dfbbff6e6bb98afccea332aa45646823.ppt

- Количество слайдов: 12

Session 16 Scheduling System Examples • • • The PAC Data Base Twin Disc Shop-Floor Control Report Finite Loading Example Steelcase Vendor Scheduling Report Concluding Principles 1

Session 16 Scheduling System Examples • • • The PAC Data Base Twin Disc Shop-Floor Control Report Finite Loading Example Steelcase Vendor Scheduling Report Concluding Principles 1

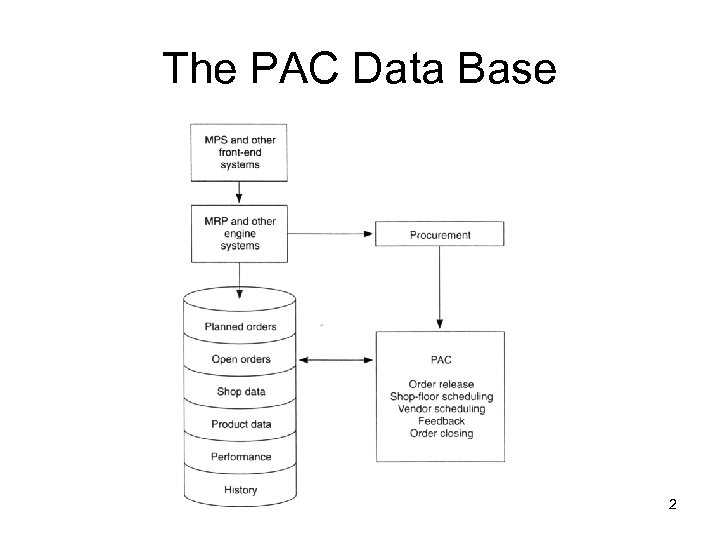

The PAC Data Base 2

The PAC Data Base 2

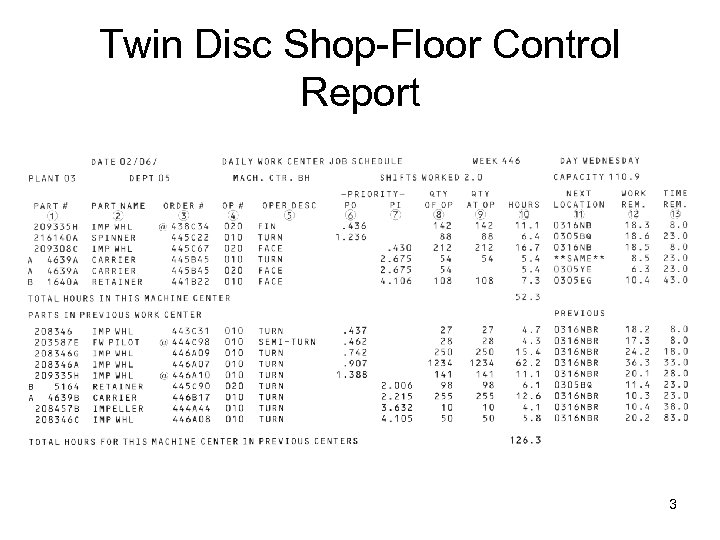

Twin Disc Shop-Floor Control Report 3

Twin Disc Shop-Floor Control Report 3

Twin Disc Example The shop floor report at Twin Disc shows the six orders that are currently in the BH machine center. The report also shows the next nine orders that are set to arrive at the BH machine. What would the order processing sequence be at the BH machine center under the two following situations? 4

Twin Disc Example The shop floor report at Twin Disc shows the six orders that are currently in the BH machine center. The report also shows the next nine orders that are set to arrive at the BH machine. What would the order processing sequence be at the BH machine center under the two following situations? 4

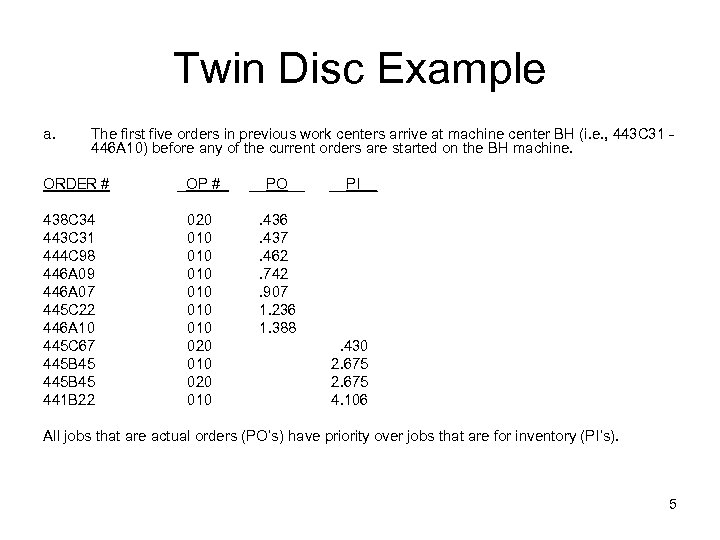

Twin Disc Example a. The first five orders in previous work centers arrive at machine center BH (i. e. , 443 C 31 446 A 10) before any of the current orders are started on the BH machine. ORDER # 438 C 34 443 C 31 444 C 98 446 A 09 446 A 07 445 C 22 446 A 10 445 C 67 445 B 45 441 B 22 _OP #_ __PO__ 020 010 010 010 020 010 __PI__ . 436. 437. 462. 742. 907 1. 236 1. 388. 430 2. 675 4. 106 All jobs that are actual orders (PO’s) have priority over jobs that are for inventory (PI’s). 5

Twin Disc Example a. The first five orders in previous work centers arrive at machine center BH (i. e. , 443 C 31 446 A 10) before any of the current orders are started on the BH machine. ORDER # 438 C 34 443 C 31 444 C 98 446 A 09 446 A 07 445 C 22 446 A 10 445 C 67 445 B 45 441 B 22 _OP #_ __PO__ 020 010 010 010 020 010 __PI__ . 436. 437. 462. 742. 907 1. 236 1. 388. 430 2. 675 4. 106 All jobs that are actual orders (PO’s) have priority over jobs that are for inventory (PI’s). 5

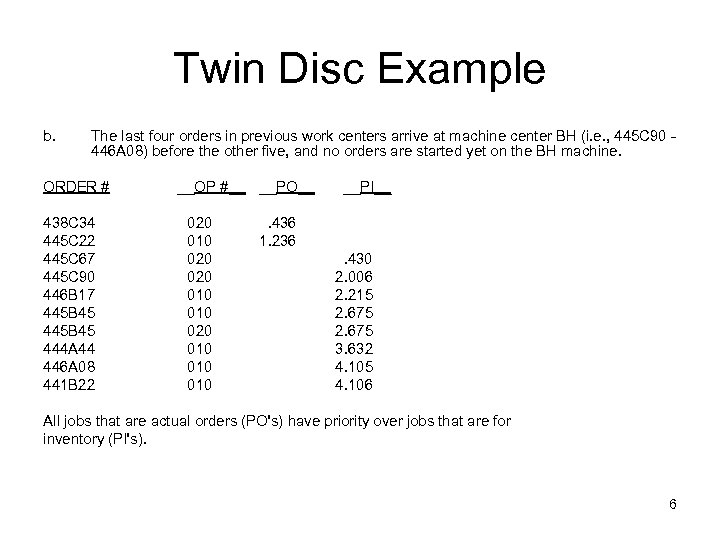

Twin Disc Example b. The last four orders in previous work centers arrive at machine center BH (i. e. , 445 C 90 446 A 08) before the other five, and no orders are started yet on the BH machine. ORDER # 438 C 34 445 C 22 445 C 67 445 C 90 446 B 17 445 B 45 444 A 44 446 A 08 441 B 22 __OP #__ __PO__ 020 010 020 010 010 __PI__ . 436 1. 236. 430 2. 006 2. 215 2. 675 3. 632 4. 105 4. 106 All jobs that are actual orders (PO's) have priority over jobs that are for inventory (PI's). 6

Twin Disc Example b. The last four orders in previous work centers arrive at machine center BH (i. e. , 445 C 90 446 A 08) before the other five, and no orders are started yet on the BH machine. ORDER # 438 C 34 445 C 22 445 C 67 445 C 90 446 B 17 445 B 45 444 A 44 446 A 08 441 B 22 __OP #__ __PO__ 020 010 020 010 010 __PI__ . 436 1. 236. 430 2. 006 2. 215 2. 675 3. 632 4. 105 4. 106 All jobs that are actual orders (PO's) have priority over jobs that are for inventory (PI's). 6

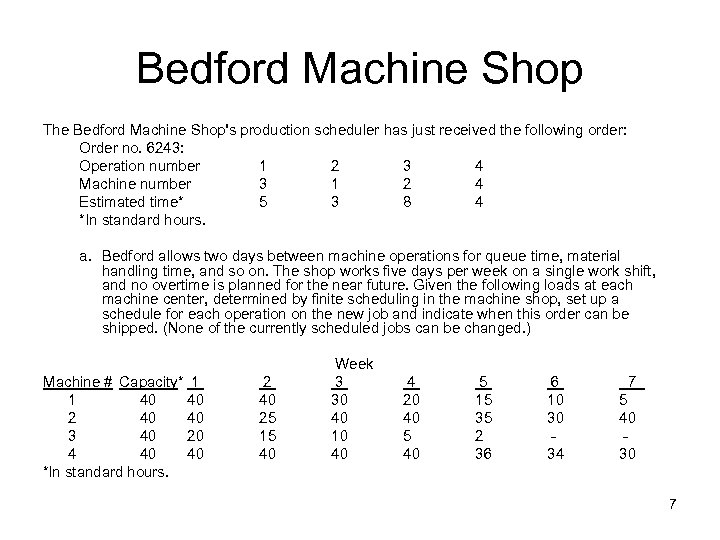

Bedford Machine Shop The Bedford Machine Shop's production scheduler has just received the following order: Order no. 6243: Operation number 1 2 3 4 Machine number 3 1 2 4 Estimated time* 5 3 8 4 *In standard hours. a. Bedford allows two days between machine operations for queue time, material handling time, and so on. The shop works five days per week on a single work shift, and no overtime is planned for the near future. Given the following loads at each machine center, determined by finite scheduling in the machine shop, set up a schedule for each operation on the new job and indicate when this order can be shipped. (None of the currently scheduled jobs can be changed. ) Machine # Capacity* 1 1 40 40 2 40 40 3 40 20 4 40 40 *ln standard hours. 2 40 25 15 40 Week 3 30 40 10 40 4 20 40 5 15 35 2 36 6 10 30 34 _7_ 5 40 30 7

Bedford Machine Shop The Bedford Machine Shop's production scheduler has just received the following order: Order no. 6243: Operation number 1 2 3 4 Machine number 3 1 2 4 Estimated time* 5 3 8 4 *In standard hours. a. Bedford allows two days between machine operations for queue time, material handling time, and so on. The shop works five days per week on a single work shift, and no overtime is planned for the near future. Given the following loads at each machine center, determined by finite scheduling in the machine shop, set up a schedule for each operation on the new job and indicate when this order can be shipped. (None of the currently scheduled jobs can be changed. ) Machine # Capacity* 1 1 40 40 2 40 40 3 40 20 4 40 40 *ln standard hours. 2 40 25 15 40 Week 3 30 40 10 40 4 20 40 5 15 35 2 36 6 10 30 34 _7_ 5 40 30 7

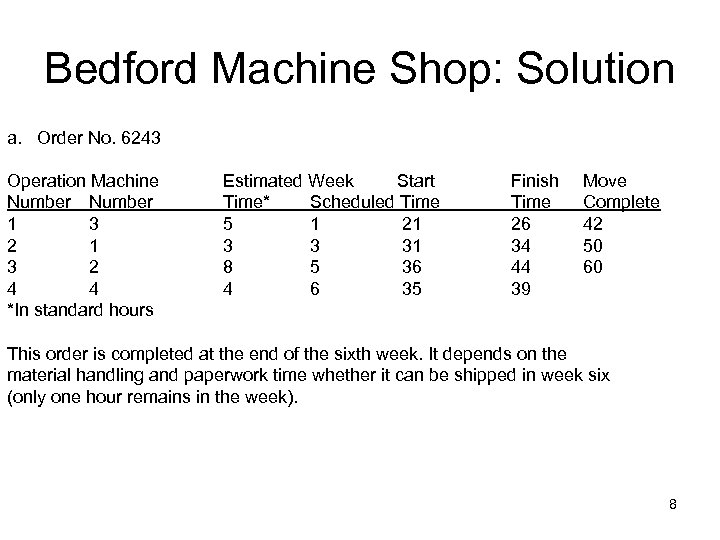

Bedford Machine Shop: Solution a. Order No. 6243 Operation Machine Number 1 3 2 4 4 *In standard hours Estimated Week Start Time* Scheduled Time 5 1 21 3 3 31 8 5 36 4 6 35 Finish Time 26 34 44 39 Move Complete 42 50 60 This order is completed at the end of the sixth week. It depends on the material handling and paperwork time whether it can be shipped in week six (only one hour remains in the week). 8

Bedford Machine Shop: Solution a. Order No. 6243 Operation Machine Number 1 3 2 4 4 *In standard hours Estimated Week Start Time* Scheduled Time 5 1 21 3 3 31 8 5 36 4 6 35 Finish Time 26 34 44 39 Move Complete 42 50 60 This order is completed at the end of the sixth week. It depends on the material handling and paperwork time whether it can be shipped in week six (only one hour remains in the week). 8

Bedford Machine Shop: Solution (Continued) b. Given the information displayed in the shop load table, what capacity recommendations would you make to management? There are heavier loads at machine center 2 and 4 than at 1 and 3. Can these be made more equal (capacity expanded, alternate routing, etc. )? 9

Bedford Machine Shop: Solution (Continued) b. Given the information displayed in the shop load table, what capacity recommendations would you make to management? There are heavier loads at machine center 2 and 4 than at 1 and 3. Can these be made more equal (capacity expanded, alternate routing, etc. )? 9

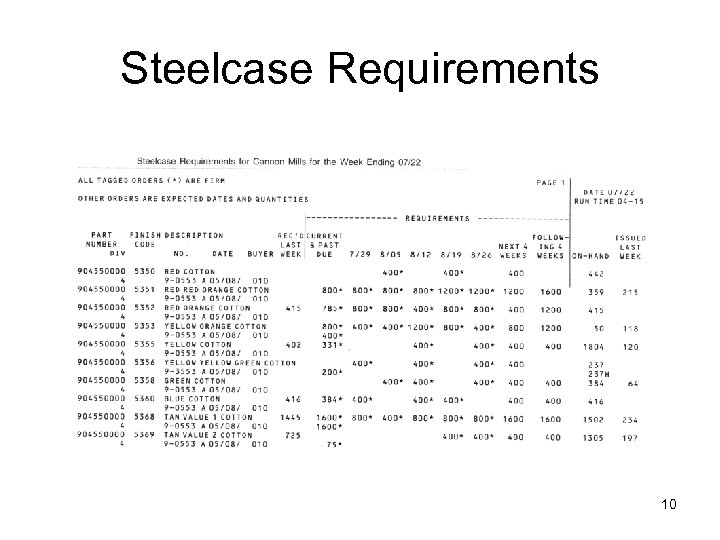

Steelcase Requirements 10

Steelcase Requirements 10

Concluding Principles • Production activity control system design must be in concert with the firm's needs. • The shop-floor control system should support users and first-line supervisors, not supplant them. • Vendor capacities should be planned and scheduled with as much diligence as are internal capacities. • Lead times are to be managed. • Organizational goals and incentives must be congruent with good PAC practice. • Discretion and decision-making responsibilities in production activity control practice need to be carefully defined for both the shop and vendors. 11

Concluding Principles • Production activity control system design must be in concert with the firm's needs. • The shop-floor control system should support users and first-line supervisors, not supplant them. • Vendor capacities should be planned and scheduled with as much diligence as are internal capacities. • Lead times are to be managed. • Organizational goals and incentives must be congruent with good PAC practice. • Discretion and decision-making responsibilities in production activity control practice need to be carefully defined for both the shop and vendors. 11

Concluding Principles • PAC performance should be defined and monitored. • Feedback from PAC should provide early warning and status information to other MPC modules. • Automated reading systems and distributed computers should facilitate data acquisition and shop-floor decision making. • Data base design and integrity must be assessed for PAC systems to be effective. • The ongoing evolution in PAC systems as firms increasingly adopt world class manufacturing methods is reduced detail, smaller data bases, and simpler systems. 12

Concluding Principles • PAC performance should be defined and monitored. • Feedback from PAC should provide early warning and status information to other MPC modules. • Automated reading systems and distributed computers should facilitate data acquisition and shop-floor decision making. • Data base design and integrity must be assessed for PAC systems to be effective. • The ongoing evolution in PAC systems as firms increasingly adopt world class manufacturing methods is reduced detail, smaller data bases, and simpler systems. 12