23c2df18e2354ab7a8b099aa60761720.ppt

- Количество слайдов: 12

Sensor Actuator Manager (SAM) Controller Considerations And Specification Identification CPAC May 2005 John Mosher – Honeywell Sensing & Control

Sensor Actuator Manager (SAM) Controller Considerations And Specification Identification CPAC May 2005 John Mosher – Honeywell Sensing & Control

SAM Controller Requirements • Automatically controls and monitors flow stream conditions (P, T, F) through sensors and actuators on the NESSI substrate • Controls a minimum of 2 Foundation Fieldbus Channels • Installs in hazardous locations (Zone 1; Class 1, Div 2) • Local & Remote Display of status • Plant level access to and control of all system data via OPC • Storage and download of configuration data • Easy programming of control functions & operation • Easy Installation • Supports integration of analyzer information (control and measurement data) • Monitors device diagnostic information • Provides diagnostics on impending faults (low flow or pressure, leak detection) • Wireless Connectivity to Local Handheld and Remote Network.

SAM Controller Requirements • Automatically controls and monitors flow stream conditions (P, T, F) through sensors and actuators on the NESSI substrate • Controls a minimum of 2 Foundation Fieldbus Channels • Installs in hazardous locations (Zone 1; Class 1, Div 2) • Local & Remote Display of status • Plant level access to and control of all system data via OPC • Storage and download of configuration data • Easy programming of control functions & operation • Easy Installation • Supports integration of analyzer information (control and measurement data) • Monitors device diagnostic information • Provides diagnostics on impending faults (low flow or pressure, leak detection) • Wireless Connectivity to Local Handheld and Remote Network.

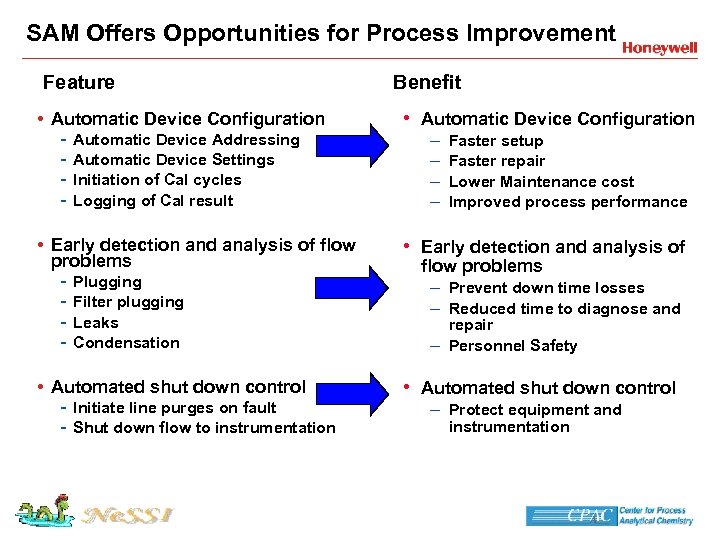

SAM Offers Opportunities for Process Improvement Feature • Automatic Device Configuration - Automatic Device Addressing Automatic Device Settings Initiation of Cal cycles Logging of Cal result • Early detection and analysis of flow problems - Plugging Filter plugging Leaks Condensation • Automated shut down control - Initiate line purges on fault - Shut down flow to instrumentation Benefit • Automatic Device Configuration – – Faster setup Faster repair Lower Maintenance cost Improved process performance • Early detection and analysis of flow problems – Prevent down time losses – Reduced time to diagnose and repair – Personnel Safety • Automated shut down control – Protect equipment and instrumentation

SAM Offers Opportunities for Process Improvement Feature • Automatic Device Configuration - Automatic Device Addressing Automatic Device Settings Initiation of Cal cycles Logging of Cal result • Early detection and analysis of flow problems - Plugging Filter plugging Leaks Condensation • Automated shut down control - Initiate line purges on fault - Shut down flow to instrumentation Benefit • Automatic Device Configuration – – Faster setup Faster repair Lower Maintenance cost Improved process performance • Early detection and analysis of flow problems – Prevent down time losses – Reduced time to diagnose and repair – Personnel Safety • Automated shut down control – Protect equipment and instrumentation

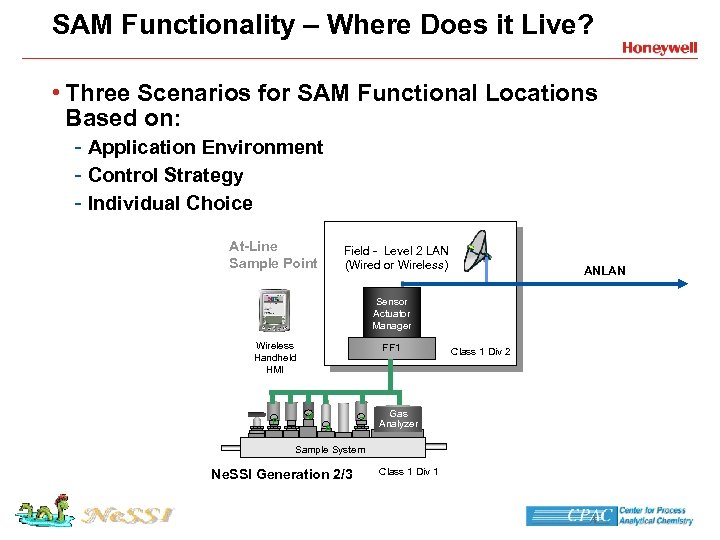

SAM Functionality – Where Does it Live? • Three Scenarios for SAM Functional Locations Based on: - Application Environment - Control Strategy - Individual Choice At-Line Sample Point Field - Level 2 LAN (Wired or Wireless) ANLAN Sensor Actuator Manager Wireless Handheld HMI P FF 1 V A T Gas Analyzer Sample System Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

SAM Functionality – Where Does it Live? • Three Scenarios for SAM Functional Locations Based on: - Application Environment - Control Strategy - Individual Choice At-Line Sample Point Field - Level 2 LAN (Wired or Wireless) ANLAN Sensor Actuator Manager Wireless Handheld HMI P FF 1 V A T Gas Analyzer Sample System Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

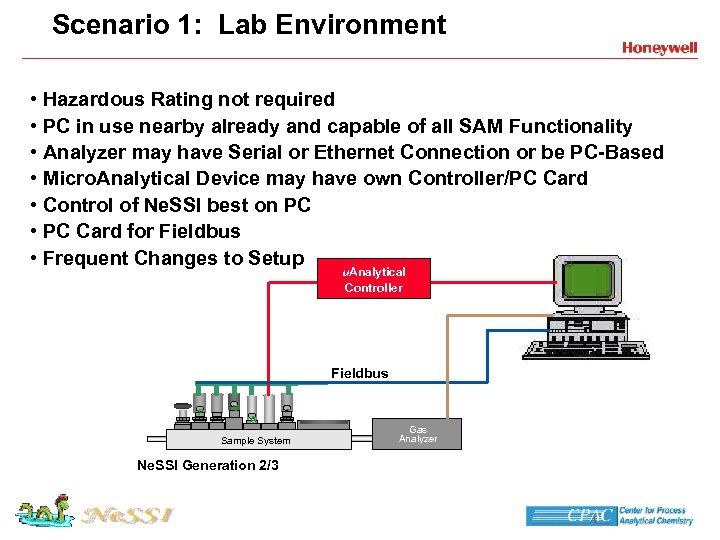

Scenario 1: Lab Environment • Hazardous Rating not required • PC in use nearby already and capable of all SAM Functionality • Analyzer may have Serial or Ethernet Connection or be PC-Based • Micro. Analytical Device may have own Controller/PC Card • Control of Ne. SSI best on PC • PC Card for Fieldbus • Frequent Changes to Setup u. Analytical Controller Fieldbus P V A T Gas Analyzer Sample System Ne. SSI Generation 2/3 Class 1 Div 1

Scenario 1: Lab Environment • Hazardous Rating not required • PC in use nearby already and capable of all SAM Functionality • Analyzer may have Serial or Ethernet Connection or be PC-Based • Micro. Analytical Device may have own Controller/PC Card • Control of Ne. SSI best on PC • PC Card for Fieldbus • Frequent Changes to Setup u. Analytical Controller Fieldbus P V A T Gas Analyzer Sample System Ne. SSI Generation 2/3 Class 1 Div 1

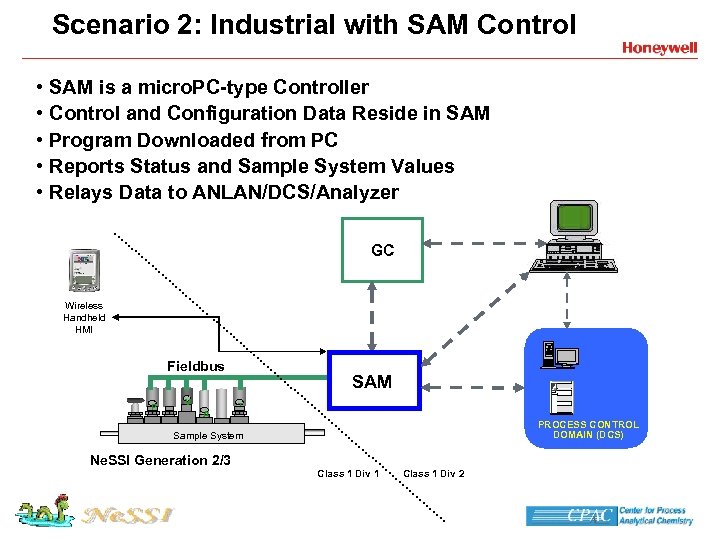

Scenario 2: Industrial with SAM Control • SAM is a micro. PC-type Controller • Control and Configuration Data Reside in SAM • Program Downloaded from PC • Reports Status and Sample System Values • Relays Data to ANLAN/DCS/Analyzer GC Wireless Handheld HMI Fieldbus P V A SAM T PROCESS CONTROL DOMAIN (DCS) Sample System Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

Scenario 2: Industrial with SAM Control • SAM is a micro. PC-type Controller • Control and Configuration Data Reside in SAM • Program Downloaded from PC • Reports Status and Sample System Values • Relays Data to ANLAN/DCS/Analyzer GC Wireless Handheld HMI Fieldbus P V A SAM T PROCESS CONTROL DOMAIN (DCS) Sample System Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

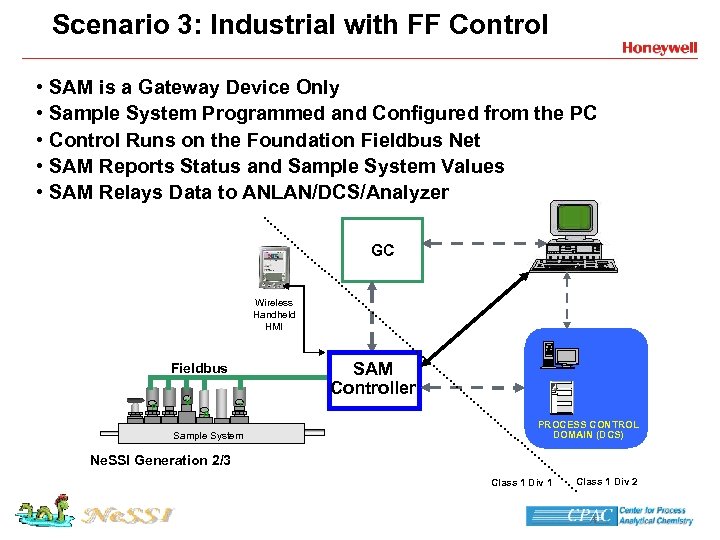

Scenario 3: Industrial with FF Control • SAM is a Gateway Device Only • Sample System Programmed and Configured from the PC • Control Runs on the Foundation Fieldbus Net • SAM Reports Status and Sample System Values • SAM Relays Data to ANLAN/DCS/Analyzer GC Wireless Handheld HMI SAM Controller Fieldbus P V A T Sample System PROCESS CONTROL DOMAIN (DCS) Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

Scenario 3: Industrial with FF Control • SAM is a Gateway Device Only • Sample System Programmed and Configured from the PC • Control Runs on the Foundation Fieldbus Net • SAM Reports Status and Sample System Values • SAM Relays Data to ANLAN/DCS/Analyzer GC Wireless Handheld HMI SAM Controller Fieldbus P V A T Sample System PROCESS CONTROL DOMAIN (DCS) Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

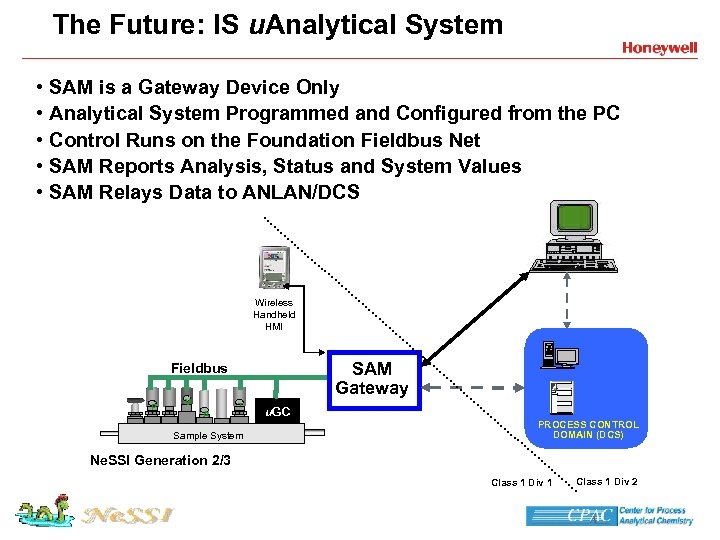

The Future: IS u. Analytical System • SAM is a Gateway Device Only • Analytical System Programmed and Configured from the PC • Control Runs on the Foundation Fieldbus Net • SAM Reports Analysis, Status and System Values • SAM Relays Data to ANLAN/DCS Wireless Handheld HMI SAM Gateway Fieldbus P V A T Sample System u. GC PROCESS CONTROL DOMAIN (DCS) Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

The Future: IS u. Analytical System • SAM is a Gateway Device Only • Analytical System Programmed and Configured from the PC • Control Runs on the Foundation Fieldbus Net • SAM Reports Analysis, Status and System Values • SAM Relays Data to ANLAN/DCS Wireless Handheld HMI SAM Gateway Fieldbus P V A T Sample System u. GC PROCESS CONTROL DOMAIN (DCS) Ne. SSI Generation 2/3 Class 1 Div 1 Class 1 Div 2

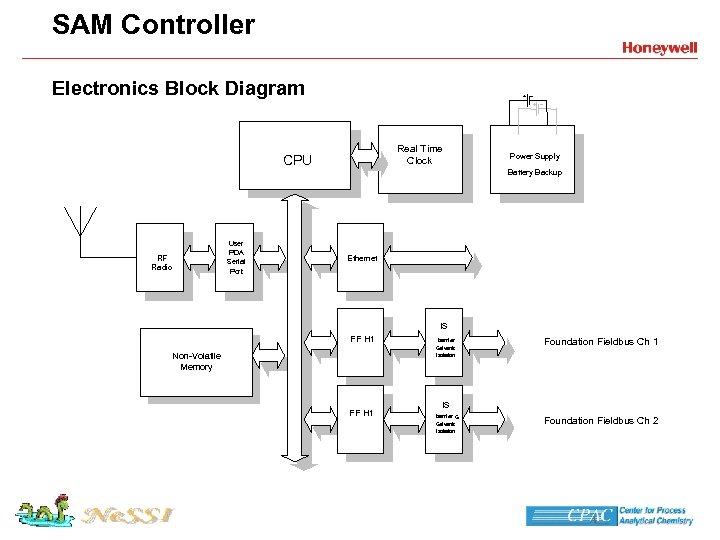

SAM Controller Electronics Block Diagram Real Time Clock CPU RF Radio User PDA Serial Port Power Supply Battery Backup Ethernet IS FF H 1 barrier Galvanic Isolation Non-Volatile Memory FF H 1 Foundation Fieldbus Ch 1 IS barrier G Galvanic Isolation Foundation Fieldbus Ch 2

SAM Controller Electronics Block Diagram Real Time Clock CPU RF Radio User PDA Serial Port Power Supply Battery Backup Ethernet IS FF H 1 barrier Galvanic Isolation Non-Volatile Memory FF H 1 Foundation Fieldbus Ch 1 IS barrier G Galvanic Isolation Foundation Fieldbus Ch 2

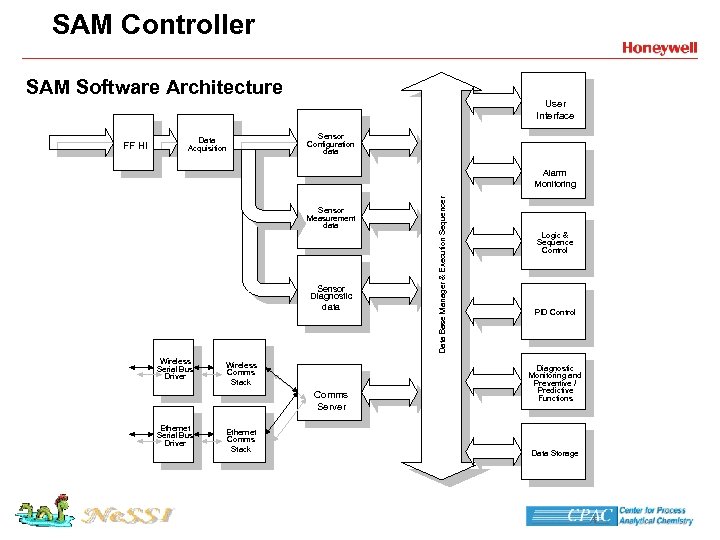

SAM Controller SAM Software Architecture Data Acquisition Sensor Configuration data Alarm Monitoring Sensor Measurement data Sensor Diagnostic data Wireless Serial Bus Driver Wireless Comms Stack Comms Server Ethernet Serial Bus Driver Ethernet Comms Stack Data Base Manager & Execution Sequencer FF HI User Interface Logic & Sequence Control PID Control Diagnostic Monitoring and Preventive / Predictive Functions Data Storage

SAM Controller SAM Software Architecture Data Acquisition Sensor Configuration data Alarm Monitoring Sensor Measurement data Sensor Diagnostic data Wireless Serial Bus Driver Wireless Comms Stack Comms Server Ethernet Serial Bus Driver Ethernet Comms Stack Data Base Manager & Execution Sequencer FF HI User Interface Logic & Sequence Control PID Control Diagnostic Monitoring and Preventive / Predictive Functions Data Storage

The Result: Configuration Easy Setup and Startup Sensors, Valves, Filters Control Real-time Sample System Control PID Loops, Flow Rates, Pressure Connectivity Connect to LAN, Analyzer or Other Higher-Level Systems Confidence! Full Diagnostics and Reporting Capability Ethernet, Serial, Discrete and/or Analog I/O to Analyzers or DCS

The Result: Configuration Easy Setup and Startup Sensors, Valves, Filters Control Real-time Sample System Control PID Loops, Flow Rates, Pressure Connectivity Connect to LAN, Analyzer or Other Higher-Level Systems Confidence! Full Diagnostics and Reporting Capability Ethernet, Serial, Discrete and/or Analog I/O to Analyzers or DCS

www. honeywell. com Thanks! John Mosher, Honeywell Sensing & Control (209) 339 -4004 John. mosher@honeywell. com

www. honeywell. com Thanks! John Mosher, Honeywell Sensing & Control (209) 339 -4004 John. mosher@honeywell. com