19721ef9a2404e6b14023f141832df54.ppt

- Количество слайдов: 27

Seminar 2006 -1 Advanced Man-Machine Interface System in Japanese Nuclear Power Plants 3 February 2006 Center for Advanced Reactor Research Jun-Seok Lee

Seminar 2006 -1 Advanced Man-Machine Interface System in Japanese Nuclear Power Plants 3 February 2006 Center for Advanced Reactor Research Jun-Seok Lee

2 Contents I. Introduction II. Current Status III. Advanced Reactors 1) 2) ABWR APWR IV. MMIS in Advanced Reactors 1) 2) 3) Toshiba : A-PODIATM Hitachi : NUCAMMTM Mitsubishi V. Summary and Conclusion VI. References

2 Contents I. Introduction II. Current Status III. Advanced Reactors 1) 2) ABWR APWR IV. MMIS in Advanced Reactors 1) 2) 3) Toshiba : A-PODIATM Hitachi : NUCAMMTM Mitsubishi V. Summary and Conclusion VI. References

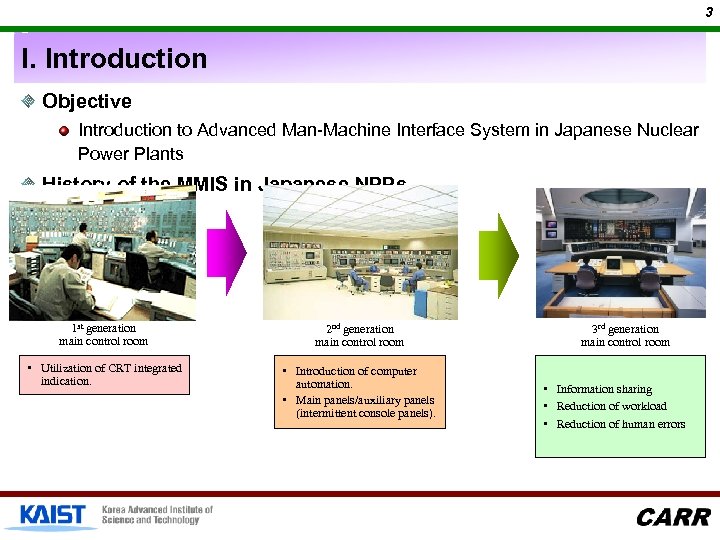

3 I. Introduction Objective Introduction to Advanced Man-Machine Interface System in Japanese Nuclear Power Plants History of the MMIS in Japanese NPPs 1 st generation main control room 2 nd generation main control room • Utilization of CRT integrated indication. • Introduction of computer automation. • Main panels/auxiliary panels (intermittent console panels). 3 rd generation main control room • Information sharing • Reduction of workload • Reduction of human errors

3 I. Introduction Objective Introduction to Advanced Man-Machine Interface System in Japanese Nuclear Power Plants History of the MMIS in Japanese NPPs 1 st generation main control room 2 nd generation main control room • Utilization of CRT integrated indication. • Introduction of computer automation. • Main panels/auxiliary panels (intermittent console panels). 3 rd generation main control room • Information sharing • Reduction of workload • Reduction of human errors

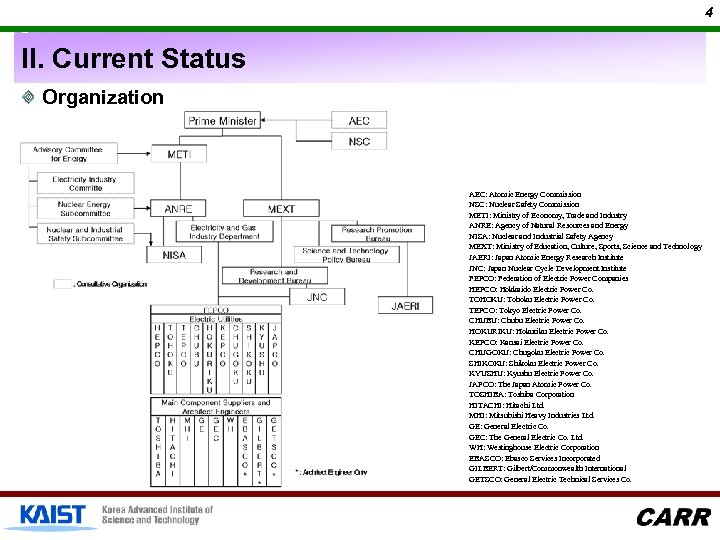

4 II. Current Status Organization AEC: Atomic Energy Commission NSC: Nuclear Safety Commission METI: Ministry of Economy, Trade and Industry ANRE: Agency of Natural Resources and Energy NISA: Nuclear and Industrial Safety Agency MEXT: Ministry of Education, Culture, Sports, Science and Technology JAERI: Japan Atomic Energy Research Institute JNC: Japan Nuclear Cycle Development Institute FEPCO: Federation of Electric Power Companies HEPCO: Hokkaido Electric Power Co. TOHOKU: Tohoku Electric Power Co. TEPCO: Tokyo Electric Power Co. CHUBU: Chubu Electric Power Co. HOKURIKU: Hokuriku Electric Power Co. KEPCO: Kansai Electric Power Co. CHUGOKU: Chugoku Electric Power Co. SHIKOKU: Shikoku Electric Power Co. KYUSHU: Kyushu Electric Power Co. JAPCO: The Japan Atomic Power Co. TOSHIBA: Toshiba Corporation HITACHI: Hitachi Ltd. MHI: Mitsubishi Heavy Industries Ltd. GE: General Electric Co. GEC: The General Electric Co. Ltd. WH: Westinghouse Electric Corporation EBASCO: Ebasco Services Incorporated GILBERT: Gilbert/Commonwealth International GETSCO: General Electric Technical Services Co.

4 II. Current Status Organization AEC: Atomic Energy Commission NSC: Nuclear Safety Commission METI: Ministry of Economy, Trade and Industry ANRE: Agency of Natural Resources and Energy NISA: Nuclear and Industrial Safety Agency MEXT: Ministry of Education, Culture, Sports, Science and Technology JAERI: Japan Atomic Energy Research Institute JNC: Japan Nuclear Cycle Development Institute FEPCO: Federation of Electric Power Companies HEPCO: Hokkaido Electric Power Co. TOHOKU: Tohoku Electric Power Co. TEPCO: Tokyo Electric Power Co. CHUBU: Chubu Electric Power Co. HOKURIKU: Hokuriku Electric Power Co. KEPCO: Kansai Electric Power Co. CHUGOKU: Chugoku Electric Power Co. SHIKOKU: Shikoku Electric Power Co. KYUSHU: Kyushu Electric Power Co. JAPCO: The Japan Atomic Power Co. TOSHIBA: Toshiba Corporation HITACHI: Hitachi Ltd. MHI: Mitsubishi Heavy Industries Ltd. GE: General Electric Co. GEC: The General Electric Co. Ltd. WH: Westinghouse Electric Corporation EBASCO: Ebasco Services Incorporated GILBERT: Gilbert/Commonwealth International GETSCO: General Electric Technical Services Co.

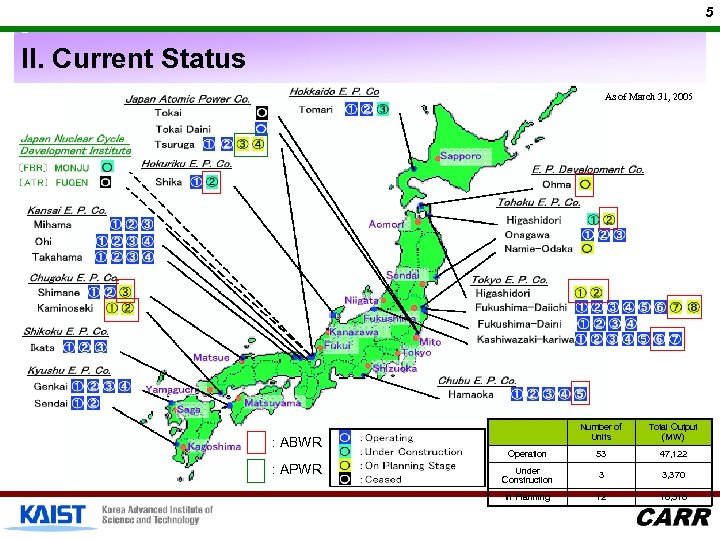

5 II. Current Status As of March 31, 2005 : ABWR : APWR Number of Units Total Output (MW) Operation 53 47, 122 Under Construction 3 3, 370 In Planning 12 16, 318

5 II. Current Status As of March 31, 2005 : ABWR : APWR Number of Units Total Output (MW) Operation 53 47, 122 Under Construction 3 3, 370 In Planning 12 16, 318

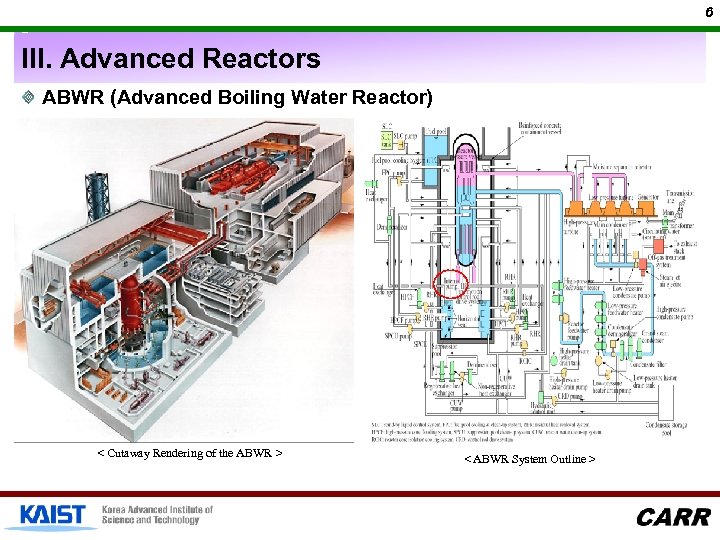

6 III. Advanced Reactors ABWR (Advanced Boiling Water Reactor) < Cutaway Rendering of the ABWR > < ABWR System Outline >

6 III. Advanced Reactors ABWR (Advanced Boiling Water Reactor) < Cutaway Rendering of the ABWR > < ABWR System Outline >

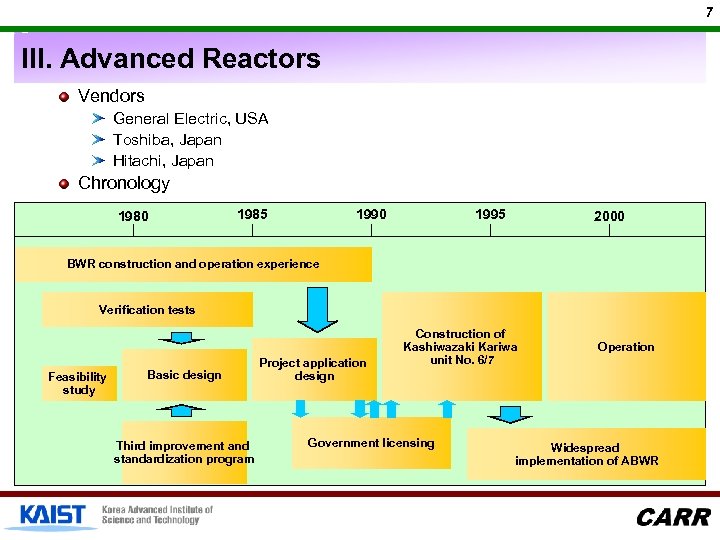

7 III. Advanced Reactors Vendors General Electric, USA Toshiba, Japan Hitachi, Japan Chronology 1980 1985 1990 1995 2000 BWR construction and operation experience Verification tests Feasibility study Basic design Third improvement and standardization program Project application design Construction of Kashiwazaki Kariwa unit No. 6/7 Government licensing Operation Widespread implementation of ABWR

7 III. Advanced Reactors Vendors General Electric, USA Toshiba, Japan Hitachi, Japan Chronology 1980 1985 1990 1995 2000 BWR construction and operation experience Verification tests Feasibility study Basic design Third improvement and standardization program Project application design Construction of Kashiwazaki Kariwa unit No. 6/7 Government licensing Operation Widespread implementation of ABWR

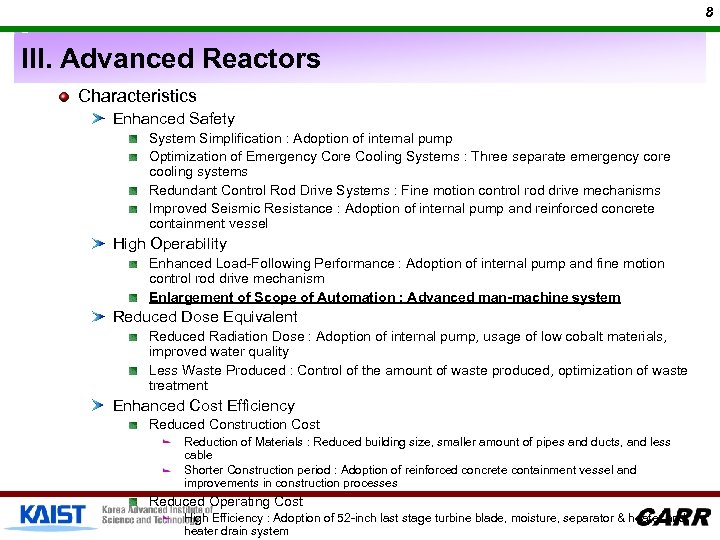

8 III. Advanced Reactors Characteristics Enhanced Safety System Simplification : Adoption of internal pump Optimization of Emergency Core Cooling Systems : Three separate emergency core cooling systems Redundant Control Rod Drive Systems : Fine motion control rod drive mechanisms Improved Seismic Resistance : Adoption of internal pump and reinforced concrete containment vessel High Operability Enhanced Load-Following Performance : Adoption of internal pump and fine motion control rod drive mechanism Enlargement of Scope of Automation : Advanced man-machine system Reduced Dose Equivalent Reduced Radiation Dose : Adoption of internal pump, usage of low cobalt materials, improved water quality Less Waste Produced : Control of the amount of waste produced, optimization of waste treatment Enhanced Cost Efficiency Reduced Construction Cost Reduction of Materials : Reduced building size, smaller amount of pipes and ducts, and less cable Shorter Construction period : Adoption of reinforced concrete containment vessel and improvements in construction processes Reduced Operating Cost High Efficiency : Adoption of 52 -inch last stage turbine blade, moisture, separator & heater and heater drain system

8 III. Advanced Reactors Characteristics Enhanced Safety System Simplification : Adoption of internal pump Optimization of Emergency Core Cooling Systems : Three separate emergency core cooling systems Redundant Control Rod Drive Systems : Fine motion control rod drive mechanisms Improved Seismic Resistance : Adoption of internal pump and reinforced concrete containment vessel High Operability Enhanced Load-Following Performance : Adoption of internal pump and fine motion control rod drive mechanism Enlargement of Scope of Automation : Advanced man-machine system Reduced Dose Equivalent Reduced Radiation Dose : Adoption of internal pump, usage of low cobalt materials, improved water quality Less Waste Produced : Control of the amount of waste produced, optimization of waste treatment Enhanced Cost Efficiency Reduced Construction Cost Reduction of Materials : Reduced building size, smaller amount of pipes and ducts, and less cable Shorter Construction period : Adoption of reinforced concrete containment vessel and improvements in construction processes Reduced Operating Cost High Efficiency : Adoption of 52 -inch last stage turbine blade, moisture, separator & heater and heater drain system

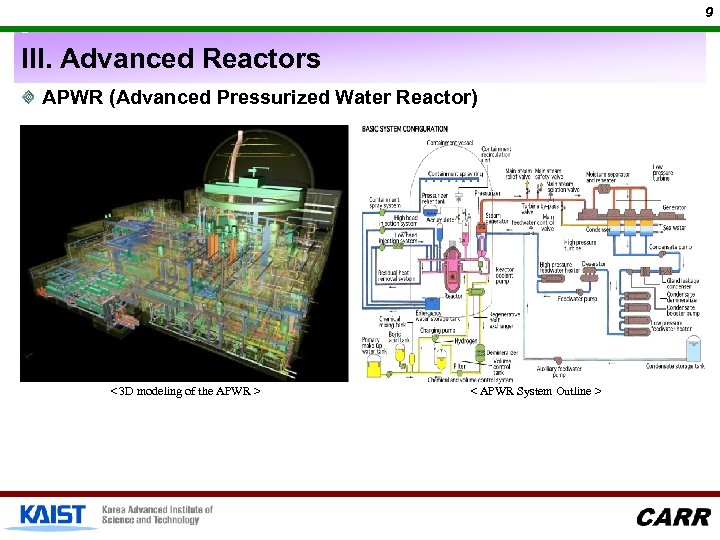

9 III. Advanced Reactors APWR (Advanced Pressurized Water Reactor) < 3 D modeling of the APWR > < APWR System Outline >

9 III. Advanced Reactors APWR (Advanced Pressurized Water Reactor) < 3 D modeling of the APWR > < APWR System Outline >

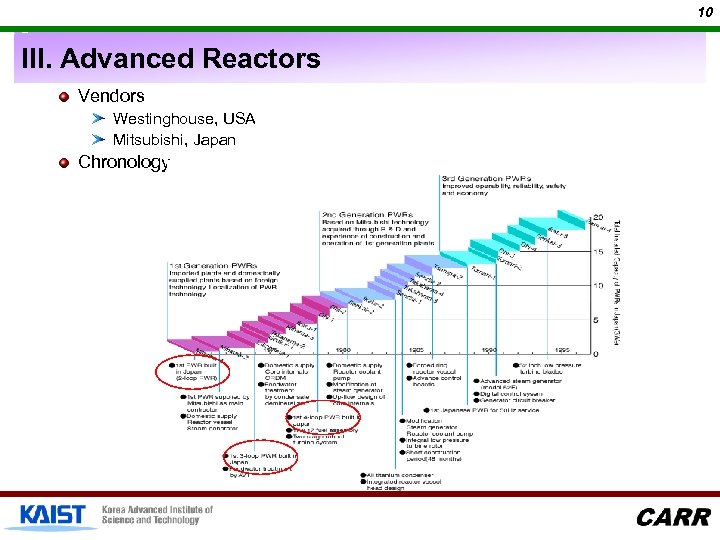

10 III. Advanced Reactors Vendors Westinghouse, USA Mitsubishi, Japan Chronology

10 III. Advanced Reactors Vendors Westinghouse, USA Mitsubishi, Japan Chronology

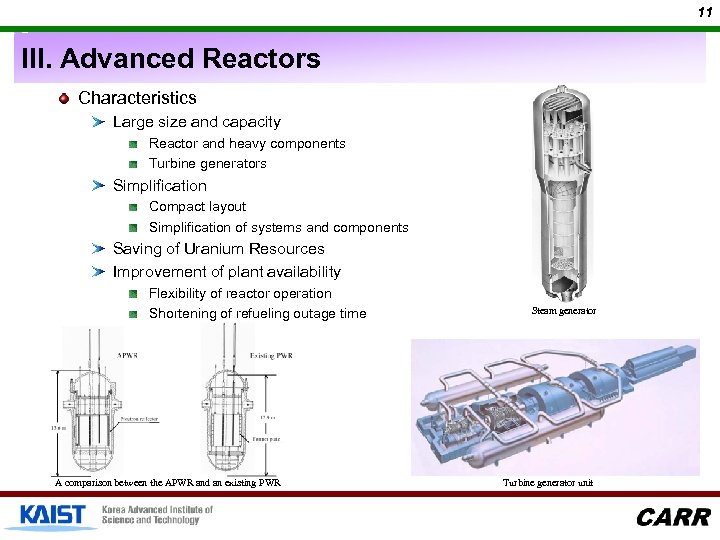

11 III. Advanced Reactors Characteristics Large size and capacity Reactor and heavy components Turbine generators Simplification Compact layout Simplification of systems and components Saving of Uranium Resources Improvement of plant availability Flexibility of reactor operation Shortening of refueling outage time A comparison between the APWR and an existing PWR Steam generator Turbine generator unit

11 III. Advanced Reactors Characteristics Large size and capacity Reactor and heavy components Turbine generators Simplification Compact layout Simplification of systems and components Saving of Uranium Resources Improvement of plant availability Flexibility of reactor operation Shortening of refueling outage time A comparison between the APWR and an existing PWR Steam generator Turbine generator unit

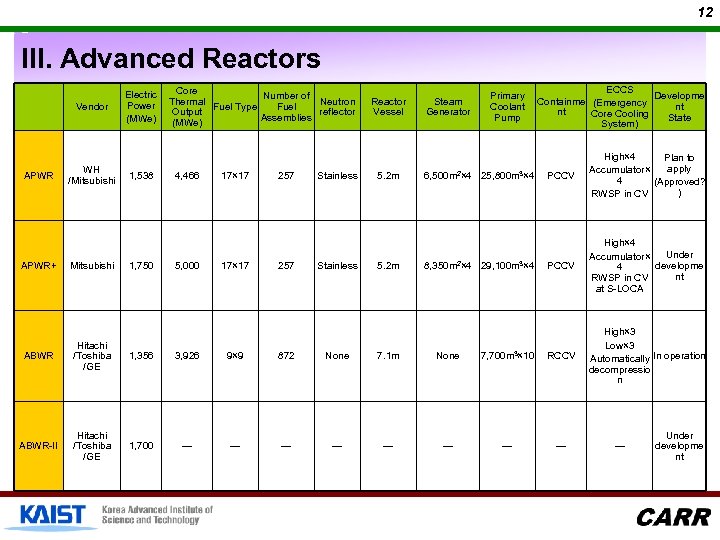

12 III. Advanced Reactors Vendor APWR+ WH /Mitsubishi Electric Power (MWe) 1, 538 1, 750 Core Number of Thermal Neutron Fuel Type Fuel Output reflector Assemblies (MWe) 4, 466 5, 000 17× 17 257 Stainless Reactor Vessel Steam Generator Primary Coolant Pump 5. 2 m 6, 500 m 2× 4 25, 800 m 3× 4 5. 2 m 8, 350 m 2× 4 29, 100 m 3× 4 ECCS Developme Containme (Emergency nt nt Core Cooling State System) PCCV High× 4 Plan to apply Accumulator× 4 (Approved? ) RWSP in CV PCCV High× 4 Under Accumulator× developme 4 nt RWSP in CV at S-LOCA High× 3 Low× 3 Automatically In operation decompressio n ABWR Hitachi /Toshiba /GE 1, 356 3, 926 9× 9 872 None 7. 1 m None 7, 700 m 3× 10 RCCV ABWR-II Hitachi /Toshiba /GE 1, 700 ― ― ― ― ― Under developme nt

12 III. Advanced Reactors Vendor APWR+ WH /Mitsubishi Electric Power (MWe) 1, 538 1, 750 Core Number of Thermal Neutron Fuel Type Fuel Output reflector Assemblies (MWe) 4, 466 5, 000 17× 17 257 Stainless Reactor Vessel Steam Generator Primary Coolant Pump 5. 2 m 6, 500 m 2× 4 25, 800 m 3× 4 5. 2 m 8, 350 m 2× 4 29, 100 m 3× 4 ECCS Developme Containme (Emergency nt nt Core Cooling State System) PCCV High× 4 Plan to apply Accumulator× 4 (Approved? ) RWSP in CV PCCV High× 4 Under Accumulator× developme 4 nt RWSP in CV at S-LOCA High× 3 Low× 3 Automatically In operation decompressio n ABWR Hitachi /Toshiba /GE 1, 356 3, 926 9× 9 872 None 7. 1 m None 7, 700 m 3× 10 RCCV ABWR-II Hitachi /Toshiba /GE 1, 700 ― ― ― ― ― Under developme nt

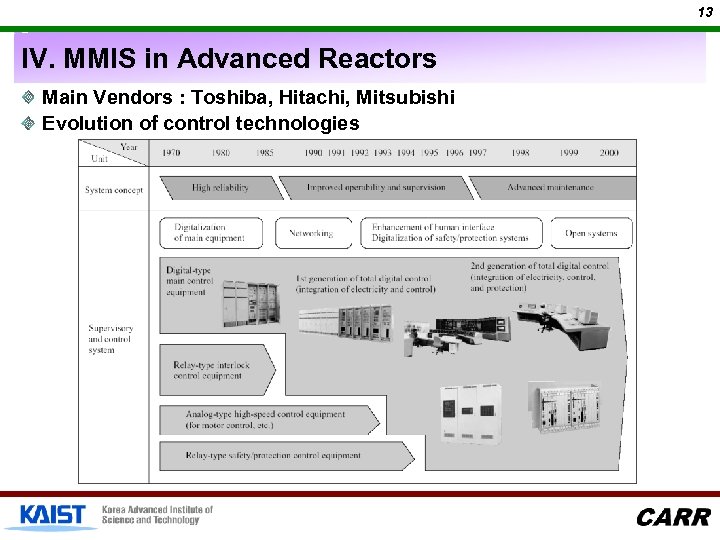

13 IV. MMIS in Advanced Reactors Main Vendors : Toshiba, Hitachi, Mitsubishi Evolution of control technologies

13 IV. MMIS in Advanced Reactors Main Vendors : Toshiba, Hitachi, Mitsubishi Evolution of control technologies

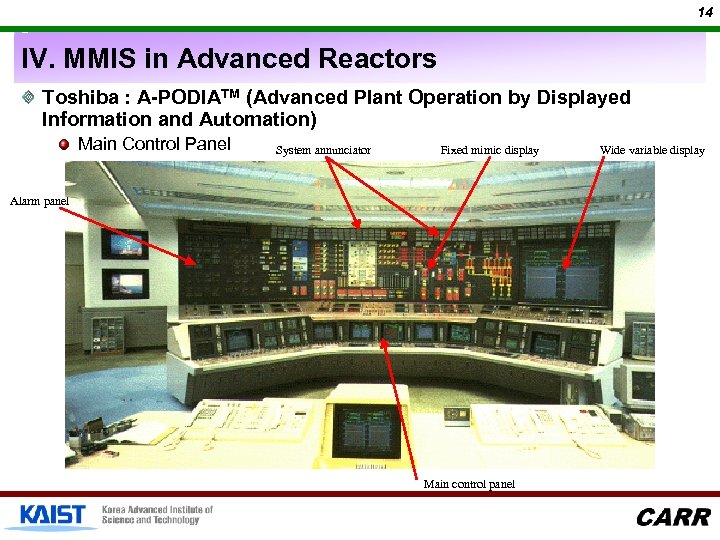

14 IV. MMIS in Advanced Reactors Toshiba : A-PODIATM (Advanced Plant Operation by Displayed Information and Automation) Main Control Panel System annunciator Fixed mimic display Alarm panel Main control panel Wide variable display

14 IV. MMIS in Advanced Reactors Toshiba : A-PODIATM (Advanced Plant Operation by Displayed Information and Automation) Main Control Panel System annunciator Fixed mimic display Alarm panel Main control panel Wide variable display

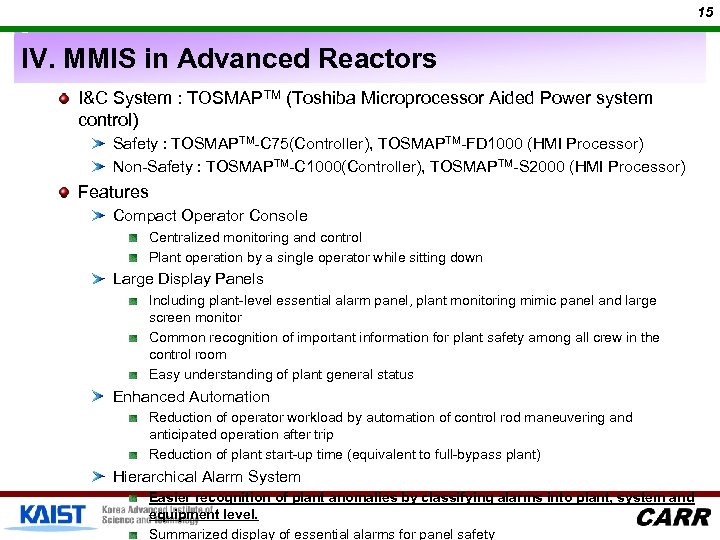

15 IV. MMIS in Advanced Reactors I&C System : TOSMAPTM (Toshiba Microprocessor Aided Power system control) Safety : TOSMAPTM-C 75(Controller), TOSMAPTM-FD 1000 (HMI Processor) Non-Safety : TOSMAPTM-C 1000(Controller), TOSMAPTM-S 2000 (HMI Processor) Features Compact Operator Console Centralized monitoring and control Plant operation by a single operator while sitting down Large Display Panels Including plant-level essential alarm panel, plant monitoring mimic panel and large screen monitor Common recognition of important information for plant safety among all crew in the control room Easy understanding of plant general status Enhanced Automation Reduction of operator workload by automation of control rod maneuvering and anticipated operation after trip Reduction of plant start-up time (equivalent to full-bypass plant) Hierarchical Alarm System Easier recognition of plant anomalies by classifying alarms into plant, system and equipment level. Summarized display of essential alarms for panel safety

15 IV. MMIS in Advanced Reactors I&C System : TOSMAPTM (Toshiba Microprocessor Aided Power system control) Safety : TOSMAPTM-C 75(Controller), TOSMAPTM-FD 1000 (HMI Processor) Non-Safety : TOSMAPTM-C 1000(Controller), TOSMAPTM-S 2000 (HMI Processor) Features Compact Operator Console Centralized monitoring and control Plant operation by a single operator while sitting down Large Display Panels Including plant-level essential alarm panel, plant monitoring mimic panel and large screen monitor Common recognition of important information for plant safety among all crew in the control room Easy understanding of plant general status Enhanced Automation Reduction of operator workload by automation of control rod maneuvering and anticipated operation after trip Reduction of plant start-up time (equivalent to full-bypass plant) Hierarchical Alarm System Easier recognition of plant anomalies by classifying alarms into plant, system and equipment level. Summarized display of essential alarms for panel safety

16 IV. MMIS in Advanced Reactors Advanced MMI Device Touch sensitive color flat LCD driven by system level digital controller (Safety systems, Reactor control systems, etc. ) High definition 110° screen monitor Touch sensitive and high resolution 20° CRTs Optical disk to replace traditional recorders Benefits Providing the best task allocation between man and machine Providing comfortable operation environment Reducing plant start-up time

16 IV. MMIS in Advanced Reactors Advanced MMI Device Touch sensitive color flat LCD driven by system level digital controller (Safety systems, Reactor control systems, etc. ) High definition 110° screen monitor Touch sensitive and high resolution 20° CRTs Optical disk to replace traditional recorders Benefits Providing the best task allocation between man and machine Providing comfortable operation environment Reducing plant start-up time

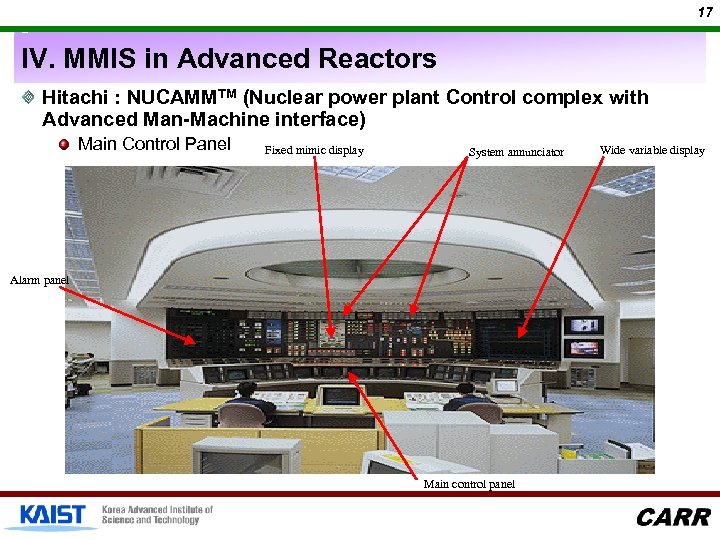

17 IV. MMIS in Advanced Reactors Hitachi : NUCAMMTM (Nuclear power plant Control complex with Advanced Man-Machine interface) Main Control Panel Fixed mimic display System annunciator Alarm panel Main control panel Wide variable display

17 IV. MMIS in Advanced Reactors Hitachi : NUCAMMTM (Nuclear power plant Control complex with Advanced Man-Machine interface) Main Control Panel Fixed mimic display System annunciator Alarm panel Main control panel Wide variable display

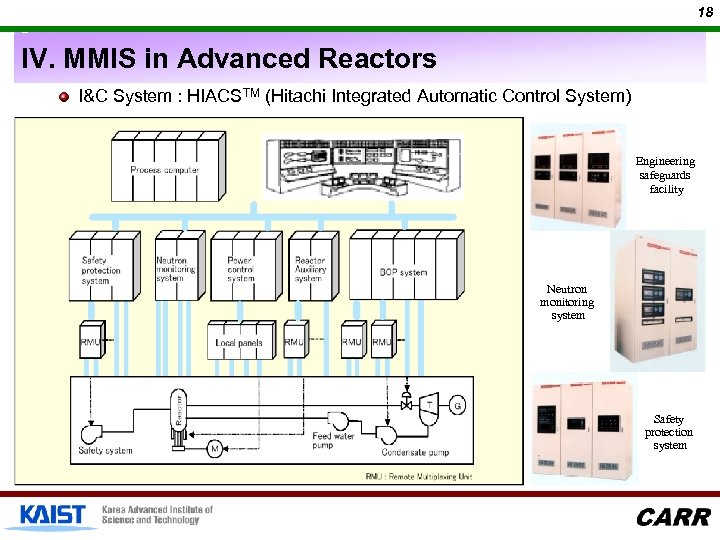

18 IV. MMIS in Advanced Reactors I&C System : HIACSTM (Hitachi Integrated Automatic Control System) Engineering safeguards facility Neutron monitoring system Safety protection system

18 IV. MMIS in Advanced Reactors I&C System : HIACSTM (Hitachi Integrated Automatic Control System) Engineering safeguards facility Neutron monitoring system Safety protection system

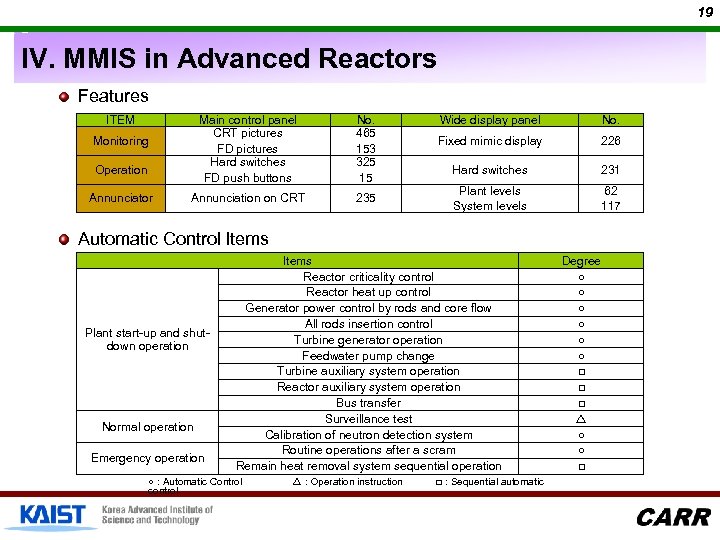

19 IV. MMIS in Advanced Reactors Features ITEM Main control panel CRT pictures FD pictures Hard switches FD push buttons No. 465 153 325 15 Annunciation on CRT 235 Monitoring Operation Annunciator Wide display panel No. Fixed mimic display 226 Hard switches 231 Plant levels System levels 62 117 Automatic Control Items Plant start-up and shutdown operation Normal operation Emergency operation Items Reactor criticality control Reactor heat up control Generator power control by rods and core flow All rods insertion control Turbine generator operation Feedwater pump change Turbine auxiliary system operation Reactor auxiliary system operation Bus transfer Surveillance test Calibration of neutron detection system Routine operations after a scram Remain heat removal system sequential operation ○ : Automatic Control control △ : Operation instruction □ : Sequential automatic Degree ○ ○ ○ □ □ □ △ ○ ○ □

19 IV. MMIS in Advanced Reactors Features ITEM Main control panel CRT pictures FD pictures Hard switches FD push buttons No. 465 153 325 15 Annunciation on CRT 235 Monitoring Operation Annunciator Wide display panel No. Fixed mimic display 226 Hard switches 231 Plant levels System levels 62 117 Automatic Control Items Plant start-up and shutdown operation Normal operation Emergency operation Items Reactor criticality control Reactor heat up control Generator power control by rods and core flow All rods insertion control Turbine generator operation Feedwater pump change Turbine auxiliary system operation Reactor auxiliary system operation Bus transfer Surveillance test Calibration of neutron detection system Routine operations after a scram Remain heat removal system sequential operation ○ : Automatic Control control △ : Operation instruction □ : Sequential automatic Degree ○ ○ ○ □ □ □ △ ○ ○ □

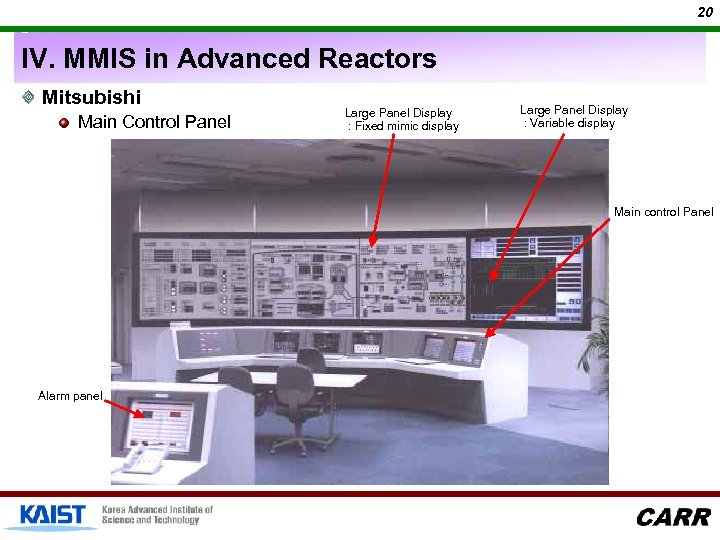

20 IV. MMIS in Advanced Reactors Mitsubishi Main Control Panel Large Panel Display : Fixed mimic display Large Panel Display : Variable display Main control Panel Alarm panel

20 IV. MMIS in Advanced Reactors Mitsubishi Main Control Panel Large Panel Display : Fixed mimic display Large Panel Display : Variable display Main control Panel Alarm panel

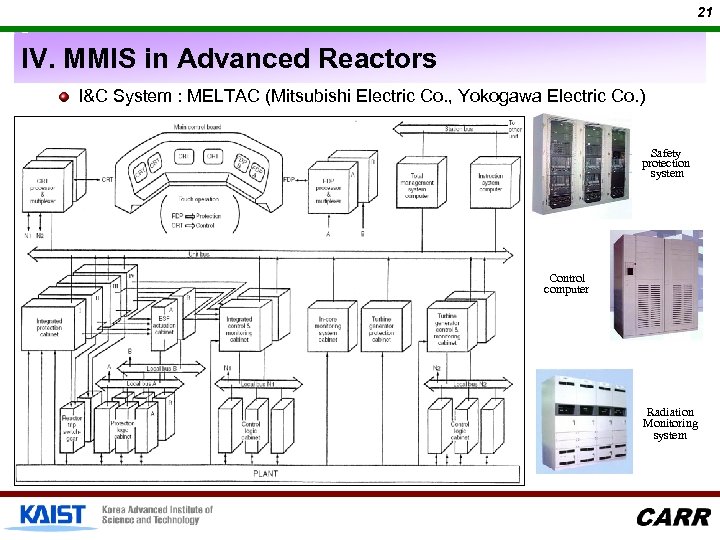

21 IV. MMIS in Advanced Reactors I&C System : MELTAC (Mitsubishi Electric Co. , Yokogawa Electric Co. ) Safety protection system Control computer Radiation Monitoring system

21 IV. MMIS in Advanced Reactors I&C System : MELTAC (Mitsubishi Electric Co. , Yokogawa Electric Co. ) Safety protection system Control computer Radiation Monitoring system

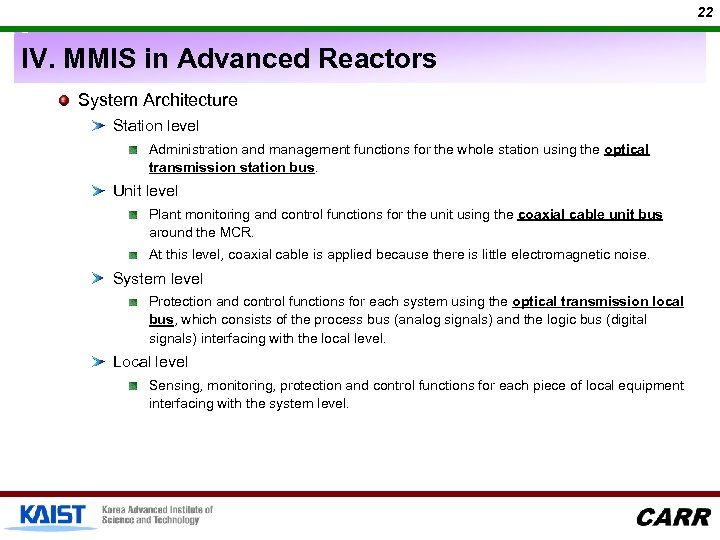

22 IV. MMIS in Advanced Reactors System Architecture Station level Administration and management functions for the whole station using the optical transmission station bus. Unit level Plant monitoring and control functions for the unit using the coaxial cable unit bus around the MCR. At this level, coaxial cable is applied because there is little electromagnetic noise. System level Protection and control functions for each system using the optical transmission local bus, which consists of the process bus (analog signals) and the logic bus (digital signals) interfacing with the local level. Local level Sensing, monitoring, protection and control functions for each piece of local equipment interfacing with the system level.

22 IV. MMIS in Advanced Reactors System Architecture Station level Administration and management functions for the whole station using the optical transmission station bus. Unit level Plant monitoring and control functions for the unit using the coaxial cable unit bus around the MCR. At this level, coaxial cable is applied because there is little electromagnetic noise. System level Protection and control functions for each system using the optical transmission local bus, which consists of the process bus (analog signals) and the logic bus (digital signals) interfacing with the local level. Local level Sensing, monitoring, protection and control functions for each piece of local equipment interfacing with the system level.

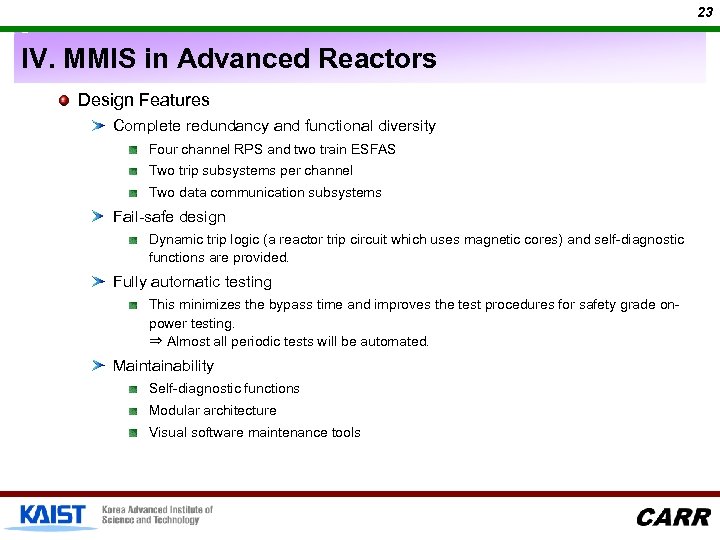

23 IV. MMIS in Advanced Reactors Design Features Complete redundancy and functional diversity Four channel RPS and two train ESFAS Two trip subsystems per channel Two data communication subsystems Fail-safe design Dynamic trip logic (a reactor trip circuit which uses magnetic cores) and self-diagnostic functions are provided. Fully automatic testing This minimizes the bypass time and improves the test procedures for safety grade onpower testing. ⇒ Almost all periodic tests will be automated. Maintainability Self-diagnostic functions Modular architecture Visual software maintenance tools

23 IV. MMIS in Advanced Reactors Design Features Complete redundancy and functional diversity Four channel RPS and two train ESFAS Two trip subsystems per channel Two data communication subsystems Fail-safe design Dynamic trip logic (a reactor trip circuit which uses magnetic cores) and self-diagnostic functions are provided. Fully automatic testing This minimizes the bypass time and improves the test procedures for safety grade onpower testing. ⇒ Almost all periodic tests will be automated. Maintainability Self-diagnostic functions Modular architecture Visual software maintenance tools

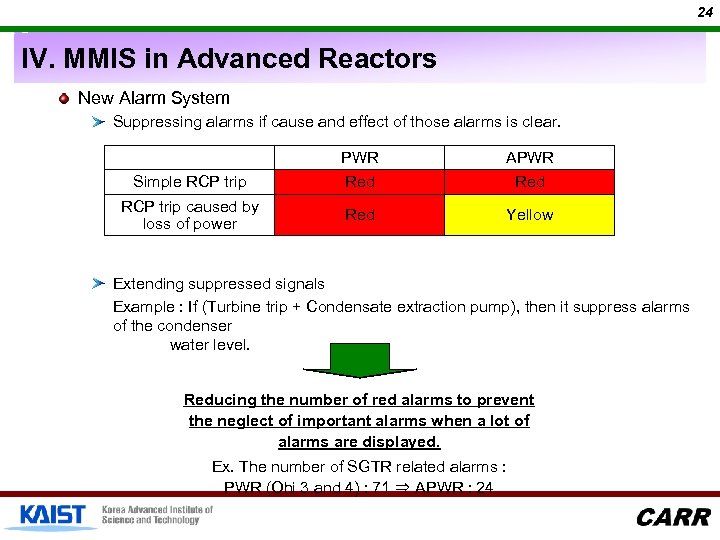

24 IV. MMIS in Advanced Reactors New Alarm System Suppressing alarms if cause and effect of those alarms is clear. PWR APWR Simple RCP trip Red RCP trip caused by loss of power Red Yellow Extending suppressed signals Example : If (Turbine trip + Condensate extraction pump), then it suppress alarms of the condenser water level. Reducing the number of red alarms to prevent the neglect of important alarms when a lot of alarms are displayed. Ex. The number of SGTR related alarms : PWR (Ohi 3 and 4) : 71 ⇒ APWR : 24

24 IV. MMIS in Advanced Reactors New Alarm System Suppressing alarms if cause and effect of those alarms is clear. PWR APWR Simple RCP trip Red RCP trip caused by loss of power Red Yellow Extending suppressed signals Example : If (Turbine trip + Condensate extraction pump), then it suppress alarms of the condenser water level. Reducing the number of red alarms to prevent the neglect of important alarms when a lot of alarms are displayed. Ex. The number of SGTR related alarms : PWR (Ohi 3 and 4) : 71 ⇒ APWR : 24

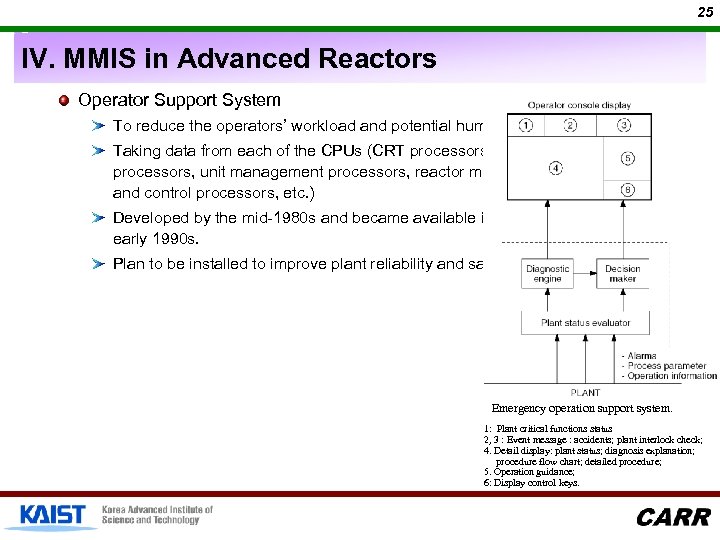

25 IV. MMIS in Advanced Reactors Operator Support System To reduce the operators’ workload and potential human errors Taking data from each of the CPUs (CRT processors, LDP processors, unit management processors, reactor monitoring and control processors, etc. ) Developed by the mid-1980 s and became available in the early 1990 s. Plan to be installed to improve plant reliability and safety Emergency operation support system. 1: Plant critical functions status 2, 3 : Event message : accidents; plant interlock check; 4. Detail display: plant status; diagnosis explanation; procedure flow chart; detailed procedure; 5. Operation guidance; 6: Display control keys.

25 IV. MMIS in Advanced Reactors Operator Support System To reduce the operators’ workload and potential human errors Taking data from each of the CPUs (CRT processors, LDP processors, unit management processors, reactor monitoring and control processors, etc. ) Developed by the mid-1980 s and became available in the early 1990 s. Plan to be installed to improve plant reliability and safety Emergency operation support system. 1: Plant critical functions status 2, 3 : Event message : accidents; plant interlock check; 4. Detail display: plant status; diagnosis explanation; procedure flow chart; detailed procedure; 5. Operation guidance; 6: Display control keys.

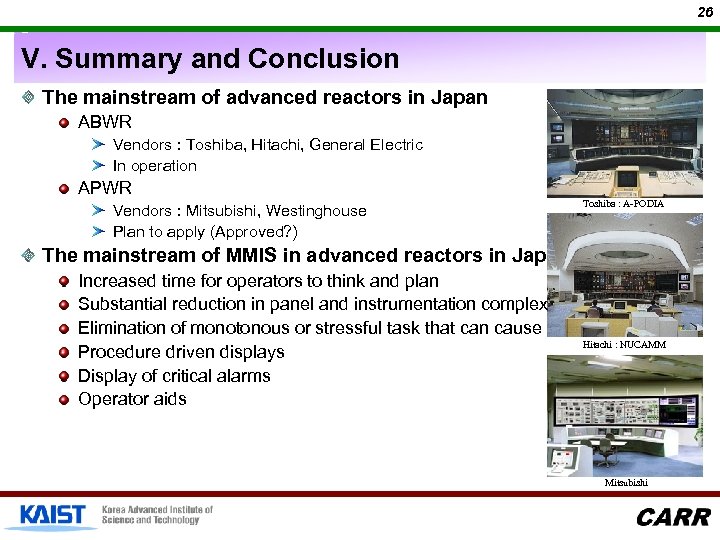

26 V. Summary and Conclusion The mainstream of advanced reactors in Japan ABWR Vendors : Toshiba, Hitachi, General Electric In operation APWR Vendors : Mitsubishi, Westinghouse Plan to apply (Approved? ) Toshiba : A-PODIA The mainstream of MMIS in advanced reactors in Japan Increased time for operators to think and plan Substantial reduction in panel and instrumentation complexity Elimination of monotonous or stressful task that can cause errors Hitachi : NUCAMM Procedure driven displays Display of critical alarms Operator aids Mitsubishi

26 V. Summary and Conclusion The mainstream of advanced reactors in Japan ABWR Vendors : Toshiba, Hitachi, General Electric In operation APWR Vendors : Mitsubishi, Westinghouse Plan to apply (Approved? ) Toshiba : A-PODIA The mainstream of MMIS in advanced reactors in Japan Increased time for operators to think and plan Substantial reduction in panel and instrumentation complexity Elimination of monotonous or stressful task that can cause errors Hitachi : NUCAMM Procedure driven displays Display of critical alarms Operator aids Mitsubishi

27 VI. References 1. Fumio Mizuki et al. , “Control and Instrumentation for ABWR Plant”, Hitachi Review Vol. 47, No. 5, pp. 164 -167, 1998. 2. Takehiko Seiji, “Advanced Supervisory and Control Systems for Nuclear Power Plants”, Hitachi Review Vol. 50, No. 3, pp. 79 -83, 2001. 3. Toshiharu Yamamori et al. , “Recent Technologies in Nuclear Power Plant Supervisory and Control Systems”, Hitachi Review, Vol. 49, No. 2, pp. 61 -65, 2002. 4. Kawakami Seishiro et al. , “Latest Nuclear Monitoring Instrumentation and Control System and Its Planned Application”, Toshiba Review, Vol. 57, No. 4, pp. 19 -22, 2002 (In Japanese). 5. Kazuo Monta et al. , “An advanced man-machine system for BWR nuclear power plants”, IEEE Fifth Conference on Human Factors and Power Plants, pp. 291 -300, 1992 (In Japanese). 6. “Advanced Boiling Water Reactor Plant General Description”, GE Nuclear Energy, 2000. 7. Masahiro Imase et al. , “Development of Advanced Main Instrumentation System in Nuclear Power Plants”, Mitsubishi-Denki. Kiho, Vol. 72, No. 6, p. 74, 1998 (In Japanese). 8. Koki Atsugi et al, “Integrated Digital System in Nuclear Power Plants”, Mitsubishi-Denki. Kiho, p. 7, 2000 (In Japanese). 9. “Modern Instrumentation and Control for Nuclear Power Plants : A Guidebook”, IAEA Technical Reports Series No. 387, 1999. 10. “Status of advanced light water reactor designs 2004”, IAEA Technical Reports Series No. 1391, 2004. 11. “Safety confirmation of Tsuruga 3 and 4 Nuclear Power Plants”, Department of the safety measure of nuclear power plants in Fukui, 2003 (In Japanese).

27 VI. References 1. Fumio Mizuki et al. , “Control and Instrumentation for ABWR Plant”, Hitachi Review Vol. 47, No. 5, pp. 164 -167, 1998. 2. Takehiko Seiji, “Advanced Supervisory and Control Systems for Nuclear Power Plants”, Hitachi Review Vol. 50, No. 3, pp. 79 -83, 2001. 3. Toshiharu Yamamori et al. , “Recent Technologies in Nuclear Power Plant Supervisory and Control Systems”, Hitachi Review, Vol. 49, No. 2, pp. 61 -65, 2002. 4. Kawakami Seishiro et al. , “Latest Nuclear Monitoring Instrumentation and Control System and Its Planned Application”, Toshiba Review, Vol. 57, No. 4, pp. 19 -22, 2002 (In Japanese). 5. Kazuo Monta et al. , “An advanced man-machine system for BWR nuclear power plants”, IEEE Fifth Conference on Human Factors and Power Plants, pp. 291 -300, 1992 (In Japanese). 6. “Advanced Boiling Water Reactor Plant General Description”, GE Nuclear Energy, 2000. 7. Masahiro Imase et al. , “Development of Advanced Main Instrumentation System in Nuclear Power Plants”, Mitsubishi-Denki. Kiho, Vol. 72, No. 6, p. 74, 1998 (In Japanese). 8. Koki Atsugi et al, “Integrated Digital System in Nuclear Power Plants”, Mitsubishi-Denki. Kiho, p. 7, 2000 (In Japanese). 9. “Modern Instrumentation and Control for Nuclear Power Plants : A Guidebook”, IAEA Technical Reports Series No. 387, 1999. 10. “Status of advanced light water reactor designs 2004”, IAEA Technical Reports Series No. 1391, 2004. 11. “Safety confirmation of Tsuruga 3 and 4 Nuclear Power Plants”, Department of the safety measure of nuclear power plants in Fukui, 2003 (In Japanese).