20f753f1345584facc8eeab860fcdbc1.ppt

- Количество слайдов: 22

Space Technology GSFC 5 “Tomorrow’s Technology Today” Section 17. 0 Propulsion Subsystem Michael S. Rhee Propulsion Lead ST 5 PDR June 19 -20, 2001

Space Technology GSFC 5 “Tomorrow’s Technology Today” Section 17. 0 Propulsion Subsystem Michael S. Rhee Propulsion Lead ST 5 PDR June 19 -20, 2001

GSFC Agenda • Requirements • Documentation • Subsystem Design • Electrical Interface Block Diagram • Delta-V Budget • Mass and Power Budget • Test and Analysis • Future Test and Analysis Plan • Propulsion Hardware Components ST 5 PDR June 19 -20, 2001 17 - 2

GSFC Agenda • Requirements • Documentation • Subsystem Design • Electrical Interface Block Diagram • Delta-V Budget • Mass and Power Budget • Test and Analysis • Future Test and Analysis Plan • Propulsion Hardware Components ST 5 PDR June 19 -20, 2001 17 - 2

GSFC Key Level II Requirements • The propulsion subsystem shall include a cold gas micro-thruster system. (MRD 10302010) – The ST 5 propulsion subsystem is a GN 2 cold gas system based on the Marotta cold gas micro-thruster. • Estimates of supply pressure shall be provided by direct pressure telemetry and/or a combination of indirect temperature telemetry and thruster on-time tracking. (MRD 10302030) – The ST 5 propulsion subsystem includes a miniature pressure transducer by GP: 50 to allow direct pressure telemetry. – Tank pressure can be calculated from tank temperature and thruster on-time data. • The thruster shall provide telemetry indicating the previous actuation activity of the thruster valve. (MRD 10101040) – The thruster control electronics (TCE) includes an indicator to monitor current pulses going to the solenoids. ST 5 PDR June 19 -20, 2001 17 - 3

GSFC Key Level II Requirements • The propulsion subsystem shall include a cold gas micro-thruster system. (MRD 10302010) – The ST 5 propulsion subsystem is a GN 2 cold gas system based on the Marotta cold gas micro-thruster. • Estimates of supply pressure shall be provided by direct pressure telemetry and/or a combination of indirect temperature telemetry and thruster on-time tracking. (MRD 10302030) – The ST 5 propulsion subsystem includes a miniature pressure transducer by GP: 50 to allow direct pressure telemetry. – Tank pressure can be calculated from tank temperature and thruster on-time data. • The thruster shall provide telemetry indicating the previous actuation activity of the thruster valve. (MRD 10101040) – The thruster control electronics (TCE) includes an indicator to monitor current pulses going to the solenoids. ST 5 PDR June 19 -20, 2001 17 - 3

GSFC Key Level II Requirements • The thruster shall operate in continuous mode, or pulsed mode. (MRD 10302011) – The cold gas micro-thruster is capable of operating from 0. 05 sec. minimum pulse width to continuous firing. • The propulsion subsystem shall provide a maximum delta-V of 7. 6 m/s. (MRD 10302020) – The 15 cm (6” OD) tank pressurized to 13. 8 Mpa (2000 psia) at BOL gives the system delta-V capability of 7. 6 m/s. • The thruster control circuitry shall have sufficient protections to preclude inadvertent thruster firings due to either hardware or software malfuctions. (MRD 10302040) – The TCE incorporates multiple safety features to prevent accidental thruster actuation that can lead to loss of propellant. ST 5 PDR June 19 -20, 2001 17 - 4

GSFC Key Level II Requirements • The thruster shall operate in continuous mode, or pulsed mode. (MRD 10302011) – The cold gas micro-thruster is capable of operating from 0. 05 sec. minimum pulse width to continuous firing. • The propulsion subsystem shall provide a maximum delta-V of 7. 6 m/s. (MRD 10302020) – The 15 cm (6” OD) tank pressurized to 13. 8 Mpa (2000 psia) at BOL gives the system delta-V capability of 7. 6 m/s. • The thruster control circuitry shall have sufficient protections to preclude inadvertent thruster firings due to either hardware or software malfuctions. (MRD 10302040) – The TCE incorporates multiple safety features to prevent accidental thruster actuation that can lead to loss of propellant. ST 5 PDR June 19 -20, 2001 17 - 4

GSFC Key Level II Requirements • The propulsion system shall be designed such that the prewelded propulsion system can be installed as one complete and tested assembly to the spacecraft. (MRD 10302050) – Small size and simplified layout of the ST 5 propulsion subsystem allows “assembly line” integration approach. – Each propulsion subsystem is integrated on a duplicate bottom deck plate, which serves as an assembly jig. – Each completed assembly is leak checked and tested for mechanical and electrical functions. – Each completed assembly is integrated on to the spacecraft structure. – The subsystem undergoes environmental test at the spacecraft level. ST 5 PDR June 19 -20, 2001 17 - 5

GSFC Key Level II Requirements • The propulsion system shall be designed such that the prewelded propulsion system can be installed as one complete and tested assembly to the spacecraft. (MRD 10302050) – Small size and simplified layout of the ST 5 propulsion subsystem allows “assembly line” integration approach. – Each propulsion subsystem is integrated on a duplicate bottom deck plate, which serves as an assembly jig. – Each completed assembly is leak checked and tested for mechanical and electrical functions. – Each completed assembly is integrated on to the spacecraft structure. – The subsystem undergoes environmental test at the spacecraft level. ST 5 PDR June 19 -20, 2001 17 - 5

GSFC Key Level III Requirements • Operational pressure range: 2000 psia BOL to 100 psia EOL – Thrust range: 2. 1 N (2000 psia) to 0. 1 N (100 psia) • GN 2 Propellant tank size – 1730 cc (106 ci) useable internal volume – 15 cm (6 “ ) maximum outer diameter • Total propellant load: 0. 27 kg of GN 2 at 20 degrees C • Minimum vacuum specific impulse: 60 seconds • Minimum pulse width: 50 ms ST 5 PDR June 19 -20, 2001 17 - 6

GSFC Key Level III Requirements • Operational pressure range: 2000 psia BOL to 100 psia EOL – Thrust range: 2. 1 N (2000 psia) to 0. 1 N (100 psia) • GN 2 Propellant tank size – 1730 cc (106 ci) useable internal volume – 15 cm (6 “ ) maximum outer diameter • Total propellant load: 0. 27 kg of GN 2 at 20 degrees C • Minimum vacuum specific impulse: 60 seconds • Minimum pulse width: 50 ms ST 5 PDR June 19 -20, 2001 17 - 6

GSFC Key Level III Requirements • ~1/3 Hz actuation frequency mode – For attitude control (spin axis precession) at 20 rpm – 50 ms to 2. 95 s pulse widths in 50 ms increments • 2 Hz actuation frequency mode – For orbit adjustment at 20 rpm – 50 ms to 450 ms pulse widths in 50 ms increments • Capable of continuous firing • Temperature range – -20 to 40 degrees C operating – -40 to 55 degrees C survival • 1 x 10 -4 scc/s He Maximum allowable system leakage rate ST 5 PDR June 19 -20, 2001 17 - 7

GSFC Key Level III Requirements • ~1/3 Hz actuation frequency mode – For attitude control (spin axis precession) at 20 rpm – 50 ms to 2. 95 s pulse widths in 50 ms increments • 2 Hz actuation frequency mode – For orbit adjustment at 20 rpm – 50 ms to 450 ms pulse widths in 50 ms increments • Capable of continuous firing • Temperature range – -20 to 40 degrees C operating – -40 to 55 degrees C survival • 1 x 10 -4 scc/s He Maximum allowable system leakage rate ST 5 PDR June 19 -20, 2001 17 - 7

GSFC Documentation Status • Propulsion Subsystem Specification ST 5 -495 -019 – Preliminary • Propulsion Subsystem Interface Control Document ST 5 -495 -015 – Preliminary • Cold Gas Micro Thruster SOW ST 5 -495 -001 – Under Project Configuration Management • Cold Gas Micro Thruster Specification ST 5 -495 -002 – Under Project Configuration Management • Other propulsion components SOWs and SPECs are in draft – Propellant tank – Pressure transducer – Propellant filter – Fill and drain valve ST 5 PDR June 19 -20, 2001 17 - 8

GSFC Documentation Status • Propulsion Subsystem Specification ST 5 -495 -019 – Preliminary • Propulsion Subsystem Interface Control Document ST 5 -495 -015 – Preliminary • Cold Gas Micro Thruster SOW ST 5 -495 -001 – Under Project Configuration Management • Cold Gas Micro Thruster Specification ST 5 -495 -002 – Under Project Configuration Management • Other propulsion components SOWs and SPECs are in draft – Propellant tank – Pressure transducer – Propellant filter – Fill and drain valve ST 5 PDR June 19 -20, 2001 17 - 8

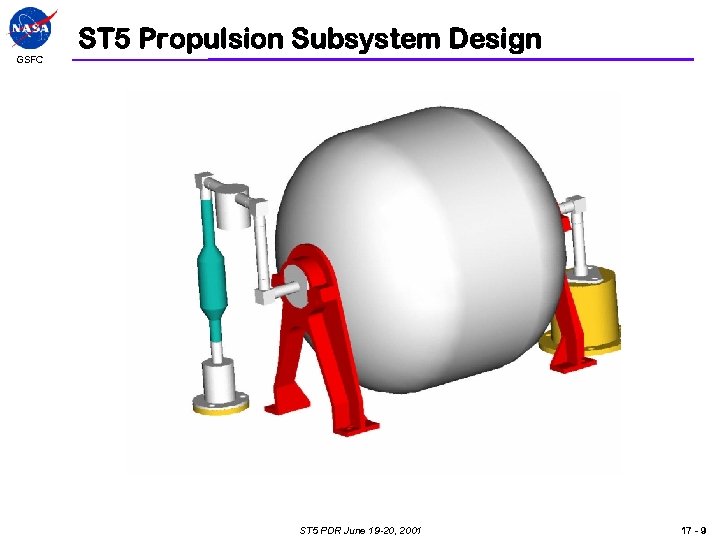

GSFC ST 5 Propulsion Subsystem Design ST 5 PDR June 19 -20, 2001 17 - 9

GSFC ST 5 Propulsion Subsystem Design ST 5 PDR June 19 -20, 2001 17 - 9

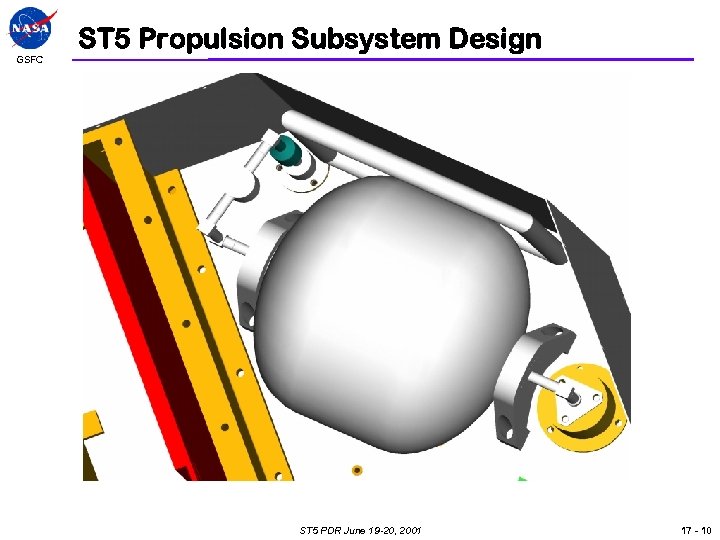

GSFC ST 5 Propulsion Subsystem Design ST 5 PDR June 19 -20, 2001 17 - 10

GSFC ST 5 Propulsion Subsystem Design ST 5 PDR June 19 -20, 2001 17 - 10

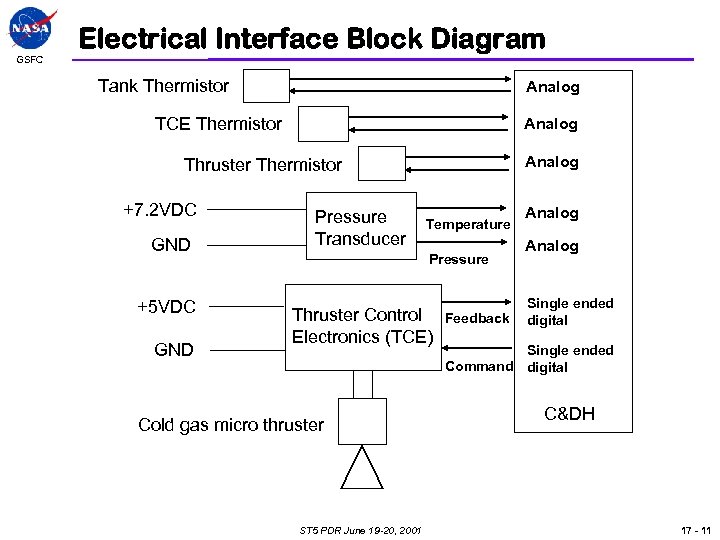

GSFC Electrical Interface Block Diagram Tank Thermistor Analog TCE Thermistor Analog Thruster Thermistor +7. 2 VDC GND +5 VDC GND Pressure Transducer Temperature Pressure Thruster Control Electronics (TCE) Cold gas micro thruster ST 5 PDR June 19 -20, 2001 Feedback Analog Single ended digital Single ended Command digital C&DH 17 - 11

GSFC Electrical Interface Block Diagram Tank Thermistor Analog TCE Thermistor Analog Thruster Thermistor +7. 2 VDC GND +5 VDC GND Pressure Transducer Temperature Pressure Thruster Control Electronics (TCE) Cold gas micro thruster ST 5 PDR June 19 -20, 2001 Feedback Analog Single ended digital Single ended Command digital C&DH 17 - 11

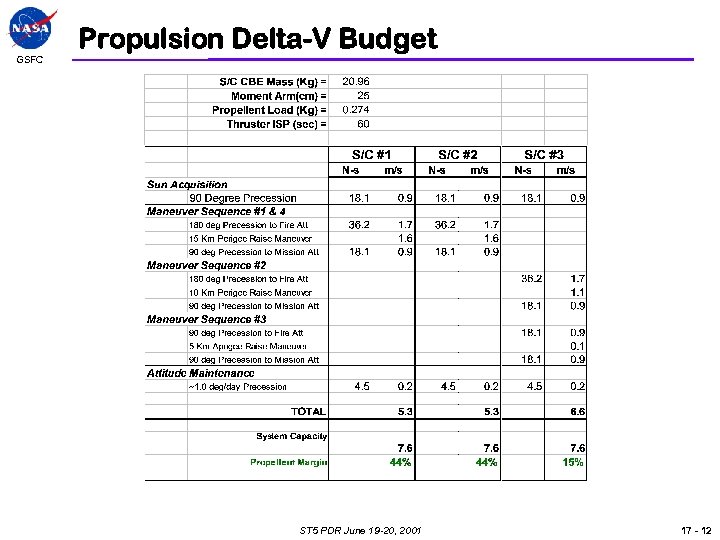

GSFC Propulsion Delta-V Budget ST 5 PDR June 19 -20, 2001 17 - 12

GSFC Propulsion Delta-V Budget ST 5 PDR June 19 -20, 2001 17 - 12

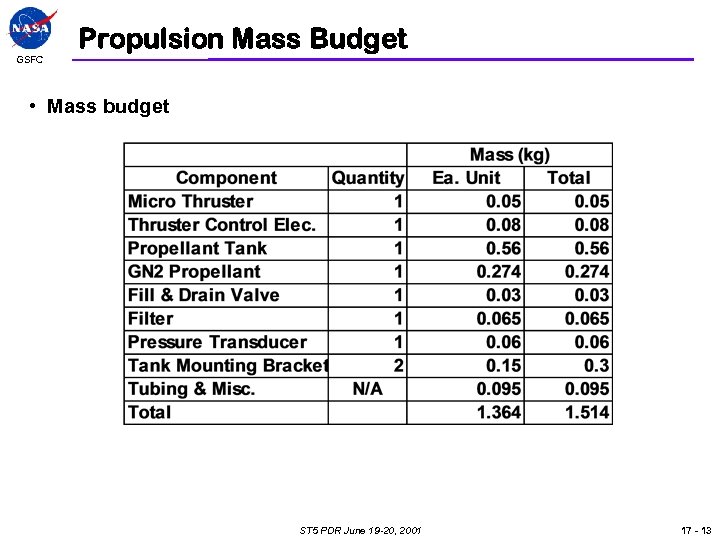

GSFC Propulsion Mass Budget • Mass budget ST 5 PDR June 19 -20, 2001 17 - 13

GSFC Propulsion Mass Budget • Mass budget ST 5 PDR June 19 -20, 2001 17 - 13

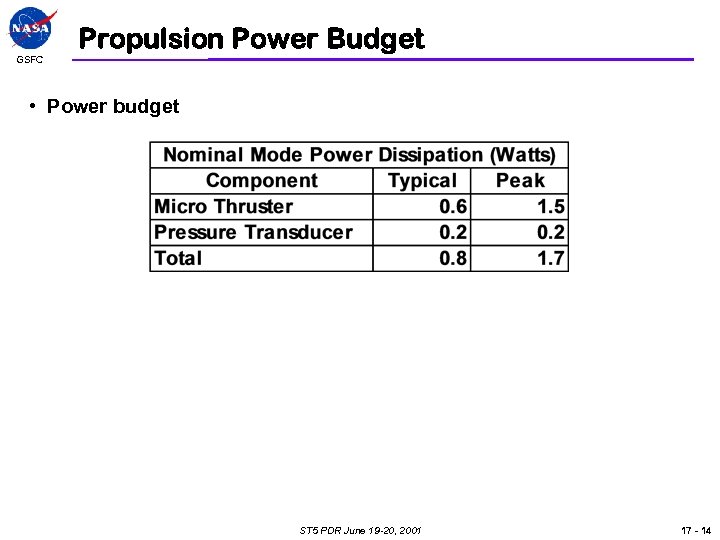

GSFC Propulsion Power Budget • Power budget ST 5 PDR June 19 -20, 2001 17 - 14

GSFC Propulsion Power Budget • Power budget ST 5 PDR June 19 -20, 2001 17 - 14

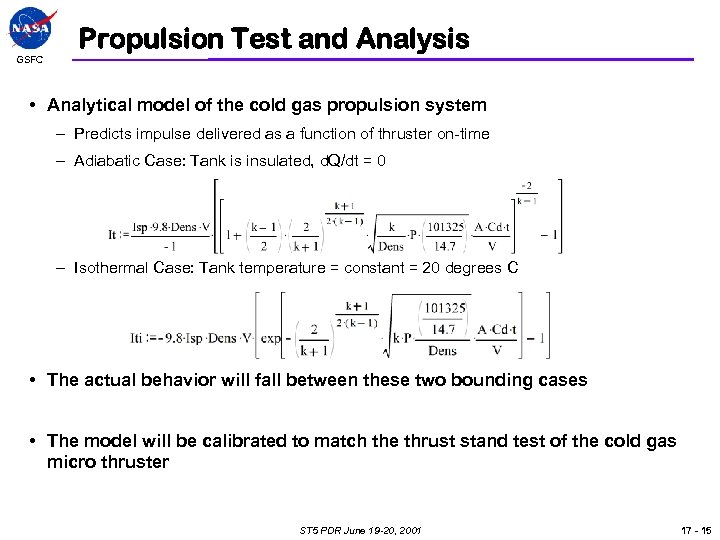

GSFC Propulsion Test and Analysis • Analytical model of the cold gas propulsion system – Predicts impulse delivered as a function of thruster on-time – Adiabatic Case: Tank is insulated, d. Q/dt = 0 – Isothermal Case: Tank temperature = constant = 20 degrees C • The actual behavior will fall between these two bounding cases • The model will be calibrated to match the thrust stand test of the cold gas micro thruster ST 5 PDR June 19 -20, 2001 17 - 15

GSFC Propulsion Test and Analysis • Analytical model of the cold gas propulsion system – Predicts impulse delivered as a function of thruster on-time – Adiabatic Case: Tank is insulated, d. Q/dt = 0 – Isothermal Case: Tank temperature = constant = 20 degrees C • The actual behavior will fall between these two bounding cases • The model will be calibrated to match the thrust stand test of the cold gas micro thruster ST 5 PDR June 19 -20, 2001 17 - 15

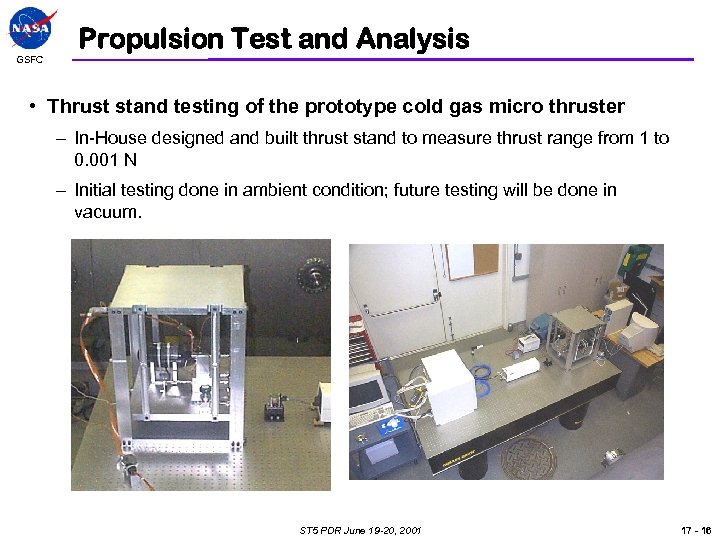

GSFC Propulsion Test and Analysis • Thrust stand testing of the prototype cold gas micro thruster – In-House designed and built thrust stand to measure thrust range from 1 to 0. 001 N – Initial testing done in ambient condition; future testing will be done in vacuum. ST 5 PDR June 19 -20, 2001 17 - 16

GSFC Propulsion Test and Analysis • Thrust stand testing of the prototype cold gas micro thruster – In-House designed and built thrust stand to measure thrust range from 1 to 0. 001 N – Initial testing done in ambient condition; future testing will be done in vacuum. ST 5 PDR June 19 -20, 2001 17 - 16

GSFC Future Test and Analysis Plan • In-House thrust stand testing of the cold gas micro thruster as a part of the qualification program • Refined analytical model of the propulsion system based on thrust stand test results • Create analytical model for predicting propellant usage based on thruster on time data and tank temperature • Structural analyses (Swales) • Thermal analyses (Code 545 or Swales) ST 5 PDR June 19 -20, 2001 17 - 17

GSFC Future Test and Analysis Plan • In-House thrust stand testing of the cold gas micro thruster as a part of the qualification program • Refined analytical model of the propulsion system based on thrust stand test results • Create analytical model for predicting propellant usage based on thruster on time data and tank temperature • Structural analyses (Swales) • Thermal analyses (Code 545 or Swales) ST 5 PDR June 19 -20, 2001 17 - 17

GSFC • Propulsion Hardware • Cold gas micro thruster (NMP Technology) – Developer: Marotta Scientific Controls, Montville, NJ – Low power (1 watt), light weight (50 g) design – Prototype hardware delivered to GSFC in July ’ 99 – In-House thrust stand testing of the prototype thruster in Dec. ’ 00 – Contract awarded to Marotta in Sep. ’ 99 for full development program – Currently in Phase B/Design stage; Phase C to begin in June ‘ 01 – Qual unit: proto-flight test levels – Flight units: acceptance test levels ST 5 PDR June 19 -20, 2001 17 - 18

GSFC • Propulsion Hardware • Cold gas micro thruster (NMP Technology) – Developer: Marotta Scientific Controls, Montville, NJ – Low power (1 watt), light weight (50 g) design – Prototype hardware delivered to GSFC in July ’ 99 – In-House thrust stand testing of the prototype thruster in Dec. ’ 00 – Contract awarded to Marotta in Sep. ’ 99 for full development program – Currently in Phase B/Design stage; Phase C to begin in June ‘ 01 – Qual unit: proto-flight test levels – Flight units: acceptance test levels ST 5 PDR June 19 -20, 2001 17 - 18

GSFC Propulsion Hardware • Thruster Control Electronics (NMP Technology) – Developer: Marotta Scientific Controls, Montville, NJ – Prototype TCE delivered to GSFC in July, ’ 99 – Contract awarded to Marotta in Sep. ’ 99 for full development program – Currently in Phase B/Design stage; Phase C to begin in June ’ 01 – Incorporates multiple safety features for increased reliability • Telemetry Feedback Signal • Thruster ON Limit Timer • Thruser ON Limit Timer Disable • Disable Valve Open Command when Capacitor Charge is too low • Automatic Valve Close on Power Loss – Qual unit: proto-flight test levels (To be performed In-House) – Flight units: acceptance test levels (To be performed In-House) ST 5 PDR June 19 -20, 2001 17 - 19

GSFC Propulsion Hardware • Thruster Control Electronics (NMP Technology) – Developer: Marotta Scientific Controls, Montville, NJ – Prototype TCE delivered to GSFC in July, ’ 99 – Contract awarded to Marotta in Sep. ’ 99 for full development program – Currently in Phase B/Design stage; Phase C to begin in June ’ 01 – Incorporates multiple safety features for increased reliability • Telemetry Feedback Signal • Thruster ON Limit Timer • Thruser ON Limit Timer Disable • Disable Valve Open Command when Capacitor Charge is too low • Automatic Valve Close on Power Loss – Qual unit: proto-flight test levels (To be performed In-House) – Flight units: acceptance test levels (To be performed In-House) ST 5 PDR June 19 -20, 2001 17 - 19

GSFC Propulsion Hardware • Baseline Pressure Transducer – Vendor: GP: 50 – 7. 2 VDC, Low power (200 m. W), lightweight (60 g) design – Analog electronics previously flown in STS – ST 5 version will undergo full qualification program based on ST 5 -495 -007, “Component Test Requirements and Guidelines” – Current status: SOW and Spec completed. Ready to start procurement. • Miniature Fill and Drain Valve and Propellant Filter – Vendor: Vacco – Fully qualified, COTS – Deliverables: Three flight units with acceptance data packages – Current Status: SOW and Spec completed. Ready to start procurement. ST 5 PDR June 19 -20, 2001 17 - 20

GSFC Propulsion Hardware • Baseline Pressure Transducer – Vendor: GP: 50 – 7. 2 VDC, Low power (200 m. W), lightweight (60 g) design – Analog electronics previously flown in STS – ST 5 version will undergo full qualification program based on ST 5 -495 -007, “Component Test Requirements and Guidelines” – Current status: SOW and Spec completed. Ready to start procurement. • Miniature Fill and Drain Valve and Propellant Filter – Vendor: Vacco – Fully qualified, COTS – Deliverables: Three flight units with acceptance data packages – Current Status: SOW and Spec completed. Ready to start procurement. ST 5 PDR June 19 -20, 2001 17 - 20

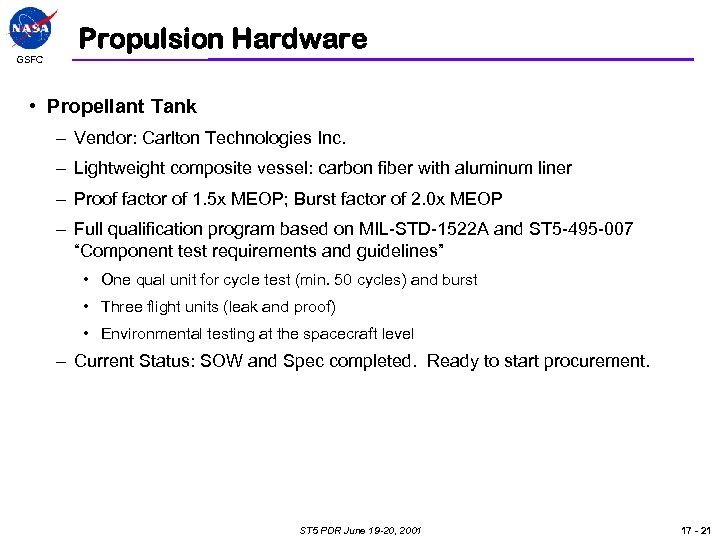

GSFC Propulsion Hardware • Propellant Tank – Vendor: Carlton Technologies Inc. – Lightweight composite vessel: carbon fiber with aluminum liner – Proof factor of 1. 5 x MEOP; Burst factor of 2. 0 x MEOP – Full qualification program based on MIL-STD-1522 A and ST 5 -495 -007 “Component test requirements and guidelines” • One qual unit for cycle test (min. 50 cycles) and burst • Three flight units (leak and proof) • Environmental testing at the spacecraft level – Current Status: SOW and Spec completed. Ready to start procurement. ST 5 PDR June 19 -20, 2001 17 - 21

GSFC Propulsion Hardware • Propellant Tank – Vendor: Carlton Technologies Inc. – Lightweight composite vessel: carbon fiber with aluminum liner – Proof factor of 1. 5 x MEOP; Burst factor of 2. 0 x MEOP – Full qualification program based on MIL-STD-1522 A and ST 5 -495 -007 “Component test requirements and guidelines” • One qual unit for cycle test (min. 50 cycles) and burst • Three flight units (leak and proof) • Environmental testing at the spacecraft level – Current Status: SOW and Spec completed. Ready to start procurement. ST 5 PDR June 19 -20, 2001 17 - 21

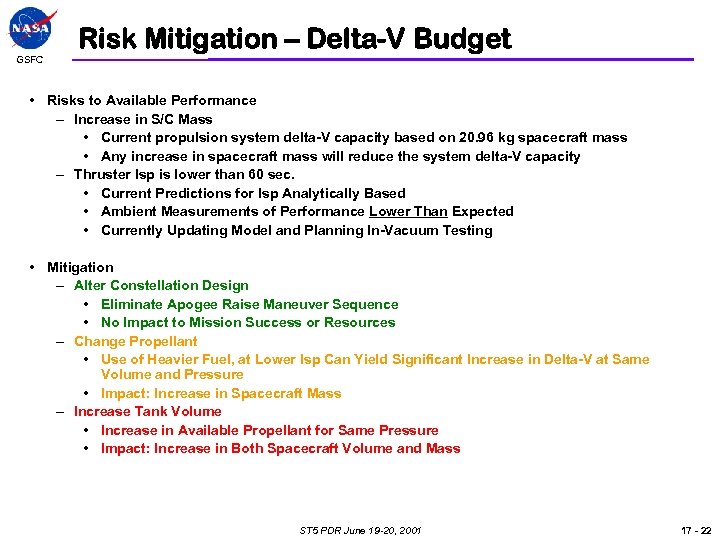

GSFC Risk Mitigation – Delta-V Budget • Risks to Available Performance – Increase in S/C Mass • Current propulsion system delta-V capacity based on 20. 96 kg spacecraft mass • Any increase in spacecraft mass will reduce the system delta-V capacity – Thruster Isp is lower than 60 sec. • Current Predictions for Isp Analytically Based • Ambient Measurements of Performance Lower Than Expected • Currently Updating Model and Planning In-Vacuum Testing • Mitigation – Alter Constellation Design • Eliminate Apogee Raise Maneuver Sequence • No Impact to Mission Success or Resources – Change Propellant • Use of Heavier Fuel, at Lower Isp Can Yield Significant Increase in Delta-V at Same Volume and Pressure • Impact: Increase in Spacecraft Mass – Increase Tank Volume • Increase in Available Propellant for Same Pressure • Impact: Increase in Both Spacecraft Volume and Mass ST 5 PDR June 19 -20, 2001 17 - 22

GSFC Risk Mitigation – Delta-V Budget • Risks to Available Performance – Increase in S/C Mass • Current propulsion system delta-V capacity based on 20. 96 kg spacecraft mass • Any increase in spacecraft mass will reduce the system delta-V capacity – Thruster Isp is lower than 60 sec. • Current Predictions for Isp Analytically Based • Ambient Measurements of Performance Lower Than Expected • Currently Updating Model and Planning In-Vacuum Testing • Mitigation – Alter Constellation Design • Eliminate Apogee Raise Maneuver Sequence • No Impact to Mission Success or Resources – Change Propellant • Use of Heavier Fuel, at Lower Isp Can Yield Significant Increase in Delta-V at Same Volume and Pressure • Impact: Increase in Spacecraft Mass – Increase Tank Volume • Increase in Available Propellant for Same Pressure • Impact: Increase in Both Spacecraft Volume and Mass ST 5 PDR June 19 -20, 2001 17 - 22