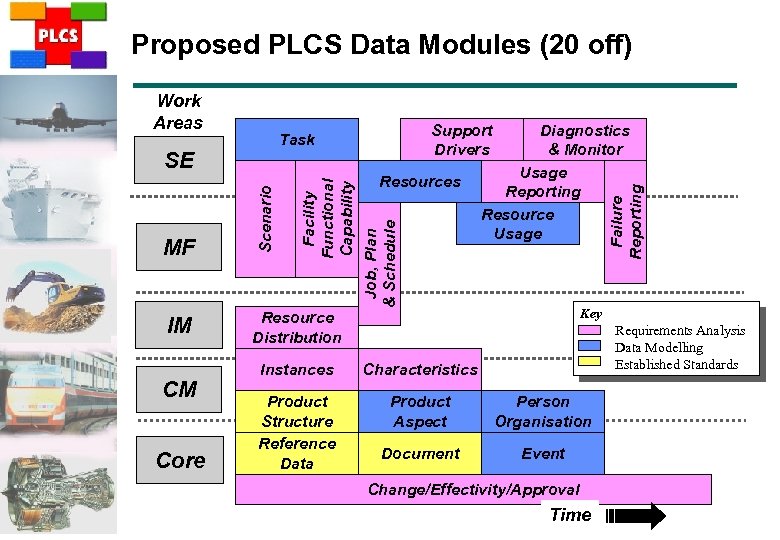

Proposed PLCS Data Modules (20 off) IM CM Core Resources Facility Functional Capability Job, Plan & Schedule Scenario SE MF Support Drivers Task Diagnostics & Monitor Usage Reporting Resource Usage Failure Reporting Work Areas Key Resource Distribution Requirements Analysis Data Modelling Established Standards Instances Characteristics Product Structure Reference Data Product Aspect Person Organisation Document Event Change/Effectivity/Approval Time

Proposed PLCS Data Modules (20 off) IM CM Core Resources Facility Functional Capability Job, Plan & Schedule Scenario SE MF Support Drivers Task Diagnostics & Monitor Usage Reporting Resource Usage Failure Reporting Work Areas Key Resource Distribution Requirements Analysis Data Modelling Established Standards Instances Characteristics Product Structure Reference Data Product Aspect Person Organisation Document Event Change/Effectivity/Approval Time

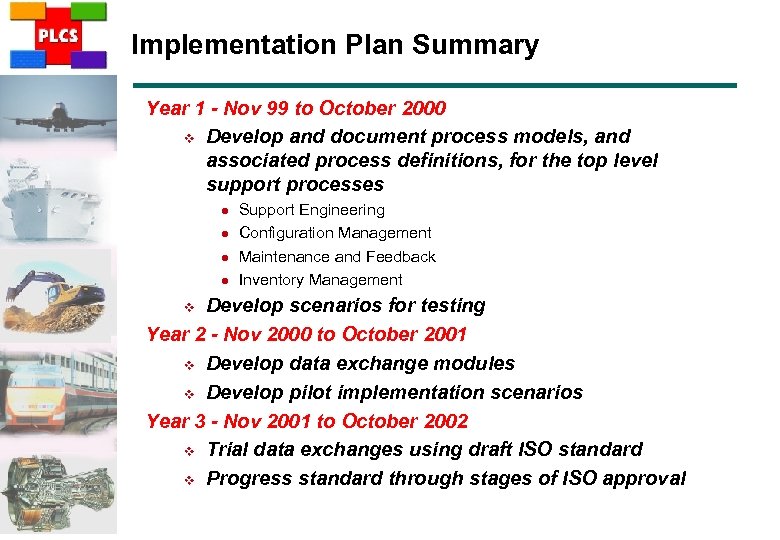

Implementation Plan Summary Year 1 - Nov 99 to October 2000 v Develop and document process models, and associated process definitions, for the top level support processes l l Support Engineering Configuration Management Maintenance and Feedback Inventory Management Develop scenarios for testing Year 2 - Nov 2000 to October 2001 v Develop data exchange modules v Develop pilot implementation scenarios Year 3 - Nov 2001 to October 2002 v Trial data exchanges using draft ISO standard v Progress standard through stages of ISO approval v

Implementation Plan Summary Year 1 - Nov 99 to October 2000 v Develop and document process models, and associated process definitions, for the top level support processes l l Support Engineering Configuration Management Maintenance and Feedback Inventory Management Develop scenarios for testing Year 2 - Nov 2000 to October 2001 v Develop data exchange modules v Develop pilot implementation scenarios Year 3 - Nov 2001 to October 2002 v Trial data exchanges using draft ISO standard v Progress standard through stages of ISO approval v

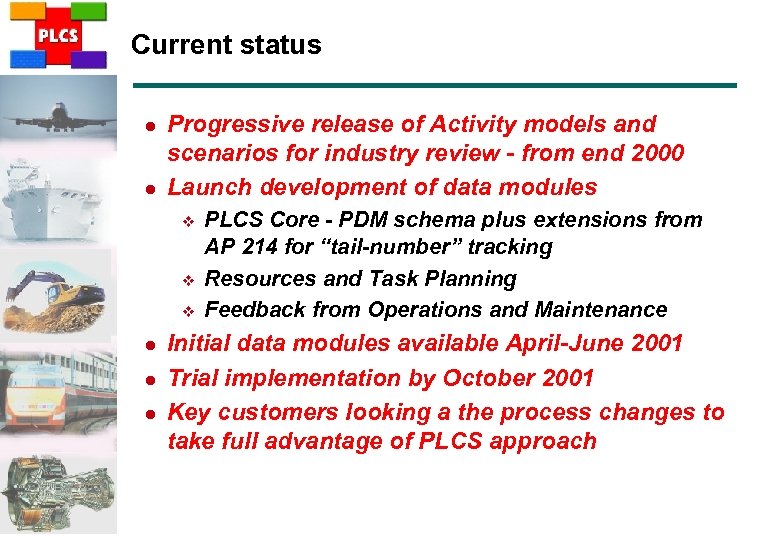

Current status l l Progressive release of Activity models and scenarios for industry review - from end 2000 Launch development of data modules v v v l l l PLCS Core - PDM schema plus extensions from AP 214 for “tail-number” tracking Resources and Task Planning Feedback from Operations and Maintenance Initial data modules available April-June 2001 Trial implementation by October 2001 Key customers looking a the process changes to take full advantage of PLCS approach

Current status l l Progressive release of Activity models and scenarios for industry review - from end 2000 Launch development of data modules v v v l l l PLCS Core - PDM schema plus extensions from AP 214 for “tail-number” tracking Resources and Task Planning Feedback from Operations and Maintenance Initial data modules available April-June 2001 Trial implementation by October 2001 Key customers looking a the process changes to take full advantage of PLCS approach

Business benefits of PLCS. . . v v v Improved quality and access to support information, throughout the product life cycle and across the supply chain Reduced costs of acquiring, maintaining and delivering Product Support information Improved asset availability Provides ability to communicate consistently across COTS software Makes product change easier to manage Protects investment in product data PLCS provides the potential to fully enable B 2 B

Business benefits of PLCS. . . v v v Improved quality and access to support information, throughout the product life cycle and across the supply chain Reduced costs of acquiring, maintaining and delivering Product Support information Improved asset availability Provides ability to communicate consistently across COTS software Makes product change easier to manage Protects investment in product data PLCS provides the potential to fully enable B 2 B

In addition- the benefits of joining PLCS as a member. . . Membership of PLCS during the development of the standard provides the following additional benefits… v v v Forum for exchange of views, experience and discussion of critical issues Develop new relationships, business contacts and sales opportunities Ability to influence the direction and scope of PLCS to ensure it meets your business needs Opportunity to learn about STEP and its benefits Early visibility of requirements to allow effective planning for implementation Access to existing data, business models and improvement initiatives from world leading organisations

In addition- the benefits of joining PLCS as a member. . . Membership of PLCS during the development of the standard provides the following additional benefits… v v v Forum for exchange of views, experience and discussion of critical issues Develop new relationships, business contacts and sales opportunities Ability to influence the direction and scope of PLCS to ensure it meets your business needs Opportunity to learn about STEP and its benefits Early visibility of requirements to allow effective planning for implementation Access to existing data, business models and improvement initiatives from world leading organisations

Summary v v v B 2 B e-commerce is set to grow significantly in the next 5 years There is a growing trend towards leveraging the information asset to win new business in the Maintenance, Repair and Overhaul (MRO) market After-market service is forecast to be a significant element of the B 2 B market Existing standards do not fully address the product support requirement PLCS standards will allow support information to be aligned with the changing product over its entire life cycle Adoption of PLCS standard will lead to reduced operating costs and increased product availability

Summary v v v B 2 B e-commerce is set to grow significantly in the next 5 years There is a growing trend towards leveraging the information asset to win new business in the Maintenance, Repair and Overhaul (MRO) market After-market service is forecast to be a significant element of the B 2 B market Existing standards do not fully address the product support requirement PLCS standards will allow support information to be aligned with the changing product over its entire life cycle Adoption of PLCS standard will lead to reduced operating costs and increased product availability

For more information. . . Visit the PLCS web site: www. plcsinc. org or contact any of the PLCS core team members: v v v John Dunford

For more information. . . Visit the PLCS web site: www. plcsinc. org or contact any of the PLCS core team members: v v v John Dunford

Any Questions? Support Engineering Resource Management CM/Change Control Maintenance and Feedback

Any Questions? Support Engineering Resource Management CM/Change Control Maintenance and Feedback