80d5848ec1879d66c97bded9c60e22b2.ppt

- Количество слайдов: 19

Sprut. CAM overview Contents

Sprut. CAM overview Contents

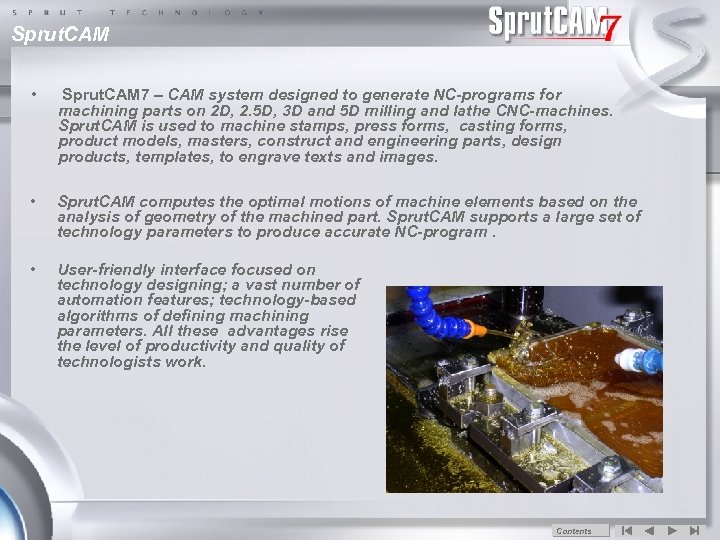

Sprut. CAM • Sprut. CAM 7 – CAM system designed to generate NC-programs for machining parts on 2 D, 2. 5 D, 3 D and 5 D milling and lathe CNC-machines. Sprut. CAM is used to machine stamps, press forms, casting forms, product models, masters, construct and engineering parts, design products, templates, to engrave texts and images. • Sprut. CAM computes the optimal motions of machine elements based on the analysis of geometry of the machined part. Sprut. CAM supports a large set of technology parameters to produce accurate NC-program. • User-friendly interface focused on technology designing; a vast number of automation features; technology-based algorithms of defining machining parameters. All these advantages rise the level of productivity and quality of technologists work. Contents

Sprut. CAM • Sprut. CAM 7 – CAM system designed to generate NC-programs for machining parts on 2 D, 2. 5 D, 3 D and 5 D milling and lathe CNC-machines. Sprut. CAM is used to machine stamps, press forms, casting forms, product models, masters, construct and engineering parts, design products, templates, to engrave texts and images. • Sprut. CAM computes the optimal motions of machine elements based on the analysis of geometry of the machined part. Sprut. CAM supports a large set of technology parameters to produce accurate NC-program. • User-friendly interface focused on technology designing; a vast number of automation features; technology-based algorithms of defining machining parameters. All these advantages rise the level of productivity and quality of technologists work. Contents

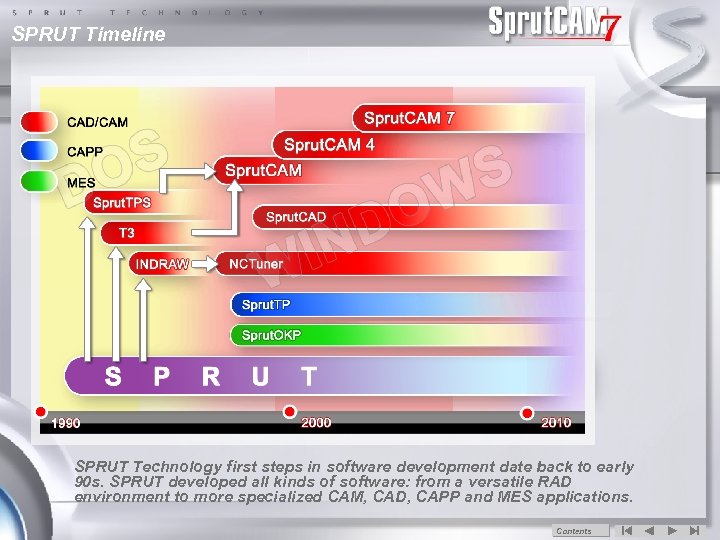

SPRUT Timeline SPRUT Technology first steps in software development date back to early 90 s. SPRUT developed all kinds of software: from a versatile RAD environment to more specialized CAM, CAD, CAPP and MES applications. Contents

SPRUT Timeline SPRUT Technology first steps in software development date back to early 90 s. SPRUT developed all kinds of software: from a versatile RAD environment to more specialized CAM, CAD, CAPP and MES applications. Contents

Collective, specialists Sprut Technology collective includes software developers, software support specialists and sales managers. Sprut Technology has two offices: • Headquarters, Naberezhnye Chelny • Moscow office, Moscow, Bauman MSTU Naberezhnye Chelny Moscow, MSTU Contents

Collective, specialists Sprut Technology collective includes software developers, software support specialists and sales managers. Sprut Technology has two offices: • Headquarters, Naberezhnye Chelny • Moscow office, Moscow, Bauman MSTU Naberezhnye Chelny Moscow, MSTU Contents

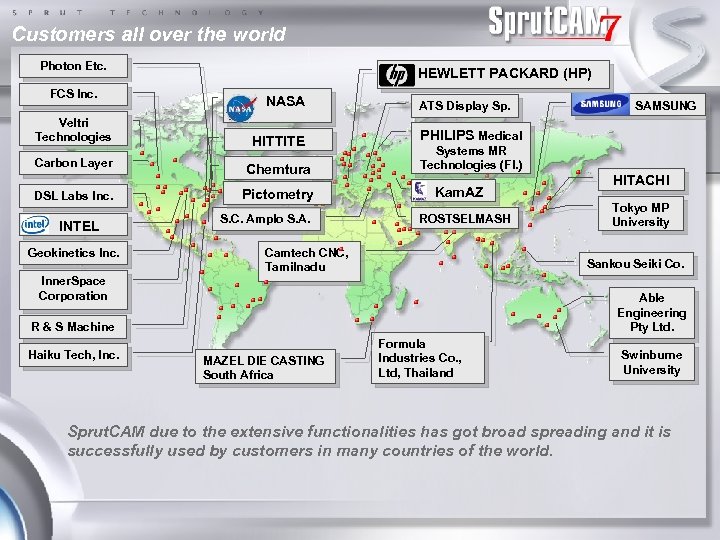

Customers all over the world Photon Etc. FCS Inc. Veltri Technologies HEWLETT PACKARD (HP) NASA HITTITE Carbon Layer Chemtura DSL Labs Inc. Pictometry INTEL Geokinetics Inc. S. C. Amplo S. A. ATS Display Sp. PHILIPS Medical Systems MR Technologies (Fl. ) Kam. AZ ROSTSELMASH Camtech CNC, Tamilnadu HITACHI Tokyo MP University Sankou Seiki Co. Inner. Space Corporation Able Engineering Pty Ltd. R & S Machine Haiku Tech, Inc. SAMSUNG MAZEL DIE CASTING South Africa Formula Industries Co. , Ltd, Thailand Swinburne University Sprut. CAM due to the extensive functionalities has got broad spreading and it is successfully used by customers in many countries of the world.

Customers all over the world Photon Etc. FCS Inc. Veltri Technologies HEWLETT PACKARD (HP) NASA HITTITE Carbon Layer Chemtura DSL Labs Inc. Pictometry INTEL Geokinetics Inc. S. C. Amplo S. A. ATS Display Sp. PHILIPS Medical Systems MR Technologies (Fl. ) Kam. AZ ROSTSELMASH Camtech CNC, Tamilnadu HITACHI Tokyo MP University Sankou Seiki Co. Inner. Space Corporation Able Engineering Pty Ltd. R & S Machine Haiku Tech, Inc. SAMSUNG MAZEL DIE CASTING South Africa Formula Industries Co. , Ltd, Thailand Swinburne University Sprut. CAM due to the extensive functionalities has got broad spreading and it is successfully used by customers in many countries of the world.

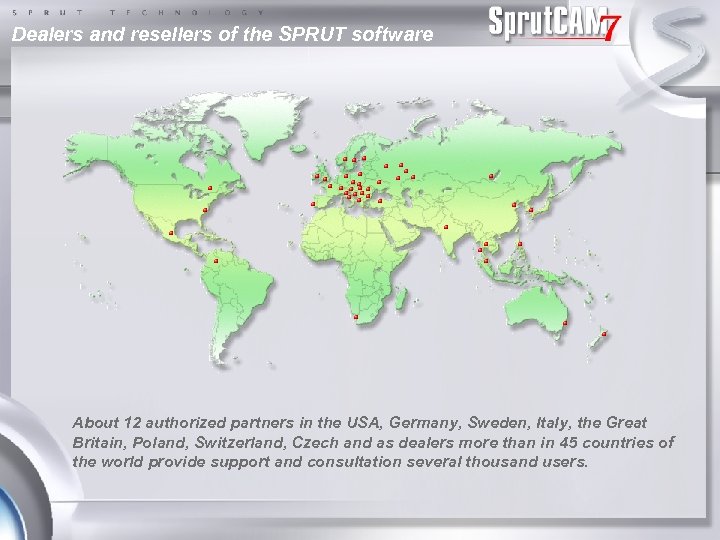

Dealers and resellers of the SPRUT software About 12 authorized partners in the USA, Germany, Sweden, Italy, the Great Britain, Poland, Switzerland, Czech and as dealers more than in 45 countries of the world provide support and consultation several thousand users.

Dealers and resellers of the SPRUT software About 12 authorized partners in the USA, Germany, Sweden, Italy, the Great Britain, Poland, Switzerland, Czech and as dealers more than in 45 countries of the world provide support and consultation several thousand users.

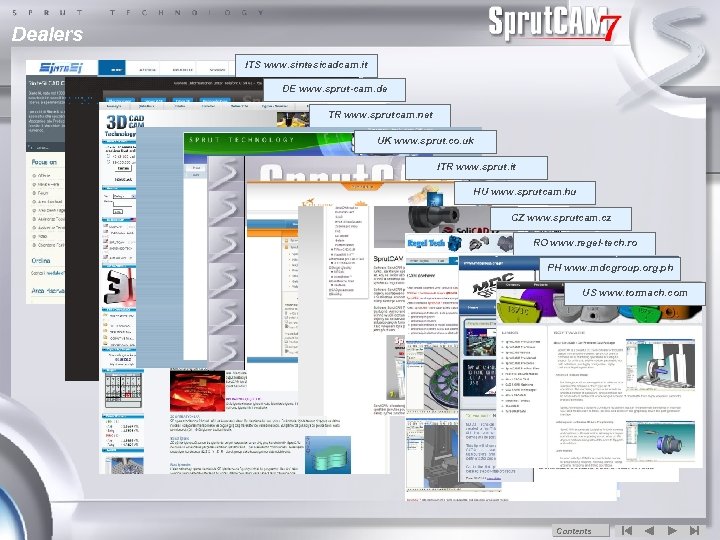

Dealers ITS www. sintesicadcam. it DE www. sprut-cam. de TR www. sprutcam. net UK www. sprut. co. uk ITR www. sprut. it HU www. sprutcam. hu CZ www. sprutcam. cz RO www. regel-tech. ro PH www. mdcgroup. org. ph US www. tormach. com Contents

Dealers ITS www. sintesicadcam. it DE www. sprut-cam. de TR www. sprutcam. net UK www. sprut. co. uk ITR www. sprut. it HU www. sprutcam. hu CZ www. sprutcam. cz RO www. regel-tech. ro PH www. mdcgroup. org. ph US www. tormach. com Contents

Sprut. CAM popularity wordwide Number of visits to Sprutcam. com over the last half-year. Legend: Dot sizes: = 1, 000+ = 100 - 999 = 10 - 99 = 1 - 9 visits Contents

Sprut. CAM popularity wordwide Number of visits to Sprutcam. com over the last half-year. Legend: Dot sizes: = 1, 000+ = 100 - 999 = 10 - 99 = 1 - 9 visits Contents

Development team • The core of developer team consists of well-educated and highly-skilled software designers • Over 20 ears of CAD/CAM software development experience • Most modern technologies are utilized to produce high quality software including: – Agile • • Source Code Management system Continuous Integration Automated Testing Bug Tracking System Contents

Development team • The core of developer team consists of well-educated and highly-skilled software designers • Over 20 ears of CAD/CAM software development experience • Most modern technologies are utilized to produce high quality software including: – Agile • • Source Code Management system Continuous Integration Automated Testing Bug Tracking System Contents

Support team • Experienced specialists – – • Successful live manufacture application of software Software training experience online support E-mail support Dealer support – Top-priority service – online training and consulting • Help. Desc - direct user support • Service Desk Contents

Support team • Experienced specialists – – • Successful live manufacture application of software Software training experience online support E-mail support Dealer support – Top-priority service – online training and consulting • Help. Desc - direct user support • Service Desk Contents

SPRUT Technology partners SPRUT Technology is partner of software and computer manufacturers: § Microsoft § Intel SPRUT Technology is partner of machine manufacturers: Contents

SPRUT Technology partners SPRUT Technology is partner of software and computer manufacturers: § Microsoft § Intel SPRUT Technology is partner of machine manufacturers: Contents

CAD systems integration SPRUT Technology is partner of leading CAD/CAM/CAE software developers. Close integration with numerous software solutions allows combined work of different applications which greatelly increases each system productivity. • • Alibre Design Cobalt Autodesk Auto. CAD, Inventor KOMPAS-3 D, KOMPAS-LT Rhinoceros Solid. Edge Solid. Works T-Flex CAD Contents

CAD systems integration SPRUT Technology is partner of leading CAD/CAM/CAE software developers. Close integration with numerous software solutions allows combined work of different applications which greatelly increases each system productivity. • • Alibre Design Cobalt Autodesk Auto. CAD, Inventor KOMPAS-3 D, KOMPAS-LT Rhinoceros Solid. Edge Solid. Works T-Flex CAD Contents

Sprut. CAM system application Technology of die punch machining Die punch Injection molding product Die mold Contents

Sprut. CAM system application Technology of die punch machining Die punch Injection molding product Die mold Contents

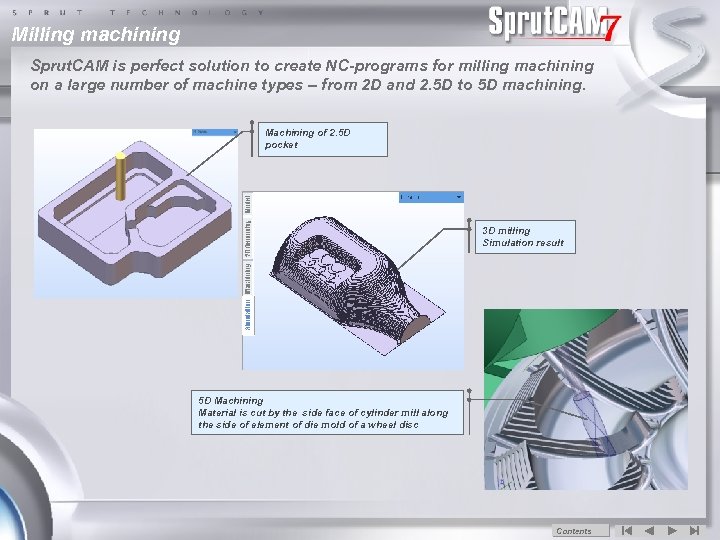

Milling machining Sprut. CAM is perfect solution to create NC-programs for milling machining on a large number of machine types – from 2 D and 2. 5 D to 5 D machining. Machining of 2. 5 D pocket 3 D milling Simulation result 5 D Machining Material is cut by the side face of cylinder mill along the side of element of die mold of a wheel disc Contents

Milling machining Sprut. CAM is perfect solution to create NC-programs for milling machining on a large number of machine types – from 2 D and 2. 5 D to 5 D machining. Machining of 2. 5 D pocket 3 D milling Simulation result 5 D Machining Material is cut by the side face of cylinder mill along the side of element of die mold of a wheel disc Contents

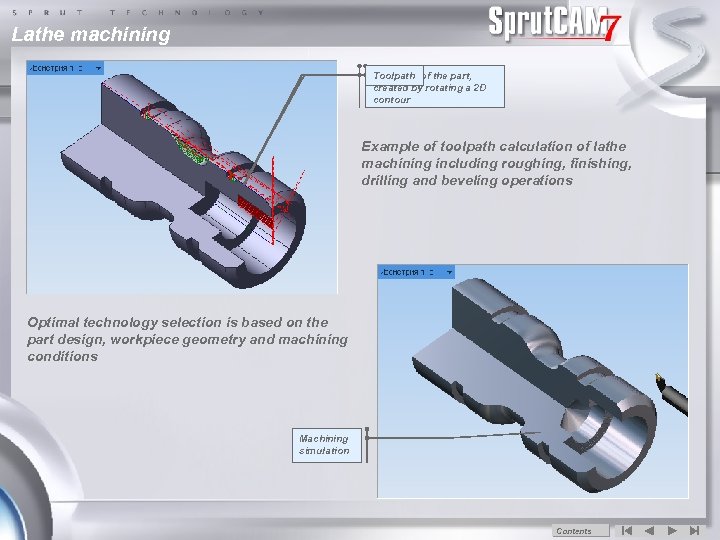

Lathe machining Toolpath 3 D model of the part, Part and Workpiece created by rotating a 2 D contours contour Example of toolpath calculation of lathe machining including roughing, finishing, drilling and beveling operations Optimal technology selection is based on the part design, workpiece geometry and machining conditions Machining simulation Contents

Lathe machining Toolpath 3 D model of the part, Part and Workpiece created by rotating a 2 D contours contour Example of toolpath calculation of lathe machining including roughing, finishing, drilling and beveling operations Optimal technology selection is based on the part design, workpiece geometry and machining conditions Machining simulation Contents

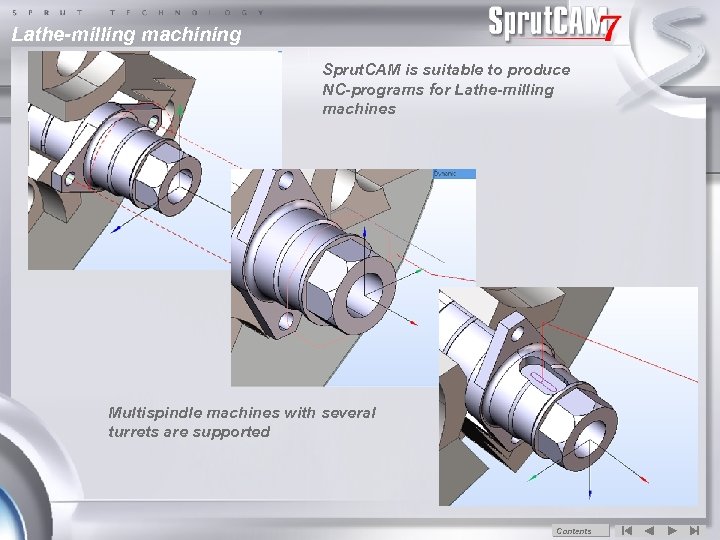

Lathe-milling machining Sprut. CAM is suitable to produce NC-programs for Lathe-milling machines Multispindle machines with several turrets are supported Contents

Lathe-milling machining Sprut. CAM is suitable to produce NC-programs for Lathe-milling machines Multispindle machines with several turrets are supported Contents

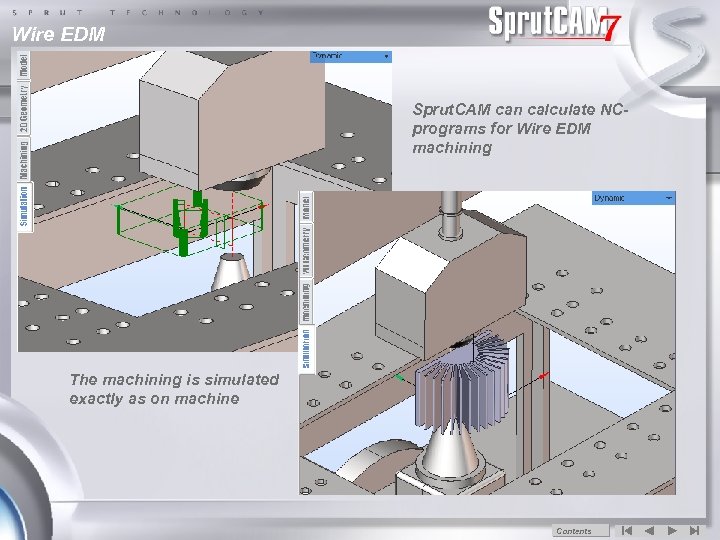

Wire EDM Sprut. CAM can calculate NCprograms for Wire EDM machining The machining is simulated exactly as on machine Contents

Wire EDM Sprut. CAM can calculate NCprograms for Wire EDM machining The machining is simulated exactly as on machine Contents

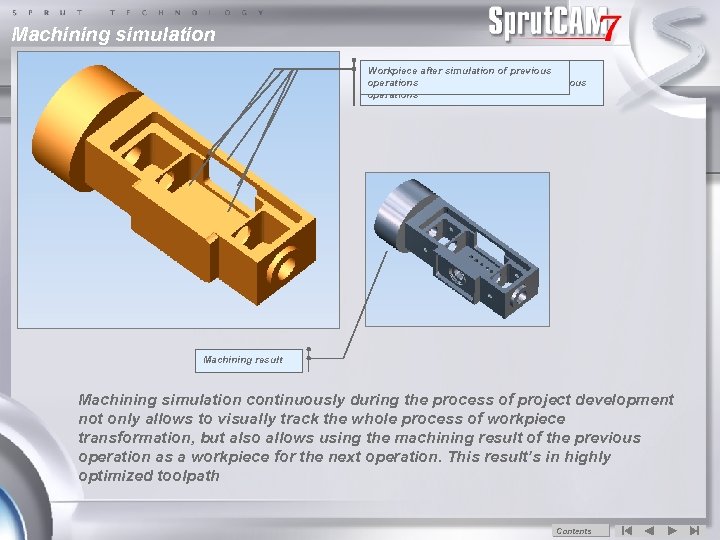

Machining simulation Workpiece after simulation of previous Initial workpiece for lathe-milling Obtained workpiece after the pocketing Toolpath of the pocketing operation with Workpiece for the next operation Toolpath calculated for the part regarding the operations machining operation for the next machining workpiece as the machining result of previous machining operations Machining result Machining simulation continuously during the process of project development not only allows to visually track the whole process of workpiece transformation, but also allows using the machining result of the previous operation as a workpiece for the next operation. This result’s in highly optimized toolpath Contents

Machining simulation Workpiece after simulation of previous Initial workpiece for lathe-milling Obtained workpiece after the pocketing Toolpath of the pocketing operation with Workpiece for the next operation Toolpath calculated for the part regarding the operations machining operation for the next machining workpiece as the machining result of previous machining operations Machining result Machining simulation continuously during the process of project development not only allows to visually track the whole process of workpiece transformation, but also allows using the machining result of the previous operation as a workpiece for the next operation. This result’s in highly optimized toolpath Contents

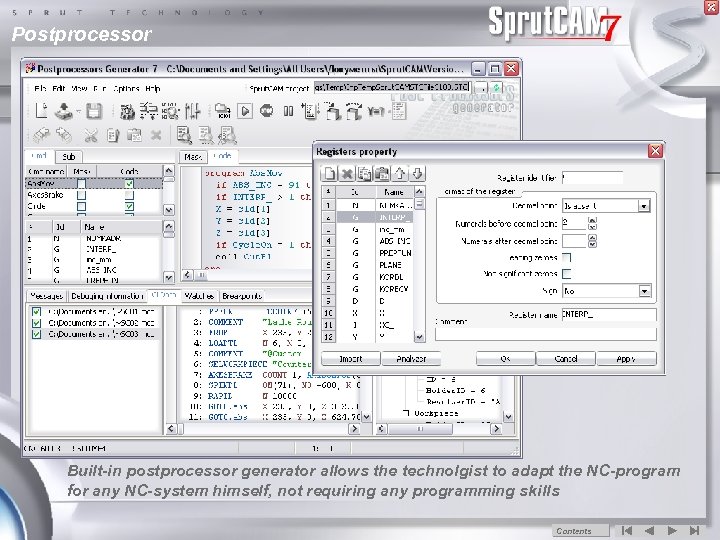

Postprocessor Built-in postprocessor generator allows the technolgist to adapt the NC-program for any NC-system himself, not requiring any programming skills Contents

Postprocessor Built-in postprocessor generator allows the technolgist to adapt the NC-program for any NC-system himself, not requiring any programming skills Contents