79666b6288abfab4cab02cc191c8526b.ppt

- Количество слайдов: 25

Shine & Salt ADVANCED VALVE ENGINEERING Share & Satisfaction Self-Creativity & Sincerity Company Introduction http: //www. snsvalve. co. kr 1

Shine & Salt ADVANCED VALVE ENGINEERING Share & Satisfaction Self-Creativity & Sincerity Company Introduction http: //www. snsvalve. co. kr 1

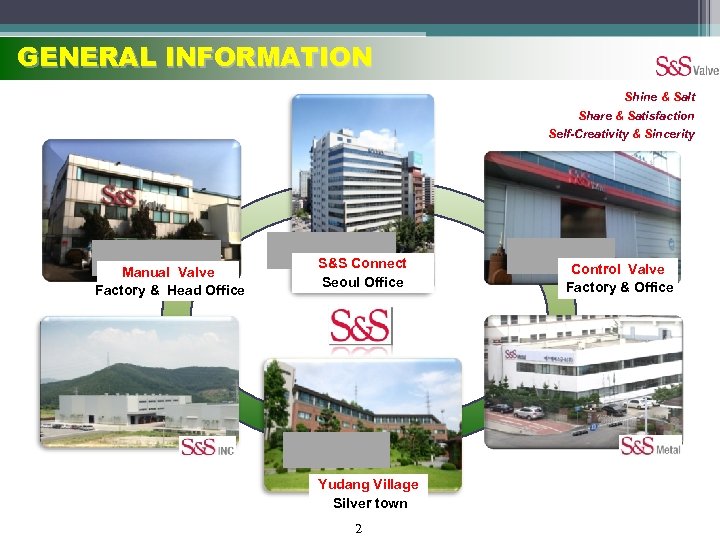

GENERAL INFORMATION Shine & Salt Share & Satisfaction Self-Creativity & Sincerity Manual Valve Factory & Head Office S&S Connect Seoul Office Yudang Village Silver town 2 Control Valve Factory & Office

GENERAL INFORMATION Shine & Salt Share & Satisfaction Self-Creativity & Sincerity Manual Valve Factory & Head Office S&S Connect Seoul Office Yudang Village Silver town 2 Control Valve Factory & Office

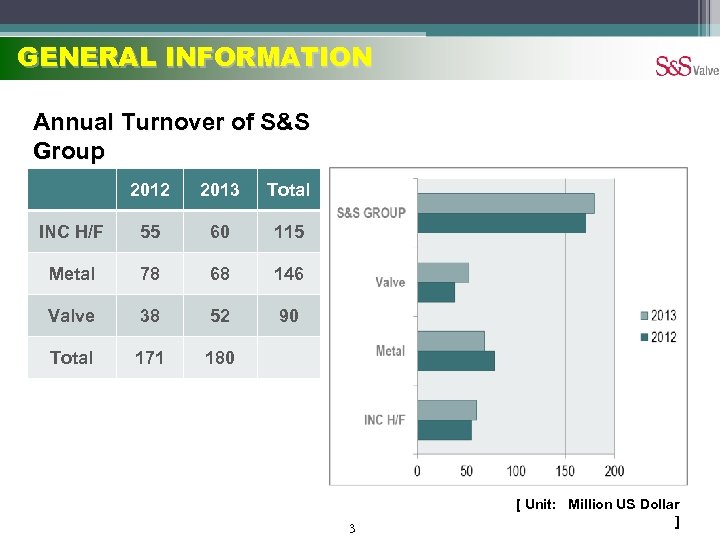

GENERAL INFORMATION Annual Turnover of S&S Group 2012 2013 Total INC H/F 55 60 115 Metal 78 68 146 Valve 38 52 90 Total 171 180 3 [ Unit: Million US Dollar ]

GENERAL INFORMATION Annual Turnover of S&S Group 2012 2013 Total INC H/F 55 60 115 Metal 78 68 146 Valve 38 52 90 Total 171 180 3 [ Unit: Million US Dollar ]

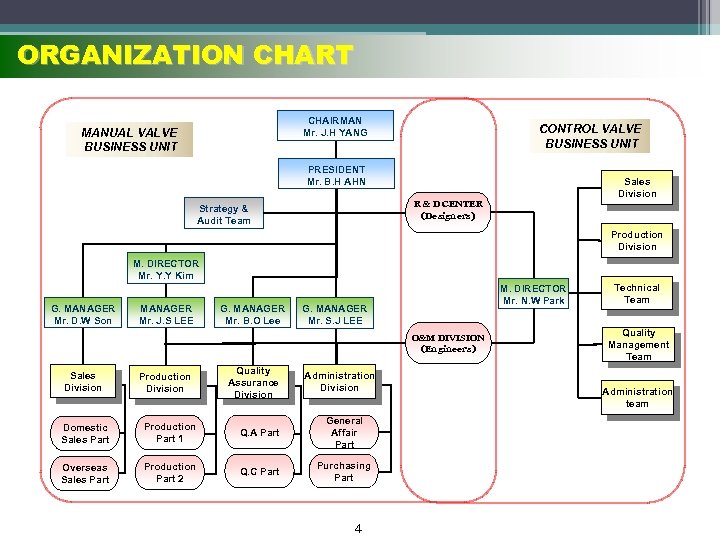

ORGANIZATION CHART CHAIRMAN Mr. J. H YANG MANUAL VALVE BUSINESS UNIT CONTROL VALVE BUSINESS UNIT PRESIDENT Mr. B. H AHN Sales Division R & D CENTER (Designers) Strategy & Audit Team Production Division M. DIRECTOR Mr. Y. Y Kim G. MANAGER Mr. D. W Son MANAGER Mr. J. S LEE G. MANAGER Mr. B. O Lee M. DIRECTOR Mr. N. W Park G. MANAGER Mr. S. J LEE O&M DIVISION (Engineers) Sales Division Production Division Quality Assurance Division Administration Division Domestic Sales Part Production Part 1 Q. A Part General Affair Part Overseas Sales Part Production Part 2 Q. C Part Purchasing Part 4 Technical Team Quality Management Team Administration team

ORGANIZATION CHART CHAIRMAN Mr. J. H YANG MANUAL VALVE BUSINESS UNIT CONTROL VALVE BUSINESS UNIT PRESIDENT Mr. B. H AHN Sales Division R & D CENTER (Designers) Strategy & Audit Team Production Division M. DIRECTOR Mr. Y. Y Kim G. MANAGER Mr. D. W Son MANAGER Mr. J. S LEE G. MANAGER Mr. B. O Lee M. DIRECTOR Mr. N. W Park G. MANAGER Mr. S. J LEE O&M DIVISION (Engineers) Sales Division Production Division Quality Assurance Division Administration Division Domestic Sales Part Production Part 1 Q. A Part General Affair Part Overseas Sales Part Production Part 2 Q. C Part Purchasing Part 4 Technical Team Quality Management Team Administration team

COMPANY HISTORY 1968 ESTABLISHED SEO-HEUNG(瑞興) CORPORATION 1979 ACQUISITION OF KOREA SPECIAL VALVE INDUSTRY COMPANY(高麗特殊閥門産業) 1983 GRANTED A LICENSE BY KOREA ELECTRIC POWER CORPORATION TO MANUFACTURE HIGH PRESSURE VALVES FOR POWER PLANT EQUIPMENT GRNATED A LICENSE BY KOREA GAS SAFETY CORPORATION TO MANUFACTURE HIGH PRESSURE EQUIPMENT REGISTERED & SUPPLIED TO KOREA GAS CORPORATION FOR MANUAL CYROGENIC VALVES 1984 ACQUISITION OF THE FACILITY OF SAMKWANG METAL CO. , LTD. AND CHANGED COMPANY NAME TO SEO HEUNG METAL CO. , LTD. (瑞興金屬) 1986 ENTERED INTO A TECHNICAL LICENSE AGREEMENT WITH KENSEI VALVE CO. , LTD. (JAPAN) FOR HIGH PRESSURE FORGED STEEL VALVES 1989 ENTERED INTO A TECHNICAL LICENSE AGREEMENT AND CO-MANUFACTURING AGREEMENT WITH KEROTEST (USA) TO PRODUCE NUCLEAR VALVES GRANTED LICENSE TO MANUFACTURE VALVES FOR NUCLEAR POWER GENERATION BY THE MINISTRY OF SCIENCE (KOREA) 1994 GRANTED ISO 9001 CERTIFICATE BY TÜV-RHEINLAND 1995 REGISTERED OWN TRADE MARK “SAVE” BRAND 1996 ENTERED INTO A TECHNICAL LICENSE AGREEMENT AND CO-MANUFACTURING AGREEMENT WITH COPES-VULCAN INC. (USA) TO PRODUCE PNEUMATIC CONTROL VALVES 1997 GRANTED A LICENSE TO MANUFACTURE CONTROL VALVES FOR POWER PLANT EQUIPMENT BY KOREA ELECTRIC POWR COMPANY 1999 GRANTED THE LICENSE OF API-6 D (LICENSE NO. 6 D-0304) GRANTED THE LICENSE OF KEPIC-MN ( NUCLEAR QUALITY ASSURANCE SYSTEM) BY KOREA ELECTRIC ASSOCIATION(KEA) 5 ADVANCED VALVE ENGINEERING

COMPANY HISTORY 1968 ESTABLISHED SEO-HEUNG(瑞興) CORPORATION 1979 ACQUISITION OF KOREA SPECIAL VALVE INDUSTRY COMPANY(高麗特殊閥門産業) 1983 GRANTED A LICENSE BY KOREA ELECTRIC POWER CORPORATION TO MANUFACTURE HIGH PRESSURE VALVES FOR POWER PLANT EQUIPMENT GRNATED A LICENSE BY KOREA GAS SAFETY CORPORATION TO MANUFACTURE HIGH PRESSURE EQUIPMENT REGISTERED & SUPPLIED TO KOREA GAS CORPORATION FOR MANUAL CYROGENIC VALVES 1984 ACQUISITION OF THE FACILITY OF SAMKWANG METAL CO. , LTD. AND CHANGED COMPANY NAME TO SEO HEUNG METAL CO. , LTD. (瑞興金屬) 1986 ENTERED INTO A TECHNICAL LICENSE AGREEMENT WITH KENSEI VALVE CO. , LTD. (JAPAN) FOR HIGH PRESSURE FORGED STEEL VALVES 1989 ENTERED INTO A TECHNICAL LICENSE AGREEMENT AND CO-MANUFACTURING AGREEMENT WITH KEROTEST (USA) TO PRODUCE NUCLEAR VALVES GRANTED LICENSE TO MANUFACTURE VALVES FOR NUCLEAR POWER GENERATION BY THE MINISTRY OF SCIENCE (KOREA) 1994 GRANTED ISO 9001 CERTIFICATE BY TÜV-RHEINLAND 1995 REGISTERED OWN TRADE MARK “SAVE” BRAND 1996 ENTERED INTO A TECHNICAL LICENSE AGREEMENT AND CO-MANUFACTURING AGREEMENT WITH COPES-VULCAN INC. (USA) TO PRODUCE PNEUMATIC CONTROL VALVES 1997 GRANTED A LICENSE TO MANUFACTURE CONTROL VALVES FOR POWER PLANT EQUIPMENT BY KOREA ELECTRIC POWR COMPANY 1999 GRANTED THE LICENSE OF API-6 D (LICENSE NO. 6 D-0304) GRANTED THE LICENSE OF KEPIC-MN ( NUCLEAR QUALITY ASSURANCE SYSTEM) BY KOREA ELECTRIC ASSOCIATION(KEA) 5 ADVANCED VALVE ENGINEERING

COMPANY HISTORY 2001 APPROVED BY CLASS LLOYD’S REGISTER TO MANUFACTURE VARIOUS RAW-MATERILAL APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE FORGED, CASTED, AND CRYOGENIC VALVES 2002 APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE VARIOUS RAW MATERIALS 2003 OBTAINED CE CERTIFICATE FROM TÜV-RHEINLAND FOR INDUSTRIAL, CONTROL & SAFETY VALVES REGISTERD WITH KOREA GAS CORPORATION(KOGAS) FOR CONTROL & SAFETY VALVES FOR CYROGENIC SERVICE GRANTED LICENSE BY KOREA HYDRO & NUCLEAR POWR CORPORATION TO MANUFACTURE CONTROL VALVES FOR NUCLEAR POWER PLANTS SUPPLIED LIQUID-FUELED ROCKET(KSR-III) CONTROL VALVES TO KOREA AEROSPACE R&D INSTITUDE 2004 OBTAINED QUALITY CERTIFICATE BY DAEWOO SHIPBUILDING ENG. FOR CYROGENIC SERVICE APPROVED BY CLASS DNV, LLOYD & BV’S REGISTER TO MANUFACTURE VARIOUS RAW MATERIALS (SUB CONSTRACTORS) 2005 2006 2007 GRANTED A LICENSE BY TAIWAN POWER COMPANY TO MANUFACTURE NUCLEAR FORGED STEEL, CASTED BELLOWS SEAL & CHEVRON SEAL PACKING VALVES FOR LUNGMEN NPP PROJECT GRANTED A LICENSE BY CTCI-IHI CPC NORTHERN LNG TERNIMAL TO MANUFACTURE CRYOGENIC GLOBE, CHECK, NEEDLE, BALL & BUTTERFLY VALVES FOR CPC NORTHERN LNG TERNIMAL PROJECT RESEARCH & DEVELOPED HIGH PRESSURE TOP ENTRY BALL VALVES WITH THE MINISTRY OF COMMERCE, INDUSTRY & ENERGY OF KOREA GOVERNMENT(MOCIE) CO-DEVELOPED A TURBINE BYPASS CONTROL VALVES & PRDS WITH KOREA ELECTRIC POWER RESEARCH INSTITUTE(KEPRI) AWARDED THE PRIZE OF US$ 5 MILLION EXPORT FROM THE MINISTRY OF COMMERCE, INDUSTRY & ENERGY REGISTERED AS AN APPROVED SUPPLIER AT JIANGSU NUCLEAR POWER CORPORATON(JNPC) FOR VARIOUS TYPES OF VALVES (QNC-CLASS) 6 ADVANCED VALVE ENGINEERING

COMPANY HISTORY 2001 APPROVED BY CLASS LLOYD’S REGISTER TO MANUFACTURE VARIOUS RAW-MATERILAL APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE FORGED, CASTED, AND CRYOGENIC VALVES 2002 APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE VARIOUS RAW MATERIALS 2003 OBTAINED CE CERTIFICATE FROM TÜV-RHEINLAND FOR INDUSTRIAL, CONTROL & SAFETY VALVES REGISTERD WITH KOREA GAS CORPORATION(KOGAS) FOR CONTROL & SAFETY VALVES FOR CYROGENIC SERVICE GRANTED LICENSE BY KOREA HYDRO & NUCLEAR POWR CORPORATION TO MANUFACTURE CONTROL VALVES FOR NUCLEAR POWER PLANTS SUPPLIED LIQUID-FUELED ROCKET(KSR-III) CONTROL VALVES TO KOREA AEROSPACE R&D INSTITUDE 2004 OBTAINED QUALITY CERTIFICATE BY DAEWOO SHIPBUILDING ENG. FOR CYROGENIC SERVICE APPROVED BY CLASS DNV, LLOYD & BV’S REGISTER TO MANUFACTURE VARIOUS RAW MATERIALS (SUB CONSTRACTORS) 2005 2006 2007 GRANTED A LICENSE BY TAIWAN POWER COMPANY TO MANUFACTURE NUCLEAR FORGED STEEL, CASTED BELLOWS SEAL & CHEVRON SEAL PACKING VALVES FOR LUNGMEN NPP PROJECT GRANTED A LICENSE BY CTCI-IHI CPC NORTHERN LNG TERNIMAL TO MANUFACTURE CRYOGENIC GLOBE, CHECK, NEEDLE, BALL & BUTTERFLY VALVES FOR CPC NORTHERN LNG TERNIMAL PROJECT RESEARCH & DEVELOPED HIGH PRESSURE TOP ENTRY BALL VALVES WITH THE MINISTRY OF COMMERCE, INDUSTRY & ENERGY OF KOREA GOVERNMENT(MOCIE) CO-DEVELOPED A TURBINE BYPASS CONTROL VALVES & PRDS WITH KOREA ELECTRIC POWER RESEARCH INSTITUTE(KEPRI) AWARDED THE PRIZE OF US$ 5 MILLION EXPORT FROM THE MINISTRY OF COMMERCE, INDUSTRY & ENERGY REGISTERED AS AN APPROVED SUPPLIER AT JIANGSU NUCLEAR POWER CORPORATON(JNPC) FOR VARIOUS TYPES OF VALVES (QNC-CLASS) 6 ADVANCED VALVE ENGINEERING

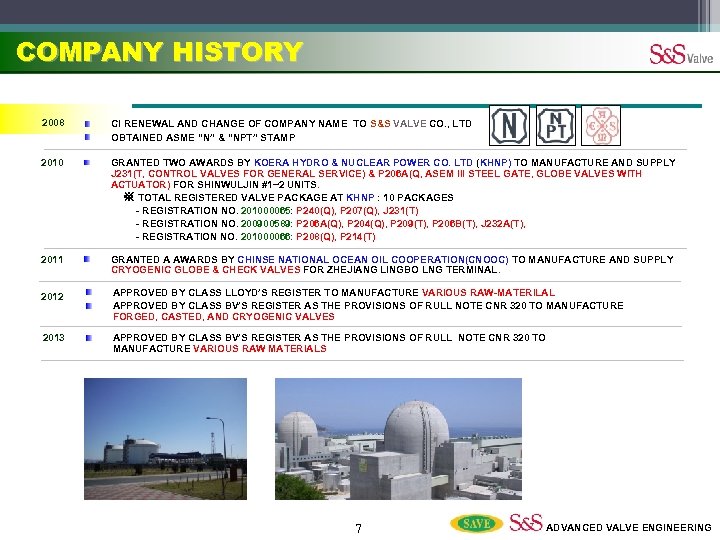

COMPANY HISTORY 2008 CI RENEWAL AND CHANGE OF COMPANY NAME TO S&S VALVE CO. , LTD OBTAINED ASME “N” & “NPT” STAMP 2010 GRANTED TWO AWARDS BY KOERA HYDRO & NUCLEAR POWER CO. LTD (KHNP) TO MANUFACTURE AND SUPPLY J 231(T, CONTROL VALVES FOR GENERAL SERVICE) & P 206 A(Q, ASEM III STEEL GATE, GLOBE VALVES WITH ACTUATOR) FOR SHINWULJIN #1~2 UNITS. ※ TOTAL REGISTERED VALVE PACKAGE AT KHNP : 10 PACKAGES - REGISTRATION NO. 201000065: P 240(Q), P 207(Q), J 231(T) - REGISTRATION NO. 200900589: P 206 A(Q), P 204(Q), P 209(T), P 206 B(T), J 232 A(T), - REGISTRATION NO. 201000066: P 208(Q), P 214(T) 2011 GRANTED A AWARDS BY CHINSE NATIONAL OCEAN OIL COOPERATION(CNOOC) TO MANUFACTURE AND SUPPLY CRYOGENIC GLOBE & CHECK VALVES FOR ZHEJIANG LINGBO LNG TERMINAL. 2012 APPROVED BY CLASS LLOYD’S REGISTER TO MANUFACTURE VARIOUS RAW-MATERILAL APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE FORGED, CASTED, AND CRYOGENIC VALVES 2013 APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE VARIOUS RAW MATERIALS 7 ADVANCED VALVE ENGINEERING

COMPANY HISTORY 2008 CI RENEWAL AND CHANGE OF COMPANY NAME TO S&S VALVE CO. , LTD OBTAINED ASME “N” & “NPT” STAMP 2010 GRANTED TWO AWARDS BY KOERA HYDRO & NUCLEAR POWER CO. LTD (KHNP) TO MANUFACTURE AND SUPPLY J 231(T, CONTROL VALVES FOR GENERAL SERVICE) & P 206 A(Q, ASEM III STEEL GATE, GLOBE VALVES WITH ACTUATOR) FOR SHINWULJIN #1~2 UNITS. ※ TOTAL REGISTERED VALVE PACKAGE AT KHNP : 10 PACKAGES - REGISTRATION NO. 201000065: P 240(Q), P 207(Q), J 231(T) - REGISTRATION NO. 200900589: P 206 A(Q), P 204(Q), P 209(T), P 206 B(T), J 232 A(T), - REGISTRATION NO. 201000066: P 208(Q), P 214(T) 2011 GRANTED A AWARDS BY CHINSE NATIONAL OCEAN OIL COOPERATION(CNOOC) TO MANUFACTURE AND SUPPLY CRYOGENIC GLOBE & CHECK VALVES FOR ZHEJIANG LINGBO LNG TERMINAL. 2012 APPROVED BY CLASS LLOYD’S REGISTER TO MANUFACTURE VARIOUS RAW-MATERILAL APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE FORGED, CASTED, AND CRYOGENIC VALVES 2013 APPROVED BY CLASS BV’S REGISTER AS THE PROVISIONS OF RULL NOTE CNR 320 TO MANUFACTURE VARIOUS RAW MATERIALS 7 ADVANCED VALVE ENGINEERING

![ANNUAL TURNOVER 60 50. 5 50 38. 7 [ Million USD] 40 39. 3 ANNUAL TURNOVER 60 50. 5 50 38. 7 [ Million USD] 40 39. 3](https://present5.com/presentation/79666b6288abfab4cab02cc191c8526b/image-8.jpg) ANNUAL TURNOVER 60 50. 5 50 38. 7 [ Million USD] 40 39. 3 33. 9 34 2010 2011 35 29. 7 30 19. 5 20 10 0 2006 2007 2008 2009 DOMESTIC EXPORT 8 TOTAL 2012 2013

ANNUAL TURNOVER 60 50. 5 50 38. 7 [ Million USD] 40 39. 3 33. 9 34 2010 2011 35 29. 7 30 19. 5 20 10 0 2006 2007 2008 2009 DOMESTIC EXPORT 8 TOTAL 2012 2013

LICENSES & CERTIFICATES 9 TYPE APPROVAL CERTIFICATE – BV/LR/KRS Certificate of Authorization ASME N STAMP Class 1, 2 & 3 Certificate of Authorization ASME NPT STAMP Class 1, 2 & 3 S&S ADVANCED VALVE ENGINEERING 9

LICENSES & CERTIFICATES 9 TYPE APPROVAL CERTIFICATE – BV/LR/KRS Certificate of Authorization ASME N STAMP Class 1, 2 & 3 Certificate of Authorization ASME NPT STAMP Class 1, 2 & 3 S&S ADVANCED VALVE ENGINEERING 9

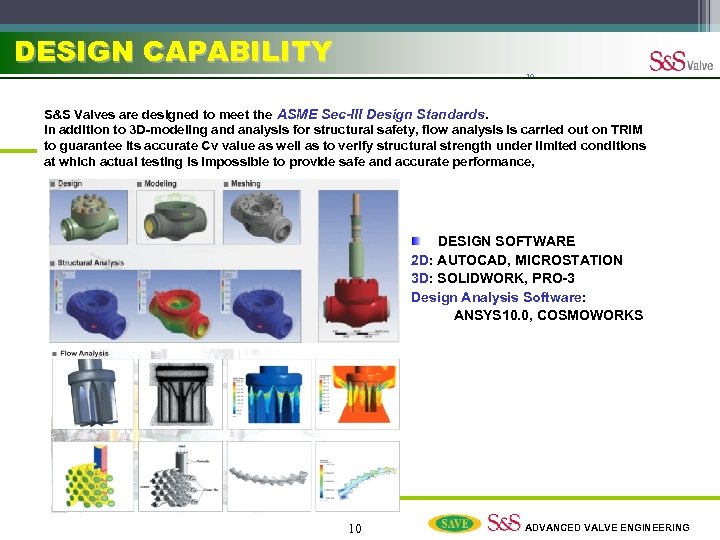

DESIGN CAPABILITY 10 S&S Valves are designed to meet the ASME Sec-III Design Standards. In addition to 3 D-modeling and analysis for structural safety, flow analysis is carried out on TRIM to guarantee its accurate Cv value as well as to verify structural strength under limited conditions at which actual testing is impossible to provide safe and accurate performance, DESIGN SOFTWARE 2 D: AUTOCAD, MICROSTATION 3 D: SOLIDWORK, PRO-3 Design Analysis Software: ANSYS 10. 0, COSMOWORKS 10 ADVANCED VALVE ENGINEERING

DESIGN CAPABILITY 10 S&S Valves are designed to meet the ASME Sec-III Design Standards. In addition to 3 D-modeling and analysis for structural safety, flow analysis is carried out on TRIM to guarantee its accurate Cv value as well as to verify structural strength under limited conditions at which actual testing is impossible to provide safe and accurate performance, DESIGN SOFTWARE 2 D: AUTOCAD, MICROSTATION 3 D: SOLIDWORK, PRO-3 Design Analysis Software: ANSYS 10. 0, COSMOWORKS 10 ADVANCED VALVE ENGINEERING

VALVE RANGES # # 2 4 1 6 1 9 5 0 0 0 • C/V : Control Valves, MOV : Motor Operated Valves, • POV/AOV : Rheumatic/Air Operated Valves, M/V : Manual Valves 11 ADVANCED VALVE ENGINEERING

VALVE RANGES # # 2 4 1 6 1 9 5 0 0 0 • C/V : Control Valves, MOV : Motor Operated Valves, • POV/AOV : Rheumatic/Air Operated Valves, M/V : Manual Valves 11 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE METAL SEATED BALL VALVE SPECIFICATIONS 1) Valve Size : 2" ~ 16" 2) Applicable Rating : ASME 600# ~ 1500#, 2500# 3) Temperature : Up to 500℃ 4) Code & Standard : API, BS, ASME, ASTM, KGSC Designed by ASME B 16. 34 / 16. 10 / 16. 25 5) Constructions • Two Piece Type • End Connection: Flanged, RTJ or Butt-welded Type • Trunnion Ball Type / Metal Seat Type • Full Bore / Reduce Bore • Blow-out Proof Stem • Double Seal, Double Block & Bleed / Anti-static Design • Pressure Relieving Seats • Fire Safety Construction (API-607) 12 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE METAL SEATED BALL VALVE SPECIFICATIONS 1) Valve Size : 2" ~ 16" 2) Applicable Rating : ASME 600# ~ 1500#, 2500# 3) Temperature : Up to 500℃ 4) Code & Standard : API, BS, ASME, ASTM, KGSC Designed by ASME B 16. 34 / 16. 10 / 16. 25 5) Constructions • Two Piece Type • End Connection: Flanged, RTJ or Butt-welded Type • Trunnion Ball Type / Metal Seat Type • Full Bore / Reduce Bore • Blow-out Proof Stem • Double Seal, Double Block & Bleed / Anti-static Design • Pressure Relieving Seats • Fire Safety Construction (API-607) 12 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE PARALLEL SLIDE GATE SPECIFICATIONS 1) Valve Size : 2" ~ 16" 2) Applicable Rating : ASME 600# ~ 1500#, 2500# 3) Temperature : Up to 500℃ 4) Code & Standard : API, BS, ASME, ASTM, KGSC Designed by ASME B 16. 34 / 16. 10 / 16. 25 5) Constructions • End Connection : Flanged Type • PSB(=Pressure- Seal Bonnet) Type • Full Bore • Manual or Motor Operated (Pneumatic, Electric, or Hydraulic) 13 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE PARALLEL SLIDE GATE SPECIFICATIONS 1) Valve Size : 2" ~ 16" 2) Applicable Rating : ASME 600# ~ 1500#, 2500# 3) Temperature : Up to 500℃ 4) Code & Standard : API, BS, ASME, ASTM, KGSC Designed by ASME B 16. 34 / 16. 10 / 16. 25 5) Constructions • End Connection : Flanged Type • PSB(=Pressure- Seal Bonnet) Type • Full Bore • Manual or Motor Operated (Pneumatic, Electric, or Hydraulic) 13 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE GENERAL SERVICE VALVES ü CASTING VALVES TYPE SIZE BONNET MATERIALS RATING END TYPE BALL, GATE, GLOBE, CHECK 2” (50 A) ~ 48” (1200 A) BB, PSB, EXT CARBON STEEL, ALLOY, HIGH ALLOY, STAINLESS STEEL, ETC. ANSI #150 ~ #2500 BW, FLANGED ü FORGED STEEL VALVES TYPE SIZE BONNET MATERIALS RATING END TYPE GATE, GLOBE, CHECK, Y-GLOBE, NEEDLE, ANGLE BALL, ¼” ~ 2” BB, WB, PSB, EXT A 105, F 304(L), F 316(L), F 1, F 5, F 9, F 11, F 22, F 347, LF 2, DUPLEX, HIGH-ALLOY, ETC. ANSI #150 ~ #4500 SW, THREADED, BW, FLANGED 14 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE GENERAL SERVICE VALVES ü CASTING VALVES TYPE SIZE BONNET MATERIALS RATING END TYPE BALL, GATE, GLOBE, CHECK 2” (50 A) ~ 48” (1200 A) BB, PSB, EXT CARBON STEEL, ALLOY, HIGH ALLOY, STAINLESS STEEL, ETC. ANSI #150 ~ #2500 BW, FLANGED ü FORGED STEEL VALVES TYPE SIZE BONNET MATERIALS RATING END TYPE GATE, GLOBE, CHECK, Y-GLOBE, NEEDLE, ANGLE BALL, ¼” ~ 2” BB, WB, PSB, EXT A 105, F 304(L), F 316(L), F 1, F 5, F 9, F 11, F 22, F 347, LF 2, DUPLEX, HIGH-ALLOY, ETC. ANSI #150 ~ #4500 SW, THREADED, BW, FLANGED 14 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE BELLOWS SEALED VALVES TYPE SIZE BODY MAT’L BELLOWS MAT’L RATING GATE, GLOBE, Y-GLOBE, POV & MOV ¼” ~ 2” (FORGED) 2” ~ 24” (CASTED) A 105, F 304(L), F 316(L), F 321, F 5, F 9, F 11, F 22, F 347, LF 2, , 316 L, 321, ETC INCONEL, HASTELLOY STEEL, ETC ANSI #150 ~ #2500 TEMP. -196℃ ~ 650℃ 15 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE BELLOWS SEALED VALVES TYPE SIZE BODY MAT’L BELLOWS MAT’L RATING GATE, GLOBE, Y-GLOBE, POV & MOV ¼” ~ 2” (FORGED) 2” ~ 24” (CASTED) A 105, F 304(L), F 316(L), F 321, F 5, F 9, F 11, F 22, F 347, LF 2, , 316 L, 321, ETC INCONEL, HASTELLOY STEEL, ETC ANSI #150 ~ #2500 TEMP. -196℃ ~ 650℃ 15 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE CRYOGENIC VALVES TYPE SIZE BONNET BODY MAT’L RATING GATE, GLOBE, ANGLE, NEEDLE, CHECK, BALL (3 PIECE) , BALL (TOP-ENTRY), SAFETY ¼” ~ 2” (FORGED), 2” ~ 36” (CASTED) LONG EXT. (DRIP-PLATE) F 304, F 316, CF 8 M, F 304 L, F 316 L, CF 3 M ANSI #150 ~ #2500 TEMP. DOWN TO - 196 ℃ OPERATION MANUAL, CONTROL AOV, MOV, HOV, PSV, PRV LEVER, HAND-WHEEL, WORM-GEAR, ACTUATORS 16 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE CRYOGENIC VALVES TYPE SIZE BONNET BODY MAT’L RATING GATE, GLOBE, ANGLE, NEEDLE, CHECK, BALL (3 PIECE) , BALL (TOP-ENTRY), SAFETY ¼” ~ 2” (FORGED), 2” ~ 36” (CASTED) LONG EXT. (DRIP-PLATE) F 304, F 316, CF 8 M, F 304 L, F 316 L, CF 3 M ANSI #150 ~ #2500 TEMP. DOWN TO - 196 ℃ OPERATION MANUAL, CONTROL AOV, MOV, HOV, PSV, PRV LEVER, HAND-WHEEL, WORM-GEAR, ACTUATORS 16 ADVANCED VALVE ENGINEERING

17 SAVE TOTAL VALVE SERVICE MOTOR OPERATED VALVES (MOV) TYPE GLOBE, GATE, BALL, BUTTERFLY SIZE ½”(15 A)~ 28”(700 A) RATING ANSI #150 ~ #4500 MAT’L BONNET ACTUATOR FORGED & CASTED STEEL BB, WB, PSB, EXT, FIN LIMITORQUE, AUMA, ROTORK, ETC. AIR OPERATED VALVES (AOV/POV) TYPE SIZE RATING MAT’L BONNET ACTUATOR GLOBE, GATE, BALL, BUTTERFLY, CRYOGENIC, BELLOWS-SEAL, ETC. ½”(15 A)~ 42”(1050 A) ANSI #150 ~ #2500 FORGED & CASTED STEEL BB, WB, PSB, EXT, FIN PISTON CYLINDER, ROTARY CYLINDER, DIAPHRAGM, ETC. 17 ADVANCED VALVE ENGINEERING

17 SAVE TOTAL VALVE SERVICE MOTOR OPERATED VALVES (MOV) TYPE GLOBE, GATE, BALL, BUTTERFLY SIZE ½”(15 A)~ 28”(700 A) RATING ANSI #150 ~ #4500 MAT’L BONNET ACTUATOR FORGED & CASTED STEEL BB, WB, PSB, EXT, FIN LIMITORQUE, AUMA, ROTORK, ETC. AIR OPERATED VALVES (AOV/POV) TYPE SIZE RATING MAT’L BONNET ACTUATOR GLOBE, GATE, BALL, BUTTERFLY, CRYOGENIC, BELLOWS-SEAL, ETC. ½”(15 A)~ 42”(1050 A) ANSI #150 ~ #2500 FORGED & CASTED STEEL BB, WB, PSB, EXT, FIN PISTON CYLINDER, ROTARY CYLINDER, DIAPHRAGM, ETC. 17 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE HYDRAULIC OPERATED VALVES (HOV) TYPE GLOBE, GATE, ANGLE, CONTROL, BUTTERFLY, BALL, ETC. SIZE ½”(15 A)~ 28”(700 A) RATING ANSI #150 ~ #4500 MATERIALS BONNET ACTUATOR FORGED & CASTED STEEL CUSTOMIZED SPECIAL MAT’L BB, WB, PSB, EXT, FIN CENTORK, DANFOSS, BERNARD, SEIL SERES, ETC. CUSTOMIZED SPECIAL HOV ASTERN GUARD VALVE HYDRAULIC OPERATED CYLINDER 8” 1500 LB A 217 -WC 6 RF STEAM TURBIN 18 ADVANCED VALVE ENGINEERING

SAVE TOTAL VALVE SERVICE HYDRAULIC OPERATED VALVES (HOV) TYPE GLOBE, GATE, ANGLE, CONTROL, BUTTERFLY, BALL, ETC. SIZE ½”(15 A)~ 28”(700 A) RATING ANSI #150 ~ #4500 MATERIALS BONNET ACTUATOR FORGED & CASTED STEEL CUSTOMIZED SPECIAL MAT’L BB, WB, PSB, EXT, FIN CENTORK, DANFOSS, BERNARD, SEIL SERES, ETC. CUSTOMIZED SPECIAL HOV ASTERN GUARD VALVE HYDRAULIC OPERATED CYLINDER 8” 1500 LB A 217 -WC 6 RF STEAM TURBIN 18 ADVANCED VALVE ENGINEERING

SERVICE 19 Technical Services Upon customer's request, S&S Valve Co. , Ltd. can provide Technical Engineering Service such as Pre-Commissioning & Commissioning Supervision, Site Engineer Training Service, Maintenance & After Sales Services according to S&S's related Quality Assurance Procedure and Service Procedure. Detailed service works, procedure and expense responsibility shall be discussed with the customer before the service performance. S&S ADVANCED VALVE ENGINEERING 19

SERVICE 19 Technical Services Upon customer's request, S&S Valve Co. , Ltd. can provide Technical Engineering Service such as Pre-Commissioning & Commissioning Supervision, Site Engineer Training Service, Maintenance & After Sales Services according to S&S's related Quality Assurance Procedure and Service Procedure. Detailed service works, procedure and expense responsibility shall be discussed with the customer before the service performance. S&S ADVANCED VALVE ENGINEERING 19

FACTORY VIEW 20 HEAD OFFICE & FACTORY SHOWROOM FACTORY R&D CENTER S&S ADVANCED VALVE ENGINEERING 20

FACTORY VIEW 20 HEAD OFFICE & FACTORY SHOWROOM FACTORY R&D CENTER S&S ADVANCED VALVE ENGINEERING 20

LICENSES & CERTIFICATES 21 New Excellent Product Certificate (NEP) Certificate of Patent Cryogenic Ball Valves ISO 9001: 2000 CE 0035 API 6 D Fire Safety Test ADVANCED VALVE ENGINEERING 21

LICENSES & CERTIFICATES 21 New Excellent Product Certificate (NEP) Certificate of Patent Cryogenic Ball Valves ISO 9001: 2000 CE 0035 API 6 D Fire Safety Test ADVANCED VALVE ENGINEERING 21

EQUIPMENTS & PRODUCTION LINE BORING MACHINE LATHE MACHINE CNC MACHINE WELDING MACHINE ASSEMBLY LINE M/V FURNACE ASSEMBLY LINE C/V 22 22 DRILL MACHINE PAINT BOOTH ASSY LINE ACTUATOR ADVANCED VALVE ENGINEERING

EQUIPMENTS & PRODUCTION LINE BORING MACHINE LATHE MACHINE CNC MACHINE WELDING MACHINE ASSEMBLY LINE M/V FURNACE ASSEMBLY LINE C/V 22 22 DRILL MACHINE PAINT BOOTH ASSY LINE ACTUATOR ADVANCED VALVE ENGINEERING

INSPECTION & TEST EQUIPMENTS 23 HYDRO TERSTER 1 HYDRO TESTER 2 HYDRO TESTER 3 ACTUATOR TESTER, DURABILITY FIRE SAFETY TEST FLOW CAPACITY TEST FLOW TEST EQUIPMENT 23 ADVANCED VALVE ENGINEERING

INSPECTION & TEST EQUIPMENTS 23 HYDRO TERSTER 1 HYDRO TESTER 2 HYDRO TESTER 3 ACTUATOR TESTER, DURABILITY FIRE SAFETY TEST FLOW CAPACITY TEST FLOW TEST EQUIPMENT 23 ADVANCED VALVE ENGINEERING

SAVE VALVE APPLICATION Pulp & Paper Water & Waste Water Chemicals & Pharmaceutical Other Customized Special General Construction Etc. Shipbuilding & Marines 24 ADVANCED VALVE ENGINEERING

SAVE VALVE APPLICATION Pulp & Paper Water & Waste Water Chemicals & Pharmaceutical Other Customized Special General Construction Etc. Shipbuilding & Marines 24 ADVANCED VALVE ENGINEERING

WORLD WIDE CUSTOMER “We are serving the best to the world” CTCI CORPORATION JGC CORPRATON 25 ADVANCED VALVE ENGINEERING

WORLD WIDE CUSTOMER “We are serving the best to the world” CTCI CORPORATION JGC CORPRATON 25 ADVANCED VALVE ENGINEERING