d3d3535ba6c84918673c8b9450674409.ppt

- Количество слайдов: 23

Simulation ROCHESTER INSTITUTE OF TECHNOLOGY MICROELECTRONIC ENGINEERING Computer Simulation of Factory Performance Katie Mc. Conky ISE Graduate Student Rochester Institute of Technology 82 Lomb Memorial Drive Rochester, NY 14623 -5604 ktr 6315@rit. edu Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 1

Simulation ROCHESTER INSTITUTE OF TECHNOLOGY MICROELECTRONIC ENGINEERING Computer Simulation of Factory Performance Katie Mc. Conky ISE Graduate Student Rochester Institute of Technology 82 Lomb Memorial Drive Rochester, NY 14623 -5604 ktr 6315@rit. edu Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 1

Simulation OUTLINE Overview of Modeling Verification and Validation of Models Model Accuracy Statistical Analysis Auto. Sched AP – Brooks Automation Auto. Mod– Brooks Automation Example Simulation Problems Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 2

Simulation OUTLINE Overview of Modeling Verification and Validation of Models Model Accuracy Statistical Analysis Auto. Sched AP – Brooks Automation Auto. Mod– Brooks Automation Example Simulation Problems Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 2

Simulation Overview of Modeling • Semiconductor Fabs are extremely complex • Reentrant Manufacturing • High variability • Long Process Routes • Complicated batching and sequencing criteria • Simulation modeling can take everything into account in order to answer questions about the fab. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 3

Simulation Overview of Modeling • Semiconductor Fabs are extremely complex • Reentrant Manufacturing • High variability • Long Process Routes • Complicated batching and sequencing criteria • Simulation modeling can take everything into account in order to answer questions about the fab. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 3

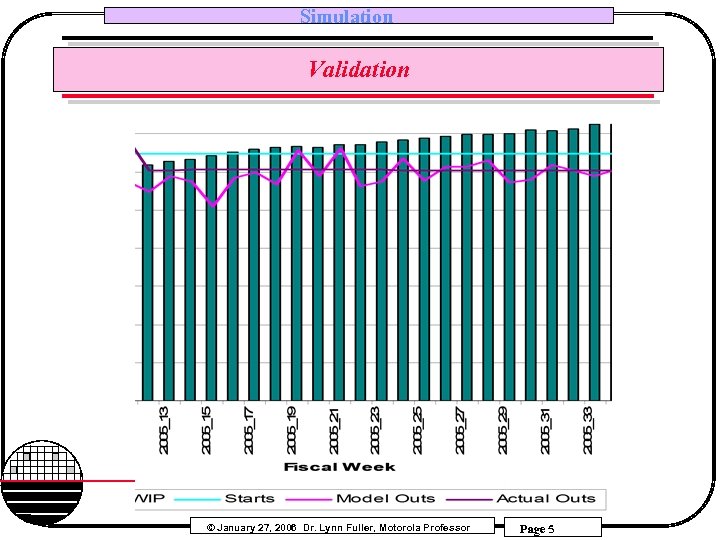

Simulation Verification and Validation Verification - Check that the model is acting how you expect it to act. - Dispatching Rules - Processing Times and other fundamentals Validation -Model results must resemble the actual fab: -Cycle Time -Total WIP Levels -WIP by Area -Model Outs -Tool Throughput Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 4

Simulation Verification and Validation Verification - Check that the model is acting how you expect it to act. - Dispatching Rules - Processing Times and other fundamentals Validation -Model results must resemble the actual fab: -Cycle Time -Total WIP Levels -WIP by Area -Model Outs -Tool Throughput Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 4

Simulation Validation Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 5

Simulation Validation Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 5

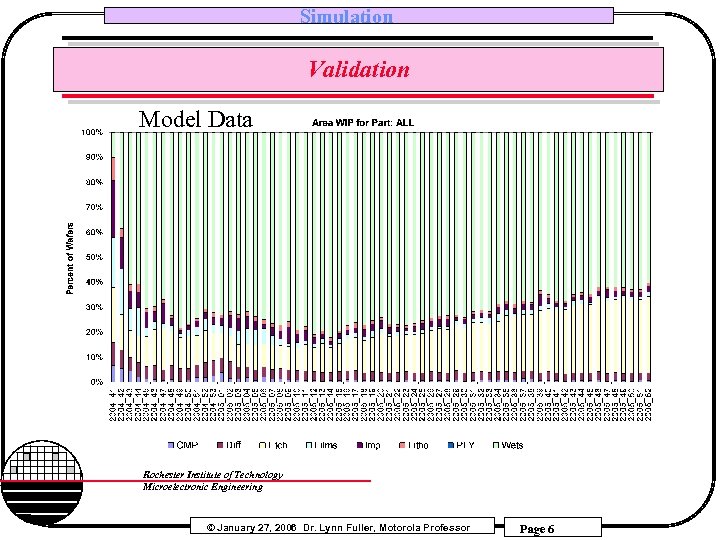

Simulation Validation Model Data Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 6

Simulation Validation Model Data Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 6

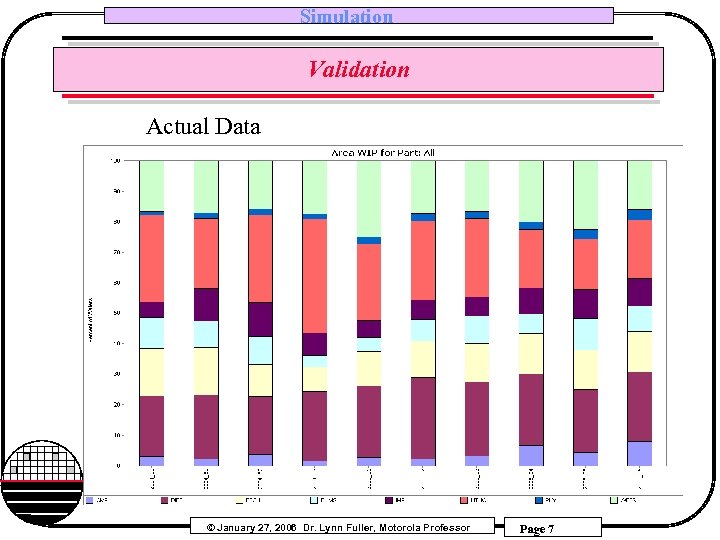

Simulation Validation Actual Data Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 7

Simulation Validation Actual Data Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 7

Simulation Model Accuracy § Models can be very accurate for short periods of time Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 8

Simulation Model Accuracy § Models can be very accurate for short periods of time Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 8

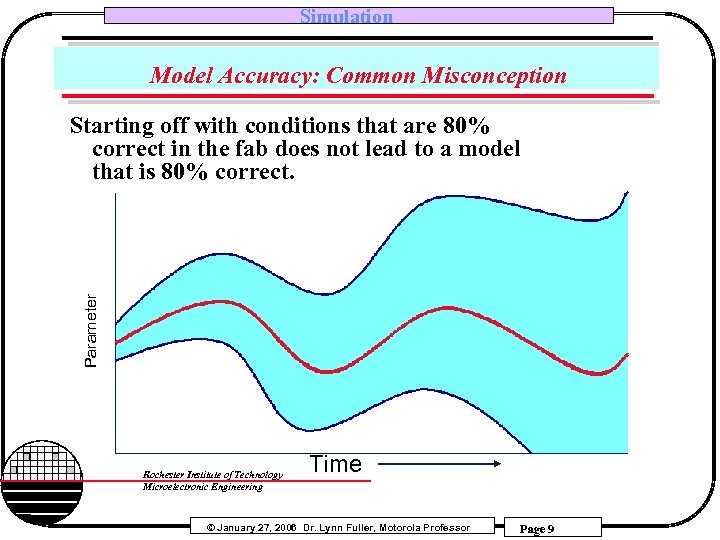

Simulation Model Accuracy: Common Misconception Parameter Starting off with conditions that are 80% correct in the fab does not lead to a model that is 80% correct. Rochester Institute of Technology Microelectronic Engineering Time © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 9

Simulation Model Accuracy: Common Misconception Parameter Starting off with conditions that are 80% correct in the fab does not lead to a model that is 80% correct. Rochester Institute of Technology Microelectronic Engineering Time © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 9

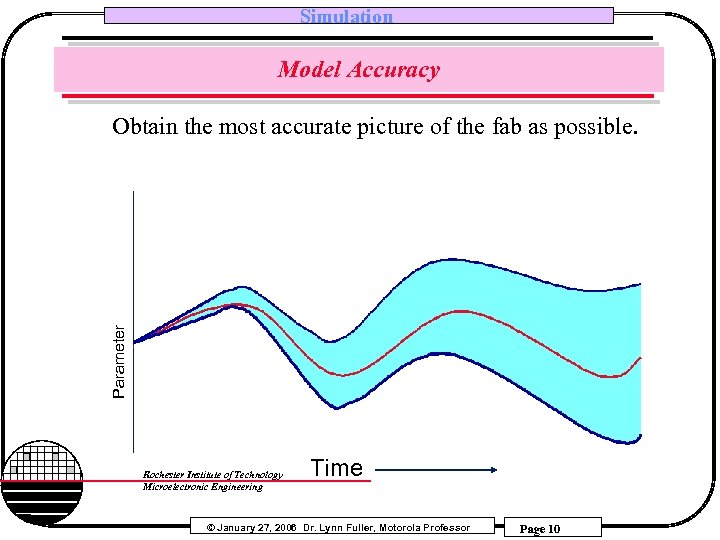

Simulation Model Accuracy Parameter Obtain the most accurate picture of the fab as possible. Rochester Institute of Technology Microelectronic Engineering Time © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 10

Simulation Model Accuracy Parameter Obtain the most accurate picture of the fab as possible. Rochester Institute of Technology Microelectronic Engineering Time © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 10

Simulation Model Accuracy § To maintain an accurate / valid model you must: § Generate route and station files very quickly § Load a snapshot of the WIP into your model § Collect and update process times and other parameters frequently § How do we accomplish all this? § Create an automated system to generate an entirely new model on a regular basis. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 11

Simulation Model Accuracy § To maintain an accurate / valid model you must: § Generate route and station files very quickly § Load a snapshot of the WIP into your model § Collect and update process times and other parameters frequently § How do we accomplish all this? § Create an automated system to generate an entirely new model on a regular basis. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 11

Simulation Statistical Analysis § Models can account for process variability. (models include some random event generators, for example: when equipment goes down) § It is therefore important to run a simulation more than once. § Multiple Replications § Simulation results should be reported as confidence intervals on a mean value. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 12

Simulation Statistical Analysis § Models can account for process variability. (models include some random event generators, for example: when equipment goes down) § It is therefore important to run a simulation more than once. § Multiple Replications § Simulation results should be reported as confidence intervals on a mean value. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 12

Simulation AUTOSCHED from Brooks Automation Inc. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 13

Simulation AUTOSCHED from Brooks Automation Inc. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 13

Simulation Auto. Sched AP and Auto. Mod § Auto. Sched AP: § Is an object-oriented modeling tool. § Uses a Windows-based Excel spreadsheet interface. § Is integrated with the APF Repository, APF Reporter, and Real Time Dispatcher. § Auto. Mod: § 3 -D graphics § Automated Material Handling Systems (AMHS) § Can be integrated with Auto. Sched AP models Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 14

Simulation Auto. Sched AP and Auto. Mod § Auto. Sched AP: § Is an object-oriented modeling tool. § Uses a Windows-based Excel spreadsheet interface. § Is integrated with the APF Repository, APF Reporter, and Real Time Dispatcher. § Auto. Mod: § 3 -D graphics § Automated Material Handling Systems (AMHS) § Can be integrated with Auto. Sched AP models Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 14

Simulation Auto. Sched AP Excel File Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 15

Simulation Auto. Sched AP Excel File Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 15

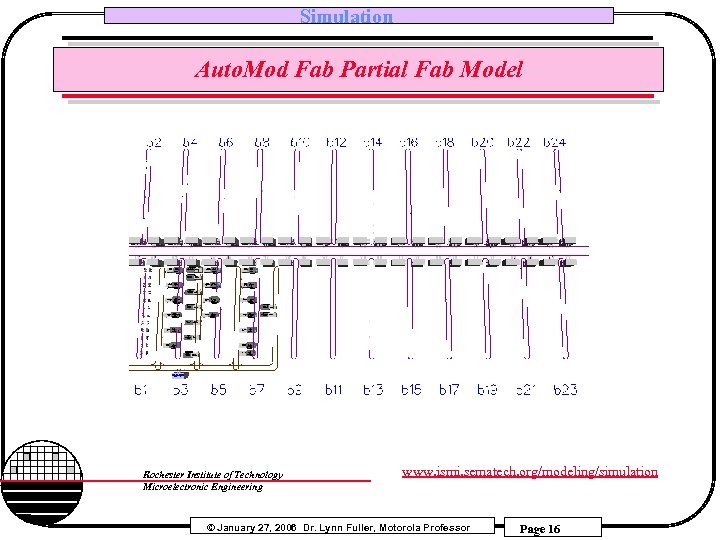

Simulation Auto. Mod Fab Partial Fab Model Rochester Institute of Technology Microelectronic Engineering www. ismi. sematech. org/modeling/simulation © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 16

Simulation Auto. Mod Fab Partial Fab Model Rochester Institute of Technology Microelectronic Engineering www. ismi. sematech. org/modeling/simulation © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 16

Simulation Typical Problems § How many tools should I purchase for a new step? § Depends on Desired Queue Length § Depends on Desired Queue Time § Importance: § Simulation results were used to justify the purchase of an extra tool in order to keep queuing times and queue lengths at a desired minimum. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 17

Simulation Typical Problems § How many tools should I purchase for a new step? § Depends on Desired Queue Length § Depends on Desired Queue Time § Importance: § Simulation results were used to justify the purchase of an extra tool in order to keep queuing times and queue lengths at a desired minimum. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 17

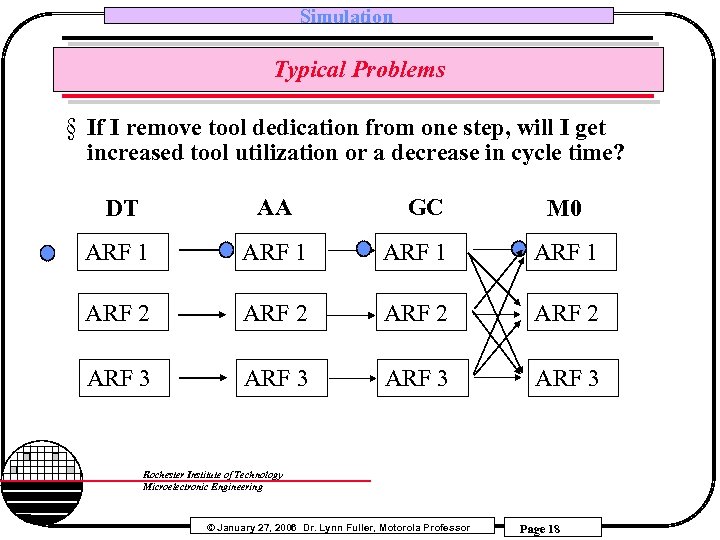

Simulation Typical Problems § If I remove tool dedication from one step, will I get increased tool utilization or a decrease in cycle time? DT AA ARF 1 ARF 2 ARF 3 GC M 0 Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 18

Simulation Typical Problems § If I remove tool dedication from one step, will I get increased tool utilization or a decrease in cycle time? DT AA ARF 1 ARF 2 ARF 3 GC M 0 Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 18

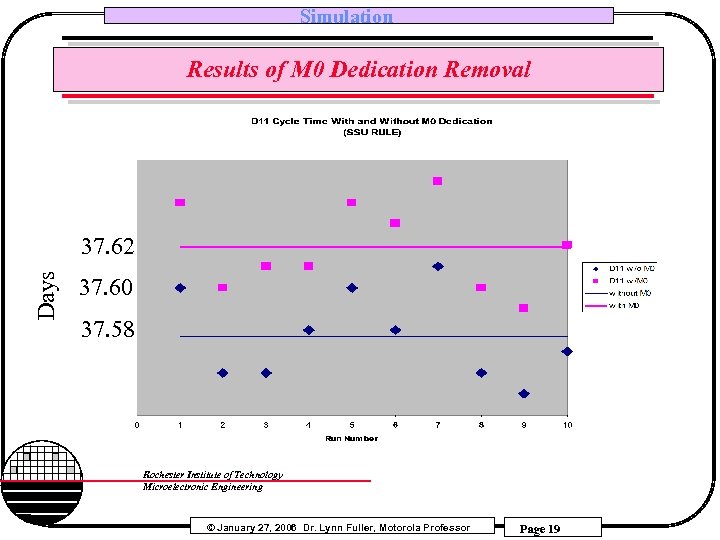

Simulation Results of M 0 Dedication Removal Days 37. 62 37. 60 37. 58 Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 19

Simulation Results of M 0 Dedication Removal Days 37. 62 37. 60 37. 58 Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 19

Simulation Results of M 0 Dedication Removal § Importance of Dedication Study: § If we could show through simulation that tool utilization or cycle time would improve the pilot lots for M 0 dedication removal could have been prioritized, to make the change happen faster. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 20

Simulation Results of M 0 Dedication Removal § Importance of Dedication Study: § If we could show through simulation that tool utilization or cycle time would improve the pilot lots for M 0 dedication removal could have been prioritized, to make the change happen faster. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 20

Simulation Typical Problems § Forecasting wafer outs: § What will be my outs of each product at the end of the week? § Importance: § Notify backend facilities of expected shipments. § Update financial people on fab productivity. § Time consuming to do forecasts by hand. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 21

Simulation Typical Problems § Forecasting wafer outs: § What will be my outs of each product at the end of the week? § Importance: § Notify backend facilities of expected shipments. § Update financial people on fab productivity. § Time consuming to do forecasts by hand. Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 21

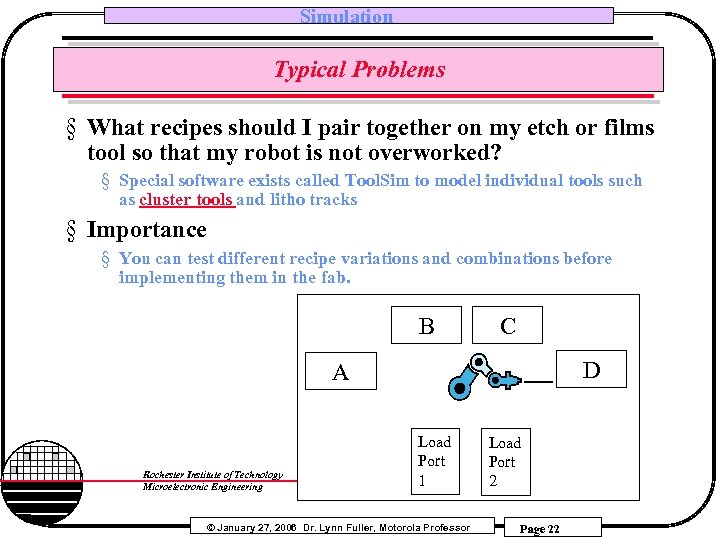

Simulation Typical Problems § What recipes should I pair together on my etch or films tool so that my robot is not overworked? § Special software exists called Tool. Sim to model individual tools such as cluster tools and litho tracks § Importance § You can test different recipe variations and combinations before implementing them in the fab. B C D A Rochester Institute of Technology Microelectronic Engineering Load Port 1 © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Load Port 2 Page 22

Simulation Typical Problems § What recipes should I pair together on my etch or films tool so that my robot is not overworked? § Special software exists called Tool. Sim to model individual tools such as cluster tools and litho tracks § Importance § You can test different recipe variations and combinations before implementing them in the fab. B C D A Rochester Institute of Technology Microelectronic Engineering Load Port 1 © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Load Port 2 Page 22

Simulation References § www. sematech. org § www. Brooks. com Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 23

Simulation References § www. sematech. org § www. Brooks. com Rochester Institute of Technology Microelectronic Engineering © January 27, 2006 Dr. Lynn Fuller, Motorola Professor Page 23