15463c6ac77555645167951d8a05dde6.ppt

- Количество слайдов: 26

Seabrook Station Biweekly Airborne Sampling • • David Perkins david_perkins@fpl. com

Objectives • Improve system reliability • Improve regulatory confidence • Reduce out-of-service time • Improve program efficiency and maintain a system of continuous sampling.

Bi-weekly Sample Feasibility Ability to increase sample frequency • Equipment reliability • Ability to achieve sensitivity for short-lived isotopes • Impact on charcoal efficiency • Excess filter loading • Eliminate missed samples

What We Found • Remotely monitor equipment with telemetry and vacuum sensing transducer • Maintain equipment with preventative maintenance • Evaluation of I-131 confirmed ability to achieve comparable sensitivity during 2 -week collection period • Charcoal efficiency testing for 2 -week run time successful • Effluent program informs REMP when I-131 release limits are exceeded for sample frequency adjustments

Automatic Remote Monitoring

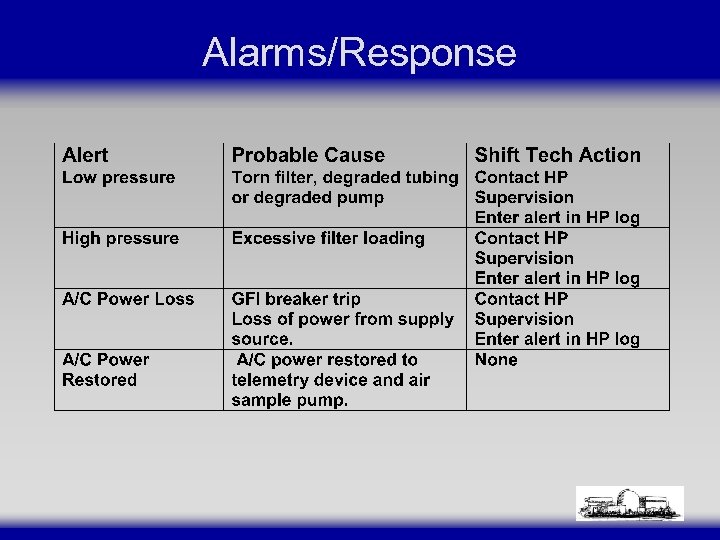

Remote System Monitoring • Reliability • Capabilities • Immediate problem notification • Power outages • Filter loading • Equipment failure • Cost effective

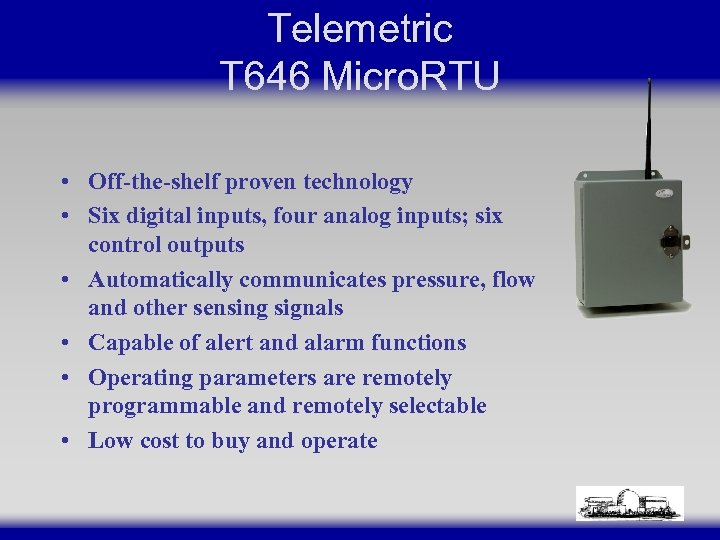

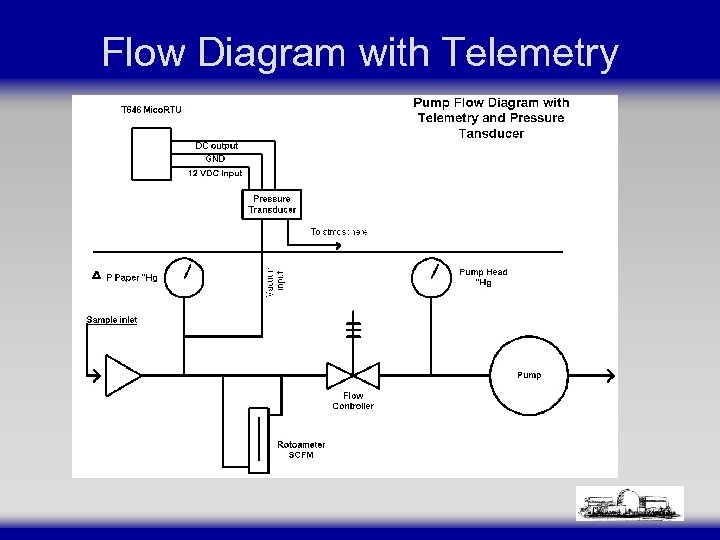

Telemetric T 646 Micro. RTU • Off-the-shelf proven technology • Six digital inputs, four analog inputs; six control outputs • Automatically communicates pressure, flow and other sensing signals • Capable of alert and alarm functions • Operating parameters are remotely programmable and remotely selectable • Low cost to buy and operate

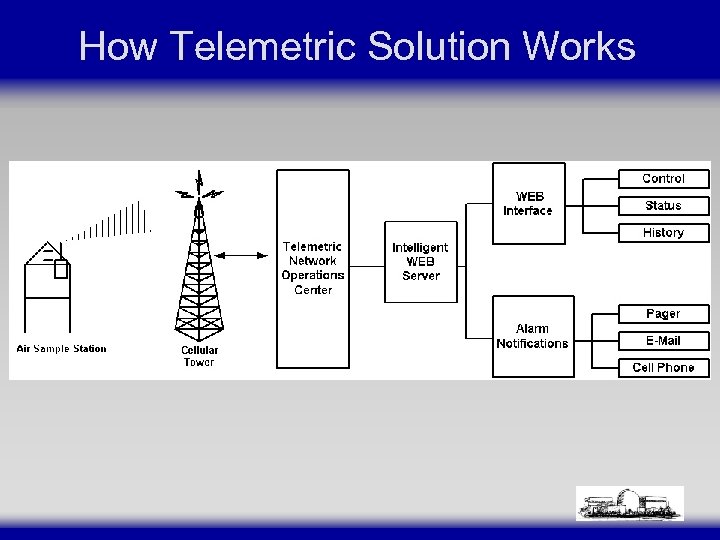

How Telemetric Solution Works

Flow Diagram with Telemetry

Alarms/Response

Equipment Maintenance

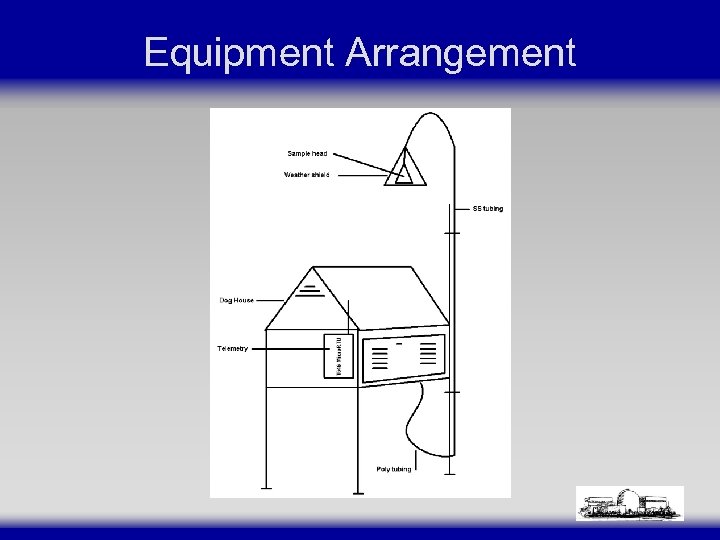

Equipment Arrangement

Preventive maintenance • Rebuild pumps – annually • Calibrate gas meters – semi-annually • Verify air flow – semi-annually or as needed • Inspect equipment for degradation – bi-weekly

Equipment Upgrades

Filter Loading & Charcoal Efficiency

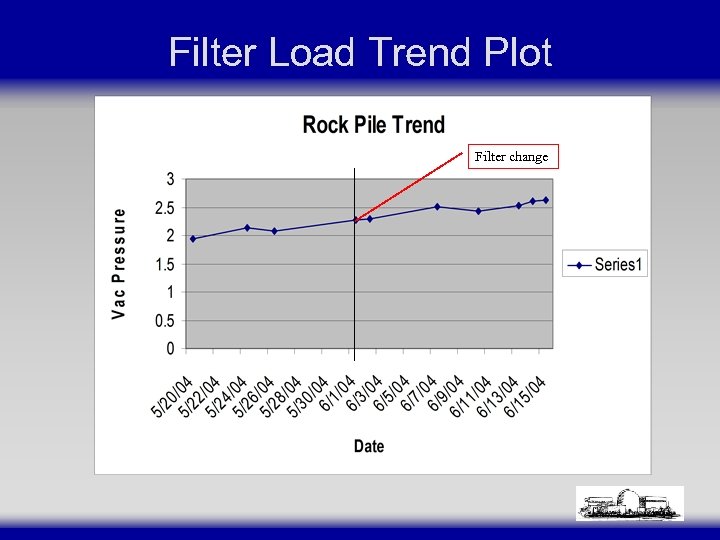

Filter Load Trend Plot Filter change

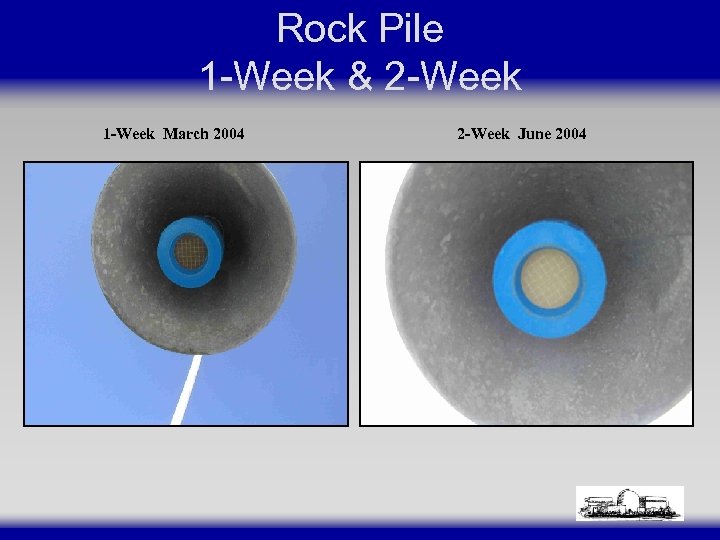

Rock Pile 1 -Week & 2 -Week 1 -Week March 2004 2 -Week June 2004

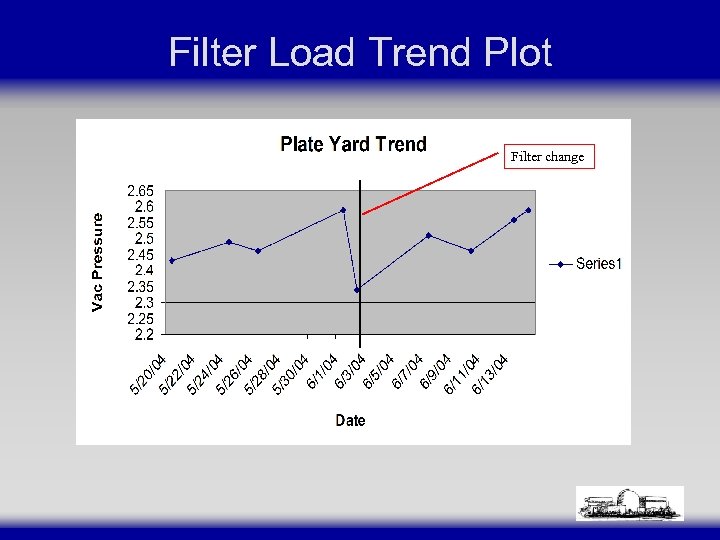

Filter Load Trend Plot Filter change

Plate Yard 2 -Week June 2004

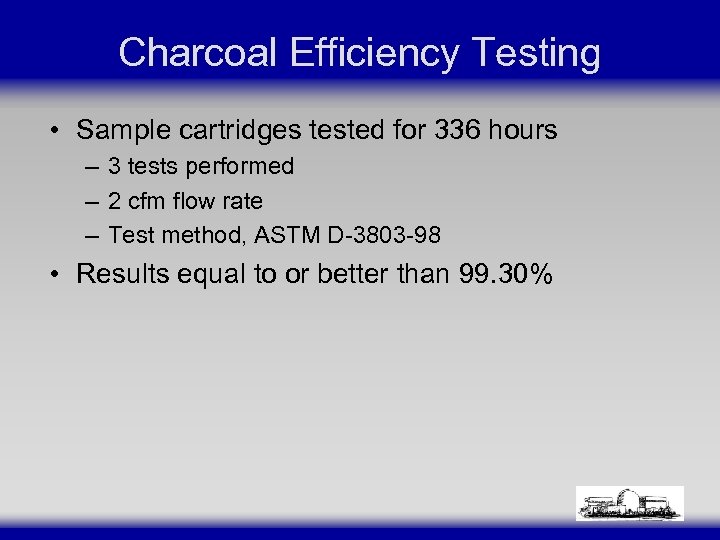

Charcoal Efficiency Testing • Sample cartridges tested for 336 hours – 3 tests performed – 2 cfm flow rate – Test method, ASTM D-3803 -98 • Results equal to or better than 99. 30%

I-131 and 2 -Week Sample Cycle

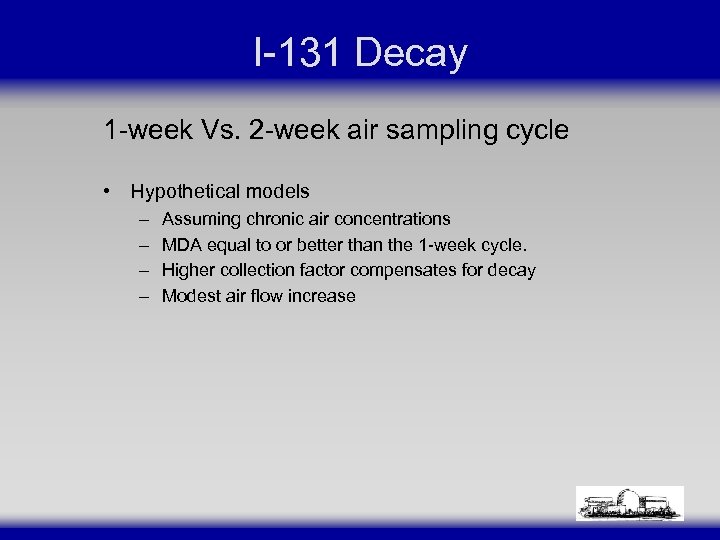

I-131 Decay 1 -week Vs. 2 -week air sampling cycle • Hypothetical models – – Assuming chronic air concentrations MDA equal to or better than the 1 -week cycle. Higher collection factor compensates for decay Modest air flow increase

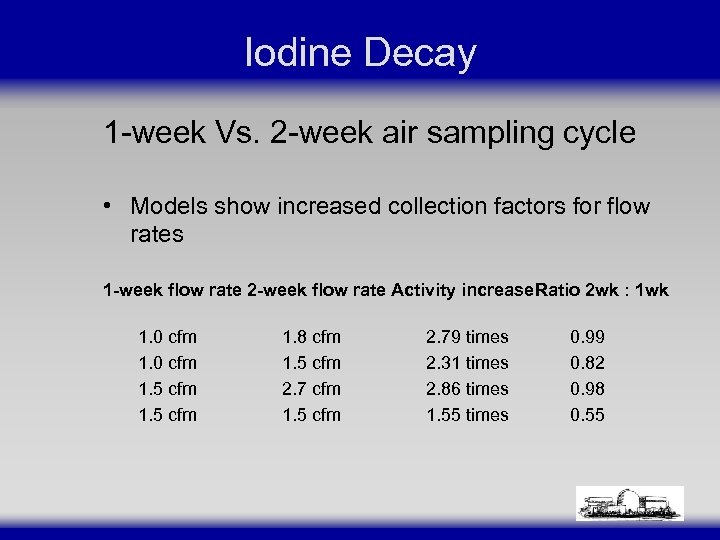

Iodine Decay 1 -week Vs. 2 -week air sampling cycle • Models show increased collection factors for flow rates 1 -week flow rate 2 -week flow rate Activity increase. Ratio 2 wk : 1 wk 1. 0 cfm 1. 5 cfm 1. 8 cfm 1. 5 cfm 2. 79 times 2. 31 times 2. 86 times 1. 55 times 0. 99 0. 82 0. 98 0. 55

Administrative Controls • REMP evaluates the need for increased sampling when: – ODCM monthly and instantaneous limits are exceeded – Failed fuel – Outages

How is 2 -Week Sampling working ? • Saved missed samples and out-of-service time – Utility turned power supply off without notification • Contacted utility and loss of power restored in 2 -hours • 150 hours of OOS time saved – Equipment problem discovered • Low pressure detected from tube connection leak • 72 hours of OOS time saved • System performs more reliably • Filter loading is monitored more closely – Slightly increasing over 2 -weeks, but NOT excessively

Questions?

15463c6ac77555645167951d8a05dde6.ppt