fff5c2bc946fc13502a21517b19fec6d.ppt

- Количество слайдов: 38

Spectroscopic Surface Analysis and Cleaning Verification with Spot. View® Systems

Spectroscopic Surface Analysis and Cleaning Verification with Spot. View® Systems

Overview © Remspec Corp. 2014

Overview © Remspec Corp. 2014

Spot. View® and Spot. View-SL Easy-to-use, portable system. Robust, transferable calibration. Realtime, in-situ detection and quantitation down to microgram levels. CFR 21/Part 11 compliant software. © Remspec Corp. 2014

Spot. View® and Spot. View-SL Easy-to-use, portable system. Robust, transferable calibration. Realtime, in-situ detection and quantitation down to microgram levels. CFR 21/Part 11 compliant software. © Remspec Corp. 2014

FTIR Spectroscopy • FTIR in the mid-IR range is the most sensitive optical measurement technique – extinction coefficients are larger than either in the NIR or the UV-visible range. • Almost all organic compounds, including oils, lubricants, and cleaning agents have distinctive mid-IR spectra. © Remspec Corp. 2014

FTIR Spectroscopy • FTIR in the mid-IR range is the most sensitive optical measurement technique – extinction coefficients are larger than either in the NIR or the UV-visible range. • Almost all organic compounds, including oils, lubricants, and cleaning agents have distinctive mid-IR spectra. © Remspec Corp. 2014

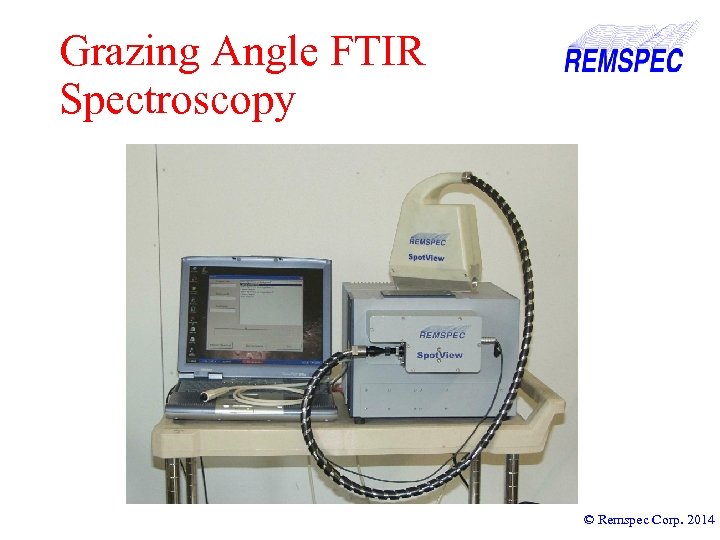

Grazing Angle FTIR Spectroscopy © Remspec Corp. 2014

Grazing Angle FTIR Spectroscopy © Remspec Corp. 2014

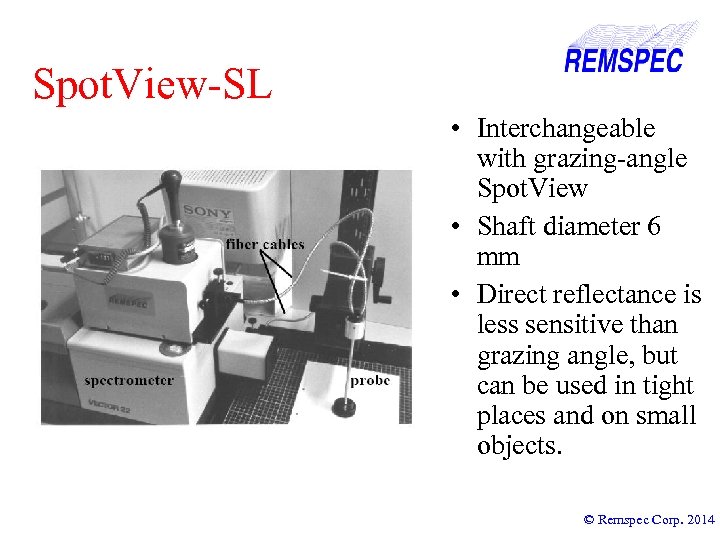

Spot. View-SL • Interchangeable with grazing-angle Spot. View • Shaft diameter 6 mm • Direct reflectance is less sensitive than grazing angle, but can be used in tight places and on small objects. © Remspec Corp. 2014

Spot. View-SL • Interchangeable with grazing-angle Spot. View • Shaft diameter 6 mm • Direct reflectance is less sensitive than grazing angle, but can be used in tight places and on small objects. © Remspec Corp. 2014

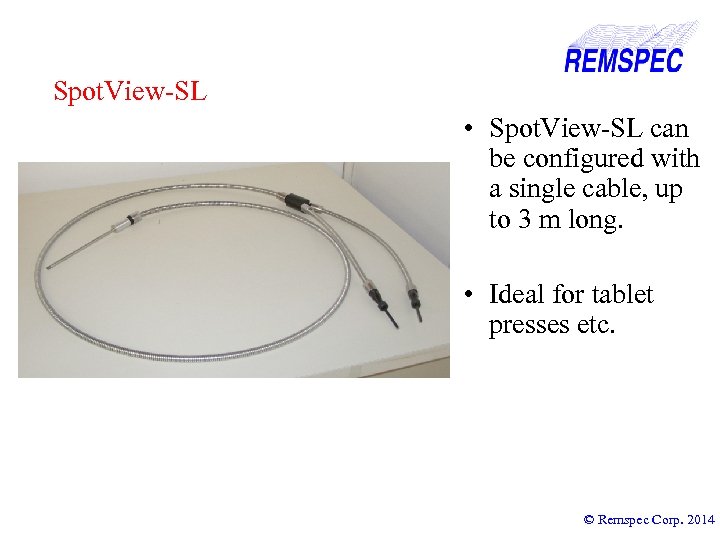

Spot. View-SL • Spot. View-SL can be configured with a single cable, up to 3 m long. • Ideal for tablet presses etc. © Remspec Corp. 2014

Spot. View-SL • Spot. View-SL can be configured with a single cable, up to 3 m long. • Ideal for tablet presses etc. © Remspec Corp. 2014

Spot. View-SL © Remspec Corp. 2014

Spot. View-SL © Remspec Corp. 2014

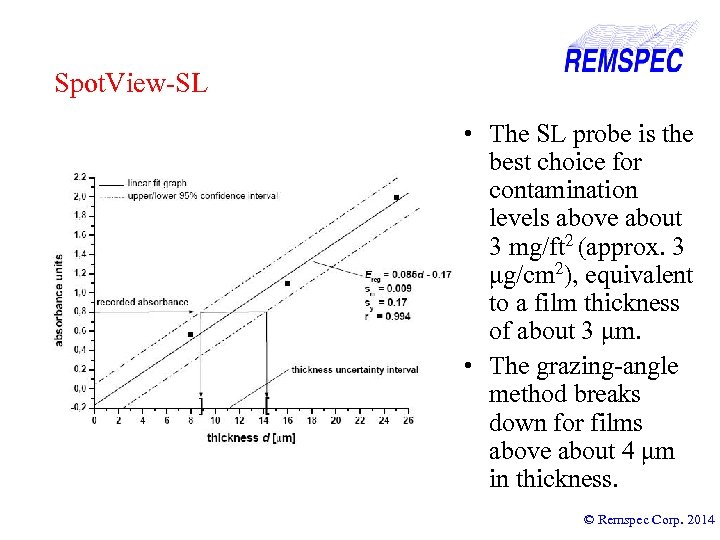

Spot. View-SL • The SL probe is the best choice for contamination levels above about 3 mg/ft 2 (approx. 3 μg/cm 2), equivalent to a film thickness of about 3 μm. • The grazing-angle method breaks down for films above about 4 μm in thickness. © Remspec Corp. 2014

Spot. View-SL • The SL probe is the best choice for contamination levels above about 3 mg/ft 2 (approx. 3 μg/cm 2), equivalent to a film thickness of about 3 μm. • The grazing-angle method breaks down for films above about 4 μm in thickness. © Remspec Corp. 2014

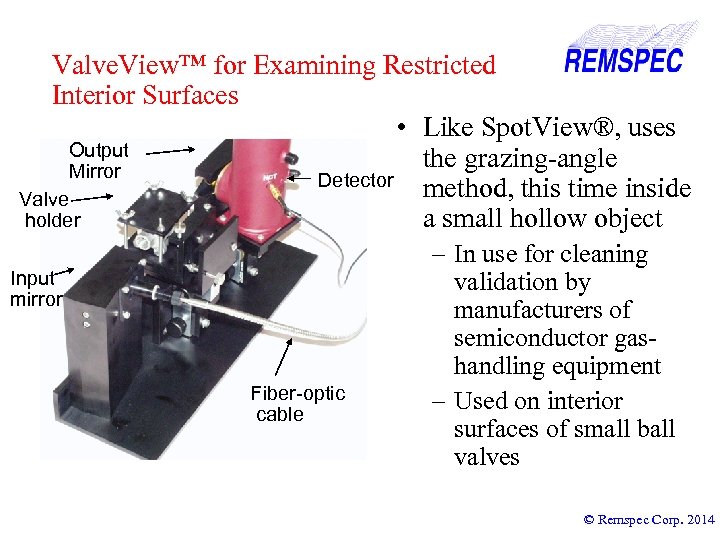

Valve. View™ for Examining Restricted Interior Surfaces • Like Spot. View®, uses Output the grazing-angle Mirror Detector method, this time inside Valve holder a small hollow object Input mirror Fiber-optic cable – In use for cleaning validation by manufacturers of semiconductor gashandling equipment – Used on interior surfaces of small ball valves © Remspec Corp. 2014

Valve. View™ for Examining Restricted Interior Surfaces • Like Spot. View®, uses Output the grazing-angle Mirror Detector method, this time inside Valve holder a small hollow object Input mirror Fiber-optic cable – In use for cleaning validation by manufacturers of semiconductor gashandling equipment – Used on interior surfaces of small ball valves © Remspec Corp. 2014

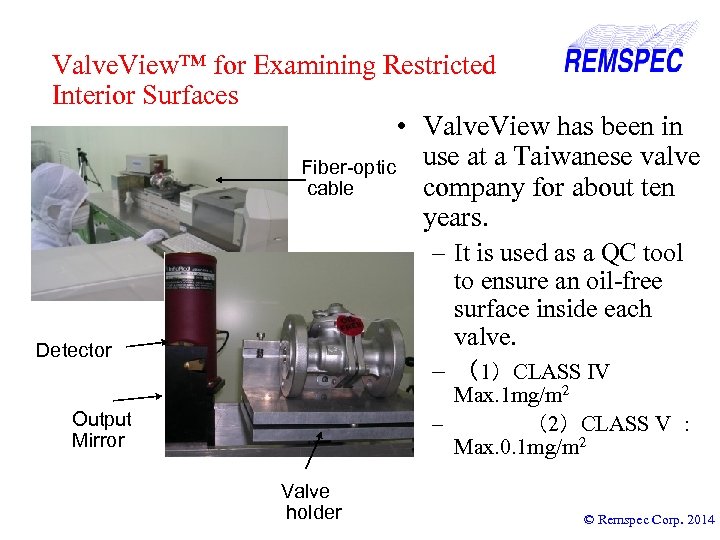

Valve. View™ for Examining Restricted Interior Surfaces • Valve. View has been in Fiber-optic use at a Taiwanese valve cable company for about ten years. – It is used as a QC tool to ensure an oil-free surface inside each valve. – (1)CLASS IV Detector Max. 1 mg/m 2 – (2)CLASS V : Max. 0. 1 mg/m 2 Output Mirror Valve holder © Remspec Corp. 2014

Valve. View™ for Examining Restricted Interior Surfaces • Valve. View has been in Fiber-optic use at a Taiwanese valve cable company for about ten years. – It is used as a QC tool to ensure an oil-free surface inside each valve. – (1)CLASS IV Detector Max. 1 mg/m 2 – (2)CLASS V : Max. 0. 1 mg/m 2 Output Mirror Valve holder © Remspec Corp. 2014

Calibration © Remspec Corp. 2014

Calibration © Remspec Corp. 2014

Sample Preparation • Smear Method – Dispense small amount of known API solution onto surface – Smear evenly – Collect spectra after drying – Estimate coverage by: • Calculation from solution concentration. – Suitable method for demonstrations and qualitative analysis. © Remspec Corp. 2014

Sample Preparation • Smear Method – Dispense small amount of known API solution onto surface – Smear evenly – Collect spectra after drying – Estimate coverage by: • Calculation from solution concentration. – Suitable method for demonstrations and qualitative analysis. © Remspec Corp. 2014

Sample Preparation • Spray Method – Spray API solution on surface with air brush – Collect spectra after drying – Wash entire surface – Analyze washing by, e. g. , HPLC – Calculate surface coverage © Remspec Corp. 2014

Sample Preparation • Spray Method – Spray API solution on surface with air brush – Collect spectra after drying – Wash entire surface – Analyze washing by, e. g. , HPLC – Calculate surface coverage © Remspec Corp. 2014

Sample Preparation • Quantitative Printing – Developed from ink-jet printing technology – Provides known surface concentrations without requiring secondary analysis method. – Available as a service from Remspec. © Remspec Corp. 2014

Sample Preparation • Quantitative Printing – Developed from ink-jet printing technology – Provides known surface concentrations without requiring secondary analysis method. – Available as a service from Remspec. © Remspec Corp. 2014

Spot. View-SL Calibration: some simple rules • Smear Method for quick feasibility studies • Use sample of the same material as the target reactor or mixer (metal, glass, plastic, etc. ) • Consider the range of surface finishes that you may encounter (mirror polish, matte, etc. ) • Spray or Print Method better for developing working calibrations and determining true detection limits. • Spray or Print Method essential for multi-compound calibration. • Secondary analysis (for Spray method) – Is the analyte UV-active? – How easy will it be to wash off the sample? © Remspec Corp. 2014

Spot. View-SL Calibration: some simple rules • Smear Method for quick feasibility studies • Use sample of the same material as the target reactor or mixer (metal, glass, plastic, etc. ) • Consider the range of surface finishes that you may encounter (mirror polish, matte, etc. ) • Spray or Print Method better for developing working calibrations and determining true detection limits. • Spray or Print Method essential for multi-compound calibration. • Secondary analysis (for Spray method) – Is the analyte UV-active? – How easy will it be to wash off the sample? © Remspec Corp. 2014

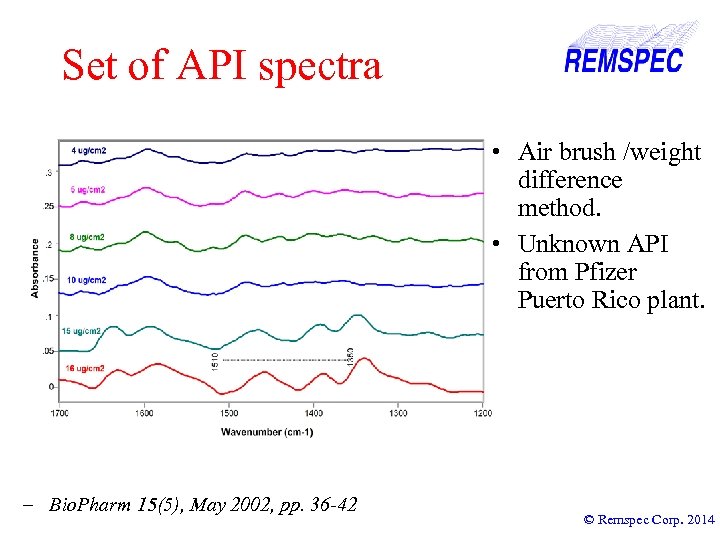

Set of API spectra • Air brush /weight difference method. • Unknown API from Pfizer Puerto Rico plant. – Bio. Pharm 15(5), May 2002, pp. 36 -42 © Remspec Corp. 2014

Set of API spectra • Air brush /weight difference method. • Unknown API from Pfizer Puerto Rico plant. – Bio. Pharm 15(5), May 2002, pp. 36 -42 © Remspec Corp. 2014

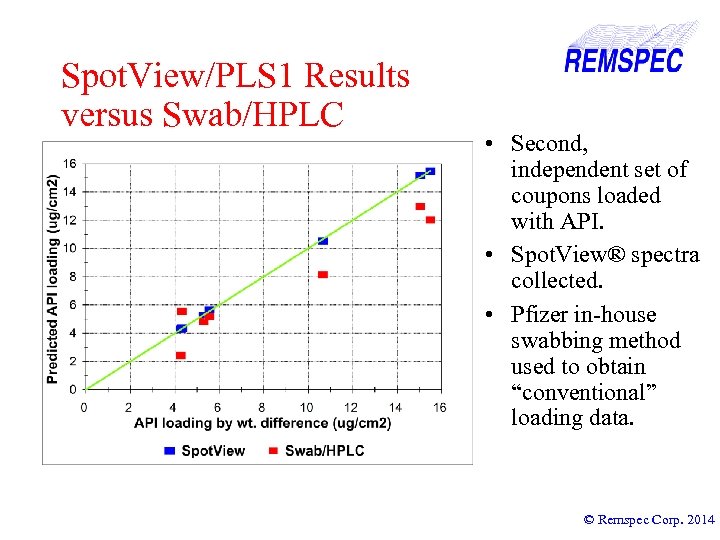

Spot. View/PLS 1 Results versus Swab/HPLC • Second, independent set of coupons loaded with API. • Spot. View® spectra collected. • Pfizer in-house swabbing method used to obtain “conventional” loading data. © Remspec Corp. 2014

Spot. View/PLS 1 Results versus Swab/HPLC • Second, independent set of coupons loaded with API. • Spot. View® spectra collected. • Pfizer in-house swabbing method used to obtain “conventional” loading data. © Remspec Corp. 2014

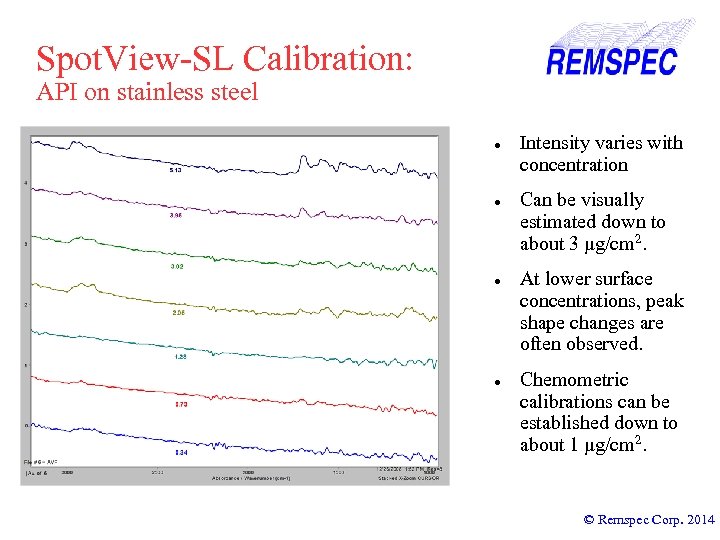

Spot. View-SL Calibration: API on stainless steel Intensity varies with concentration Can be visually estimated down to about 3 μg/cm 2. At lower surface concentrations, peak shape changes are often observed. Chemometric calibrations can be established down to about 1 μg/cm 2. © Remspec Corp. 2014

Spot. View-SL Calibration: API on stainless steel Intensity varies with concentration Can be visually estimated down to about 3 μg/cm 2. At lower surface concentrations, peak shape changes are often observed. Chemometric calibrations can be established down to about 1 μg/cm 2. © Remspec Corp. 2014

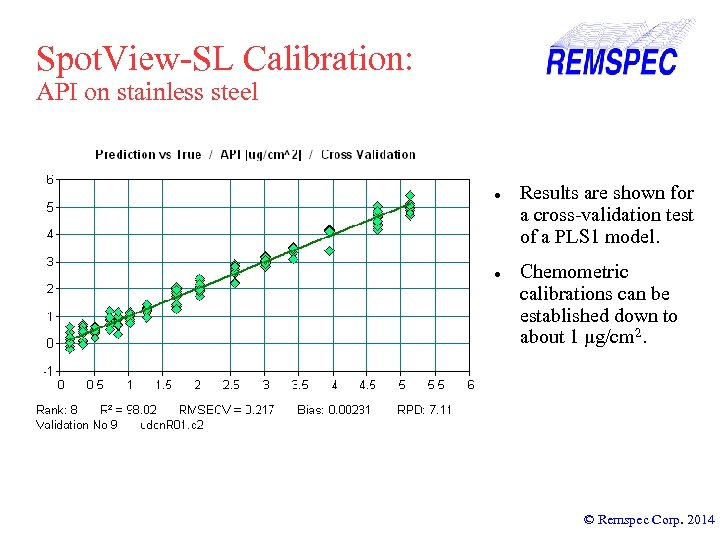

Spot. View-SL Calibration: API on stainless steel Results are shown for a cross-validation test of a PLS 1 model. Chemometric calibrations can be established down to about 1 μg/cm 2. © Remspec Corp. 2014

Spot. View-SL Calibration: API on stainless steel Results are shown for a cross-validation test of a PLS 1 model. Chemometric calibrations can be established down to about 1 μg/cm 2. © Remspec Corp. 2014

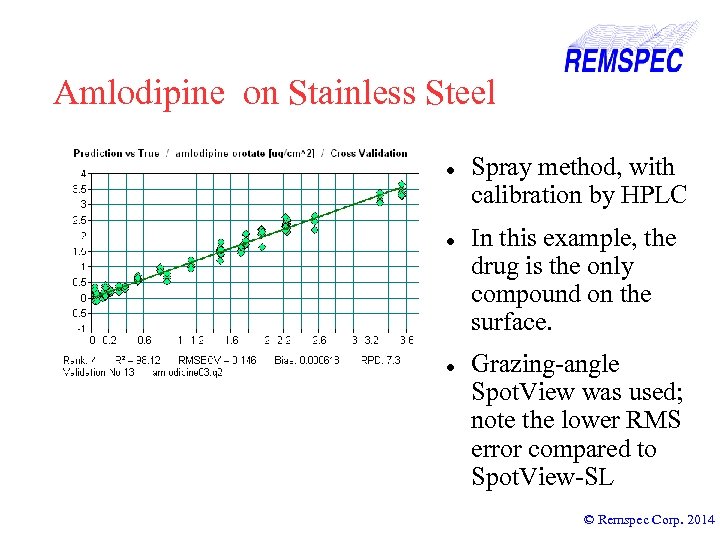

Amlodipine on Stainless Steel Spray method, with calibration by HPLC In this example, the drug is the only compound on the surface. Grazing-angle Spot. View was used; note the lower RMS error compared to Spot. View-SL © Remspec Corp. 2014

Amlodipine on Stainless Steel Spray method, with calibration by HPLC In this example, the drug is the only compound on the surface. Grazing-angle Spot. View was used; note the lower RMS error compared to Spot. View-SL © Remspec Corp. 2014

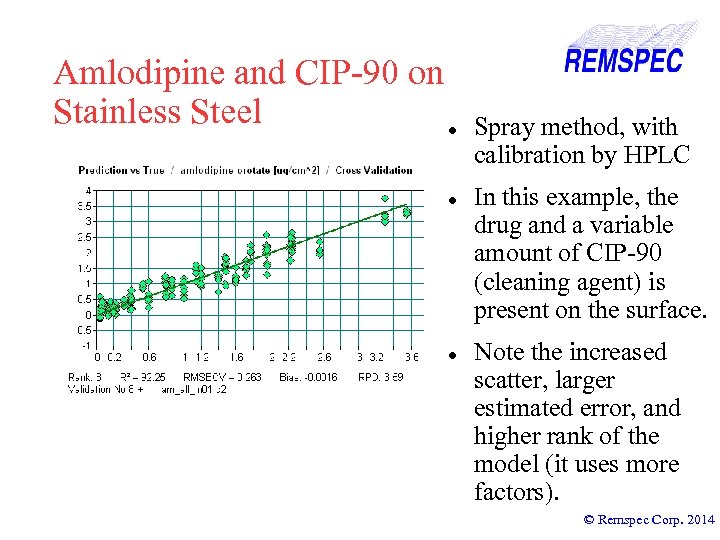

Amlodipine and CIP-90 on Stainless Steel Spray method, with calibration by HPLC In this example, the drug and a variable amount of CIP-90 (cleaning agent) is present on the surface. Note the increased scatter, larger estimated error, and higher rank of the model (it uses more factors). © Remspec Corp. 2014

Amlodipine and CIP-90 on Stainless Steel Spray method, with calibration by HPLC In this example, the drug and a variable amount of CIP-90 (cleaning agent) is present on the surface. Note the increased scatter, larger estimated error, and higher rank of the model (it uses more factors). © Remspec Corp. 2014

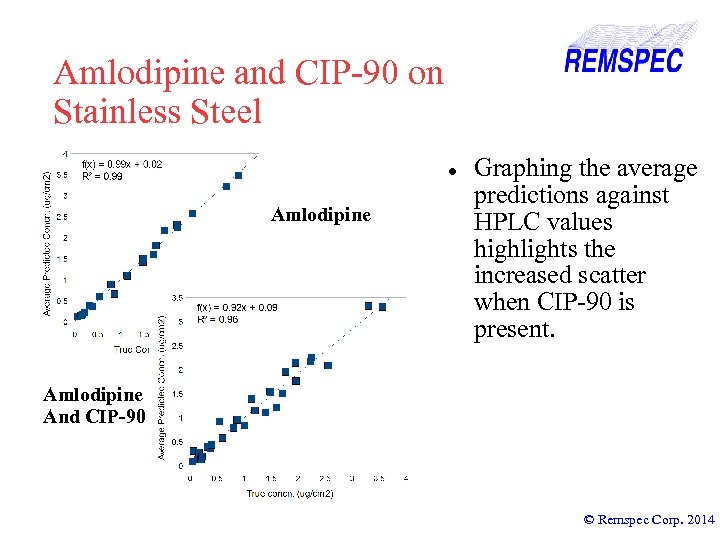

Amlodipine and CIP-90 on Stainless Steel Amlodipine Graphing the average predictions against HPLC values highlights the increased scatter when CIP-90 is present. Amlodipine And CIP-90 © Remspec Corp. 2014

Amlodipine and CIP-90 on Stainless Steel Amlodipine Graphing the average predictions against HPLC values highlights the increased scatter when CIP-90 is present. Amlodipine And CIP-90 © Remspec Corp. 2014

Case Study © Remspec Corp. 2014

Case Study © Remspec Corp. 2014

Case Study: inside stainless steel production tanks The Spot. View FTIR system for surface analysis was used to examine the interior surfaces of two tanks, T-2221 and T-2211, interior surfaces of the CIP recovery tank and pump, and of the CIP return pump P 8211. A operator was lowered into the tank carrying the operating spectrometer. The Spot. View head and fiber-optic cable were lowered separately and connected in situ. The computer was operated by a second person outside the tank. A total of 69 spectra was collected over a period of three days from selected sites on the walls of the tanks, on agitator shafts and spray balls, and from the manways and manway covers. Separately, spectra were collected from surfaces of the CIP recovery tank and pump. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks The Spot. View FTIR system for surface analysis was used to examine the interior surfaces of two tanks, T-2221 and T-2211, interior surfaces of the CIP recovery tank and pump, and of the CIP return pump P 8211. A operator was lowered into the tank carrying the operating spectrometer. The Spot. View head and fiber-optic cable were lowered separately and connected in situ. The computer was operated by a second person outside the tank. A total of 69 spectra was collected over a period of three days from selected sites on the walls of the tanks, on agitator shafts and spray balls, and from the manways and manway covers. Separately, spectra were collected from surfaces of the CIP recovery tank and pump. © Remspec Corp. 2014

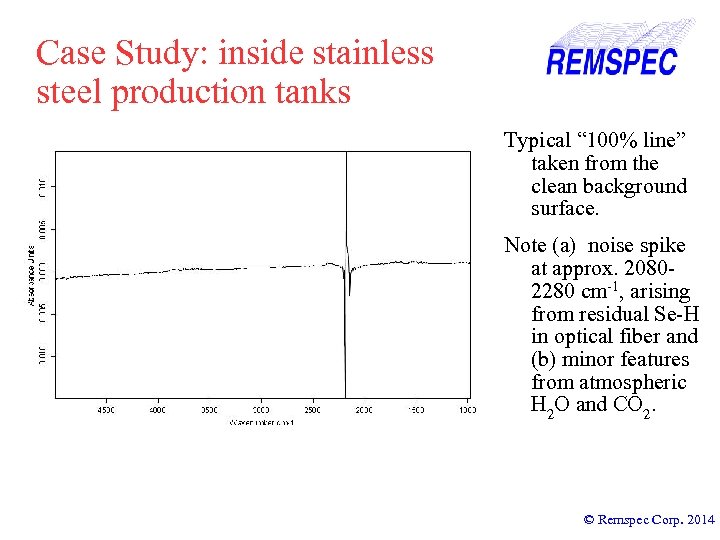

Case Study: inside stainless steel production tanks Typical “ 100% line” taken from the clean background surface. Note (a) noise spike at approx. 20802280 cm-1, arising from residual Se-H in optical fiber and (b) minor features from atmospheric H 2 O and CO 2. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks Typical “ 100% line” taken from the clean background surface. Note (a) noise spike at approx. 20802280 cm-1, arising from residual Se-H in optical fiber and (b) minor features from atmospheric H 2 O and CO 2. © Remspec Corp. 2014

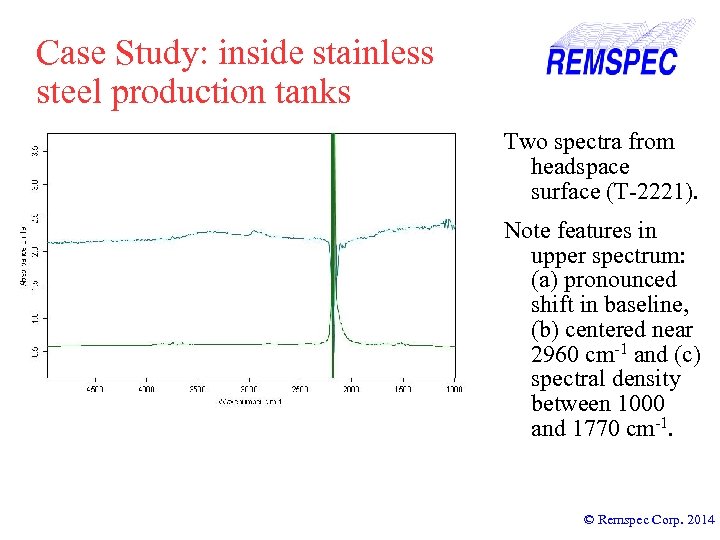

Case Study: inside stainless steel production tanks Two spectra from headspace surface (T-2221). Note features in upper spectrum: (a) pronounced shift in baseline, (b) centered near 2960 cm-1 and (c) spectral density between 1000 and 1770 cm-1. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks Two spectra from headspace surface (T-2221). Note features in upper spectrum: (a) pronounced shift in baseline, (b) centered near 2960 cm-1 and (c) spectral density between 1000 and 1770 cm-1. © Remspec Corp. 2014

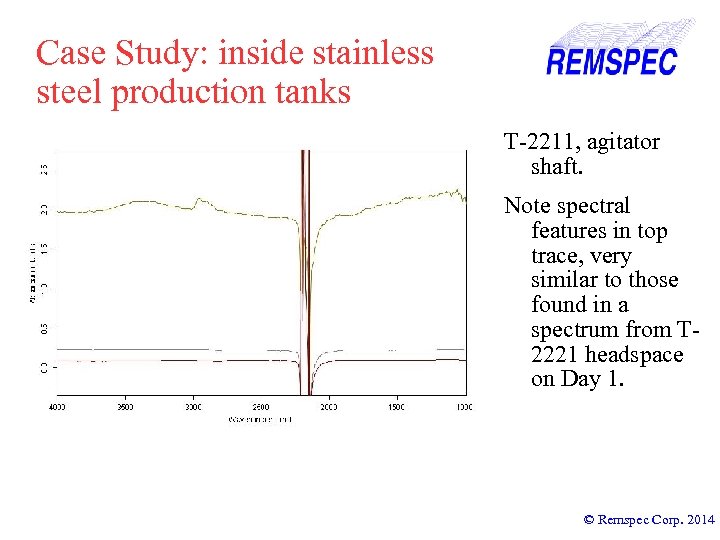

Case Study: inside stainless steel production tanks T-2211, agitator shaft. Note spectral features in top trace, very similar to those found in a spectrum from T 2221 headspace on Day 1. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks T-2211, agitator shaft. Note spectral features in top trace, very similar to those found in a spectrum from T 2221 headspace on Day 1. © Remspec Corp. 2014

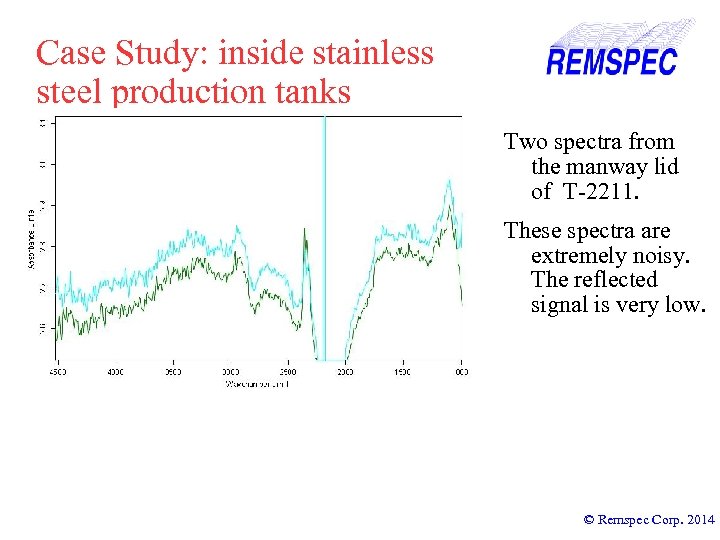

Case Study: inside stainless steel production tanks Two spectra from the manway lid of T-2211. These spectra are extremely noisy. The reflected signal is very low. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks Two spectra from the manway lid of T-2211. These spectra are extremely noisy. The reflected signal is very low. © Remspec Corp. 2014

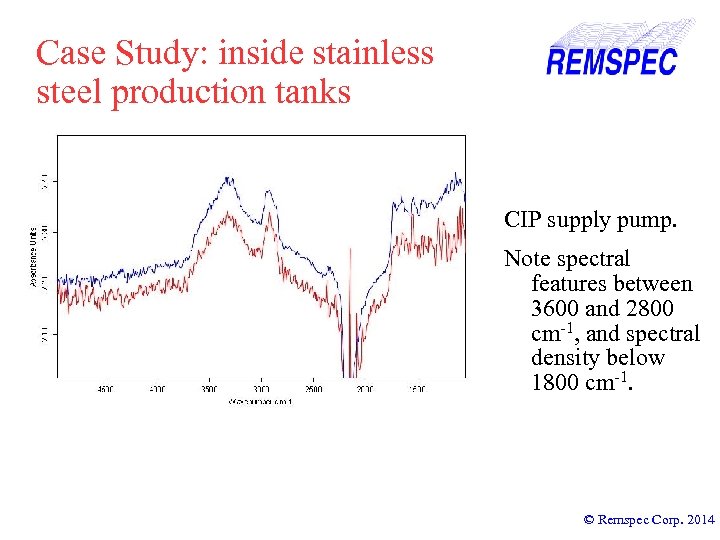

Case Study: inside stainless steel production tanks CIP supply pump. Note spectral features between 3600 and 2800 cm-1, and spectral density below 1800 cm-1. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks CIP supply pump. Note spectral features between 3600 and 2800 cm-1, and spectral density below 1800 cm-1. © Remspec Corp. 2014

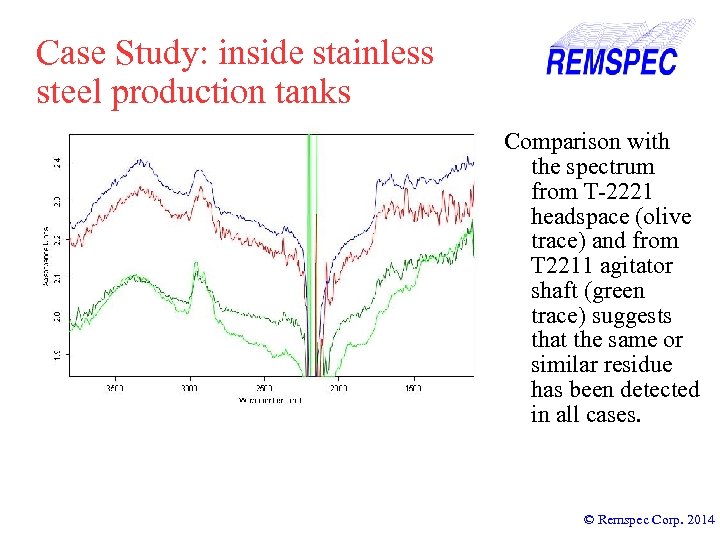

Case Study: inside stainless steel production tanks Comparison with the spectrum from T-2221 headspace (olive trace) and from T 2211 agitator shaft (green trace) suggests that the same or similar residue has been detected in all cases. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks Comparison with the spectrum from T-2221 headspace (olive trace) and from T 2211 agitator shaft (green trace) suggests that the same or similar residue has been detected in all cases. © Remspec Corp. 2014

Case Study: inside stainless steel production tanks Of the 69 spectra collected, 65 showed no features attributable to organic residue on the surface. This indicates that the surfaces are free of spectroscopically detectable organic residue to a level better than 0. 5 μg/cm 2. Four spectra—one each from tanks T-2221 and T 2211 and two from the pump on the CIP recovery skip--showed a very small spectroscopic signature for an organic residue that was (a) the same or very similar in each case (b) highly localized in the two tanks (attempts to detect anything on immediately adjacent surfaces resulted in featureless spectra). © Remspec Corp. 2014

Case Study: inside stainless steel production tanks Of the 69 spectra collected, 65 showed no features attributable to organic residue on the surface. This indicates that the surfaces are free of spectroscopically detectable organic residue to a level better than 0. 5 μg/cm 2. Four spectra—one each from tanks T-2221 and T 2211 and two from the pump on the CIP recovery skip--showed a very small spectroscopic signature for an organic residue that was (a) the same or very similar in each case (b) highly localized in the two tanks (attempts to detect anything on immediately adjacent surfaces resulted in featureless spectra). © Remspec Corp. 2014

Software © Remspec Corp. 2014

Software © Remspec Corp. 2014

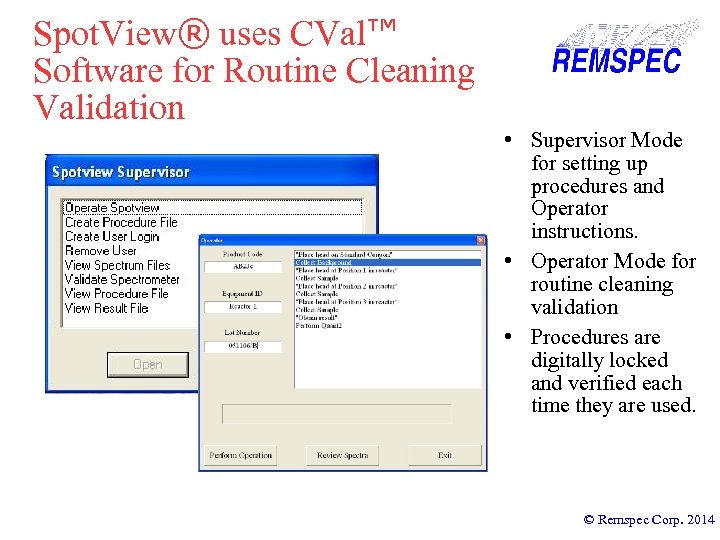

Spot. View® uses CVal™ Software for Routine Cleaning Validation • Supervisor Mode for setting up procedures and Operator instructions. • Operator Mode for routine cleaning validation • Procedures are digitally locked and verified each time they are used. © Remspec Corp. 2014

Spot. View® uses CVal™ Software for Routine Cleaning Validation • Supervisor Mode for setting up procedures and Operator instructions. • Operator Mode for routine cleaning validation • Procedures are digitally locked and verified each time they are used. © Remspec Corp. 2014

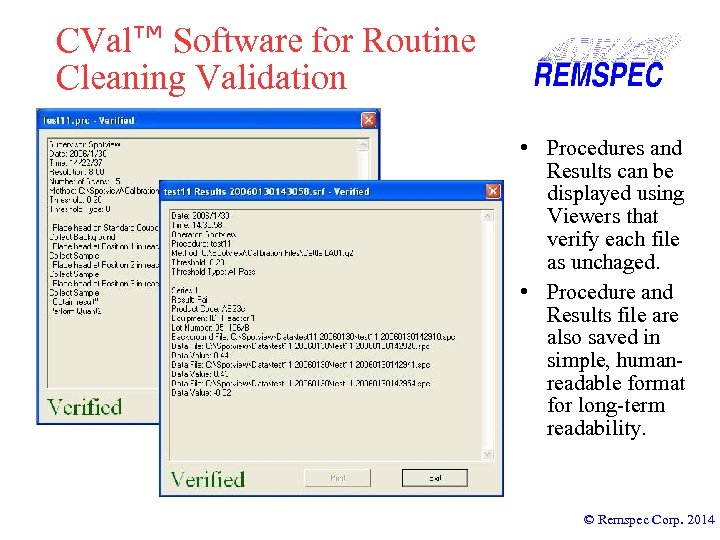

CVal™ Software for Routine Cleaning Validation • Procedures and Results can be displayed using Viewers that verify each file as unchaged. • Procedure and Results file are also saved in simple, humanreadable format for long-term readability. © Remspec Corp. 2014

CVal™ Software for Routine Cleaning Validation • Procedures and Results can be displayed using Viewers that verify each file as unchaged. • Procedure and Results file are also saved in simple, humanreadable format for long-term readability. © Remspec Corp. 2014

Conclusions © Remspec Corp. 2014

Conclusions © Remspec Corp. 2014

Expanding the Scope of Reflectance FTIR Spectroscopy • Spot. View® is ideal • Spot. View®-SL is for surfaces that are: ideal for surfaces that are: – Flat or moderately curved – Accessible with the Spot. View® head – Interior surfaces of large reactors, for example – Highly curved – Restricted access – Valves and nozzles, for example © Remspec Corp. 2014

Expanding the Scope of Reflectance FTIR Spectroscopy • Spot. View® is ideal • Spot. View®-SL is for surfaces that are: ideal for surfaces that are: – Flat or moderately curved – Accessible with the Spot. View® head – Interior surfaces of large reactors, for example – Highly curved – Restricted access – Valves and nozzles, for example © Remspec Corp. 2014

In Summary • Spot. View can measure surface laodigns down to 0. 2 μg/cm 2. • Spot. View-SL can measure loadings down to about 1 -3 μg/cm 2. • The results are quantitative and compare well with existing pharma industry methods like swabbing. • In-situ results are obtained from a hand-held device in seconds. © Remspec Corp. 2014

In Summary • Spot. View can measure surface laodigns down to 0. 2 μg/cm 2. • Spot. View-SL can measure loadings down to about 1 -3 μg/cm 2. • The results are quantitative and compare well with existing pharma industry methods like swabbing. • In-situ results are obtained from a hand-held device in seconds. © Remspec Corp. 2014