77fc50f378798d8acf505b3bff33676a.ppt

- Количество слайдов: 23

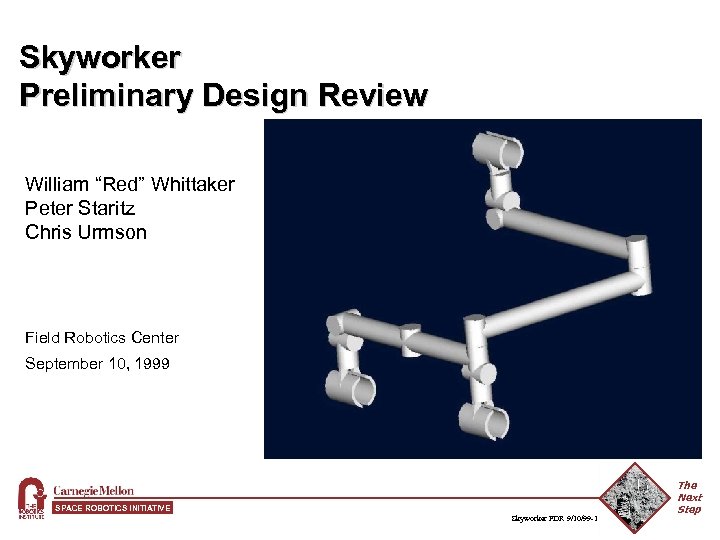

Skyworker Preliminary Design Review William “Red” Whittaker Peter Staritz Chris Urmson Field Robotics Center September 10, 1999 SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -1 The Next Step

Skyworker Preliminary Design Review William “Red” Whittaker Peter Staritz Chris Urmson Field Robotics Center September 10, 1999 SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -1 The Next Step

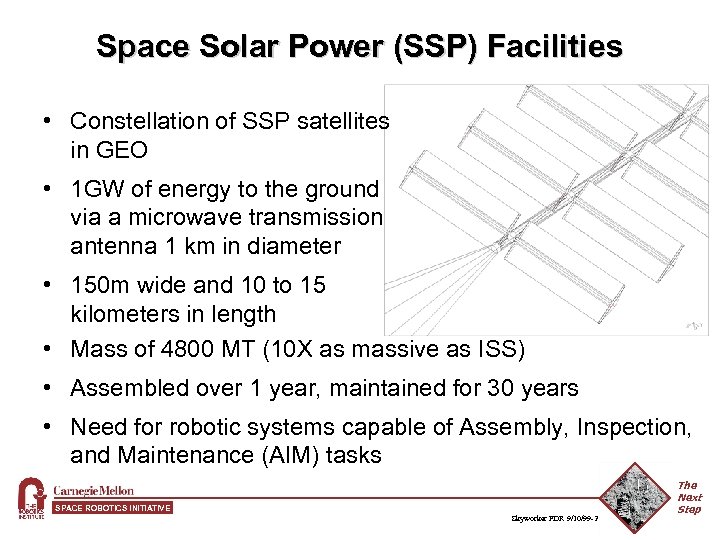

Space Solar Power (SSP) Facilities • Constellation of SSP satellites in GEO • 1 GW of energy to the ground via a microwave transmission antenna 1 km in diameter • 150 m wide and 10 to 15 kilometers in length • Mass of 4800 MT (10 X as massive as ISS) • Assembled over 1 year, maintained for 30 years • Need for robotic systems capable of Assembly, Inspection, and Maintenance (AIM) tasks SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -2 The Next Step

Space Solar Power (SSP) Facilities • Constellation of SSP satellites in GEO • 1 GW of energy to the ground via a microwave transmission antenna 1 km in diameter • 150 m wide and 10 to 15 kilometers in length • Mass of 4800 MT (10 X as massive as ISS) • Assembled over 1 year, maintained for 30 years • Need for robotic systems capable of Assembly, Inspection, and Maintenance (AIM) tasks SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -2 The Next Step

SSP Facility AIM • Solar array – Assembled through automated docking and deployment • Microwave antenna – Requires completion of complicated assembly tasks • Joining of deployable truss sections • Attaching transmitter elements • Coupling Power Management and Distribution (PMAD) system • Entire facility will benefit from automated inspection and maintenance capabilities SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -3 The Next Step

SSP Facility AIM • Solar array – Assembled through automated docking and deployment • Microwave antenna – Requires completion of complicated assembly tasks • Joining of deployable truss sections • Attaching transmitter elements • Coupling Power Management and Distribution (PMAD) system • Entire facility will benefit from automated inspection and maintenance capabilities SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -3 The Next Step

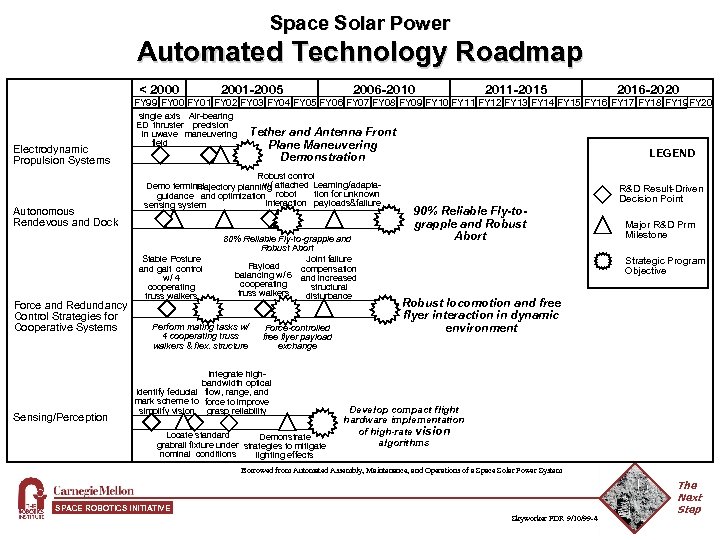

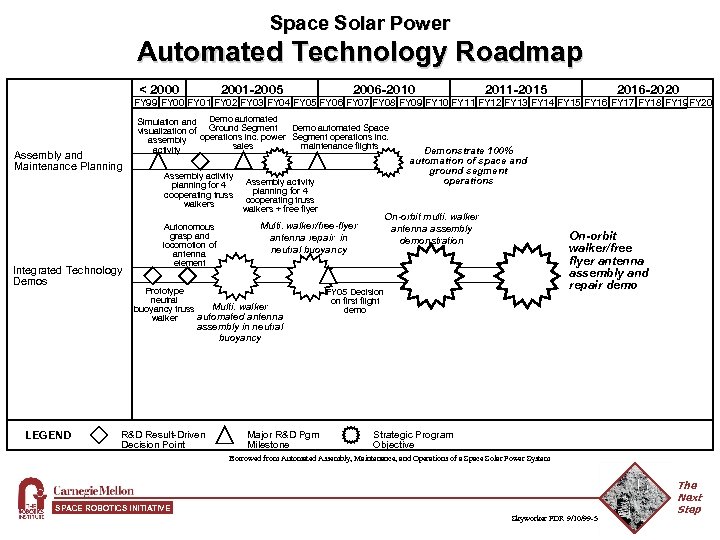

Space Solar Power Automated Technology Roadmap < 2000 2001 -2005 2006 -2010 2011 -2015 2016 -2020 FY 99 FY 00 FY 01 FY 02 FY 03 FY 04 FY 05 FY 06 FY 07 FY 08 FY 09 FY 10 FY 11 FY 12 FY 13 FY 14 FY 15 FY 16 FY 17 FY 18 FY 19 FY 20 Electrodynamic Propulsion Systems Autonomous Rendevous and Dock Force and Redundancy Control Strategies for Cooperative Systems Sensing/Perception single axis Air-bearing ED thruster precision in uwave maneuvering field Tether and Antenna Front Plane Maneuvering Demonstration Robust control w/ Demo terminal Trajectory planning attached Learning/adaptation for unknown guidance and optimization robot interaction payloads&failure sensing system Stable Posture and gait control w/ 4 cooperating truss walkers 80% Reliable Fly-to-grapple and Robust Abort Joint failure Payload compensation balancing w/ 6 and increased cooperating structural truss walkers disturbance Perform mating tasks w/ 4 cooperating truss walkers & flex. structure Force-controlled free flyer payload exchange Integrate highbandwidth optical Identify feducial flow, range, and mark scheme to force to improve simplify vision grasp reliability Locate standard Demonstrate grabrail fixture under strategies to mitigate nominal conditions lighting effects LEGEND R&D Result-Driven Decision Point 90% Reliable Fly-tograpple and Robust Abort Major R&D Prm Milestone Strategic Program Objective Robust locomotion and free flyer interaction in dynamic environment Develop compact flight hardware implementation of high-rate vision algorithms Borrowed from Automated Assembly, Maintenance, and Operations of a Space Solar Power System SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -4 The Next Step

Space Solar Power Automated Technology Roadmap < 2000 2001 -2005 2006 -2010 2011 -2015 2016 -2020 FY 99 FY 00 FY 01 FY 02 FY 03 FY 04 FY 05 FY 06 FY 07 FY 08 FY 09 FY 10 FY 11 FY 12 FY 13 FY 14 FY 15 FY 16 FY 17 FY 18 FY 19 FY 20 Electrodynamic Propulsion Systems Autonomous Rendevous and Dock Force and Redundancy Control Strategies for Cooperative Systems Sensing/Perception single axis Air-bearing ED thruster precision in uwave maneuvering field Tether and Antenna Front Plane Maneuvering Demonstration Robust control w/ Demo terminal Trajectory planning attached Learning/adaptation for unknown guidance and optimization robot interaction payloads&failure sensing system Stable Posture and gait control w/ 4 cooperating truss walkers 80% Reliable Fly-to-grapple and Robust Abort Joint failure Payload compensation balancing w/ 6 and increased cooperating structural truss walkers disturbance Perform mating tasks w/ 4 cooperating truss walkers & flex. structure Force-controlled free flyer payload exchange Integrate highbandwidth optical Identify feducial flow, range, and mark scheme to force to improve simplify vision grasp reliability Locate standard Demonstrate grabrail fixture under strategies to mitigate nominal conditions lighting effects LEGEND R&D Result-Driven Decision Point 90% Reliable Fly-tograpple and Robust Abort Major R&D Prm Milestone Strategic Program Objective Robust locomotion and free flyer interaction in dynamic environment Develop compact flight hardware implementation of high-rate vision algorithms Borrowed from Automated Assembly, Maintenance, and Operations of a Space Solar Power System SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -4 The Next Step

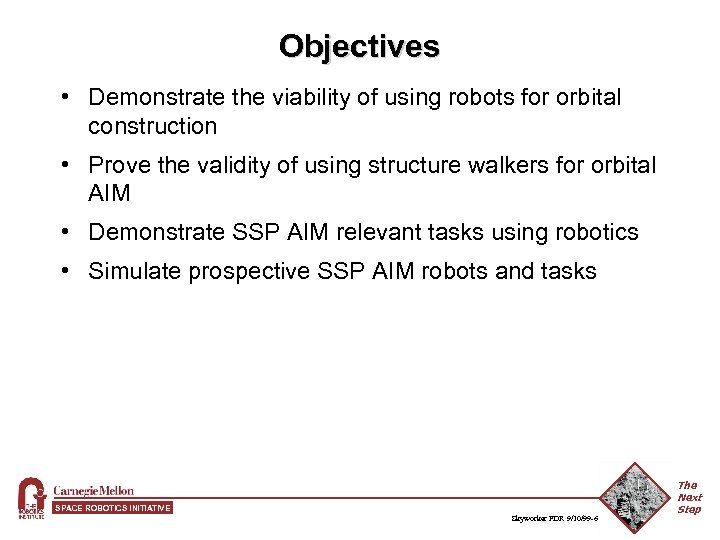

Space Solar Power Automated Technology Roadmap < 2000 2001 -2005 2006 -2010 2011 -2015 2016 -2020 FY 99 FY 00 FY 01 FY 02 FY 03 FY 04 FY 05 FY 06 FY 07 FY 08 FY 09 FY 10 FY 11 FY 12 FY 13 FY 14 FY 15 FY 16 FY 17 FY 18 FY 19 FY 20 Assembly and Maintenance Planning Integrated Technology Demos Simulation and Demo automated Space visualization of Ground Segment operations inc. power Segment operations inc. assembly sales maintenance flights activity Assembly activity planning for 4 cooperating truss walkers Autonomous grasp and locomotion of antenna element Assembly activity planning for 4 cooperating truss walkers + free flyer On-orbit multi. walker antenna assembly demonstration Multi. walker/free-flyer antenna repair in neutral buoyancy Prototype neutral Multi. walker buoyancy truss automated antenna walker Demonstrate 100% automation of space and ground segment operations On-orbit walker/free flyer antenna assembly and repair demo FY 05 Decision on first flight demo assembly in neutral buoyancy LEGEND R&D Result-Driven Decision Point Major R&D Pgm Milestone Strategic Program Objective Borrowed from Automated Assembly, Maintenance, and Operations of a Space Solar Power System SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -5 The Next Step

Space Solar Power Automated Technology Roadmap < 2000 2001 -2005 2006 -2010 2011 -2015 2016 -2020 FY 99 FY 00 FY 01 FY 02 FY 03 FY 04 FY 05 FY 06 FY 07 FY 08 FY 09 FY 10 FY 11 FY 12 FY 13 FY 14 FY 15 FY 16 FY 17 FY 18 FY 19 FY 20 Assembly and Maintenance Planning Integrated Technology Demos Simulation and Demo automated Space visualization of Ground Segment operations inc. power Segment operations inc. assembly sales maintenance flights activity Assembly activity planning for 4 cooperating truss walkers Autonomous grasp and locomotion of antenna element Assembly activity planning for 4 cooperating truss walkers + free flyer On-orbit multi. walker antenna assembly demonstration Multi. walker/free-flyer antenna repair in neutral buoyancy Prototype neutral Multi. walker buoyancy truss automated antenna walker Demonstrate 100% automation of space and ground segment operations On-orbit walker/free flyer antenna assembly and repair demo FY 05 Decision on first flight demo assembly in neutral buoyancy LEGEND R&D Result-Driven Decision Point Major R&D Pgm Milestone Strategic Program Objective Borrowed from Automated Assembly, Maintenance, and Operations of a Space Solar Power System SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -5 The Next Step

Objectives • Demonstrate the viability of using robots for orbital construction • Prove the validity of using structure walkers for orbital AIM • Demonstrate SSP AIM relevant tasks using robotics • Simulate prospective SSP AIM robots and tasks SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -6 The Next Step

Objectives • Demonstrate the viability of using robots for orbital construction • Prove the validity of using structure walkers for orbital AIM • Demonstrate SSP AIM relevant tasks using robotics • Simulate prospective SSP AIM robots and tasks SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -6 The Next Step

Representative Tasks • Walk, turn, and transition across planes on a truss structure • Pick up and place a payload at arbitrary locations and orientations in space • Carry a payload while walking, turning, and transitioning • Conduct calibration and inspection tasks • Connect power and communications cables • Cooperatively carry massive or large payloads • Perform tasks that require multiple robot collaboration SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -7 The Next Step

Representative Tasks • Walk, turn, and transition across planes on a truss structure • Pick up and place a payload at arbitrary locations and orientations in space • Carry a payload while walking, turning, and transitioning • Conduct calibration and inspection tasks • Connect power and communications cables • Cooperatively carry massive or large payloads • Perform tasks that require multiple robot collaboration SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -7 The Next Step

Demonstration • Prototype Robot – Pick up and carry a model transmitting element the length of the truss, turn while carrying, couple the element to the structure – Connect Power Management and Distribution (PMAD) to the element – Perform a mock calibration • Simulation – Large scale construction utilizing multiple robots – Coordinated installation of full scale transmitting elements – Demonstrate extended lifetime operations SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -8 The Next Step

Demonstration • Prototype Robot – Pick up and carry a model transmitting element the length of the truss, turn while carrying, couple the element to the structure – Connect Power Management and Distribution (PMAD) to the element – Perform a mock calibration • Simulation – Large scale construction utilizing multiple robots – Coordinated installation of full scale transmitting elements – Demonstrate extended lifetime operations SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -8 The Next Step

Program Philosophies • Design for Earth based demonstration, but always maintain a path to orbital application • Accept a baseline environment (structure, tasks, etc. . ) • Leverage heritage technologies when available • Design and manufacture in house whenever possible • Consider physical scalability of design • Ensure robust software operation through incremental testing of components • Maintain software scalability through Object Oriented Principles SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -9 The Next Step

Program Philosophies • Design for Earth based demonstration, but always maintain a path to orbital application • Accept a baseline environment (structure, tasks, etc. . ) • Leverage heritage technologies when available • Design and manufacture in house whenever possible • Consider physical scalability of design • Ensure robust software operation through incremental testing of components • Maintain software scalability through Object Oriented Principles SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -9 The Next Step

Configuration - Key Metrics • Control Complexity – The number of joints that must be actuated in synchrony • Continuous Motion – System supports a gait in which the payload can maintain a constant velocity – How difficult it is to control that gait • Cost – DOF, links, grippers, sensors, control complexity, gravity compensation • Compatibility with gravity compensation – Possible to compensate with available resources, new system or recycled heritage system • Forces exerted / Forces experienced – Maximum forces and torques experience/exerted by the robot SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -10 The Next Step

Configuration - Key Metrics • Control Complexity – The number of joints that must be actuated in synchrony • Continuous Motion – System supports a gait in which the payload can maintain a constant velocity – How difficult it is to control that gait • Cost – DOF, links, grippers, sensors, control complexity, gravity compensation • Compatibility with gravity compensation – Possible to compensate with available resources, new system or recycled heritage system • Forces exerted / Forces experienced – Maximum forces and torques experience/exerted by the robot SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -10 The Next Step

Configuration - Key Metrics (Cont. ) • Workspace – Effective working volume with one gripper attached to the structure • Energy Consumption – The energy consumed by the machine to move a specified distance and speed with a given payload • DOF – Total number of joints – Number of different joint types • Mass – DOF, links, grippers, sensors, constants • Layout of available volume – Sufficient room for onboard components SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -11 The Next Step

Configuration - Key Metrics (Cont. ) • Workspace – Effective working volume with one gripper attached to the structure • Energy Consumption – The energy consumed by the machine to move a specified distance and speed with a given payload • DOF – Total number of joints – Number of different joint types • Mass – DOF, links, grippers, sensors, constants • Layout of available volume – Sufficient room for onboard components SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -11 The Next Step

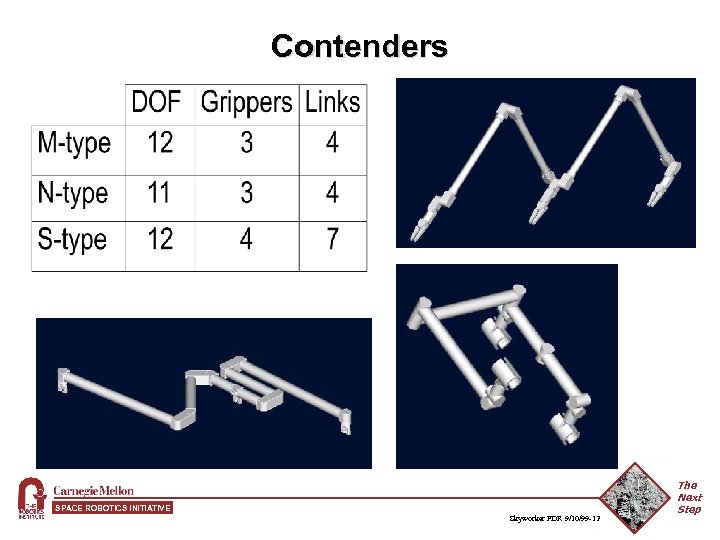

Contenders SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -12 The Next Step

Contenders SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -12 The Next Step

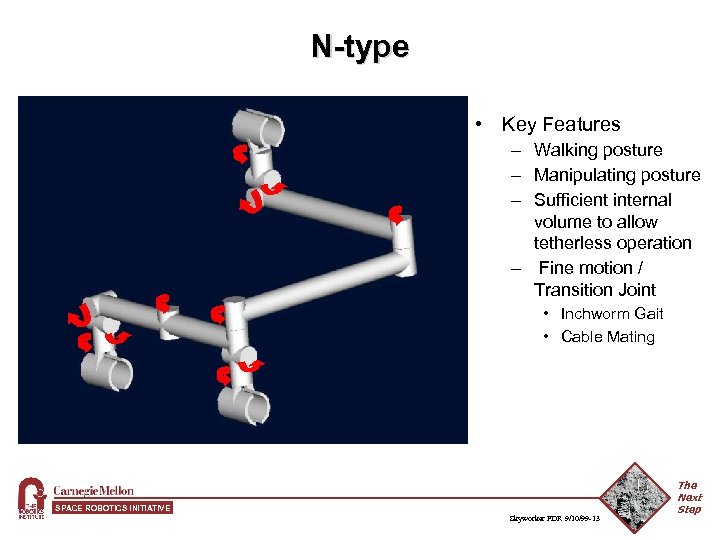

N-type • Key Features – Walking posture – Manipulating posture – Sufficient internal volume to allow tetherless operation – Fine motion / Transition Joint • Inchworm Gait • Cable Mating SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -13 The Next Step

N-type • Key Features – Walking posture – Manipulating posture – Sufficient internal volume to allow tetherless operation – Fine motion / Transition Joint • Inchworm Gait • Cable Mating SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -13 The Next Step

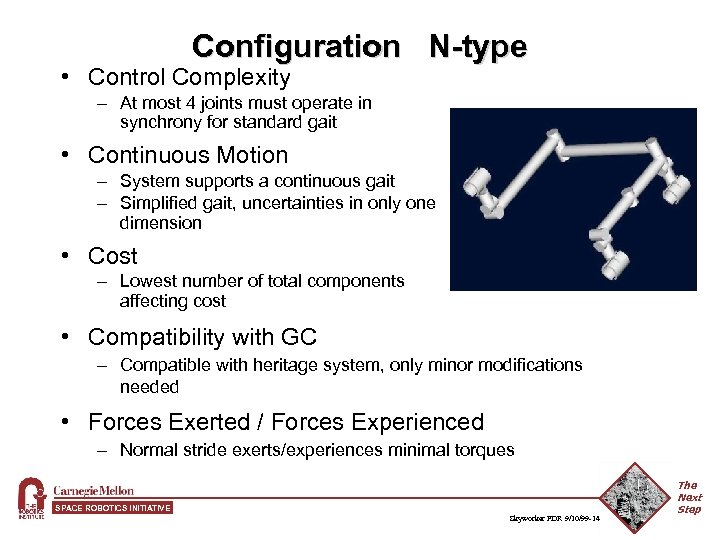

Configuration N-type • Control Complexity – At most 4 joints must operate in synchrony for standard gait • Continuous Motion – System supports a continuous gait – Simplified gait, uncertainties in only one dimension • Cost – Lowest number of total components affecting cost • Compatibility with GC – Compatible with heritage system, only minor modifications needed • Forces Exerted / Forces Experienced – Normal stride exerts/experiences minimal torques SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -14 The Next Step

Configuration N-type • Control Complexity – At most 4 joints must operate in synchrony for standard gait • Continuous Motion – System supports a continuous gait – Simplified gait, uncertainties in only one dimension • Cost – Lowest number of total components affecting cost • Compatibility with GC – Compatible with heritage system, only minor modifications needed • Forces Exerted / Forces Experienced – Normal stride exerts/experiences minimal torques SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -14 The Next Step

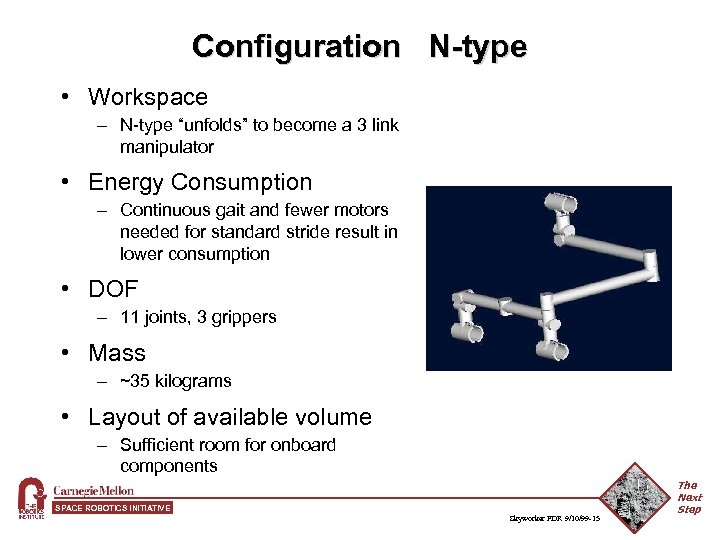

Configuration N-type • Workspace – N-type “unfolds” to become a 3 link manipulator • Energy Consumption – Continuous gait and fewer motors needed for standard stride result in lower consumption • DOF – 11 joints, 3 grippers • Mass – ~35 kilograms • Layout of available volume – Sufficient room for onboard components SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -15 The Next Step

Configuration N-type • Workspace – N-type “unfolds” to become a 3 link manipulator • Energy Consumption – Continuous gait and fewer motors needed for standard stride result in lower consumption • DOF – 11 joints, 3 grippers • Mass – ~35 kilograms • Layout of available volume – Sufficient room for onboard components SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -15 The Next Step

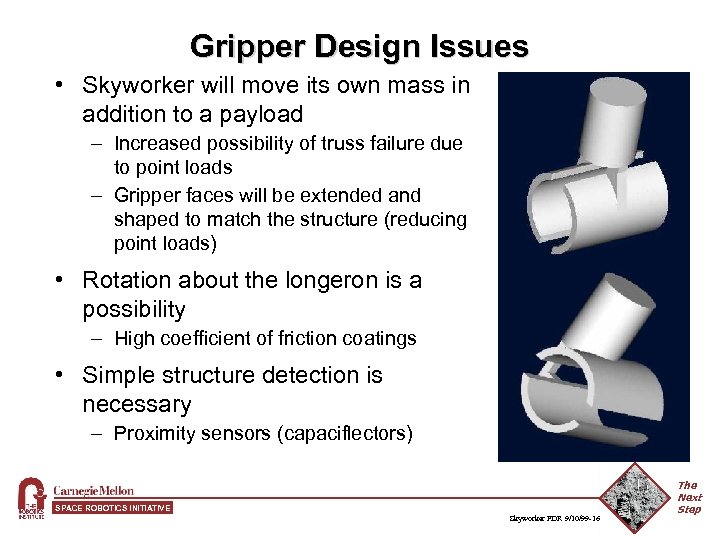

Gripper Design Issues • Skyworker will move its own mass in addition to a payload – Increased possibility of truss failure due to point loads – Gripper faces will be extended and shaped to match the structure (reducing point loads) • Rotation about the longeron is a possibility – High coefficient of friction coatings • Simple structure detection is necessary – Proximity sensors (capaciflectors) SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -16 The Next Step

Gripper Design Issues • Skyworker will move its own mass in addition to a payload – Increased possibility of truss failure due to point loads – Gripper faces will be extended and shaped to match the structure (reducing point loads) • Rotation about the longeron is a possibility – High coefficient of friction coatings • Simple structure detection is necessary – Proximity sensors (capaciflectors) SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -16 The Next Step

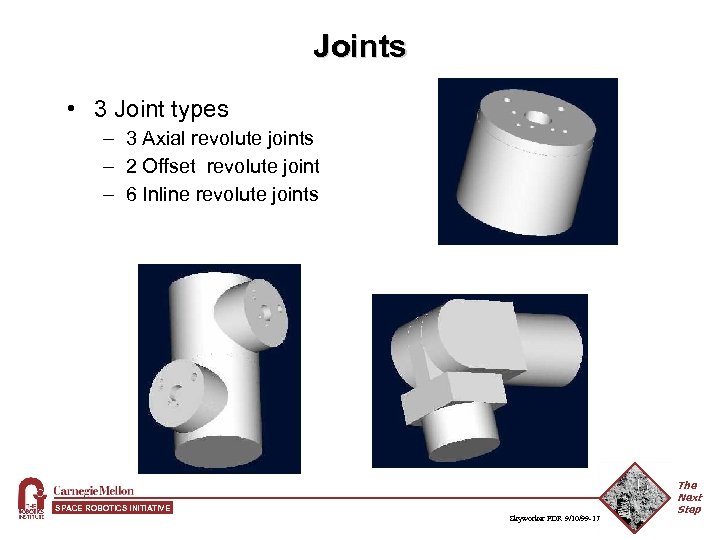

Joints • 3 Joint types – 3 Axial revolute joints – 2 Offset revolute joint – 6 Inline revolute joints SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -17 The Next Step

Joints • 3 Joint types – 3 Axial revolute joints – 2 Offset revolute joint – 6 Inline revolute joints SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -17 The Next Step

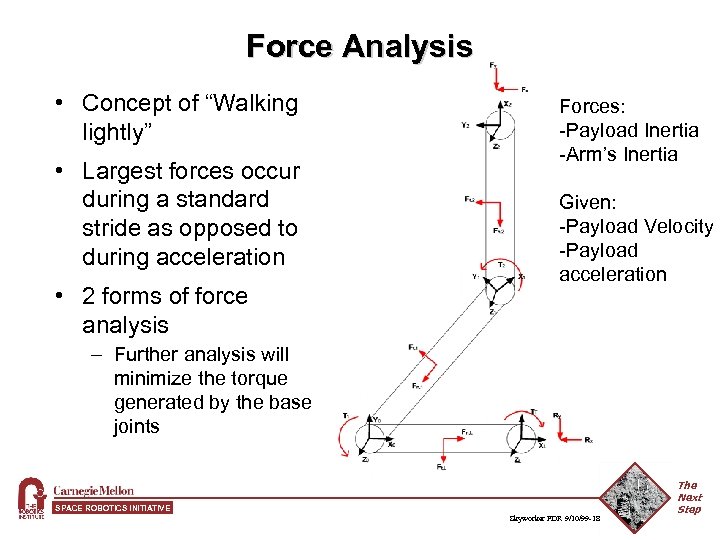

Force Analysis • Concept of “Walking lightly” • Largest forces occur during a standard stride as opposed to during acceleration • 2 forms of force analysis Forces: -Payload Inertia -Arm’s Inertia Given: -Payload Velocity -Payload acceleration – Further analysis will minimize the torque generated by the base joints SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -18 The Next Step

Force Analysis • Concept of “Walking lightly” • Largest forces occur during a standard stride as opposed to during acceleration • 2 forms of force analysis Forces: -Payload Inertia -Arm’s Inertia Given: -Payload Velocity -Payload acceleration – Further analysis will minimize the torque generated by the base joints SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -18 The Next Step

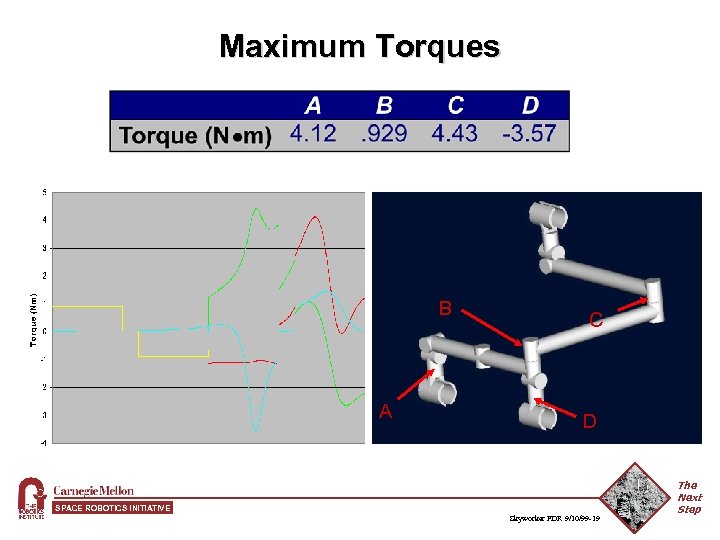

Maximum Torques B A C D SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -19 The Next Step

Maximum Torques B A C D SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -19 The Next Step

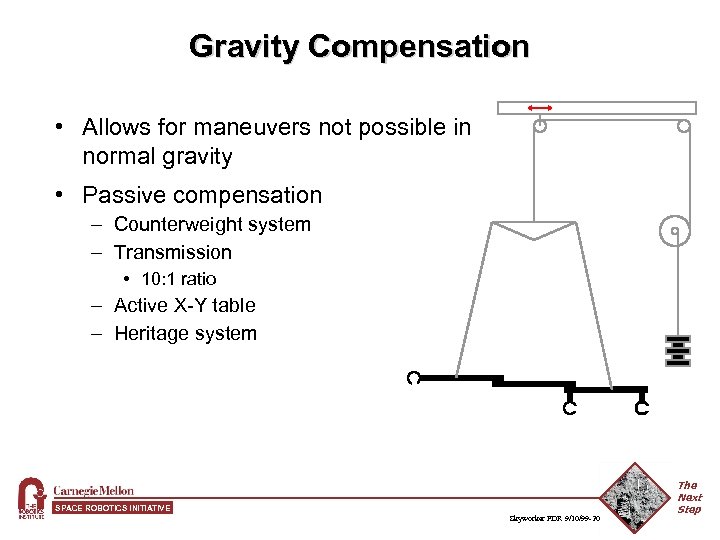

Gravity Compensation • Allows for maneuvers not possible in normal gravity • Passive compensation – Counterweight system – Transmission • 10: 1 ratio – Active X-Y table – Heritage system SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -20 The Next Step

Gravity Compensation • Allows for maneuvers not possible in normal gravity • Passive compensation – Counterweight system – Transmission • 10: 1 ratio – Active X-Y table – Heritage system SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -20 The Next Step

Power Electronics • Tetherless operations • 20 minute demonstration • Less than 40 watt-hours of energy at a peak rate of 120 W +/- 30% • Mass Constraint – 3 kg (batteries/charger/converters) • Volume Constraint SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -21 The Next Step

Power Electronics • Tetherless operations • 20 minute demonstration • Less than 40 watt-hours of energy at a peak rate of 120 W +/- 30% • Mass Constraint – 3 kg (batteries/charger/converters) • Volume Constraint SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -21 The Next Step

Battery Recharging • Onboard Charging Solution – – Power obtained through special gripper Contact with electrified terminal on demonstration structure Inductively Coupled Charging a future possibility All charging electronics/distribution onboard • Battery Monitoring System – Automatically detects when charge is necessary – Returns to ‘Charging Station’ when needed – Disconnects and returns to work when fully recharged SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -22 The Next Step

Battery Recharging • Onboard Charging Solution – – Power obtained through special gripper Contact with electrified terminal on demonstration structure Inductively Coupled Charging a future possibility All charging electronics/distribution onboard • Battery Monitoring System – Automatically detects when charge is necessary – Returns to ‘Charging Station’ when needed – Disconnects and returns to work when fully recharged SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -22 The Next Step

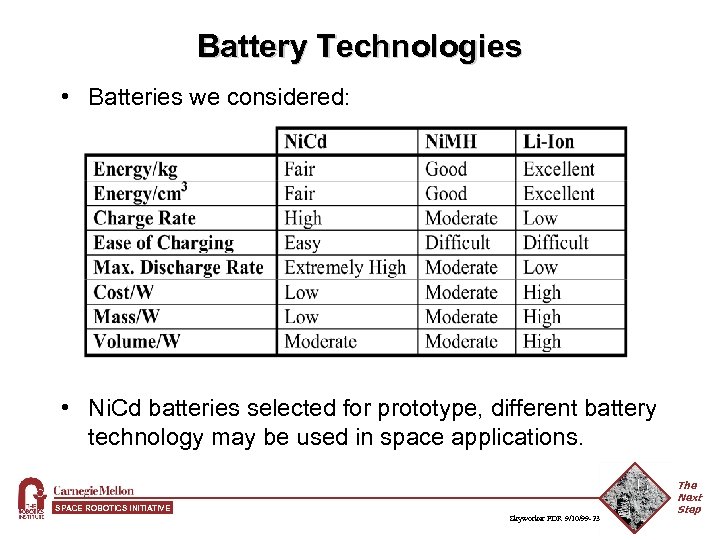

Battery Technologies • Batteries we considered: • Ni. Cd batteries selected for prototype, different battery technology may be used in space applications. SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -23 The Next Step

Battery Technologies • Batteries we considered: • Ni. Cd batteries selected for prototype, different battery technology may be used in space applications. SPACE ROBOTICS INITIATIVE Skyworker PDR 9/10/99 -23 The Next Step