fb3f8f8519a6f2ed1be7125027a3de47.ppt

- Количество слайдов: 40

Speed Cooking Technologies • Jet-Impingement – Technical Background – Companies Involved in JIM Ovens – JIM Ovens • Turbo. Chef 1

Technical Background • • • Technical Terms Hot Air Impinging on Food Applications and Advantages Temperature Profile Nusselt Number vs. Reynolds Number 2

Technical Terms • Jet impingement technology Technology in which jets of gas or liquid are made to impinge on a desired product for faster heat transfer or faster chemical reactions • Jet impingement oven Device used for baking and drying of food materials using jets of hot air at velocities (20 -40 m/s) to impinge on the product • Jet-impingement Microwave (JIM) Ovens operated in jet-impingement mode and microwave mode either individually or in combination. 3

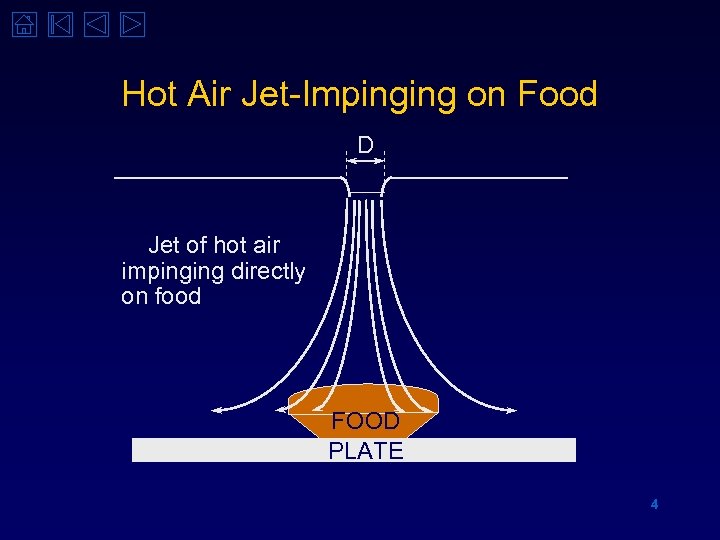

Hot Air Jet-Impinging on Food D Jet of hot air impinging directly on food FOOD PLATE 4

Applications and Advantages • Applications – Baking for pizza shells, crackers, matzo, cookies – Toasting for ready-to-eat cereals – Roasting for coffee beans • Advantages Over Other Technologies – – Efficient heat transfer Energy efficient Uniform heating Better moisture retention in food 5

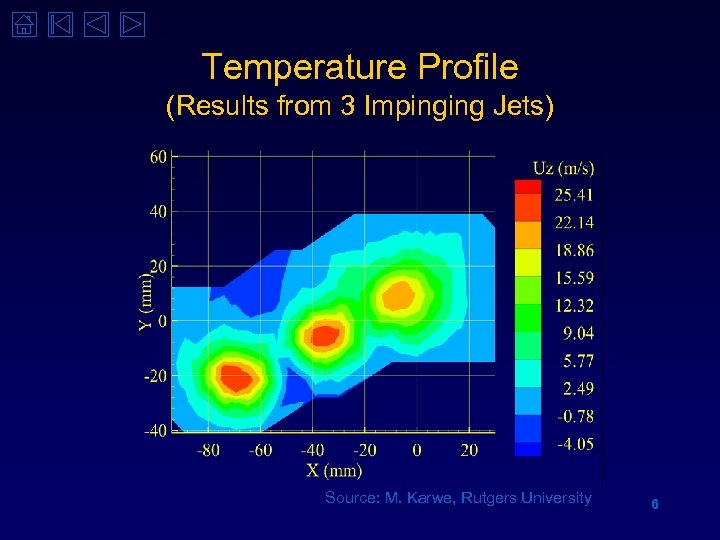

Temperature Profile (Results from 3 Impinging Jets) Source: M. Karwe, Rutgers University 6

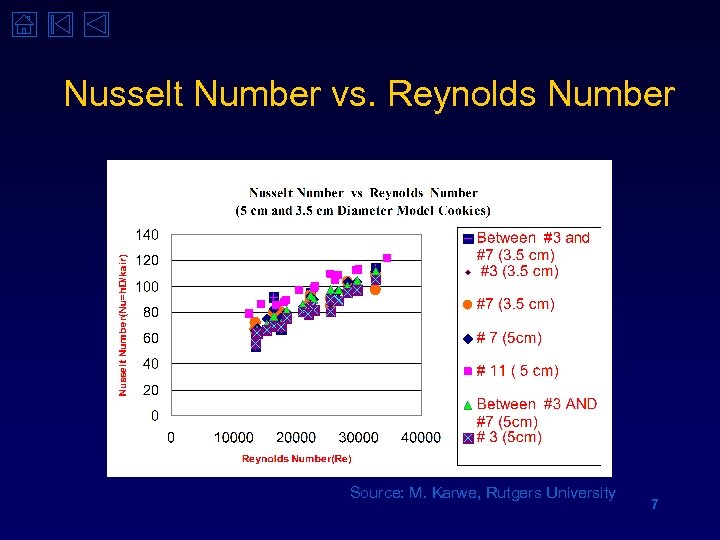

Nusselt Number vs. Reynolds Number Source: M. Karwe, Rutgers University 7

Companies Involved in JIM Ovens • • Enersyst Development Center KRh Thermal Systems Thermador Fujimak Incorporated 8

JIM Ovens • Enersyst Development Center – Enersyst Prototype JIM Oven • KRh Thermal Systems – KRh JIM Ovens – Hot Choice Systems • Thermador – Thermador JIM Oven • Fujimak Incorporated – Fujimak JIM Oven 9

Enersyst Development Center • A research and development company whose main business is to develop and license its flagship jetimpingement technology • Licensees – KRh Thermal Systems – Thermador – A&W Restaurants • Acquired by Moseley Corporation as an independently operated subsidiary in late 1999 10

Moseley Corporation • Parent company of Enersyst Development Center • A full service provider of merchandising solutions and consulting services for leading international corporations and emerging entrepreneurs in the food and beverage industry • Located at Franklin, Massachusetts • Appears to be a small private company (limited information available in the Internet) • http: //www. moseleycorp. com/ 11

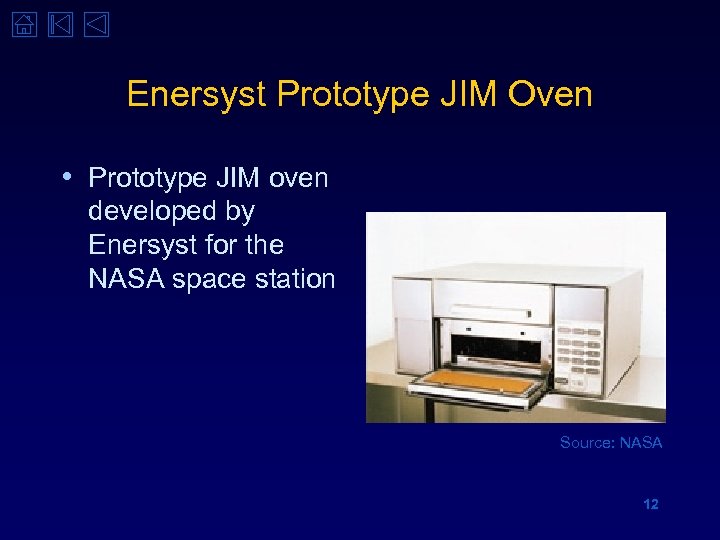

Enersyst Prototype JIM Oven • Prototype JIM oven developed by Enersyst for the NASA space station Source: NASA 12

KRh Thermal Systems • Major Products – KRh Thermal Systems JIM Ovens – Hot Choice System • Company Profile – A limited liability company managed by Kaiser Aerospace and Electronics and Thermal. Tech Development Inc. – Located at Irvine, California – http: //www. krhthermal. com/ 13

Kaiser Aerospace and Electronics • A U. S. defense contractor • About 1200 employees and $226 million annual sales • A partner of KRh Thermal Systems • http: //www. kaiseraerospace. com/ 14

Thermal. Tech Development Inc. • A marketing and development company for KRh Thermal Systems • Directed by a consortium of business leaders, including a number of executives from Fortune 500 companies • Appears to be a very small company with just a few employees 15

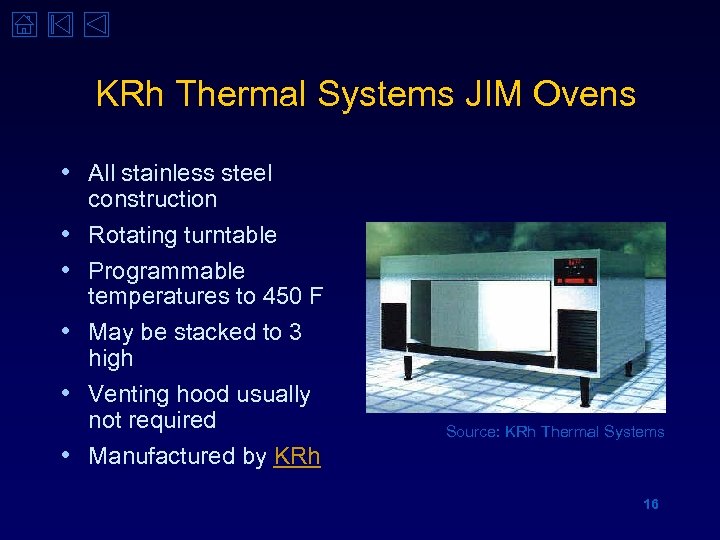

KRh Thermal Systems JIM Ovens • All stainless steel • • • construction Rotating turntable Programmable temperatures to 450 F May be stacked to 3 high Venting hood usually not required Manufactured by KRh Source: KRh Thermal Systems 16

Hot Choice System A food service system marketed by KRh Systems 17

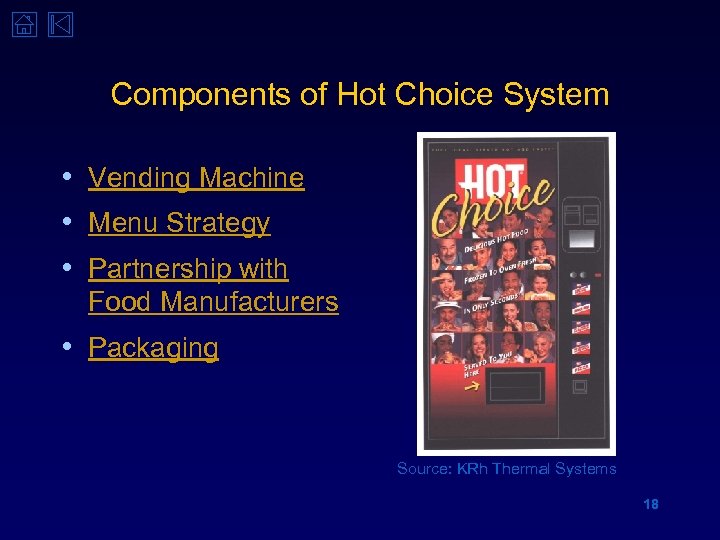

Components of Hot Choice System • Vending Machine • Menu Strategy • Partnership with Food Manufacturers • Packaging Source: KRh Thermal Systems 18

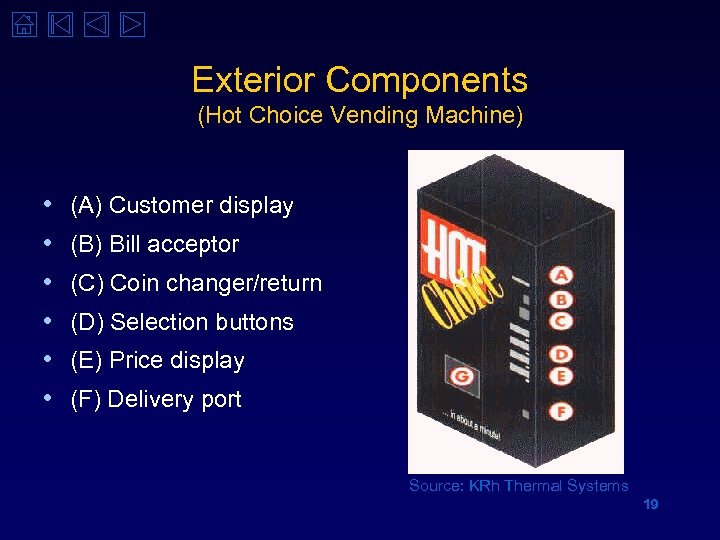

Exterior Components (Hot Choice Vending Machine) • • • (A) Customer display (B) Bill acceptor (C) Coin changer/return (D) Selection buttons (E) Price display (F) Delivery port Source: KRh Thermal Systems 19

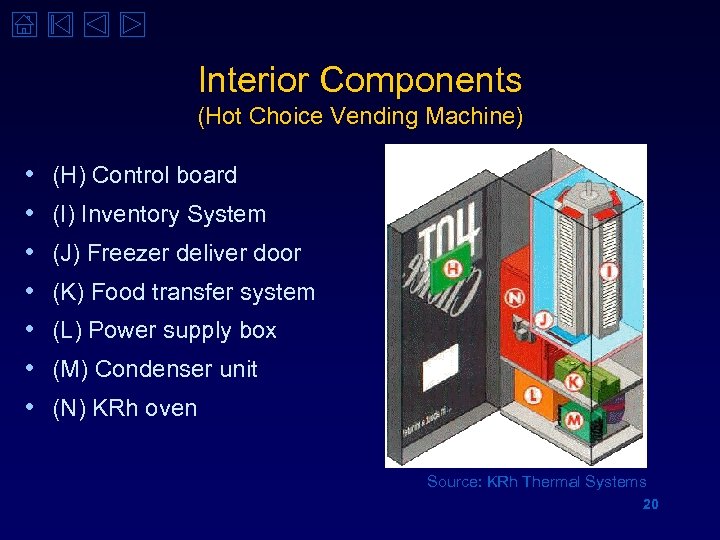

Interior Components (Hot Choice Vending Machine) • • (H) Control board (I) Inventory System (J) Freezer deliver door (K) Food transfer system (L) Power supply box (M) Condenser unit (N) KRh oven Source: KRh Thermal Systems 20

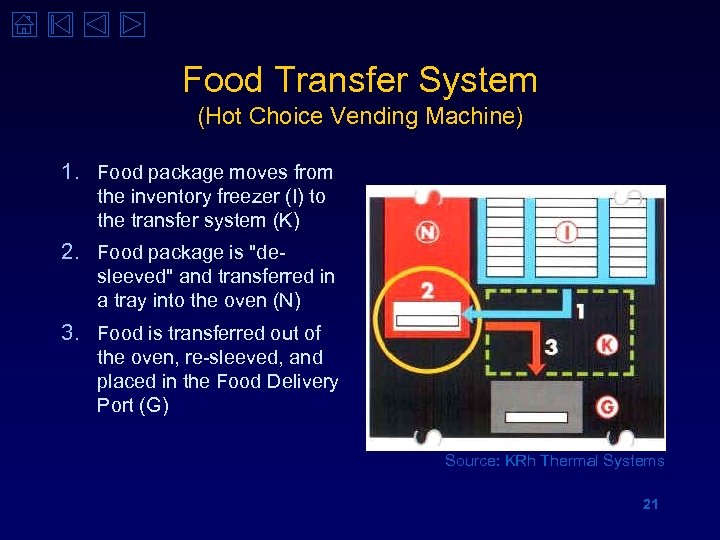

Food Transfer System (Hot Choice Vending Machine) 1. Food package moves from the inventory freezer (I) to the transfer system (K) 2. Food package is "desleeved" and transferred in a tray into the oven (N) 3. Food is transferred out of the oven, re-sleeved, and placed in the Food Delivery Port (G) Source: KRh Thermal Systems 21

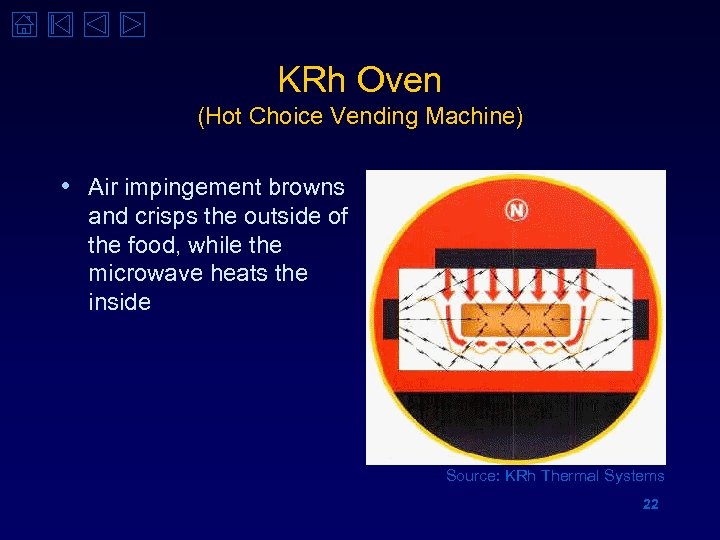

KRh Oven (Hot Choice Vending Machine) • Air impingement browns and crisps the outside of the food, while the microwave heats the inside Source: KRh Thermal Systems 22

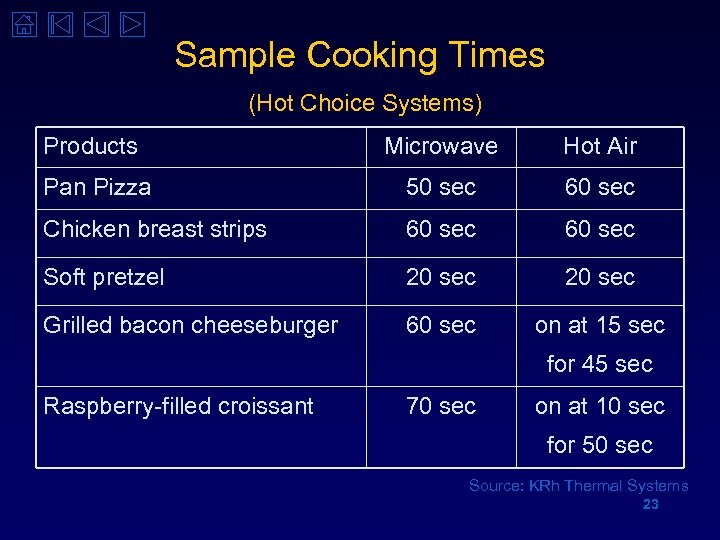

Sample Cooking Times (Hot Choice Systems) Products Microwave Hot Air Pan Pizza 50 sec 60 sec Chicken breast strips 60 sec Soft pretzel 20 sec Grilled bacon cheeseburger 60 sec on at 15 sec for 45 sec Raspberry-filled croissant 70 sec on at 10 sec for 50 sec Source: KRh Thermal Systems 23

Menu Strategy (Hot Choice Systems) • • Breakfast Lunch/Light Meals Snacks Selection Factors – High perceived value – Excellent quality – Board based consumer appeal 24

Breakfast Hot Choice Systems • Egg and sausage sandwich • Raspberry croissant • Breakfast pocket and potato stix Source: KRh Thermal Systems 25

Lunch and Light Meals Hot Choice Systems • Deluxe pan pizza • Golden chicken strip • Smoked turkey and chicken calzone • Grilled bacon cheeseburger • Grilled chicken sandwich Source: KRh Thermal Systems 26

Snacks Hot Choice Systems • Crinkle cut fries • Soft pretzel Source: KRh Thermal Systems 27

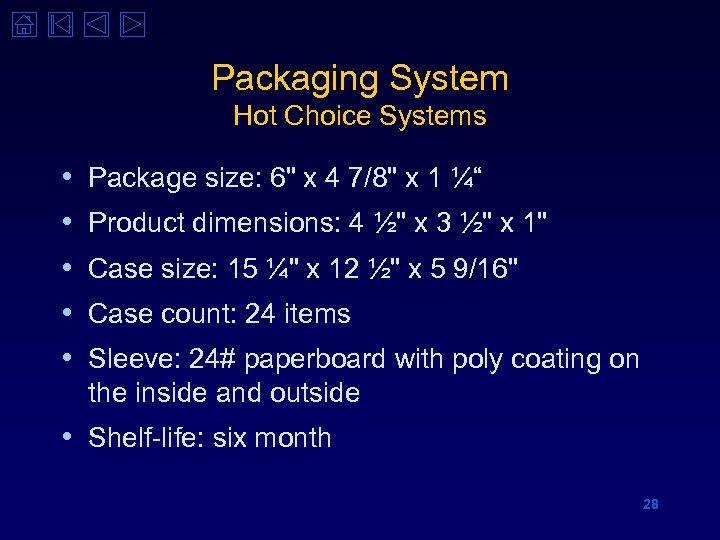

Packaging System Hot Choice Systems • • • Package size: 6" x 4 7/8" x 1 ¼“ Product dimensions: 4 ½" x 3 ½" x 1" Case size: 15 ¼" x 12 ½" x 5 9/16" Case count: 24 items Sleeve: 24# paperboard with poly coating on the inside and outside • Shelf-life: six month 28

Food Manufacturers of Hot Choice • • • J. R. Simplot Company Michael Angelo's Cousins' Foods Buddy's Kitchens Brakebush Brothers – Http: //www. brakebush. com/ 29

J. R. Simplot Company • One of Hot Choice Systems’ food manufacturer partners • Annual revenues are approximately $2. 8 billion, derived principally from food processing, fertilizer manufacturing, agriculture, and related businesses. • Major food products: potatoes, vegetables and fruits • http: //www. simplot. com/ 30

Thermador • Company Profile • Thermador JIM Oven • http: //www. thermador. com/home. cfm 31

Thermador JIM Oven • Marketed as CJ Oven by Thermador • Features – 30” wide – 700 watt built-in microwave – Cook. Smart™ automatically converts the time and temperature of recipes • CJ Oven versus Normal Oven Source: Thermador 32

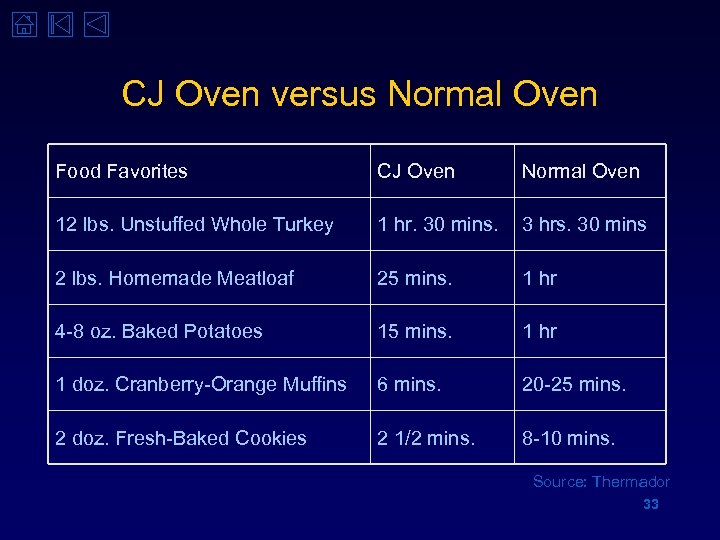

CJ Oven versus Normal Oven Food Favorites CJ Oven Normal Oven 12 lbs. Unstuffed Whole Turkey 1 hr. 30 mins. 3 hrs. 30 mins 2 lbs. Homemade Meatloaf 25 mins. 1 hr 4 -8 oz. Baked Potatoes 15 mins. 1 hr 1 doz. Cranberry-Orange Muffins 6 mins. 20 -25 mins. 2 doz. Fresh-Baked Cookies 2 1/2 mins. 8 -10 mins. Source: Thermador 33

Fujimak Incorporated • Company Profile – Kitchen cooking equipment manufacturer – Established in 1950 – Located in Toyo, Japan – 2 factories, about 1000 employees • Fujimak JIM Oven • http: //www. fujimak. co. jp/en/ 34

Fujimak JIM Oven • Marketed as “Super Jet Heating System” by Fujimak • Width 570 mm length 625 mm height 540 mm • 6 KW power Source: Fujimak 35

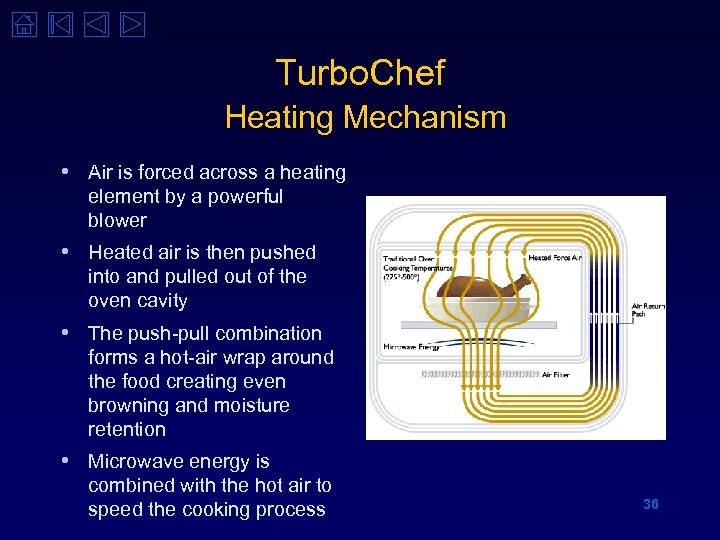

Turbo. Chef Heating Mechanism • Air is forced across a heating element by a powerful blower • Heated air is then pushed into and pulled out of the oven cavity • The push-pull combination forms a hot-air wrap around the food creating even browning and moisture retention • Microwave energy is combined with the hot air to speed the cooking process 36

Turbo. Chef Jenn-Air Accellis 5 XP • Assistant Jenn-Air Brand Manager Gareth Morgan shows off the new Jenn-Air Accellis 5 XP wall oven. The oven, the first to feature Maytag's exclusive "rapid cook" technology, can cook a three-pound chicken in under 20 minutes. (AP) 37

Turbo. Chef Intelligent Cooking Feature • Employs proprietary hardware and software technologies to "cook-to-order" a variety of foods very rapidly • Use a microprocessor to control the cooking processes to ensure consistent quality and also has the ability to communicate with users and service personnel over computer networks and the Internet 38

Turbo. Chef Company Profile • Design, develop, assemble and market highspeed commercial cooking systems for foodservice industry • Strategic alliance with Maytag • Located in Dallas, Texas • 50 employees 39

Turbo. Chef Financial Summary • Nasd aq symbol: TRBO • For the nine months ended 9/30/00, revenues increased 52% to $5. 4 million. Net loss increased 1% to $7. 4 million. Results reflect an increase in research and development revenues pursuant to the commercial license agreement with Maytag, offset by increased marketing expenses associated with the Company's new C-3 counter top 40

fb3f8f8519a6f2ed1be7125027a3de47.ppt