f0c296a23a78b2738978c84f814446ba.ppt

- Количество слайдов: 42

Specifications for Geotextiles in India by R. P. Indoria Secretary General, Indian Roads Congress 19 November 2010

ABOUT IRC Ø Indian Roads Congress is a Society of Highways Engineers established in 1934 Ø Frames Codes of Practice , Standards, Guidelines, Manuals etc. on various subjects for Roads and Bridges Ø Identification of research topics and Institutions Ø Collection of data on research done and utilization there of (Cont…)

ABOUT IRC Ø Dissemination of Research findings for revision of IRC Codes and Special Publications Ø Holding Workshops and Seminars on Crucial Topics for dissemination of knowldge Ø Promoting Usages of New Materials and Technologies

IMPORTANCE AND USAGES OF GEOTEXTILE IN ROAD SECTOR Ø Ø Ø Ø Use as Separator to Improve Pavement Performance Use as reinforcement and drainage layer Use for Ground Improvement Use for drainage of ground (PVD/piped drains) Jute Geogrid for Erosion Control of Denuded Slopes Jute Geotextile for Drainage and Filtration Application Jute is low cost, renewable, biodegradable and eco-friendly natural product (Cont…)

IMPORTANCE AND USAGES OF GEOTEXTILE IN ROAD SECTOR Ø Ø Construction of road embankments in water logged area Soil Nailing River Bank Protection Embankment slope protection

TYPES OF GEOTEXTILES l Geotextile: Non Biodegradable Synthetics Woven / Non Woven Fiber and perform discrete function i. e. separation, reinforcement, filtration, drainage and moisture barrier (when impregnated). l Geogrids : Open, grid like configuration, i. e. , they have large apertures and used for the purpose of separation, but invariably they are being used in some form of reinforcement. ( Cont…)

TYPES OF GEOTEXTILES l Geonets: another specialized segment of Geosynthetics and Geonets are used for the purpose of drainage. It is to be noted that geonets are always used with a geotextile. Geonets used in protective works for highway structures l Geocomposite: A geocomposite consists of a combination of geotextile and/or geogrid and/or geomembrane or any of these three materials with another material in laminated or composite form and used for accelerating the consolidation of soft soils.

TYPES OF GEOTEXTILES l Geomembranes : Geomembranes are also synthetic materials but they are impervious and made of thin sheets of rubber or plastic materials used primarily for lining and cover of liquid-or solid-storage facilities l Geocell : A three dimensional structure with interconnected cells which can be filled with soil/granular material forming a mattress for increased bearing capacity and manoeuvrability on loose or compressible subsoil of base or sub-base in pavements and slope protection (Cont…)

TYPES OF GEOTEXTILES l Natural Geotextiles: Natural fibres are extracted from plants and are then converted into yarns by spinning. These fabrics are sometimes treated with rot resistance materials or reinforced with synthetic fibres to enhance their durability under different soil conditions without affecting its strength and other properties. Natural fibres such as jute, coconut and coir fabrics are used to improve soil erosion control and drainage applications.

USE OF GEOTEXTILE FOR IMPROVING PERFORMANCE OF ROADS l Geosynthetics for Highway Pavements l Geosynthetics Over Existing Bituminous Surface l Provision of Geotextiles Against Subgrade and Embankment Erosion l Geotextiles In Sub-surface and Composite Drains l Geogrid Applications For Reinforced Soil Slope Protection

USE OF GEOTEXTILE FOR IMPROVING PERFORMANCE OF ROADS l • • Road pavement as a drainage layer, Bioengineering measure for shoulders and earthen slopes, Improving the pavement performance and Reducing the pavement crust (? ) Construction of road embankments in water logged area Soil Nailing , Soil Stabilization

IRC DOCUMENTS ON GEOTEXTILES l IRC has one document titled “State of the Art: Application of Geotextiles in Highway Engineering” published by IRC in 1994 l It is a compilation of available literature (at the time of preparation of the report) l Since then a lot of developments have taken place in manufacturing and preparation of geotextiles, their usage and applications etc.

IRC DOCUMENTS ON GEOTEXTILES l IRC has another document titled SP: 59 – 2002 `Guidelines for use of Geotextiles in road pavements and associated works` l Being a Special Publication, this document does not have the status of a ‘Code of Practice” per se but nevertheless covers the following: Ø Scope Ø Raw Material and types of Geotextiles Ø Functions of Geotextiles

IRC DOCUMENTS ON GEOTEXTILES Ø Handling and storage of geotextiles Ø Geotextiles properties and test methods Ø Geotextiles property requirements for various applications Ø Construction guidelines for use of geotextiles in various applications Ø References have been made to ASTM standards for test methods

GEOTEXTILES SPECIFICATIONS l More comprehensive specifications are included in the Ministry of Road Transport and Highways book of Specifications, popularly known as the “Orange Book” l The current edition of this book is also very old (2001) and a revision of the book has been almost finalised and is likely to be published soon

GEOTEXTILES SPECIFICATIONS l The proposed specifications(section 700) cover the following: 1 GEOSYNTHETICS IN ROAD AND BRIDGE WORKS Ø Scope Ø Testing, handling, certification, and acceptance

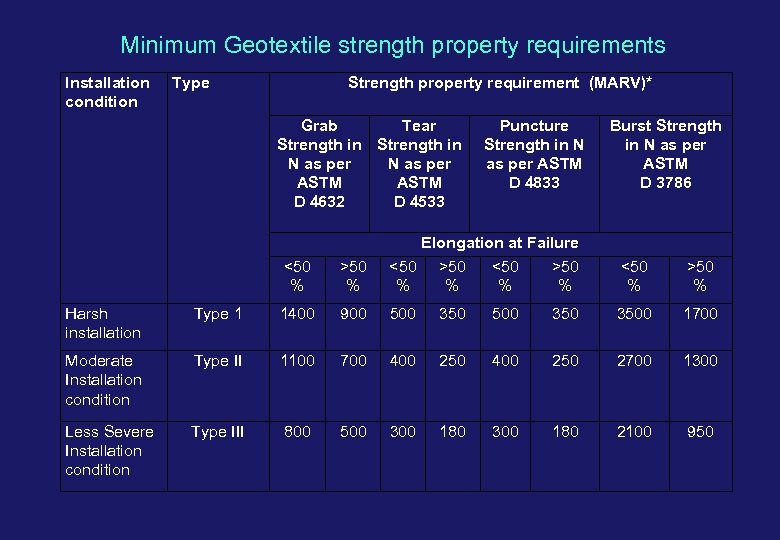

Minimum Geotextile strength property requirements Installation condition Type Strength property requirement (MARV)* Grab Tear Strength in N as per ASTM D 4632 D 4533 Puncture Strength in N as per ASTM D 4833 <50 % >50 % Elongation at Failure <50 >50 % % Burst Strength in N as per ASTM D 3786 <50 % >50 % Harsh installation Type 1 1400 900 500 350 3500 1700 Moderate Installation condition Type II 1100 700 400 250 2700 1300 Less Severe Installation condition Type III 800 500 300 180 2100 950

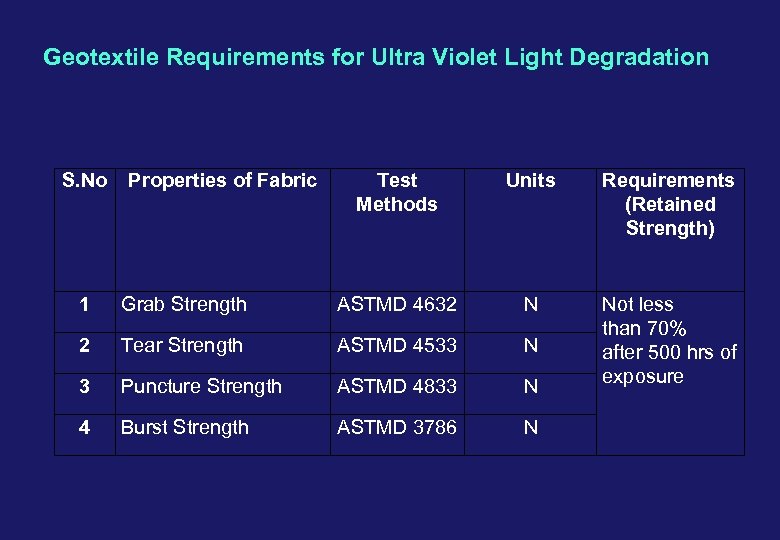

Geotextile Requirements for Ultra Violet Light Degradation S. No Properties of Fabric Test Methods Units Requirements (Retained Strength) Not less than 70% after 500 hrs of exposure 1 Grab Strength ASTMD 4632 N 2 Tear Strength ASTMD 4533 N 3 Puncture Strength ASTMD 4833 N 4 Burst Strength ASTMD 3786 N

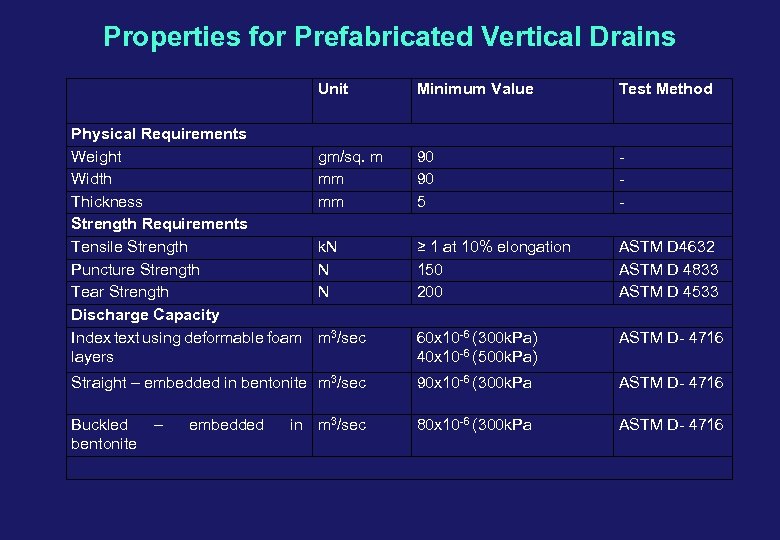

Properties for Prefabricated Vertical Drains Unit Minimum Value Test Method gm/sq. m mm mm 90 90 5 - k. N N N ≥ 1 at 10% elongation 150 200 ASTM D 4632 ASTM D 4833 ASTM D 4533 m 3/sec 60 x 10 -6 (300 k. Pa) 40 x 10 -6 (500 k. Pa) ASTM D- 4716 Straight – embedded in bentonite m 3/sec 90 x 10 -6 (300 k. Pa ASTM D- 4716 Buckled bentonite 80 x 10 -6 (300 k. Pa ASTM D- 4716 Physical Requirements Weight Width Thickness Strength Requirements Tensile Strength Puncture Strength Tear Strength Discharge Capacity Index text using deformable foam layers – embedded in m 3/sec

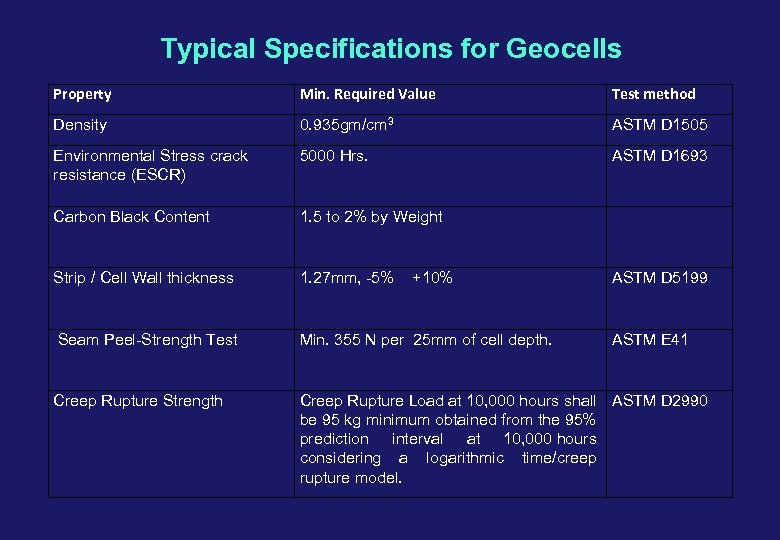

Typical Specifications for Geocells Property Min. Required Value Test method Density 0. 935 gm/cm 3 ASTM D 1505 Environmental Stress crack resistance (ESCR) 5000 Hrs. ASTM D 1693 Carbon Black Content 1. 5 to 2% by Weight Strip / Cell Wall thickness 1. 27 mm, -5% +10% ASTM D 5199 Seam Peel-Strength Test Min. 355 N per 25 mm of cell depth. ASTM E 41 Creep Rupture Strength Creep Rupture Load at 10, 000 hours shall ASTM D 2990 be 95 kg minimum obtained from the 95% prediction interval at 10, 000 hours considering a logarithmic time/creep rupture model.

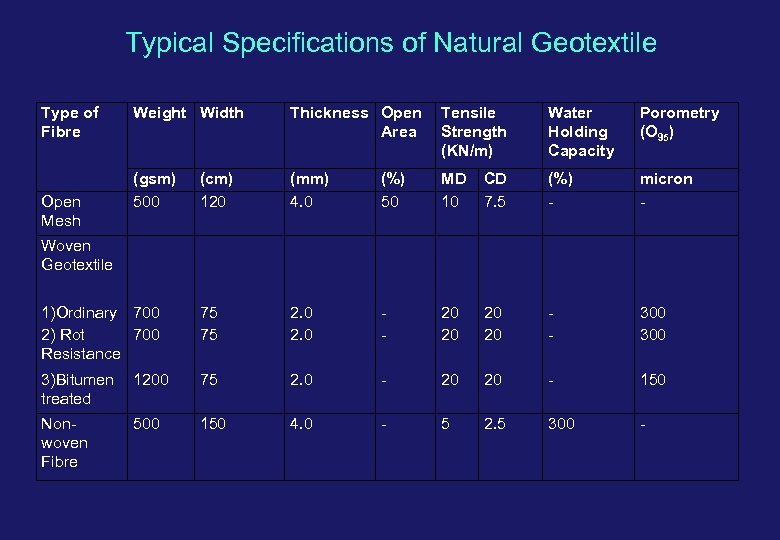

Typical Specifications of Natural Geotextile Type of Fibre Weight Width Thickness Open Tensile Area Strength (KN/m) Water Holding Capacity Porometry (O 95) (gsm) 500 (cm) 120 (mm) 4. 0 (%) 50 MD 10 CD 7. 5 (%) - micron - 1)Ordinary 700 2) Rot 700 Resistance 75 75 2. 0 - 20 20 - 300 3)Bitumen 1200 treated 75 2. 0 - 20 20 - 150 Non- woven Fibre 150 4. 0 - 5 2. 5 300 - Open Mesh Woven Geotextile 500

2 GEOTEXTILES IN SUB SURFACE DRAINS Ø Scope Ø Materials Ø Construction requirements Ø Measurement for payment Ø Rate

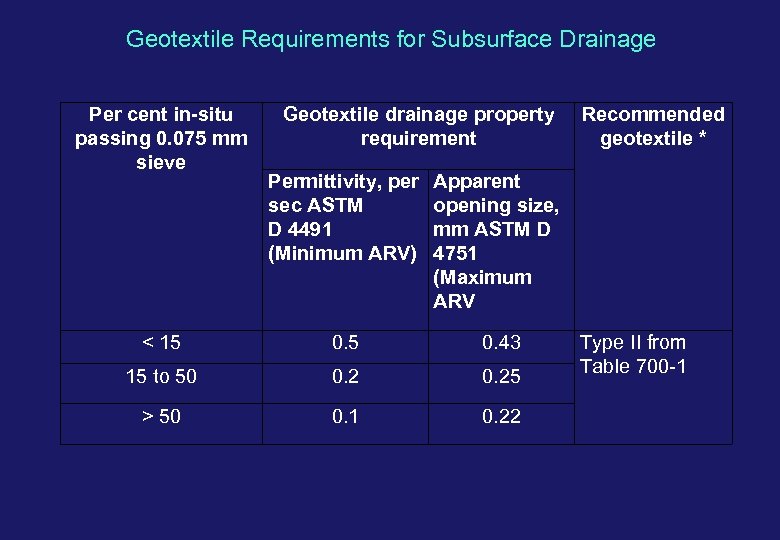

Geotextile Requirements for Subsurface Drainage Per cent in-situ passing 0. 075 mm sieve Geotextile drainage property requirement Permittivity, per sec ASTM D 4491 (Minimum ARV) Apparent opening size, mm ASTM D 4751 (Maximum ARV < 15 0. 43 15 to 50 0. 25 > 50 0. 1 0. 22 Recommended geotextile * Type II from Table 700 -1

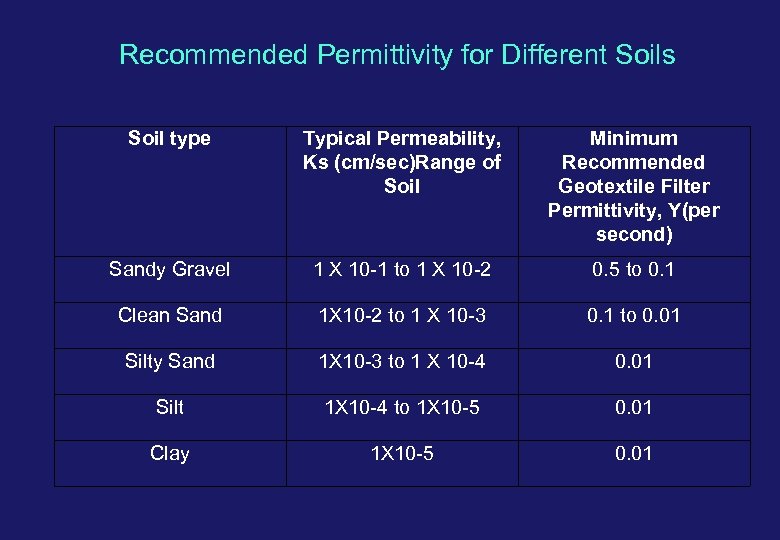

Recommended Permittivity for Different Soils Soil type Typical Permeability, Ks (cm/sec)Range of Soil Minimum Recommended Geotextile Filter Permittivity, Y(per second) Sandy Gravel 1 X 10 -1 to 1 X 10 -2 0. 5 to 0. 1 Clean Sand 1 X 10 -2 to 1 X 10 -3 0. 1 to 0. 01 Silty Sand 1 X 10 -3 to 1 X 10 -4 0. 01 Silt 1 X 10 -4 to 1 X 10 -5 0. 01 Clay 1 X 10 -5 0. 01

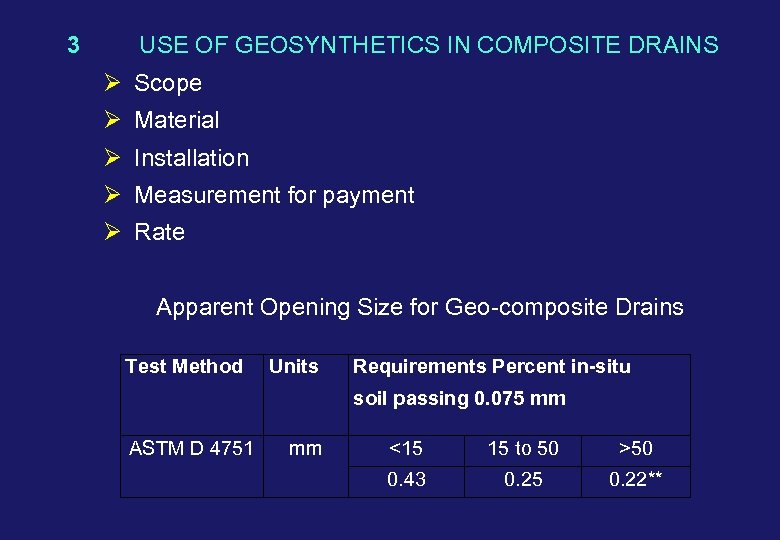

3 USE OF GEOSYNTHETICS IN COMPOSITE DRAINS Ø Scope Ø Material Ø Installation Ø Measurement for payment Ø Rate Apparent Opening Size for Geo-composite Drains Test Method Units Requirements Percent in-situ soil passing 0. 075 mm ASTM D 4751 mm <15 15 to 50 >50 0. 43 0. 25 0. 22**

4 GEOTEXTILES FOR EROSION CONTROL Ø Scope Ø Materials Ø Construction requirements Ø Slope protection placement Ø Seams Ø Repair Ø Measurement for payment Ø Rates

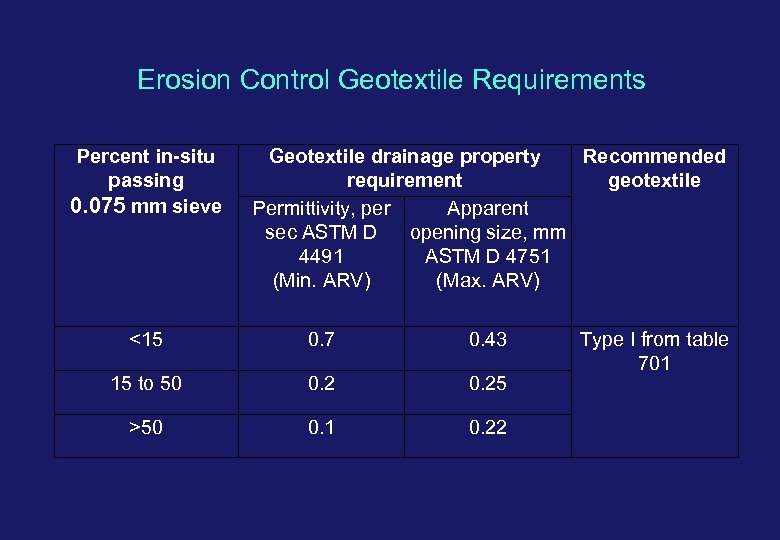

Erosion Control Geotextile Requirements Percent in-situ passing 0. 075 mm sieve Geotextile drainage property Recommended requirement geotextile Permittivity, per Apparent sec ASTM D opening size, mm 4491 ASTM D 4751 (Min. ARV) (Max. ARV) <15 0. 7 0. 43 15 to 50 0. 25 >50 0. 1 0. 22 Type I from table 701

5 GEOGRID APPLICATIONS FOR REINFORCED SOIL SLOPE PROTECTION Ø Description Ø Material Ø Installation Ø Measurement and basis for payment Ø Rates

6 GEOSYNTHETICS FOR HIGHWAY PAVEMENTS Ø Scope Ø Materials Ø Certification Ø Installation Ø Measurement for payment Ø Rate

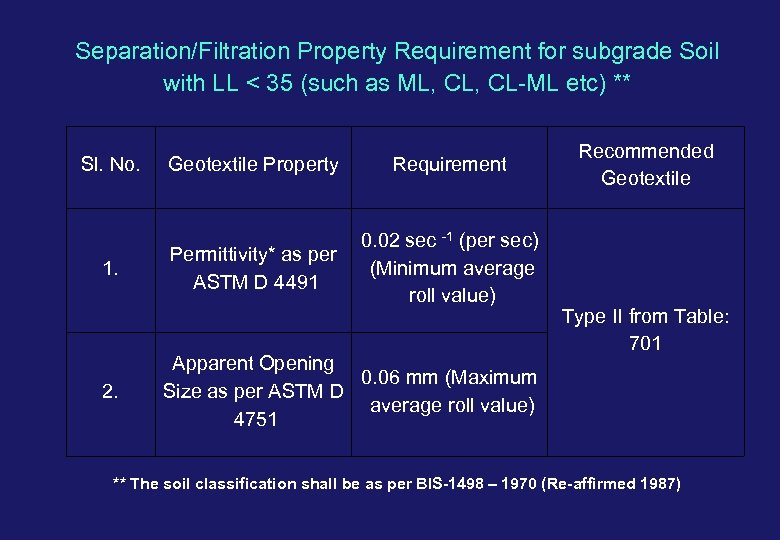

Separation/Filtration Property Requirement for subgrade Soil with LL < 35 (such as ML, CL-ML etc) ** Sl. No. 1. 2. Geotextile Property Requirement Permittivity* as per ASTM D 4491 0. 02 sec -1 (per sec) (Minimum average roll value) Apparent Opening 0. 06 mm (Maximum Size as per ASTM D average roll value) 4751 Recommended Geotextile Type II from Table: 701 ** The soil classification shall be as per BIS-1498 – 1970 (Re-affirmed 1987)

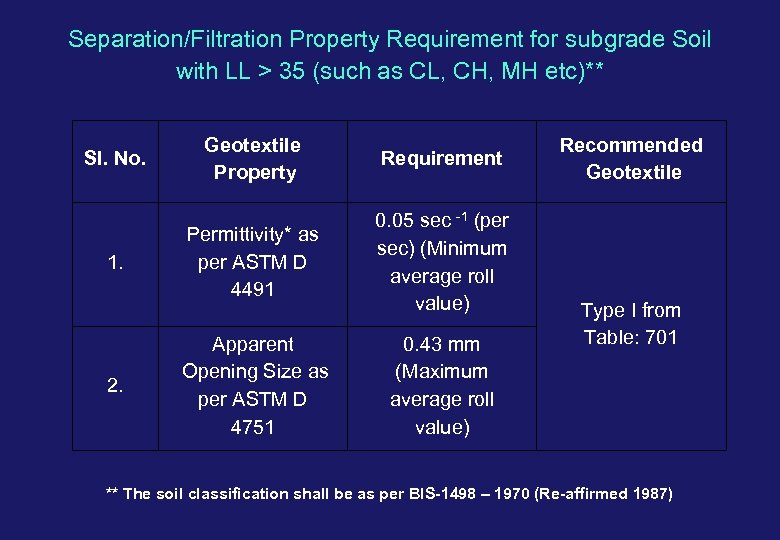

Separation/Filtration Property Requirement for subgrade Soil with LL > 35 (such as CL, CH, MH etc)** Sl. No. 1. 2. Geotextile Property Requirement Permittivity* as per ASTM D 4491 0. 05 sec -1 (per sec) (Minimum average roll value) Apparent Opening Size as per ASTM D 4751 0. 43 mm (Maximum average roll value) Recommended Geotextile Type I from Table: 701 ** The soil classification shall be as per BIS-1498 – 1970 (Re-affirmed 1987)

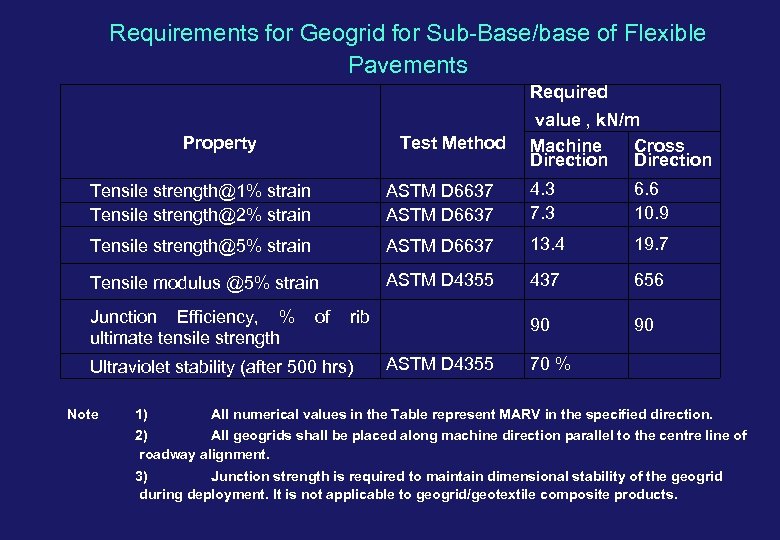

Requirements for Geogrid for Sub-Base/base of Flexible Pavements Required Property Test Method value , k. N/m Machine Cross Direction Tensile strength@1% strain Tensile strength@2% strain ASTM D 6637 4. 3 7. 3 6. 6 10. 9 Tensile strength@5% strain ASTM D 6637 13. 4 19. 7 Tensile modulus @5% strain ASTM D 4355 437 656 90 90 70 % Junction Efficiency, % of rib ultimate tensile strength ASTM D 4355 Ultraviolet stability (after 500 hrs) Note 1) All numerical values in the Table represent MARV in the specified direction. 2) All geogrids shall be placed along machine direction parallel to the centre line of roadway alignment. 3) Junction strength is required to maintain dimensional stability of the geogrid during deployment. It is not applicable to geogrid/geotextile composite products.

7 GEOSYNTHETICS OVER EXISTING BITUMENOUS SURFACE Ø Scope Ø Paving Fabrics Ø Material Requirement Ø Specifications for bitumen coated fiber glass fabric Ø Placement Ø Measurement Ø Rate

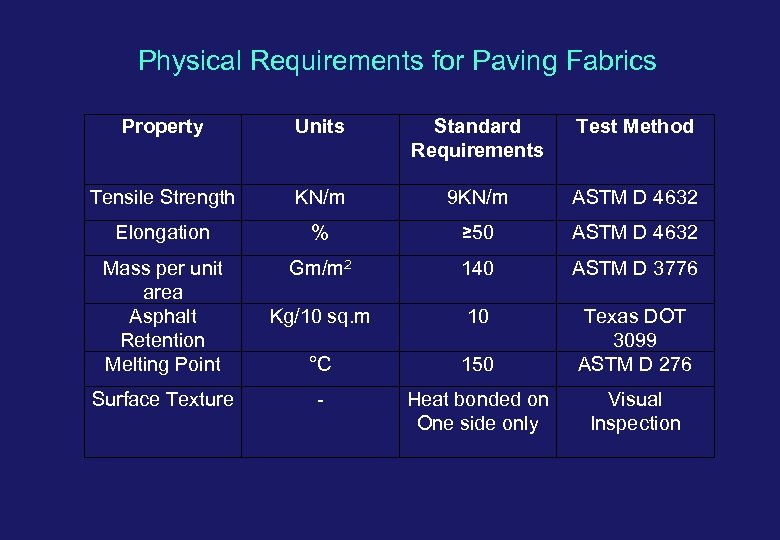

Physical Requirements for Paving Fabrics Property Units Standard Requirements Test Method Tensile Strength KN/m 9 KN/m ASTM D 4632 Elongation % ≥ 50 ASTM D 4632 Mass per unit area Asphalt Retention Melting Point Gm/m 2 140 ASTM D 3776 Kg/10 sq. m 10 °C 150 Texas DOT 3099 ASTM D 276 Surface Texture - Heat bonded on One side only Visual Inspection

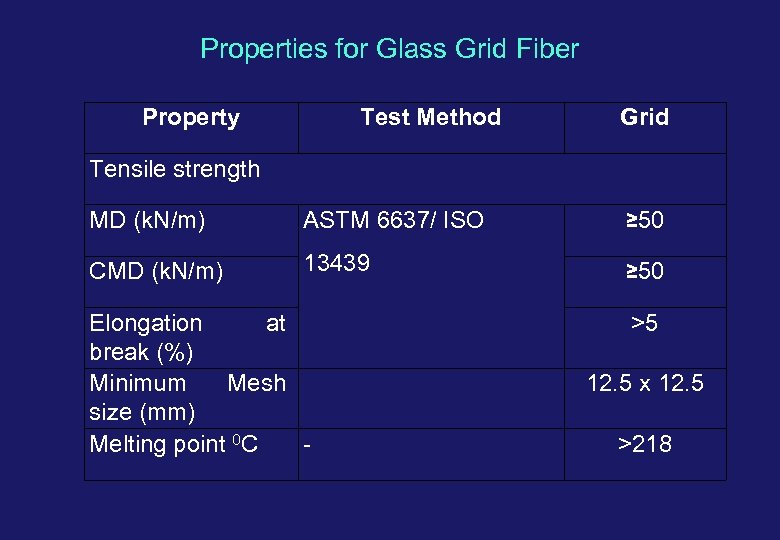

Properties for Glass Grid Fiber Property Test Method Grid Tensile strength MD (k. N/m) ASTM 6637/ ISO ≥ 50 CMD (k. N/m) 13439 ≥ 50 Elongation at break (%) Minimum Mesh size (mm) Melting point 0 C - >5 12. 5 x 12. 5 >218

Framework for promoting usages of Geotextile Ø Majority of the National Highway Development Programme to be implemented on PPP mode on BOT basis Ø The use of geotextile for road structure i. e. part of new or existing pavement does not bring the desired reduction in crust thickness since the pavement has to be designed as per IRC: 37 Ø There is a strong need to establish relationship between use of a type of geosynthetic and corresponding reduction in crust thickness

Framework for promoting usages of Geotextile l This can only be achieved by concerted research (may be industry sponsored) with the involvement of research institutes and academia l This could lead to formulation of definitive specifications and design methods using geotextiles/ geosynthetics l For the interim, the Government has created an enabling environment for the Concessionaire to use any material / technology / equipment as long as it meets any of the established international standards

Framework for promoting usages of Geotextile l The Manuals for four and six laning of highways, which form part of the Concession agreement, have been published by IRC containing this provision l Industry need to come out with ways and means to demonstrate to the prospective users (Concessionaires) the cost effectiveness (short term and long term) of the use of geotextiles l Industry also to come out with other innovative usage of geosynthetics besides the existing ones

Framework for promoting usages of Geotextile l On our part in IRC we have started a process of accreditation of new material / technologies / equipment etc. for use in the design and construction of highways l The proposals are examined by an Accreditation Committee constituted within IRC and comprising of experts from public as well as private sector l Upon satisfaction, the Committee issues an Accreditation Certificate which acts as a confidence measure with the prospective buyers

Framework for promoting usages of Geotextile l We also insist on field trial / usage reports from clients l In case of satisfactory performance reports, the new material, technology or equipment will then be suitably incorporated in Codes of Practices / Specifications

Conclusion l Need to establish relationship with cost (crust) reduction with usage of geosynthetics l Concerted research to have road crust design methods and formulate specifications l Concessionaires to be apprised of benefits of geosynthetics

Thank You for your kind attention

f0c296a23a78b2738978c84f814446ba.ppt