2bdaf4c0a207375bbfcee57640cbc33a.ppt

- Количество слайдов: 32

Services Provided by LCBO Quality Assurance Leading Sensory Evaluation Services LC Quality Assurance

VQA Appellation System VQA Mandate Appellation of Origin System Quality Standard Control of use of specified terms, descriptions and designations associated with the VQA appellation system LC Quality Assurance

Role of Sensory Evaluation Testing Quality of Beverage Alcohol Products Sensory Quality Chemical Composition Microbiological Stability Packaging and Labelling Standards LC Quality Assurance

Role of VQA Sensory Evaluation Testing Scope Free of technical faults / defects Typicity of varietal character – for varietal wines “A wine bearing varietal designation shall be assessed to determine if the varietal designation for the wine exhibits the predominant character of a wine produced from the designated grape variety/varieties” (VQA Rules) Typicity of the wine category: Late Harvest, Icewine, Nouveau, Sparkling – Traditional Method, Icewine Dosage, Botrytized Wine (VQA Rules) LC Quality Assurance

Role of VQA Sensory Evaluation Testing “A wine shall be deemed to have passed the taste test if a majority of the members of the Tasting Panel determine: That the wine’s attributes fairly reflect the viticultural and oenological quality standards established in O. Reg. 406/00 (Rules) without defects or flaws; and That the wine is representative of quality wines of the stated category” (VQA Rules) LC Quality Assurance

Sensory Panels Grading Panel – 4 panel groups of 5 panellists each 28 Members (20 regular panellists, 8 alternate tasters) LC Quality Assurance

Panel Member Selection Criteria Panel members are LCBO Product Consultants who work in retail stores within metropolitan Toronto area Continuous training/ development opportunities LCBO Product Knowledge I, I, III Certification from the Wine and Spirit Education Trust Master of Wine Certification LC Quality Assurance

Panel Member Selection Criteria Panel members are subjected to annual : Sensory evaluation testing Product knowledge testing 25 % of the questions are VQA specific Demonstrated professionalism – Sensory Evaluations Code of Conduct LC Quality Assurance

Panels Composition Panel Groups Assembly Criteria: Consistent Performance Reproducible Results Balanced Panels Results from the annual testing Testing performance history Previous experience (as a Grading Panel member, from the industry) Performance monitoring data Sensory sensitivities LC Quality Assurance

Panel Training Elements Aroma, flavour recognition Product category recognition Varietal character recognition Regional character recognition Winemaking techniques Technological influences Defect identification LC Quality Assurance

Sample Presentation Blind sample presentation: Samples are presented without identifying markings Uniform sample presentation Sample information: Varietal composition, vintage year, wine category, method of production (where applicable: sparkling wines, icewine dosage, etc) LC Quality Assurance

Sensory Evaluation Method Sensory Evaluation Grading System LC Quality Assurance

Sensory Evaluation Grading System Objectives Ob jec Applicability tiv ity Client Satisfaction E ci ffi e y nc Superior objectivity – system design eliminates bias Wider system applicability– system design equally applies to all wine categories Efficient and effective calculation of results – time savings, accuracy Data Analysis Tools & Traceability of results – enabled by automated data collection and quantification of the results LC Quality Assurance

Sensory Evaluation Grading System Sensory evaluation grading system elements: New sensory evaluation grading method Integrating technology: • Automated data collection • Automated data quantification, analysis and reporting LC Quality Assurance

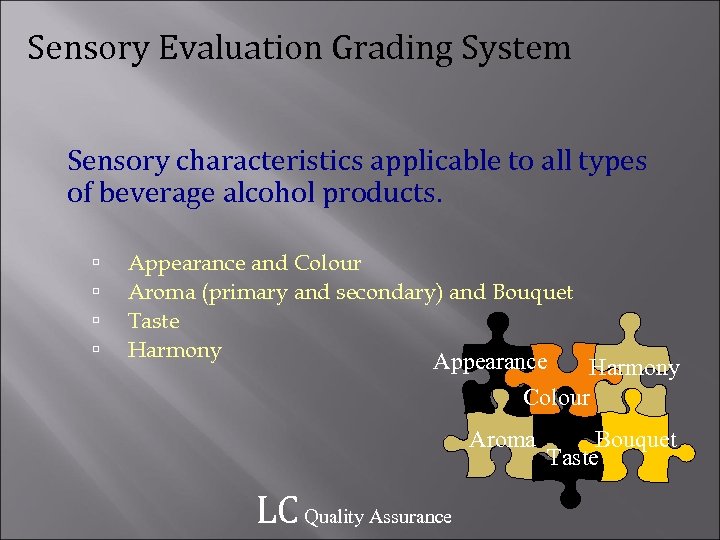

Sensory Evaluation Grading System Sensory characteristics applicable to all types of beverage alcohol products. Appearance and Colour Aroma (primary and secondary) and Bouquet Taste Harmony Appearance Harmony Colour Aroma LC Quality Assurance Bouquet Taste

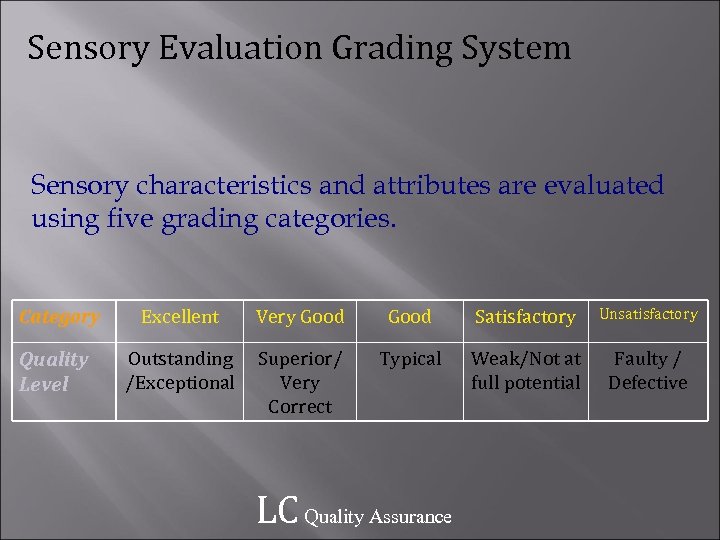

Sensory Evaluation Grading System Sensory characteristics and attributes are evaluated using five grading categories. Category Excellent Very Good Satisfactory Unsatisfactory Quality Level Outstanding /Exceptional Superior/ Very Correct Typical Weak/Not at full potential Faulty / Defective LC Quality Assurance

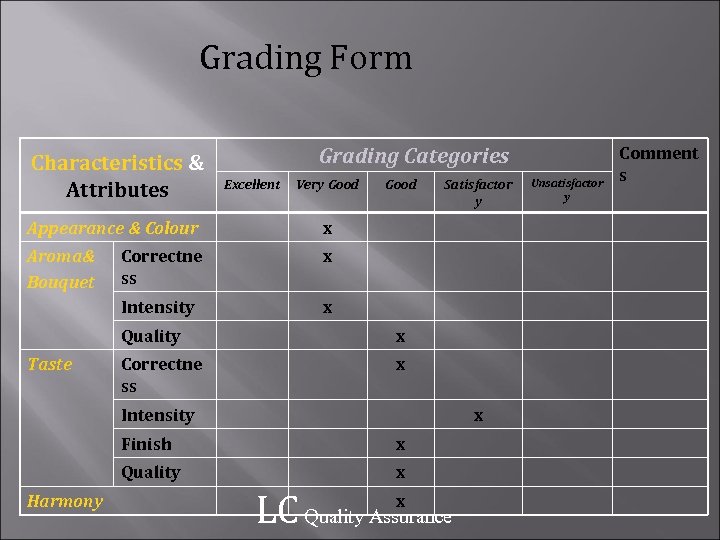

Grading Form Characteristics & Attributes Grading Categories Excellent Very Good Appearance & Colour Correctne ss x Intensity Satisfactor y x Aroma& Bouquet Good x Quality Taste x Correctne ss x Intensity x Finish Quality Harmony x x LC Quality Assurance x Unsatisfactor y Comment s

Innovative Technology Integrated Sensory Evaluation Software Data collection Data quantification Data analysis Data reporting LC Quality Assurance

Data Collection – Tablet PCs Automated Interactive Flexible-Wireless Pen or/and keyboard Handwritten notes LC Quality Assurance

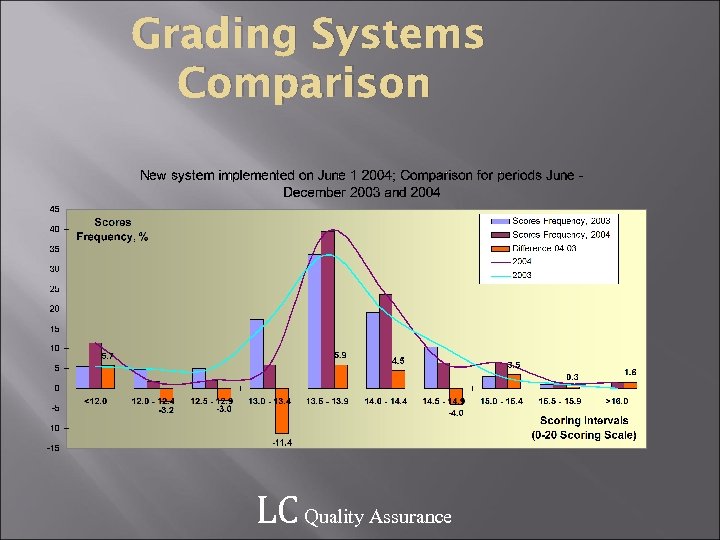

Grading Systems Comparison LC Quality Assurance

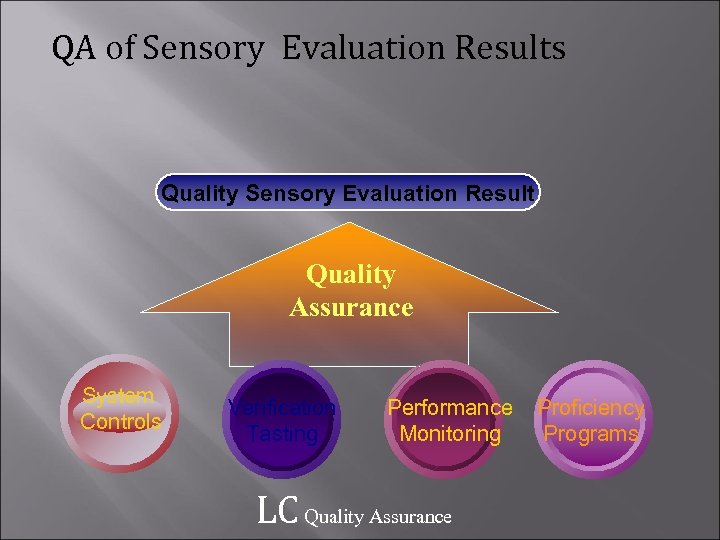

QA of Sensory Evaluation Results Quality Sensory Evaluation Result Quality Assurance System Controls Verification Tasting Performance Monitoring LC Quality Assurance Proficiency Programs

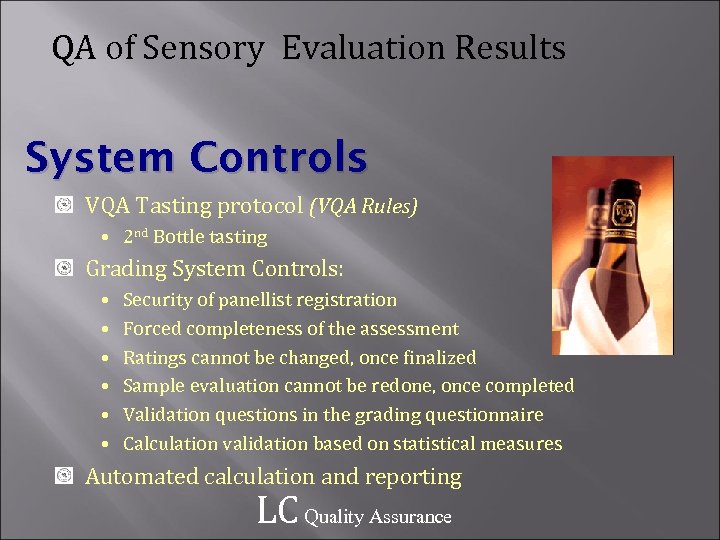

QA of Sensory Evaluation Results System Controls VQA Tasting protocol (VQA Rules) • 2 nd Bottle tasting Grading System Controls: • • • Security of panellist registration Forced completeness of the assessment Ratings cannot be changed, once finalized Sample evaluation cannot be redone, once completed Validation questions in the grading questionnaire Calculation validation based on statistical measures Automated calculation and reporting LC Quality Assurance

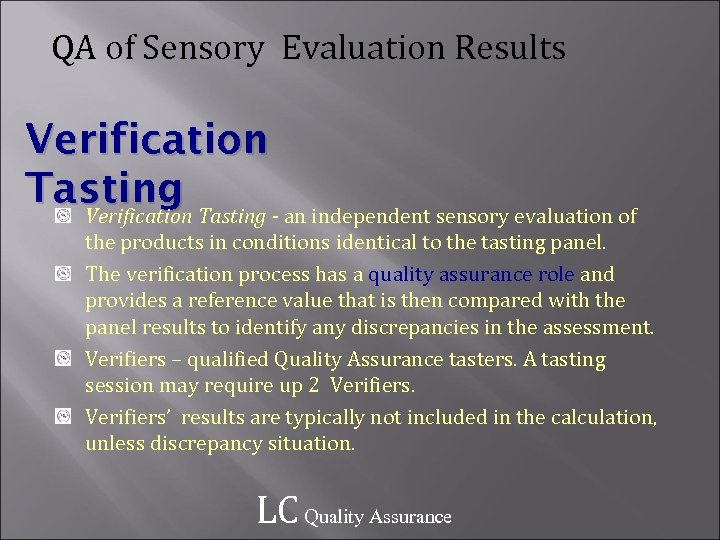

QA of Sensory Evaluation Results Verification Tasting - an independent sensory evaluation of the products in conditions identical to the tasting panel. The verification process has a quality assurance role and provides a reference value that is then compared with the panel results to identify any discrepancies in the assessment. Verifiers – qualified Quality Assurance tasters. A tasting session may require up 2 Verifiers’ results are typically not included in the calculation, unless discrepancy situation. LC Quality Assurance

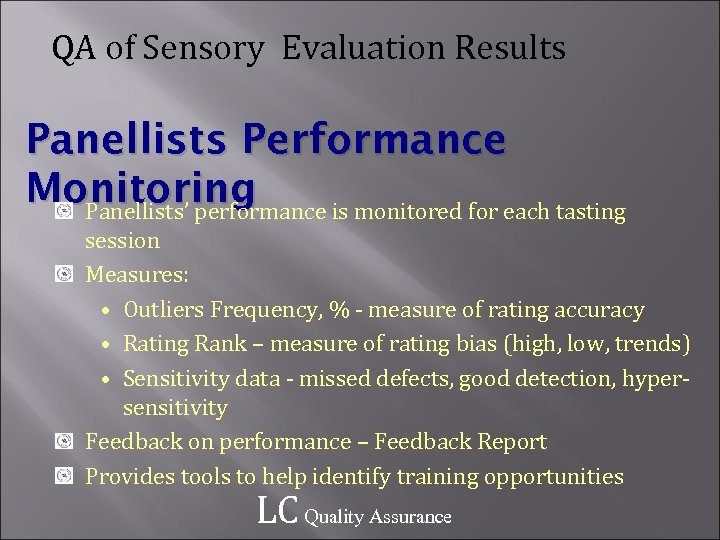

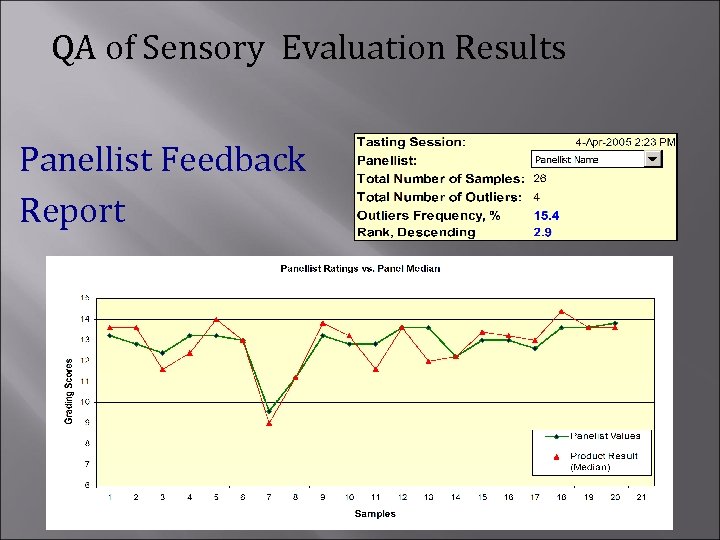

QA of Sensory Evaluation Results Panellists Performance Monitoring Panellists’ performance is monitored for each tasting session Measures: • Outliers Frequency, % - measure of rating accuracy • Rating Rank – measure of rating bias (high, low, trends) • Sensitivity data - missed defects, good detection, hypersensitivity Feedback on performance – Feedback Report Provides tools to help identify training opportunities LC Quality Assurance

QA of Sensory Evaluation Results Panellist Feedback Report LC Quality Assurance

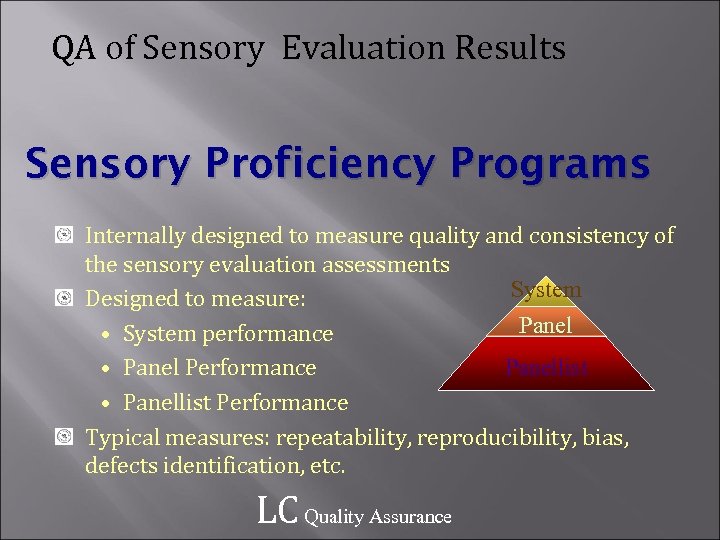

QA of Sensory Evaluation Results Sensory Proficiency Programs Internally designed to measure quality and consistency of the sensory evaluation assessments System Designed to measure: Panel • System performance Panellist • Panel Performance • Panellist Performance Typical measures: repeatability, reproducibility, bias, defects identification, etc. LC Quality Assurance

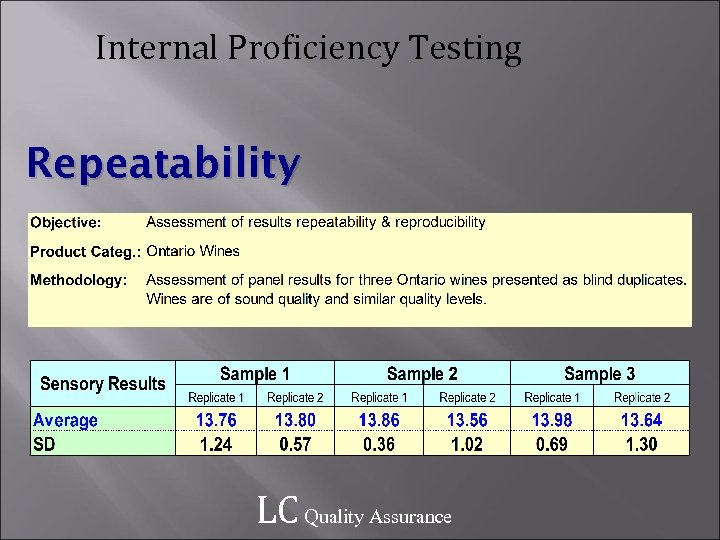

Internal Proficiency Testing Repeatability LC Quality Assurance

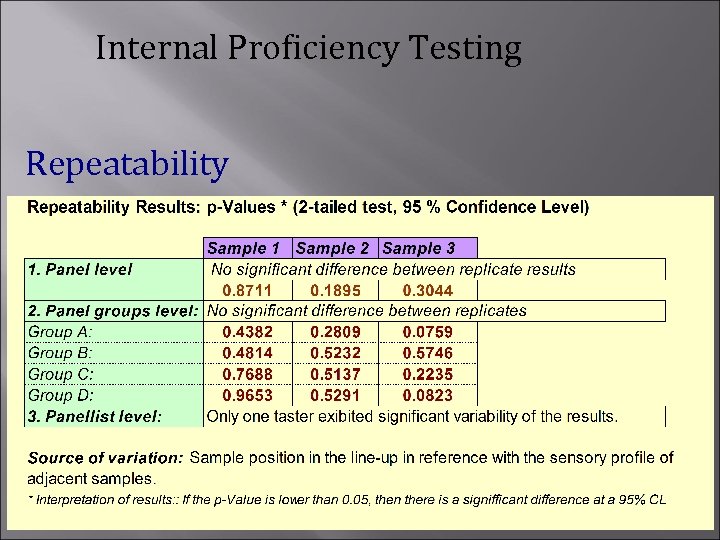

Internal Proficiency Testing Repeatability LC Quality Assurance

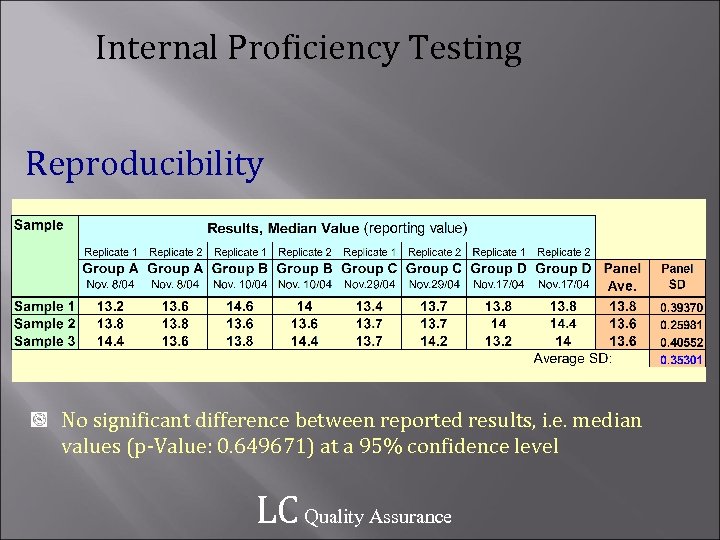

Internal Proficiency Testing Reproducibility No significant difference between reported results, i. e. median values (p-Value: 0. 649671) at a 95% confidence level LC Quality Assurance

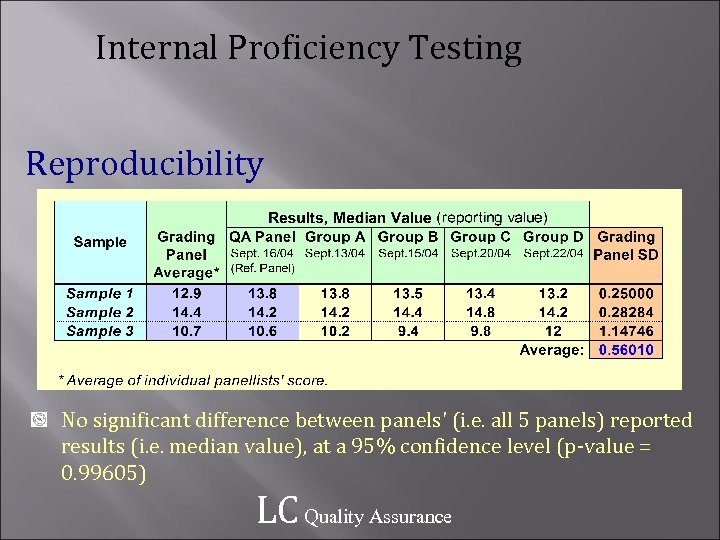

Internal Proficiency Testing Reproducibility No significant difference between panels' (i. e. all 5 panels) reported results (i. e. median value), at a 95% confidence level (p-value = 0. 99605) LC Quality Assurance

Sensory Evaluation Grading System Summary A superior method for performing sensory evaluations. Eliminates many sources of bias. Customized for use with all beverage alcohol products. Flexibility (data collection, quantification & reporting). Provides significant time savings in data management. Provides tools to analyze panellist results to help identify training opportunities. LC Quality Assurance

C LC Leading the Sensory Evaluation of Beverage Alcohol LC Quality Assurance

2bdaf4c0a207375bbfcee57640cbc33a.ppt