338bc7411e325ade55fdc1a6960e2ff6.ppt

- Количество слайдов: 108

South Dakota School of Mines & Technology Introduction to Probability & Statistics Industrial Engineering

South Dakota School of Mines & Technology Introduction to Probability & Statistics Industrial Engineering

South Dakota School of Mines & Technology Applications in Quality Industrial Engineering

South Dakota School of Mines & Technology Applications in Quality Industrial Engineering

South Dakota School of Mines & Technology Acceptance Sampling Industrial Engineering

South Dakota School of Mines & Technology Acceptance Sampling Industrial Engineering

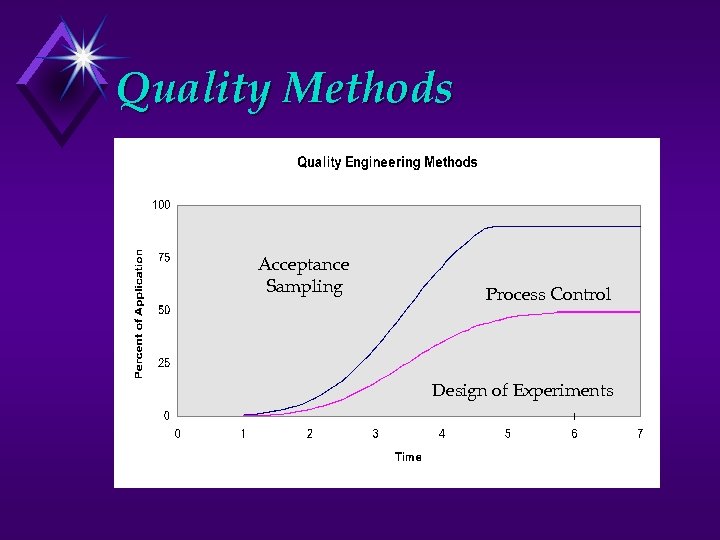

Quality Methods Acceptance Sampling Process Control Design of Experiments

Quality Methods Acceptance Sampling Process Control Design of Experiments

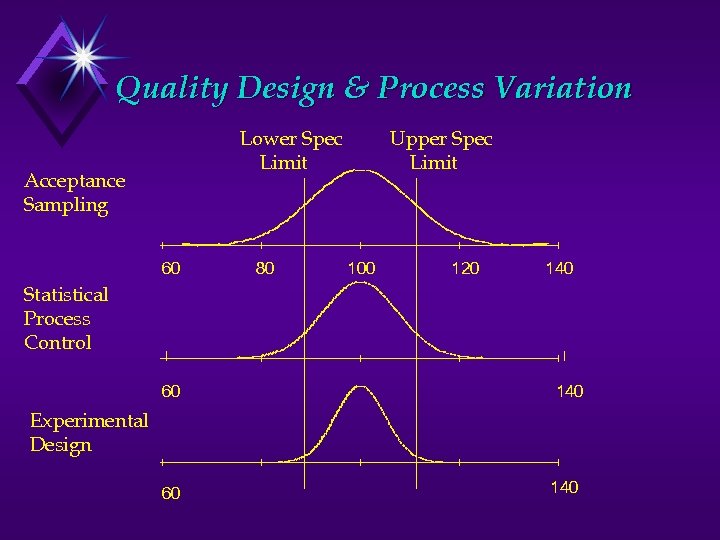

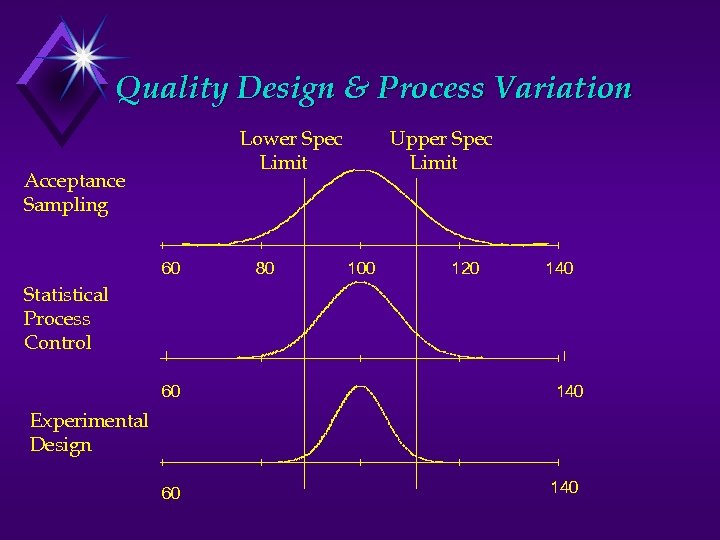

Quality Design & Process Variation Lower Spec Limit Acceptance Sampling 60 80 Upper Spec Limit 100 120 140 Statistical Process Control 60 140 Experimental Design 60 140

Quality Design & Process Variation Lower Spec Limit Acceptance Sampling 60 80 Upper Spec Limit 100 120 140 Statistical Process Control 60 140 Experimental Design 60 140

Acceptance Sampling Suppose we buy parts in lot sizes of 5, 000 and we wish to inspect to ensure that the incoming quality is sufficient. Obviously, we would not like to do 100% inspection. Idea: Select a portion, n, of the lot at random and determine the number of defects in the sample. If the number of defects, d, surpasses some critical value, c, assume the entire lot is defective and ship it back.

Acceptance Sampling Suppose we buy parts in lot sizes of 5, 000 and we wish to inspect to ensure that the incoming quality is sufficient. Obviously, we would not like to do 100% inspection. Idea: Select a portion, n, of the lot at random and determine the number of defects in the sample. If the number of defects, d, surpasses some critical value, c, assume the entire lot is defective and ship it back.

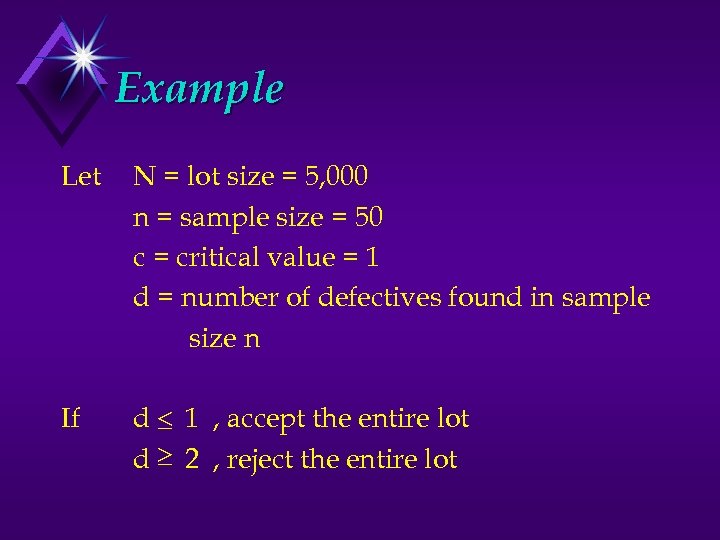

Example Let N = lot size = 5, 000 n = sample size = 50 c = critical value = 1 d = number of defectives found in sample size n If d 1 , accept the entire lot d 2 , reject the entire lot

Example Let N = lot size = 5, 000 n = sample size = 50 c = critical value = 1 d = number of defectives found in sample size n If d 1 , accept the entire lot d 2 , reject the entire lot

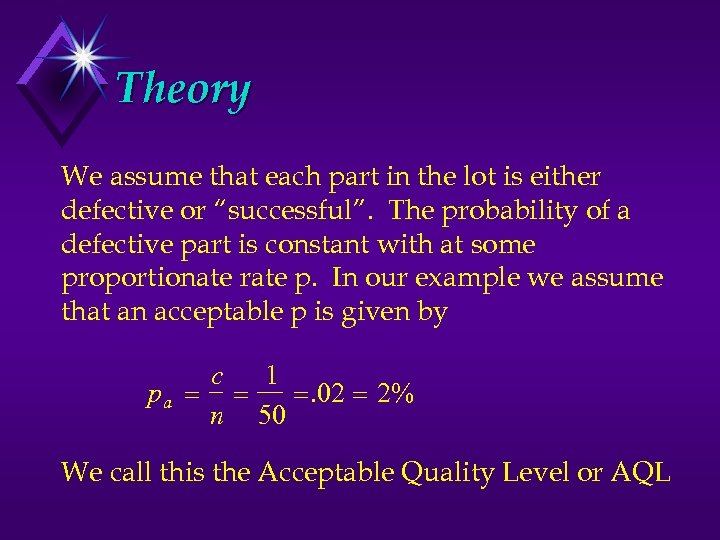

Theory We assume that each part in the lot is either defective or “successful”. The probability of a defective part is constant with at some proportionate rate p. In our example we assume that an acceptable p is given by c 1 pa . 02 2% n 50 We call this the Acceptable Quality Level or AQL

Theory We assume that each part in the lot is either defective or “successful”. The probability of a defective part is constant with at some proportionate rate p. In our example we assume that an acceptable p is given by c 1 pa . 02 2% n 50 We call this the Acceptable Quality Level or AQL

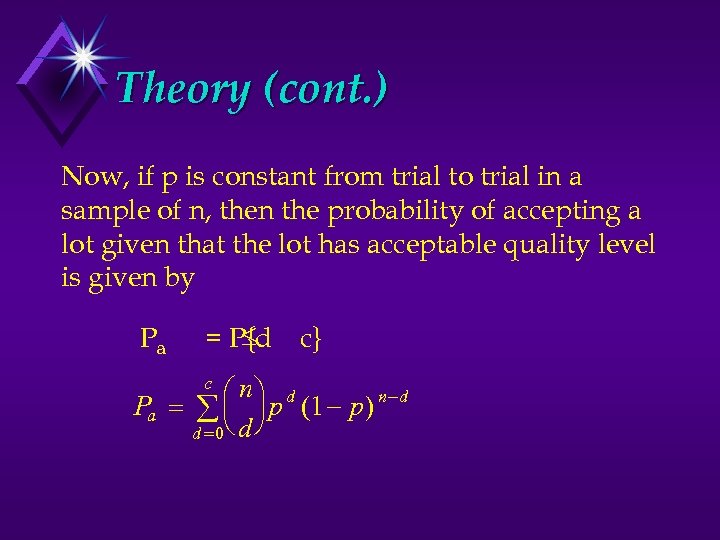

Theory (cont. ) Now, if p is constant from trial to trial in a sample of n, then the probability of accepting a lot given that the lot has acceptable quality level is given by Pa = P{d c} n p d (1 p ) n d Pa d 0 d c

Theory (cont. ) Now, if p is constant from trial to trial in a sample of n, then the probability of accepting a lot given that the lot has acceptable quality level is given by Pa = P{d c} n p d (1 p ) n d Pa d 0 d c

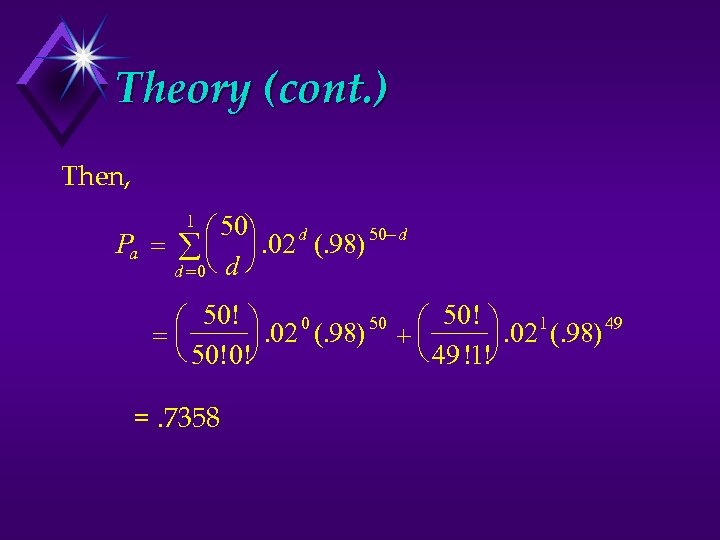

Theory (cont. ) Then, 50 . 02 d (. 98) 50 d Pa d 0 d 1 50! . 02 0 (. 98) 50 50! . 02 1 (. 98) 49 50!0! 49 !1! =. 7358

Theory (cont. ) Then, 50 . 02 d (. 98) 50 d Pa d 0 d 1 50! . 02 0 (. 98) 50 50! . 02 1 (. 98) 49 50!0! 49 !1! =. 7358

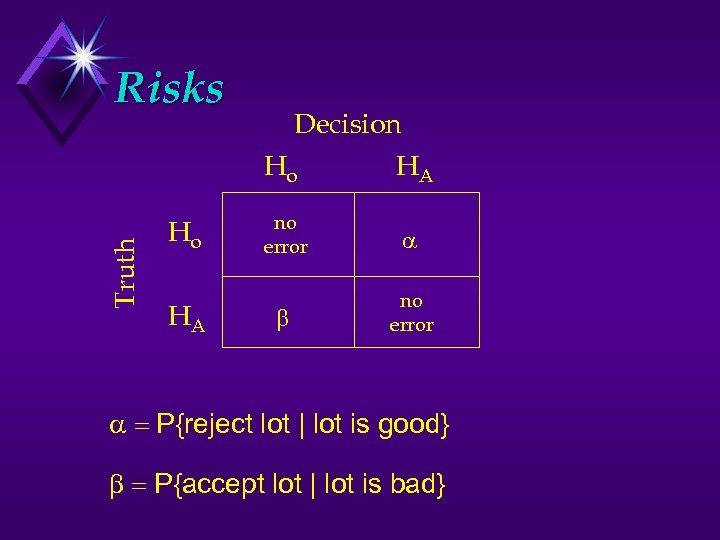

Truth Risks Ho HA Decision Ho HA no error P{reject lot | lot is good} P{accept lot | lot is bad}

Truth Risks Ho HA Decision Ho HA no error P{reject lot | lot is good} P{accept lot | lot is bad}

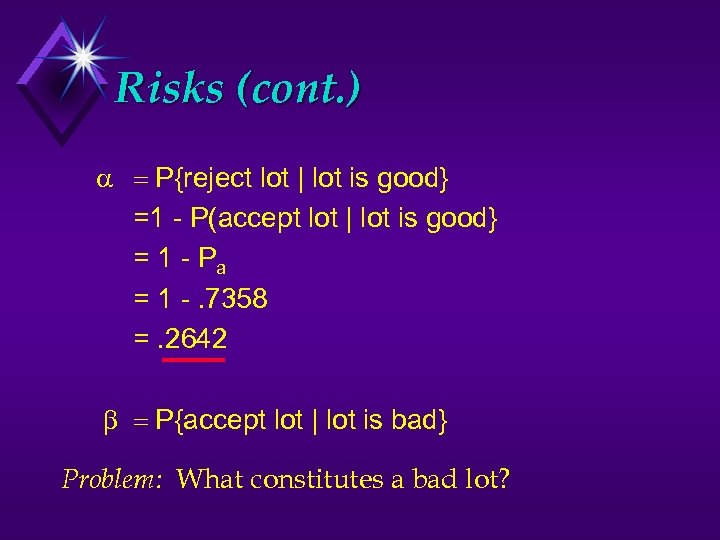

Risks (cont. ) P{reject lot | lot is good} =1 - P(accept lot | lot is good} = 1 - Pa = 1 -. 7358 =. 2642 P{accept lot | lot is bad} Problem: What constitutes a bad lot?

Risks (cont. ) P{reject lot | lot is good} =1 - P(accept lot | lot is good} = 1 - Pa = 1 -. 7358 =. 2642 P{accept lot | lot is bad} Problem: What constitutes a bad lot?

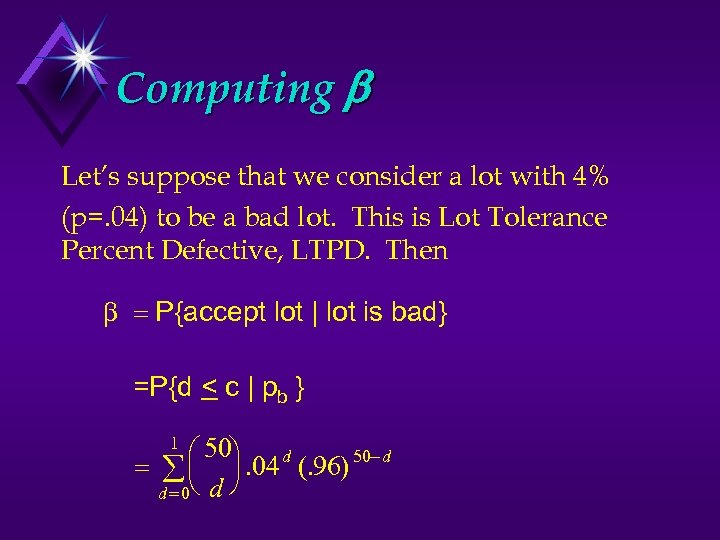

Computing Let’s suppose that we consider a lot with 4% (p=. 04) to be a bad lot. This is Lot Tolerance Percent Defective, LTPD. Then P{accept lot | lot is bad} =P{d < c | pb } 50 . 04 d (. 96) 50 d d 0 d 1

Computing Let’s suppose that we consider a lot with 4% (p=. 04) to be a bad lot. This is Lot Tolerance Percent Defective, LTPD. Then P{accept lot | lot is bad} =P{d < c | pb } 50 . 04 d (. 96) 50 d d 0 d 1

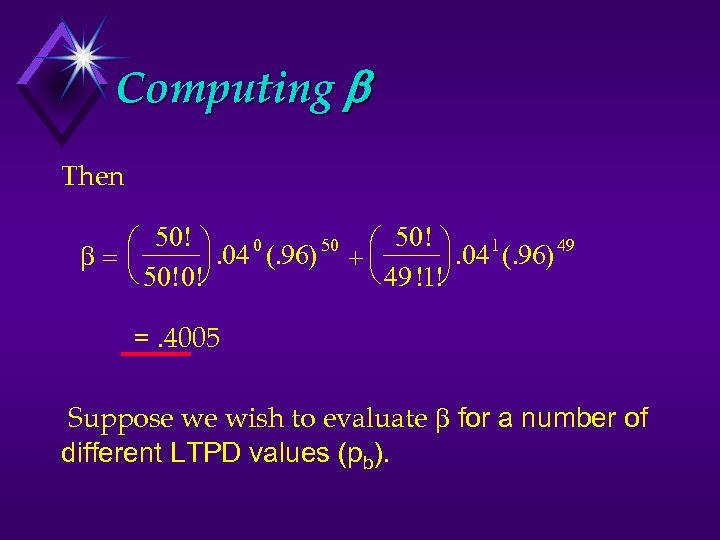

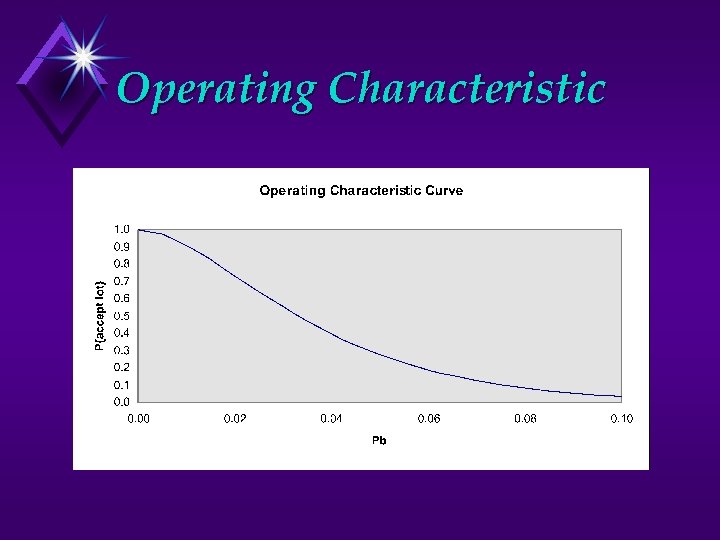

Computing Then 50! . 04 0 (. 96) 50 50! . 04 1 (. 96) 49 50!0! 49 !1! =. 4005 Suppose we wish to evaluate for a number of different LTPD values (pb).

Computing Then 50! . 04 0 (. 96) 50 50! . 04 1 (. 96) 49 50!0! 49 !1! =. 4005 Suppose we wish to evaluate for a number of different LTPD values (pb).

Operating Characteristic

Operating Characteristic

Acceptance Sampling u Uses u when testing is destructive u cost of 100% inspection is high u inspection error rate is high u cost of passing limited number of defective products is low u the process is stable

Acceptance Sampling u Uses u when testing is destructive u cost of 100% inspection is high u inspection error rate is high u cost of passing limited number of defective products is low u the process is stable

Acceptance Sampling u Limitations u does not estimate lot quality u does not provide for quality control u risks associated with accepting bad lots and rejecting good lots u Today’s Trends u high quality u small lots FRO’s find Acceptance Sampling of little use

Acceptance Sampling u Limitations u does not estimate lot quality u does not provide for quality control u risks associated with accepting bad lots and rejecting good lots u Today’s Trends u high quality u small lots FRO’s find Acceptance Sampling of little use

South Dakota School of Mines & Technology Introductory SPC The “Magnificent 7” Industrial Engineering

South Dakota School of Mines & Technology Introductory SPC The “Magnificent 7” Industrial Engineering

Quality Design & Process Variation Lower Spec Limit Acceptance Sampling 60 80 Upper Spec Limit 100 120 140 Statistical Process Control 60 140 Experimental Design 60 140

Quality Design & Process Variation Lower Spec Limit Acceptance Sampling 60 80 Upper Spec Limit 100 120 140 Statistical Process Control 60 140 Experimental Design 60 140

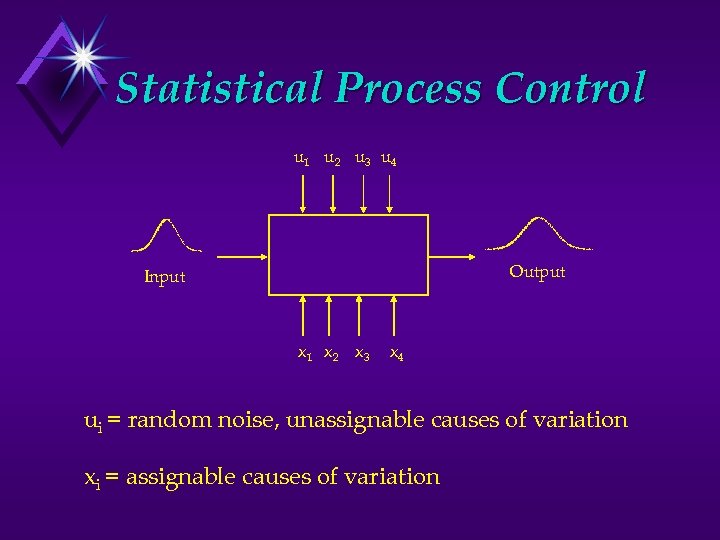

Statistical Process Control u 1 u 2 u 3 u 4 Output Input x 1 x 2 x 3 x 4 ui = random noise, unassignable causes of variation xi = assignable causes of variation

Statistical Process Control u 1 u 2 u 3 u 4 Output Input x 1 x 2 x 3 x 4 ui = random noise, unassignable causes of variation xi = assignable causes of variation

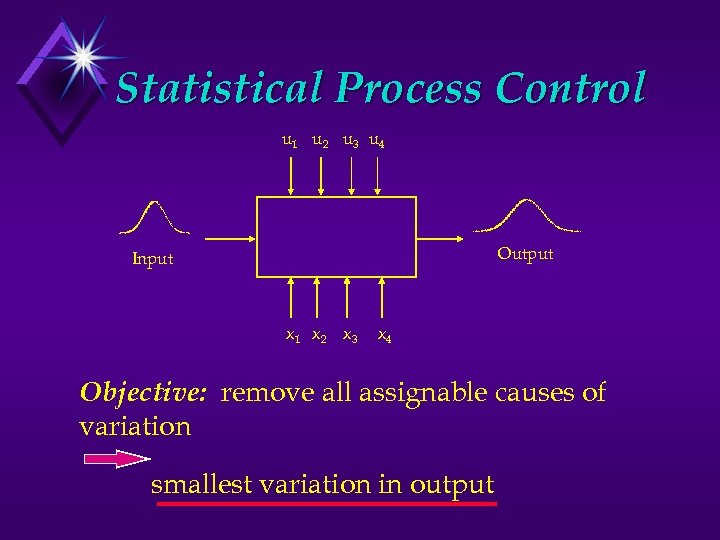

Statistical Process Control u 1 u 2 u 3 u 4 Output Input x 1 x 2 x 3 x 4 Objective: remove all assignable causes of variation smallest variation in output

Statistical Process Control u 1 u 2 u 3 u 4 Output Input x 1 x 2 x 3 x 4 Objective: remove all assignable causes of variation smallest variation in output

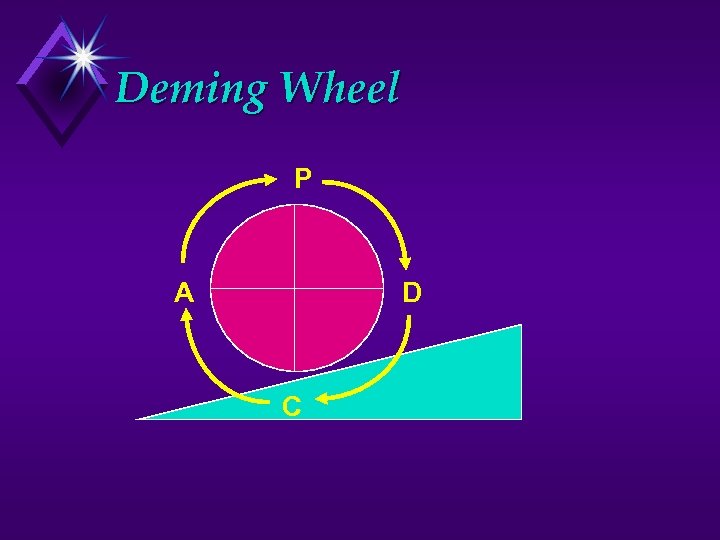

Deming Wheel P A D C

Deming Wheel P A D C

The Magnificent “ 7” Problem Solving Step Useful Tools Understand Mess Find Facts Identify Problems Flow Charts Check Sheets Pareto Diagrams Histograms Cause-and-Effect Scatter Diagrams Control Charts Generate Ideas Develop Solutions Implementation

The Magnificent “ 7” Problem Solving Step Useful Tools Understand Mess Find Facts Identify Problems Flow Charts Check Sheets Pareto Diagrams Histograms Cause-and-Effect Scatter Diagrams Control Charts Generate Ideas Develop Solutions Implementation

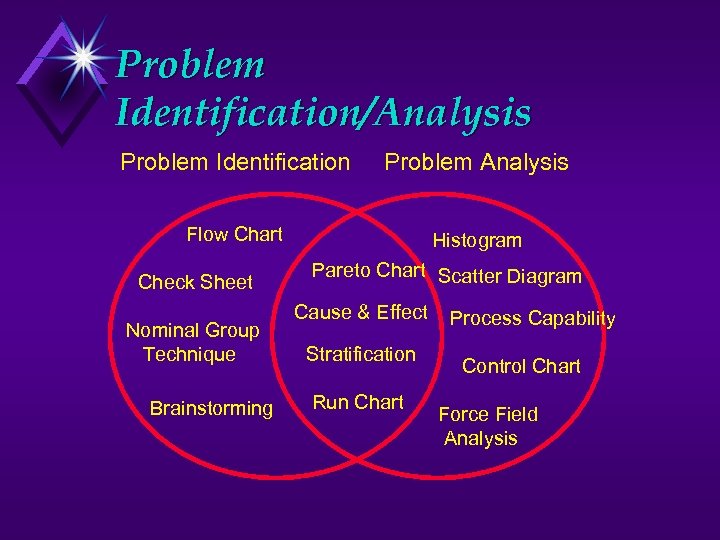

Problem Identification/Analysis Problem Identification Problem Analysis Flow Chart Histogram Check Sheet Nominal Group Technique Brainstorming Pareto Chart Scatter Diagram Cause & Effect Stratification Run Chart Process Capability Control Chart Force Field Analysis

Problem Identification/Analysis Problem Identification Problem Analysis Flow Chart Histogram Check Sheet Nominal Group Technique Brainstorming Pareto Chart Scatter Diagram Cause & Effect Stratification Run Chart Process Capability Control Chart Force Field Analysis

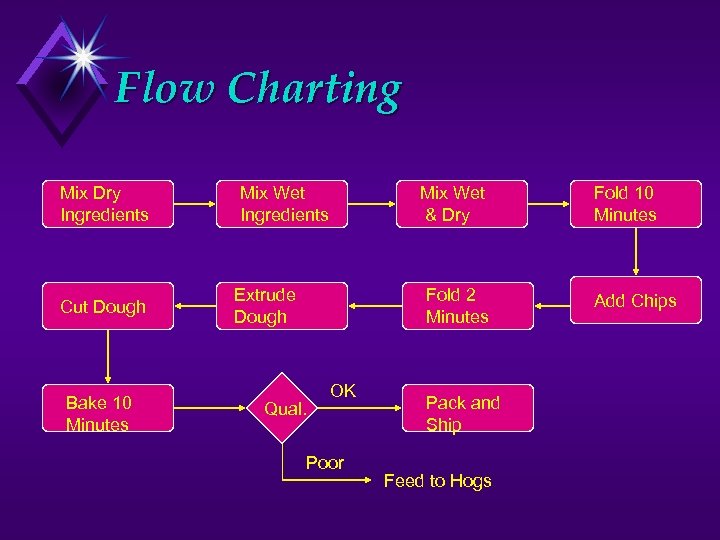

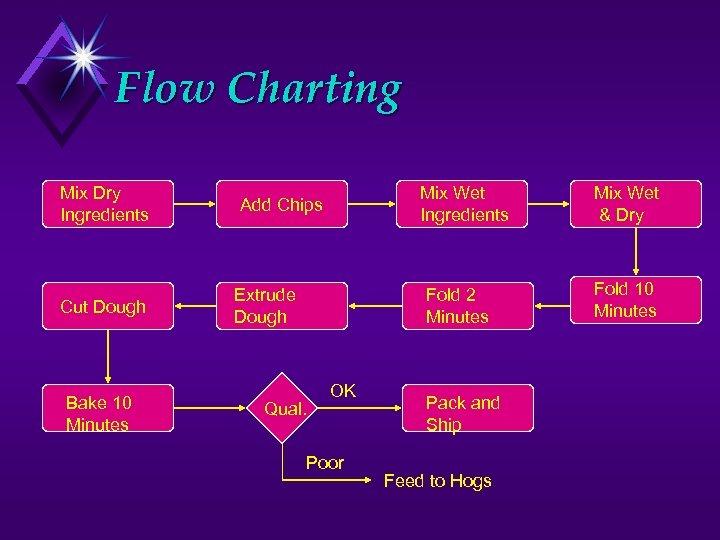

Flow Charting Mix Dry Ingredients Cut Dough Bake 10 Minutes Mix Wet Ingredients Mix Wet & Dry Extrude Dough Fold 2 Minutes Qual. OK Poor Pack and Ship Feed to Hogs Fold 10 Minutes Add Chips

Flow Charting Mix Dry Ingredients Cut Dough Bake 10 Minutes Mix Wet Ingredients Mix Wet & Dry Extrude Dough Fold 2 Minutes Qual. OK Poor Pack and Ship Feed to Hogs Fold 10 Minutes Add Chips

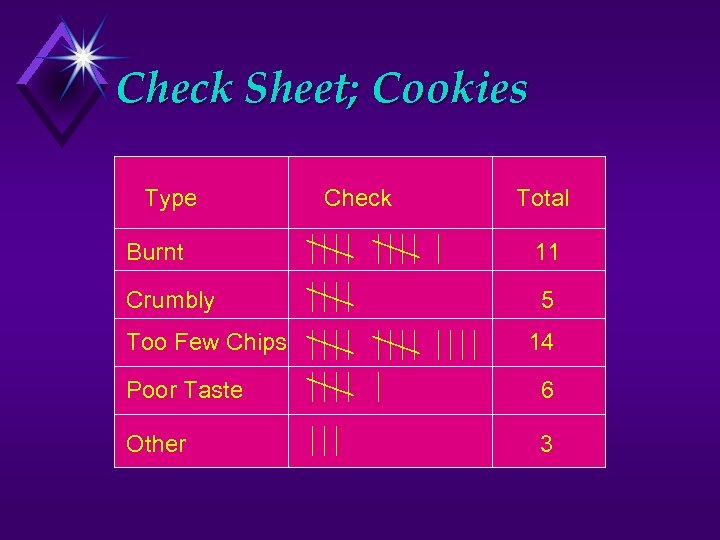

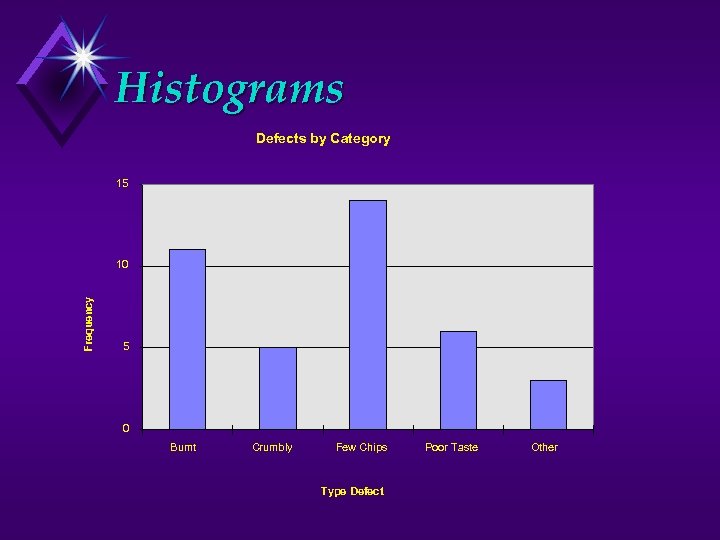

Check Sheet; Cookies Type Check Total Burnt 11 Crumbly 5 Too Few Chips 14 Poor Taste 6 Other 3

Check Sheet; Cookies Type Check Total Burnt 11 Crumbly 5 Too Few Chips 14 Poor Taste 6 Other 3

Histograms Defects by Category 15 Frequency 10 5 0 Burnt Crumbly Few Chips Type Defect Poor Taste Other

Histograms Defects by Category 15 Frequency 10 5 0 Burnt Crumbly Few Chips Type Defect Poor Taste Other

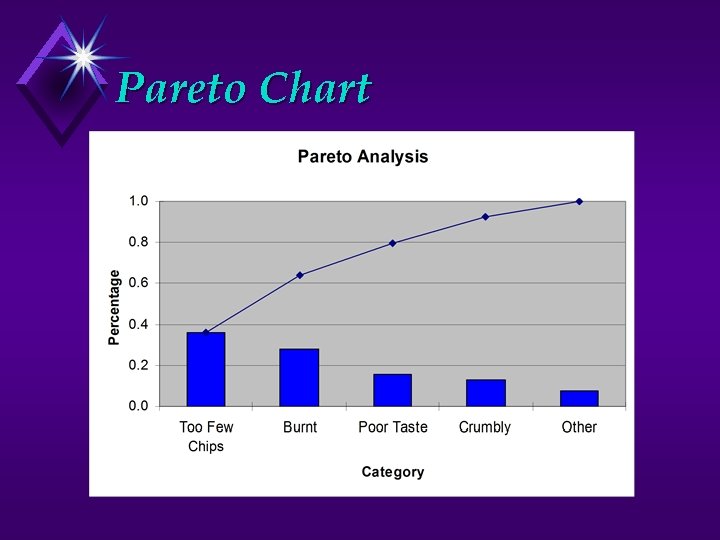

Pareto Chart

Pareto Chart

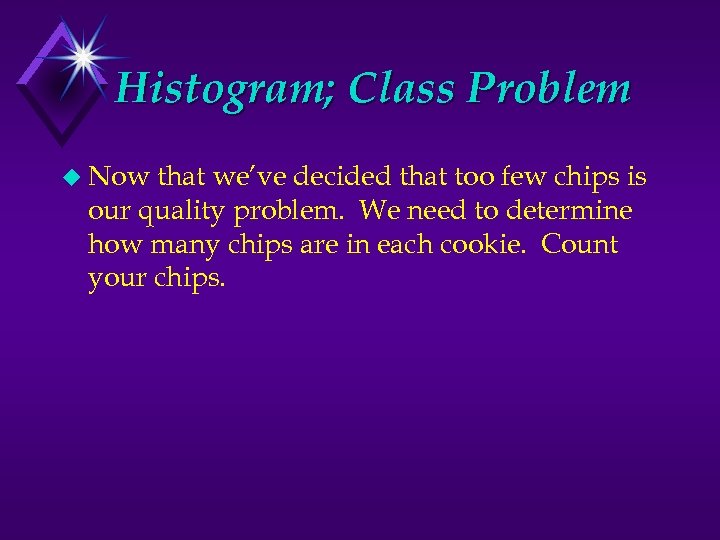

Histogram; Class Problem u Now that we’ve decided that too few chips is our quality problem. We need to determine how many chips are in each cookie. Count your chips.

Histogram; Class Problem u Now that we’ve decided that too few chips is our quality problem. We need to determine how many chips are in each cookie. Count your chips.

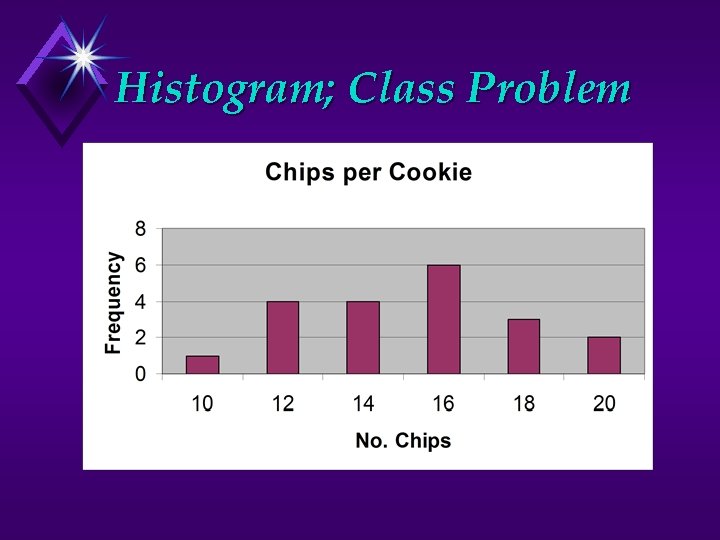

Histogram; Class Problem

Histogram; Class Problem

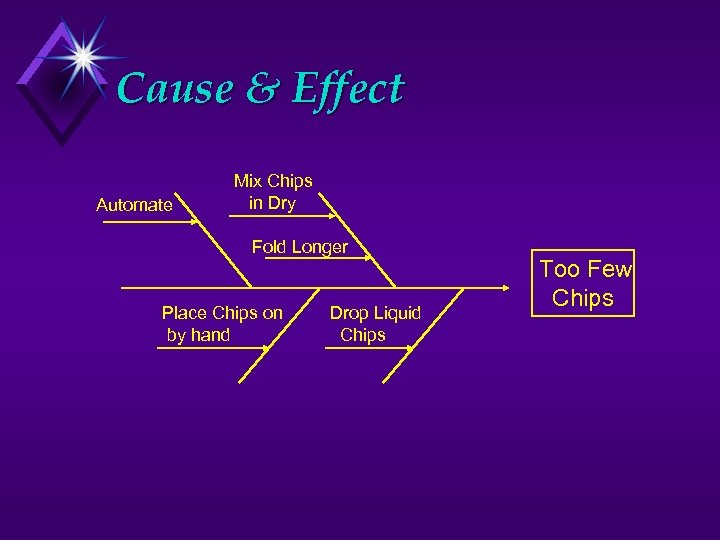

Cause & Effect Automate Mix Chips in Dry Fold Longer Place Chips on by hand Drop Liquid Chips Too Few Chips

Cause & Effect Automate Mix Chips in Dry Fold Longer Place Chips on by hand Drop Liquid Chips Too Few Chips

Cause & Effect People Methods Handling Effect Design Tools

Cause & Effect People Methods Handling Effect Design Tools

Idea; Cookies As a first step, let’s try Increasing Folding Time

Idea; Cookies As a first step, let’s try Increasing Folding Time

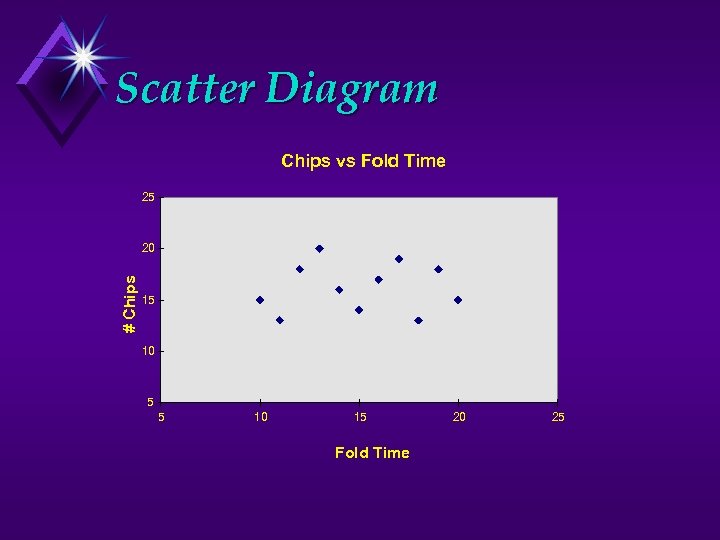

Scatter Diagram Chips vs Fold Time 25 # Chips 20 15 10 5 5 10 15 Fold Time 20 25

Scatter Diagram Chips vs Fold Time 25 # Chips 20 15 10 5 5 10 15 Fold Time 20 25

New Idea; Cookies Try Mixing Chips in With Dry Ingredients

New Idea; Cookies Try Mixing Chips in With Dry Ingredients

Flow Charting Mix Dry Ingredients Cut Dough Bake 10 Minutes Mix Wet Ingredients Add Chips Extrude Dough Fold 2 Minutes Qual. OK Poor Pack and Ship Feed to Hogs Mix Wet & Dry Fold 10 Minutes

Flow Charting Mix Dry Ingredients Cut Dough Bake 10 Minutes Mix Wet Ingredients Add Chips Extrude Dough Fold 2 Minutes Qual. OK Poor Pack and Ship Feed to Hogs Mix Wet & Dry Fold 10 Minutes

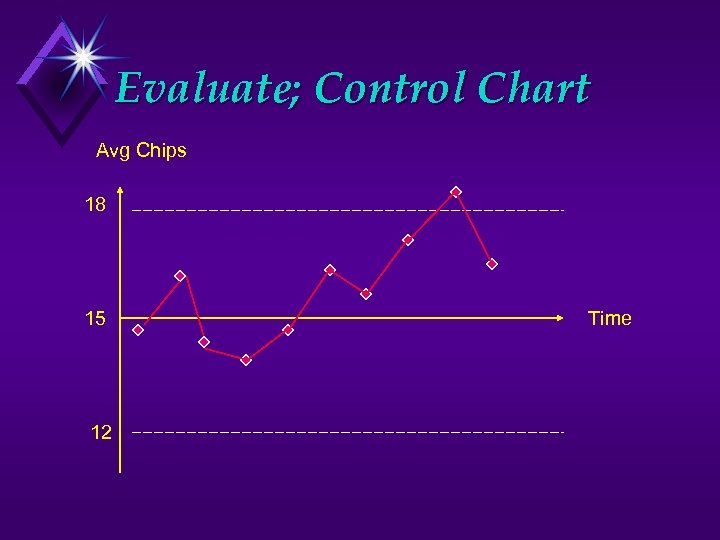

Evaluate; Control Chart Avg Chips 18 15 12 Time

Evaluate; Control Chart Avg Chips 18 15 12 Time

South Dakota School of Mines & Technology Control Charts Industrial Engineering

South Dakota School of Mines & Technology Control Charts Industrial Engineering

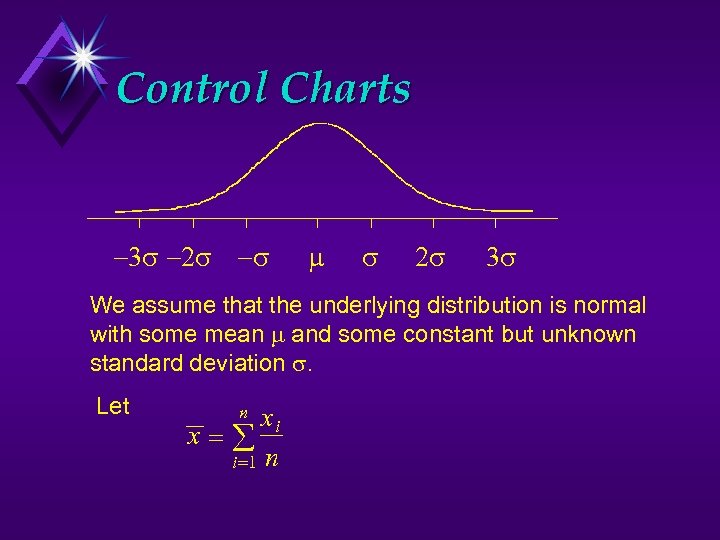

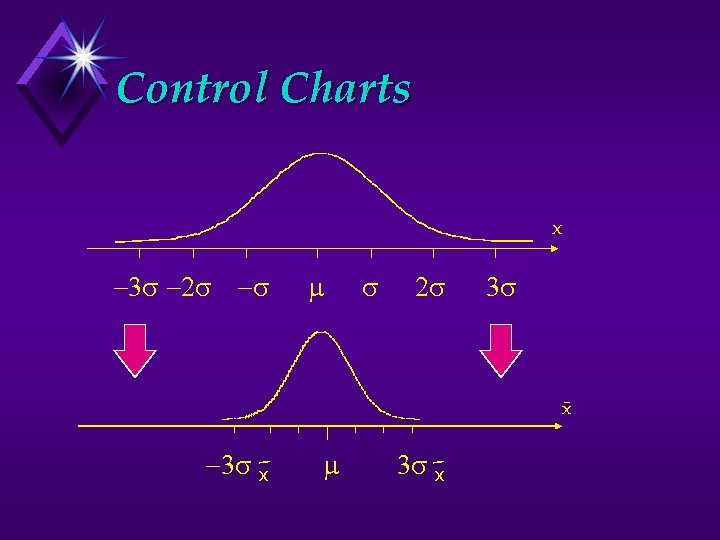

Control Charts We assume that the underlying distribution is normal with some mean and some constant but unknown standard deviation . Let xi x i 1 n n

Control Charts We assume that the underlying distribution is normal with some mean and some constant but unknown standard deviation . Let xi x i 1 n n

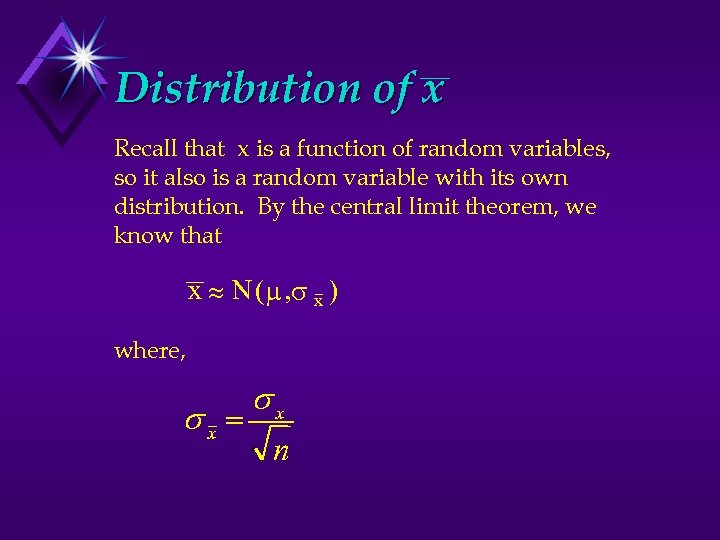

Distribution of x Recall that x is a function of random variables, so it also is a random variable with its own distribution. By the central limit theorem, we know that x N ( , x ) where, x x n

Distribution of x Recall that x is a function of random variables, so it also is a random variable with its own distribution. By the central limit theorem, we know that x N ( , x ) where, x x n

Control Charts x x x x

Control Charts x x x x

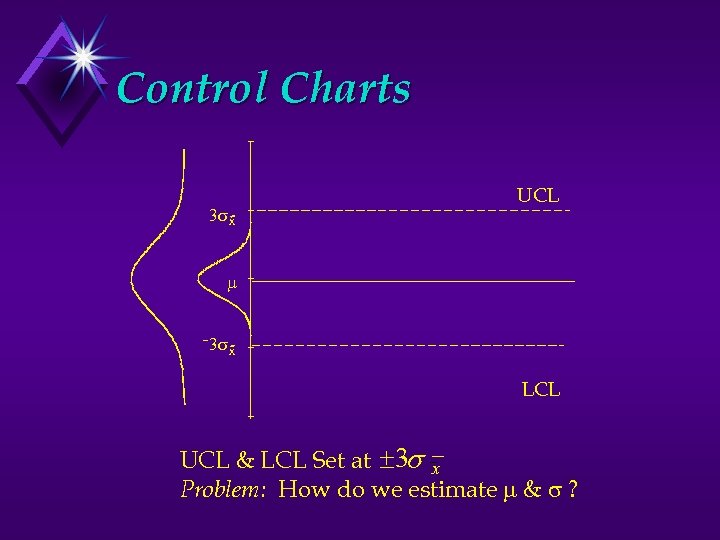

Control Charts x UCL x LCL UCL & LCL Set at 3 x Problem: How do we estimate & ?

Control Charts x UCL x LCL UCL & LCL Set at 3 x Problem: How do we estimate & ?

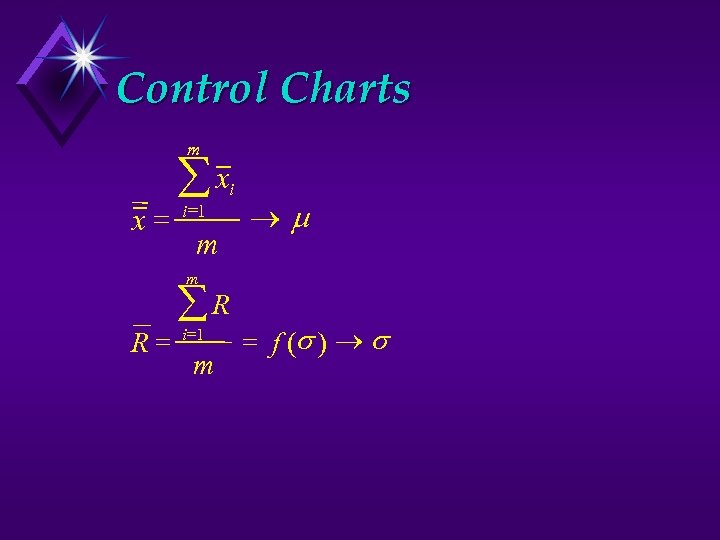

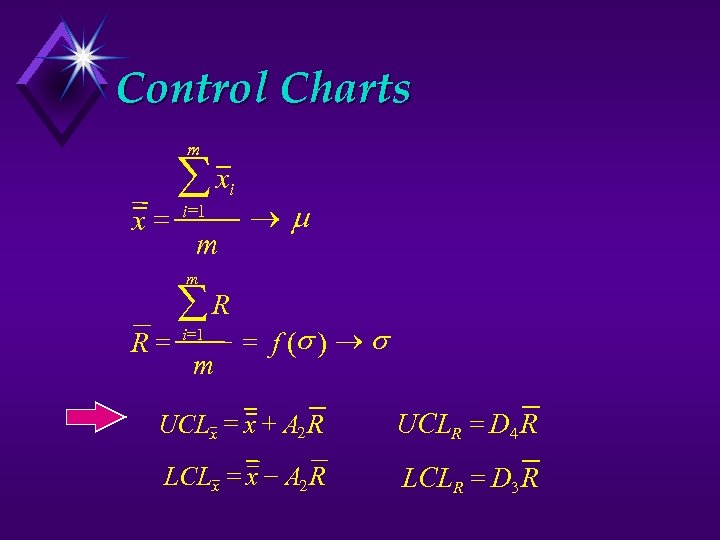

Control Charts m x x i 1 i m ® m R R i 1 m f ( ) ®

Control Charts m x x i 1 i m ® m R R i 1 m f ( ) ®

Control Charts m x x i 1 i m ® m R R i 1 m f ( ) ® UCLx x A 2 R UCLR D 4 R LCLx x A 2 R LCLR D 3 R

Control Charts m x x i 1 i m ® m R R i 1 m f ( ) ® UCLx x A 2 R UCLR D 4 R LCLx x A 2 R LCLR D 3 R

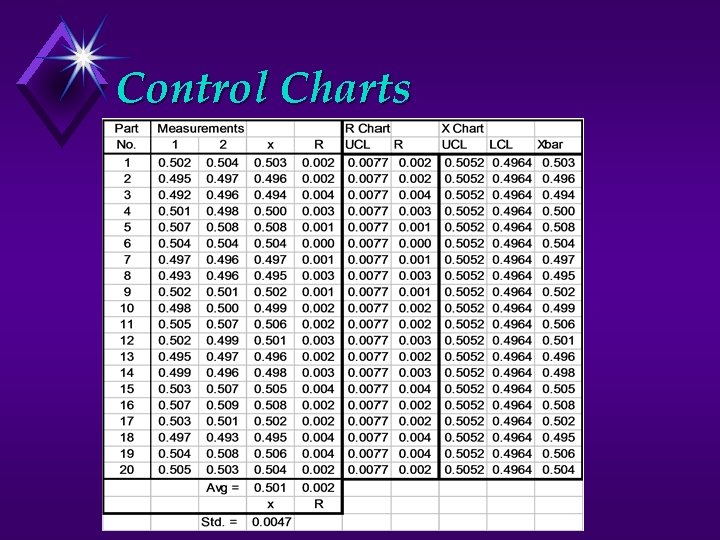

Example u Suppose specialized o-rings are to be manufactured at. 5 inches. Too big and they won’t provide the necessary seal. Too little and they won’t fit on the shaft. Twenty samples of 2 rings each are taken. Results follow.

Example u Suppose specialized o-rings are to be manufactured at. 5 inches. Too big and they won’t provide the necessary seal. Too little and they won’t fit on the shaft. Twenty samples of 2 rings each are taken. Results follow.

Control Charts

Control Charts

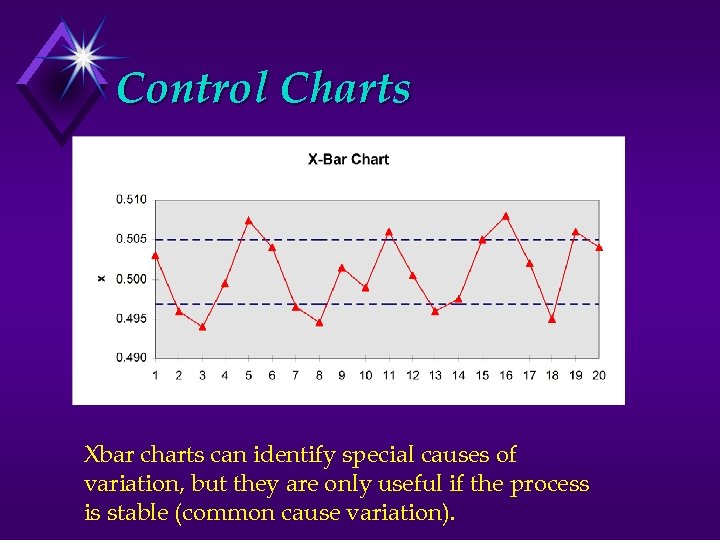

Control Charts Xbar charts can identify special causes of variation, but they are only useful if the process is stable (common cause variation).

Control Charts Xbar charts can identify special causes of variation, but they are only useful if the process is stable (common cause variation).

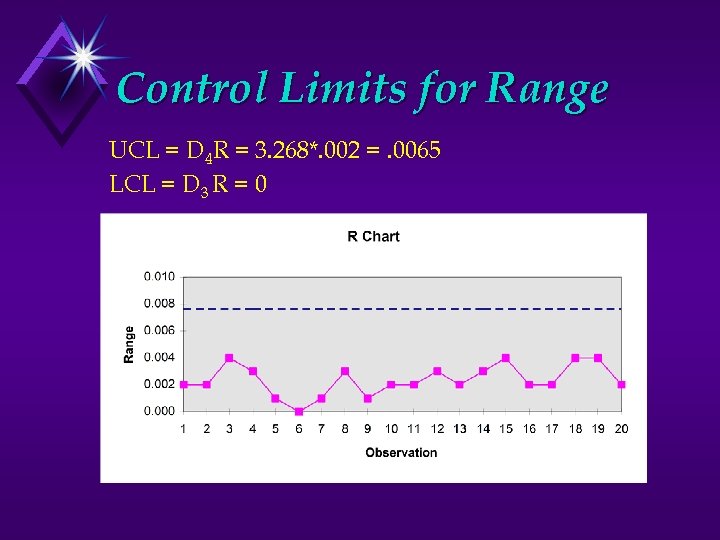

Control Limits for Range UCL = D 4 R = 3. 268*. 002 =. 0065 LCL = D 3 R = 0

Control Limits for Range UCL = D 4 R = 3. 268*. 002 =. 0065 LCL = D 3 R = 0

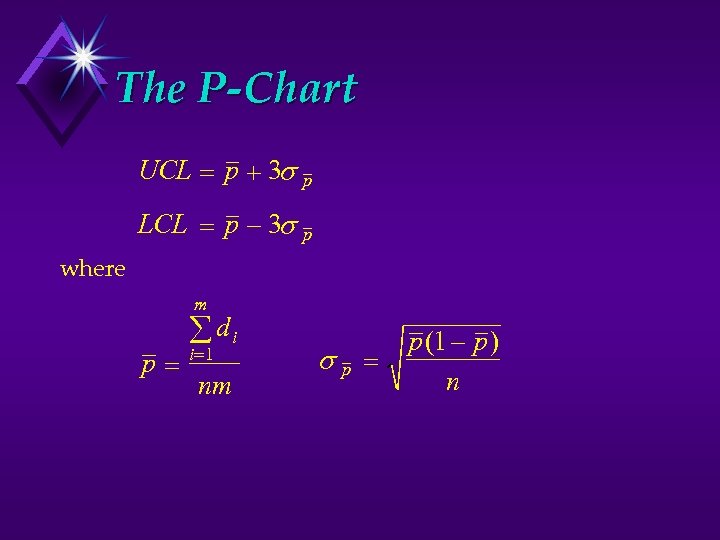

The P-Chart UCL p 3 p LCL p 3 p where m p di i 1 nm p p (1 p ) n

The P-Chart UCL p 3 p LCL p 3 p where m p di i 1 nm p p (1 p ) n

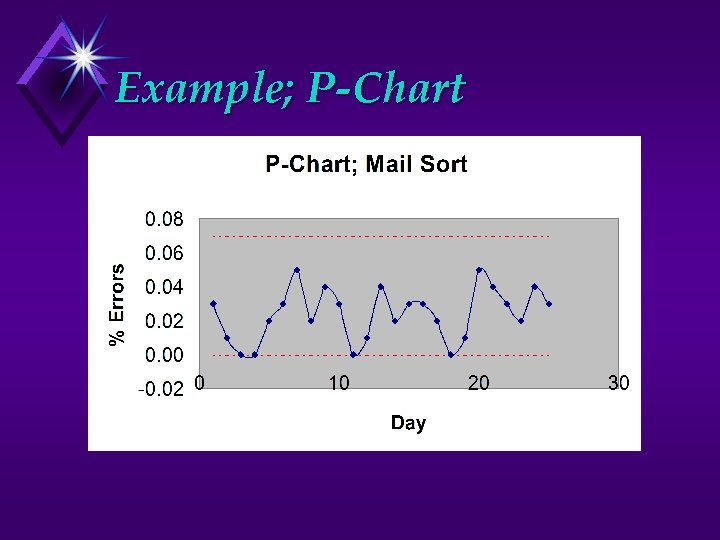

Example; P-Chart u Operators of a sorting machine must read the zip code on a letter and diver the letter to the proper carrier route. Over one month’s time, 25 samples of 100 letters were chosen, and the number of errors was recorded. Error counts for each of the 25 days follows.

Example; P-Chart u Operators of a sorting machine must read the zip code on a letter and diver the letter to the proper carrier route. Over one month’s time, 25 samples of 100 letters were chosen, and the number of errors was recorded. Error counts for each of the 25 days follows.

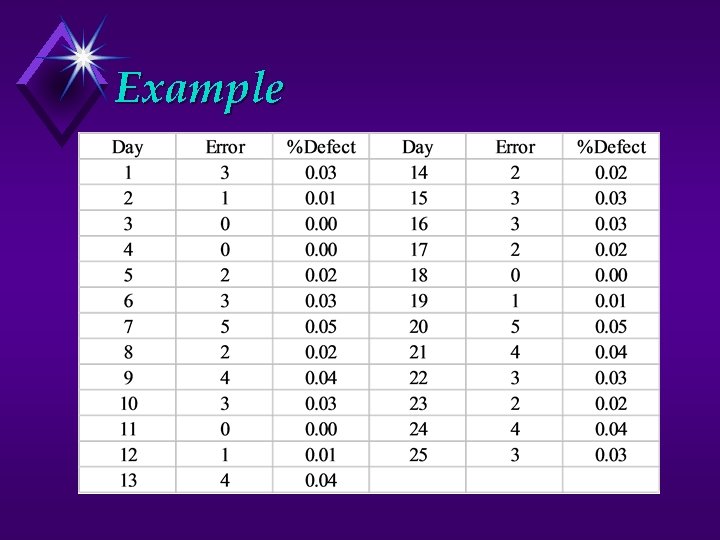

Example

Example

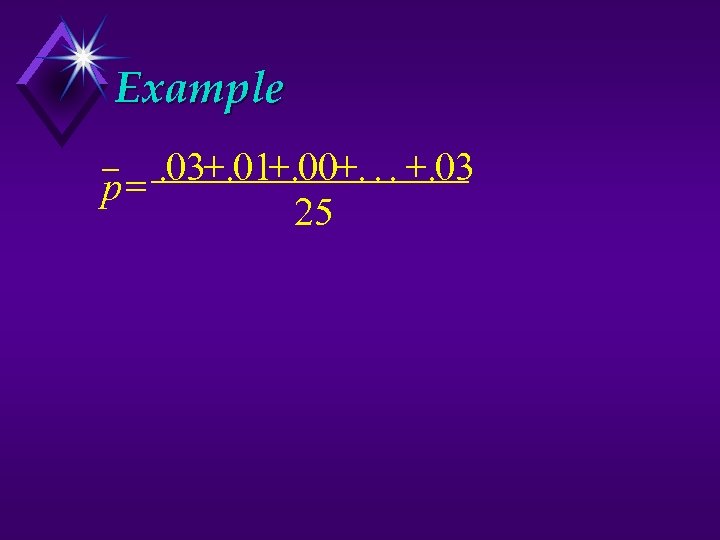

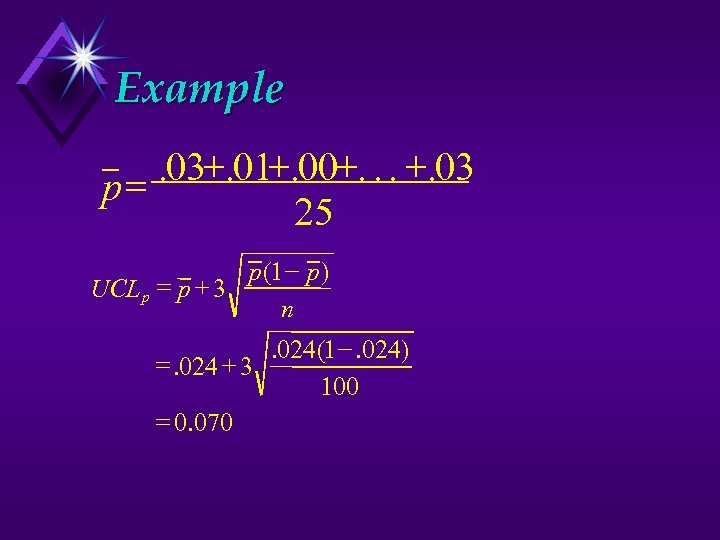

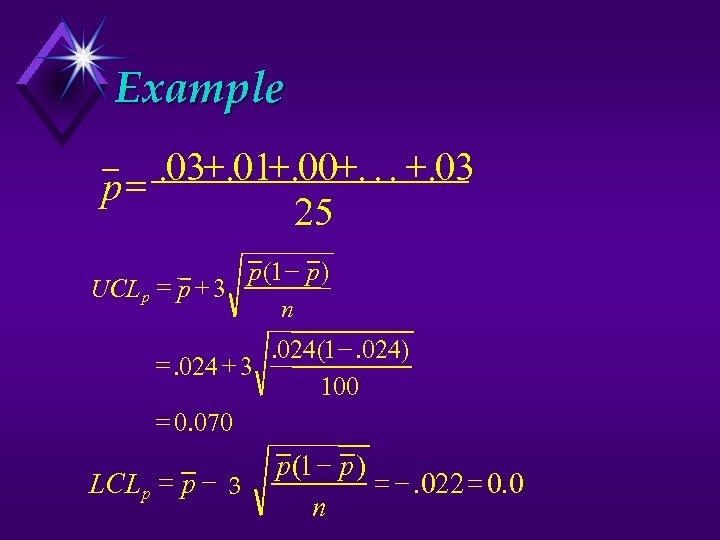

Example. 03. 01. 00. . 03 p 25

Example. 03. 01. 00. . 03 p 25

Example. 03. 01. 00. . 03 p 25 p (1 p ) UCL p p 3 n. 024(1 . 024) . 024 3 100 0. 070

Example. 03. 01. 00. . 03 p 25 p (1 p ) UCL p p 3 n. 024(1 . 024) . 024 3 100 0. 070

Example. 03. 01. 00. . 03 p 25 p (1 p ) UCL p p 3 n. 024(1 . 024) . 024 3 100 0. 070 LCL p p 3 p (1 p ) . 022 0. 0 n

Example. 03. 01. 00. . 03 p 25 p (1 p ) UCL p p 3 n. 024(1 . 024) . 024 3 100 0. 070 LCL p p 3 p (1 p ) . 022 0. 0 n

Example; P-Chart

Example; P-Chart

South Dakota School of Mines & Technology Process Capability Industrial Engineering

South Dakota School of Mines & Technology Process Capability Industrial Engineering

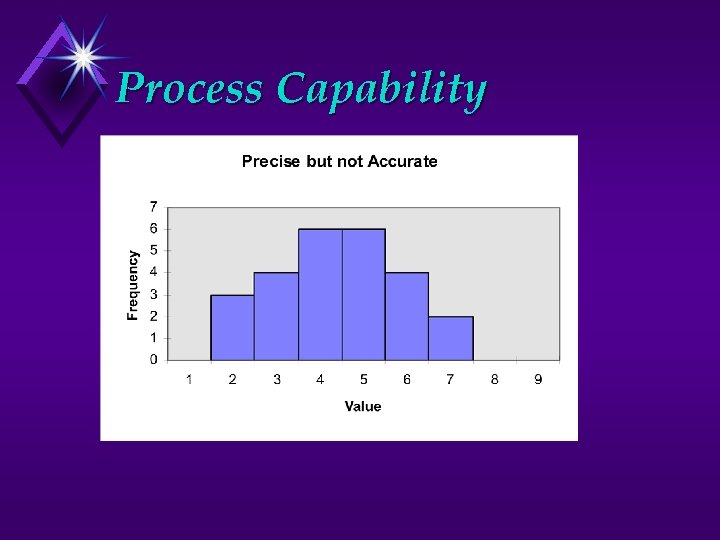

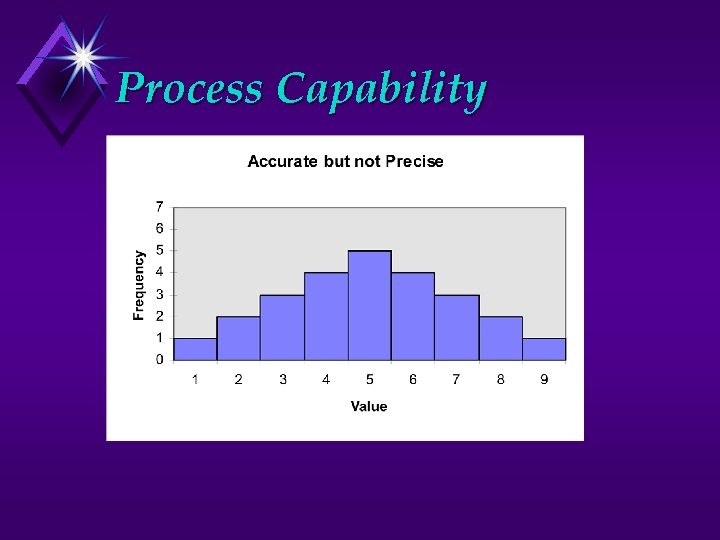

Process Capability

Process Capability

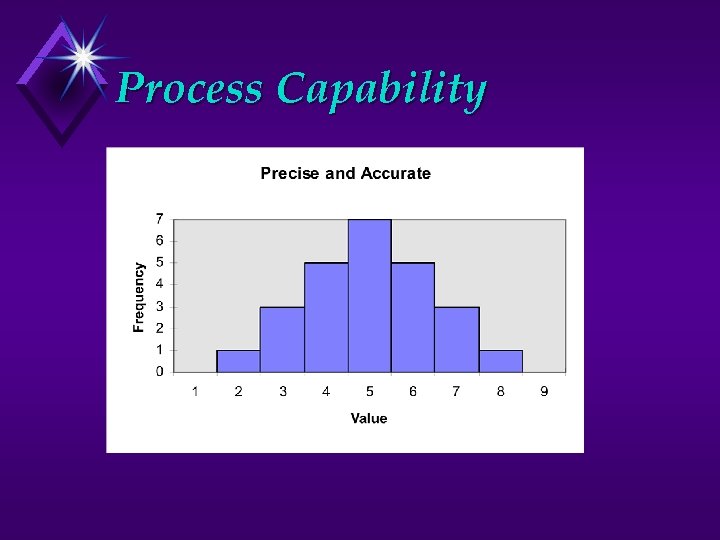

Process Capability

Process Capability

Process Capability

Process Capability

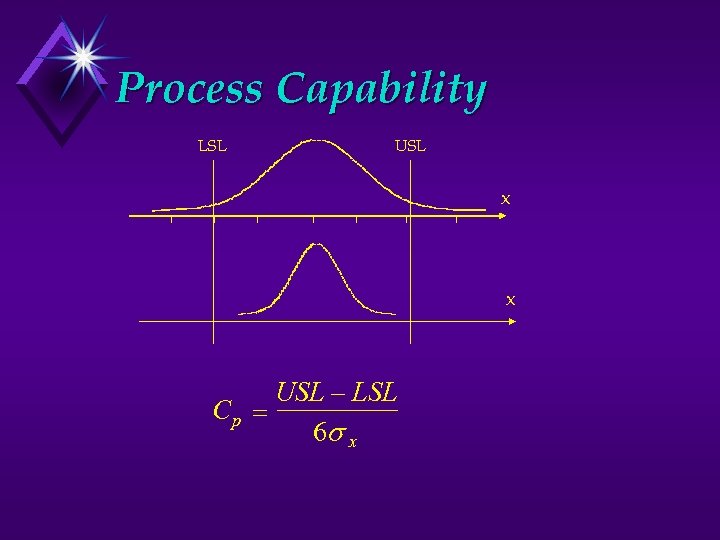

Process Capability LSL USL x x USL LSL Cp 6 x

Process Capability LSL USL x x USL LSL Cp 6 x

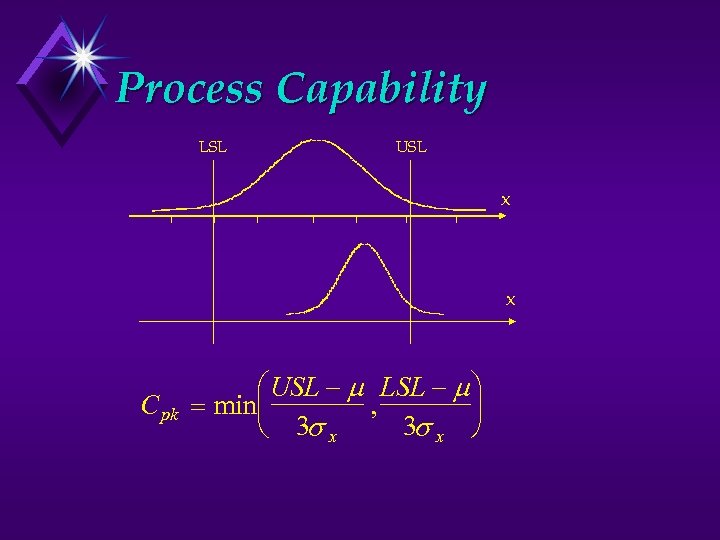

Process Capability LSL USL x x C pk USL LSL , min 3 x

Process Capability LSL USL x x C pk USL LSL , min 3 x

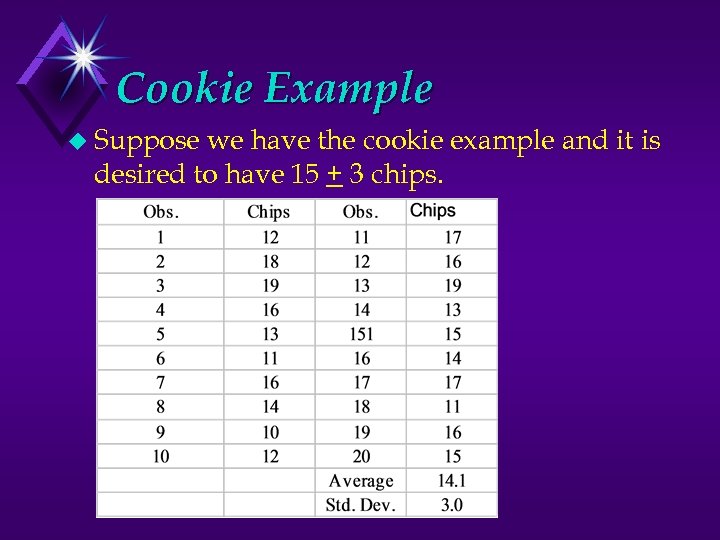

Cookie Example u Suppose we have the cookie example and it is desired to have 15 + 3 chips.

Cookie Example u Suppose we have the cookie example and it is desired to have 15 + 3 chips.

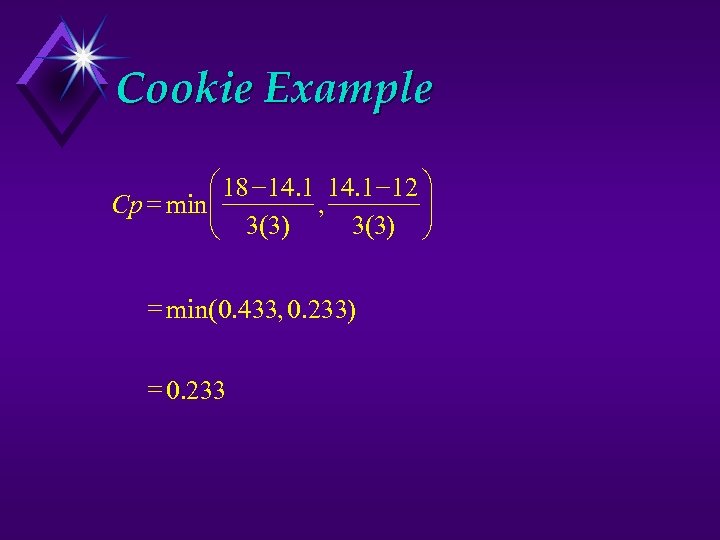

Cookie Example 18 14. 1 12 Cp min , 3(3) min(0. 433, 0. 233) 0. 233

Cookie Example 18 14. 1 12 Cp min , 3(3) min(0. 433, 0. 233) 0. 233

South Dakota School of Mines & Technology Funnel Experiment Industrial Engineering

South Dakota School of Mines & Technology Funnel Experiment Industrial Engineering

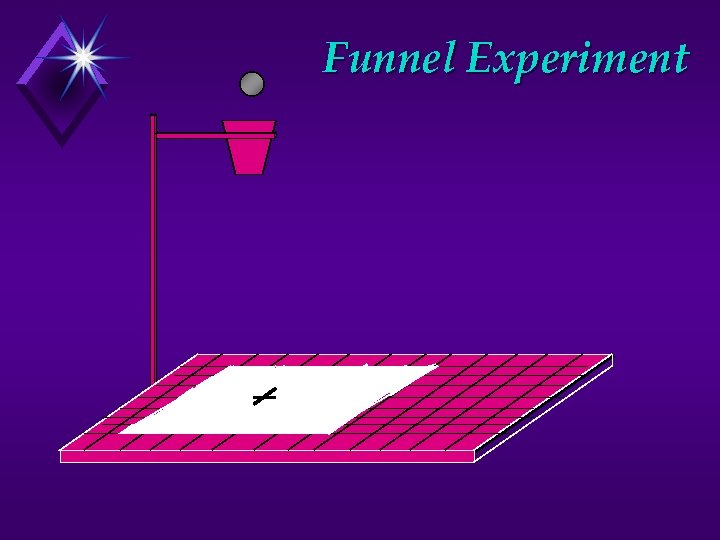

Funnel Experiment u The Funnel Experiment is a famous experiment first developed by Dr. Deming. It was designed to show primarily two things: 1. All processes have statistical variation 2. Improving processes to reduce variation is infinitely better than trying to control process variation

Funnel Experiment u The Funnel Experiment is a famous experiment first developed by Dr. Deming. It was designed to show primarily two things: 1. All processes have statistical variation 2. Improving processes to reduce variation is infinitely better than trying to control process variation

Funnel Experiment

Funnel Experiment

Funnel Experiment Rule 1: Do nothing Rule 2: Move the funnel in an equal but opposite direction Rule 3: Move the funnel in an equal but opposite direction from (0, 0) Rule 4: Move the funnel to the last position where the last hit.

Funnel Experiment Rule 1: Do nothing Rule 2: Move the funnel in an equal but opposite direction Rule 3: Move the funnel in an equal but opposite direction from (0, 0) Rule 4: Move the funnel to the last position where the last hit.

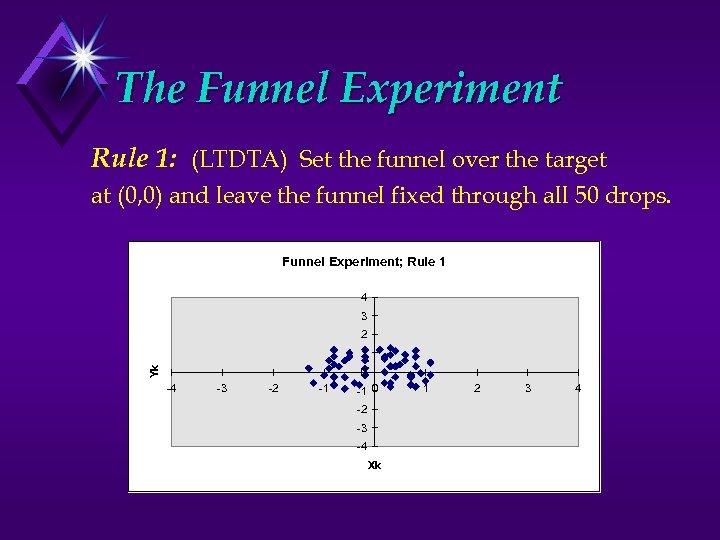

The Funnel Experiment Rule 1: (LTDTA) Set the funnel over the target at (0, 0) and leave the funnel fixed through all 50 drops. Funnel Experiment; Rule 1 4 3 2 Yk 1 0 -4 -3 -2 -1 -1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 1: (LTDTA) Set the funnel over the target at (0, 0) and leave the funnel fixed through all 50 drops. Funnel Experiment; Rule 1 4 3 2 Yk 1 0 -4 -3 -2 -1 -1 0 -2 -3 -4 Xk 1 2 3 4

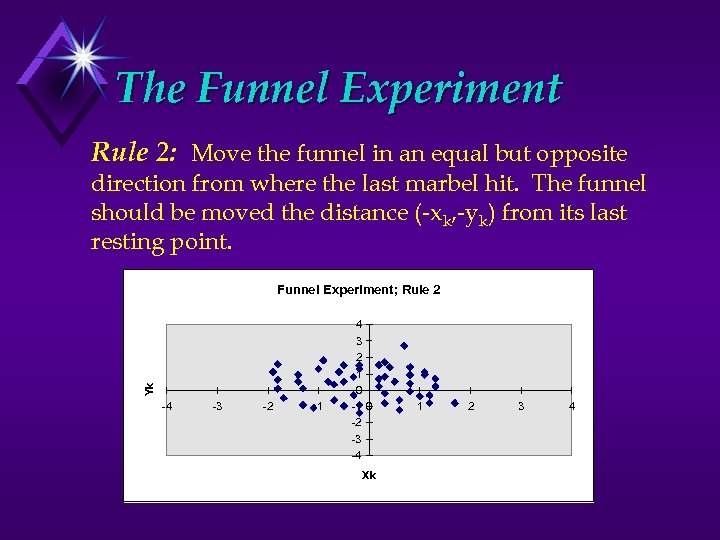

The Funnel Experiment Rule 2: Move the funnel in an equal but opposite direction from where the last marbel hit. The funnel should be moved the distance (-xk, -yk) from its last resting point. Yk Funnel Experiment; Rule 2 -4 -3 -2 -1 4 3 2 1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 2: Move the funnel in an equal but opposite direction from where the last marbel hit. The funnel should be moved the distance (-xk, -yk) from its last resting point. Yk Funnel Experiment; Rule 2 -4 -3 -2 -1 4 3 2 1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 2: Move the funnel in an equal but opposite direction from where the last marbel hit. The funnel should be moved the distance (-xk, -yk) from its last resting point. Machine/Process adjustment rules using control chart limits. Automatic compensating machinery

The Funnel Experiment Rule 2: Move the funnel in an equal but opposite direction from where the last marbel hit. The funnel should be moved the distance (-xk, -yk) from its last resting point. Machine/Process adjustment rules using control chart limits. Automatic compensating machinery

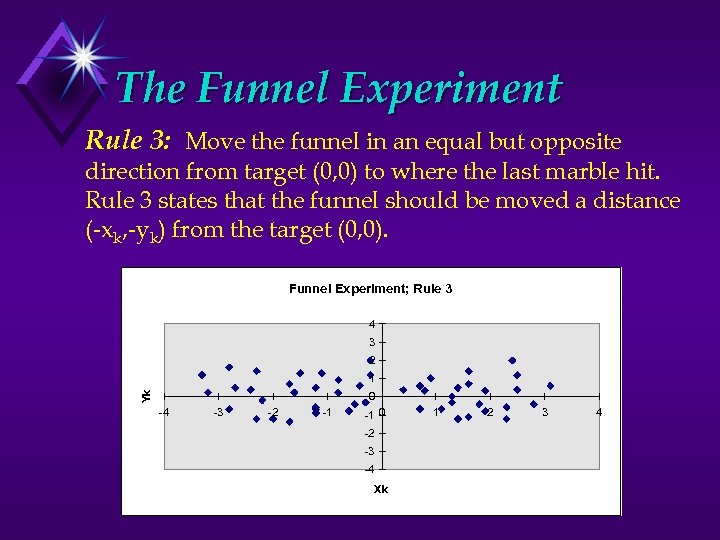

The Funnel Experiment Rule 3: Move the funnel in an equal but opposite direction from target (0, 0) to where the last marble hit. Rule 3 states that the funnel should be moved a distance (-xk, -yk) from the target (0, 0). Funnel Experiment; Rule 3 4 3 2 Yk 1 0 -4 -3 -2 -1 -1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 3: Move the funnel in an equal but opposite direction from target (0, 0) to where the last marble hit. Rule 3 states that the funnel should be moved a distance (-xk, -yk) from the target (0, 0). Funnel Experiment; Rule 3 4 3 2 Yk 1 0 -4 -3 -2 -1 -1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 3: Move the funnel in an equal but opposite direction from target (0, 0) to where the last marble hit. Rule 3 states that the funnel should be moved a distance (-xk, -yk) from the target (0, 0). Management by Objectives Committees

The Funnel Experiment Rule 3: Move the funnel in an equal but opposite direction from target (0, 0) to where the last marble hit. Rule 3 states that the funnel should be moved a distance (-xk, -yk) from the target (0, 0). Management by Objectives Committees

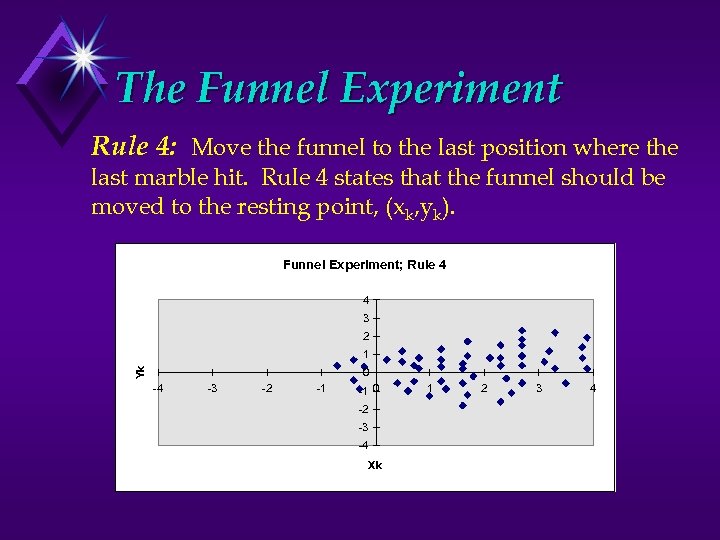

The Funnel Experiment Rule 4: Move the funnel to the last position where the last marble hit. Rule 4 states that the funnel should be moved to the resting point, (xk, yk). Funnel Experiment; Rule 4 4 3 2 Yk 1 0 -4 -3 -2 -1 -1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 4: Move the funnel to the last position where the last marble hit. Rule 4 states that the funnel should be moved to the resting point, (xk, yk). Funnel Experiment; Rule 4 4 3 2 Yk 1 0 -4 -3 -2 -1 -1 0 -2 -3 -4 Xk 1 2 3 4

The Funnel Experiment Rule 4: Move the funnel to the last position where the last marble hit. Rule 4 states that the funnel should be moved to the resting point, (xk, yk). Operator matches color from batch to batch without reference to original swatch. Operator attempts to make every piece like the last one. On the job training.

The Funnel Experiment Rule 4: Move the funnel to the last position where the last marble hit. Rule 4 states that the funnel should be moved to the resting point, (xk, yk). Operator matches color from batch to batch without reference to original swatch. Operator attempts to make every piece like the last one. On the job training.

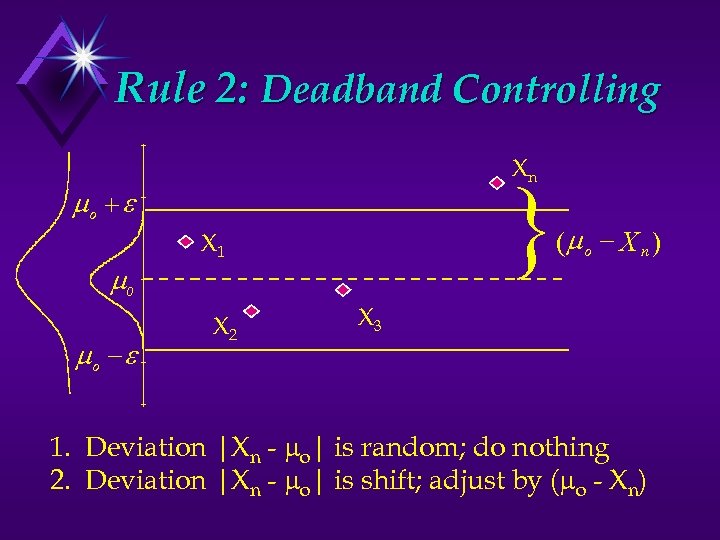

Rule 2: Deadband Controlling Xn } o e o o e X 1 X 2 ( o X n ) X 3 1. Deviation |Xn - o| is random; do nothing 2. Deviation |Xn - o| is shift; adjust by ( o - Xn)

Rule 2: Deadband Controlling Xn } o e o o e X 1 X 2 ( o X n ) X 3 1. Deviation |Xn - o| is random; do nothing 2. Deviation |Xn - o| is shift; adjust by ( o - Xn)

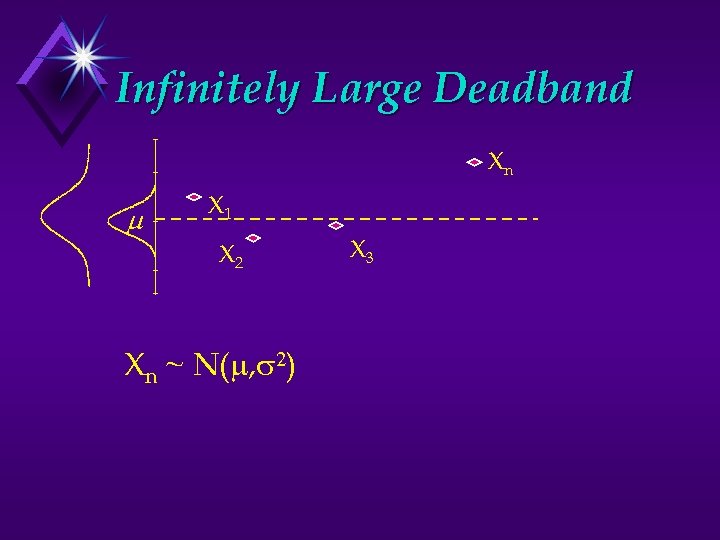

Infinitely Large Deadband Xn X 1 X 2 Xn ~ N( , ) X 3

Infinitely Large Deadband Xn X 1 X 2 Xn ~ N( , ) X 3

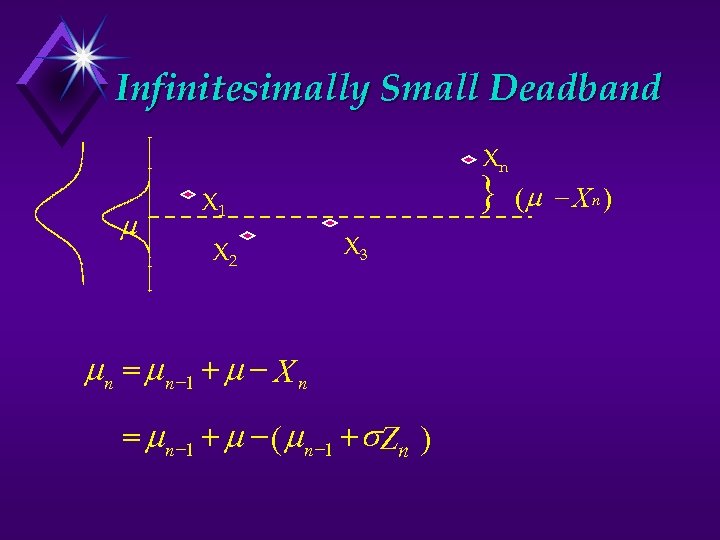

Infinitesimally Small Deadband Xn } X 1 X 2 X 3 n n 1 X n n 1 ( n 1 Zn ) ( X n )

Infinitesimally Small Deadband Xn } X 1 X 2 X 3 n n 1 X n n 1 ( n 1 Zn ) ( X n )

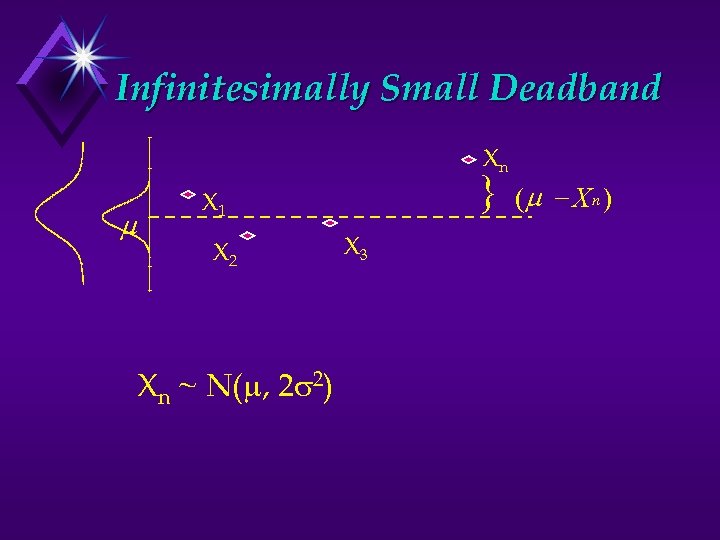

Infinitesimally Small Deadband Xn } X 1 X 2 Xn ~ N( , 2 2) X 3 ( X n )

Infinitesimally Small Deadband Xn } X 1 X 2 Xn ~ N( , 2 2) X 3 ( X n )

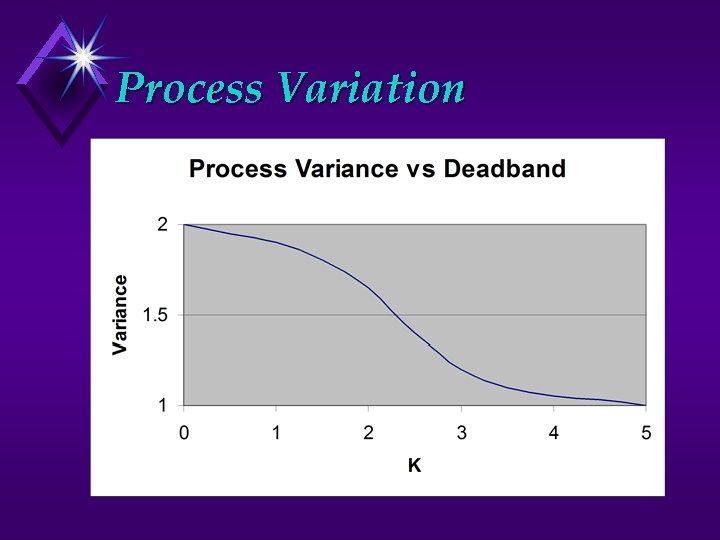

Process Variation

Process Variation

South Dakota School of Mines & Technology Loss Functions Industrial Engineering

South Dakota School of Mines & Technology Loss Functions Industrial Engineering

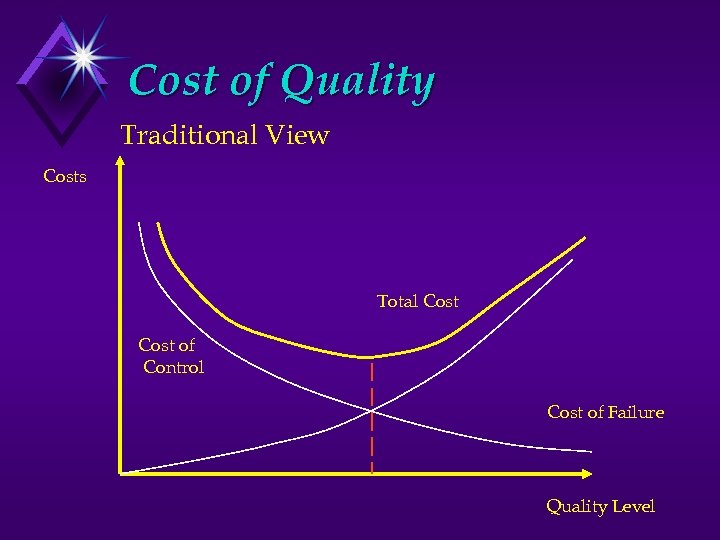

Cost of Quality Traditional View Costs Total Cost of Control Cost of Failure Quality Level

Cost of Quality Traditional View Costs Total Cost of Control Cost of Failure Quality Level

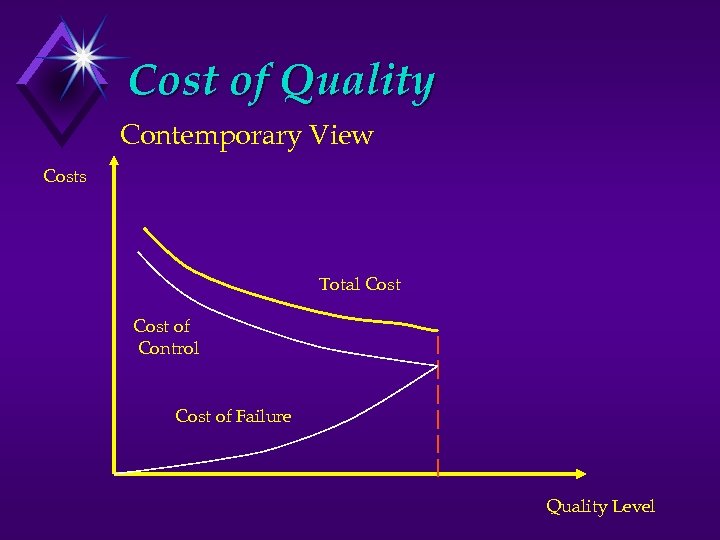

Cost of Quality Contemporary View Costs Total Cost of Control Cost of Failure Quality Level

Cost of Quality Contemporary View Costs Total Cost of Control Cost of Failure Quality Level

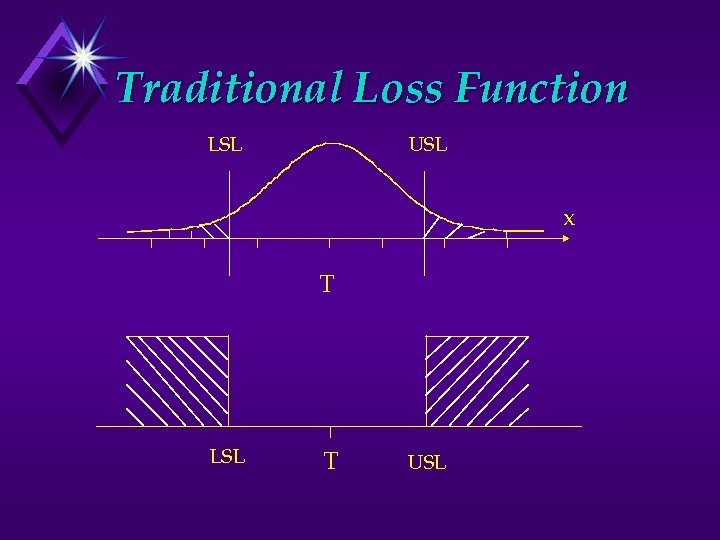

Traditional Loss Function LSL USL x T LSL T USL

Traditional Loss Function LSL USL x T LSL T USL

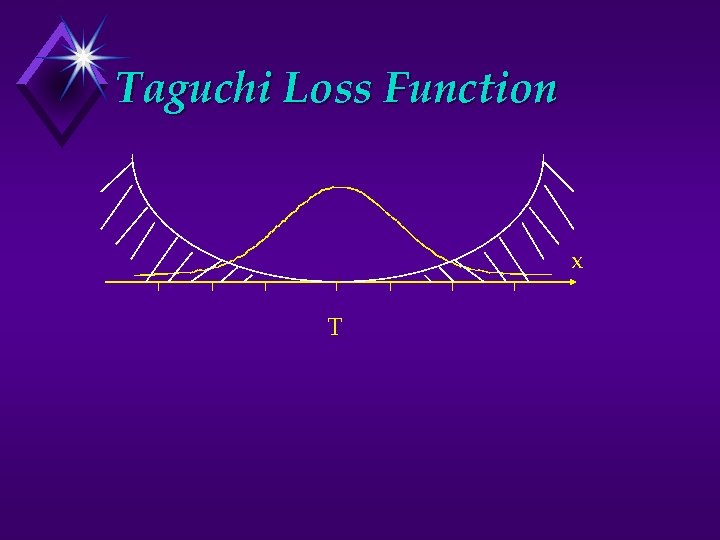

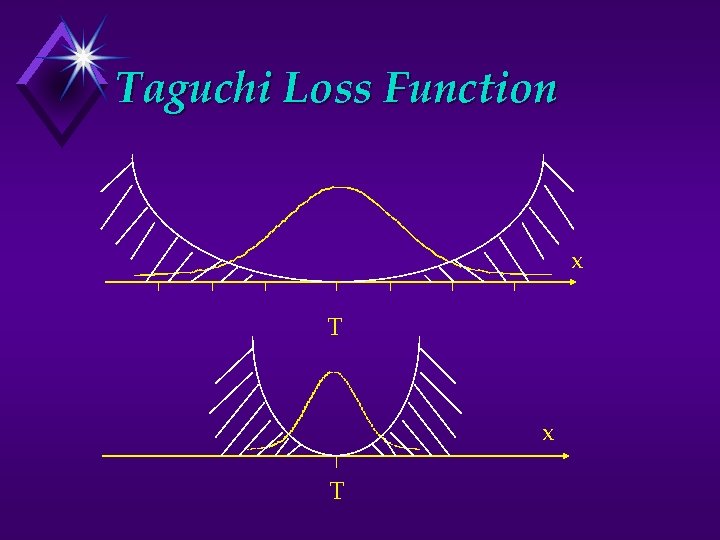

Taguchi Loss Function x T

Taguchi Loss Function x T

Taguchi Loss Function x T

Taguchi Loss Function x T

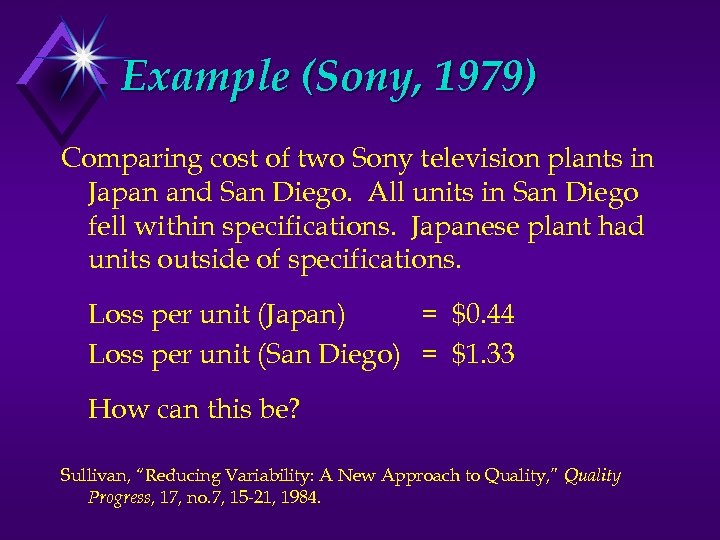

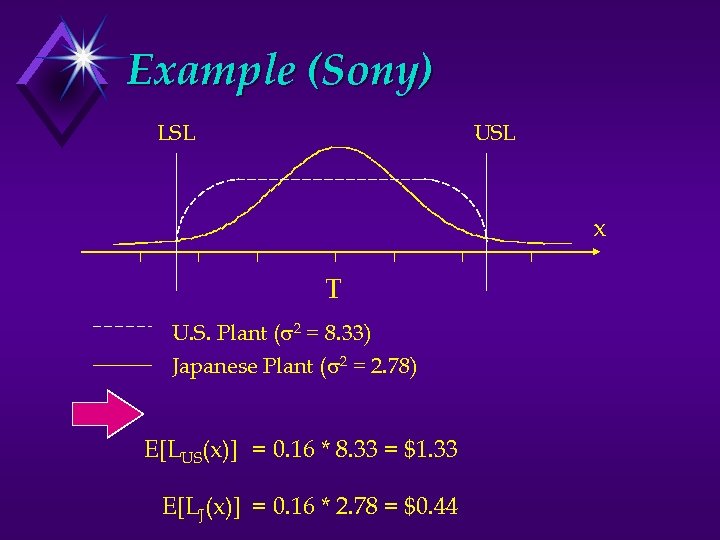

Example (Sony, 1979) Comparing cost of two Sony television plants in Japan and San Diego. All units in San Diego fell within specifications. Japanese plant had units outside of specifications. Loss per unit (Japan) = $0. 44 Loss per unit (San Diego) = $1. 33 How can this be? Sullivan, “Reducing Variability: A New Approach to Quality, ” Quality Progress, 17, no. 7, 15 -21, 1984.

Example (Sony, 1979) Comparing cost of two Sony television plants in Japan and San Diego. All units in San Diego fell within specifications. Japanese plant had units outside of specifications. Loss per unit (Japan) = $0. 44 Loss per unit (San Diego) = $1. 33 How can this be? Sullivan, “Reducing Variability: A New Approach to Quality, ” Quality Progress, 17, no. 7, 15 -21, 1984.

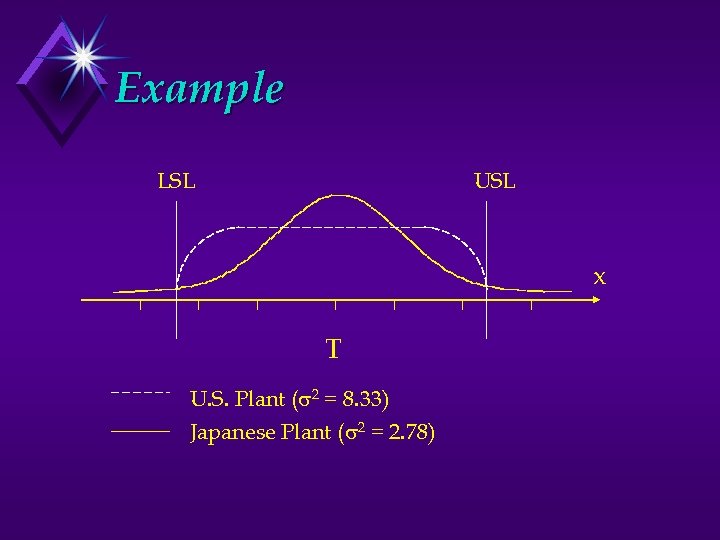

Example LSL USL x T U. S. Plant ( 2 = 8. 33) Japanese Plant ( 2 = 2. 78)

Example LSL USL x T U. S. Plant ( 2 = 8. 33) Japanese Plant ( 2 = 2. 78)

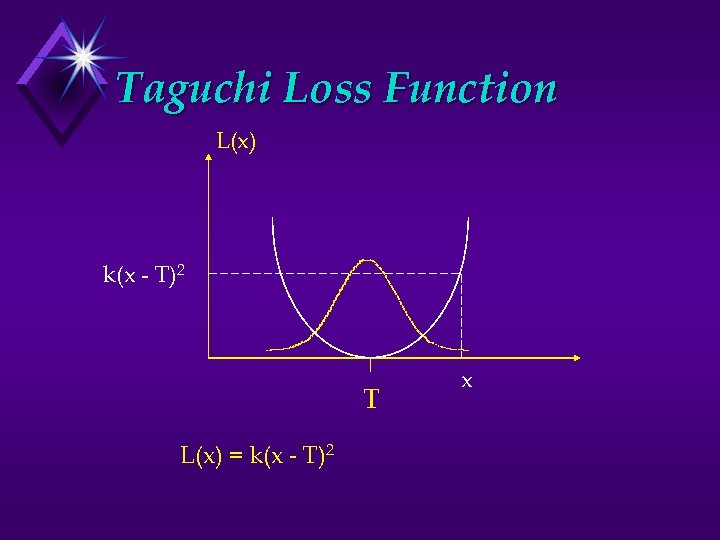

Taguchi Loss Function L(x) k(x - T)2 T L(x) = k(x - T)2 x

Taguchi Loss Function L(x) k(x - T)2 T L(x) = k(x - T)2 x

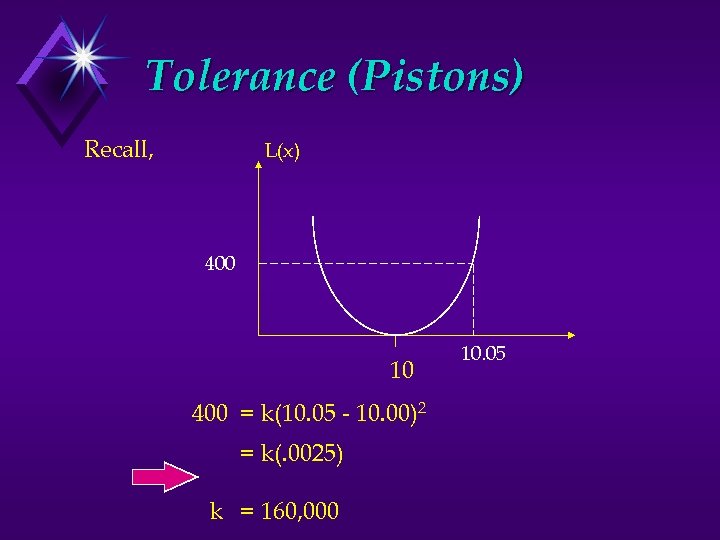

Estimating Loss Function Suppose we desire to make pistons with diameter D = 10 cm. Too big and they create too much friction. Too little and the engine will have lower gas milage. Suppose tolerances are set at D = 10 +. 05 cm. Studies show that if D > 10. 05, the engine will likely fail during the warranty period. Average cost of a warranty repair is $400.

Estimating Loss Function Suppose we desire to make pistons with diameter D = 10 cm. Too big and they create too much friction. Too little and the engine will have lower gas milage. Suppose tolerances are set at D = 10 +. 05 cm. Studies show that if D > 10. 05, the engine will likely fail during the warranty period. Average cost of a warranty repair is $400.

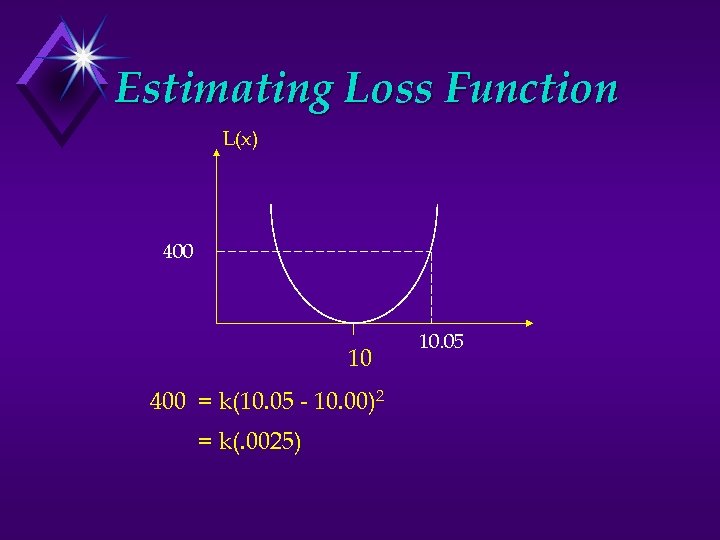

Estimating Loss Function L(x) 400 10 400 = k(10. 05 - 10. 00)2 = k(. 0025) 10. 05

Estimating Loss Function L(x) 400 10 400 = k(10. 05 - 10. 00)2 = k(. 0025) 10. 05

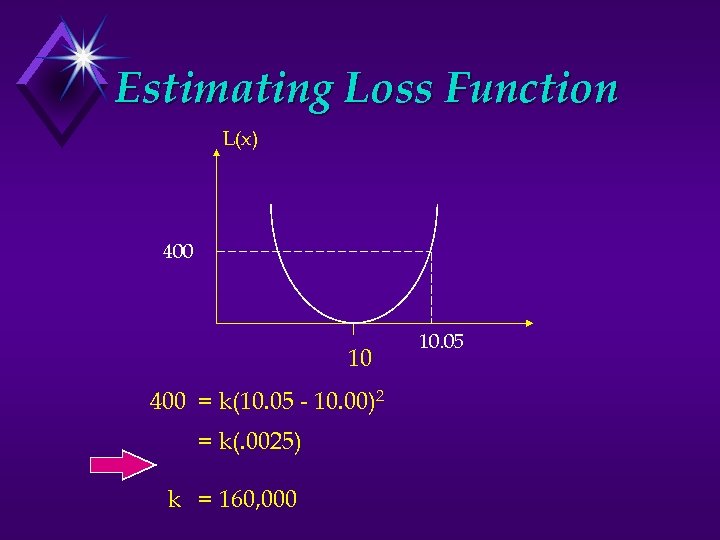

Estimating Loss Function L(x) 400 10 400 = k(10. 05 - 10. 00)2 = k(. 0025) k = 160, 000 10. 05

Estimating Loss Function L(x) 400 10 400 = k(10. 05 - 10. 00)2 = k(. 0025) k = 160, 000 10. 05

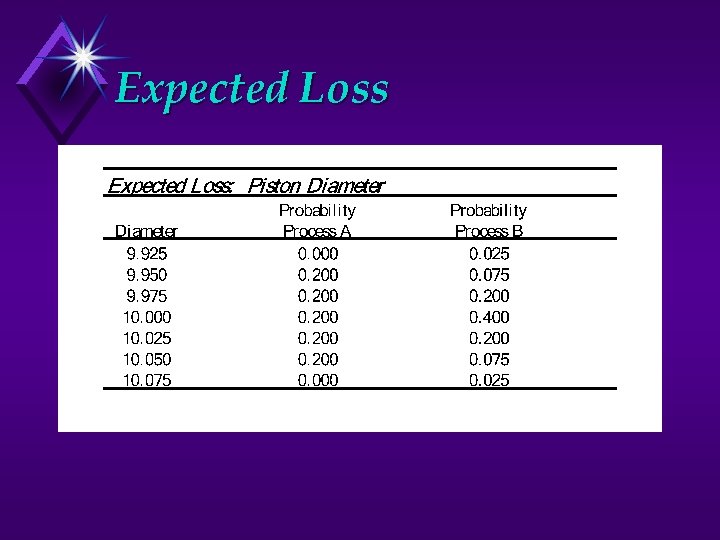

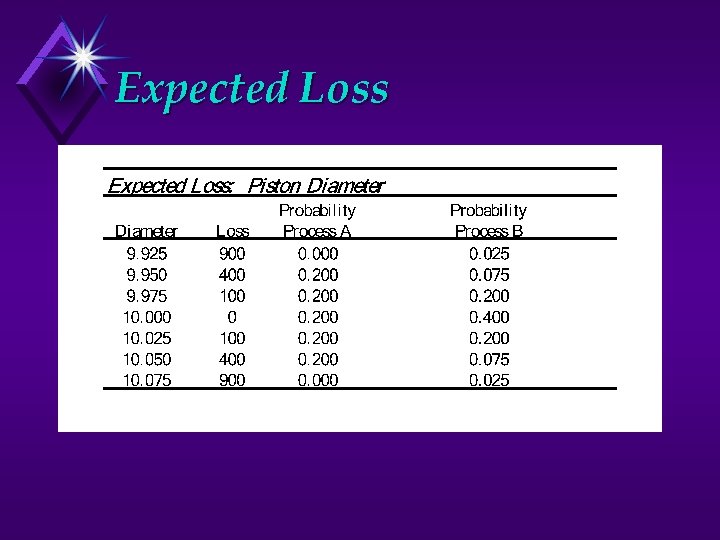

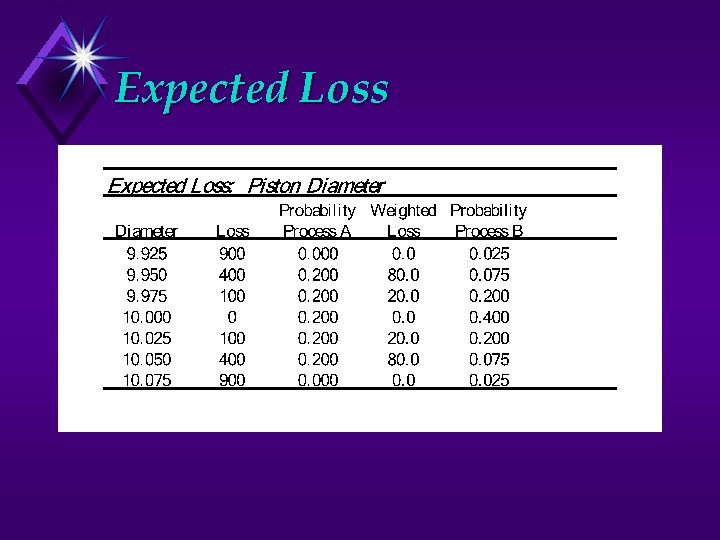

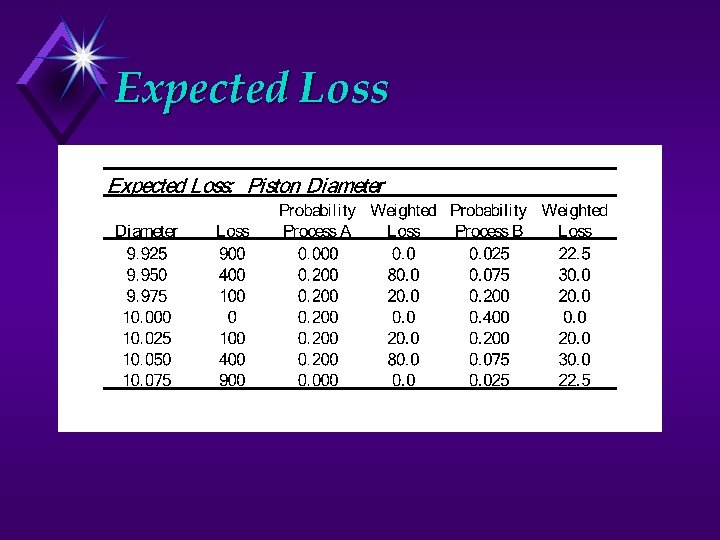

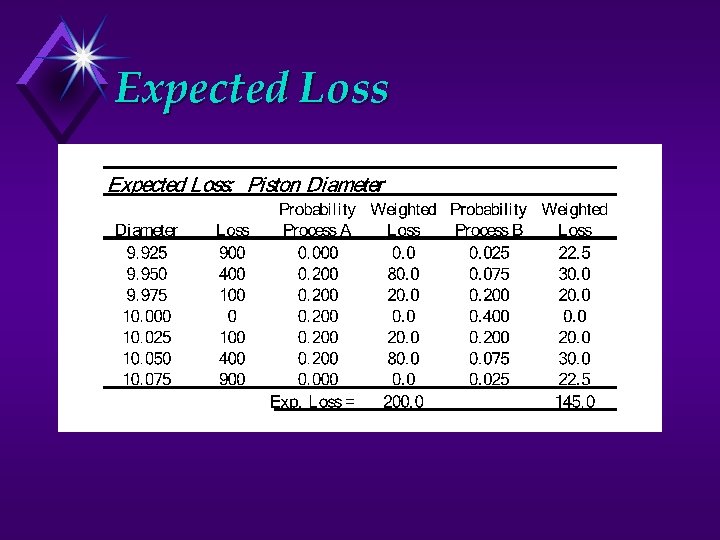

Expected Loss

Expected Loss

Expected Loss

Expected Loss

Expected Loss

Expected Loss

Expected Loss

Expected Loss

Expected Loss

Expected Loss

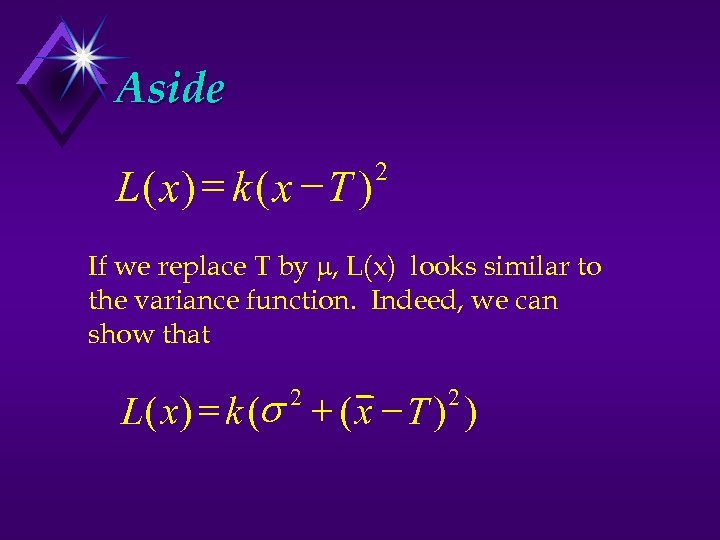

Aside L( x) k ( x T ) 2 If we replace T by , L(x) looks similar to the variance function. Indeed, we can show that L( x) k ( ( x T ) ) 2 2

Aside L( x) k ( x T ) 2 If we replace T by , L(x) looks similar to the variance function. Indeed, we can show that L( x) k ( ( x T ) ) 2 2

Example (Sony) LSL USL x T U. S. Plant ( 2 = 8. 33) Japanese Plant ( 2 = 2. 78) E[LUS(x)] = 0. 16 * 8. 33 = $1. 33 E[LJ(x)] = 0. 16 * 2. 78 = $0. 44

Example (Sony) LSL USL x T U. S. Plant ( 2 = 8. 33) Japanese Plant ( 2 = 2. 78) E[LUS(x)] = 0. 16 * 8. 33 = $1. 33 E[LJ(x)] = 0. 16 * 2. 78 = $0. 44

Tolerance (Pistons) Recall, L(x) 400 10 400 = k(10. 05 - 10. 00)2 = k(. 0025) k = 160, 000 10. 05

Tolerance (Pistons) Recall, L(x) 400 10 400 = k(10. 05 - 10. 00)2 = k(. 0025) k = 160, 000 10. 05

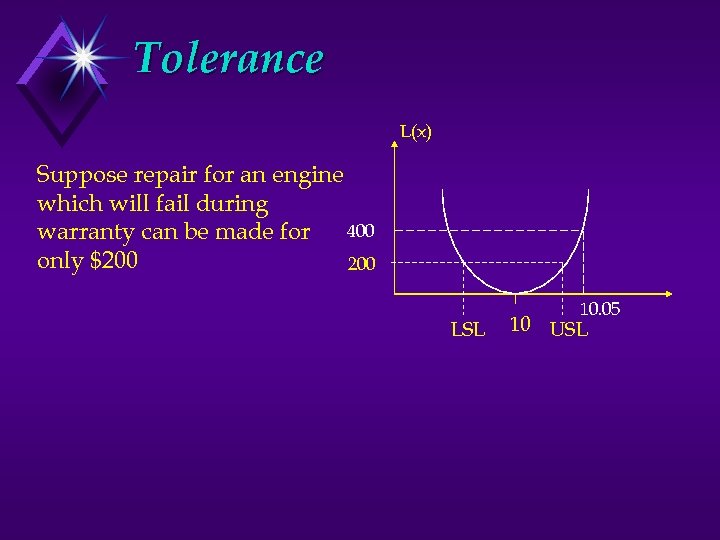

Tolerance L(x) Suppose repair for an engine which will fail during 400 warranty can be made for only $200 LSL 10. 05 10 USL

Tolerance L(x) Suppose repair for an engine which will fail during 400 warranty can be made for only $200 LSL 10. 05 10 USL

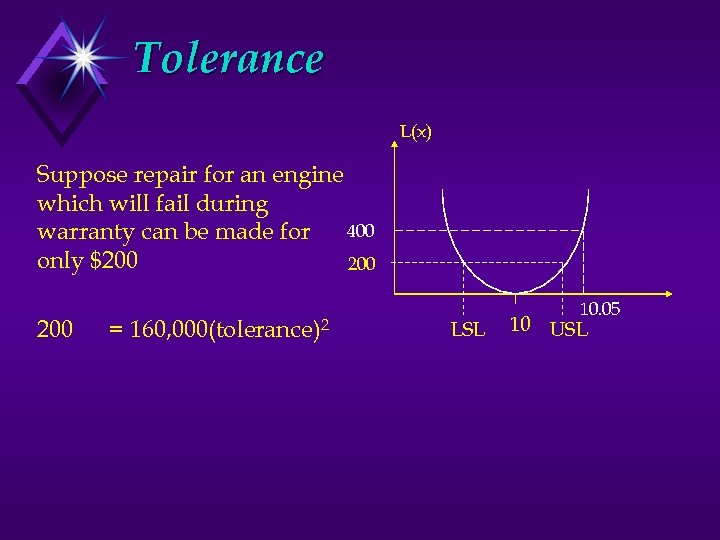

Tolerance L(x) Suppose repair for an engine which will fail during 400 warranty can be made for only $200 200 = 160, 000(tolerance)2 LSL 10. 05 10 USL

Tolerance L(x) Suppose repair for an engine which will fail during 400 warranty can be made for only $200 200 = 160, 000(tolerance)2 LSL 10. 05 10 USL

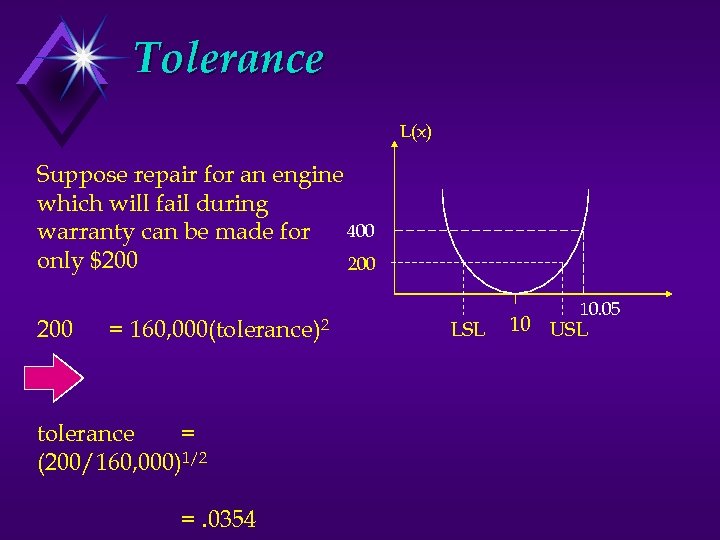

Tolerance L(x) Suppose repair for an engine which will fail during 400 warranty can be made for only $200 200 = 160, 000(tolerance)2 tolerance = (200/160, 000)1/2 =. 0354 LSL 10. 05 10 USL

Tolerance L(x) Suppose repair for an engine which will fail during 400 warranty can be made for only $200 200 = 160, 000(tolerance)2 tolerance = (200/160, 000)1/2 =. 0354 LSL 10. 05 10 USL