Sonic Scanner presentation_Uche_p2v2.pptx

- Количество слайдов: 71

Sonic Scanner PEPTEC-2 Schlumberger Private Middle East & Asia Training Center

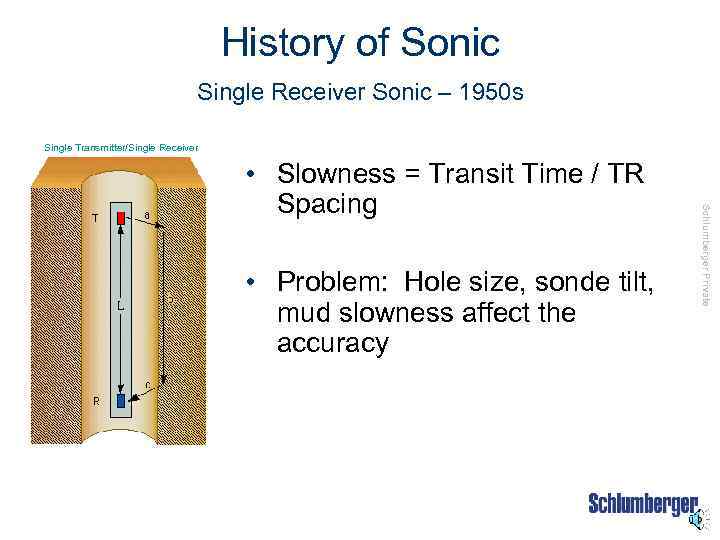

History of Sonic Single Receiver Sonic – 1950 s Single Transmitter/Single Receiver • Problem: Hole size, sonde tilt, mud slowness affect the accuracy Schlumberger Private • Slowness = Transit Time / TR Spacing

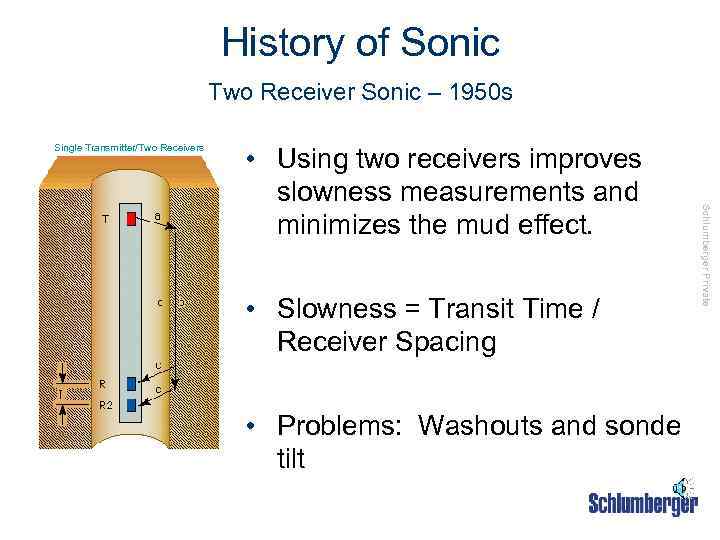

History of Sonic Two Receiver Sonic – 1950 s Single Transmitter/Two Receivers • Slowness = Transit Time / Receiver Spacing • Problems: Washouts and sonde tilt Schlumberger Private • Using two receivers improves slowness measurements and minimizes the mud effect.

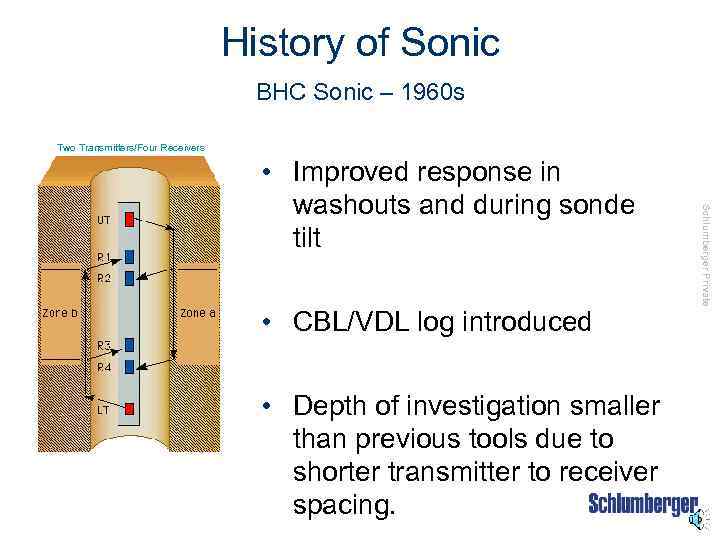

History of Sonic BHC Sonic – 1960 s Two Transmitters/Four Receivers • CBL/VDL log introduced • Depth of investigation smaller than previous tools due to shorter transmitter to receiver spacing. Schlumberger Private • Improved response in washouts and during sonde tilt

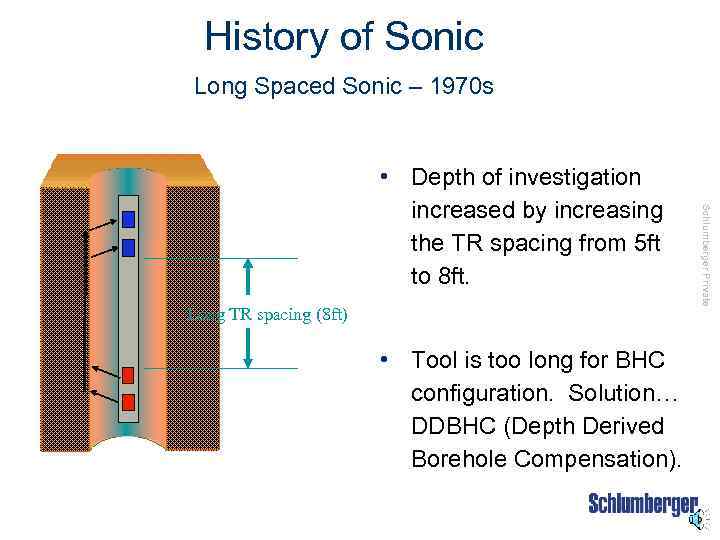

History of Sonic Long Spaced Sonic – 1970 s Long TR spacing (8 ft) • Tool is too long for BHC configuration. Solution… DDBHC (Depth Derived Borehole Compensation). Schlumberger Private • Depth of investigation increased by increasing the TR spacing from 5 ft to 8 ft.

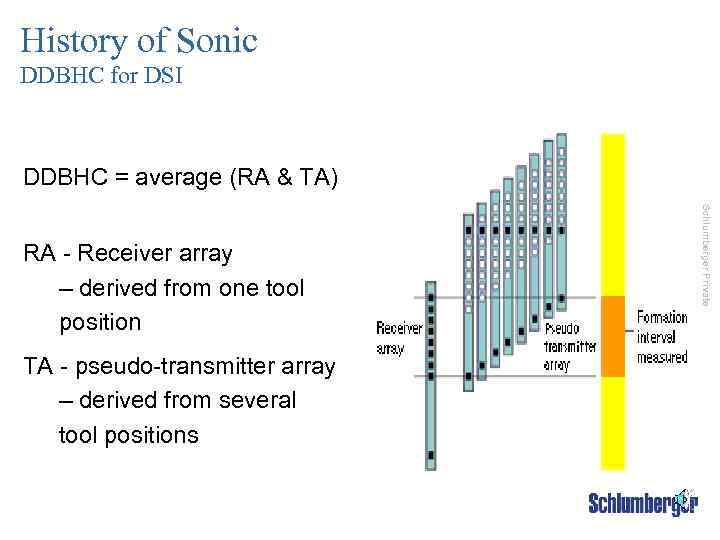

History of Sonic DDBHC for DSI DDBHC = average (RA & TA) TA - pseudo-transmitter array – derived from several tool positions Schlumberger Private RA - Receiver array – derived from one tool position

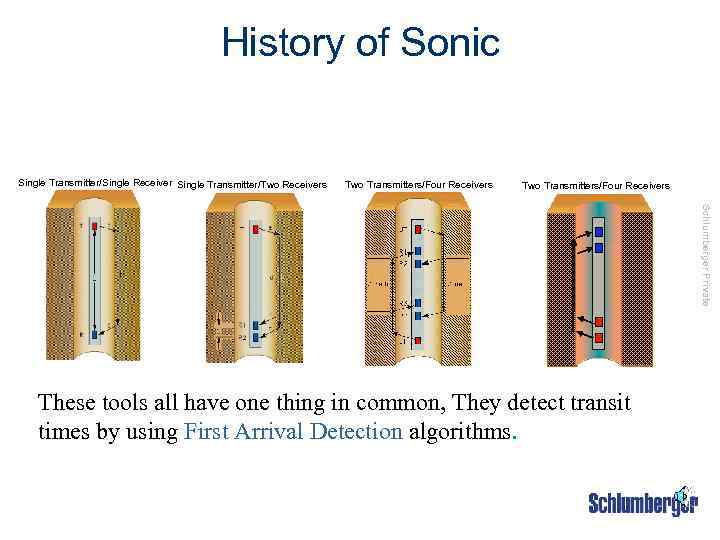

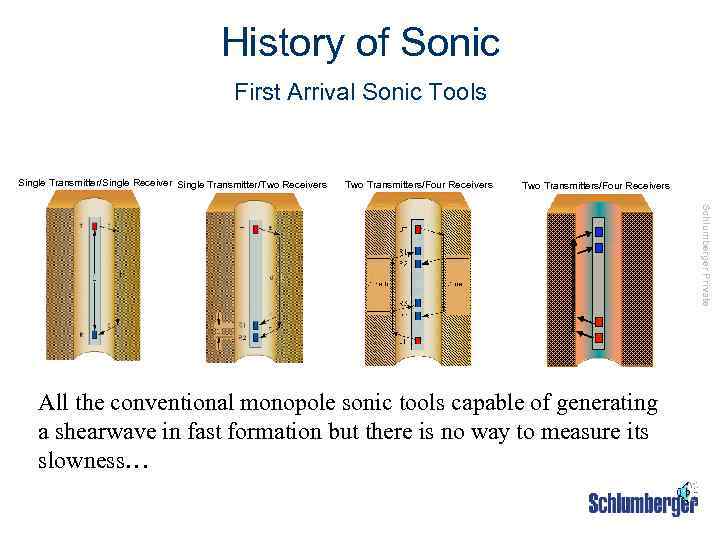

History of Sonic Single Transmitter/Single Receiver Single Transmitter/Two Receivers Two Transmitters/Four Receivers Schlumberger Private These tools all have one thing in common, They detect transit times by using First Arrival Detection algorithms.

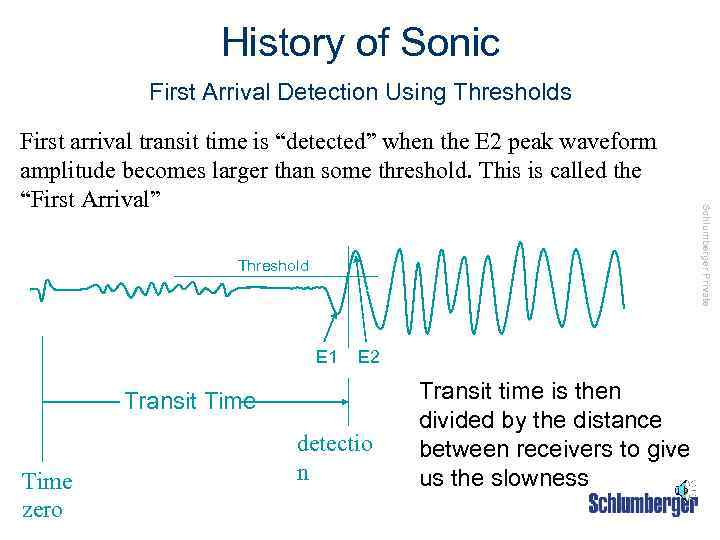

History of Sonic First Arrival Detection Using Thresholds Threshold E 1 E 2 Transit Time zero detectio n Transit time is then divided by the distance between receivers to give us the slowness Schlumberger Private First arrival transit time is “detected” when the E 2 peak waveform amplitude becomes larger than some threshold. This is called the “First Arrival”

History of Sonic First Arrival Sonic Tools Single Transmitter/Single Receiver Single Transmitter/Two Receivers Two Transmitters/Four Receivers Schlumberger Private All the conventional monopole sonic tools capable of generating a shearwave in fast formation but there is no way to measure its slowness…

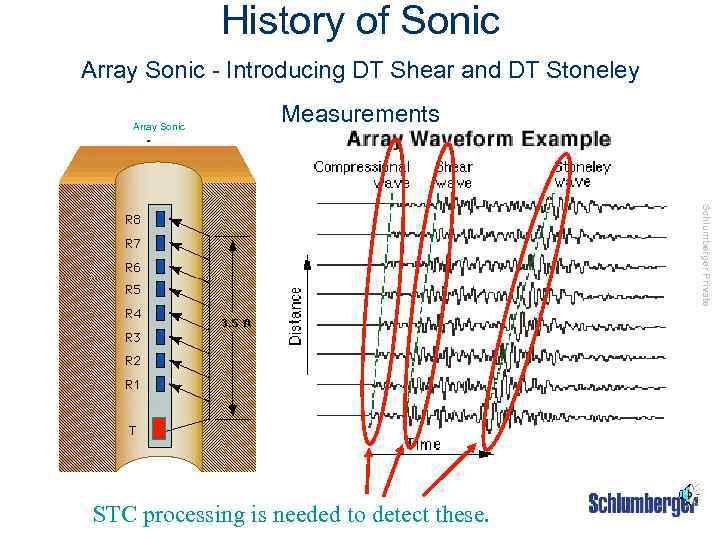

History of Sonic Array Sonic - Introducing DT Shear and DT Stoneley Array Sonic Measurements Schlumberger Private STC processing is needed to detect these.

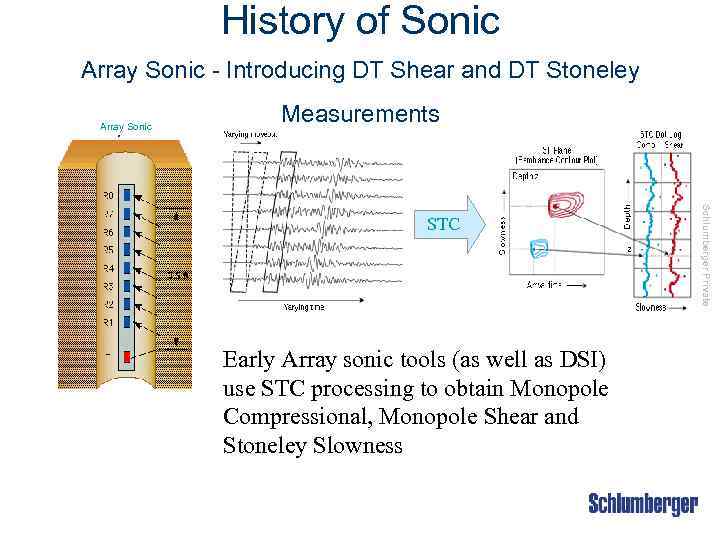

History of Sonic Array Sonic - Introducing DT Shear and DT Stoneley Array Sonic Measurements Early Array sonic tools (as well as DSI) use STC processing to obtain Monopole Compressional, Monopole Shear and Stoneley Slowness Schlumberger Private STC

History of Sonic Concept review First Arrival detection vs STC: First Arrival tools detect the compressional arrival only and are based on the concept of amplitude thresholds • Array Sonic tools use STC to extract multiple arrivals and are based on the concept of finding the coherent energy across a waveform array. Schlumberger Private •

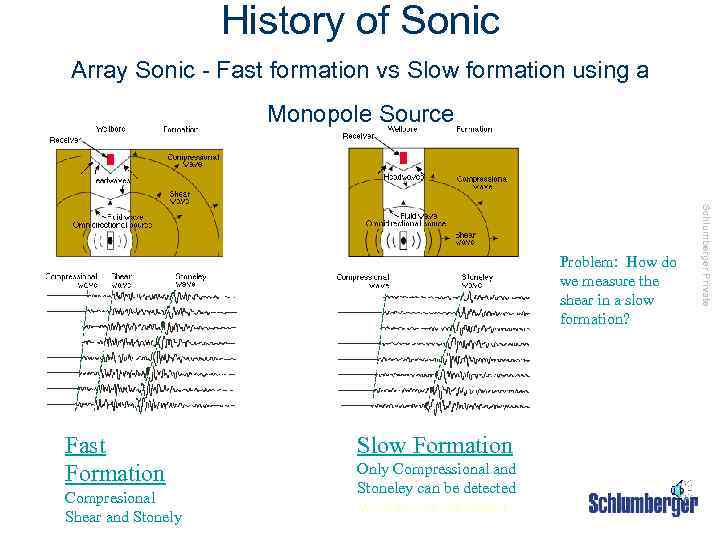

History of Sonic Array Sonic - Fast formation vs Slow formation using a Monopole Source Fast Formation Compresional Shear and Stonely Slow Formation Only Compressional and Stoneley can be detected We Cant see the Shear! Schlumberger Private Problem: How do we measure the shear in a slow formation?

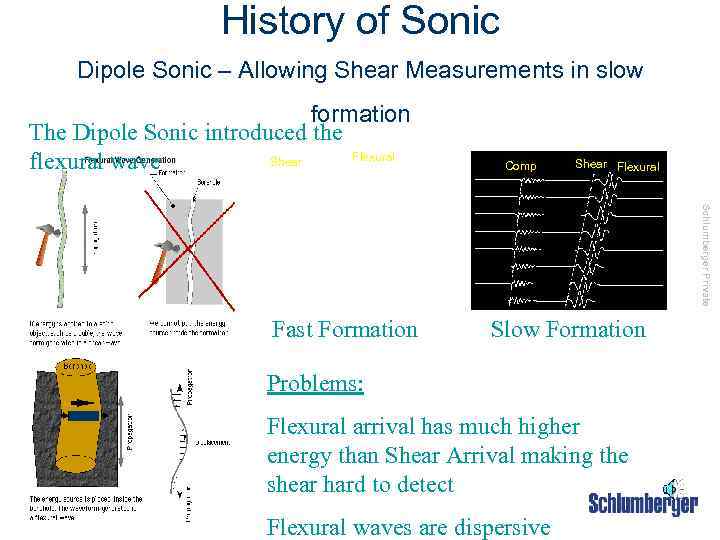

History of Sonic Dipole Sonic – Allowing Shear Measurements in slow formation The Dipole Sonic introduced the Flexural Shear flexural wave Comp Shear Flexural Schlumberger Private Fast Formation Slow Formation Problems: Flexural arrival has much higher energy than Shear Arrival making the shear hard to detect Flexural waves are dispersive

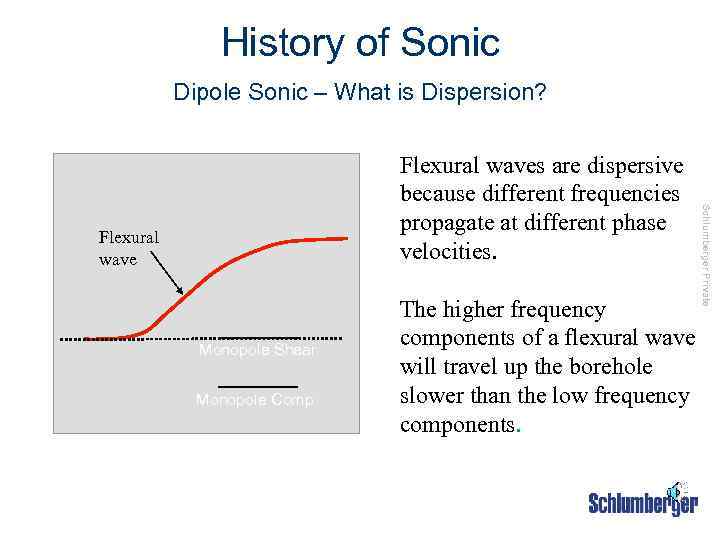

History of Sonic Flexural waves are dispersive because different frequencies propagate at different phase velocities. Flexural wave Monopole Shear Monopole Comp Frequency The higher frequency components of a flexural wave will travel up the borehole slower than the low frequency components. Schlumberger Private Slowness Dipole Sonic – What is Dispersion?

Objectives (Sonic Theory) You should be able to: 1. Explain two main borehole modes of wave propagation 3. Discuss Sonic Tools History & why the need of Sonic Scanner 4. Discuss the limitation of Shear slowness measurement by DSI. 5. Explain main differences between monopole source and dipole source. 6. Describe how the STC processing works. 7. Explain why sonic centralization is important. Schlumberger Private 2. Define dispersive wave and state which waves are naturally dispersive.

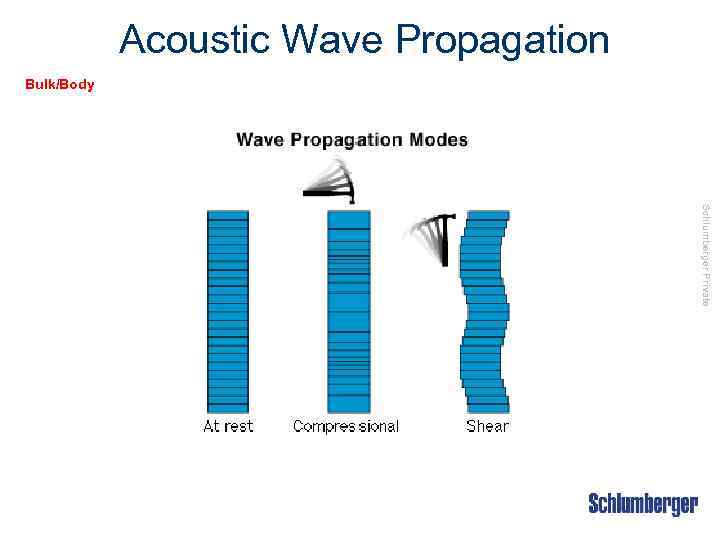

Acoustic Wave Propagation Bulk/Body Schlumberger Private

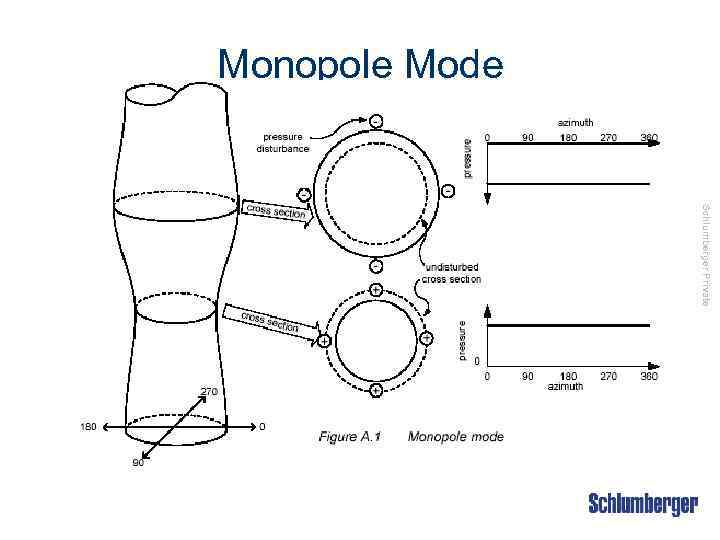

Monopole Mode Schlumberger Private

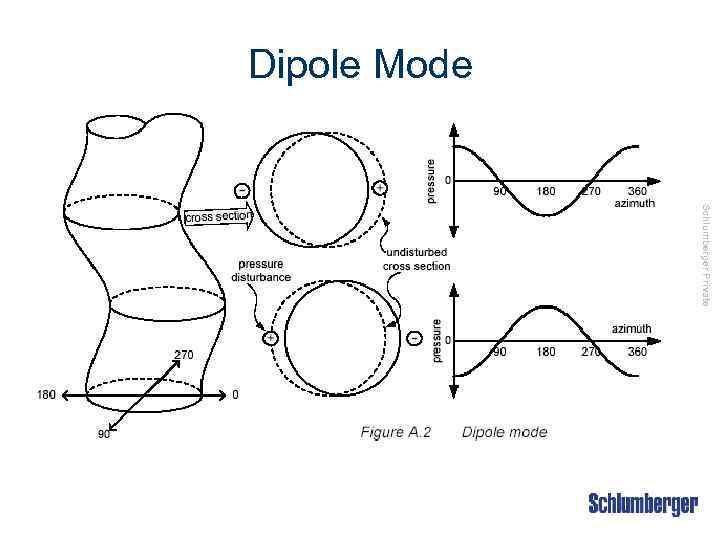

Dipole Mode Schlumberger Private

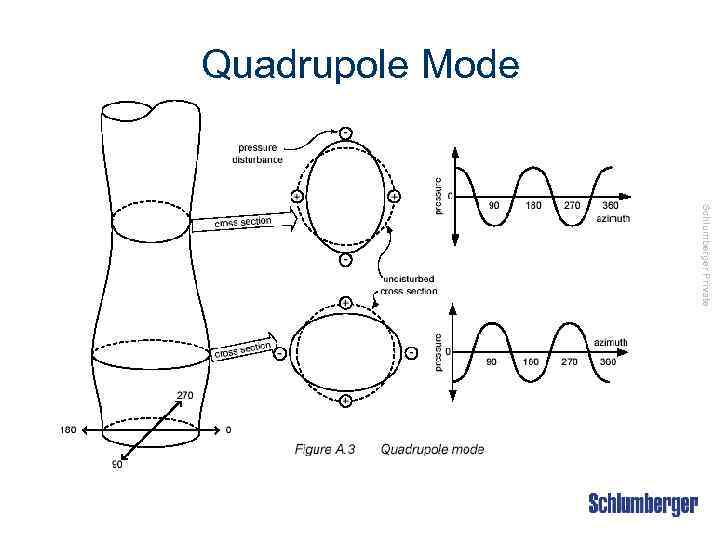

Quadrupole Mode Schlumberger Private

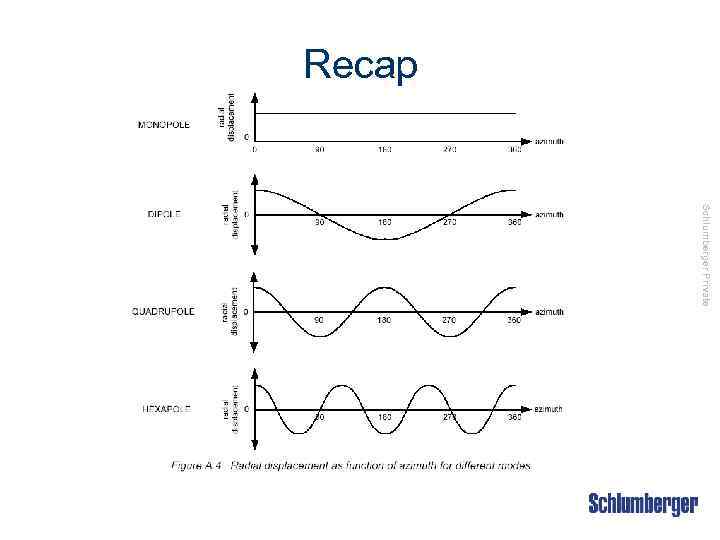

Recap Schlumberger Private

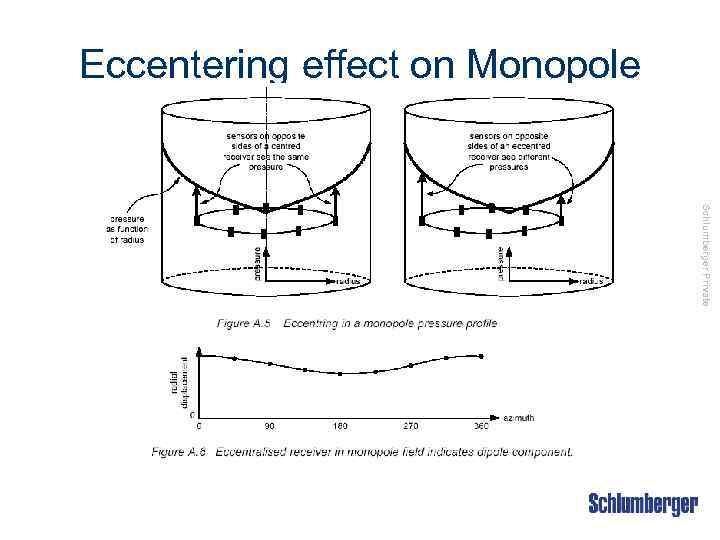

Eccentering effect on Monopole Schlumberger Private

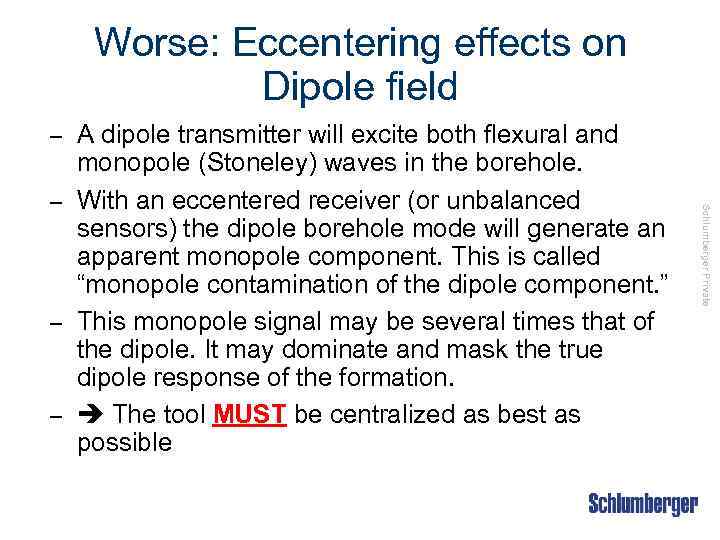

Worse: Eccentering effects on Dipole field A dipole transmitter will excite both flexural and monopole (Stoneley) waves in the borehole. – With an eccentered receiver (or unbalanced sensors) the dipole borehole mode will generate an apparent monopole component. This is called “monopole contamination of the dipole component. ” – This monopole signal may be several times that of the dipole. It may dominate and mask the true dipole response of the formation. – The tool MUST be centralized as best as possible – Schlumberger Private

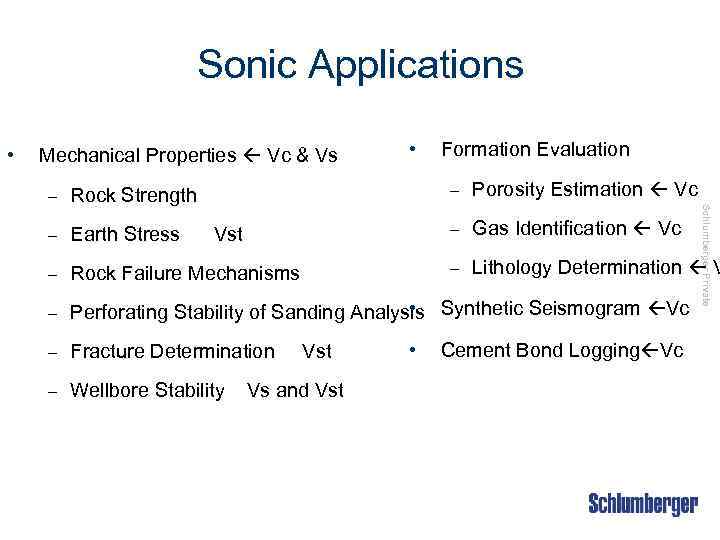

Sonic Applications • Mechanical Properties Vc & Vs • Formation Evaluation Rock Strength – Porosity Estimation Vc – Earth Stress Vst – Gas Identification Vc – Rock Failure Mechanisms – Lithology Determination V – • Perforating Stability of Sanding Analysis Synthetic Seismogram Vc – Fracture Determination Vst – Wellbore Stability Vs and Vst • Cement Bond Logging Vc Schlumberger Private –

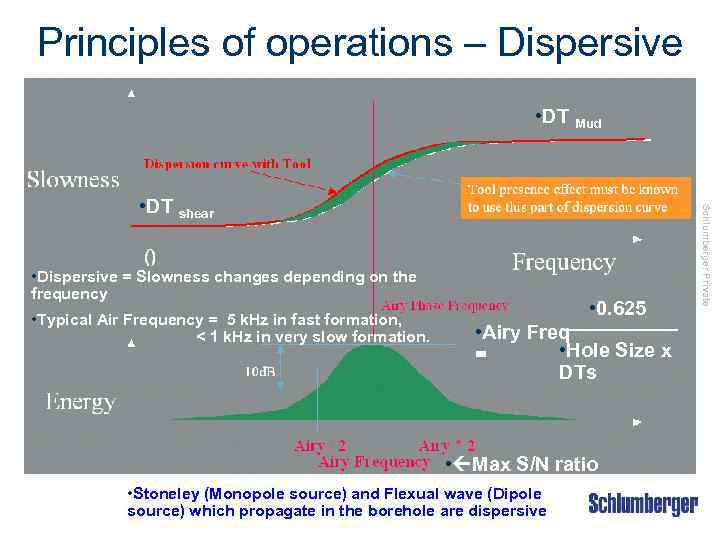

Principles of operations – Dispersive wave • DT Mud • Dispersive = Slowness changes depending on the frequency • Typical Air Frequency = 5 k. Hz in fast formation, < 1 k. Hz in very slow formation. • 0. 625 • Airy Freq • Hole Size x = DTs • Max S/N ratio • Stoneley (Monopole source) and Flexual wave (Dipole source) which propagate in the borehole are dispersive Schlumberger Private • DT shear

Array Sonic Quick History Schlumberger Private • SDT (Mid 1980 s) : Introduction of the array measurement And Slowness-Time-Coherence (STC) processing • DSI, DSI 2 (End 1980 s) : Introduction of shear measurement in slow formation by Flexural wave from Dipole source. DSI-2 increased the DTs measurement up to 1200 us/ft. • Sonic Scanner (2006)

Dipole vs Monopole Source • Monopole • Directional • Omni-directional • Electromagnetic • Piezoceramic • Generates a flexural wave in borehole (+ pressure on one side of borehole and – pressure on the other) – which tends to propate best along the borehole • Generates a compressional wave in borehole (+ pressure on both sides of borehole and then – pressure on both sides) – which propagate to formation Schlumberger Private • Dipole

Review (Sonic Theory) 1. Explain two main borehole modes of wave propagation 3. Discuss Sonic Tools History & why the need of Sonic Scanner 4. Discuss the limitation of Shear slowness measurement by DSI. 5. Explain main differences between monopole source and dipole source. 6. Explain why sonic centralization is important. Schlumberger Private 2. Define dispersive wave and state which waves are naturally dispersive.

Objectives (Sonic Scanner Hardware) You should be able to: 1. Identify the components that are used for the basic and advanced MAST sets and explain their functions. Describe how many transmitters and receivers a MAST have. 3. Describe the type of transmitters and receivers used in MAST 4. Describe the CBL configuration 5. Identify the MAST dipole transmitter component and explain benefit over the DSST dipole. 6. Describe the frequency band for the monopole, dipole and CBL measurement. 7. Describe the advantage of the MAST tool design in the measurement. Schlumberger Private 2.

MAST picture • MAST does not look like previous SLB sonic tools … Schlumberger Private

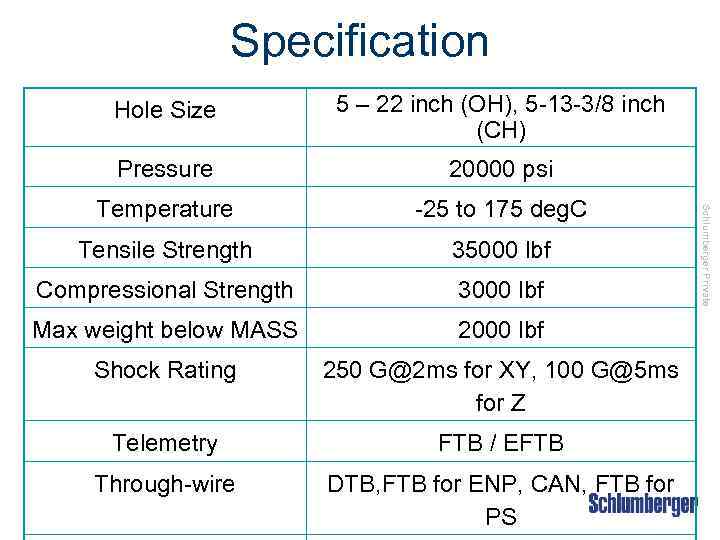

Specification 5 – 22 inch (OH), 5 -13 -3/8 inch (CH) Pressure 20000 psi Temperature -25 to 175 deg. C Tensile Strength 35000 lbf Compressional Strength 3000 lbf Max weight below MASS 2000 lbf Shock Rating 250 G@2 ms for XY, 100 G@5 ms for Z Telemetry FTB / EFTB Through-wire DTB, FTB for ENP, CAN, FTB for PS Schlumberger Private Hole Size

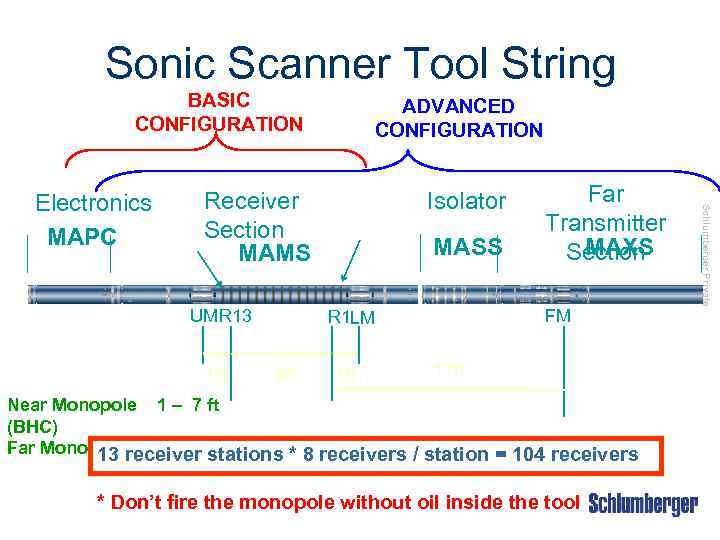

Sonic Scanner Tool String BASIC CONFIGURATION Receiver Section MAMS UM R 13 1 ft Isolator MASS FM R 1 LM 6 ft 1 ft Far Transmitter MAXS Section 11 ft Near Monopole 1 – 7 ft (BHC) Far Monopolereceiver stations * 8 receivers / station = 104 receivers 11 - 17 ft 13 * Don’t fire the monopole without oil inside the tool Schlumberger Private Electronics MAPC ADVANCED CONFIGURATION

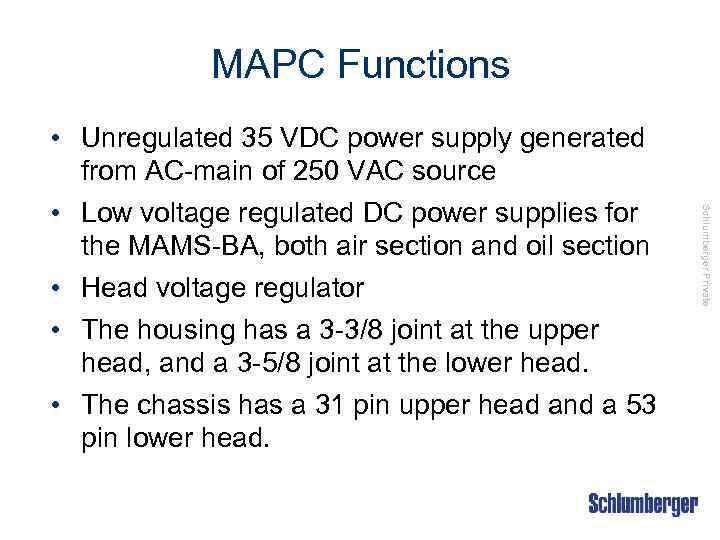

MAPC Functions Schlumberger Private • Unregulated 35 VDC power supply generated from AC-main of 250 VAC source • Low voltage regulated DC power supplies for the MAMS-BA, both air section and oil section • Head voltage regulator • The housing has a 3 -3/8 joint at the upper head, and a 3 -5/8 joint at the lower head. • The chassis has a 31 pin upper head and a 53 pin lower head.

MAMS Functions Schlumberger Private • The main structure made of mandrel and steel mass, which functions as receiver mounts as compensator is located. • Receivers, front-end electronics with digital controllers. • Segmented sleeves to protect electronics from mechanical damage and downhole fluid. • The main structure has two important functions, tensile and buckling strength for fishing and Tough Logging Condition (TLC) jobs, and acoustically slow structure that minimizes the tool arrival

MASS Functions Schlumberger Private • Mechanical filter that prevents acoustical tool arrivals and reduces road noise from below the receiver section. • Can bear up to 2000 lbs below it. • Isolation effective even in horizontal wells.

MAXS Function • 2 Dipoles (Shakers) and 1 monopole (piezoelectric ceramic transducer). Schlumberger Private

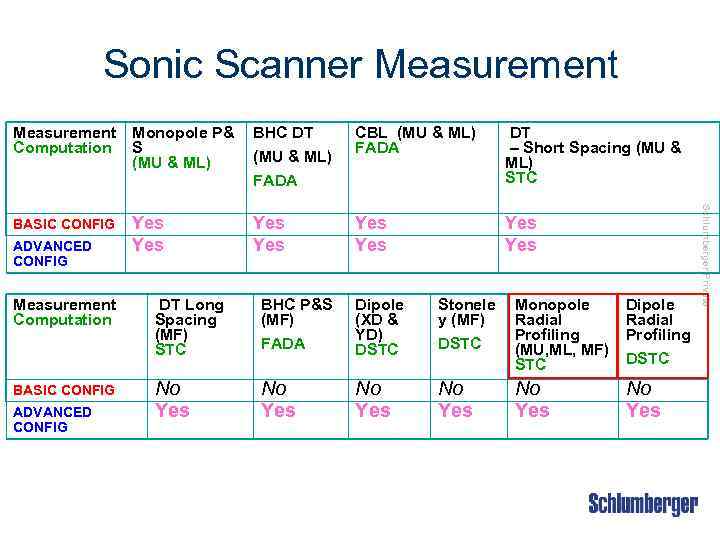

Sonic Scanner Measurement Monopole P& Computation S (MU & ML) ADVANCED CONFIG Measurement Computation BASIC CONFIG ADVANCED CONFIG Yes (MU & ML) FADA Yes CBL (MU & ML) FADA DT – Short Spacing (MU & ML) STC Yes Yes DT Long Spacing (MF) STC BHC P&S (MF) FADA Dipole (XD & YD) DSTC Stonele y (MF) DSTC Monopole Radial Profiling (MU, ML, MF) STC Dipole Radial Profiling No Yes No Yes DSTC Schlumberger Private BASIC CONFIG BHC DT

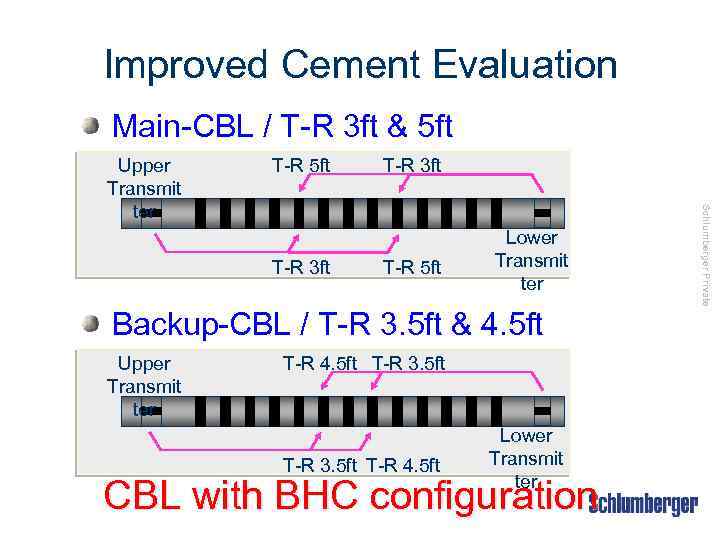

Improved Cement Evaluation Main-CBL / T-R 3 ft & 5 ft T-R 3 ft T-R 5 ft Lower Transmit ter Backup-CBL / T-R 3. 5 ft & 4. 5 ft Upper Transmit ter T-R 4. 5 ft T-R 3. 5 ft T-R 4. 5 ft Lower Transmit ter CBL with BHC configuration Schlumberger Private Upper Transmit ter

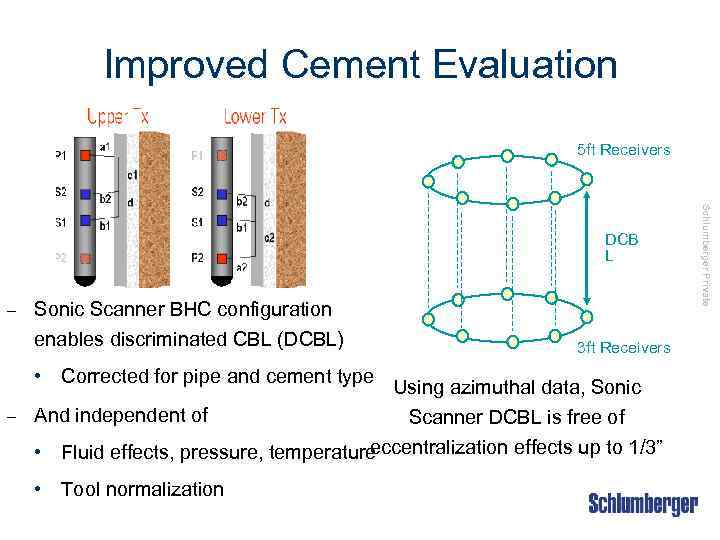

Improved Cement Evaluation 5 ft Receivers – Sonic Scanner BHC configuration enables discriminated CBL (DCBL) 3 ft Receivers • Corrected for pipe and cement type Using azimuthal data, Sonic – And independent of Scanner DCBL is free of eccentralization effects up to 1/3” • Fluid effects, pressure, temperature • Tool normalization Schlumberger Private DCB L

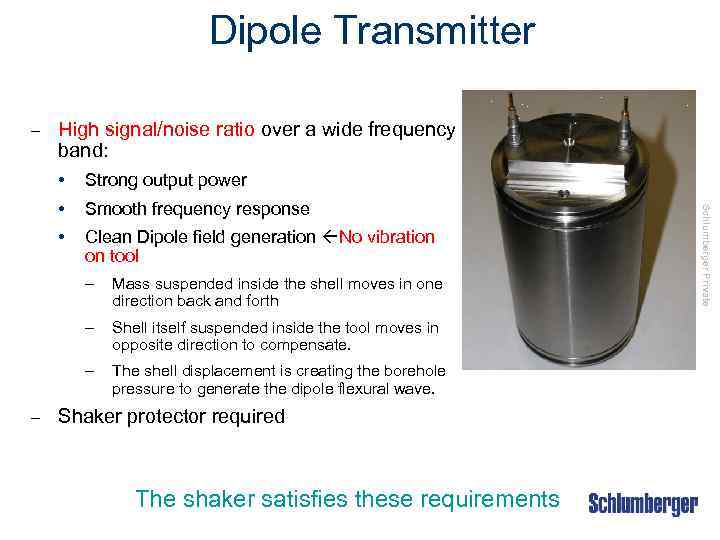

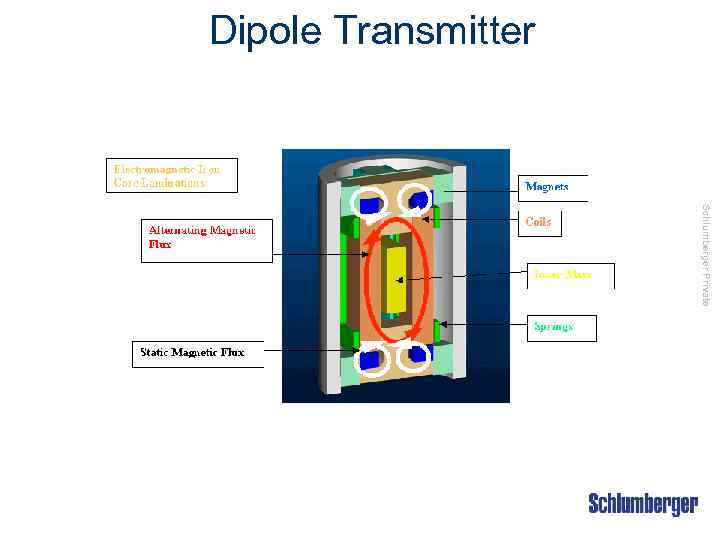

Dipole Transmitter – High signal/noise ratio over a wide frequency band: Strong output power • Smooth frequency response • Clean Dipole field generation No vibration on tool – – Shell itself suspended inside the tool moves in opposite direction to compensate. – – Mass suspended inside the shell moves in one direction back and forth The shell displacement is creating the borehole pressure to generate the dipole flexural wave. Shaker protector required The shaker satisfies these requirements Schlumberger Private •

Dipole Transmitter Schlumberger Private

Traditional Sonic Tools • Tool modes attenuated and slowed through Slotted sleeves – Complex receiver structures – Schlumberger Private • Behavior is complicated and hard to predict

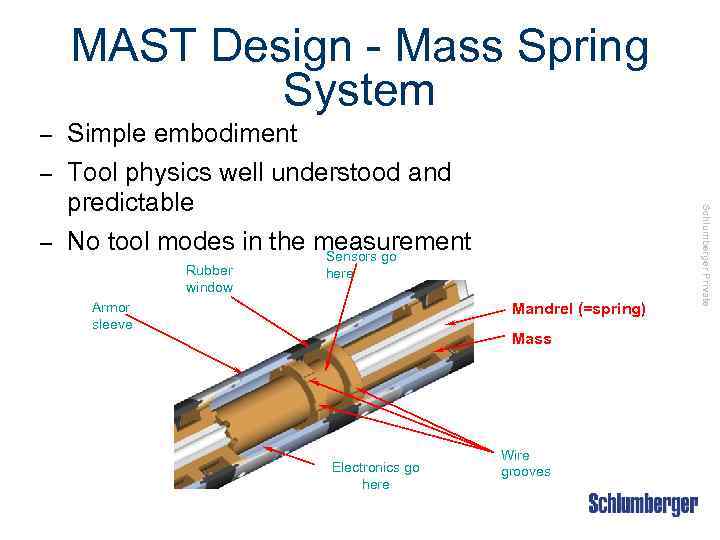

MAST Design - Mass Spring System Simple embodiment – Tool physics well understood and predictable – No tool modes in the measurement Sensors go Rubber window here Armor sleeve Mandrel (=spring) Mass Electronics go here Wire grooves Schlumberger Private –

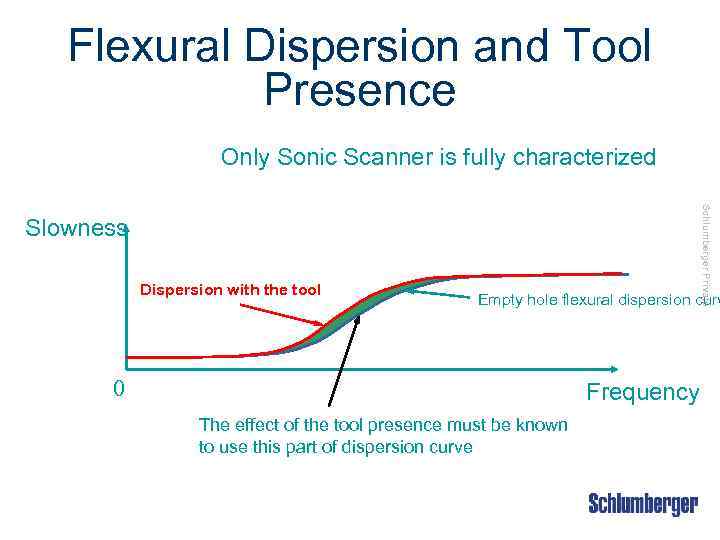

Flexural Dispersion and Tool Presence Only Sonic Scanner is fully characterized Schlumberger Private Slowness Dispersion with the tool Empty hole flexural dispersion curv 0 Frequency The effect of the tool presence must be known to use this part of dispersion curve

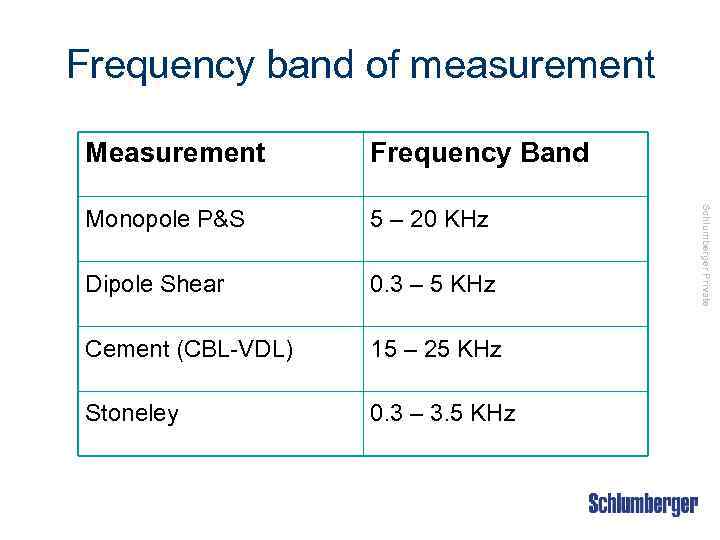

Frequency band of measurement Frequency Band Monopole P&S 5 – 20 KHz Dipole Shear 0. 3 – 5 KHz Cement (CBL-VDL) 15 – 25 KHz Stoneley 0. 3 – 3. 5 KHz Schlumberger Private Measurement

Advantages over previous Sonic Tools Reduced uncertainty Eliminated multiple frequency passes Less "no log" scenarios Reduction of risk Eliminated separate run for cement evaluation Real-time decision making made possible with wellsite quicklook reports 7. Real-time quality control Schlumberger Private 1. 2. 3. 4. 5. 6.

Review (Sonic Scanner Hardware) 1. Identify the components that are used for the basic and advanced MAST sets and explain their functions. Describe how many transmitters and receivers a MAST have. 3. Describe the type of transmitters and receivers used in MAST 4. Describe the CBL configuration 5. Identify the MAST dipole transmitter component and explain benefit over the DSST dipole. 6. Describe the frequency band for the monopole, dipole and CBL measurement. 7. Describe the advantage of the MAST tool design in the measurement. Schlumberger Private 2.

Objectives (Sonic Scanner Theory) You should be able to: 1. 2. 3. 4. Schlumberger Private Explain the “New Vision” of sonic applications. List four main causes of formation anisotropy. Explain chirp drive of dipole transmitter. Define which detection technique MAST uses for first arrival of transit time for P&S. 5. Explain Discriminated CBL measurement.

The New Sonic Vision • Integrated inversion of all sonic logging measurements – Delivers appropriate answer products based on advanced formation characterization of inhomogeneity and anisotropy. Schlumberger Private • Advance towards full three-dimensional (3 D) characterization of sound propagation around the borehole, deriving answer products targeted at all end-users of sonic measurements. • There are two key elements to this vision: Record all data from all modes of measurement – All the data allow us to provide critical information with the highest level of quality control (QC).

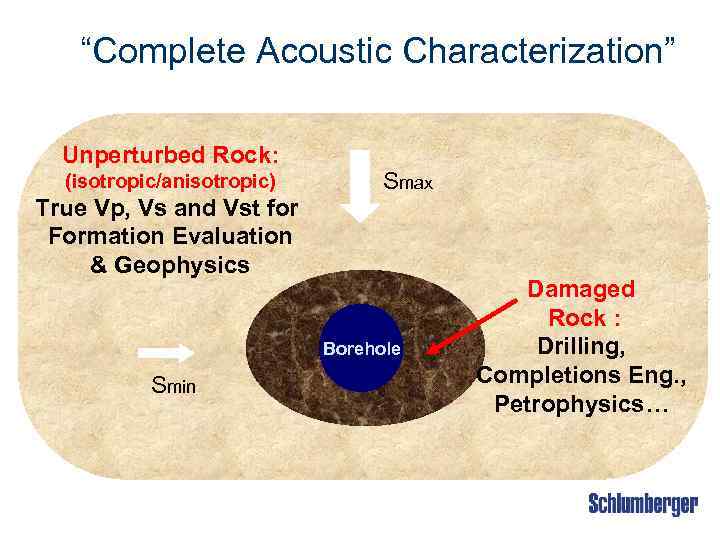

“Complete Acoustic Characterization” Unperturbed Rock: (isotropic/anisotropic) Smax Borehole Smin Damaged Rock : Drilling, Completions Eng. , Petrophysics… Schlumberger Private True Vp, Vs and Vst for Formation Evaluation & Geophysics

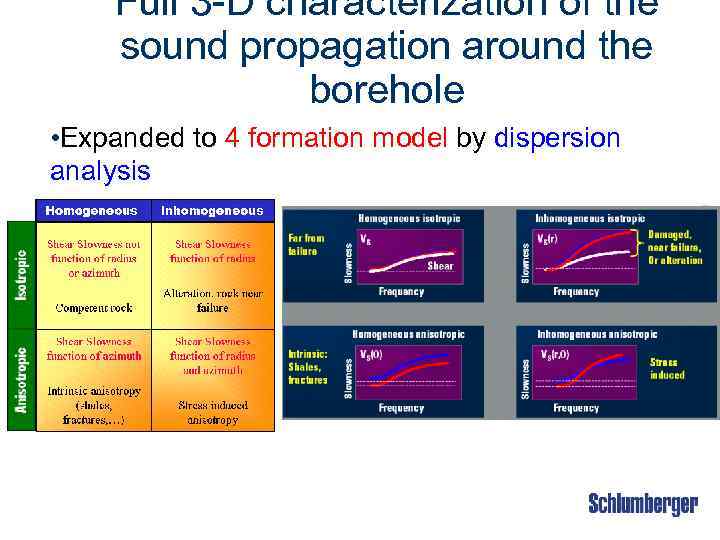

Full 3 -D characterization of the sound propagation around the borehole • Expanded to 4 formation model by dispersion analysis Schlumberger Private

Main Causes of Anisotropy Aligned fractures Thin beddings Any tectonics stresses Intrinsic Microlayerings such as shales Schlumberger Private • •

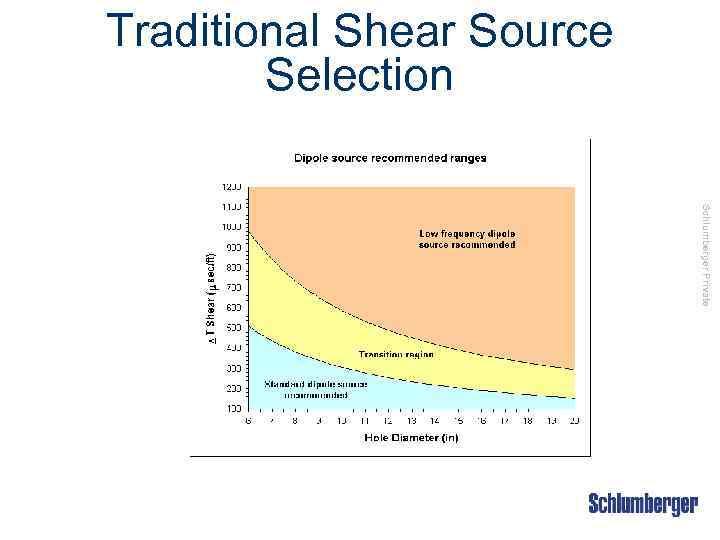

Traditional Shear Source Selection Schlumberger Private

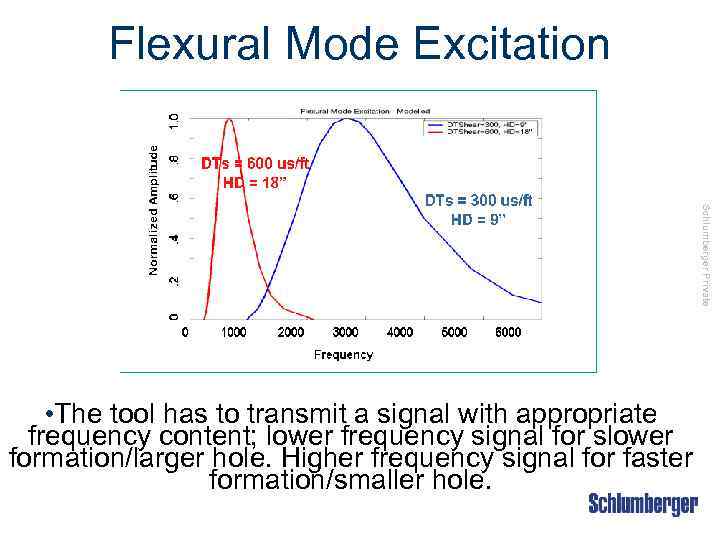

Flexural Mode Excitation Schlumberger Private • The tool has to transmit a signal with appropriate frequency content; lower frequency signal for slower formation/larger hole. Higher frequency signal for faster formation/smaller hole.

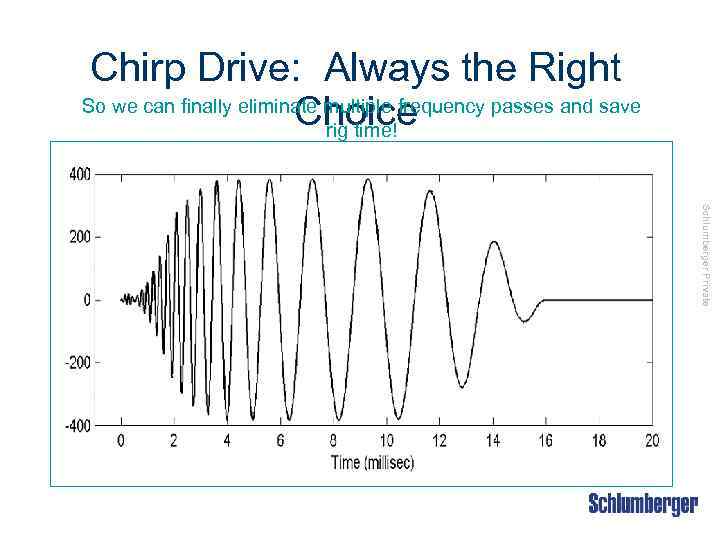

Chirp Drive: Always the Right So we can finally eliminate multiple frequency passes and save Choice rig time! Zoom Schlumberger Private Chirp outputs more energy than the Mid and Low Frequency drives

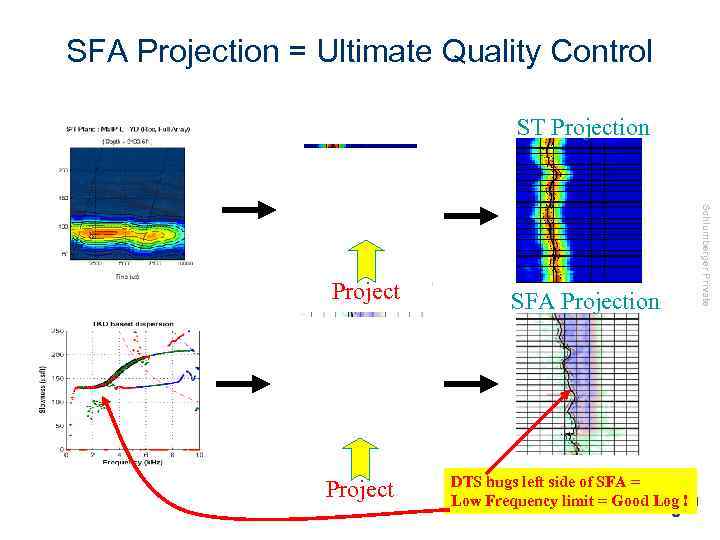

SFA Projection = Ultimate Quality Control ST Projection Project SFA Projection DTS hugs left side of SFA = Low Frequency limit = Good Log ! Schlumberger Private Project

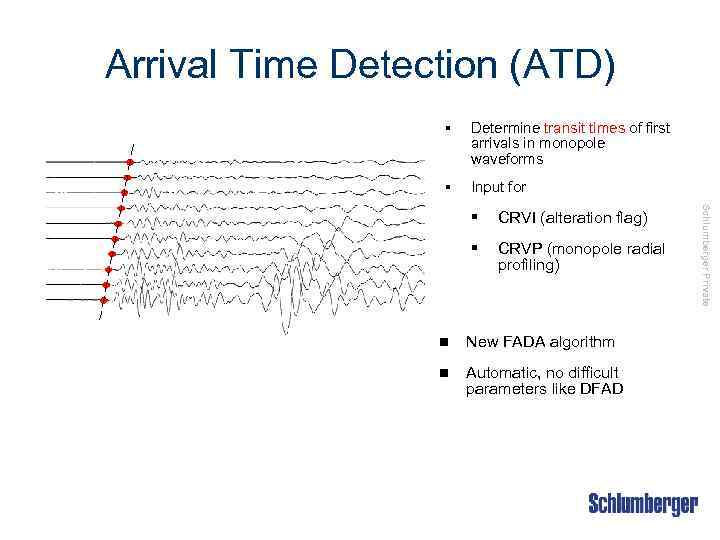

Arrival Time Detection (ATD) § Determine transit times of first arrivals in monopole waveforms § Input for CRVI (alteration flag) § CRVP (monopole radial profiling) n New FADA algorithm n Automatic, no difficult parameters like DFAD Schlumberger Private §

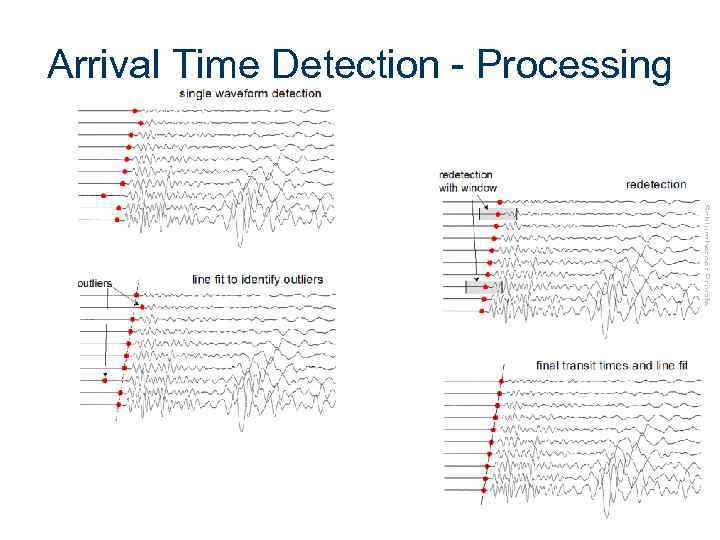

Arrival Time Detection - Processing Schlumberger Private

ATD, FADA Algorithm features • Parameter-less first motion detection algorithm Robust, automatic, easy to use – Used for • Transit times for – • Amplitude for Cement Evaluation – Algorithm also provides quality control outputs • Processing available at wellsite or computing center – Parameter-less operation, no user intervention required Schlumberger Private – Slowness – alteration flag – Monopole Radial Profiling

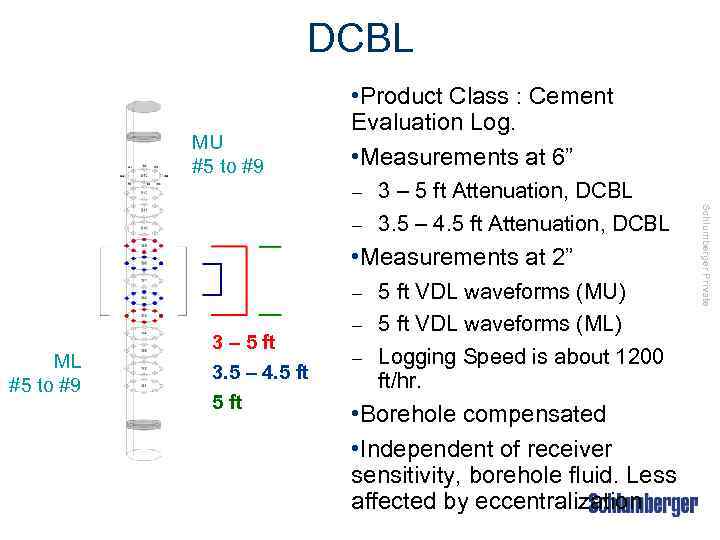

DCBL MU #5 to #9 • Product Class : Cement Evaluation Log. • Measurements at 6” 3 – 5 ft Attenuation, DCBL – 3. 5 – 4. 5 ft Attenuation, DCBL – 5 ft VDL waveforms (MU) – 5 ft VDL waveforms (ML) – Logging Speed is about 1200 ft/hr. – ML #5 to #9 3 – 5 ft 3. 5 – 4. 5 ft • Borehole compensated • Independent of receiver sensitivity, borehole fluid. Less affected by eccentralization Schlumberger Private • Measurements at 2”

Review(Sonic Scanner Theory) You should be able to: Explain the “New Vision” of sonic applications. List four main causes of formation anisotropy. Explain chirp drive of dipole transmitter. Explain Discriminated CBL measurement. Schlumberger Private 1. 2. 3. 4.

Objectives (Job Preparation-Safety-Maintenance) You will be able to: List at least 4 informations required as a part of job preparation. 2. Know standard and additional hardware required to run the tool. 3. List at least 4 product classes available in MAST setup console 4. Explain how to protect the MAST dipole transmitters during transportation. 5. Discuss how to identify the oil level in MAST 6. Explain what type of oil can be used for MAST 7. List four factors that affect sensor sensitivity mismatch 8. Explain the purpose and steps of the master calibration Schlumberger Private 1.

Pre-Job Informations required Formation Slowness and Characteristic Acquisition parameters (Firing mode? ) Other tools or equipment necessary How to centralize the tool correctly Estimated logging speed Estimated data volume Field Presentation and Field output to the client How to back up the data Sonic Scanner Help file with you? Schlumberger Private • • •

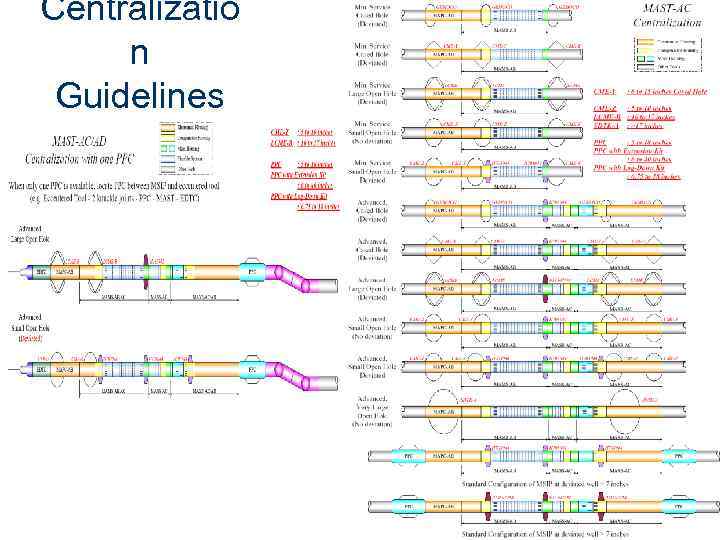

Centralizatio n Guidelines Schlumberger Private

MAST Product Class • Record All Data • Record All Modes • Test & Maintenance • Cement Evaluation Log • Standard • BHC Log • Calibration • Imaging Schlumberger Private • Monopole P&S Log

FIT-1: Oil Filling Schlumberger Private • MAST must be filled up with oil prior to every descent in the well • Shin-Etsu silicon oil KF 96, 50 cs ONLY : MAMS, MASS and MAXS • Note: The adapter used is the same as for TLD. • Recommendation: Have a MAST ready box in your location (dedicated pump and adapter)

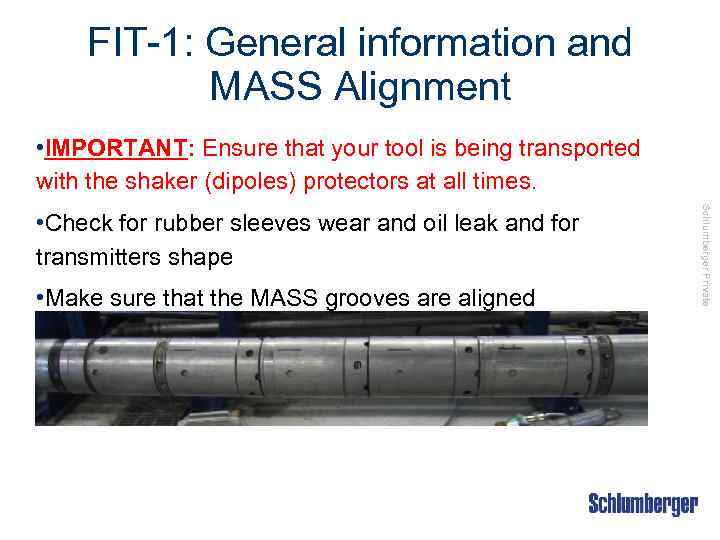

FIT-1: General information and MASS Alignment • IMPORTANT: Ensure that your tool is being transported with the shaker (dipoles) protectors at all times. • Make sure that the MASS grooves are aligned Schlumberger Private • Check for rubber sleeves wear and oil leak and for transmitters shape

Other precautions • Danger to person – • Danger to equipment – Using silicone oil (Shin-Etsu KF 96 -50 CS) for all oil sections. Never mix with any other hydraulic oil. – Use SN 96 solder only. – MAMS has plastic/rubber sleeves and it is weak for sharp edge. Request special care for handing – Vertical makeup one by one module (Tool is flexible) – Dipole transportation jig Schlumberger Private Tool is heavy and flexible, use proper way for handling (MAMS 150 Kg): use mechanical lifting when possible or at least three people.

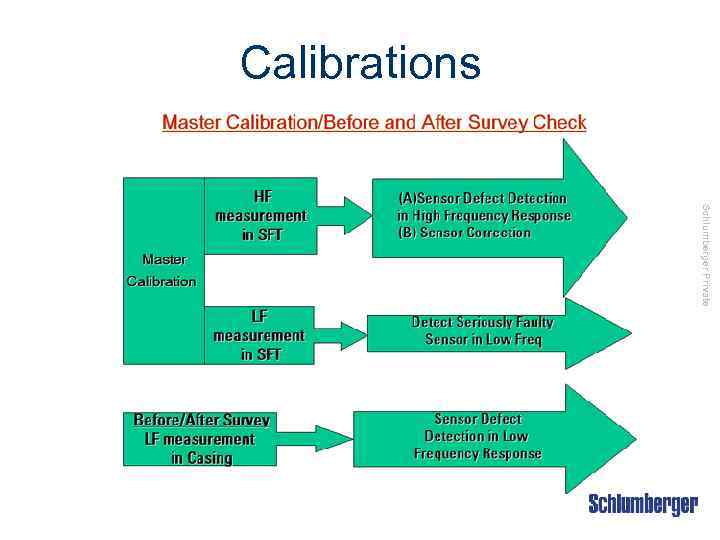

Calibrations Schlumberger Private

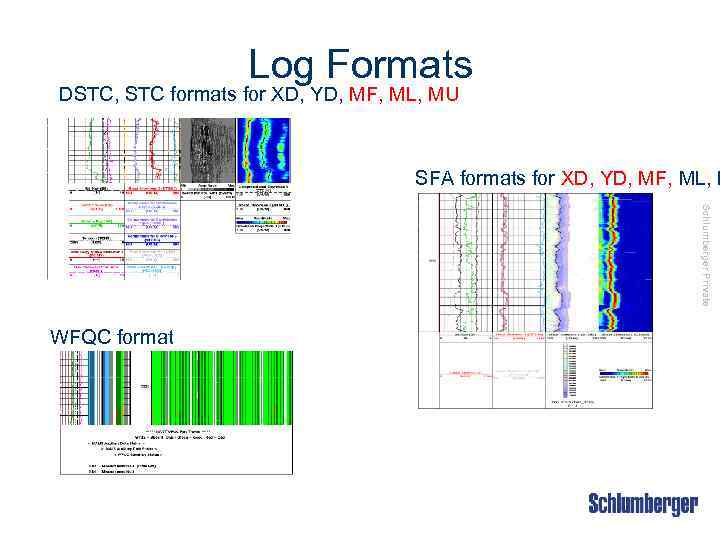

Log Formats DSTC, STC formats for XD, YD, MF, ML, MU SFA formats for XD, YD, MF, ML, M Schlumberger Private WFQC format

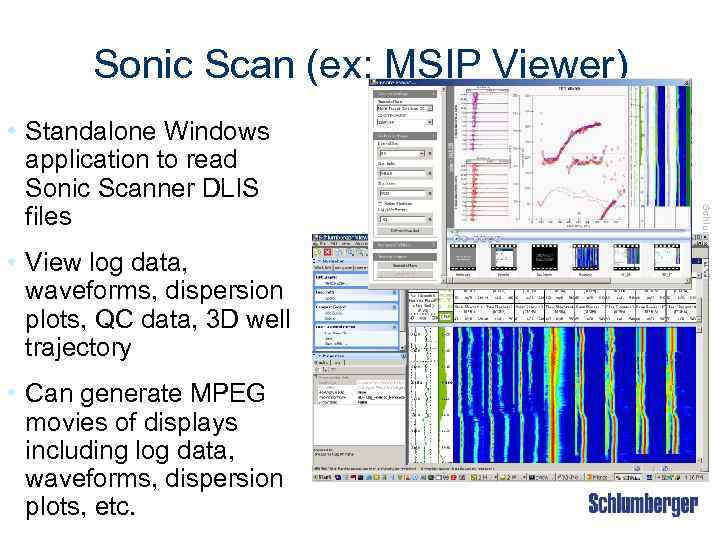

Sonic Scan (ex: MSIP Viewer) • View log data, waveforms, dispersion plots, QC data, 3 D well trajectory • Can generate MPEG movies of displays including log data, waveforms, dispersion plots, etc. Schlumberger Private • Standalone Windows application to read Sonic Scanner DLIS files

Sonic Scanner presentation_Uche_p2v2.pptx