2755216c0cadfa3773cf5f49758ae078.ppt

- Количество слайдов: 13

Status of PWO crystal growth at SIC Peizhi YANG on Behalf of PWO Crystal Growth Group SIC, 10 th July 2004 July 10 P. Z. Yang SIC 1

Status of PWO crystal growth at SIC Peizhi YANG on Behalf of PWO Crystal Growth Group SIC, 10 th July 2004 July 10 P. Z. Yang SIC 1

Outline Ø Current status of PWO crystal growth at SIC ¾ Advantages of modified multi-crucible Bridgman method ¾ Current status of PWO crystal growth Ø Next plan for collaboration with CMS-ECAL ¾ Build-up the infrastructure A. Build the furnaces B. Buy Pt C. Buy crystal processing machinery ¾ Total investment ¾ Processing cost July 10 P. Z. Yang SIC 2

Outline Ø Current status of PWO crystal growth at SIC ¾ Advantages of modified multi-crucible Bridgman method ¾ Current status of PWO crystal growth Ø Next plan for collaboration with CMS-ECAL ¾ Build-up the infrastructure A. Build the furnaces B. Buy Pt C. Buy crystal processing machinery ¾ Total investment ¾ Processing cost July 10 P. Z. Yang SIC 2

Advantages of Bridgman growth method Compared with other crystal growth method, Bridgman has the following advantages: 1) simple in operation without complicated control system; 2) possibility of using multi-crucible for growth of crystals with different sizes; 3) ability to get uniform crystals owing to low temperature gradient; 4) suitable for growing crystals with components having higher vapor pressures because the melts are sealed in crucibles and evaporation can be avoided; 5) the crystals with desired shape can be grown and the utilization ratio of materials is high. Bridgman technique is very suitable for PWO crystal growth July 10 P. Z. Yang SIC 3

Advantages of Bridgman growth method Compared with other crystal growth method, Bridgman has the following advantages: 1) simple in operation without complicated control system; 2) possibility of using multi-crucible for growth of crystals with different sizes; 3) ability to get uniform crystals owing to low temperature gradient; 4) suitable for growing crystals with components having higher vapor pressures because the melts are sealed in crucibles and evaporation can be avoided; 5) the crystals with desired shape can be grown and the utilization ratio of materials is high. Bridgman technique is very suitable for PWO crystal growth July 10 P. Z. Yang SIC 3

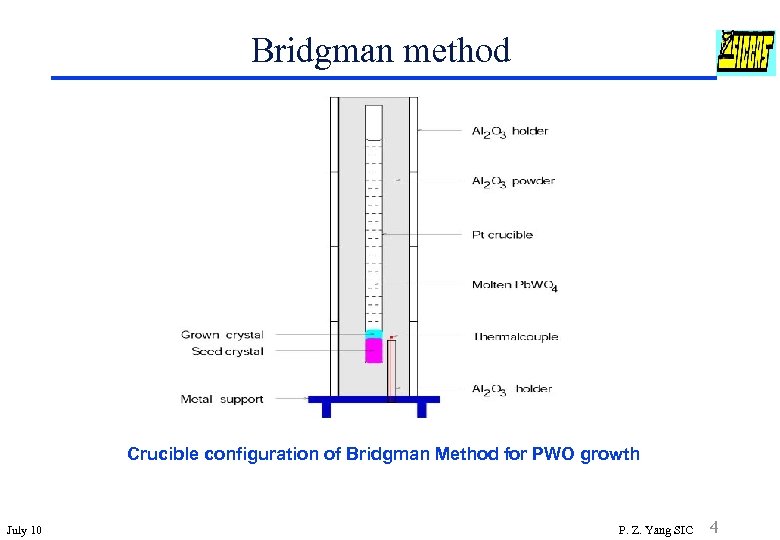

Bridgman method Crucible configuration of Bridgman Method for PWO growth July 10 P. Z. Yang SIC 4

Bridgman method Crucible configuration of Bridgman Method for PWO growth July 10 P. Z. Yang SIC 4

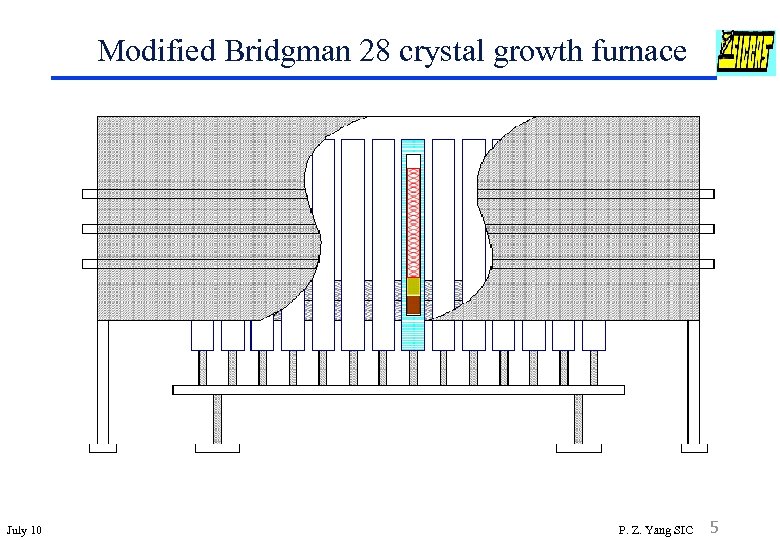

Modified Bridgman 28 crystal growth furnace July 10 P. Z. Yang SIC 5

Modified Bridgman 28 crystal growth furnace July 10 P. Z. Yang SIC 5

Current furnaces and crystal growth rate × Currently there are 5 sets of furnaces in operation: – 3 sets of them for crystal growth – 2 sets of them for first crystallization and growth of seeds × 3 sets of furnaces can produce 90~100 crystal ingots per month. The growth time is about 20 days. The growth yield is about 80%. July 10 P. Z. Yang SIC 6

Current furnaces and crystal growth rate × Currently there are 5 sets of furnaces in operation: – 3 sets of them for crystal growth – 2 sets of them for first crystallization and growth of seeds × 3 sets of furnaces can produce 90~100 crystal ingots per month. The growth time is about 20 days. The growth yield is about 80%. July 10 P. Z. Yang SIC 6

Growth condition and parameters – Vertical Bridgman Furnace with 28 crucibles – DWJ-100 temperature control system – Temperature precision is 1 o. C – Growth temperature 1173 o. C (melting point 1123 o. C +50 o. C) – Two times re-crystallization – Doping with Y 2 O 3(150 ppm) – Lowering rate 0. 8~1. 0 mm/hr – Crystal size up to 250 mm, 32 mm*32 mm section July 10 P. Z. Yang SIC 7

Growth condition and parameters – Vertical Bridgman Furnace with 28 crucibles – DWJ-100 temperature control system – Temperature precision is 1 o. C – Growth temperature 1173 o. C (melting point 1123 o. C +50 o. C) – Two times re-crystallization – Doping with Y 2 O 3(150 ppm) – Lowering rate 0. 8~1. 0 mm/hr – Crystal size up to 250 mm, 32 mm*32 mm section July 10 P. Z. Yang SIC 7

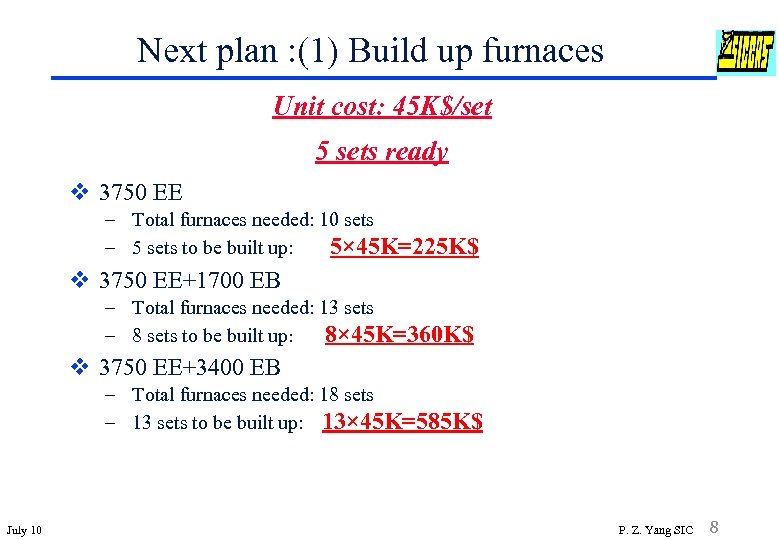

Next plan : (1) Build up furnaces Unit cost: 45 K$/set 5 sets ready v 3750 EE – Total furnaces needed: 10 sets – 5 sets to be built up: 5× 45 K=225 K$ v 3750 EE+1700 EB – Total furnaces needed: 13 sets – 8 sets to be built up: 8× 45 K=360 K$ v 3750 EE+3400 EB – Total furnaces needed: 18 sets – 13 sets to be built up: 13× 45 K=585 K$ July 10 P. Z. Yang SIC 8

Next plan : (1) Build up furnaces Unit cost: 45 K$/set 5 sets ready v 3750 EE – Total furnaces needed: 10 sets – 5 sets to be built up: 5× 45 K=225 K$ v 3750 EE+1700 EB – Total furnaces needed: 13 sets – 8 sets to be built up: 8× 45 K=360 K$ v 3750 EE+3400 EB – Total furnaces needed: 18 sets – 13 sets to be built up: 13× 45 K=585 K$ July 10 P. Z. Yang SIC 8

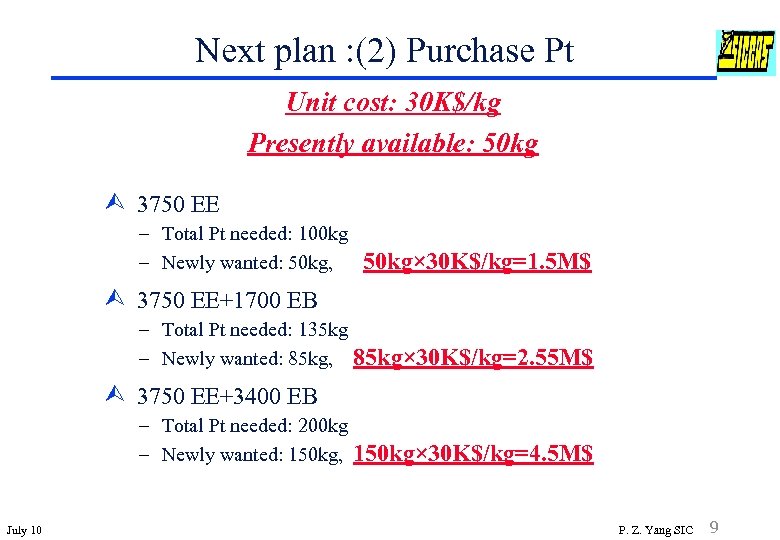

Next plan : (2) Purchase Pt Unit cost: 30 K$/kg Presently available: 50 kg Ù 3750 EE – Total Pt needed: 100 kg – Newly wanted: 50 kg, 50 kg× 30 K$/kg=1. 5 M$ Ù 3750 EE+1700 EB – Total Pt needed: 135 kg – Newly wanted: 85 kg, 85 kg× 30 K$/kg=2. 55 M$ Ù 3750 EE+3400 EB – Total Pt needed: 200 kg – Newly wanted: 150 kg, 150 kg× 30 K$/kg=4. 5 M$ July 10 P. Z. Yang SIC 9

Next plan : (2) Purchase Pt Unit cost: 30 K$/kg Presently available: 50 kg Ù 3750 EE – Total Pt needed: 100 kg – Newly wanted: 50 kg, 50 kg× 30 K$/kg=1. 5 M$ Ù 3750 EE+1700 EB – Total Pt needed: 135 kg – Newly wanted: 85 kg, 85 kg× 30 K$/kg=2. 55 M$ Ù 3750 EE+3400 EB – Total Pt needed: 200 kg – Newly wanted: 150 kg, 150 kg× 30 K$/kg=4. 5 M$ July 10 P. Z. Yang SIC 9

Investment : (3) Crystal processing machinery Total investment: 350 K$ Crystal processing investments mainly include: (1) cutting machines; (2) lapping machines; (3) polishing machines, et al. July 10 P. Z. Yang SIC 10

Investment : (3) Crystal processing machinery Total investment: 350 K$ Crystal processing investments mainly include: (1) cutting machines; (2) lapping machines; (3) polishing machines, et al. July 10 P. Z. Yang SIC 10

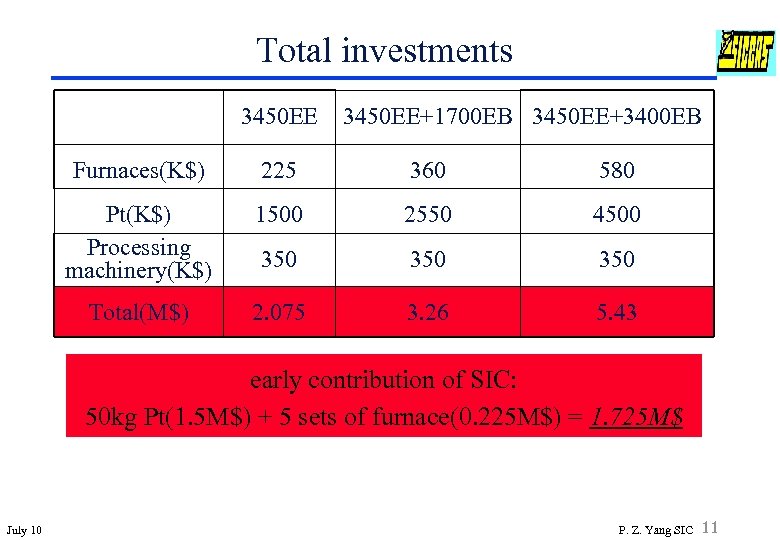

Total investments 3450 EE+1700 EB 3450 EE+3400 EB Furnaces(K$) 225 360 580 Pt(K$) Processing machinery(K$) 1500 2550 4500 350 350 Total(M$) 2. 075 3. 26 5. 43 early contribution of SIC: 50 kg Pt(1. 5 M$) + 5 sets of furnace(0. 225 M$) = 1. 725 M$ July 10 P. Z. Yang SIC 11

Total investments 3450 EE+1700 EB 3450 EE+3400 EB Furnaces(K$) 225 360 580 Pt(K$) Processing machinery(K$) 1500 2550 4500 350 350 Total(M$) 2. 075 3. 26 5. 43 early contribution of SIC: 50 kg Pt(1. 5 M$) + 5 sets of furnace(0. 225 M$) = 1. 725 M$ July 10 P. Z. Yang SIC 11

(4) Processing cost: 2. 4$/cc Processing cost include: (1) raw materials and other consumables; (2) Pt crucible processing cost and loss; (3) crystal processing; (4) electricity consumption; (5) manpower, et al. July 10 P. Z. Yang SIC 12

(4) Processing cost: 2. 4$/cc Processing cost include: (1) raw materials and other consumables; (2) Pt crucible processing cost and loss; (3) crystal processing; (4) electricity consumption; (5) manpower, et al. July 10 P. Z. Yang SIC 12

Summary Modified Bridgman technique is very suitable for growing PWO crystals with high quality. ( Optimal growth parameters for mass produced PWO crystals were established. Growth yield is about 80% and will be stepwise increased in the coming 6 months. Meanwhile, the crystal quality will also be improved. ( We estimated the total investment for meeting CMS-ECAL demands. Pt cost is the large one. ( July 10 P. Z. Yang SIC 13

Summary Modified Bridgman technique is very suitable for growing PWO crystals with high quality. ( Optimal growth parameters for mass produced PWO crystals were established. Growth yield is about 80% and will be stepwise increased in the coming 6 months. Meanwhile, the crystal quality will also be improved. ( We estimated the total investment for meeting CMS-ECAL demands. Pt cost is the large one. ( July 10 P. Z. Yang SIC 13