fc630169d05c1f2e724c10915f49b444.ppt

- Количество слайдов: 15

Standard Portion Cost: Butcher Test designed to determine standard portion costs for those items portioned before cooking Goal : Determine Serving price (SPC) versus Purchase price. Concept: What you serve can cost more than what you bought it for. - Applies to wholesale cuts, not portion cut - wholesale cuts usually ‘render’ more than what you bought it for - Focus is on “primary part” of the wholesale cut Process: Usually involves a team: chef/manager/cost controller/butcher 1. One member does the recording 2. As piece is “broken down”, various cuts/parts are separated 3. Total weight of cuts/parts almost never = original weight - difference is a DERIVED number based on weight difference

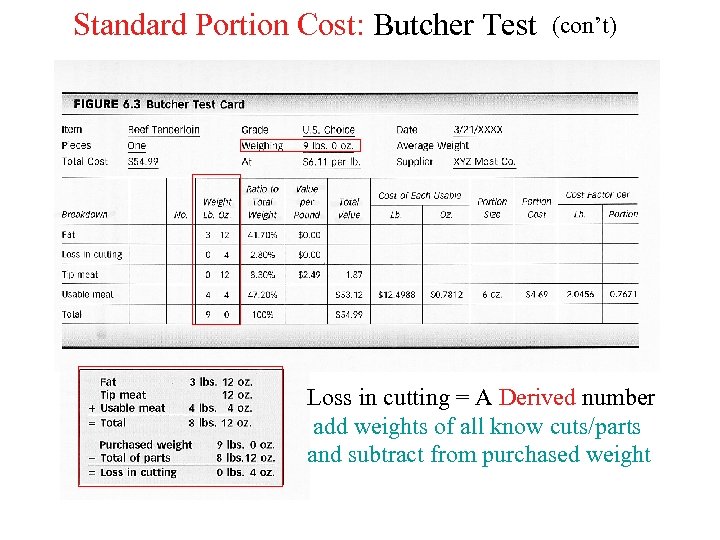

Standard Portion Cost: Butcher Test (con’t) Loss in cutting = A Derived number add weights of all know cuts/parts and subtract from purchased weight

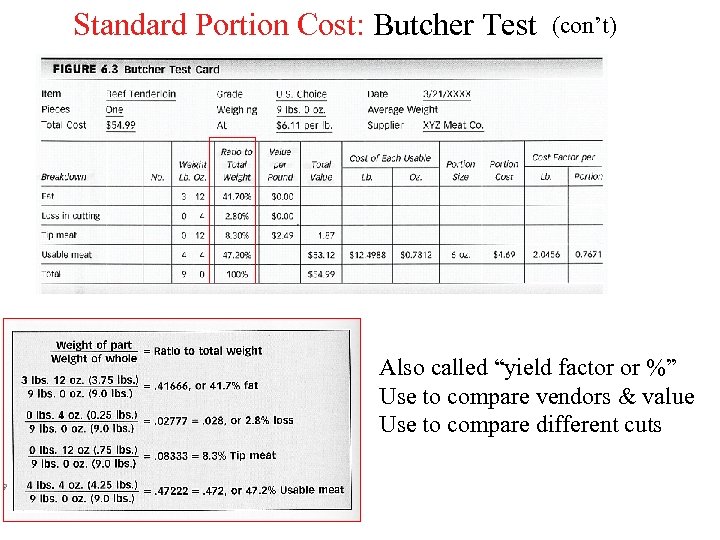

Standard Portion Cost: Butcher Test (con’t) Also called “yield factor or %” Use to compare vendors & value Use to compare different cuts

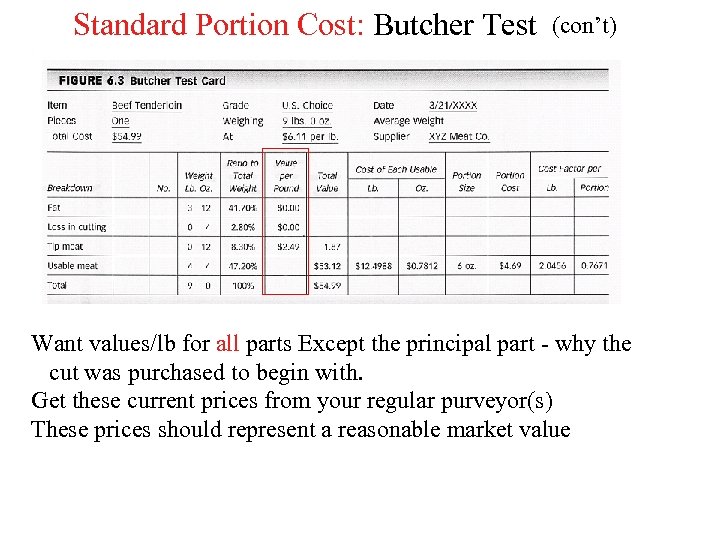

Standard Portion Cost: Butcher Test (con’t) Want values/lb for all parts Except the principal part - why the cut was purchased to begin with. Get these current prices from your regular purveyor(s) These prices should represent a reasonable market value

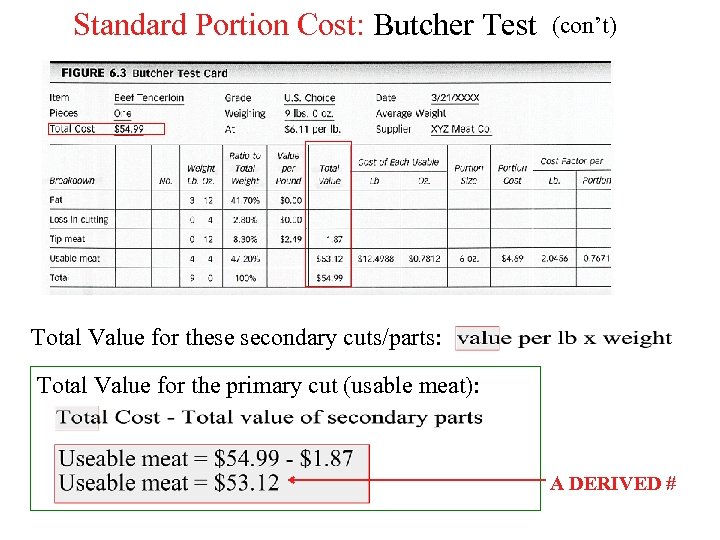

Standard Portion Cost: Butcher Test (con’t) Total Value for these secondary cuts/parts: Total Value for the primary cut (usable meat): A DERIVED #

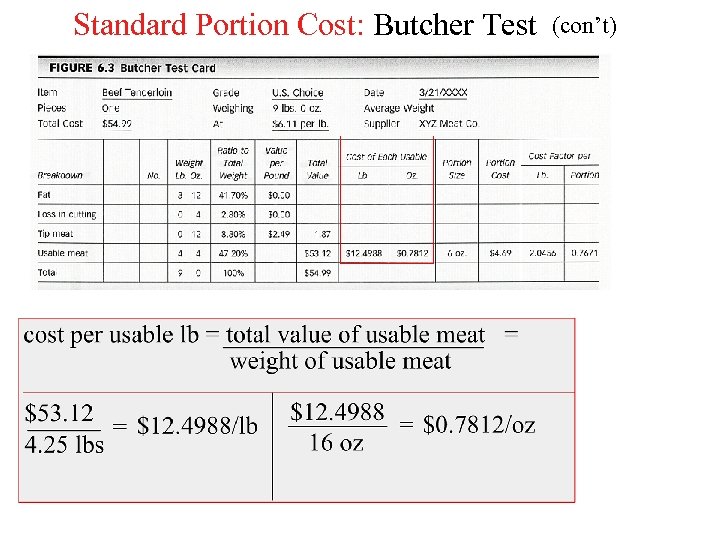

Standard Portion Cost: Butcher Test (con’t)

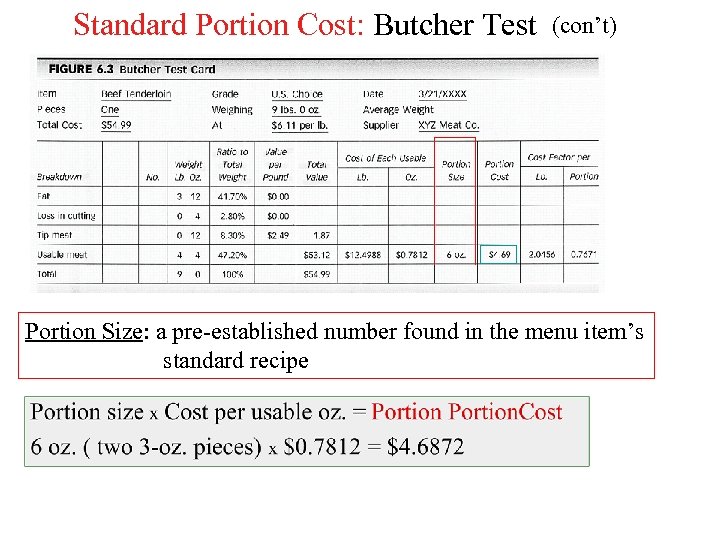

Standard Portion Cost: Butcher Test (con’t) Portion Size: a pre-established number found in the menu item’s standard recipe

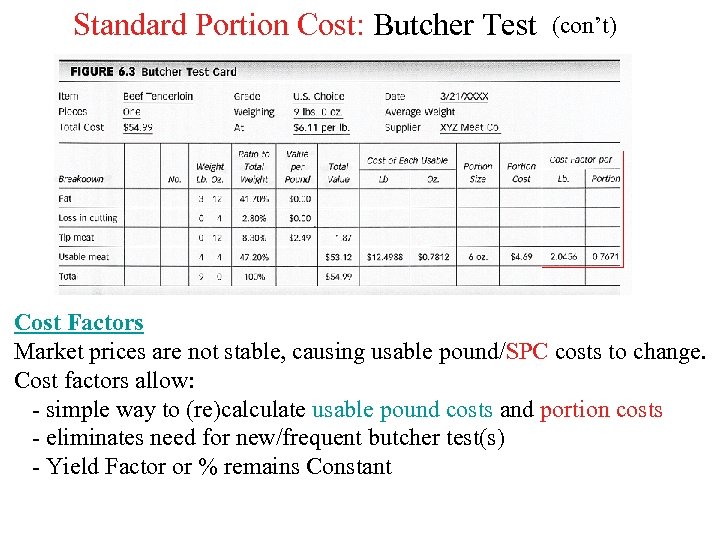

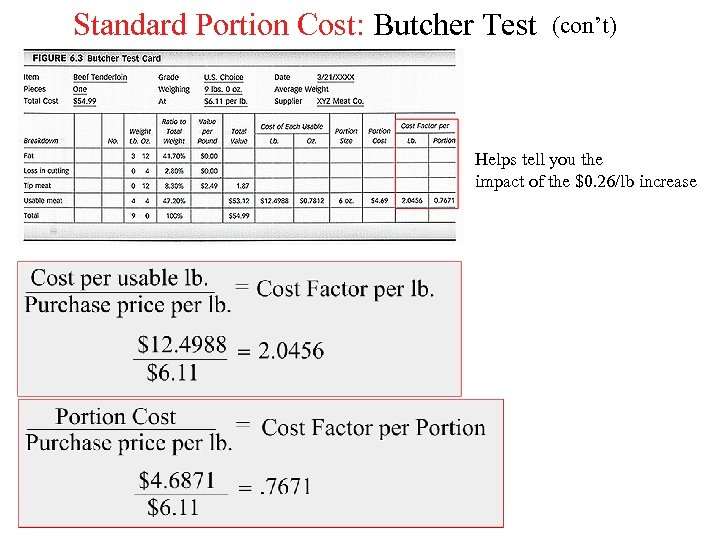

Standard Portion Cost: Butcher Test (con’t) Cost Factors Market prices are not stable, causing usable pound/SPC costs to change. Cost factors allow: - simple way to (re)calculate usable pound costs and portion costs - eliminates need for new/frequent butcher test(s) - Yield Factor or % remains Constant

Standard Portion Cost: Butcher Test (con’t) Helps tell you the impact of the $0. 26/lb increase

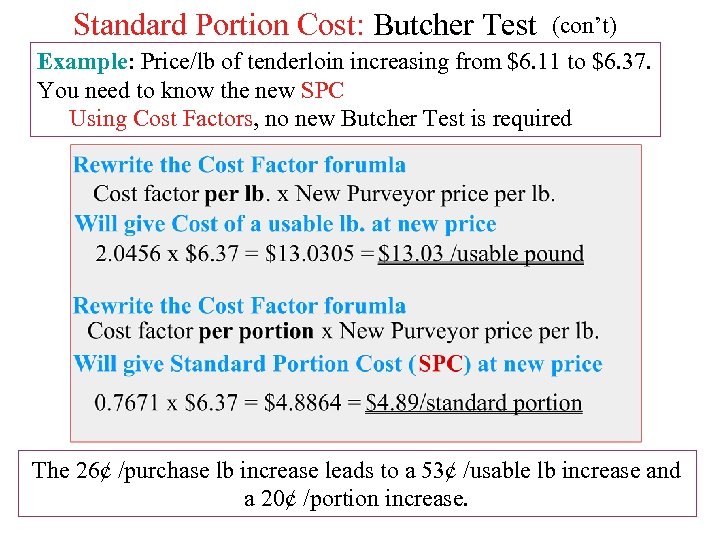

Standard Portion Cost: Butcher Test (con’t) Example: Price/lb of tenderloin increasing from $6. 11 to $6. 37. You need to know the new SPC Using Cost Factors, no new Butcher Test is required The 26¢ /purchase lb increase leads to a 53¢ /usable lb increase and a 20¢ /portion increase.

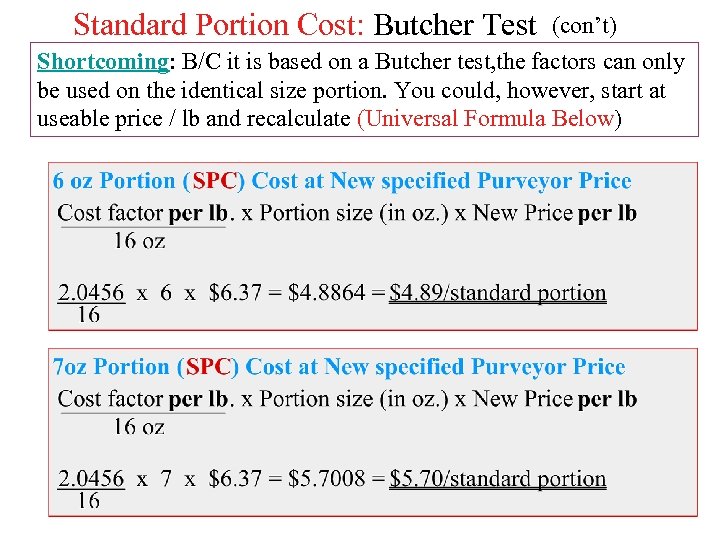

Standard Portion Cost: Butcher Test (con’t) Shortcoming: B/C it is based on a Butcher test, the factors can only be used on the identical size portion. You could, however, start at useable price / lb and recalculate (Universal Formula Below)

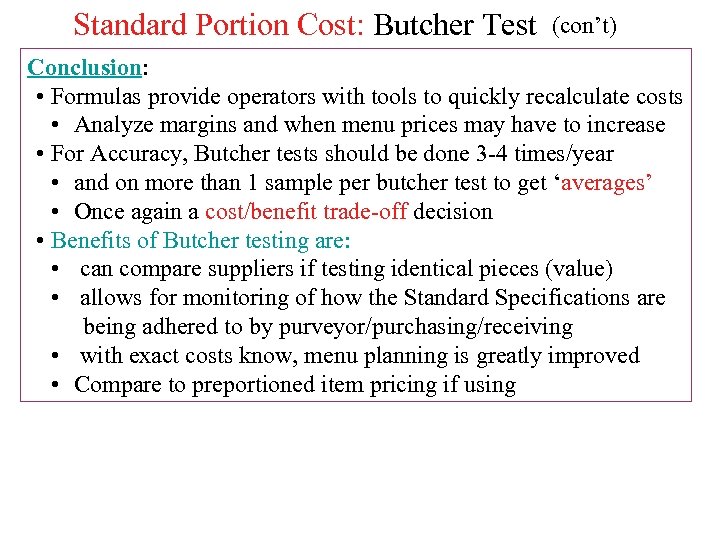

Standard Portion Cost: Butcher Test (con’t) Conclusion: • Formulas provide operators with tools to quickly recalculate costs • Analyze margins and when menu prices may have to increase • For Accuracy, Butcher tests should be done 3 -4 times/year • and on more than 1 sample per butcher test to get ‘averages’ • Once again a cost/benefit trade-off decision • Benefits of Butcher testing are: • can compare suppliers if testing identical pieces (value) • allows for monitoring of how the Standard Specifications are being adhered to by purveyor/purchasing/receiving • with exact costs know, menu planning is greatly improved • Compare to preportioned item pricing if using

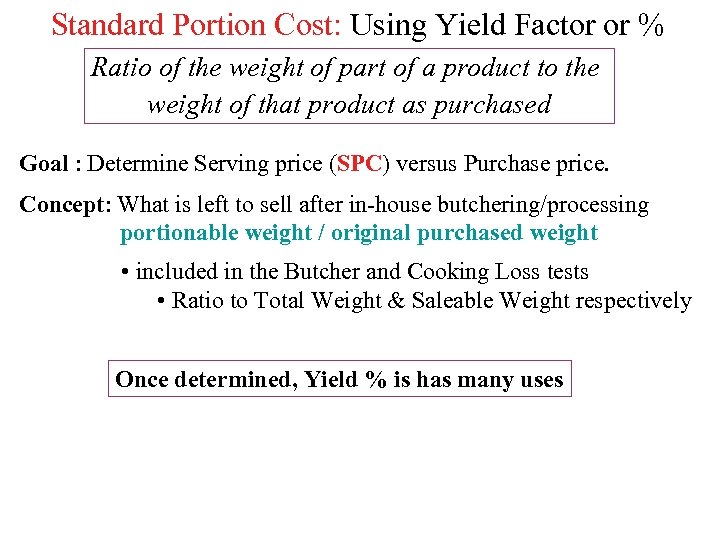

Standard Portion Cost: Using Yield Factor or % Ratio of the weight of part of a product to the weight of that product as purchased Goal : Determine Serving price (SPC) versus Purchase price. Concept: What is left to sell after in-house butchering/processing portionable weight / original purchased weight • included in the Butcher and Cooking Loss tests • Ratio to Total Weight & Saleable Weight respectively Once determined, Yield % is has many uses

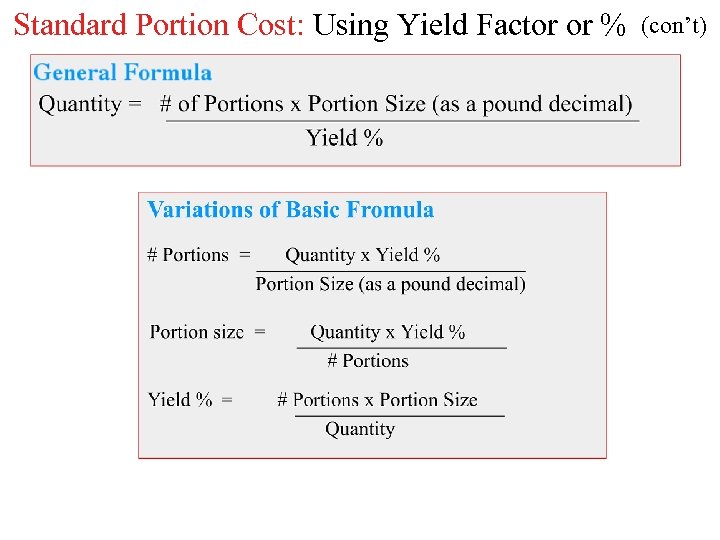

Standard Portion Cost: Using Yield Factor or % (con’t)

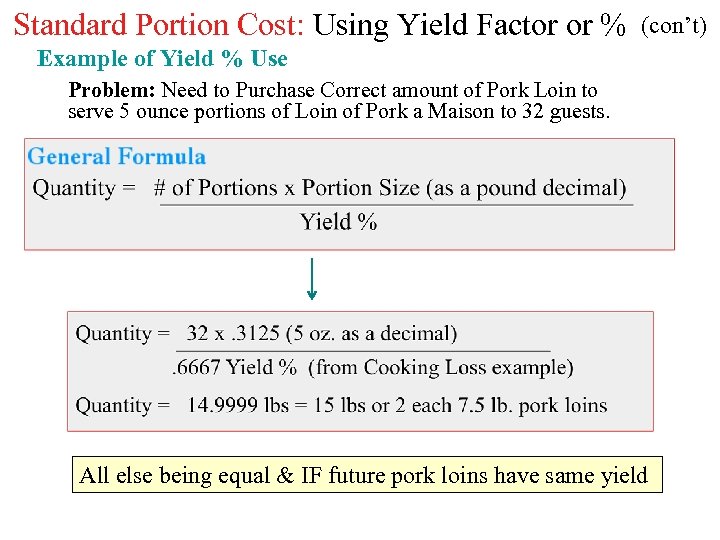

Standard Portion Cost: Using Yield Factor or % (con’t) Example of Yield % Use Problem: Need to Purchase Correct amount of Pork Loin to serve 5 ounce portions of Loin of Pork a Maison to 32 guests. All else being equal & IF future pork loins have same yield

fc630169d05c1f2e724c10915f49b444.ppt