730636989cfa214a6011f8c9700b4b5f.ppt

- Количество слайдов: 18

SO SR QMS – from basic form to continual development Mária Dologová, QM, SO SR, Slovakia Ján Dolog, EOQ senior consultant for QMS Statistics 2009, Prague, 14 -15 September 2009

SO SR Contents QMS of the SO SR background, choice, aim implementation development Mária Dologová, Ján Dolog 2

QMS - background, choice, aim SO SR Demanding environment of the SO SR (high requirements – incl. Q; limited resources required change, i. e. : implementation of an institution-wide QMS based on: QMS long-term view, leadership customer orientation + ability to provide value . to customers (+ other stakeholders) process approach, minimisation of activities . not adding value continual improvement Mária Dologová, Ján Dolog 3

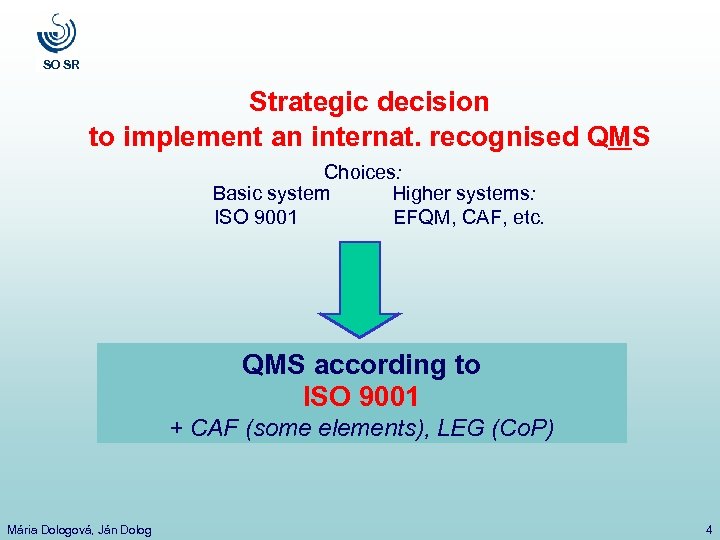

SO SR Strategic decision to implement an internat. recognised QMS Choices: Basic system Higher systems: ISO 9001 EFQM, CAF, etc. QMS according to ISO 9001 + CAF (some elements), LEG (Co. P) Mária Dologová, Ján Dolog 4

SO SR . . . the QMS provided framework for: development of system approach to management with the aim to continually improve performance by enhancing customer satisfaction (+ other inter. parties) . . . to improve value of the SO SR. . . the implemented QMS at the same time: demonstrates ability of the SO SR to provide products that consistently meet requirements (of its customers and regulations) Mária Dologová, Ján Dolog 5

SO SR QMS - implementation Approach to developing and implementing QMS the SO SR adapted its existing system to the ISO requirements and followed the value creation process flow Mária Dologová, Ján Dolog 6

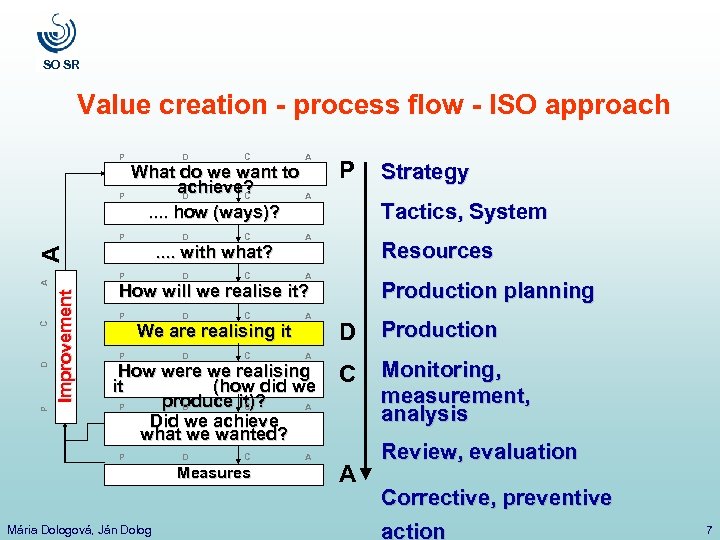

SO SR Value creation - process flow - ISO approach P D C A What do we want to achieve? P D C A. . how (ways)? P Tactics, System P D C A A P D C A Improvement P D C A Resources . . with what? Production planning How will we realise it? P D C A We are realising it Strategy D Production P D C A How were we realising C Monitoring, it (how did we measurement, produce it)? P D C A analysis Did we achieve what we wanted? P D C A Measures Mária Dologová, Ján Dolog A Review, evaluation Corrective, preventive action 7

SO SR QMS implementation - achieved status the SO SR has: General defined scope of the QMS, identified, specified, described processes needed for QMS, + process interfaces; way of managing and improving processes elaborated QMS documentation, incl. control Mária Dologová, Ján Dolog 8

SO SR Strategy - Tactics – System procedure to determine customer needs & expectations established quality policy, development strategy, strategic obj. ; quality objectives at relevant functions and levels determined responsibilities, authorities and internal communication channels necessary to achieve these objectives, top management representative re QMS Resource management determined and provided resources for QMS, for enhancement of the customer satisfaction (HR – competence, infrastructure, work environment) Mária Dologová, Ján Dolog 9

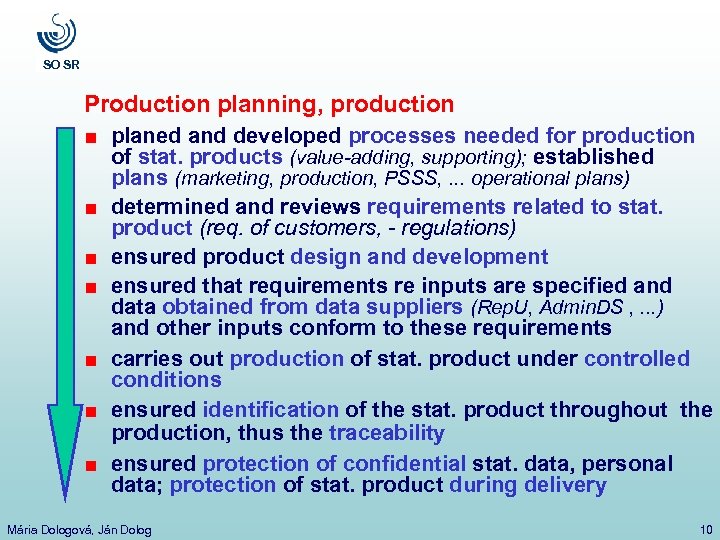

SO SR Production planning, production planed and developed processes needed for production of stat. products (value-adding, supporting); established plans (marketing, production, PSSS, . . . operational plans) determined and reviews requirements related to stat. product (req. of customers, - regulations) ensured product design and development ensured that requirements re inputs are specified and data obtained from data suppliers (Rep. U, Admin. DS , . . . ) and other inputs conform to these requirements carries out production of stat. product under controlled conditions ensured identification of the stat. product throughout the production, thus the traceability ensured protection of confidential stat. data, personal data; protection of stat. product during delivery Mária Dologová, Ján Dolog 10

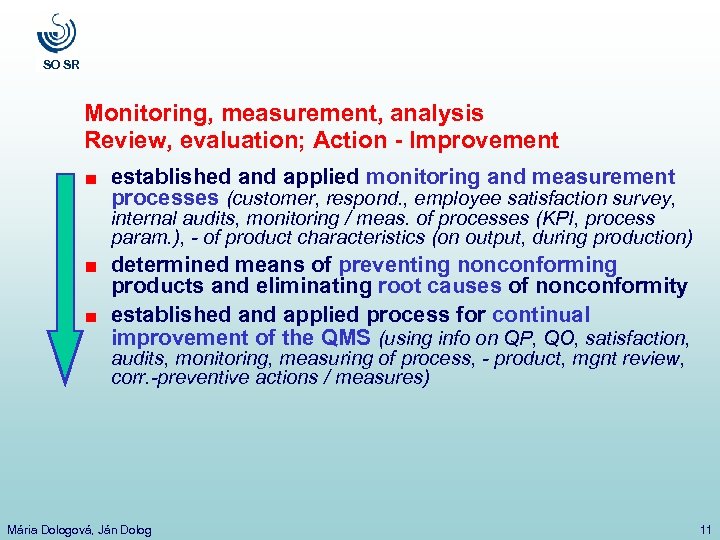

SO SR Monitoring, measurement, analysis Review, evaluation; Action - Improvement established and applied monitoring and measurement processes (customer, respond. , employee satisfaction survey, internal audits, monitoring / meas. of processes (KPI, process param. ), - of product characteristics (on output, during production) determined means of preventing nonconforming products and eliminating root causes of nonconformity established and applied process for continual improvement of the QMS (using info on QP, QO, satisfaction, audits, monitoring, measuring of process, - product, mgnt review, corr. -preventive actions / measures) Mária Dologová, Ján Dolog 11

SO SR Systemised way of doing things in the institution Good basis for effectiveness gains through further development of the QMS Mária Dologová, Ján Dolog 12

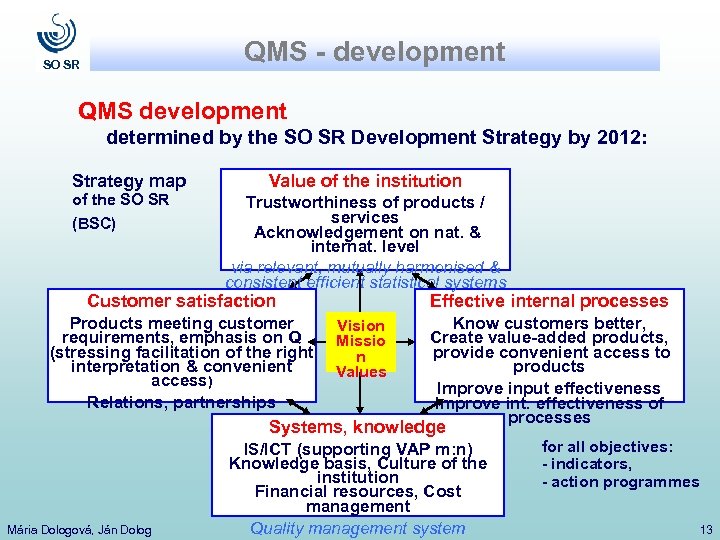

QMS - development SO SR QMS development determined by the SO SR Development Strategy by 2012: Value of the institution Strategy map of the SO SR (BSC) Trustworthiness of products / services Acknowledgement on nat. & internat. level via relevant, mutually harmonised & consistent efficient statistical systems Customer satisfaction Products meeting customer Vision requirements, emphasis on Q Missio (stressing facilitation of the right n interpretation & convenient Values access) Relations, partnerships Effective internal processes Know customers better, Create value-added products, provide convenient access to products Improve input effectiveness Improve int. effectiveness of processes Systems, knowledge Mária Dologová, Ján Dolog IS/ICT (supporting VAP m: n) Knowledge basis, Culture of the institution Financial resources, Cost management Quality management system for all objectives: - indicators, - action programmes 13

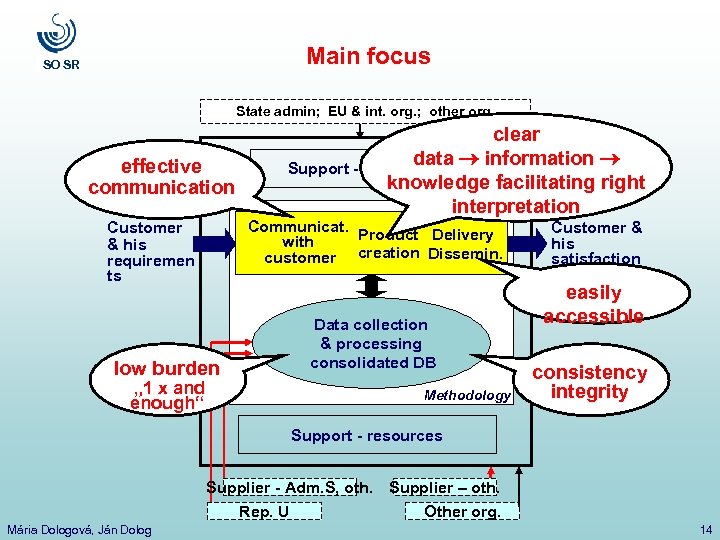

Main focus SO SR State admin; EU & int. org. ; other org. effective communication clear data information Support - managerial knowledge facilitating right interpretation Customer Communicat. Product Delivery with & his customer creation Dissemin. requiremen ts Data collection & processing consolidated DB low burden „ 1 x and Methodology enough“ Customer & his satisfaction easily accessible consistency integrity Support - resources Supplier - Adm. S, oth. Supplier – oth. Rep. U Mária Dologová, Ján Dolog Other org. 14

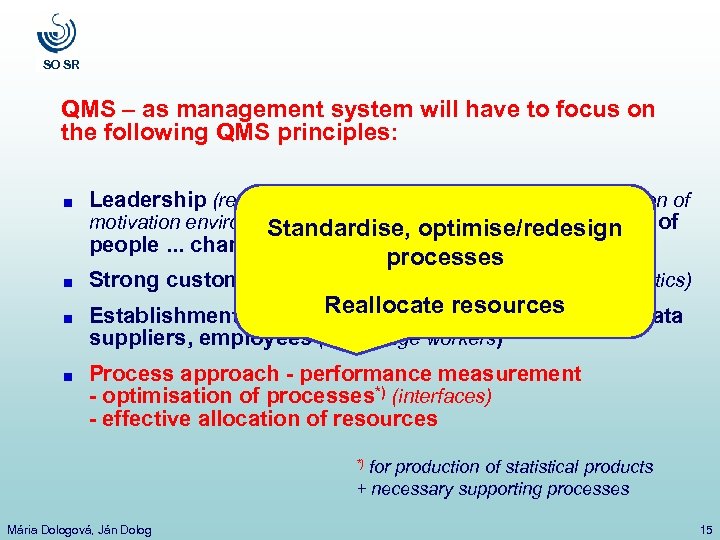

SO SR QMS – as management system will have to focus on the following QMS principles: Leadership (react to challenges from ext. environment; creation of motivation environment for managing change) & Involvement of Standardise, optimise/redesign people. . . change of mental model processes Strong customer orientation (statistical product characteristics) Reallocate resources Establishment of effective relations with customers, data suppliers, employees (knowledge workers) Process approach - performance measurement - optimisation of processes*) (interfaces) - effective allocation of resources for production of statistical products + necessary supporting processes *) Mária Dologová, Ján Dolog 15

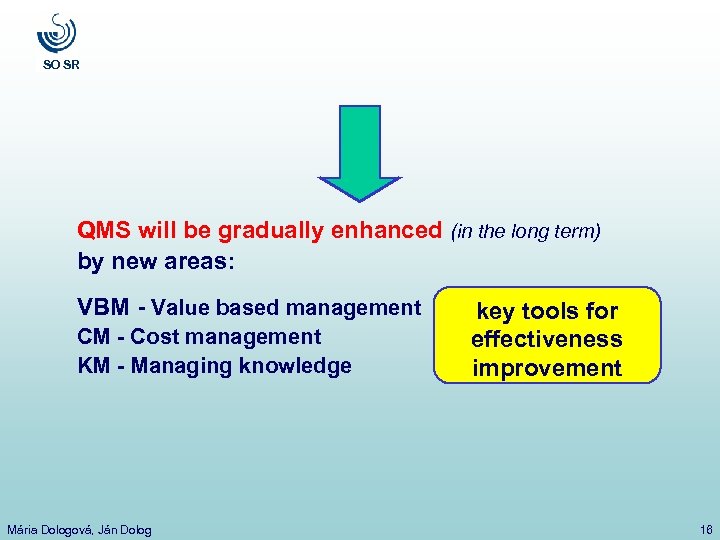

SO SR QMS will be gradually enhanced (in the long term) by new areas: VBM - Value based management CM - Cost management KM - Managing knowledge Mária Dologová, Ján Dolog key tools for effectiveness improvement 16

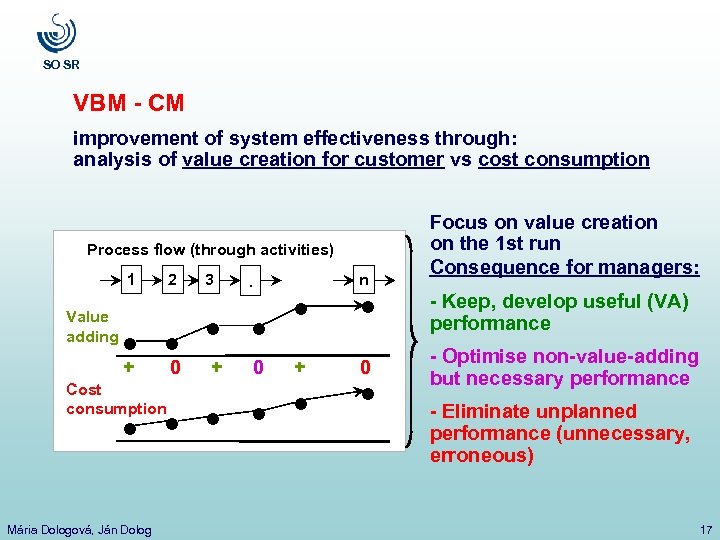

SO SR VBM - CM improvement of system effectiveness through: analysis of value creation for customer vs cost consumption Process flow (through activities) 1 Value adding 2 3 n . + 0 Cost consumption Mária Dologová, Ján Dolog Focus on value creation on the 1 st run Consequence for managers: - Keep, develop useful (VA) performance - Optimise non-value-adding but necessary performance - Eliminate unplanned performance (unnecessary, erroneous) 17

SO SR Change of mental model Thank you for your attention Mária Dologová, Ján Dolog 18

730636989cfa214a6011f8c9700b4b5f.ppt