0a717c81d67e858a7ae22337917021d7.ppt

- Количество слайдов: 17

Shell Global Solutions Gas Coning Control and Gaslift Stabilisation in Shell Gabon By Aat Eken, Shell Global Solutions, Rijswijk NL Mike Harper, Shell Gabon, Rabi Cor Koster, Shell Gabon, Gamba Azmi Mohd. Noor, Shell Global Solutions, Kuala Lumpur, Malaysia Shell Global Solutions

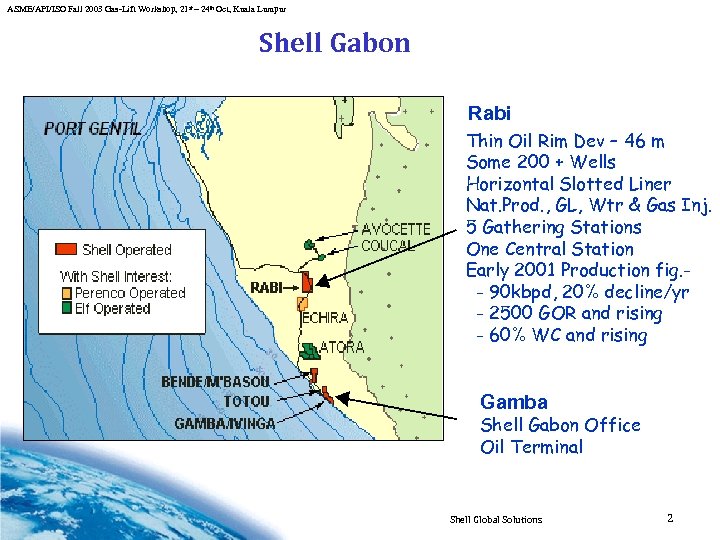

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur Shell Gabon Rabi Thin Oil Rim Dev – 46 m Some 200 + Wells Horizontal Slotted Liner Nat. Prod. , GL, Wtr & Gas Inj. 5 Gathering Stations One Central Station Early 2001 Production fig. - 90 kbpd, 20% decline/yr - 2500 GOR and rising - 60% WC and rising Gamba Shell Gabon Office Oil Terminal Shell Global Solutions 2

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “Rabi Dumb Well” • Wellhead measurements are all local • Production choke control by fixed bean (expressed in ~n*8/64 th inch) • Operator visits well by car • If bean too small: well dies, seen by change of THP • If bean too large: well “cones gas”, seen by change of THP and THT/FLT • After a start-up a well needs smaller beans as time progresses • Pigging and scraping for wax removal at ~2 d intervals. Shell Global Solutions 3

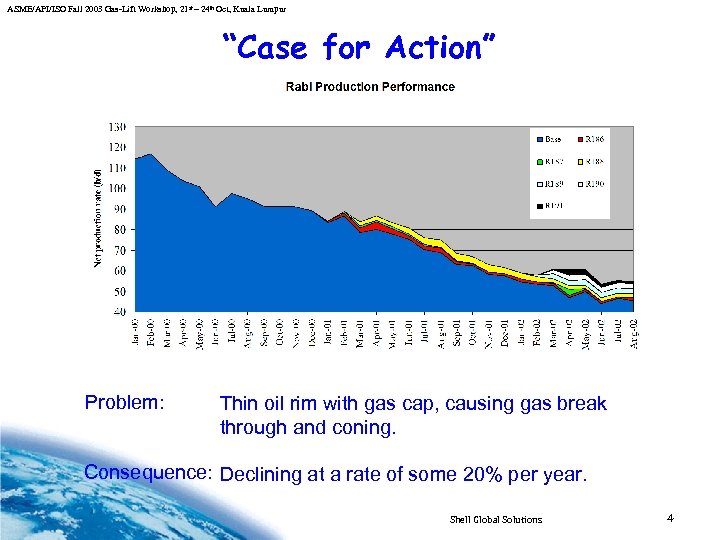

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “Case for Action” Problem: Thin oil rim with gas cap, causing gas break through and coning. Consequence: Declining at a rate of some 20% per year. Shell Global Solutions 4

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “Project Objectives” • Automated well control via an algorithm control loop to arrest gas coning • CAO network, providing remote monitoring and control • Provide live well data onto the SWW • Fast track project to arrest rapid decline (20% per year) • Technology to be maintainable • Provide the basic infrastructure to allow remote control of Rabi gathering stations Shell Global Solutions 5

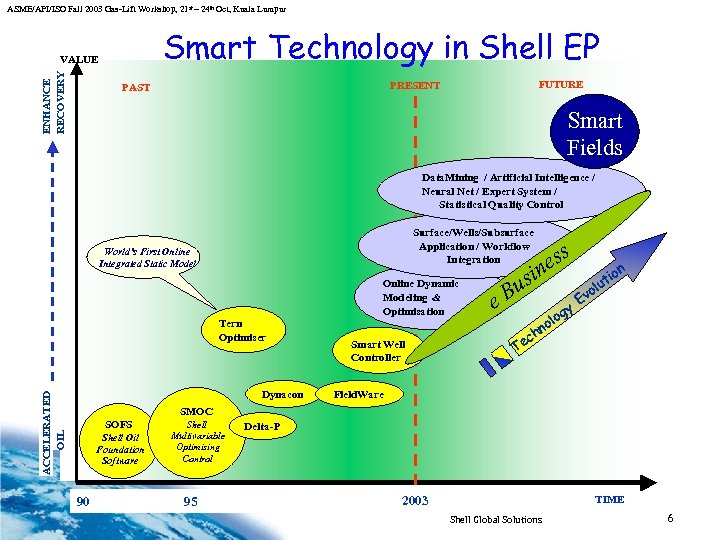

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur Smart Technology in Shell EP ENHANCE RECOVERY VALUE FUTURE PRESENT PAST Smart Fields Data. Mining / Artificial Intelligence / Neural Net / Expert System / Statistical Quality Control Surface/Wells/Subsurface Application / Workflow Integration World’s First Online Integrated Static Model Online Dynamic Modeling & Optimisation Tern Optimiser ACCELERATED OIL Dynacon Smart Well Controller ess in us e. B y log o n tio lu vo E hn c Te Field. Ware SMOC SOFS Shell Oil Foundation Software 90 Shell Multivariable Optimising Control 95 Delta-P 2003 TIME Shell Global Solutions 6

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “Project Specifics” Choke Valve Design & Selection • Interchangeable trims so that standard body sizes could be deployed • Given high GOR wells, chokes used as in the NAM fields were chosen • Linear characteristics and high rangeability for controllability • Easier identification of bean size equivalent for choke trim sizes Control System • Delta-P, Delta-T measurements for coning detection and well instability • Leverage existing eqpt, contracts for fast tracking • Minimal maintenance due to the remoteness of Rabi Shell Global Solutions 7

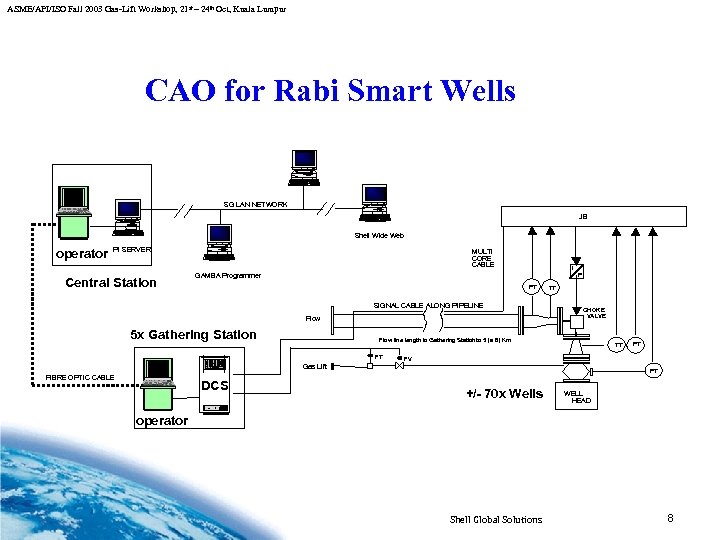

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur CAO for Rabi Smart Wells SG LAN NETWORK JB Shell Wide Web operator PI SERVER Central Station MULTI CORE CABLE I P GAMBA Programmer PT SIGNAL CABLE ALONG PIPELINE Flow 5 x Gathering Station Gas Lift DCS CHOKE VALVE Flow line length to Gathering Stationto 5 (a 6) Km. 1 FT FIBRE OPTIC CABLE TT TT PT FV PT +/- 70 x Wells WELL HEAD operator Shell Global Solutions 8

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “Rabi Smart Well Controller” Shell Global Solutions 9

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “SWC Multiphase Flowmeter” Shell Global Solutions 10

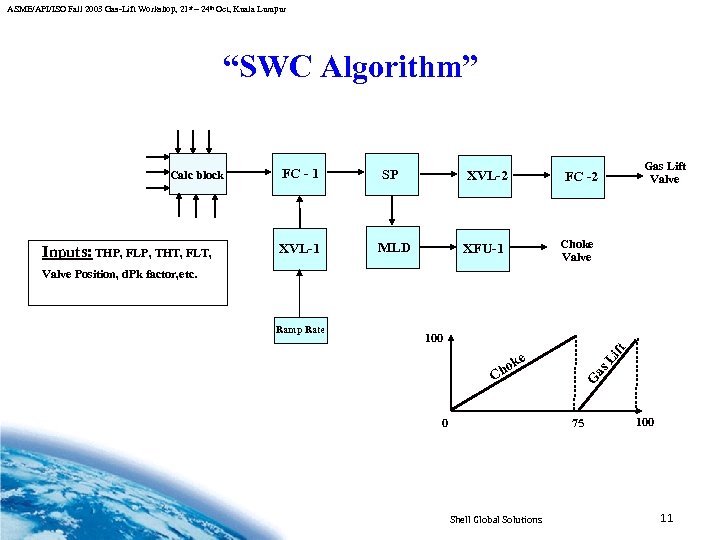

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “SWC Algorithm” Calc block Inputs: THP, FLP, THT, FLT, FC - 1 SP XVL-2 XVL-1 MLD XFU-1 Gas Lift Valve FC -2 Choke Valve Position, d. Pk factor, etc. ft 100 0 as Li ke o Ch G Ramp Rate 75 Shell Global Solutions 100 11

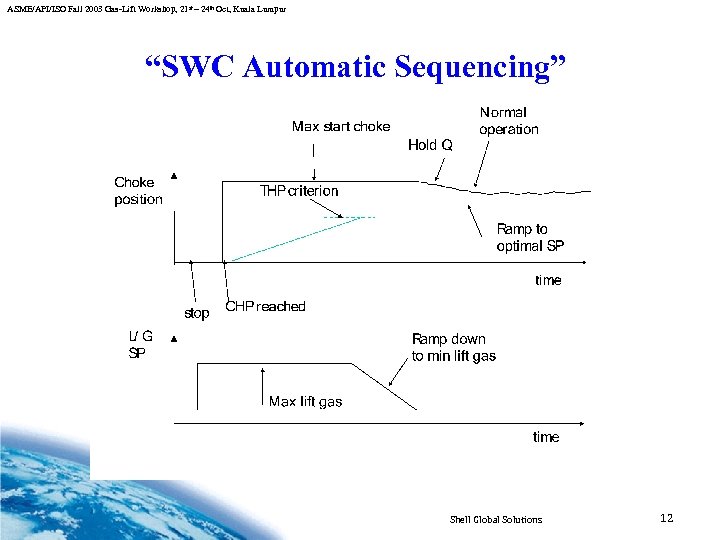

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “SWC Automatic Sequencing” Shell Global Solutions 12

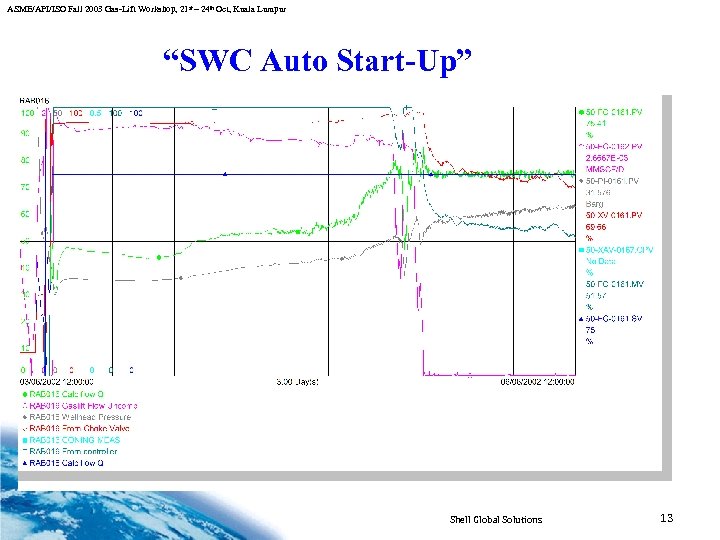

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “SWC Auto Start-Up” Shell Global Solutions 13

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “SWC Well Stability” Rab-016 Scraping/Pigging Shell Global Solutions 14

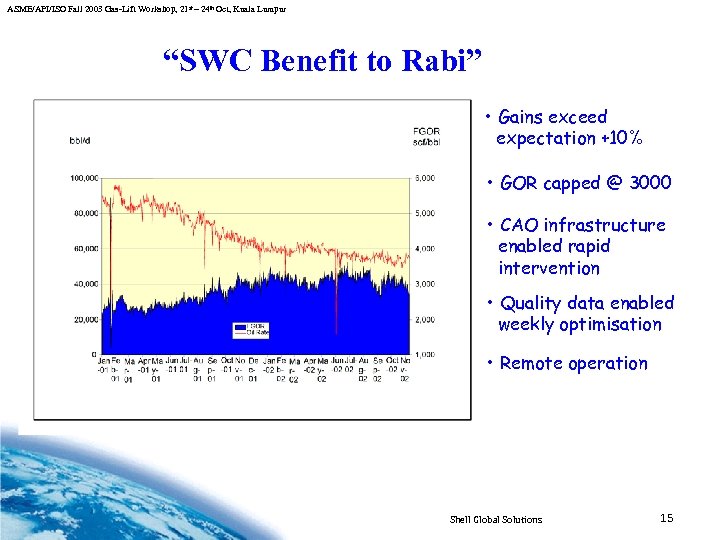

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “SWC Benefit to Rabi” • Gains exceed expectation +10% • GOR capped @ 3000 • CAO infrastructure enabled rapid intervention • Quality data enabled weekly optimisation • Remote operation Shell Global Solutions 15

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur Conclusions • Production of oil from thin oil rims lead to gas coning • Limited gas coning helps optimise production • Uncontrolled gas coning leads to rapid depletion of the gas cap and strong production decline • Better production information and better well stability through Cone. Control assists the production optimisation team in their task to produce the oil field in the best possible way. Shell Global Solutions 16

ASME/API/ISO Fall 2003 Gas-Lift Workshop, 21 st – 24 th Oct, Kuala Lumpur “Rabi Smart Team” Shell Global Solutions 17

0a717c81d67e858a7ae22337917021d7.ppt