b449c67795f093c990cbbc9398338d4c.ppt

- Количество слайдов: 20

Status of Vacuum Process Facilities at SSL 16 October 2009 Sharon R Jelinsky Space Sciences Laboratory, UC Berkeley 1

Status of Vacuum Process Facilities at SSL 16 October 2009 Sharon R Jelinsky Space Sciences Laboratory, UC Berkeley 1

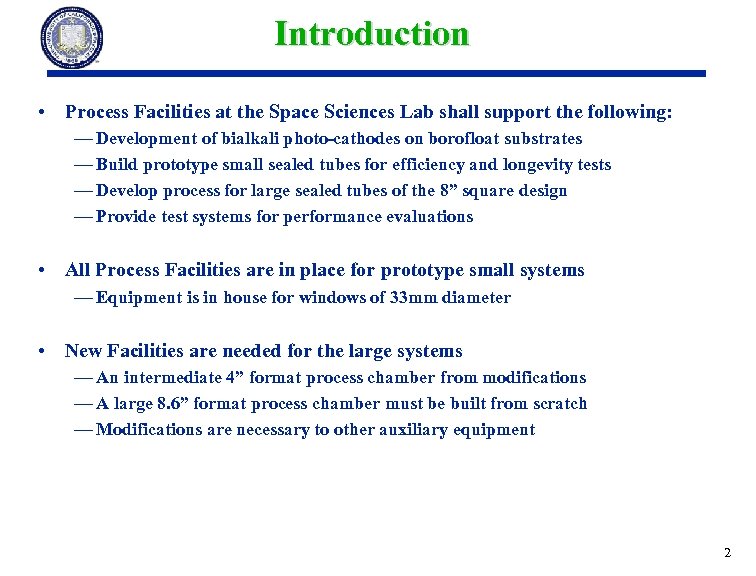

Introduction • Process Facilities at the Space Sciences Lab shall support the following: — Development of bialkali photo-cathodes on borofloat substrates — Build prototype small sealed tubes for efficiency and longevity tests — Develop process for large sealed tubes of the 8” square design — Provide test systems for performance evaluations • All Process Facilities are in place for prototype small systems — Equipment is in house for windows of 33 mm diameter • New Facilities are needed for the large systems — An intermediate 4” format process chamber from modifications — A large 8. 6” format process chamber must be built from scratch — Modifications are necessary to other auxiliary equipment 2

Introduction • Process Facilities at the Space Sciences Lab shall support the following: — Development of bialkali photo-cathodes on borofloat substrates — Build prototype small sealed tubes for efficiency and longevity tests — Develop process for large sealed tubes of the 8” square design — Provide test systems for performance evaluations • All Process Facilities are in place for prototype small systems — Equipment is in house for windows of 33 mm diameter • New Facilities are needed for the large systems — An intermediate 4” format process chamber from modifications — A large 8. 6” format process chamber must be built from scratch — Modifications are necessary to other auxiliary equipment 2

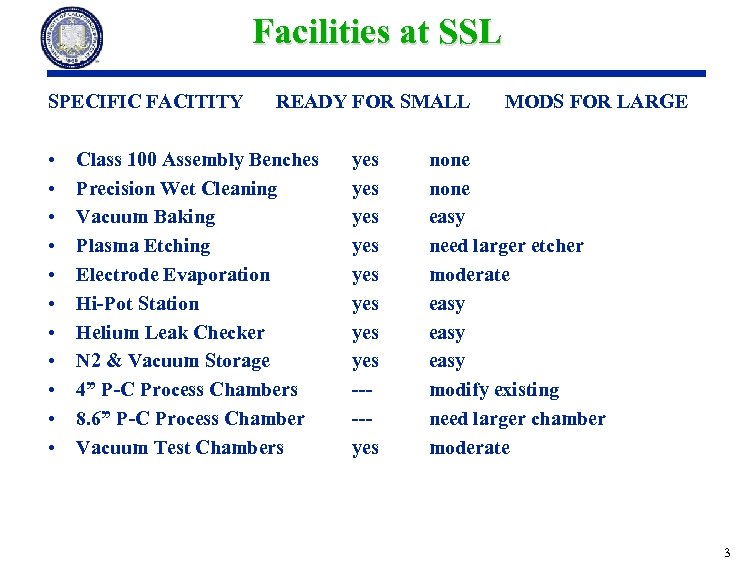

Facilities at SSL SPECIFIC FACITITY • • • READY FOR SMALL Class 100 Assembly Benches Precision Wet Cleaning Vacuum Baking Plasma Etching Electrode Evaporation Hi-Pot Station Helium Leak Checker N 2 & Vacuum Storage 4” P-C Process Chambers 8. 6” P-C Process Chamber Vacuum Test Chambers yes yes ----yes MODS FOR LARGE none easy need larger etcher moderate easy modify existing need larger chamber moderate 3

Facilities at SSL SPECIFIC FACITITY • • • READY FOR SMALL Class 100 Assembly Benches Precision Wet Cleaning Vacuum Baking Plasma Etching Electrode Evaporation Hi-Pot Station Helium Leak Checker N 2 & Vacuum Storage 4” P-C Process Chambers 8. 6” P-C Process Chamber Vacuum Test Chambers yes yes ----yes MODS FOR LARGE none easy need larger etcher moderate easy modify existing need larger chamber moderate 3

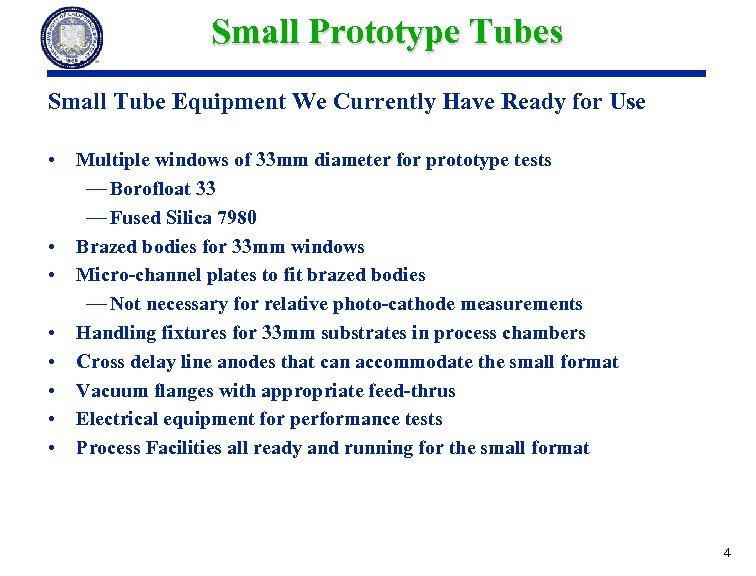

Small Prototype Tubes Small Tube Equipment We Currently Have Ready for Use • • Multiple windows of 33 mm diameter for prototype tests — Borofloat 33 — Fused Silica 7980 Brazed bodies for 33 mm windows Micro-channel plates to fit brazed bodies — Not necessary for relative photo-cathode measurements Handling fixtures for 33 mm substrates in process chambers Cross delay line anodes that can accommodate the small format Vacuum flanges with appropriate feed-thrus Electrical equipment for performance tests Process Facilities all ready and running for the small format 4

Small Prototype Tubes Small Tube Equipment We Currently Have Ready for Use • • Multiple windows of 33 mm diameter for prototype tests — Borofloat 33 — Fused Silica 7980 Brazed bodies for 33 mm windows Micro-channel plates to fit brazed bodies — Not necessary for relative photo-cathode measurements Handling fixtures for 33 mm substrates in process chambers Cross delay line anodes that can accommodate the small format Vacuum flanges with appropriate feed-thrus Electrical equipment for performance tests Process Facilities all ready and running for the small format 4

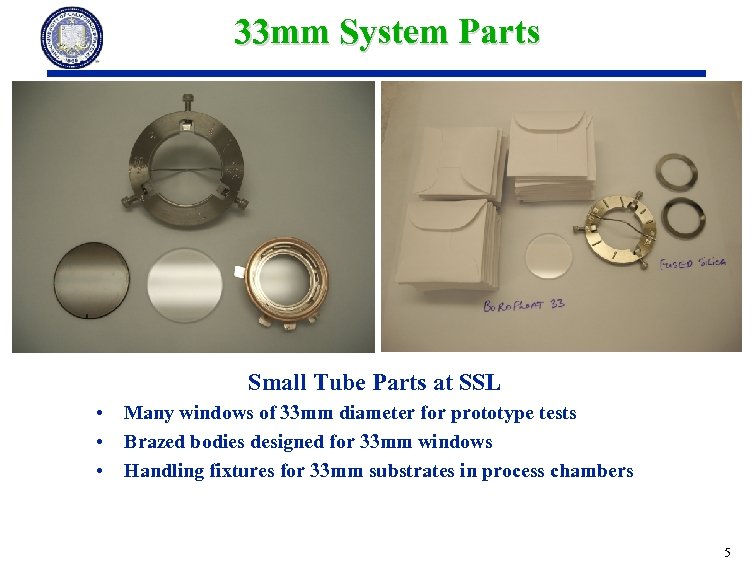

33 mm System Parts Small Tube Parts at SSL • • • Many windows of 33 mm diameter for prototype tests Brazed bodies designed for 33 mm windows Handling fixtures for 33 mm substrates in process chambers 5

33 mm System Parts Small Tube Parts at SSL • • • Many windows of 33 mm diameter for prototype tests Brazed bodies designed for 33 mm windows Handling fixtures for 33 mm substrates in process chambers 5

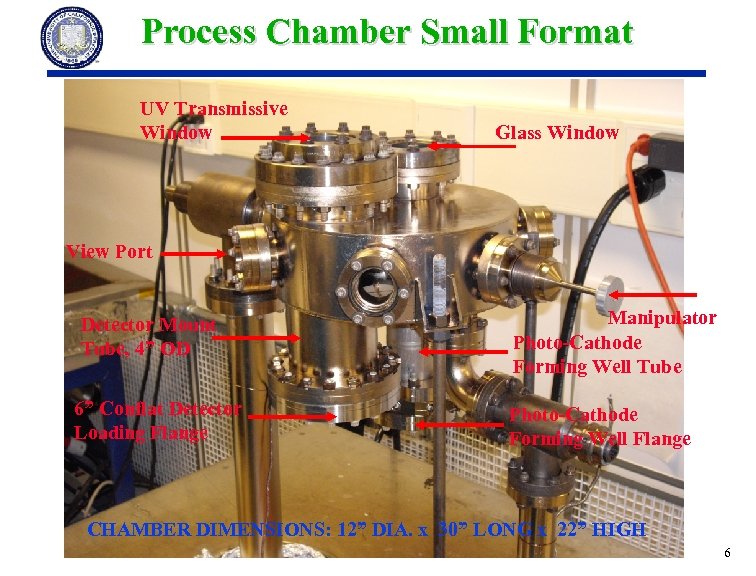

Process Chamber Small Format UV Transmissive Window Glass Window View Port Detector Mount Tube, 4” OD 6” Conflat Detector Loading Flange Manipulator Photo-Cathode Forming Well Tube Photo-Cathode Forming Well Flange CHAMBER DIMENSIONS: 12” DIA. x 30” LONG x 22” HIGH 6

Process Chamber Small Format UV Transmissive Window Glass Window View Port Detector Mount Tube, 4” OD 6” Conflat Detector Loading Flange Manipulator Photo-Cathode Forming Well Tube Photo-Cathode Forming Well Flange CHAMBER DIMENSIONS: 12” DIA. x 30” LONG x 22” HIGH 6

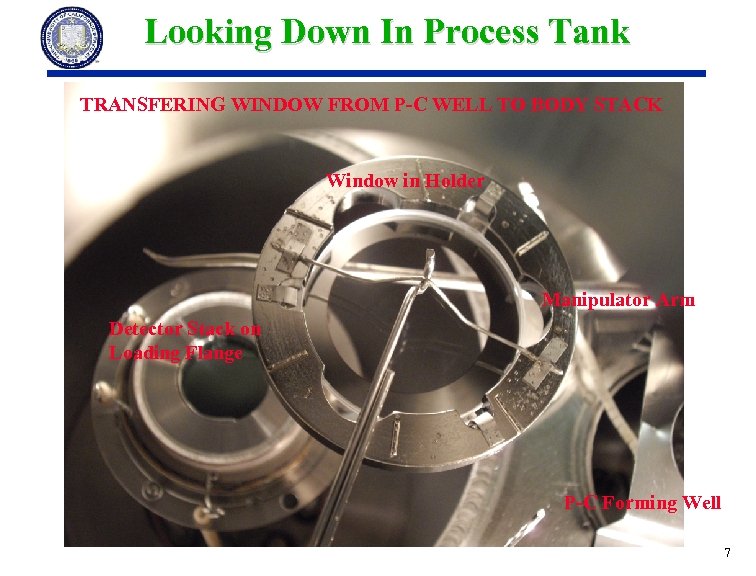

Looking Down In Process Tank TRANSFERING WINDOW FROM P-C WELL TO BODY STACK Window in Holder Manipulator Arm Detector Stack on Loading Flange P-C Forming Well 7

Looking Down In Process Tank TRANSFERING WINDOW FROM P-C WELL TO BODY STACK Window in Holder Manipulator Arm Detector Stack on Loading Flange P-C Forming Well 7

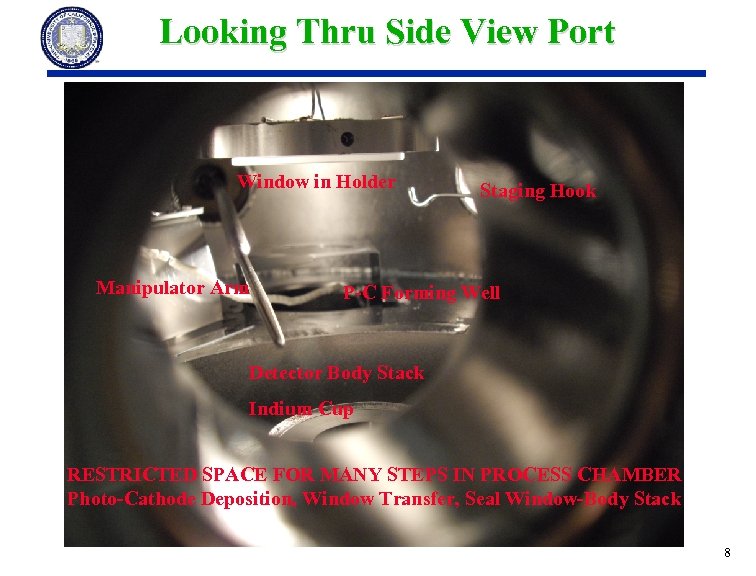

Looking Thru Side View Port Window in Holder Manipulator Arm Staging Hook P-C Forming Well Detector Body Stack Indium Cup RESTRICTED SPACE FOR MANY STEPS IN PROCESS CHAMBER Photo-Cathode Deposition, Window Transfer, Seal Window-Body Stack 8

Looking Thru Side View Port Window in Holder Manipulator Arm Staging Hook P-C Forming Well Detector Body Stack Indium Cup RESTRICTED SPACE FOR MANY STEPS IN PROCESS CHAMBER Photo-Cathode Deposition, Window Transfer, Seal Window-Body Stack 8

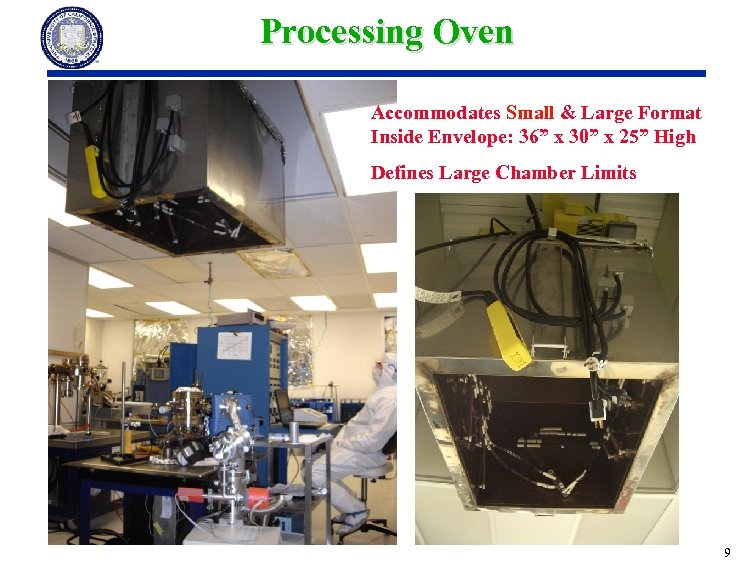

Processing Oven Accommodates Small & Large Format Inside Envelope: 36” x 30” x 25” High Defines Large Chamber Limits 9

Processing Oven Accommodates Small & Large Format Inside Envelope: 36” x 30” x 25” High Defines Large Chamber Limits 9

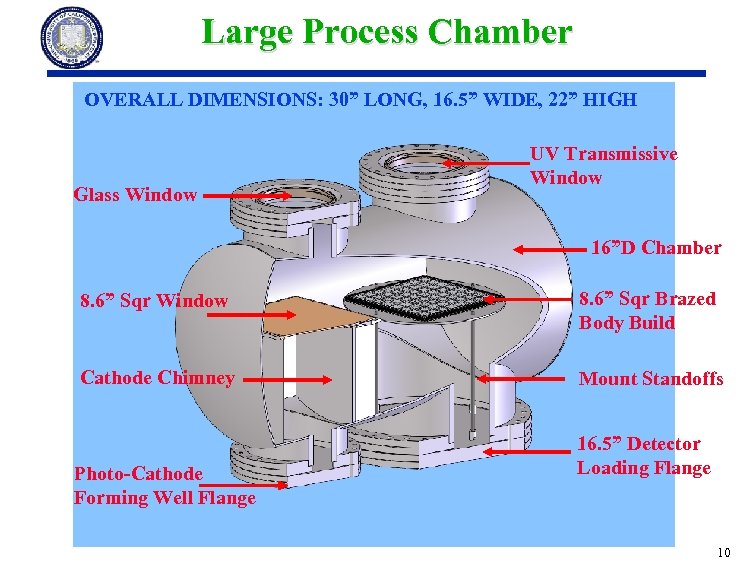

Large Process Chamber OVERALL DIMENSIONS: 30” LONG, 16. 5” WIDE, 22” HIGH Glass Window UV Transmissive Window 16”D Chamber 8. 6” Sqr Window 8. 6” Sqr Brazed Body Build Cathode Chimney Mount Standoffs Photo-Cathode Forming Well Flange 16. 5” Detector Loading Flange 10

Large Process Chamber OVERALL DIMENSIONS: 30” LONG, 16. 5” WIDE, 22” HIGH Glass Window UV Transmissive Window 16”D Chamber 8. 6” Sqr Window 8. 6” Sqr Brazed Body Build Cathode Chimney Mount Standoffs Photo-Cathode Forming Well Flange 16. 5” Detector Loading Flange 10

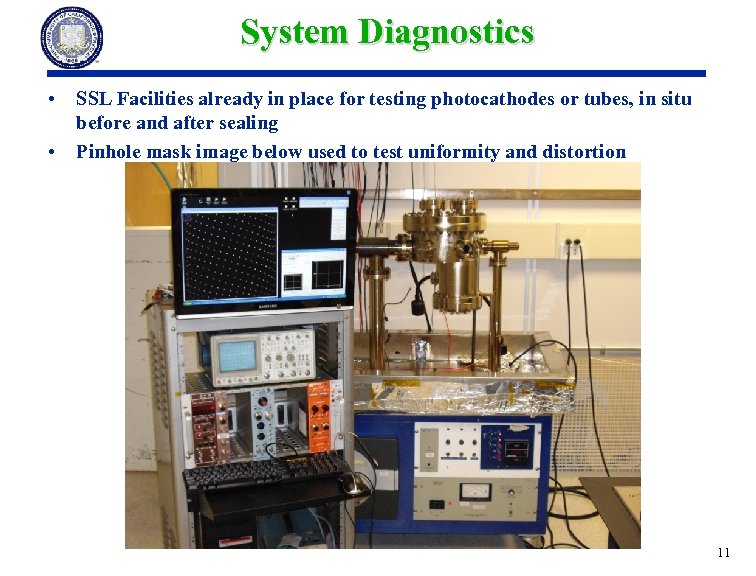

System Diagnostics • • SSL Facilities already in place for testing photocathodes or tubes, in situ before and after sealing Pinhole mask image below used to test uniformity and distortion 11

System Diagnostics • • SSL Facilities already in place for testing photocathodes or tubes, in situ before and after sealing Pinhole mask image below used to test uniformity and distortion 11

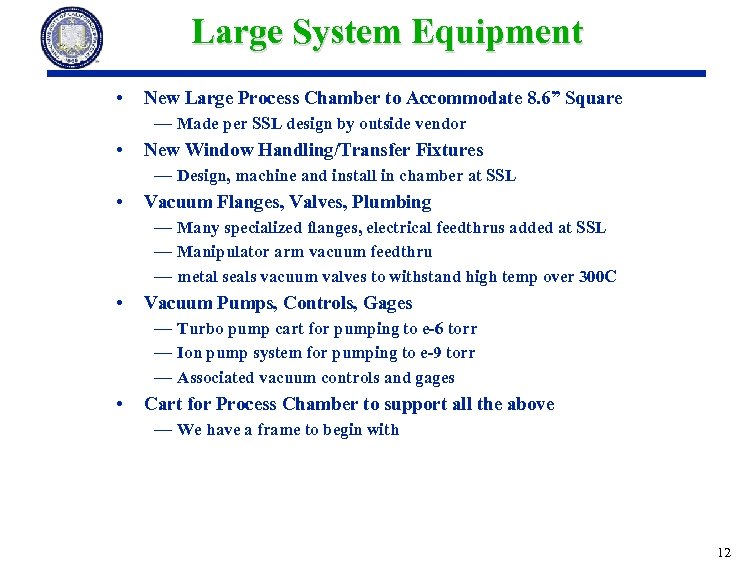

Large System Equipment • New Large Process Chamber to Accommodate 8. 6” Square — Made per SSL design by outside vendor • New Window Handling/Transfer Fixtures — Design, machine and install in chamber at SSL • Vacuum Flanges, Valves, Plumbing — Many specialized flanges, electrical feedthrus added at SSL — Manipulator arm vacuum feedthru — metal seals vacuum valves to withstand high temp over 300 C • Vacuum Pumps, Controls, Gages — Turbo pump cart for pumping to e-6 torr — Ion pump system for pumping to e-9 torr — Associated vacuum controls and gages • Cart for Process Chamber to support all the above — We have a frame to begin with 12

Large System Equipment • New Large Process Chamber to Accommodate 8. 6” Square — Made per SSL design by outside vendor • New Window Handling/Transfer Fixtures — Design, machine and install in chamber at SSL • Vacuum Flanges, Valves, Plumbing — Many specialized flanges, electrical feedthrus added at SSL — Manipulator arm vacuum feedthru — metal seals vacuum valves to withstand high temp over 300 C • Vacuum Pumps, Controls, Gages — Turbo pump cart for pumping to e-6 torr — Ion pump system for pumping to e-9 torr — Associated vacuum controls and gages • Cart for Process Chamber to support all the above — We have a frame to begin with 12

Status of Process Chambers • 33 mm Format Prototype Process Chamber — Have all parts, fixtures and chamber needed to deposit photocathodes — Must clean and prep chamber and parts, then begin test runs • 4” Format Intermediate Process Chamber — — • Have a chamber that must be modified to fit Must design and build fixtures Must design and procure windows, bodies and anodes Must clean and prep chamber and parts, then begin test runs 8. 6” Square Large Process Chamber — — — Must finish the design of process chamber and send out for bid Must design and build window transfer system/fixtures and flanges Must design and procure windows, bodies and anodes Must clean and prep chamber and parts Operate process chamber and make test runs Build a complete detector (hopefully by due date of June 30, 2010) 13

Status of Process Chambers • 33 mm Format Prototype Process Chamber — Have all parts, fixtures and chamber needed to deposit photocathodes — Must clean and prep chamber and parts, then begin test runs • 4” Format Intermediate Process Chamber — — • Have a chamber that must be modified to fit Must design and build fixtures Must design and procure windows, bodies and anodes Must clean and prep chamber and parts, then begin test runs 8. 6” Square Large Process Chamber — — — Must finish the design of process chamber and send out for bid Must design and build window transfer system/fixtures and flanges Must design and procure windows, bodies and anodes Must clean and prep chamber and parts Operate process chamber and make test runs Build a complete detector (hopefully by due date of June 30, 2010) 13

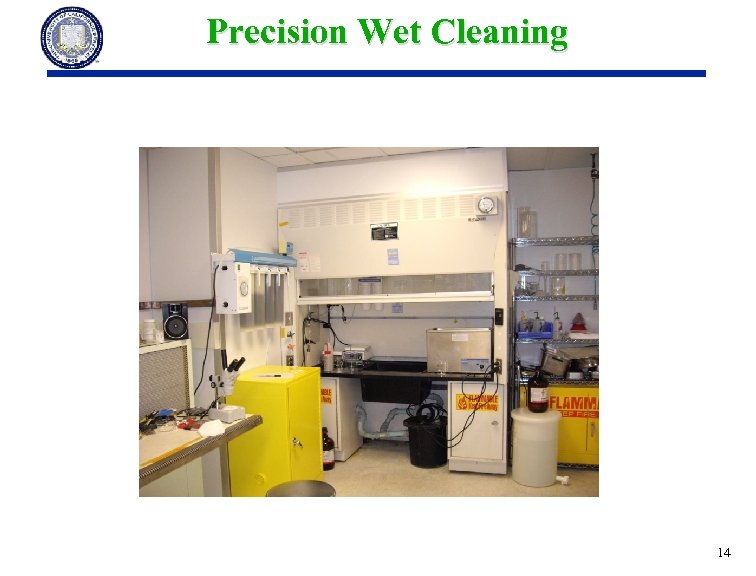

Precision Wet Cleaning 14

Precision Wet Cleaning 14

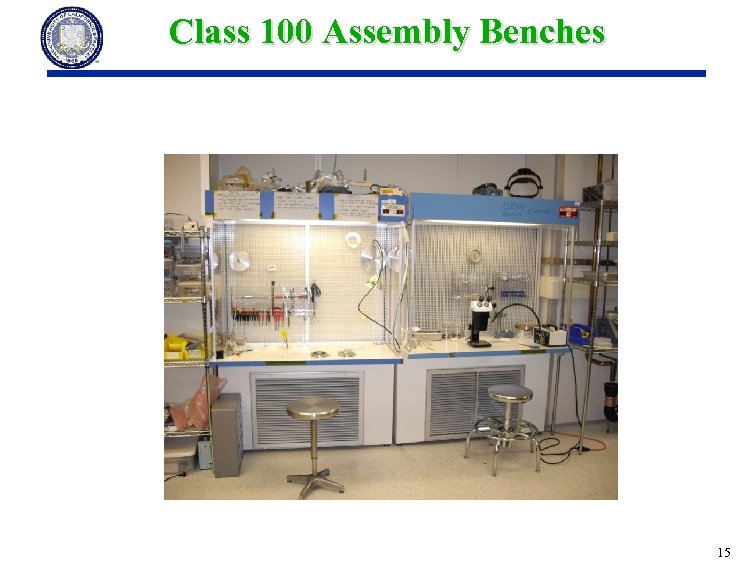

Class 100 Assembly Benches 15

Class 100 Assembly Benches 15

N 2 Storage, Welder 16

N 2 Storage, Welder 16

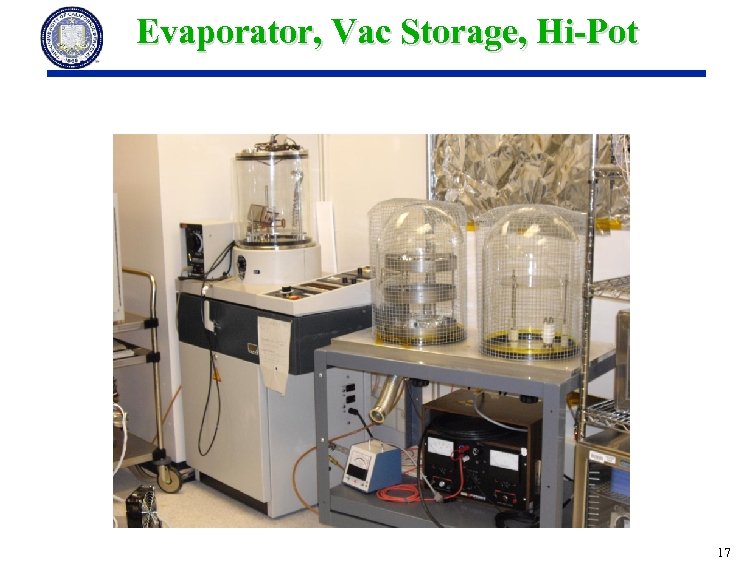

Evaporator, Vac Storage, Hi-Pot 17

Evaporator, Vac Storage, Hi-Pot 17

Plasma Etcher, Evaporator 18

Plasma Etcher, Evaporator 18

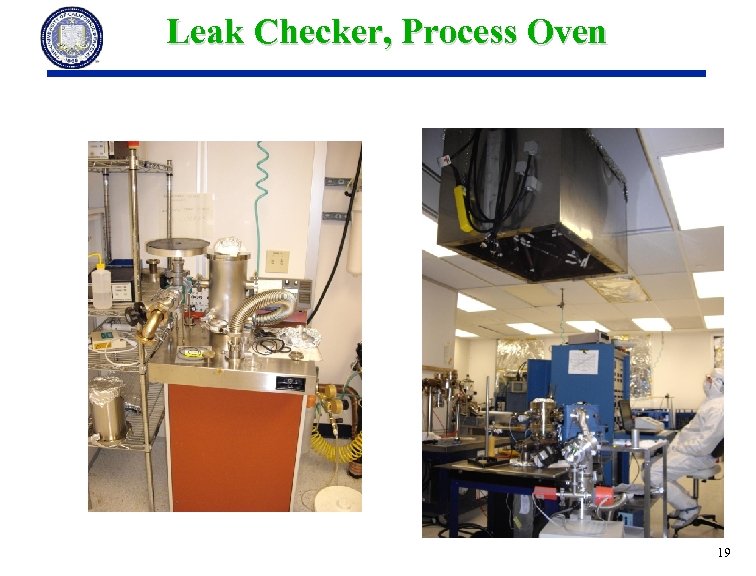

Leak Checker, Process Oven 19

Leak Checker, Process Oven 19

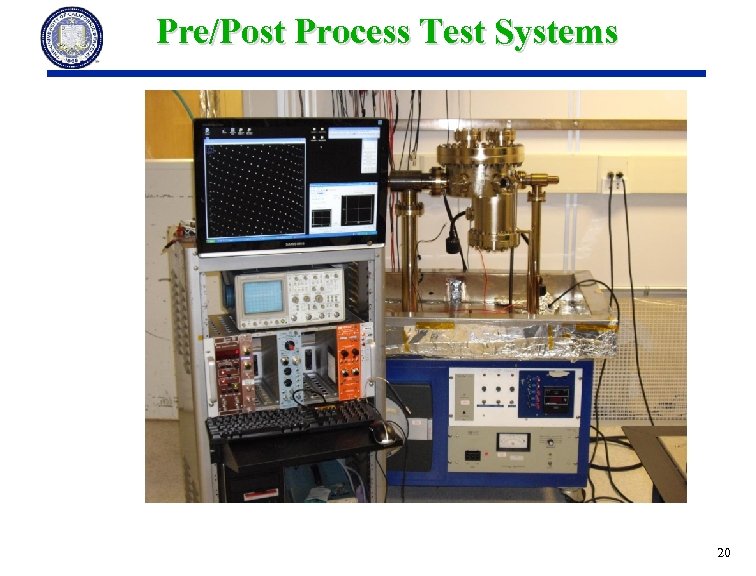

Pre/Post Process Test Systems 20

Pre/Post Process Test Systems 20