7e01cb65ba6940b33dbdb7a57d706656.ppt

- Количество слайдов: 16

Solidimension User Operation Training Confidential and Proprietary 1

Solidimension User Operation Training Confidential and Proprietary 1

UOT Agenda • Introduction of the SD 300 printer • Capabilities – specifications • SDview application software - Model preparation - Model building • Technology and operation concept • Geometry Capabilities • Basic components and parts • Post build activities: - Removing model from the printer - Peeling residual material - Finishing the model • Material kit – consumables • Getting started: - Initialization - Consumable loading • Control panel and menu options • Panel Errors • User Troubleshooting • User maintenance and safety Confidential and Proprietary 2

UOT Agenda • Introduction of the SD 300 printer • Capabilities – specifications • SDview application software - Model preparation - Model building • Technology and operation concept • Geometry Capabilities • Basic components and parts • Post build activities: - Removing model from the printer - Peeling residual material - Finishing the model • Material kit – consumables • Getting started: - Initialization - Consumable loading • Control panel and menu options • Panel Errors • User Troubleshooting • User maintenance and safety Confidential and Proprietary 2

The SD 300 Printer • Creates 3 D models • Concept modeler Plus: Creates parts for evaluation, demonstration and functional verification • Desktop user friendly machine • Office environment • Intended for: engineers, industrial designers, 3 D model users Confidential and Proprietary 3

The SD 300 Printer • Creates 3 D models • Concept modeler Plus: Creates parts for evaluation, demonstration and functional verification • Desktop user friendly machine • Office environment • Intended for: engineers, industrial designers, 3 D model users Confidential and Proprietary 3

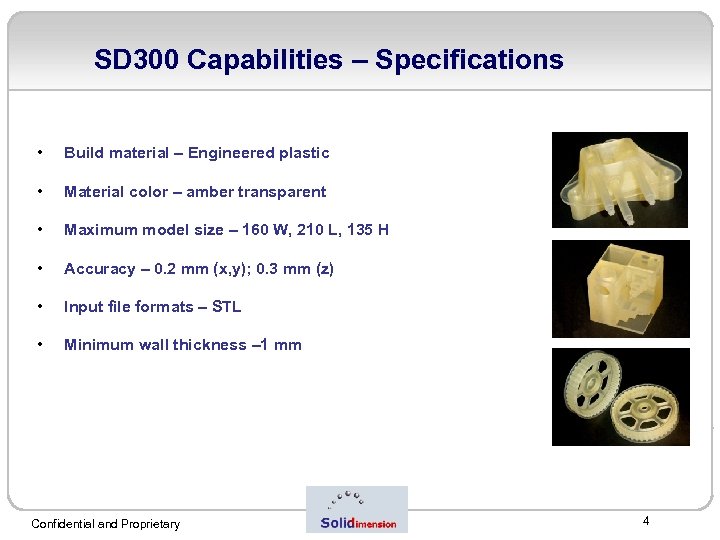

SD 300 Capabilities – Specifications • Build material – Engineered plastic • Material color – amber transparent • Maximum model size – 160 W, 210 L, 135 H • Accuracy – 0. 2 mm (x, y); 0. 3 mm (z) • Input file formats – STL • Minimum wall thickness – 1 mm Confidential and Proprietary 4

SD 300 Capabilities – Specifications • Build material – Engineered plastic • Material color – amber transparent • Maximum model size – 160 W, 210 L, 135 H • Accuracy – 0. 2 mm (x, y); 0. 3 mm (z) • Input file formats – STL • Minimum wall thickness – 1 mm Confidential and Proprietary 4

Technology and operation concept • Bottom to top layer by layer build-up • Layer build-up cycle : - Preparing a new plastic sheet layer in the buffer - Glue application on the whole area - Ironing the new plastic sheet layer on the model block - Cutting the new plastic sheet layer according to the pattern - Trimming the new plastic sheet layer and roll back - Masking fluid application by the 3 AG pens Confidential and Proprietary 5

Technology and operation concept • Bottom to top layer by layer build-up • Layer build-up cycle : - Preparing a new plastic sheet layer in the buffer - Glue application on the whole area - Ironing the new plastic sheet layer on the model block - Cutting the new plastic sheet layer according to the pattern - Trimming the new plastic sheet layer and roll back - Masking fluid application by the 3 AG pens Confidential and Proprietary 5

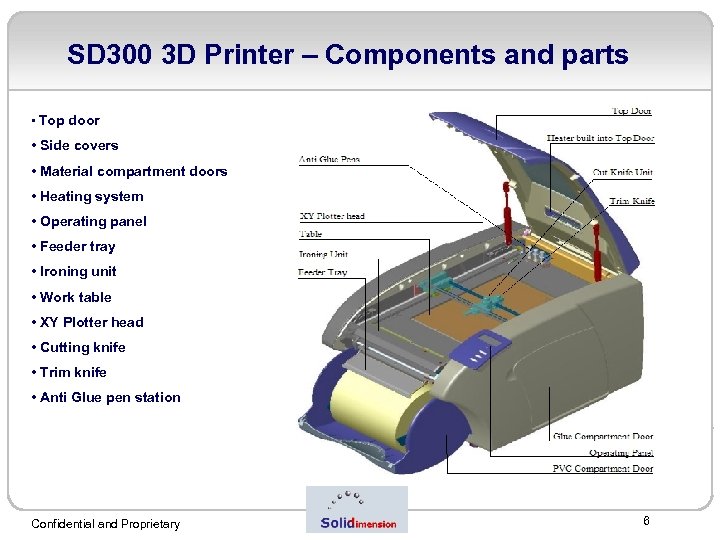

SD 300 3 D Printer – Components and parts • Top door • Side covers • Material compartment doors • Heating system • Operating panel • Feeder tray • Ironing unit • Work table • XY Plotter head • Cutting knife • Trim knife • Anti Glue pen station Confidential and Proprietary 6

SD 300 3 D Printer – Components and parts • Top door • Side covers • Material compartment doors • Heating system • Operating panel • Feeder tray • Ironing unit • Work table • XY Plotter head • Cutting knife • Trim knife • Anti Glue pen station Confidential and Proprietary 6

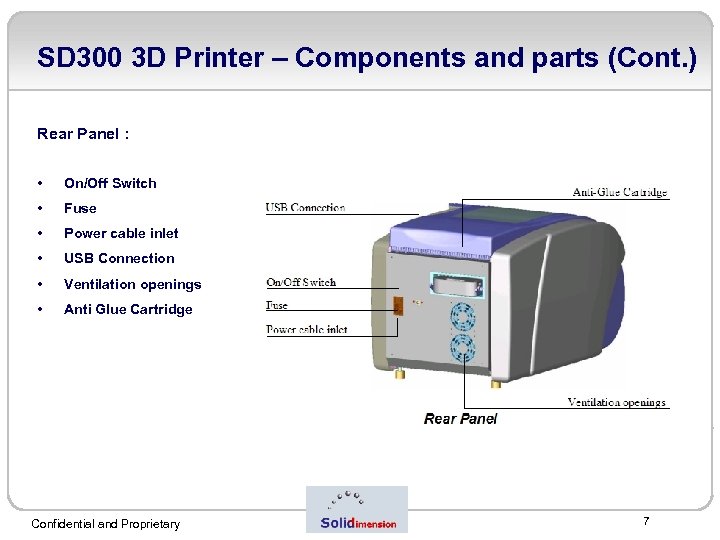

SD 300 3 D Printer – Components and parts (Cont. ) Rear Panel : • On/Off Switch • Fuse • Power cable inlet • USB Connection • Ventilation openings • Anti Glue Cartridge Confidential and Proprietary 7

SD 300 3 D Printer – Components and parts (Cont. ) Rear Panel : • On/Off Switch • Fuse • Power cable inlet • USB Connection • Ventilation openings • Anti Glue Cartridge Confidential and Proprietary 7

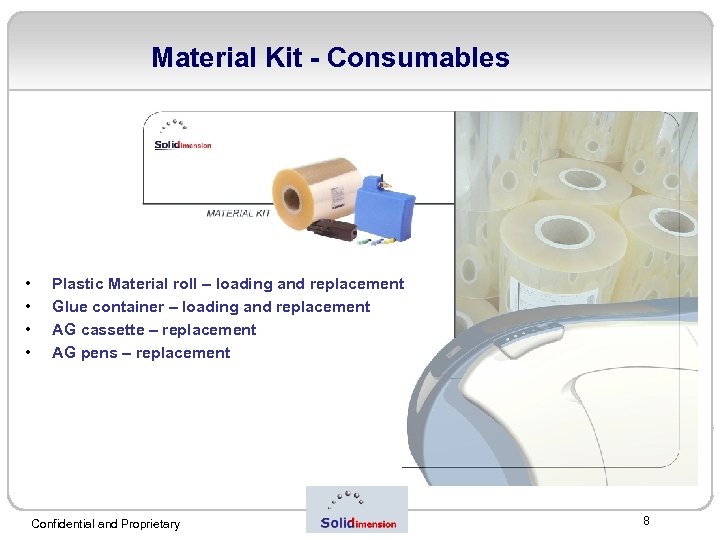

Material Kit - Consumables • • Plastic Material roll – loading and replacement Glue container – loading and replacement AG cassette – replacement AG pens – replacement Confidential and Proprietary 8

Material Kit - Consumables • • Plastic Material roll – loading and replacement Glue container – loading and replacement AG cassette – replacement AG pens – replacement Confidential and Proprietary 8

Getting started (practice) • Initializing the printer • Consumable loading: - Material roll - Glue cartridge - AG cassette and pens • Hands on practice Confidential and Proprietary 9

Getting started (practice) • Initializing the printer • Consumable loading: - Material roll - Glue cartridge - AG cassette and pens • Hands on practice Confidential and Proprietary 9

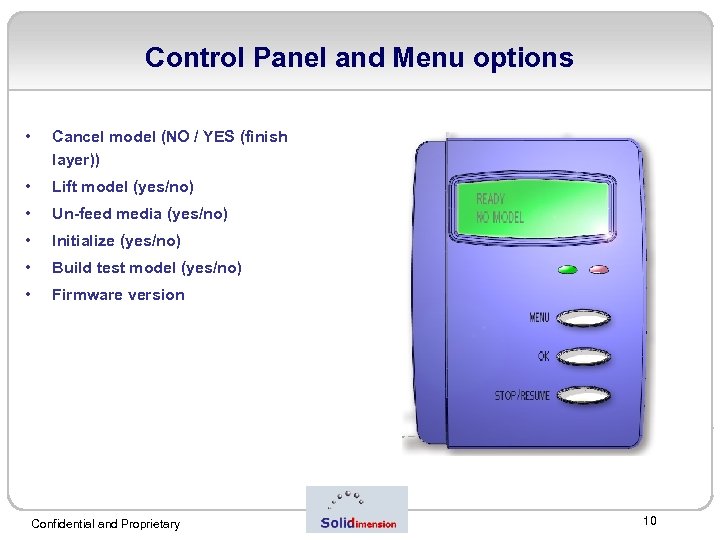

Control Panel and Menu options • Cancel model (NO / YES (finish layer)) • Lift model (yes/no) • Un-feed media (yes/no) • Initialize (yes/no) • Build test model (yes/no) • Firmware version Confidential and Proprietary 10

Control Panel and Menu options • Cancel model (NO / YES (finish layer)) • Lift model (yes/no) • Un-feed media (yes/no) • Initialize (yes/no) • Build test model (yes/no) • Firmware version Confidential and Proprietary 10

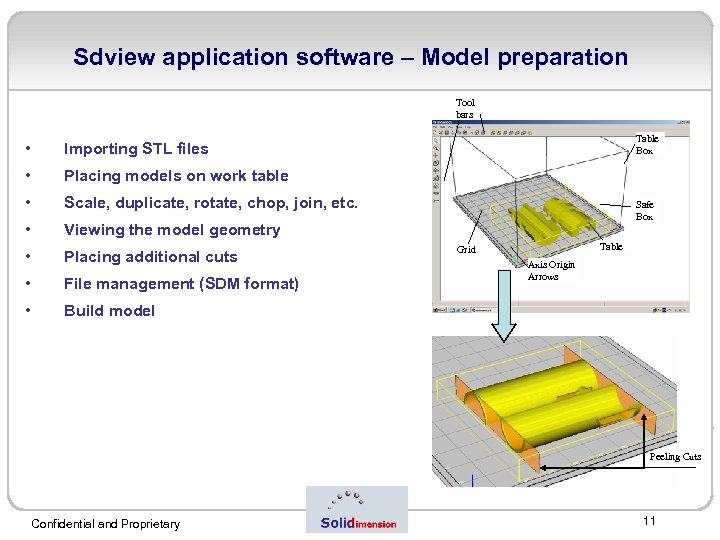

Sdview application software – Model preparation Tool bars • • Placing models on work table • Scale, duplicate, rotate, chop, join, etc. • Viewing the model geometry • Placing additional cuts • File management (SDM format) • Table Box Importing STL files Build model Safe Box Table Grid Axis Origin Arrows Peeling Cuts Confidential and Proprietary 11

Sdview application software – Model preparation Tool bars • • Placing models on work table • Scale, duplicate, rotate, chop, join, etc. • Viewing the model geometry • Placing additional cuts • File management (SDM format) • Table Box Importing STL files Build model Safe Box Table Grid Axis Origin Arrows Peeling Cuts Confidential and Proprietary 11

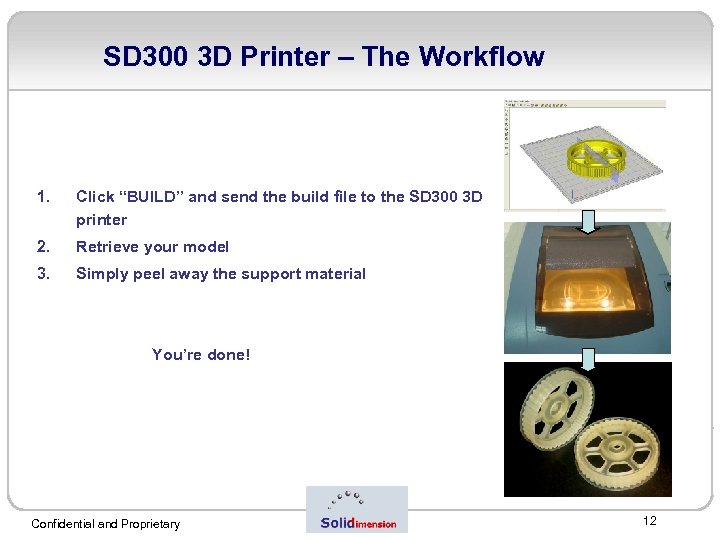

SD 300 3 D Printer – The Workflow 1. Click “BUILD” and send the build file to the SD 300 3 D printer 2. Retrieve your model 3. Simply peel away the support material You’re done! Confidential and Proprietary 12

SD 300 3 D Printer – The Workflow 1. Click “BUILD” and send the build file to the SD 300 3 D printer 2. Retrieve your model 3. Simply peel away the support material You’re done! Confidential and Proprietary 12

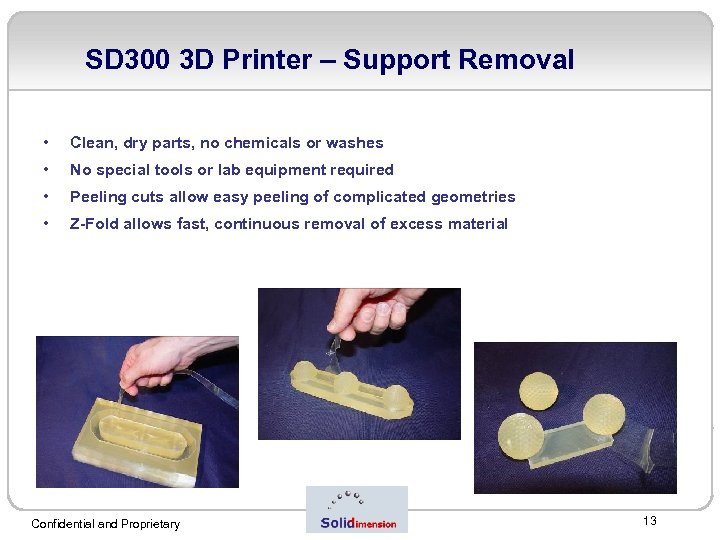

SD 300 3 D Printer – Support Removal • Clean, dry parts, no chemicals or washes • No special tools or lab equipment required • Peeling cuts allow easy peeling of complicated geometries • Z-Fold allows fast, continuous removal of excess material Confidential and Proprietary 13

SD 300 3 D Printer – Support Removal • Clean, dry parts, no chemicals or washes • No special tools or lab equipment required • Peeling cuts allow easy peeling of complicated geometries • Z-Fold allows fast, continuous removal of excess material Confidential and Proprietary 13

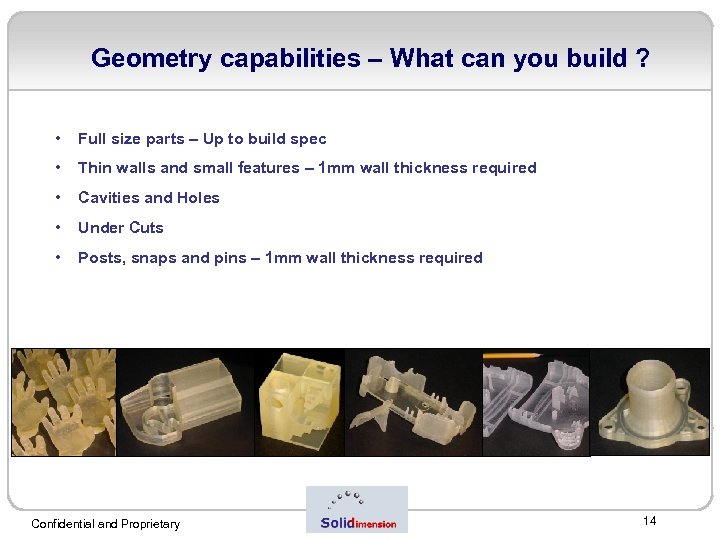

Geometry capabilities – What can you build ? • Full size parts – Up to build spec • Thin walls and small features – 1 mm wall thickness required • Cavities and Holes • Under Cuts • Posts, snaps and pins – 1 mm wall thickness required Confidential and Proprietary 14

Geometry capabilities – What can you build ? • Full size parts – Up to build spec • Thin walls and small features – 1 mm wall thickness required • Cavities and Holes • Under Cuts • Posts, snaps and pins – 1 mm wall thickness required Confidential and Proprietary 14

SD 300 3 D Printer – User maintenance • Clean printer after each build – Glue residues – AG residues – Plastic sheet particles • Test build in case the printer was not in use for a week • Clean bubbles – if necessary Confidential and Proprietary 15

SD 300 3 D Printer – User maintenance • Clean printer after each build – Glue residues – AG residues – Plastic sheet particles • Test build in case the printer was not in use for a week • Clean bubbles – if necessary Confidential and Proprietary 15

SD 300 3 D Printer – Machine Safety • Electrical safety measures • Keep work area clear and free of clutter • Inspect the power cord periodically for cracks, kinks or any other signs of wear • Do not pull the Printer by the cords • Keep the area dry • Keep the area well lit • Do not touch any moving parts • Clean up any spills immediately. Good house keeping pays • Do not wear loose clothing or dangling jewelry while working with the printer • Keep all doors and panels closed during operation • Working with the tweezers Confidential and Proprietary 16

SD 300 3 D Printer – Machine Safety • Electrical safety measures • Keep work area clear and free of clutter • Inspect the power cord periodically for cracks, kinks or any other signs of wear • Do not pull the Printer by the cords • Keep the area dry • Keep the area well lit • Do not touch any moving parts • Clean up any spills immediately. Good house keeping pays • Do not wear loose clothing or dangling jewelry while working with the printer • Keep all doors and panels closed during operation • Working with the tweezers Confidential and Proprietary 16