047bcee07b9ef8e8f20d034b55a147e7.ppt

- Количество слайдов: 16

© SRU CPM- PRU MES for Metals - 1 Heiner Termeer , MES for CRM & PL en. ppt Plant Management & Optimization MES solutions for Cold Rolling Mills and Processing Lines

© SRU CPM- PRU MES for Metals - 1 Heiner Termeer , MES for CRM & PL en. ppt Plant Management & Optimization MES solutions for Cold Rolling Mills and Processing Lines

How to maximize the profit? Increase Throughput Improve Quality © SRU CPM- PRU MES for Metals - 2 Reduce Production Costs Optimize Logistics

How to maximize the profit? Increase Throughput Improve Quality © SRU CPM- PRU MES for Metals - 2 Reduce Production Costs Optimize Logistics

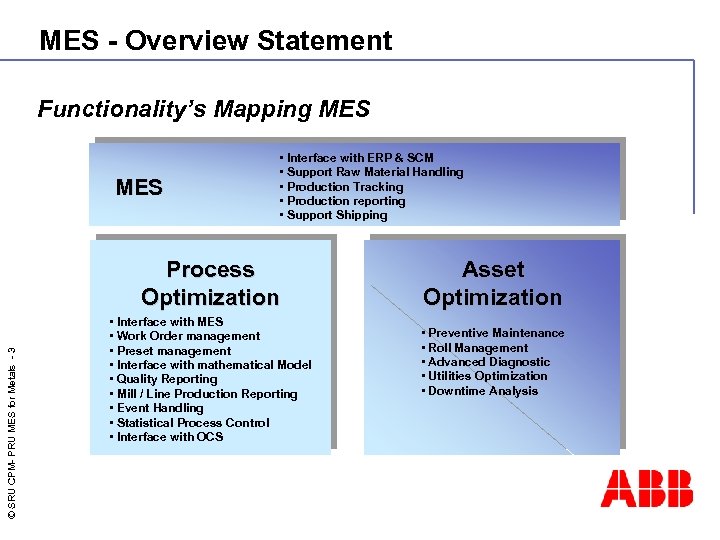

MES - Overview Statement Functionality’s Mapping MES • Interface with ERP & SCM • Support Raw Material Handling • Production Tracking • Production reporting • Support Shipping © SRU CPM- PRU MES for Metals - 3 Process Optimization • Interface with MES • Work Order management • Preset management • Interface with mathematical Model • Quality Reporting • Mill / Line Production Reporting • Event Handling • Statistical Process Control • Interface with OCS Asset Optimization • Preventive Maintenance • Roll Management • Advanced Diagnostic • Utilities Optimization • Downtime Analysis

MES - Overview Statement Functionality’s Mapping MES • Interface with ERP & SCM • Support Raw Material Handling • Production Tracking • Production reporting • Support Shipping © SRU CPM- PRU MES for Metals - 3 Process Optimization • Interface with MES • Work Order management • Preset management • Interface with mathematical Model • Quality Reporting • Mill / Line Production Reporting • Event Handling • Statistical Process Control • Interface with OCS Asset Optimization • Preventive Maintenance • Roll Management • Advanced Diagnostic • Utilities Optimization • Downtime Analysis

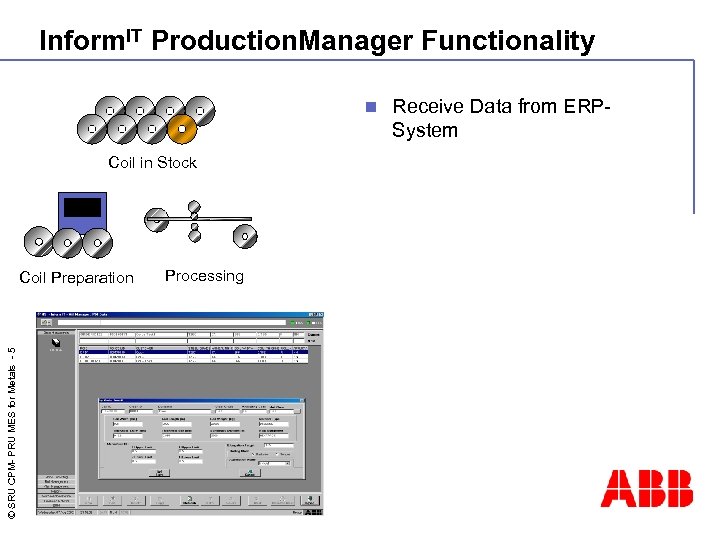

Inform. IT Production. Manager Functionality n Coil in Stock © SRU CPM- PRU MES for Metals - 5 Coil Preparation Processing Receive Data from ERPSystem

Inform. IT Production. Manager Functionality n Coil in Stock © SRU CPM- PRU MES for Metals - 5 Coil Preparation Processing Receive Data from ERPSystem

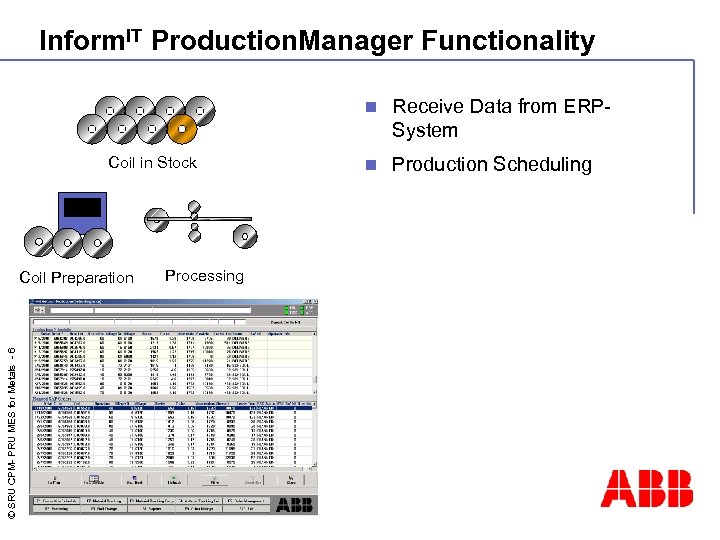

Inform. IT Production. Manager Functionality n Coil in Stock © SRU CPM- PRU MES for Metals - 6 Coil Preparation Processing Receive Data from ERPSystem n Production Scheduling

Inform. IT Production. Manager Functionality n Coil in Stock © SRU CPM- PRU MES for Metals - 6 Coil Preparation Processing Receive Data from ERPSystem n Production Scheduling

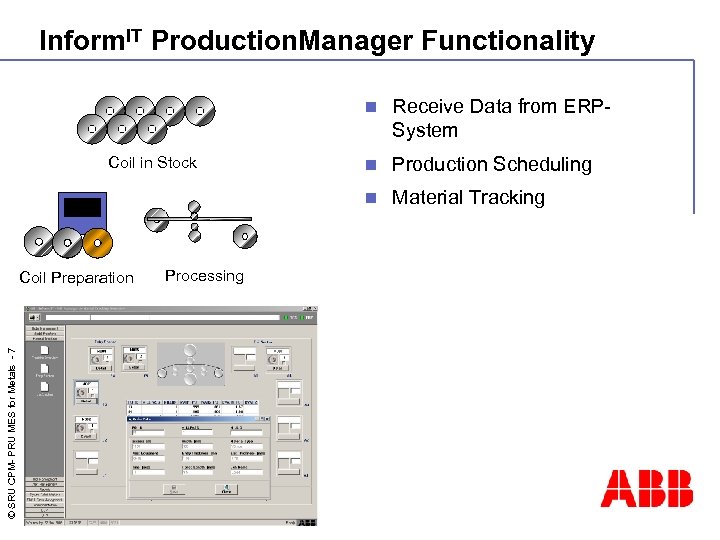

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 7 Coil Preparation Processing n Production Scheduling n Coil in Stock Receive Data from ERPSystem Material Tracking

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 7 Coil Preparation Processing n Production Scheduling n Coil in Stock Receive Data from ERPSystem Material Tracking

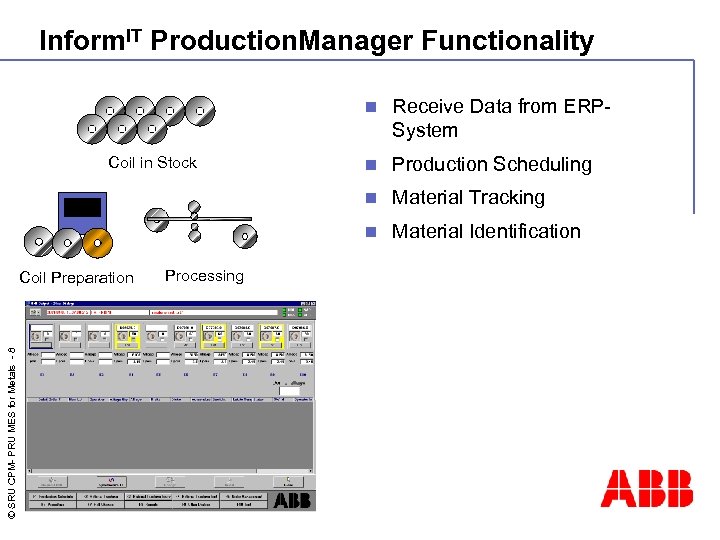

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 8 Processing Production Scheduling Material Tracking n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Material Identification

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 8 Processing Production Scheduling Material Tracking n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Material Identification

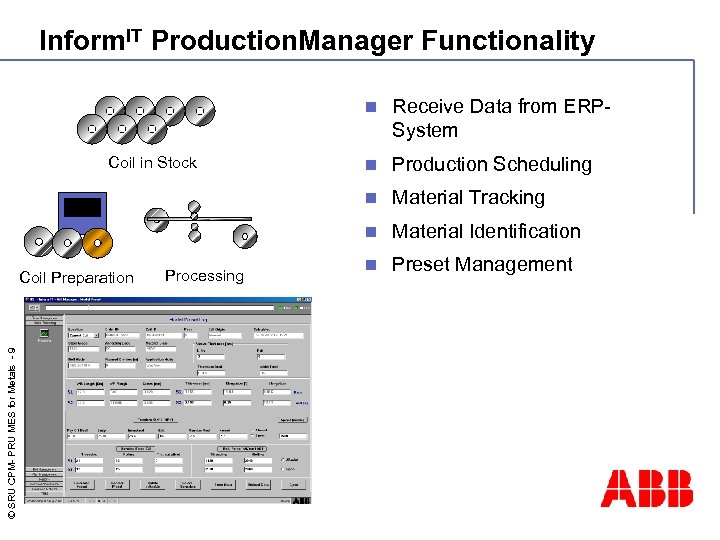

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 9 Processing Production Scheduling Material Tracking n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Material Identification n Preset Management

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 9 Processing Production Scheduling Material Tracking n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Material Identification n Preset Management

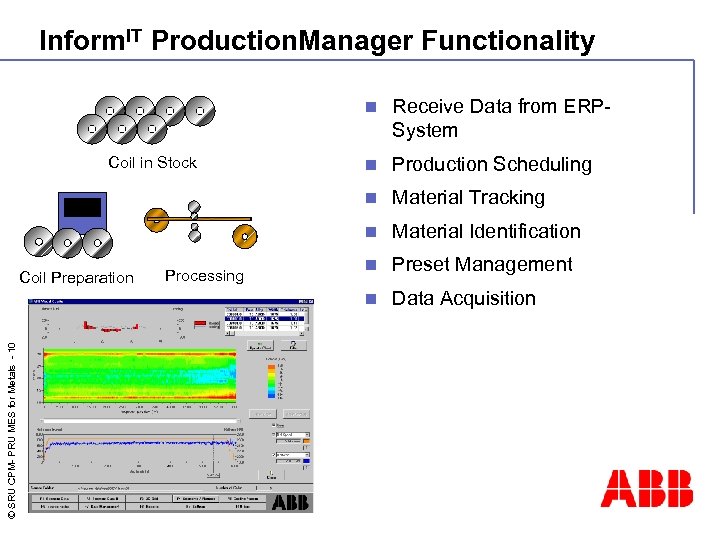

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 10 Material Tracking Material Identification n Preset Management n Processing Production Scheduling n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Data Acquisition

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 10 Material Tracking Material Identification n Preset Management n Processing Production Scheduling n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Data Acquisition

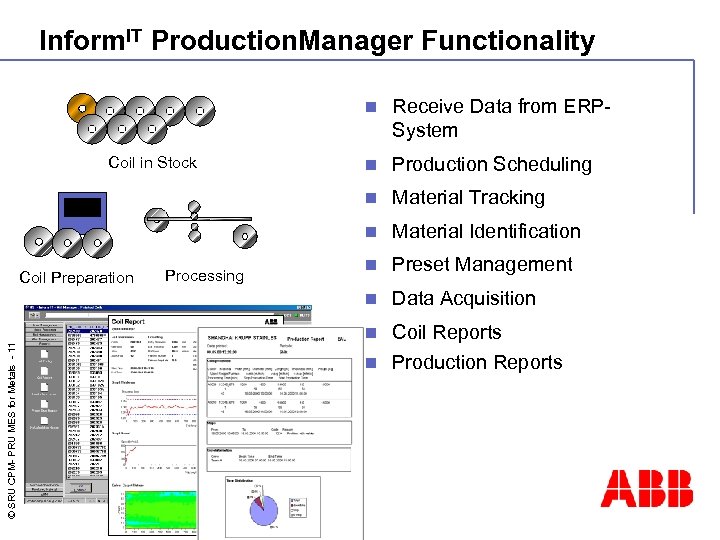

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 11 Material Tracking Material Identification n Preset Management n Processing Production Scheduling n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Data Acquisition n Coil Reports n Production Reports

Inform. IT Production. Manager Functionality n © SRU CPM- PRU MES for Metals - 11 Material Tracking Material Identification n Preset Management n Processing Production Scheduling n Coil Preparation n n Coil in Stock Receive Data from ERPSystem Data Acquisition n Coil Reports n Production Reports

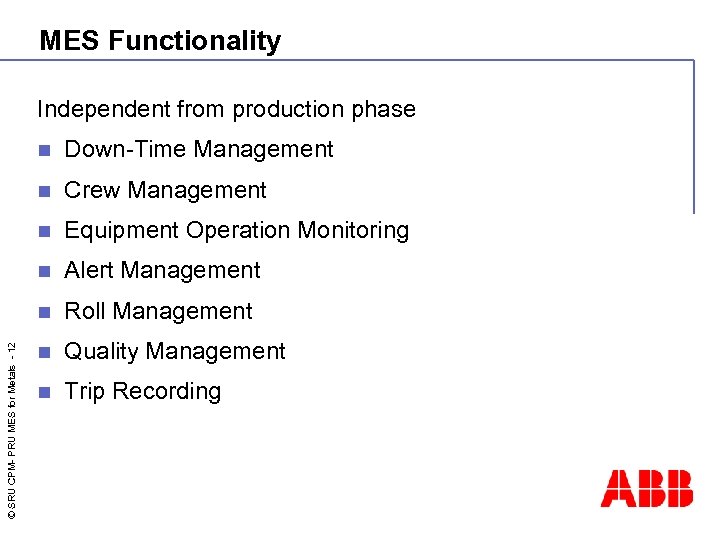

MES Functionality Independent from production phase Down-Time Management n Crew Management n Equipment Operation Monitoring n Alert Management n © SRU CPM- PRU MES for Metals - 12 n Roll Management n Quality Management n Trip Recording

MES Functionality Independent from production phase Down-Time Management n Crew Management n Equipment Operation Monitoring n Alert Management n © SRU CPM- PRU MES for Metals - 12 n Roll Management n Quality Management n Trip Recording

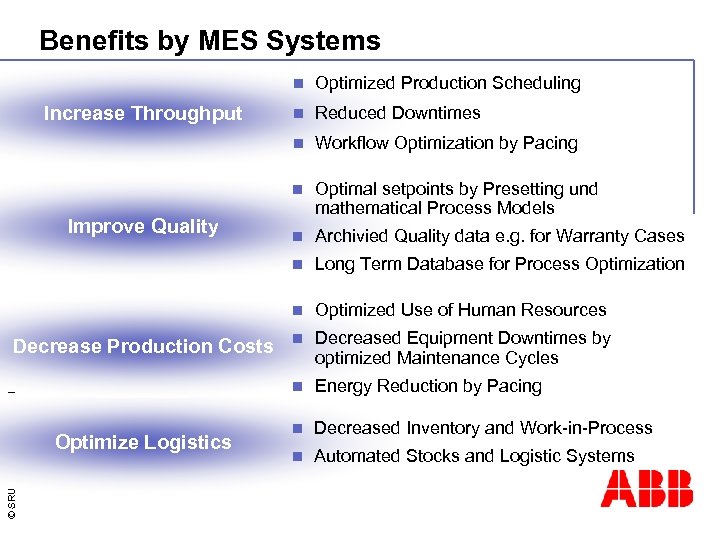

Benefits by MES Systems n © SRU CPM- PRU MES for Metals - 13 Optimal setpoints by Presetting und mathematical Process Models n Archivied Quality data e. g. for Warranty Cases Long Term Database for Process Optimization n Optimized Use of Human Resources n Decreased Equipment Downtimes by optimized Maintenance Cycles n Optimize Logistics Workflow Optimization by Pacing n Decrease Production Costs Reduced Downtimes n Improve Quality n n Increase Throughput Optimized Production Scheduling Energy Reduction by Pacing n Decreased Inventory and Work-in-Process n Automated Stocks and Logistic Systems

Benefits by MES Systems n © SRU CPM- PRU MES for Metals - 13 Optimal setpoints by Presetting und mathematical Process Models n Archivied Quality data e. g. for Warranty Cases Long Term Database for Process Optimization n Optimized Use of Human Resources n Decreased Equipment Downtimes by optimized Maintenance Cycles n Optimize Logistics Workflow Optimization by Pacing n Decrease Production Costs Reduced Downtimes n Improve Quality n n Increase Throughput Optimized Production Scheduling Energy Reduction by Pacing n Decreased Inventory and Work-in-Process n Automated Stocks and Logistic Systems

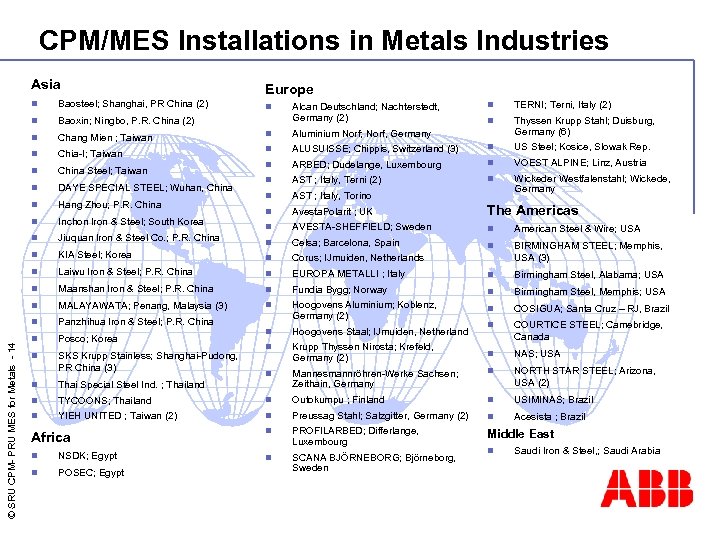

CPM/MES Installations in Metals Industries Asia Europe n Baosteel; Shanghai, PR China (2) n Baoxin; Ningbo, P. R. China (2) n Chang Mien ; Taiwan n Aluminium Norf; Norf, Germany n Chia-I; Taiwan n n China Steel; Taiwan n DAYE SPECIAL STEEL; Wuhan, China n Hang Zhou; P. R. China n Inchon Iron & Steel; South Korea n Jiuquan Iron & Steel Co. ; P. R. China n TERNI; Terni, Italy (2) n Thyssen Krupp Stahl; Duisburg, Germany (6) ALUSUISSE; Chippis, Switzerland (3) n US Steel; Kosice, Slowak Rep. n ARBED; Dudelange, Luxembourg n VOEST ALPINE; Linz, Austria n AST ; Italy, Terni (2) n n AST ; Italy, Torino Wickeder Westfalenstahl; Wickede, Germany n Avesta. Polarit ; UK The Americas n AVESTA-SHEFFIELD; Sweden n American Steel & Wire; USA n Celsa; Barcelona, Spain KIA Steel; Korea n n Corus; IJmuiden, Netherlands BIRMINGHAM STEEL; Memphis, USA (3) n Laiwu Iron & Steel; P. R. China n EUROPA METALLI ; Italy n Birmingham Steel, Alabama; USA n Maanshan Iron & Steel; P. R. China n Fundia Bygg; Norway n Birmingham Steel, Memphis; USA n MALAYAWATA; Penang, Malaysia (3) n COSIGUA; Santa Cruz – RJ, Brazil Panzhihua Iron & Steel; P. R. China Hoogovens Aluminium; Koblenz, Germany (2) n n © SRU CPM- PRU MES for Metals - 14 n Posco; Korea n Hoogovens Staal; IJmuiden, Netherland n n n SKS Krupp Stainless; Shanghai-Pudong, PR China (3) n Krupp Thyssen Nirosta; Krefeld, Germany (2) COURTICE STEEL; Camebridge, Canada n NAS; USA n Thai Special Steel Ind. ; Thailand Mannesmannröhren-Werke Sachsen; Zeithain, Germany n n NORTH STAR STEEL; Arizona, USA (2) n TYCOONS; Thailand n Outokumpu ; Finland n USIMINAS; Brazil n YIEH UNITED ; Taiwan (2) n Preussag Stahl; Salzgitter, Germany (2) n Acesista ; Brazil n PROFILARBED; Differlange, Luxembourg Middle East n SCANA BJÖRNEBORG; Björneborg, Sweden Africa n NSDK; Egypt n POSEC; Egypt n Alcan Deutschland; Nachterstedt, Germany (2) n Saudi Iron & Steel, ; Saudi Arabia

CPM/MES Installations in Metals Industries Asia Europe n Baosteel; Shanghai, PR China (2) n Baoxin; Ningbo, P. R. China (2) n Chang Mien ; Taiwan n Aluminium Norf; Norf, Germany n Chia-I; Taiwan n n China Steel; Taiwan n DAYE SPECIAL STEEL; Wuhan, China n Hang Zhou; P. R. China n Inchon Iron & Steel; South Korea n Jiuquan Iron & Steel Co. ; P. R. China n TERNI; Terni, Italy (2) n Thyssen Krupp Stahl; Duisburg, Germany (6) ALUSUISSE; Chippis, Switzerland (3) n US Steel; Kosice, Slowak Rep. n ARBED; Dudelange, Luxembourg n VOEST ALPINE; Linz, Austria n AST ; Italy, Terni (2) n n AST ; Italy, Torino Wickeder Westfalenstahl; Wickede, Germany n Avesta. Polarit ; UK The Americas n AVESTA-SHEFFIELD; Sweden n American Steel & Wire; USA n Celsa; Barcelona, Spain KIA Steel; Korea n n Corus; IJmuiden, Netherlands BIRMINGHAM STEEL; Memphis, USA (3) n Laiwu Iron & Steel; P. R. China n EUROPA METALLI ; Italy n Birmingham Steel, Alabama; USA n Maanshan Iron & Steel; P. R. China n Fundia Bygg; Norway n Birmingham Steel, Memphis; USA n MALAYAWATA; Penang, Malaysia (3) n COSIGUA; Santa Cruz – RJ, Brazil Panzhihua Iron & Steel; P. R. China Hoogovens Aluminium; Koblenz, Germany (2) n n © SRU CPM- PRU MES for Metals - 14 n Posco; Korea n Hoogovens Staal; IJmuiden, Netherland n n n SKS Krupp Stainless; Shanghai-Pudong, PR China (3) n Krupp Thyssen Nirosta; Krefeld, Germany (2) COURTICE STEEL; Camebridge, Canada n NAS; USA n Thai Special Steel Ind. ; Thailand Mannesmannröhren-Werke Sachsen; Zeithain, Germany n n NORTH STAR STEEL; Arizona, USA (2) n TYCOONS; Thailand n Outokumpu ; Finland n USIMINAS; Brazil n YIEH UNITED ; Taiwan (2) n Preussag Stahl; Salzgitter, Germany (2) n Acesista ; Brazil n PROFILARBED; Differlange, Luxembourg Middle East n SCANA BJÖRNEBORG; Björneborg, Sweden Africa n NSDK; Egypt n POSEC; Egypt n Alcan Deutschland; Nachterstedt, Germany (2) n Saudi Iron & Steel, ; Saudi Arabia

Excerpt Reference List Mills & Processing Lines n n n n n © SRU CPM- PRU MES for Metals - 15 n n n n Hoogovens Aluminium, Koblenz Aluminium Cold Rolling Mill Aluminium Norf Gmb. H 2 -Stand Aluminium Rolling Mill Preussag Stahl AG Blast Furnace B Mannesmann Röhrenwerke Sachsen Tube Rolling Mill Krupp Thyssen Nirosta Cluster Cold Rolling Mill Alusuisse Revamp of a Hot Rolling Mill Alcan Deutschland Gmb. H Continious Annealing and Coating Line Preussag Stahl AG Blast Furnace A Wickeder Westfahlenstahl Gmb. H Six-high CVC Reversing Mill Jiuquan Iron & Steel Co. Plate Mill Hoogovens Stahl BV Temper Mill VSZ U. S. Steel Kosice DCR Mill Alusuisse Revamp of Q 30 Cold Rolling Mill Baosteel Temper Mill Corus IJmuiden DCR Mill Baoxin, Ningbo 2 x 20 -high Reversing Mill Thyssen. Krupp Nirosta 20 -high Reversing Mill = with mathematical model Home

Excerpt Reference List Mills & Processing Lines n n n n n © SRU CPM- PRU MES for Metals - 15 n n n n Hoogovens Aluminium, Koblenz Aluminium Cold Rolling Mill Aluminium Norf Gmb. H 2 -Stand Aluminium Rolling Mill Preussag Stahl AG Blast Furnace B Mannesmann Röhrenwerke Sachsen Tube Rolling Mill Krupp Thyssen Nirosta Cluster Cold Rolling Mill Alusuisse Revamp of a Hot Rolling Mill Alcan Deutschland Gmb. H Continious Annealing and Coating Line Preussag Stahl AG Blast Furnace A Wickeder Westfahlenstahl Gmb. H Six-high CVC Reversing Mill Jiuquan Iron & Steel Co. Plate Mill Hoogovens Stahl BV Temper Mill VSZ U. S. Steel Kosice DCR Mill Alusuisse Revamp of Q 30 Cold Rolling Mill Baosteel Temper Mill Corus IJmuiden DCR Mill Baoxin, Ningbo 2 x 20 -high Reversing Mill Thyssen. Krupp Nirosta 20 -high Reversing Mill = with mathematical model Home

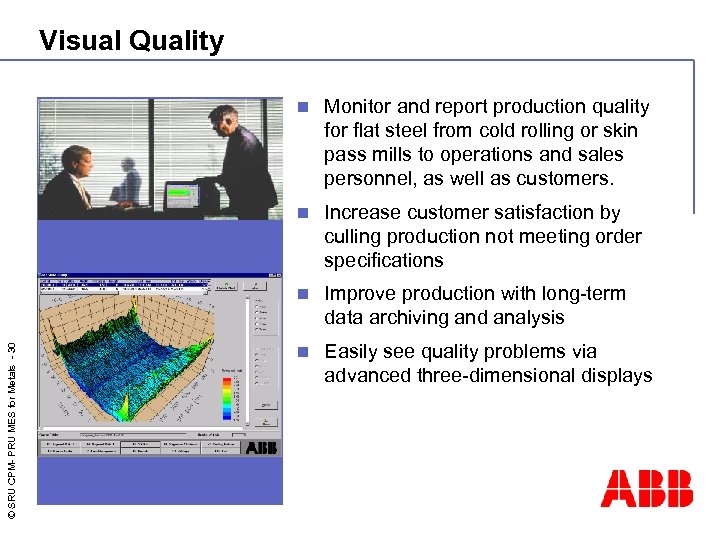

Visual Quality Monitor and report production quality for flat steel from cold rolling or skin pass mills to operations and sales personnel, as well as customers. n Increase customer satisfaction by culling production not meeting order specifications n © SRU CPM- PRU MES for Metals - 30 n Improve production with long-term data archiving and analysis n Easily see quality problems via advanced three-dimensional displays

Visual Quality Monitor and report production quality for flat steel from cold rolling or skin pass mills to operations and sales personnel, as well as customers. n Increase customer satisfaction by culling production not meeting order specifications n © SRU CPM- PRU MES for Metals - 30 n Improve production with long-term data archiving and analysis n Easily see quality problems via advanced three-dimensional displays