1f5569f945020b1462059ed0041df0d2.ppt

- Количество слайдов: 18

Status of the Mu. Cool Cavity Prototype MICE Collaboration Meeting October 21, 2005 Steve Virostek Lawrence Berkeley National Laboratory

Status of the Mu. Cool Cavity Prototype MICE Collaboration Meeting October 21, 2005 Steve Virostek Lawrence Berkeley National Laboratory

Progress Since Last Year • Leak check of all e-beam welds was performed • Cooling tubes were TIG brazed to cavity exterior • A final mechanical buff of the interior was completed • Cavity interior surfaces were electropolished • RF couplers were fabricated and conditioned • First 201 MHz beryllium window delivered to LBNL • Cavity manual tuner and support stand were fabricated • Final assembly and leak check performed at J-Lab • Cavity was shipped to the MTA, assembled and leak checked RF Module Fabrication Steve Virostek - LBNL 2

Progress Since Last Year • Leak check of all e-beam welds was performed • Cooling tubes were TIG brazed to cavity exterior • A final mechanical buff of the interior was completed • Cavity interior surfaces were electropolished • RF couplers were fabricated and conditioned • First 201 MHz beryllium window delivered to LBNL • Cavity manual tuner and support stand were fabricated • Final assembly and leak check performed at J-Lab • Cavity was shipped to the MTA, assembled and leak checked RF Module Fabrication Steve Virostek - LBNL 2

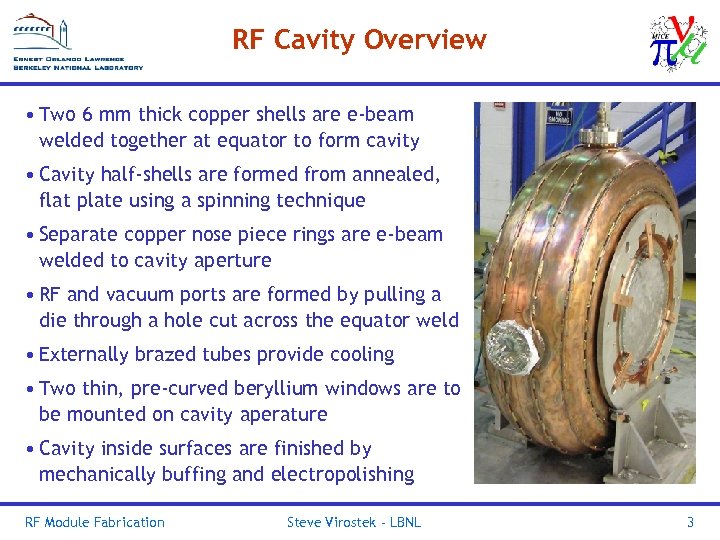

RF Cavity Overview • Two 6 mm thick copper shells are e-beam welded together at equator to form cavity • Cavity half-shells are formed from annealed, flat plate using a spinning technique • Separate copper nose piece rings are e-beam welded to cavity aperture • RF and vacuum ports are formed by pulling a die through a hole cut across the equator weld • Externally brazed tubes provide cooling • Two thin, pre-curved beryllium windows are to be mounted on cavity aperature • Cavity inside surfaces are finished by mechanically buffing and electropolishing RF Module Fabrication Steve Virostek - LBNL 3

RF Cavity Overview • Two 6 mm thick copper shells are e-beam welded together at equator to form cavity • Cavity half-shells are formed from annealed, flat plate using a spinning technique • Separate copper nose piece rings are e-beam welded to cavity aperture • RF and vacuum ports are formed by pulling a die through a hole cut across the equator weld • Externally brazed tubes provide cooling • Two thin, pre-curved beryllium windows are to be mounted on cavity aperature • Cavity inside surfaces are finished by mechanically buffing and electropolishing RF Module Fabrication Steve Virostek - LBNL 3

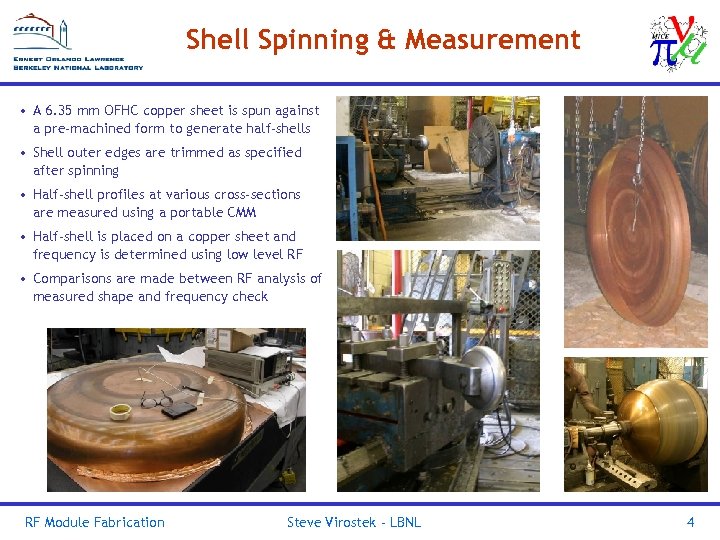

Shell Spinning & Measurement • A 6. 35 mm OFHC copper sheet is spun against a pre-machined form to generate half-shells • Shell outer edges are trimmed as specified after spinning • Half-shell profiles at various cross-sections are measured using a portable CMM • Half-shell is placed on a copper sheet and frequency is determined using low level RF • Comparisons are made between RF analysis of measured shape and frequency check RF Module Fabrication Steve Virostek - LBNL 4

Shell Spinning & Measurement • A 6. 35 mm OFHC copper sheet is spun against a pre-machined form to generate half-shells • Shell outer edges are trimmed as specified after spinning • Half-shell profiles at various cross-sections are measured using a portable CMM • Half-shell is placed on a copper sheet and frequency is determined using low level RF • Comparisons are made between RF analysis of measured shape and frequency check RF Module Fabrication Steve Virostek - LBNL 4

Cavity Stiffener Ring • Hard copper stiffener ring is e-beam welded on inside and outside edges to the outside of the cavity shell • Rings initially provide for safe handling the half-shells • Rings are turned on a lathe after being welded on to provide an accurate reference for subsequent operations • Rings provide an interface for tuner mechanisms and for mounting the finished cavity to the support structure • Load tests on sample welds indicate the e-beam weld strength is much higher than required for tuning RF Module Fabrication Steve Virostek - LBNL 5

Cavity Stiffener Ring • Hard copper stiffener ring is e-beam welded on inside and outside edges to the outside of the cavity shell • Rings initially provide for safe handling the half-shells • Rings are turned on a lathe after being welded on to provide an accurate reference for subsequent operations • Rings provide an interface for tuner mechanisms and for mounting the finished cavity to the support structure • Load tests on sample welds indicate the e-beam weld strength is much higher than required for tuning RF Module Fabrication Steve Virostek - LBNL 5

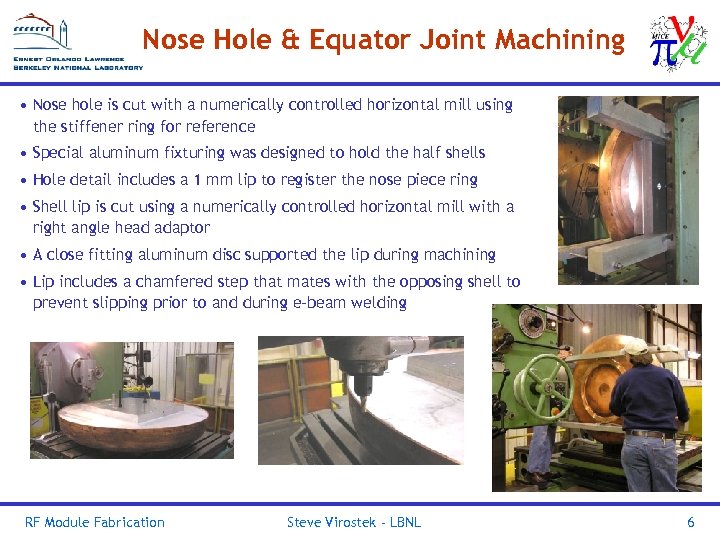

Nose Hole & Equator Joint Machining • Nose hole is cut with a numerically controlled horizontal mill using the stiffener ring for reference • Special aluminum fixturing was designed to hold the half shells • Hole detail includes a 1 mm lip to register the nose piece ring • Shell lip is cut using a numerically controlled horizontal mill with a right angle head adaptor • A close fitting aluminum disc supported the lip during machining • Lip includes a chamfered step that mates with the opposing shell to prevent slipping prior to and during e-beam welding RF Module Fabrication Steve Virostek - LBNL 6

Nose Hole & Equator Joint Machining • Nose hole is cut with a numerically controlled horizontal mill using the stiffener ring for reference • Special aluminum fixturing was designed to hold the half shells • Hole detail includes a 1 mm lip to register the nose piece ring • Shell lip is cut using a numerically controlled horizontal mill with a right angle head adaptor • A close fitting aluminum disc supported the lip during machining • Lip includes a chamfered step that mates with the opposing shell to prevent slipping prior to and during e-beam welding RF Module Fabrication Steve Virostek - LBNL 6

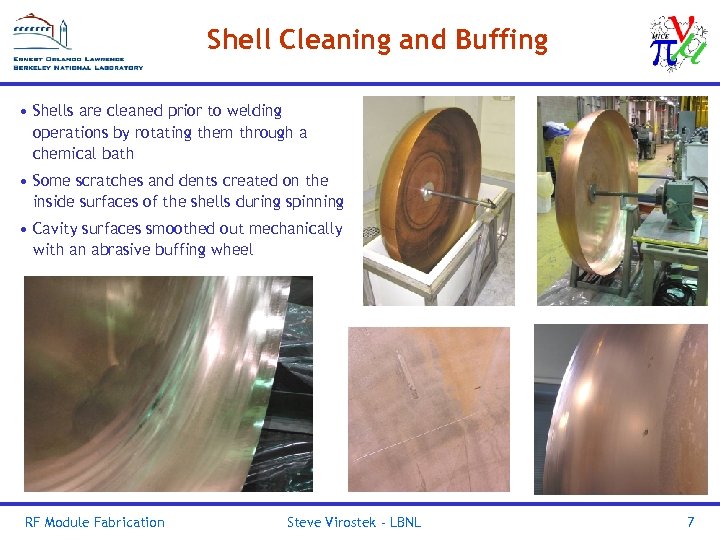

Shell Cleaning and Buffing • Shells are cleaned prior to welding operations by rotating them through a chemical bath • Some scratches and dents created on the inside surfaces of the shells during spinning • Cavity surfaces smoothed out mechanically with an abrasive buffing wheel RF Module Fabrication Steve Virostek - LBNL 7

Shell Cleaning and Buffing • Shells are cleaned prior to welding operations by rotating them through a chemical bath • Some scratches and dents created on the inside surfaces of the shells during spinning • Cavity surfaces smoothed out mechanically with an abrasive buffing wheel RF Module Fabrication Steve Virostek - LBNL 7

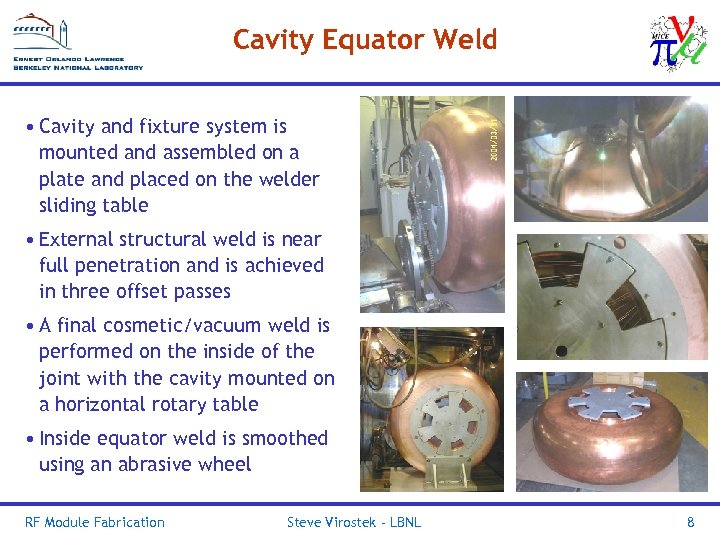

Cavity Equator Weld • Cavity and fixture system is mounted and assembled on a plate and placed on the welder sliding table • External structural weld is near full penetration and is achieved in three offset passes • A final cosmetic/vacuum weld is performed on the inside of the joint with the cavity mounted on a horizontal rotary table • Inside equator weld is smoothed using an abrasive wheel RF Module Fabrication Steve Virostek - LBNL 8

Cavity Equator Weld • Cavity and fixture system is mounted and assembled on a plate and placed on the welder sliding table • External structural weld is near full penetration and is achieved in three offset passes • A final cosmetic/vacuum weld is performed on the inside of the joint with the cavity mounted on a horizontal rotary table • Inside equator weld is smoothed using an abrasive wheel RF Module Fabrication Steve Virostek - LBNL 8

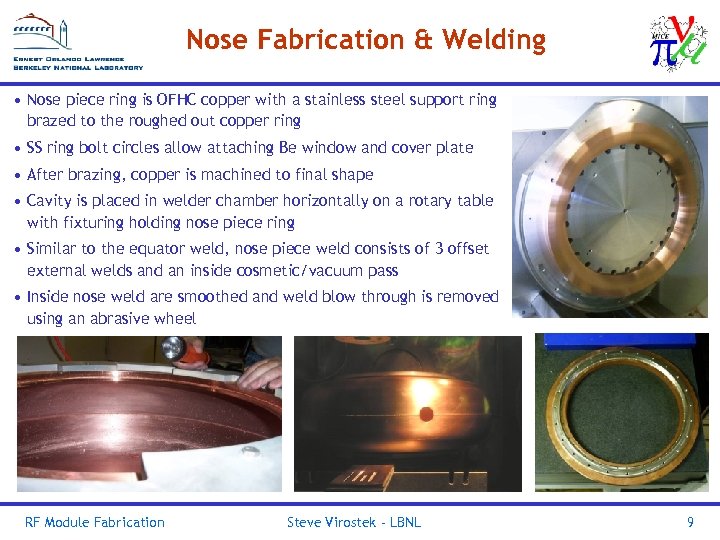

Nose Fabrication & Welding • Nose piece ring is OFHC copper with a stainless steel support ring brazed to the roughed out copper ring • SS ring bolt circles allow attaching Be window and cover plate • After brazing, copper is machined to final shape • Cavity is placed in welder chamber horizontally on a rotary table with fixturing holding nose piece ring • Similar to the equator weld, nose piece weld consists of 3 offset external welds and an inside cosmetic/vacuum pass • Inside nose weld are smoothed and weld blow through is removed using an abrasive wheel RF Module Fabrication Steve Virostek - LBNL 9

Nose Fabrication & Welding • Nose piece ring is OFHC copper with a stainless steel support ring brazed to the roughed out copper ring • SS ring bolt circles allow attaching Be window and cover plate • After brazing, copper is machined to final shape • Cavity is placed in welder chamber horizontally on a rotary table with fixturing holding nose piece ring • Similar to the equator weld, nose piece weld consists of 3 offset external welds and an inside cosmetic/vacuum pass • Inside nose weld are smoothed and weld blow through is removed using an abrasive wheel RF Module Fabrication Steve Virostek - LBNL 9

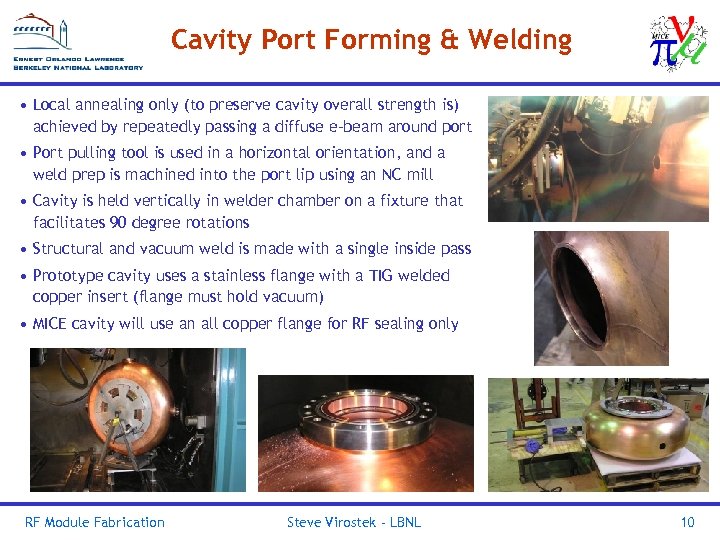

Cavity Port Forming & Welding • Local annealing only (to preserve cavity overall strength is) achieved by repeatedly passing a diffuse e-beam around port • Port pulling tool is used in a horizontal orientation, and a weld prep is machined into the port lip using an NC mill • Cavity is held vertically in welder chamber on a fixture that facilitates 90 degree rotations • Structural and vacuum weld is made with a single inside pass • Prototype cavity uses a stainless flange with a TIG welded copper insert (flange must hold vacuum) • MICE cavity will use an all copper flange for RF sealing only RF Module Fabrication Steve Virostek - LBNL 10

Cavity Port Forming & Welding • Local annealing only (to preserve cavity overall strength is) achieved by repeatedly passing a diffuse e-beam around port • Port pulling tool is used in a horizontal orientation, and a weld prep is machined into the port lip using an NC mill • Cavity is held vertically in welder chamber on a fixture that facilitates 90 degree rotations • Structural and vacuum weld is made with a single inside pass • Prototype cavity uses a stainless flange with a TIG welded copper insert (flange must hold vacuum) • MICE cavity will use an all copper flange for RF sealing only RF Module Fabrication Steve Virostek - LBNL 10

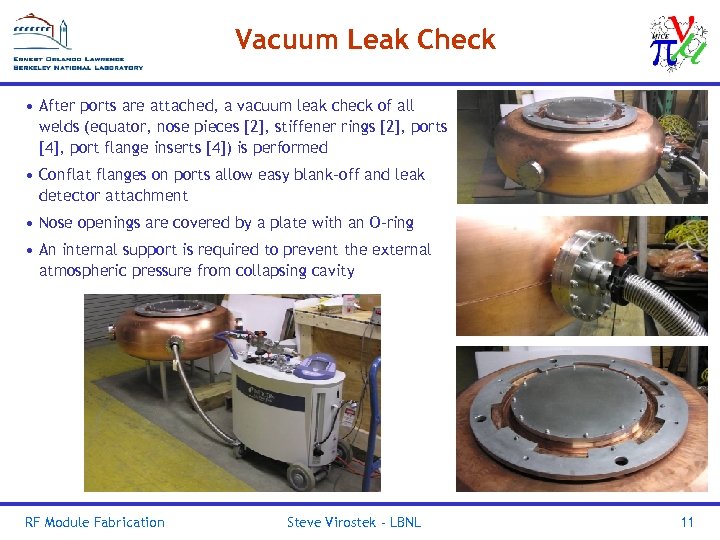

Vacuum Leak Check • After ports are attached, a vacuum leak check of all welds (equator, nose pieces [2], stiffener rings [2], ports [4], port flange inserts [4]) is performed • Conflat flanges on ports allow easy blank-off and leak detector attachment • Nose openings are covered by a plate with an O-ring • An internal support is required to prevent the external atmospheric pressure from collapsing cavity RF Module Fabrication Steve Virostek - LBNL 11

Vacuum Leak Check • After ports are attached, a vacuum leak check of all welds (equator, nose pieces [2], stiffener rings [2], ports [4], port flange inserts [4]) is performed • Conflat flanges on ports allow easy blank-off and leak detector attachment • Nose openings are covered by a plate with an O-ring • An internal support is required to prevent the external atmospheric pressure from collapsing cavity RF Module Fabrication Steve Virostek - LBNL 11

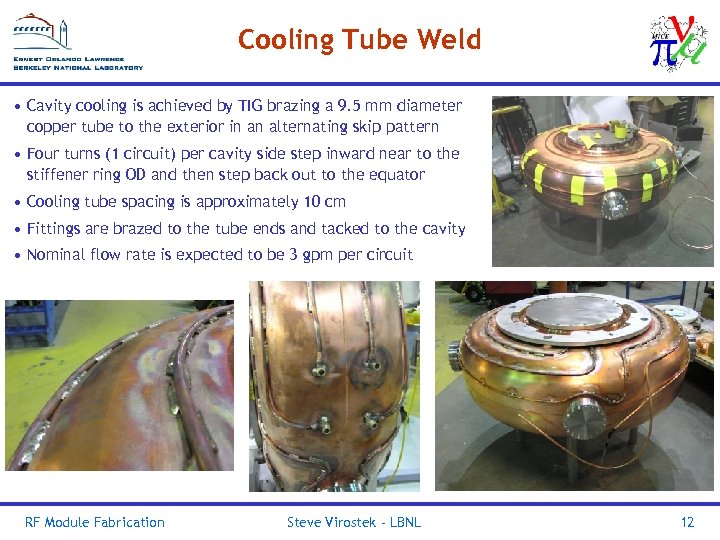

Cooling Tube Weld • Cavity cooling is achieved by TIG brazing a 9. 5 mm diameter copper tube to the exterior in an alternating skip pattern • Four turns (1 circuit) per cavity side step inward near to the stiffener ring OD and then step back out to the equator • Cooling tube spacing is approximately 10 cm • Fittings are brazed to the tube ends and tacked to the cavity • Nominal flow rate is expected to be 3 gpm per circuit RF Module Fabrication Steve Virostek - LBNL 12

Cooling Tube Weld • Cavity cooling is achieved by TIG brazing a 9. 5 mm diameter copper tube to the exterior in an alternating skip pattern • Four turns (1 circuit) per cavity side step inward near to the stiffener ring OD and then step back out to the equator • Cooling tube spacing is approximately 10 cm • Fittings are brazed to the tube ends and tacked to the cavity • Nominal flow rate is expected to be 3 gpm per circuit RF Module Fabrication Steve Virostek - LBNL 12

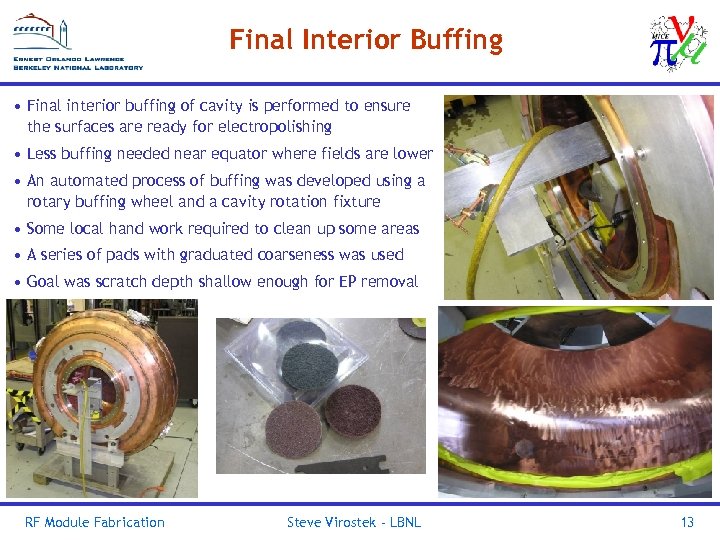

Final Interior Buffing • Final interior buffing of cavity is performed to ensure the surfaces are ready for electropolishing • Less buffing needed near equator where fields are lower • An automated process of buffing was developed using a rotary buffing wheel and a cavity rotation fixture • Some local hand work required to clean up some areas • A series of pads with graduated coarseness was used • Goal was scratch depth shallow enough for EP removal RF Module Fabrication Steve Virostek - LBNL 13

Final Interior Buffing • Final interior buffing of cavity is performed to ensure the surfaces are ready for electropolishing • Less buffing needed near equator where fields are lower • An automated process of buffing was developed using a rotary buffing wheel and a cavity rotation fixture • Some local hand work required to clean up some areas • A series of pads with graduated coarseness was used • Goal was scratch depth shallow enough for EP removal RF Module Fabrication Steve Virostek - LBNL 13

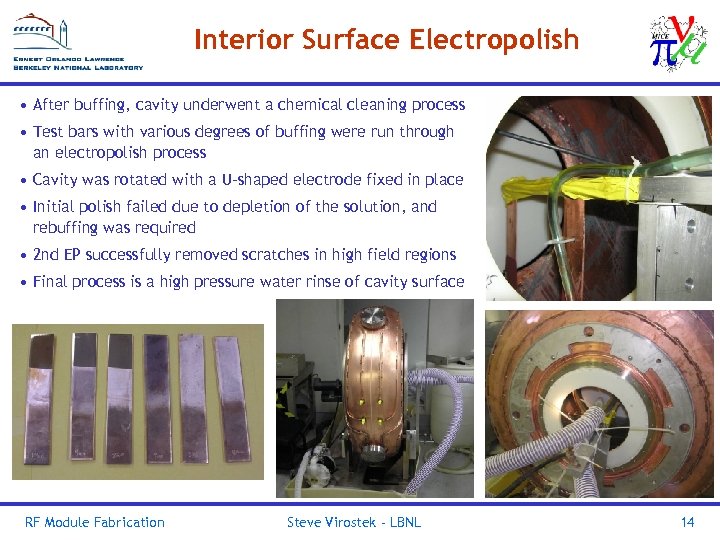

Interior Surface Electropolish • After buffing, cavity underwent a chemical cleaning process • Test bars with various degrees of buffing were run through an electropolish process • Cavity was rotated with a U-shaped electrode fixed in place • Initial polish failed due to depletion of the solution, and rebuffing was required • 2 nd EP successfully removed scratches in high field regions • Final process is a high pressure water rinse of cavity surface RF Module Fabrication Steve Virostek - LBNL 14

Interior Surface Electropolish • After buffing, cavity underwent a chemical cleaning process • Test bars with various degrees of buffing were run through an electropolish process • Cavity was rotated with a U-shaped electrode fixed in place • Initial polish failed due to depletion of the solution, and rebuffing was required • 2 nd EP successfully removed scratches in high field regions • Final process is a high pressure water rinse of cavity surface RF Module Fabrication Steve Virostek - LBNL 14

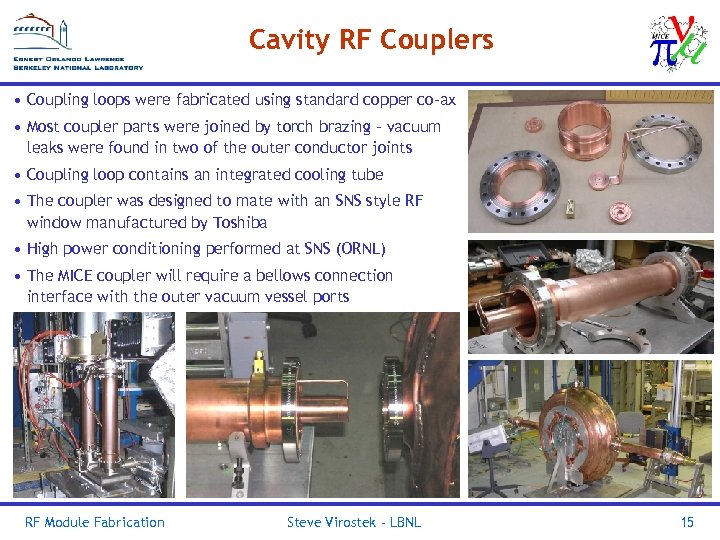

Cavity RF Couplers • Coupling loops were fabricated using standard copper co-ax • Most coupler parts were joined by torch brazing – vacuum leaks were found in two of the outer conductor joints • Coupling loop contains an integrated cooling tube • The coupler was designed to mate with an SNS style RF window manufactured by Toshiba • High power conditioning performed at SNS (ORNL) • The MICE coupler will require a bellows connection interface with the outer vacuum vessel ports RF Module Fabrication Steve Virostek - LBNL 15

Cavity RF Couplers • Coupling loops were fabricated using standard copper co-ax • Most coupler parts were joined by torch brazing – vacuum leaks were found in two of the outer conductor joints • Coupling loop contains an integrated cooling tube • The coupler was designed to mate with an SNS style RF window manufactured by Toshiba • High power conditioning performed at SNS (ORNL) • The MICE coupler will require a bellows connection interface with the outer vacuum vessel ports RF Module Fabrication Steve Virostek - LBNL 15

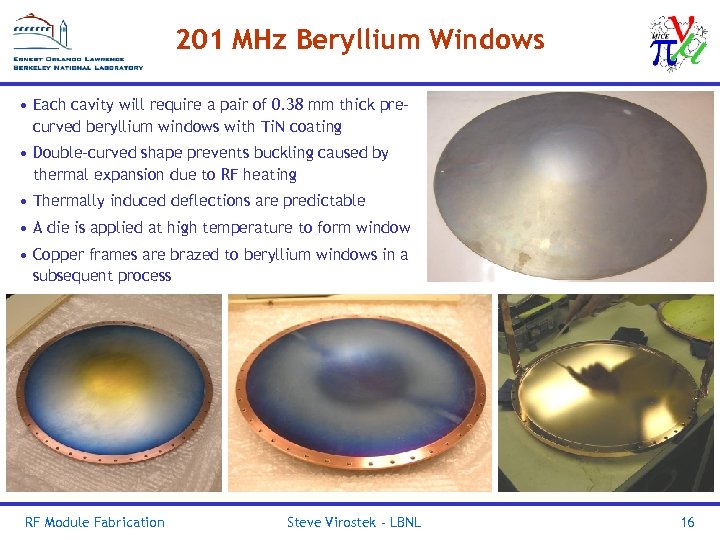

201 MHz Beryllium Windows • Each cavity will require a pair of 0. 38 mm thick precurved beryllium windows with Ti. N coating • Double-curved shape prevents buckling caused by thermal expansion due to RF heating • Thermally induced deflections are predictable • A die is applied at high temperature to form window • Copper frames are brazed to beryllium windows in a subsequent process RF Module Fabrication Steve Virostek - LBNL 16

201 MHz Beryllium Windows • Each cavity will require a pair of 0. 38 mm thick precurved beryllium windows with Ti. N coating • Double-curved shape prevents buckling caused by thermal expansion due to RF heating • Thermally induced deflections are predictable • A die is applied at high temperature to form window • Copper frames are brazed to beryllium windows in a subsequent process RF Module Fabrication Steve Virostek - LBNL 16

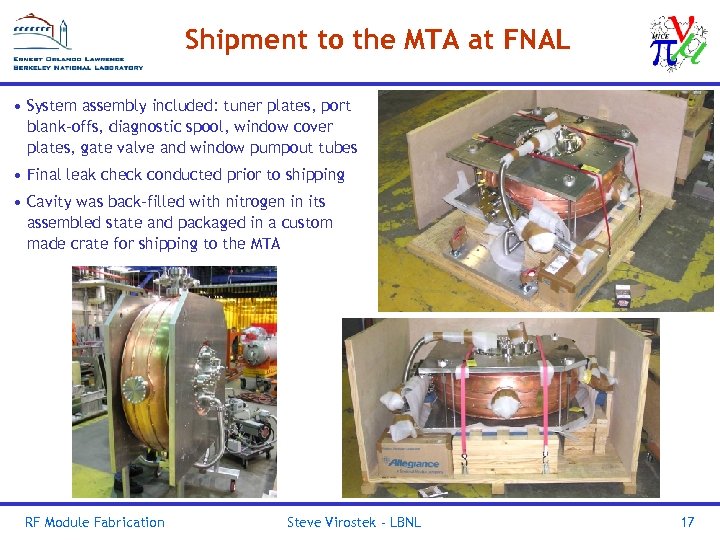

Shipment to the MTA at FNAL • System assembly included: tuner plates, port blank-offs, diagnostic spool, window cover plates, gate valve and window pumpout tubes • Final leak check conducted prior to shipping • Cavity was back-filled with nitrogen in its assembled state and packaged in a custom made crate for shipping to the MTA RF Module Fabrication Steve Virostek - LBNL 17

Shipment to the MTA at FNAL • System assembly included: tuner plates, port blank-offs, diagnostic spool, window cover plates, gate valve and window pumpout tubes • Final leak check conducted prior to shipping • Cavity was back-filled with nitrogen in its assembled state and packaged in a custom made crate for shipping to the MTA RF Module Fabrication Steve Virostek - LBNL 17

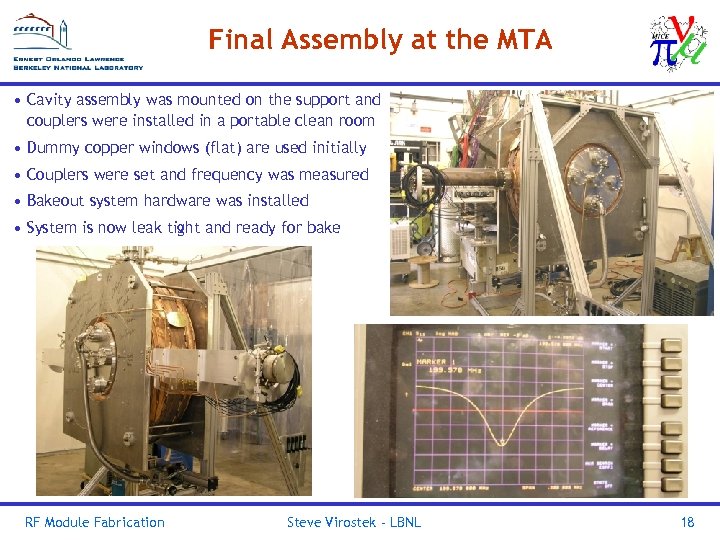

Final Assembly at the MTA • Cavity assembly was mounted on the support and couplers were installed in a portable clean room • Dummy copper windows (flat) are used initially • Couplers were set and frequency was measured • Bakeout system hardware was installed • System is now leak tight and ready for bake RF Module Fabrication Steve Virostek - LBNL 18

Final Assembly at the MTA • Cavity assembly was mounted on the support and couplers were installed in a portable clean room • Dummy copper windows (flat) are used initially • Couplers were set and frequency was measured • Bakeout system hardware was installed • System is now leak tight and ready for bake RF Module Fabrication Steve Virostek - LBNL 18