SHMS Spectrometer Update Hall C 2008 Users Meeting Paul Brindza January 18, 2008

SHMS Spectrometer Update Hall C 2008 Users Meeting Paul Brindza January 18, 2008

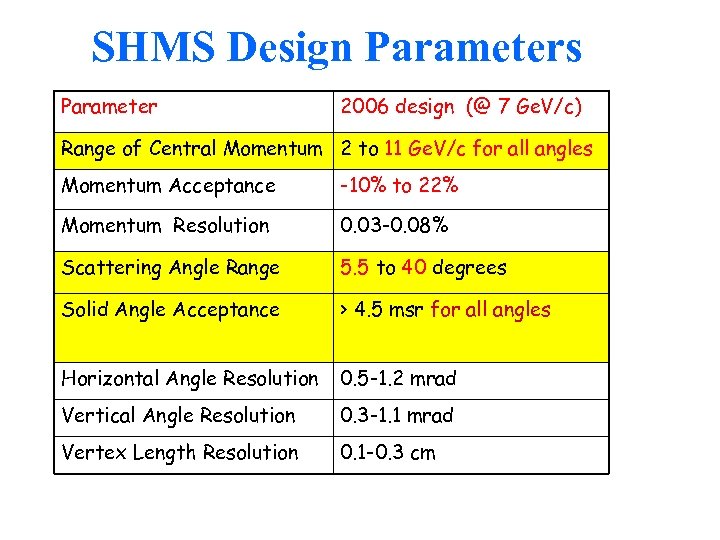

SHMS Design Parameters Parameter 2006 design (@ 7 Ge. V/c) Range of Central Momentum 2 to 11 Ge. V/c for all angles Momentum Acceptance -10% to 22% Momentum Resolution 0. 03 -0. 08% Scattering Angle Range 5. 5 to 40 degrees Solid Angle Acceptance > 4. 5 msr for all angles Horizontal Angle Resolution 0. 5 -1. 2 mrad Vertical Angle Resolution 0. 3 -1. 1 mrad Vertex Length Resolution 0. 1 -0. 3 cm

SHMS Design Parameters Parameter 2006 design (@ 7 Ge. V/c) Range of Central Momentum 2 to 11 Ge. V/c for all angles Momentum Acceptance -10% to 22% Momentum Resolution 0. 03 -0. 08% Scattering Angle Range 5. 5 to 40 degrees Solid Angle Acceptance > 4. 5 msr for all angles Horizontal Angle Resolution 0. 5 -1. 2 mrad Vertical Angle Resolution 0. 3 -1. 1 mrad Vertex Length Resolution 0. 1 -0. 3 cm

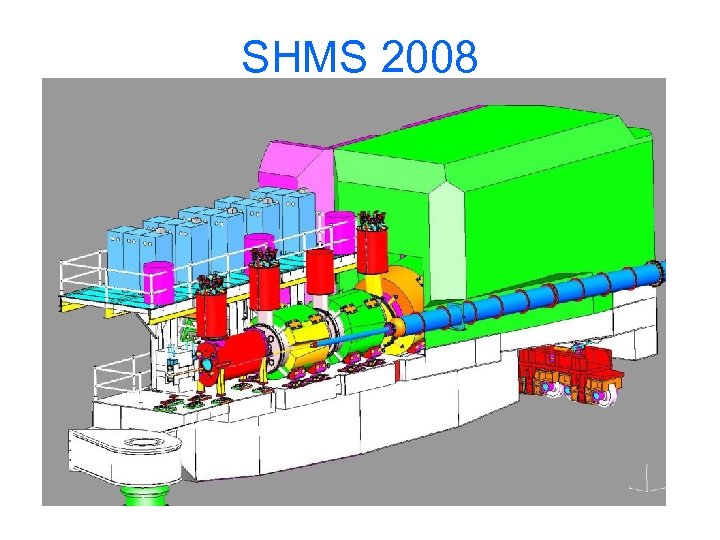

SHMS 2008

SHMS 2008

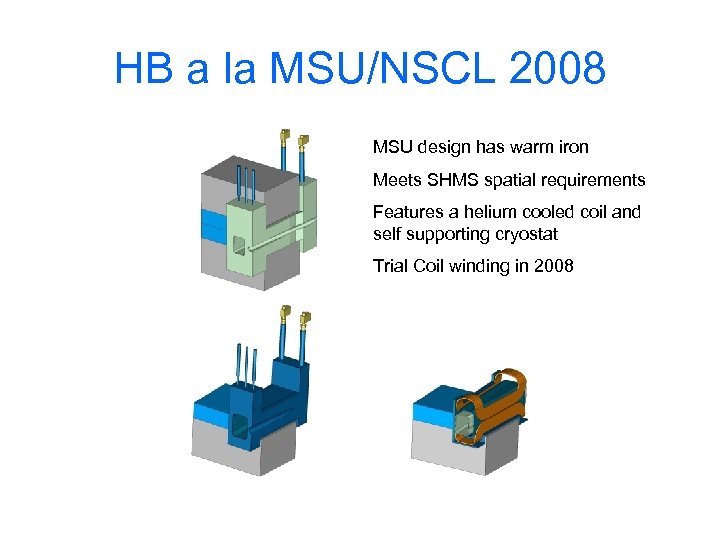

HB a la MSU/NSCL 2008 MSU design has warm iron Meets SHMS spatial requirements Features a helium cooled coil and self supporting cryostat Trial Coil winding in 2008

HB a la MSU/NSCL 2008 MSU design has warm iron Meets SHMS spatial requirements Features a helium cooled coil and self supporting cryostat Trial Coil winding in 2008

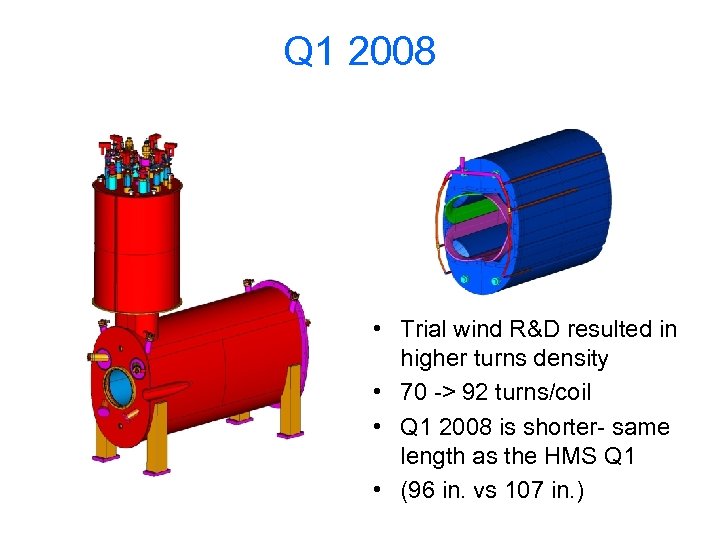

Q 1 2008 • Trial wind R&D resulted in higher turns density • 70 -> 92 turns/coil • Q 1 2008 is shorter- same length as the HMS Q 1 • (96 in. vs 107 in. )

Q 1 2008 • Trial wind R&D resulted in higher turns density • 70 -> 92 turns/coil • Q 1 2008 is shorter- same length as the HMS Q 1 • (96 in. vs 107 in. )

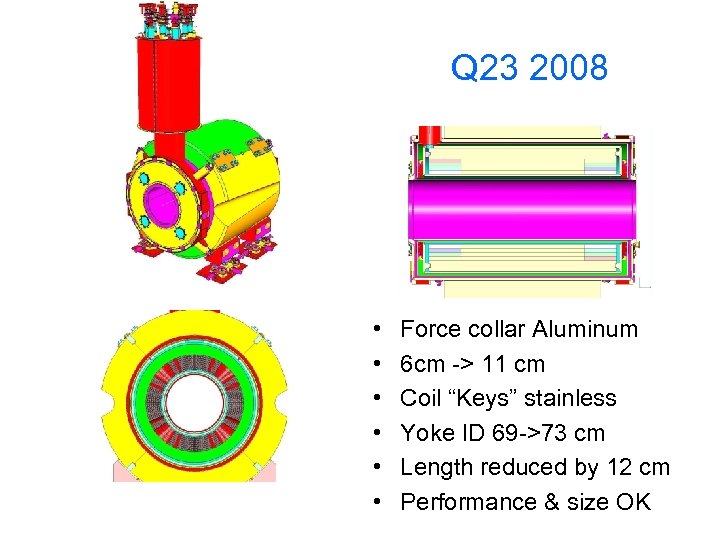

Q 23 2008 • • • Force collar Aluminum 6 cm -> 11 cm Coil “Keys” stainless Yoke ID 69 ->73 cm Length reduced by 12 cm Performance & size OK

Q 23 2008 • • • Force collar Aluminum 6 cm -> 11 cm Coil “Keys” stainless Yoke ID 69 ->73 cm Length reduced by 12 cm Performance & size OK

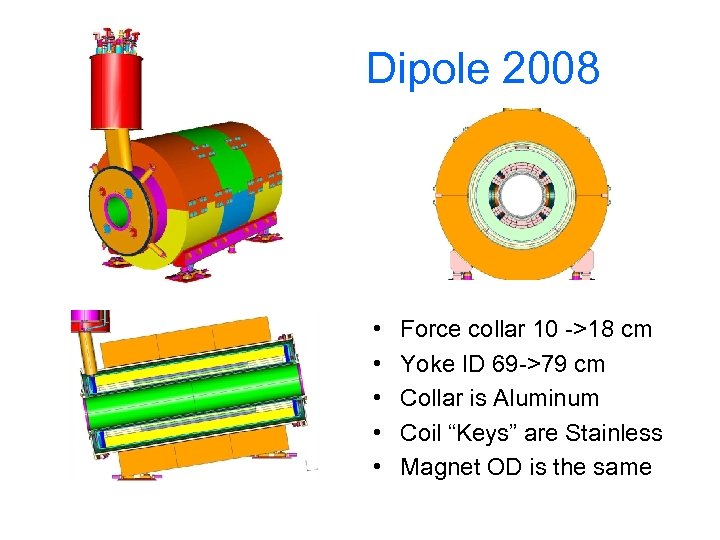

Dipole 2008 • • • Force collar 10 ->18 cm Yoke ID 69 ->79 cm Collar is Aluminum Coil “Keys” are Stainless Magnet OD is the same

Dipole 2008 • • • Force collar 10 ->18 cm Yoke ID 69 ->79 cm Collar is Aluminum Coil “Keys” are Stainless Magnet OD is the same

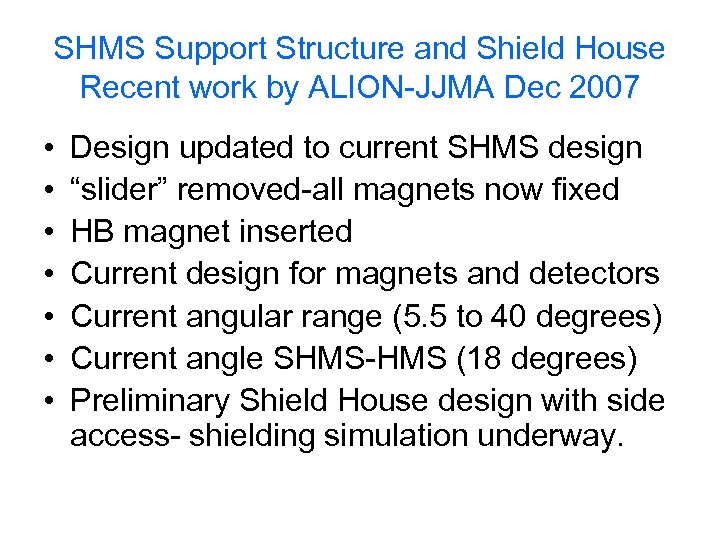

SHMS Support Structure and Shield House Recent work by ALION-JJMA Dec 2007 • • Design updated to current SHMS design “slider” removed-all magnets now fixed HB magnet inserted Current design for magnets and detectors Current angular range (5. 5 to 40 degrees) Current angle SHMS-HMS (18 degrees) Preliminary Shield House design with side access- shielding simulation underway.

SHMS Support Structure and Shield House Recent work by ALION-JJMA Dec 2007 • • Design updated to current SHMS design “slider” removed-all magnets now fixed HB magnet inserted Current design for magnets and detectors Current angular range (5. 5 to 40 degrees) Current angle SHMS-HMS (18 degrees) Preliminary Shield House design with side access- shielding simulation underway.

Q 1 Trial winding- 2007 results • JLAB contracted with Scientific Magnetics to develop Q 1 coil tooling and wind coils • Phase 1 is complete and produced one full size trial coil that passed all tests • Phase 2 is about to start and will produce 2 full size Q 1 coils • Phase 1 demonstrated a higher turns density(92 vs 70) resulting in a shorter Q 1

Q 1 Trial winding- 2007 results • JLAB contracted with Scientific Magnetics to develop Q 1 coil tooling and wind coils • Phase 1 is complete and produced one full size trial coil that passed all tests • Phase 2 is about to start and will produce 2 full size Q 1 coils • Phase 1 demonstrated a higher turns density(92 vs 70) resulting in a shorter Q 1

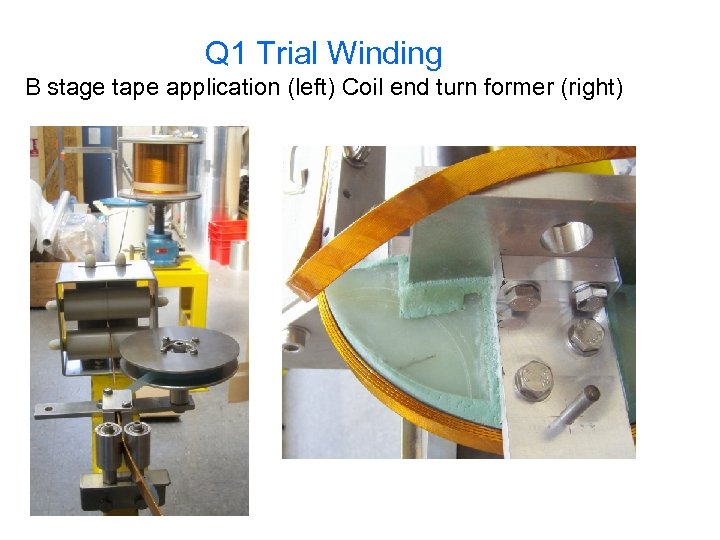

Q 1 Trial Winding B stage tape application (left) Coil end turn former (right)

Q 1 Trial Winding B stage tape application (left) Coil end turn former (right)

Q 1 Winding Tooling

Q 1 Winding Tooling

Q 1 Full Size Coil Sept 2007

Q 1 Full Size Coil Sept 2007

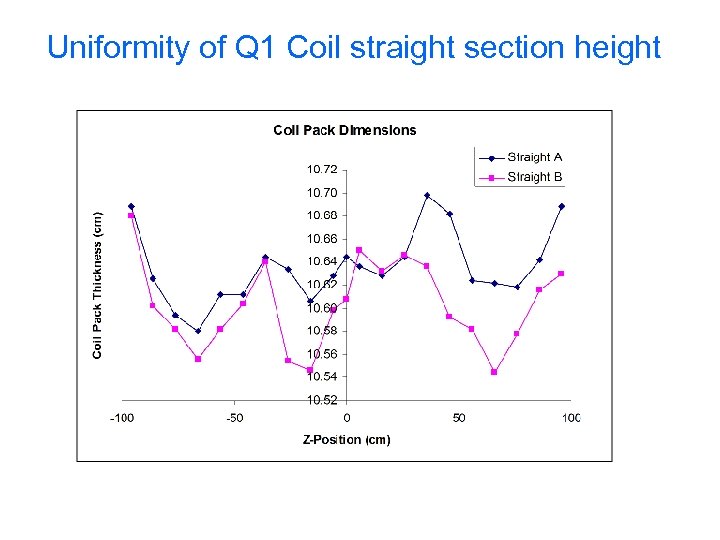

Uniformity of Q 1 Coil straight section height

Uniformity of Q 1 Coil straight section height

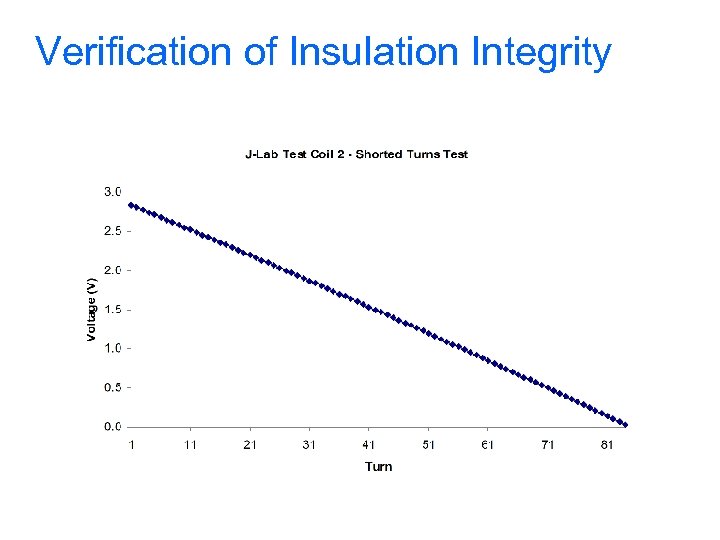

Verification of Insulation Integrity

Verification of Insulation Integrity

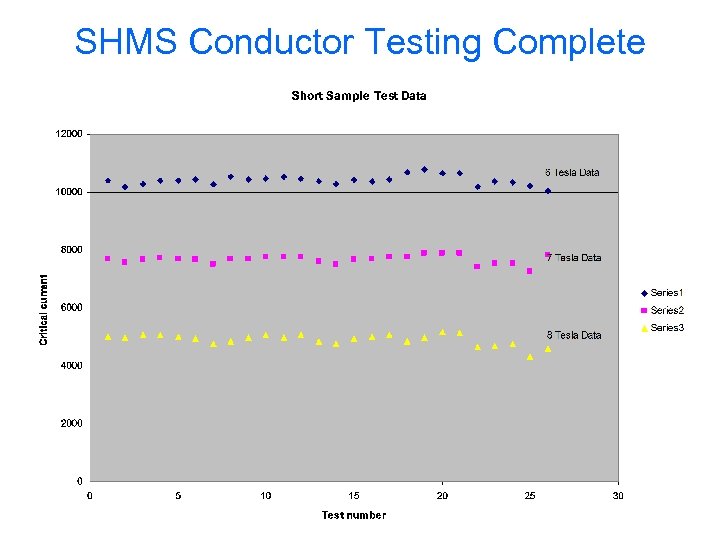

SHMS Conductor Testing Complete

SHMS Conductor Testing Complete

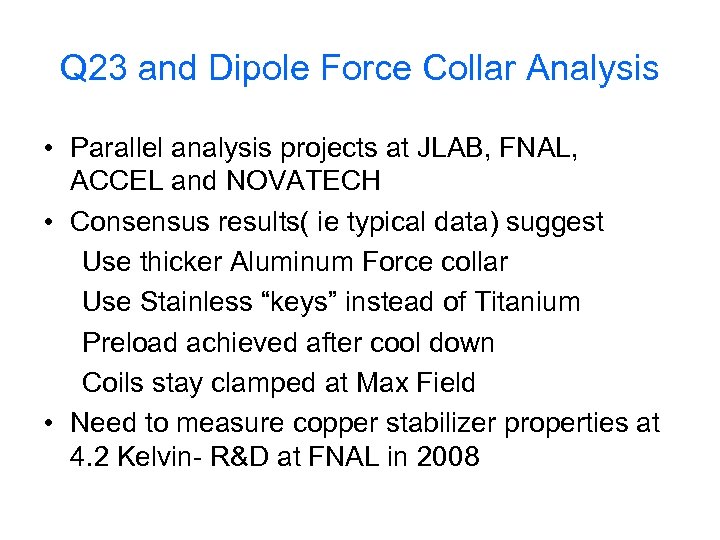

Q 23 and Dipole Force Collar Analysis • Parallel analysis projects at JLAB, FNAL, ACCEL and NOVATECH • Consensus results( ie typical data) suggest Use thicker Aluminum Force collar Use Stainless “keys” instead of Titanium Preload achieved after cool down Coils stay clamped at Max Field • Need to measure copper stabilizer properties at 4. 2 Kelvin- R&D at FNAL in 2008

Q 23 and Dipole Force Collar Analysis • Parallel analysis projects at JLAB, FNAL, ACCEL and NOVATECH • Consensus results( ie typical data) suggest Use thicker Aluminum Force collar Use Stainless “keys” instead of Titanium Preload achieved after cool down Coils stay clamped at Max Field • Need to measure copper stabilizer properties at 4. 2 Kelvin- R&D at FNAL in 2008

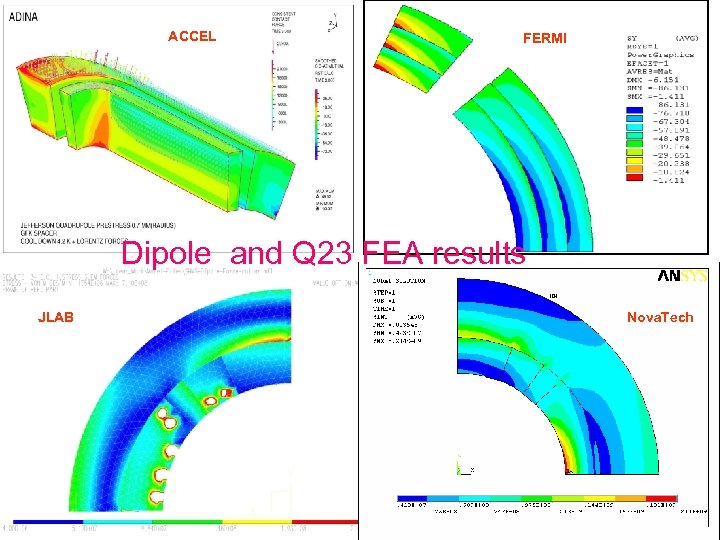

ACCEL FERMI Dipole and Q 23 FEA results JLAB Nova. Tech

ACCEL FERMI Dipole and Q 23 FEA results JLAB Nova. Tech

SHMS Conclusions • Improvements in magnet designs have increased the available free space along SHMS optical axis • R&D program: HB Design, Q 1 Trial Wind and Force Collar Analysis resulted in improvements in the SHMS design and Value Engineering • Support Structure design work has advanced credibility and confidence in SHMS Design. • Believe it or not we will start SC magnet procurement this summer!!!!!

SHMS Conclusions • Improvements in magnet designs have increased the available free space along SHMS optical axis • R&D program: HB Design, Q 1 Trial Wind and Force Collar Analysis resulted in improvements in the SHMS design and Value Engineering • Support Structure design work has advanced credibility and confidence in SHMS Design. • Believe it or not we will start SC magnet procurement this summer!!!!!