14_04_2016_KostjukSV.ppt

- Количество слайдов: 21

Sergei Kostjuk Head of the Laboratory of Catalysis of Polymerization Processes Research Institute for Physical Chemical Problems of the Belarusian State University Minsk, Belarus 1

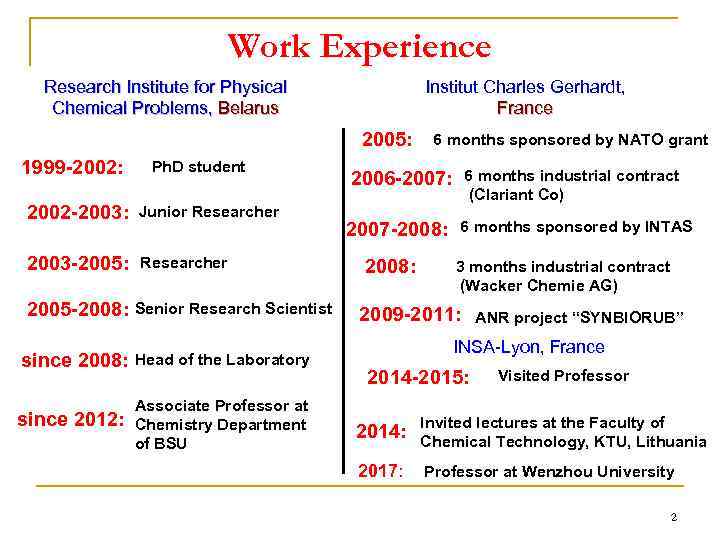

Work Experience Research Institute for Physical Chemical Problems, Belarus Institut Charles Gerhardt, France 2005: 1999 -2002: Ph. D student 2002 -2003: Junior Researcher 2003 -2005: Researcher 2005 -2008: Senior Research Scientist since 2008: Head of the Laboratory since 2012: Associate Professor at Chemistry Department of BSU 6 months sponsored by NATO grant 2006 -2007: 6 months industrial contract (Clariant Co) 2007 -2008: 6 months sponsored by INTAS 2008: 3 months industrial contract (Wacker Chemie AG) 2009 -2011: ANR project “SYNBIORUB” INSA-Lyon, France 2014 -2015: Visited Professor 2014: Invited lectures at the Faculty of Chemical Technology, KTU, Lithuania 2017: Professor at Wenzhou University 2

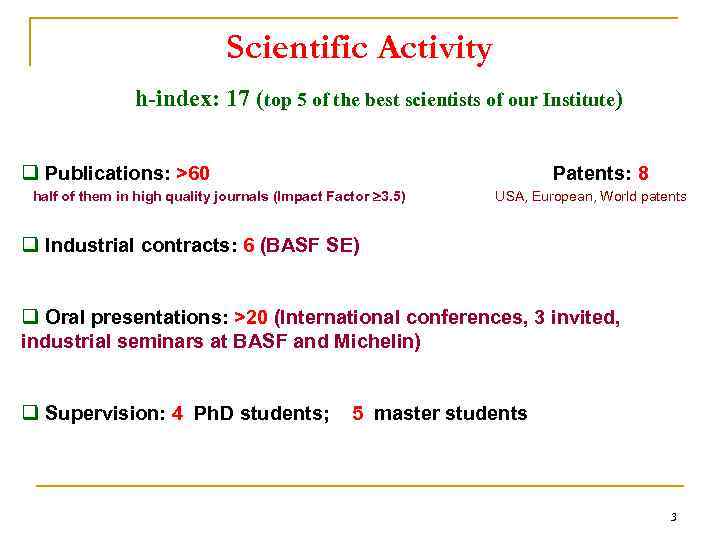

Scientific Activity h-index: 17 (top 5 of the best scientists of our Institute) q Publications: >60 Patents: 8 half of them in high quality journals (Impact Factor 3. 5) USA, European, World patents q Industrial contracts: 6 (BASF SE) q Oral presentations: >20 (International conferences, 3 invited, industrial seminars at BASF and Michelin) q Supervision: 4 Ph. D students; 5 master students 3

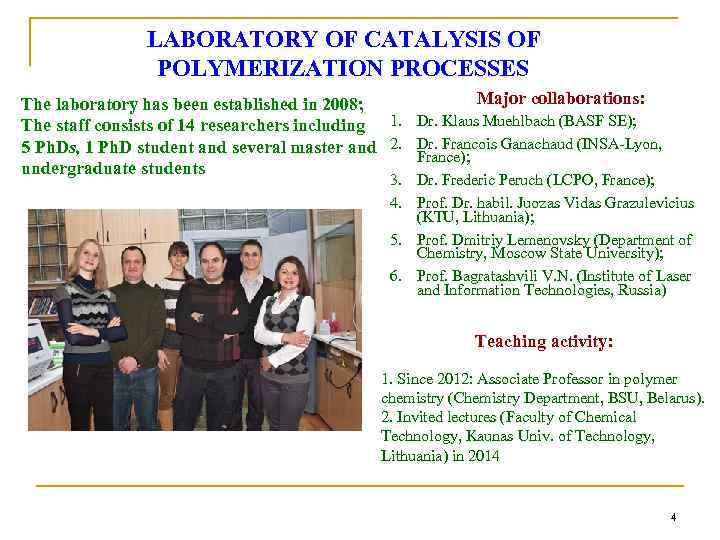

LABORATORY OF CATALYSIS OF POLYMERIZATION PROCESSES Major collaborations: The laboratory has been established in 2008; The staff consists of 14 researchers including 1. Dr. Klaus Muehlbach (BASF SE); 5 Ph. Ds, 1 Ph. D student and several master and 2. Dr. Francois Ganachaud (INSA-Lyon, France); undergraduate students 3. Dr. Frederic Peruch (LCPO, France); 4. Prof. Dr. habil. Juozas Vidas Grazulevicius (KTU, Lithuania); 5. Prof. Dmitriy Lemenovsky (Department of Chemistry, Moscow State University); 6. Prof. Bagratashvili V. N. (Institute of Laser and Information Technologies, Russia) Teaching activity: 1. Since 2012: Associate Professor in polymer chemistry (Chemistry Department, BSU, Belarus). 2. Invited lectures (Faculty of Chemical Technology, Kaunas Univ. of Technology, Lithuania) in 2014 4

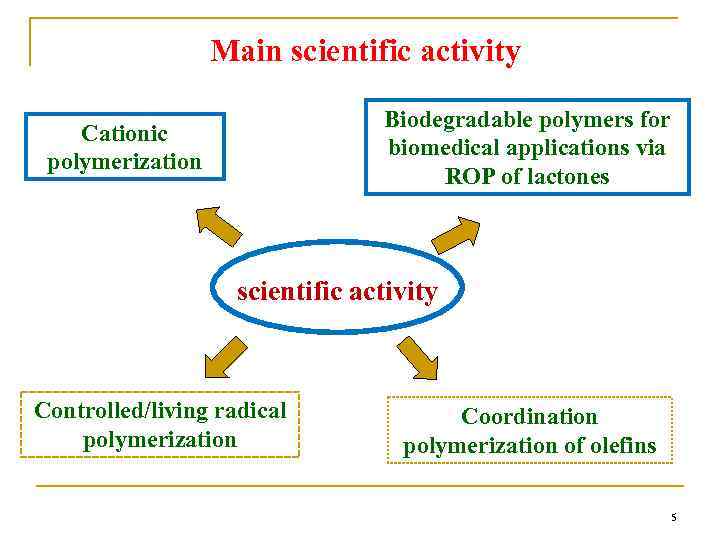

Main scientific activity Biodegradable polymers for biomedical applications via ROP of lactones Cationic polymerization scientific activity Controlled/living radical polymerization Coordination polymerization of olefins 5

SYNTHESIS OF LINEAR AND STAR-SHAPED (CO)POLYMERS FOR PREPARATION OF BIODEGRADABLE SCAFFOLDS FOR BONE REGENERATION S. V. Kostjuk 1, Yu. A. Piskun 1, I. V. Vasilenko 1, T. S. Yupat 1, P. Timashev 2 Research Institute for Physical Chemical Problems of the Belarusian State University, 14 Leningradskaya St. , 220030 Minsk, Belarus, 2 Institute of Photonic Technologies, Research Center of Crystallography and Photonics RAS, 108840, Troitsk, Moscow, Russia 1 BPS 2016, Klaipeda, September 21 -24, 2016 6

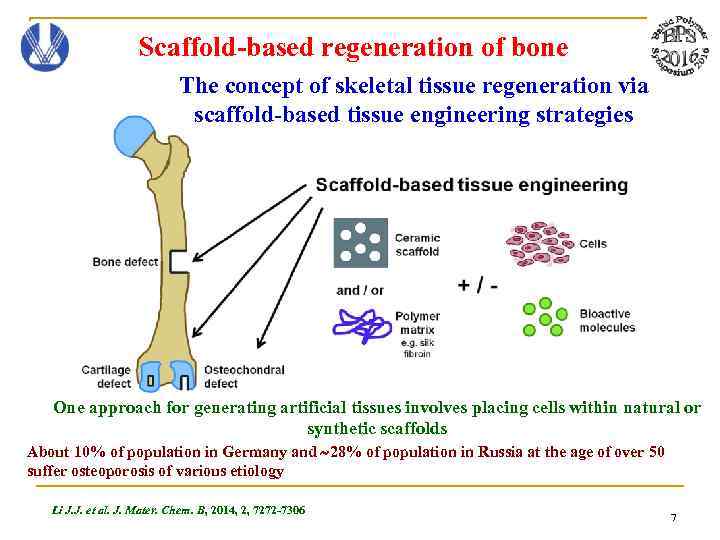

Scaffold-based regeneration of bone The concept of skeletal tissue regeneration via scaffold-based tissue engineering strategies One approach for generating artificial tissues involves placing cells within natural or synthetic scaffolds About 10% of population in Germany and 28% of population in Russia at the age of over 50 suffer osteoporosis of various etiology Li J. J. et al. J. Mater. Chem. B, 2014, 2, 7272 -7306 7

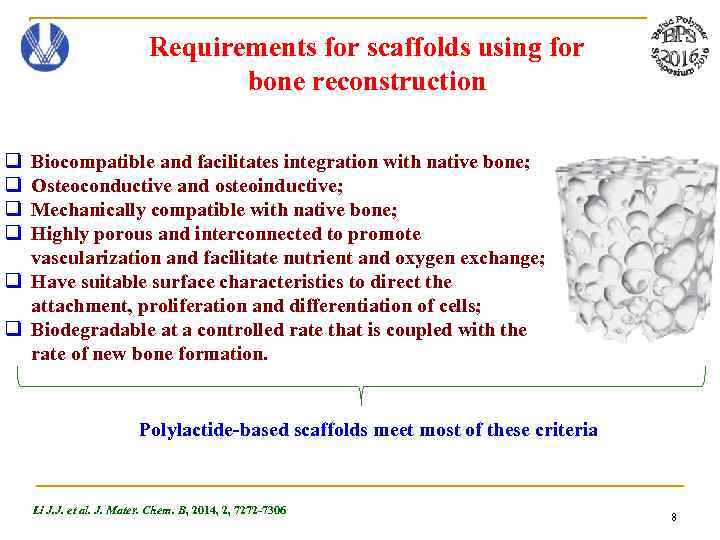

Requirements for scaffolds using for bone reconstruction q q Biocompatible and facilitates integration with native bone; Osteoconductive and osteoinductive; Mechanically compatible with native bone; Highly porous and interconnected to promote vascularization and facilitate nutrient and oxygen exchange; q Have suitable surface characteristics to direct the attachment, proliferation and differentiation of cells; q Biodegradable at a controlled rate that is coupled with the rate of new bone formation. Polylactide-based scaffolds meet most of these criteria Li J. J. et al. J. Mater. Chem. B, 2014, 2, 7272 -7306 8

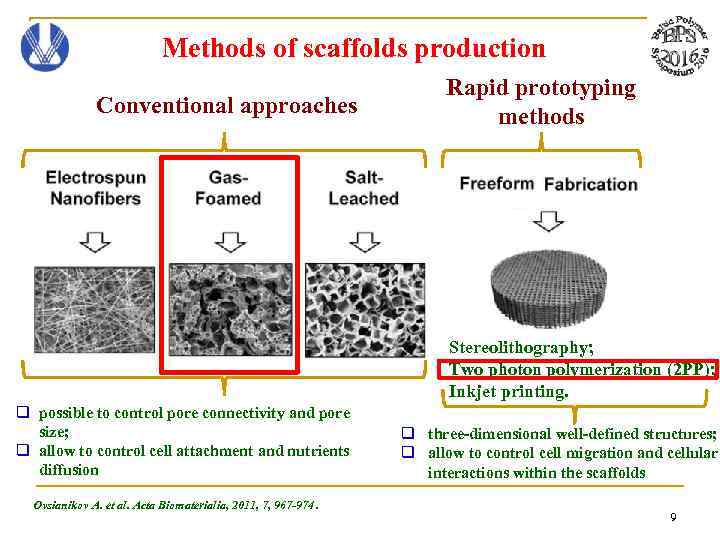

Methods of scaffolds production Conventional approaches Rapid prototyping methods Stereolithography; Two photon polymerization (2 PP); Inkjet printing. q possible to control pore connectivity and pore size; q allow to control cell attachment and nutrients diffusion Ovsianikov A. et al. Acta Biomaterialia, 2011, 7, 967 -974. q three-dimensional well-defined structures; q allow to control cell migration and cellular interactions within the scaffolds 9

Constructing of scaffolds using two photon polymerization (2 PP) technique BPS 2016, Klaipeda, September 21 -24, 2016 10

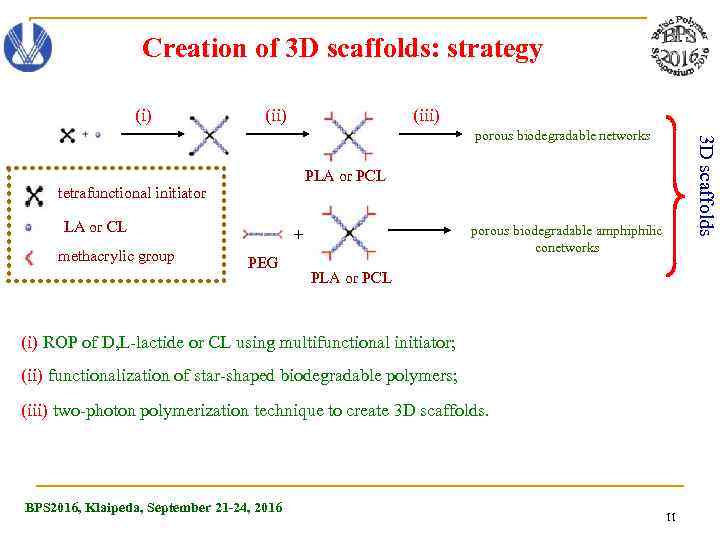

Creation of 3 D scaffolds: strategy (i) (iii) PLA or PCL tetrafunctional initiator LA or CL methacrylic group 3 D scaffolds porous biodegradable networks porous biodegradable amphiphilic conetworks + PEG PLA or PCL (i) ROP of D, L-lactide or CL using multifunctional initiator; (ii) functionalization of star-shaped biodegradable polymers; (iii) two-photon polymerization technique to create 3 D scaffolds. BPS 2016, Klaipeda, September 21 -24, 2016 11

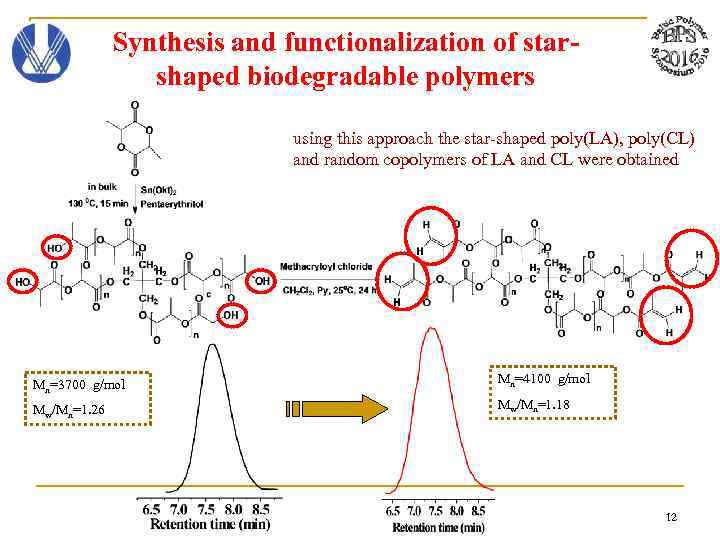

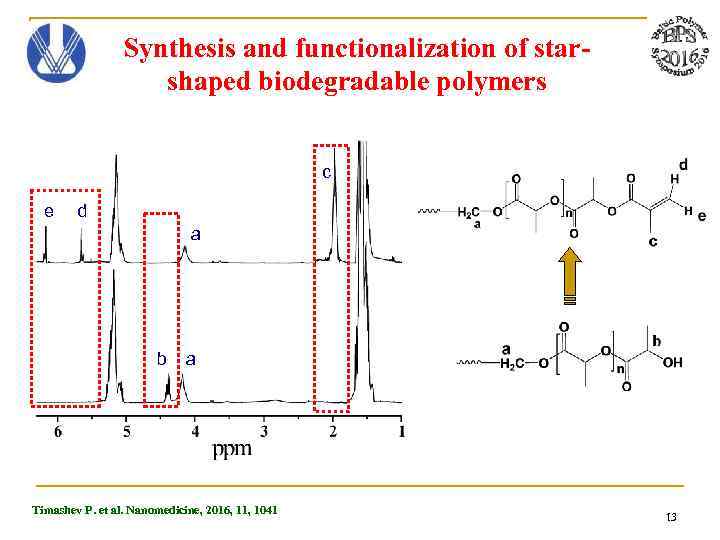

Synthesis and functionalization of starshaped biodegradable polymers using this approach the star-shaped poly(LA), poly(CL) and random copolymers of LA and CL were obtained Mn=3700 g/mol Mn=4100 g/mol Mw/Mn=1. 26 Mw/Mn=1. 18 12

Synthesis and functionalization of starshaped biodegradable polymers c e d a b a Timashev P. et al. Nanomedicine, 2016, 11, 1041 13

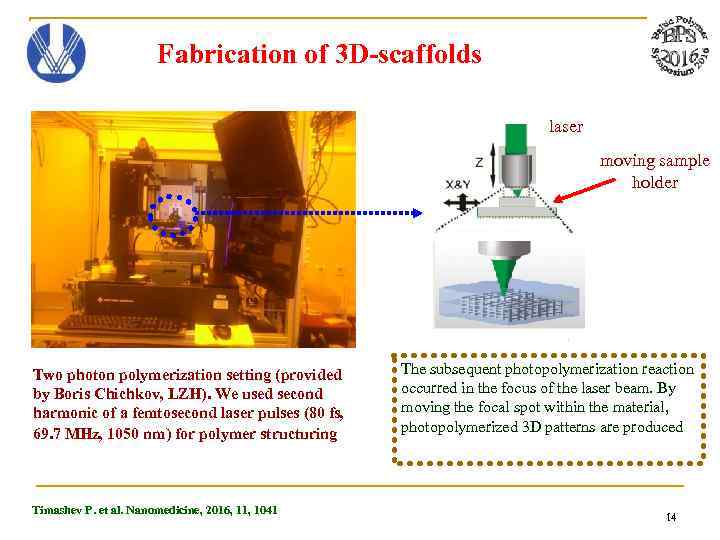

Fabrication of 3 D-scaffolds laser moving sample holder Two photon polymerization setting (provided by Boris Chichkov, LZH). We used second harmonic of a femtosecond laser pulses (80 fs, 69. 7 MHz, 1050 nm) for polymer structuring Timashev P. et al. Nanomedicine, 2016, 11, 1041 The subsequent photopolymerization reaction occurred in the focus of the laser beam. By moving the focal spot within the material, photopolymerized 3 D patterns are produced 14

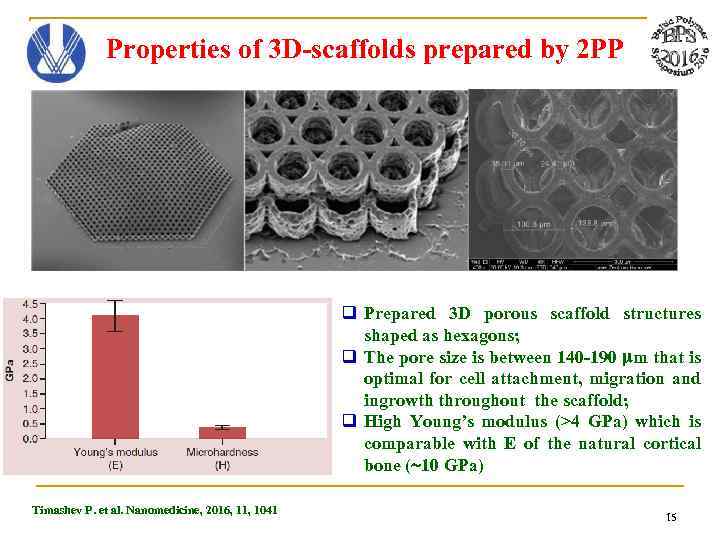

Properties of 3 D-scaffolds prepared by 2 PP q Prepared 3 D porous scaffold structures shaped as hexagons; q The pore size is between 140 -190 m that is optimal for cell attachment, migration and ingrowth throughout the scaffold; q High Young’s modulus (>4 GPa) which is comparable with E of the natural cortical bone ( 10 GPa) Timashev P. et al. Nanomedicine, 2016, 11, 1041 15

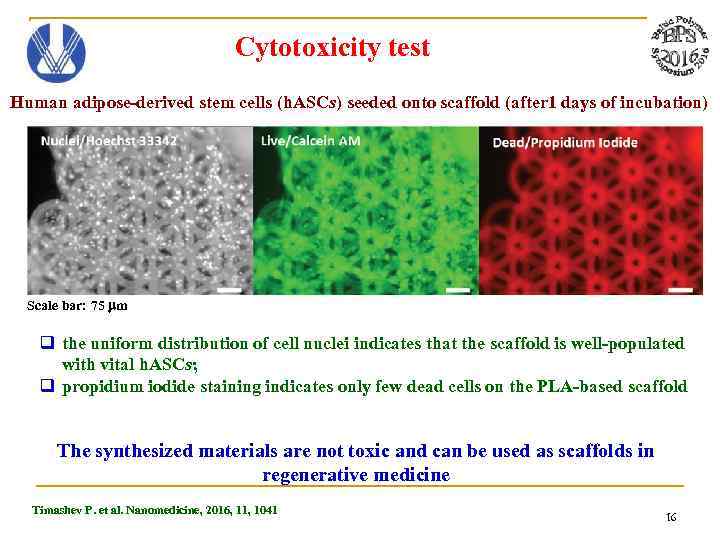

Cytotoxicity test Human adipose-derived stem cells (h. ASCs) seeded onto scaffold (after 1 days of incubation) Scale bar: 75 m q the uniform distribution of cell nuclei indicates that the scaffold is well-populated with vital h. ASCs; q propidium iodide staining indicates only few dead cells on the PLA-based scaffold The synthesized materials are not toxic and can be used as scaffolds in regenerative medicine Timashev P. et al. Nanomedicine, 2016, 11, 1041 16

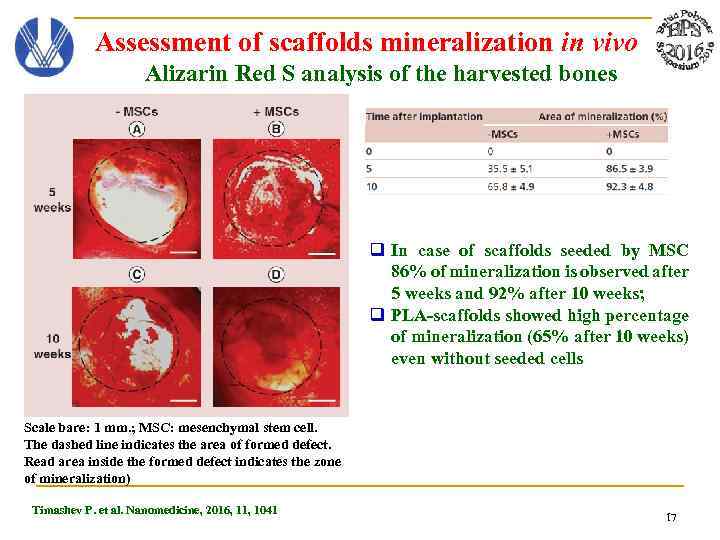

Assessment of scaffolds mineralization in vivo Alizarin Red S analysis of the harvested bones q In case of scaffolds seeded by MSC 86% of mineralization is observed after 5 weeks and 92% after 10 weeks; q PLA-scaffolds showed high percentage of mineralization (65% after 10 weeks) even without seeded cells Scale bare: 1 mm. ; MSC: mesenchymal stem cell. The dashed line indicates the area of formed defect. Read area inside the formed defect indicates the zone of mineralization) Timashev P. et al. Nanomedicine, 2016, 11, 1041 17

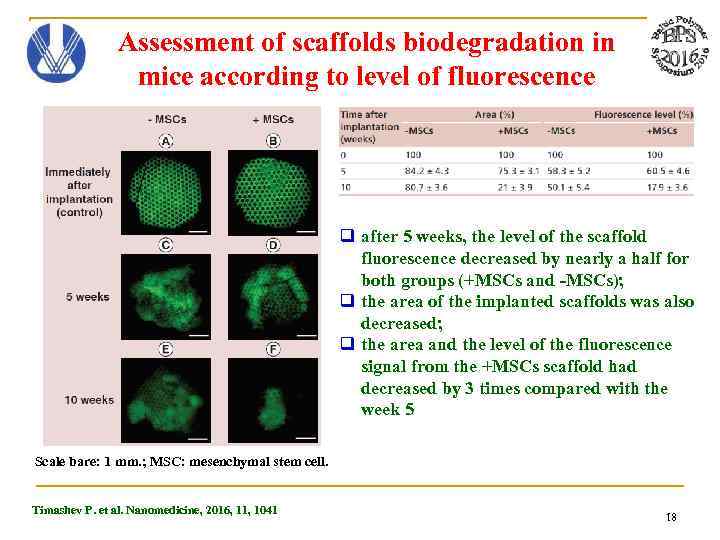

Assessment of scaffolds biodegradation in mice according to level of fluorescence q after 5 weeks, the level of the scaffold fluorescence decreased by nearly a half for both groups (+MSCs and -MSCs); q the area of the implanted scaffolds was also decreased; q the area and the level of the fluorescence signal from the +MSCs scaffold had decreased by 3 times compared with the week 5 Scale bare: 1 mm. ; MSC: mesenchymal stem cell. Timashev P. et al. Nanomedicine, 2016, 11, 1041 18

Conclusion q The use of two photon polymerization technique allows to prepare welldefined scaffolds with pore size optimal for cell attachment and growth; q The materials synthesized showed zero cytotoxicity; q Scaffolds prepared by 2 PP technique are very promising 3 D microstructured implants for bone regeneration applications 19

Acknowledgements Dr. Daria Kuznetsova Nizhny Novgorod State Medical Academy, Nizhny Novgorod, Russia Prof. V. V. Lunin Chemistry Department, Lomonosov Moscow State University, Moscow, Russia Dr. Andrea Deiwick, Prof. Boris Chichkov Laser Zentrum Hannover e. V. , Germany Prof. Viktor Bagratashvili Institute of Photonic Technologies, Research Center of Crystallography and Photonics RAS Belarussian Republican Foundation for Fundamental Research (projects X 15 PM-002, X 15 PM-041) Dr. Yuri Rochev National Centre for Biomedical Engineering Science, College of Science, National University of Ireland, Galway, Ireland 20

Thank you for your attention ! 21

14_04_2016_KostjukSV.ppt