a930d8586bcf32bb1bf1e230dbb1fc34.ppt

- Количество слайдов: 16

SLOVAK POWER STATIONS NOVÁKY POWER STATION

SLOVAK POWER STATIONS NOVÁKY POWER STATION

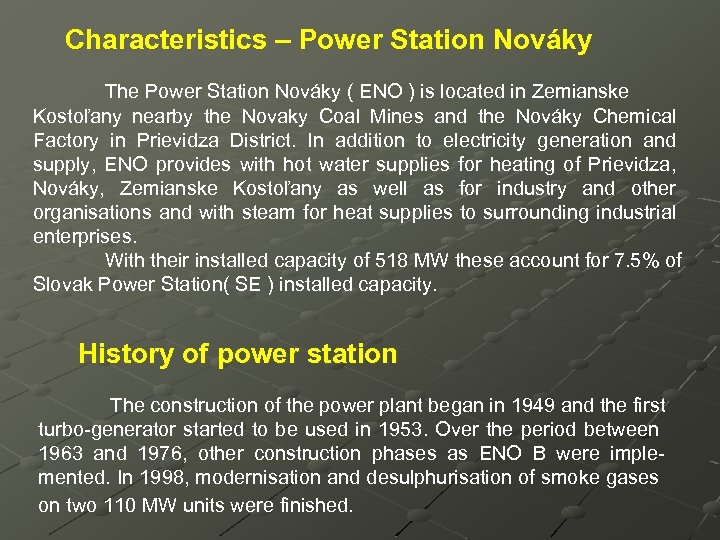

Characteristics – Power Station Nováky The Power Station Nováky ( ENO ) is located in Zemianske Kostoľany nearby the Novaky Coal Mines and the Nováky Chemical Factory in Prievidza District. In addition to electricity generation and supply, ENO provides with hot water supplies for heating of Prievidza, Nováky, Zemianske Kostoľany as well as for industry and other organisations and with steam for heat supplies to surrounding industrial enterprises. With their installed capacity of 518 MW these account for 7. 5% of Slovak Power Station( SE ) installed capacity. History of power station The construction of the power plant began in 1949 and the first turbo-generator started to be used in 1953. Over the period between 1963 and 1976, other construction phases as ENO B were implemented. In 1998, modernisation and desulphurisation of smoke gases on two 110 MW units were finished.

Characteristics – Power Station Nováky The Power Station Nováky ( ENO ) is located in Zemianske Kostoľany nearby the Novaky Coal Mines and the Nováky Chemical Factory in Prievidza District. In addition to electricity generation and supply, ENO provides with hot water supplies for heating of Prievidza, Nováky, Zemianske Kostoľany as well as for industry and other organisations and with steam for heat supplies to surrounding industrial enterprises. With their installed capacity of 518 MW these account for 7. 5% of Slovak Power Station( SE ) installed capacity. History of power station The construction of the power plant began in 1949 and the first turbo-generator started to be used in 1953. Over the period between 1963 and 1976, other construction phases as ENO B were implemented. In 1998, modernisation and desulphurisation of smoke gases on two 110 MW units were finished.

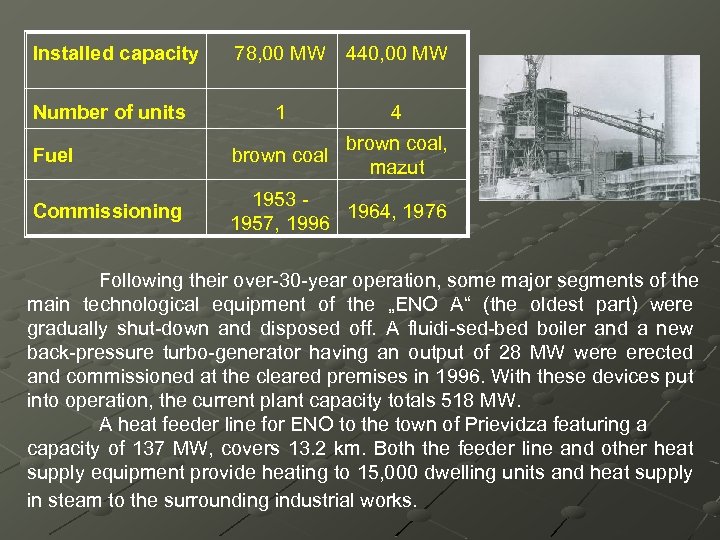

Installed capacity 78, 00 MW 440, 00 MW 1 4 Fuel brown coal, mazut Commissioning 1953 - 1964, 1976 1957, 1996 Number of units Following their over-30 -year operation, some major segments of the main technological equipment of the „ENO A“ (the oldest part) were gradually shut-down and disposed off. A fluidi-sed-bed boiler and a new back-pressure turbo-generator having an output of 28 MW were erected and commissioned at the cleared premises in 1996. With these devices put into operation, the current plant capacity totals 518 MW. A heat feeder line for ENO to the town of Prievidza featuring a capacity of 137 MW, covers 13. 2 km. Both the feeder line and other heat supply equipment provide heating to 15, 000 dwelling units and heat supply in steam to the surrounding industrial works.

Installed capacity 78, 00 MW 440, 00 MW 1 4 Fuel brown coal, mazut Commissioning 1953 - 1964, 1976 1957, 1996 Number of units Following their over-30 -year operation, some major segments of the main technological equipment of the „ENO A“ (the oldest part) were gradually shut-down and disposed off. A fluidi-sed-bed boiler and a new back-pressure turbo-generator having an output of 28 MW were erected and commissioned at the cleared premises in 1996. With these devices put into operation, the current plant capacity totals 518 MW. A heat feeder line for ENO to the town of Prievidza featuring a capacity of 137 MW, covers 13. 2 km. Both the feeder line and other heat supply equipment provide heating to 15, 000 dwelling units and heat supply in steam to the surrounding industrial works.

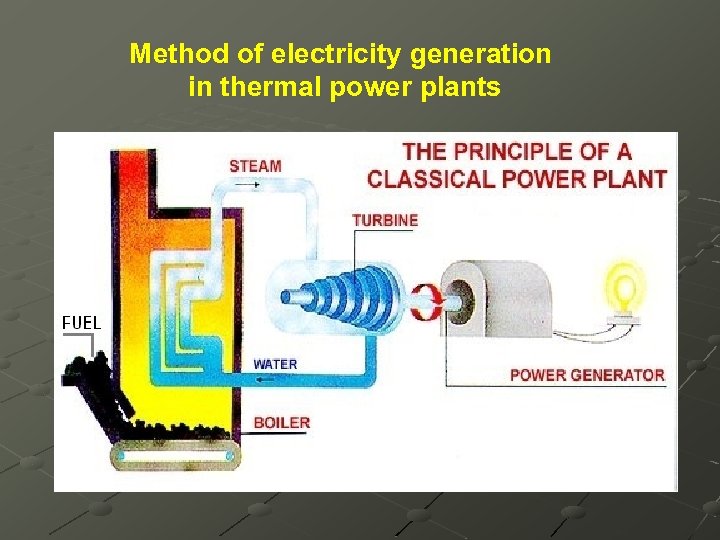

Method of electricity generation in thermal power plants

Method of electricity generation in thermal power plants

Climatic Changes Impact of operation on environment Roughly 80% of the world energy is currently obtained from fossil fuels. However their supplies will have been used up over a certain time, apart from thay are being irreplaceable in the chemical industry. Assuming the current annual production, oil supplies are estimated for 45 years, as gas supplies for 70 years, and coal supplies for 250 years. Moreover, fossil fuels burden the environment with not only sulphur and nitrogen oxides, but in particular with CO 2, which causes global warming, and thereby also climatic changes on the globe. The Earth´s average temperature over the last 100 years has risen by 0. 6°C; it is expected to increase in the next century from 1, 5 up to 3, 5°C, some experts even from 2 -5°C. The global problem such as climatic changes call for a global solution. This was tried attempted by the conference in Kyoto, Japan, however unsuccessfully, where merely partial solutions were proposed. These proposals only apply to OECD countries and the former Soviet bloc´s countries. The limitations do not concern the countries where a critical increase in greenhouse gases (GHG) is expected, i. e. developing countries. Europe and North America have increasingly shifted away to natural gas, which however the developing world cannot afford because of high prices of the fuel.

Climatic Changes Impact of operation on environment Roughly 80% of the world energy is currently obtained from fossil fuels. However their supplies will have been used up over a certain time, apart from thay are being irreplaceable in the chemical industry. Assuming the current annual production, oil supplies are estimated for 45 years, as gas supplies for 70 years, and coal supplies for 250 years. Moreover, fossil fuels burden the environment with not only sulphur and nitrogen oxides, but in particular with CO 2, which causes global warming, and thereby also climatic changes on the globe. The Earth´s average temperature over the last 100 years has risen by 0. 6°C; it is expected to increase in the next century from 1, 5 up to 3, 5°C, some experts even from 2 -5°C. The global problem such as climatic changes call for a global solution. This was tried attempted by the conference in Kyoto, Japan, however unsuccessfully, where merely partial solutions were proposed. These proposals only apply to OECD countries and the former Soviet bloc´s countries. The limitations do not concern the countries where a critical increase in greenhouse gases (GHG) is expected, i. e. developing countries. Europe and North America have increasingly shifted away to natural gas, which however the developing world cannot afford because of high prices of the fuel.

Slovak Power Stations joint stock company’s Environmental Policy Slovak Power Stations ( SE ) mission is to generate, sell and trade electricity and heat safely, reliably, efficiently and competitively while continually decreasing its production process’s negative impact on the environment. To meet the above goals, SE is undertaking in its Environmental Policy by to the following principles : • protecting the environment by decreasing and managing waste production, its emissions into the atmosphere and any water and soil contamination during construction, operation and maintenance • continuing our trend by improving the Company’s environmental behaviour systematically • keeping with current environmental law and other regulations in connection with the Company’s activities and provision of services • orienting development of the Company’s production and technical base toward such technologies in electricity and heat generation which decrease any negative impact on the environment

Slovak Power Stations joint stock company’s Environmental Policy Slovak Power Stations ( SE ) mission is to generate, sell and trade electricity and heat safely, reliably, efficiently and competitively while continually decreasing its production process’s negative impact on the environment. To meet the above goals, SE is undertaking in its Environmental Policy by to the following principles : • protecting the environment by decreasing and managing waste production, its emissions into the atmosphere and any water and soil contamination during construction, operation and maintenance • continuing our trend by improving the Company’s environmental behaviour systematically • keeping with current environmental law and other regulations in connection with the Company’s activities and provision of services • orienting development of the Company’s production and technical base toward such technologies in electricity and heat generation which decrease any negative impact on the environment

• performing activities that save energy and raw material and promote the use of sustainable and renewable resources by increasing its share in potential hydroenergy utilisation • managing the generation and use of its products and services to avoid serious and irreversible environmental degradation • monitoring and evaluating environmental impact indicators and regularly publishing information about the environment • keeping an open dialogue with the public, civil service and municipal authorities in the field of the environment • continually increasing its employees’ environmental awareness and working with its suppliers and contractors to take into account the environmental protection. Waste processing in SE : • detoxication at own stock-piles and sludges • transfer to stock-piles of contractor companies • reuse at own or contractor production lines

• performing activities that save energy and raw material and promote the use of sustainable and renewable resources by increasing its share in potential hydroenergy utilisation • managing the generation and use of its products and services to avoid serious and irreversible environmental degradation • monitoring and evaluating environmental impact indicators and regularly publishing information about the environment • keeping an open dialogue with the public, civil service and municipal authorities in the field of the environment • continually increasing its employees’ environmental awareness and working with its suppliers and contractors to take into account the environmental protection. Waste processing in SE : • detoxication at own stock-piles and sludges • transfer to stock-piles of contractor companies • reuse at own or contractor production lines

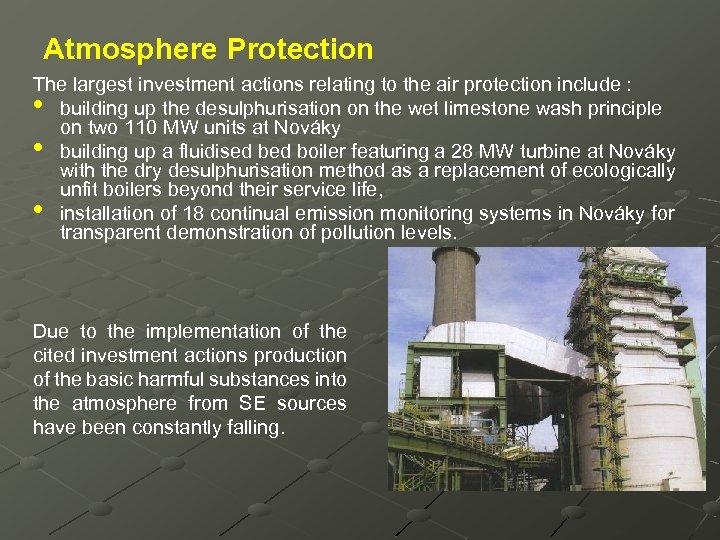

Atmosphere Protection The largest investment actions relating to the air protection include : • building up the desulphurisation on the wet limestone wash principle on two 110 MW units at Nováky • building up a fluidised boiler featuring a 28 MW turbine at Nováky with the dry desulphurisation method as a replacement of ecologically unfit boilers beyond their service life, • installation of 18 continual emission monitoring systems in Nováky for transparent demonstration of pollution levels. Due to the implementation of the cited investment actions production of the basic harmful substances into the atmosphere from SE sources have been constantly falling.

Atmosphere Protection The largest investment actions relating to the air protection include : • building up the desulphurisation on the wet limestone wash principle on two 110 MW units at Nováky • building up a fluidised boiler featuring a 28 MW turbine at Nováky with the dry desulphurisation method as a replacement of ecologically unfit boilers beyond their service life, • installation of 18 continual emission monitoring systems in Nováky for transparent demonstration of pollution levels. Due to the implementation of the cited investment actions production of the basic harmful substances into the atmosphere from SE sources have been constantly falling.

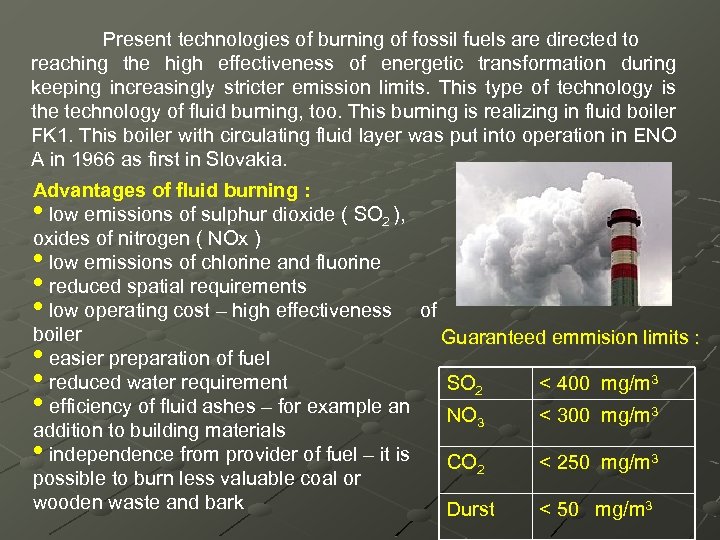

Present technologies of burning of fossil fuels are directed to reaching the high effectiveness of energetic transformation during keeping increasingly stricter emission limits. This type of technology is the technology of fluid burning, too. This burning is realizing in fluid boiler FK 1. This boiler with circulating fluid layer was put into operation in ENO A in 1966 as first in Slovakia. Advantages of fluid burning : • low emissions of sulphur dioxide ( SO 2 ), oxides of nitrogen ( NOx ) • low emissions of chlorine and fluorine • reduced spatial requirements • low operating cost – high effectiveness of boiler Guaranteed emmision limits : • easier preparation of fuel • reduced water requirement SO 2 < 400 mg/m 3 • efficiency of fluid ashes – for example an NO 3 < 300 mg/m 3 addition to building materials • independence from provider of fuel – it is CO 2 < 250 mg/m 3 possible to burn less valuable coal or wooden waste and bark Durst < 50 mg/m 3

Present technologies of burning of fossil fuels are directed to reaching the high effectiveness of energetic transformation during keeping increasingly stricter emission limits. This type of technology is the technology of fluid burning, too. This burning is realizing in fluid boiler FK 1. This boiler with circulating fluid layer was put into operation in ENO A in 1966 as first in Slovakia. Advantages of fluid burning : • low emissions of sulphur dioxide ( SO 2 ), oxides of nitrogen ( NOx ) • low emissions of chlorine and fluorine • reduced spatial requirements • low operating cost – high effectiveness of boiler Guaranteed emmision limits : • easier preparation of fuel • reduced water requirement SO 2 < 400 mg/m 3 • efficiency of fluid ashes – for example an NO 3 < 300 mg/m 3 addition to building materials • independence from provider of fuel – it is CO 2 < 250 mg/m 3 possible to burn less valuable coal or wooden waste and bark Durst < 50 mg/m 3

Benefits from the building up of the desulphurisation unit • lowering the emmisions of SO 2 into the air of about 40 000 tons / year • lowering dust of about 700 tons/ year • catching the harful emissions such as fluorine, chlorine and arsenic • dumping the waste and reusing it as an inferior-secondary product • improving the environment by the significant impact on our fauna and flora Water Protection Before its usage the taken water has to be treated mechanically and chemically in order to decrease its contamination and to meet the quality requests of water for the operation in power plants.

Benefits from the building up of the desulphurisation unit • lowering the emmisions of SO 2 into the air of about 40 000 tons / year • lowering dust of about 700 tons/ year • catching the harful emissions such as fluorine, chlorine and arsenic • dumping the waste and reusing it as an inferior-secondary product • improving the environment by the significant impact on our fauna and flora Water Protection Before its usage the taken water has to be treated mechanically and chemically in order to decrease its contamination and to meet the quality requests of water for the operation in power plants.

Water waste produced by the respective power plants have especially a character of waters from technological and cooling processes. Water waste from technology is chemically contaminated. Water used for cooling is usually contaminated by heat. Water waste containing oil substances are treated in oil waste water treatment plants. The contamination of sewage water is usually biological, such water is treated in waste water plant with mechanical and biological treatment. The prescribed limit indicators of discharged water are constantly in compliance with concentration and balance value parameters. In order to protect and prevent the contamination, there are monitoring systems, which monitor the impact of operation in power plans on the environment.

Water waste produced by the respective power plants have especially a character of waters from technological and cooling processes. Water waste from technology is chemically contaminated. Water used for cooling is usually contaminated by heat. Water waste containing oil substances are treated in oil waste water treatment plants. The contamination of sewage water is usually biological, such water is treated in waste water plant with mechanical and biological treatment. The prescribed limit indicators of discharged water are constantly in compliance with concentration and balance value parameters. In order to protect and prevent the contamination, there are monitoring systems, which monitor the impact of operation in power plans on the environment.

Novácke chemické závody Nováky Chemical Factory

Novácke chemické závody Nováky Chemical Factory

NCHZ and the natural environment Nováky Chemical Factory ( NCHZ ) belongs to the biggest chemical producers in Slovakia. It employs approximately 1600 workers. It produces the products : Inorganic chemistry - calcium carbide chemistry (Ca. C 2), carbidic mixture to desulphurisation, sodium hydroxide, hydrogen (H 2), chlorine (Cl 2), hydrochloric acid (HCl), sodium hypochlorite (Na. Cl. O), acetylene (C 2 H 2), nitrogen (N 2) Organic chemistry – chlorinated paraffins, chemistry glycols, PVAC, etc Powdered PVC – to the production of PVC window profiles and facing isolating material The production of softened PVC, which toys and flooring were manufactured out of, was cancelled, because it contained carcinogenic softener.

NCHZ and the natural environment Nováky Chemical Factory ( NCHZ ) belongs to the biggest chemical producers in Slovakia. It employs approximately 1600 workers. It produces the products : Inorganic chemistry - calcium carbide chemistry (Ca. C 2), carbidic mixture to desulphurisation, sodium hydroxide, hydrogen (H 2), chlorine (Cl 2), hydrochloric acid (HCl), sodium hypochlorite (Na. Cl. O), acetylene (C 2 H 2), nitrogen (N 2) Organic chemistry – chlorinated paraffins, chemistry glycols, PVAC, etc Powdered PVC – to the production of PVC window profiles and facing isolating material The production of softened PVC, which toys and flooring were manufactured out of, was cancelled, because it contained carcinogenic softener.

The problems in term of the protection of the natural environment The biggest pollution is caused by : Chlorine – poisonous, yellow, unbreathable gas. It is made by Chlorine electrolysis, which chlorine and mercury get into the air and largely into waste-waters. Chlorine and mercury together with chlorinated paraffins get into the sewer, in which it looks like in the uncontrolled reactor. Calcium carbide – its production produces tenths of tons of the waste carbide like carbidic and calcic powder per one year, in spite of a new technology of production by Norwegian licence, which was installed a few years ago. Vinyl chloride – it is gas and carcinogen. PVC is made by the polymechloride risation of it. A part of powdered PVC gets into the air. Chlorinated paraffins – they pollute the river Nitra as wastewaters. paraffins Wastewaters of NCHZ comprise approximately 10% of the flow of this river.

The problems in term of the protection of the natural environment The biggest pollution is caused by : Chlorine – poisonous, yellow, unbreathable gas. It is made by Chlorine electrolysis, which chlorine and mercury get into the air and largely into waste-waters. Chlorine and mercury together with chlorinated paraffins get into the sewer, in which it looks like in the uncontrolled reactor. Calcium carbide – its production produces tenths of tons of the waste carbide like carbidic and calcic powder per one year, in spite of a new technology of production by Norwegian licence, which was installed a few years ago. Vinyl chloride – it is gas and carcinogen. PVC is made by the polymechloride risation of it. A part of powdered PVC gets into the air. Chlorinated paraffins – they pollute the river Nitra as wastewaters. paraffins Wastewaters of NCHZ comprise approximately 10% of the flow of this river.

Calcium hydroxide – Ca (OH) 2 – it is hydroxide a waste of production of calcium carbide. The factory can not use it or sell it, so it is exported on the waste dump nearby the town. Window profiles of PVC – the factory PVC produces around 6000 tons per year of them. But tenths of kilograms of hardly processible waste is created too, especially from unsuccessful products. NCHZ invests tenths millions of Slovak crowns to the protection of the natural environment per year. It has own purification plant of wastewaters, which however can t clean everything. Various external firms are also authorized to process municipal waste ( 2000 tons/year ), dangerous waste ( 100 -500 tons/year ) and industrial waste ( 3000 tons/year ).

Calcium hydroxide – Ca (OH) 2 – it is hydroxide a waste of production of calcium carbide. The factory can not use it or sell it, so it is exported on the waste dump nearby the town. Window profiles of PVC – the factory PVC produces around 6000 tons per year of them. But tenths of kilograms of hardly processible waste is created too, especially from unsuccessful products. NCHZ invests tenths millions of Slovak crowns to the protection of the natural environment per year. It has own purification plant of wastewaters, which however can t clean everything. Various external firms are also authorized to process municipal waste ( 2000 tons/year ), dangerous waste ( 100 -500 tons/year ) and industrial waste ( 3000 tons/year ).

According to an expression of the head of the domain of the natural environment, the company can t afford to spend much money to satisfy permitted European norms of the pollution of air, water and land. The company must meet these four basic requirements : · Internal safety rule · Norms of the pollution · Rules of the frame of The Association of Industrial Ecology of Slovakia (ASPEK) · Active connection to worldwide program Responsible Care, consequently responsible for business in the chemistry European Union is making stricter norms of the pollution. At present, according to the press, the major owner of NCHZ is looking for an investor, who would buy a company and invest bigger sum of money to the protection of the natural environment in the factory.

According to an expression of the head of the domain of the natural environment, the company can t afford to spend much money to satisfy permitted European norms of the pollution of air, water and land. The company must meet these four basic requirements : · Internal safety rule · Norms of the pollution · Rules of the frame of The Association of Industrial Ecology of Slovakia (ASPEK) · Active connection to worldwide program Responsible Care, consequently responsible for business in the chemistry European Union is making stricter norms of the pollution. At present, according to the press, the major owner of NCHZ is looking for an investor, who would buy a company and invest bigger sum of money to the protection of the natural environment in the factory.