d93bfd05dfc9e8adb9dd36035d618830.ppt

- Количество слайдов: 25

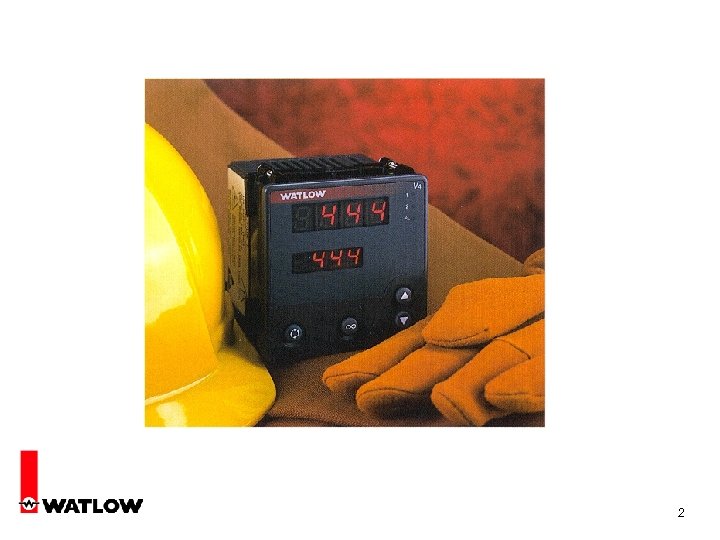

Series V 4 T 1/4 DIN Temperature Controllers 1

Series V 4 T 1/4 DIN Temperature Controllers 1

2

2

Watlow’s Next Generation Styling Series 97 Matching 1/16 DIN Limit Controller Series F 4 S and F 4 D Ramping Controller Series V 4 T 1/4 DIN Temperature Controller 3

Watlow’s Next Generation Styling Series 97 Matching 1/16 DIN Limit Controller Series F 4 S and F 4 D Ramping Controller Series V 4 T 1/4 DIN Temperature Controller 3

Watlow’s New V 4 T 1/4 DIN Controller u General purpose, market targeted features u. Based on the proven Series 93 and Series 965 1/16 DIN controllers u Value priced essential feature design u. Accurate control at a low cost u. Year 2000 compliant 4

Watlow’s New V 4 T 1/4 DIN Controller u General purpose, market targeted features u. Based on the proven Series 93 and Series 965 1/16 DIN controllers u Value priced essential feature design u. Accurate control at a low cost u. Year 2000 compliant 4

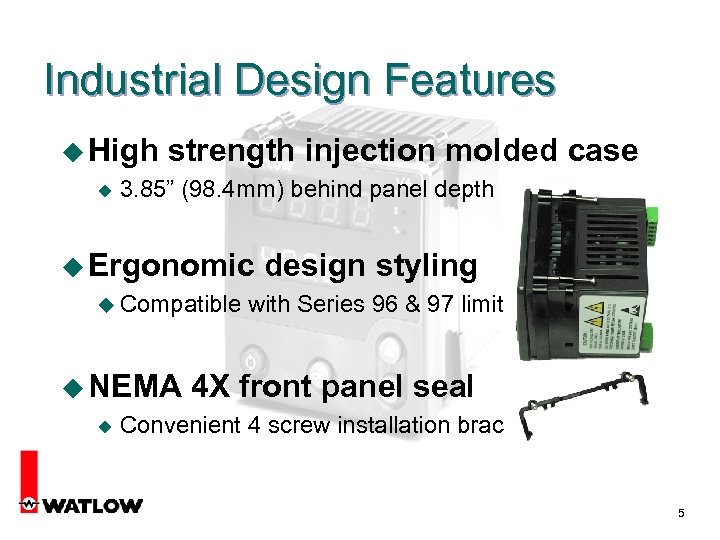

Industrial Design Features u High strength injection molded u 3. 85” (98. 4 mm) behind panel depth case u Ergonomic design styling u Compatible with Series 96 & 97 limit u NEMA 4 X front panel seal u Convenient 4 screw installation brackets 5

Industrial Design Features u High strength injection molded u 3. 85” (98. 4 mm) behind panel depth case u Ergonomic design styling u Compatible with Series 96 & 97 limit u NEMA 4 X front panel seal u Convenient 4 screw installation brackets 5

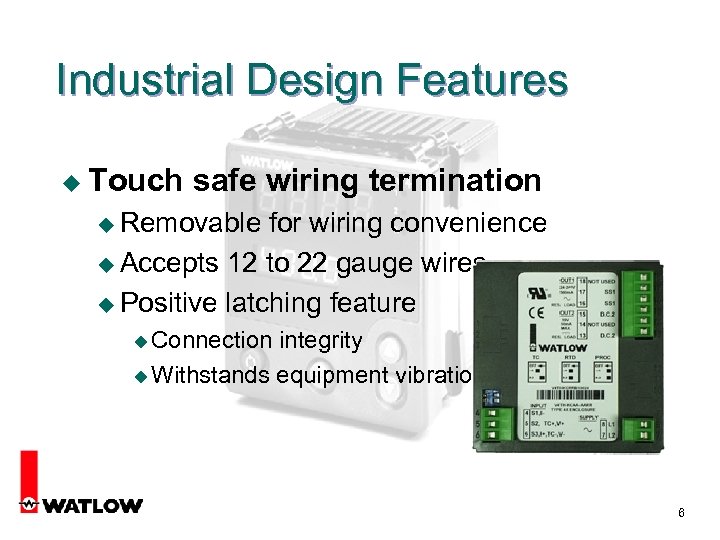

Industrial Design Features u Touch safe wiring termination u Removable for wiring convenience u Accepts 12 to 22 gauge wires u Positive latching feature u Connection integrity u Withstands equipment vibration 6

Industrial Design Features u Touch safe wiring termination u Removable for wiring convenience u Accepts 12 to 22 gauge wires u Positive latching feature u Connection integrity u Withstands equipment vibration 6

V 4 T Focus Markets 7

V 4 T Focus Markets 7

Furnace and Oven u u Heat treating Kilns Autoclaves Foundry & metal processing 8

Furnace and Oven u u Heat treating Kilns Autoclaves Foundry & metal processing 8

Components and Assembly u u Semiconductor processing equipment Electronic assembly equipment 9

Components and Assembly u u Semiconductor processing equipment Electronic assembly equipment 9

Food Processing u u NEMA 4 X Short case depth 10

Food Processing u u NEMA 4 X Short case depth 10

Other Focus Industries u u u Analytical instruments Incubators Packaging 11

Other Focus Industries u u u Analytical instruments Incubators Packaging 11

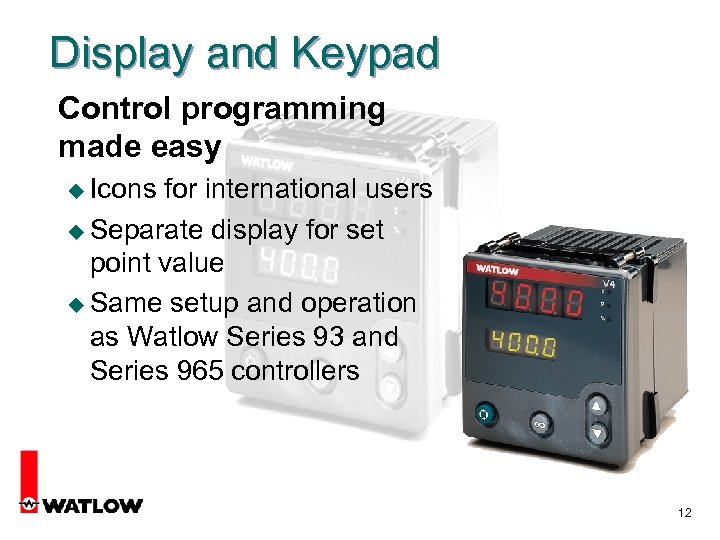

Display and Keypad Control programming made easy u Icons for international users u Separate display for set point value u Same setup and operation as Watlow Series 93 and Series 965 controllers 12

Display and Keypad Control programming made easy u Icons for international users u Separate display for set point value u Same setup and operation as Watlow Series 93 and Series 965 controllers 12

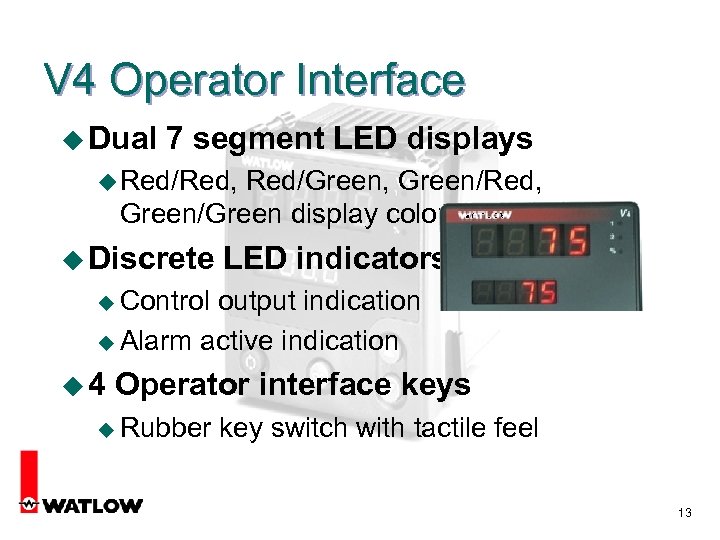

V 4 Operator Interface u Dual 7 segment LED displays u Red/Red, Red/Green, Green/Red, Green/Green display color options u Discrete LED indicators u Control output indication u Alarm active indication u 4 Operator interface keys u Rubber key switch with tactile feel 13

V 4 Operator Interface u Dual 7 segment LED displays u Red/Red, Red/Green, Green/Red, Green/Green display color options u Discrete LED indicators u Control output indication u Alarm active indication u 4 Operator interface keys u Rubber key switch with tactile feel 13

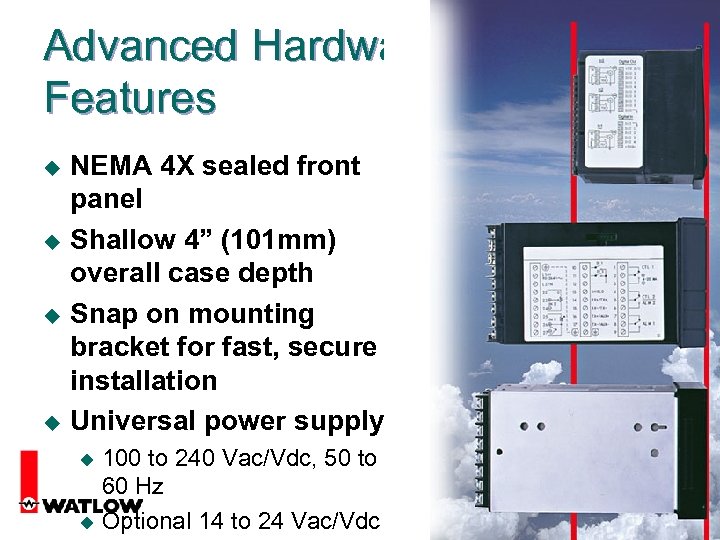

Advanced Hardware Features u u NEMA 4 X sealed front panel Shallow 4” (101 mm) overall case depth Snap on mounting bracket for fast, secure installation Universal power supply 100 to 240 Vac/Vdc, 50 to 60 Hz u Optional 14 to 24 Vac/Vdc u 14

Advanced Hardware Features u u NEMA 4 X sealed front panel Shallow 4” (101 mm) overall case depth Snap on mounting bracket for fast, secure installation Universal power supply 100 to 240 Vac/Vdc, 50 to 60 Hz u Optional 14 to 24 Vac/Vdc u 14

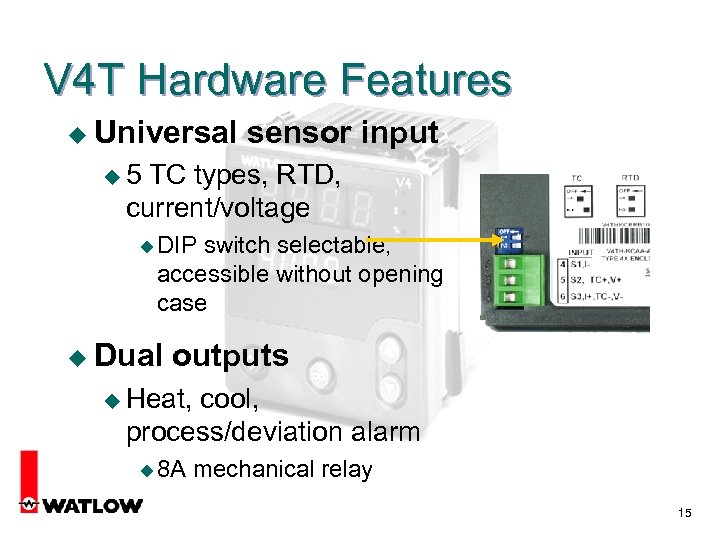

V 4 T Hardware Features u Universal sensor input u 5 TC types, RTD, current/voltage u DIP switch selectable, accessible without opening case u Dual outputs u Heat, cool, process/deviation alarm u 8 A mechanical relay 15

V 4 T Hardware Features u Universal sensor input u 5 TC types, RTD, current/voltage u DIP switch selectable, accessible without opening case u Dual outputs u Heat, cool, process/deviation alarm u 8 A mechanical relay 15

Performance Specifications u Operating u range 0 to +65 C u Calibration u 0. 1% of span, +/- 1°C u Sensor u accuracy update rate 2. 5 Hz 16

Performance Specifications u Operating u range 0 to +65 C u Calibration u 0. 1% of span, +/- 1°C u Sensor u accuracy update rate 2. 5 Hz 16

Agency Approvals u UL, c-UL 508 recognized u European CE conformity EN 50082 -2, Immunity Standard u EN 50081 -2, Emission Standard u EN 61010 -1 Low-Voltage Directive, Safety u u NEMA 4 X front panel seal 17

Agency Approvals u UL, c-UL 508 recognized u European CE conformity EN 50082 -2, Immunity Standard u EN 50081 -2, Emission Standard u EN 61010 -1 Low-Voltage Directive, Safety u u NEMA 4 X front panel seal 17

V 4 T Software Features u Ramp to set point u Reduces u Percent u Avoids stress on process changes power limit stressing system components u Automatic or manual control u Application versatility 18

V 4 T Software Features u Ramp to set point u Reduces u Percent u Avoids stress on process changes power limit stressing system components u Automatic or manual control u Application versatility 18

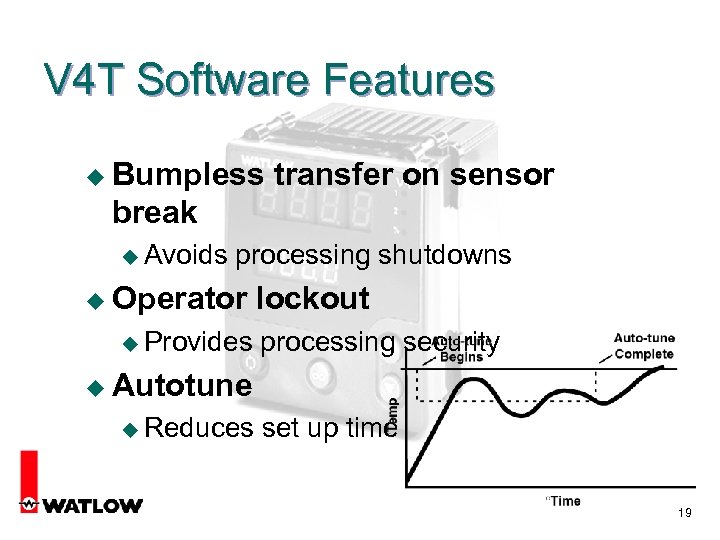

V 4 T Software Features u Bumpless transfer on sensor break u Avoids processing shutdowns u Operator u Provides lockout processing security u Autotune u Reduces set up time 19

V 4 T Software Features u Bumpless transfer on sensor break u Avoids processing shutdowns u Operator u Provides lockout processing security u Autotune u Reduces set up time 19

V 4 T Product Summary u On/Off, P, PID operation u Simple autotune function u Optional output 2 for alarm or heat/cool operation u Automatic or manual operation u Bumpless transfer on sensor break u Ramp to set point u Universal analog input 20

V 4 T Product Summary u On/Off, P, PID operation u Simple autotune function u Optional output 2 for alarm or heat/cool operation u Automatic or manual operation u Bumpless transfer on sensor break u Ramp to set point u Universal analog input 20

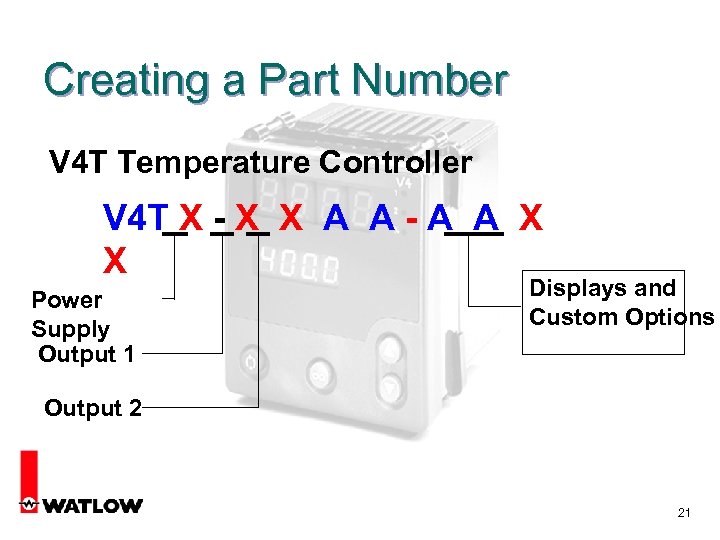

Creating a Part Number V 4 T Temperature Controller V 4 T X - X X A A - A A X X Power Supply Output 1 Displays and Custom Options Output 2 21

Creating a Part Number V 4 T Temperature Controller V 4 T X - X X A A - A A X X Power Supply Output 1 Displays and Custom Options Output 2 21

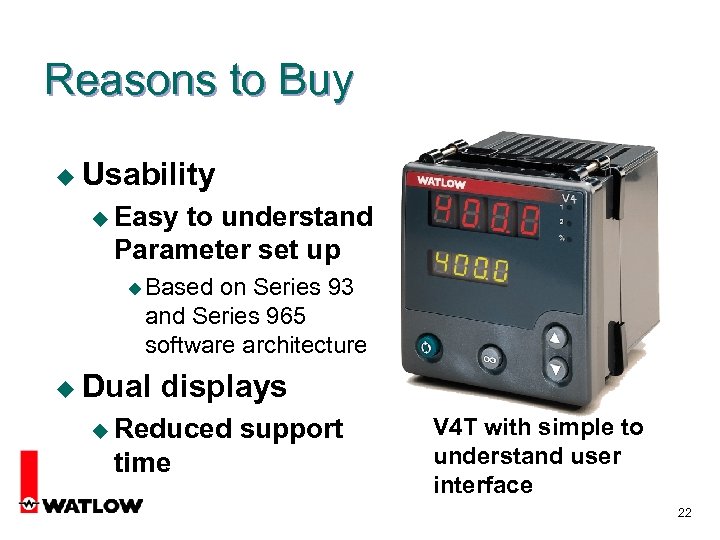

Reasons to Buy u Usability u Easy to understand Parameter set up u Based on Series 93 and Series 965 software architecture u Dual displays u Reduced time support V 4 T with simple to understand user interface 22

Reasons to Buy u Usability u Easy to understand Parameter set up u Based on Series 93 and Series 965 software architecture u Dual displays u Reduced time support V 4 T with simple to understand user interface 22

Reasons to Buy u Performance u Control accuracy u Exhaustive life & qualification testing u Three year warranty u Availability u Ship from stock on most popular configurations 23

Reasons to Buy u Performance u Control accuracy u Exhaustive life & qualification testing u Three year warranty u Availability u Ship from stock on most popular configurations 23

Reasons to Buy u Support u Local sales specialists u Applications engineering support u Field returns department 24

Reasons to Buy u Support u Local sales specialists u Applications engineering support u Field returns department 24

Series V 4 T 1/4 DIN Temperature Controllers 25

Series V 4 T 1/4 DIN Temperature Controllers 25