e62ba26c507b1117b1f4828f9cffb37f.ppt

- Количество слайдов: 35

SCM Master Data - 2 Master Data for Distribution & Production Processes (Review) EGN 5346 Logistics Engineering Fall, 2017

SCM Master Data - 2 Master Data for Distribution & Production Processes (Review) EGN 5346 Logistics Engineering Fall, 2017

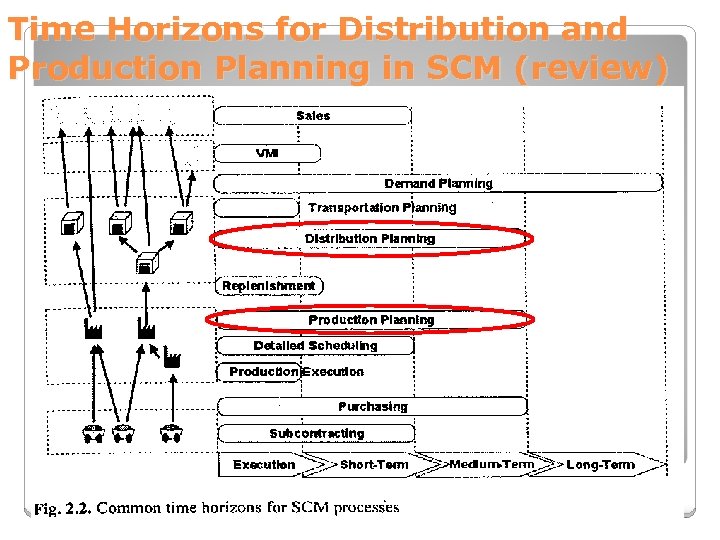

Time Horizons for Distribution and Production Planning in SCM (review)

Time Horizons for Distribution and Production Planning in SCM (review)

Time Horizon Identify the time horizon for the following planning: Planning type in SCM: Sales Demand planning Transportation planning Distribution planning Replenishment Production planning Detail scheduling Production Purchasing Horizon type: 1. Execution 2. Short-term 3. Medium-term 4. Long-term

Time Horizon Identify the time horizon for the following planning: Planning type in SCM: Sales Demand planning Transportation planning Distribution planning Replenishment Production planning Detail scheduling Production Purchasing Horizon type: 1. Execution 2. Short-term 3. Medium-term 4. Long-term

Time Horizon Identify the time horizon for the following planning: Planning type in SCM: Sales (2) Demand planning (4) Transportation planning (1) Distribution planning (3) Replenishment (2) Production planning (3) Detail scheduling (2) Production execution (1) Purchasing (3) Horizon type: 1. Execution 2. Short-term 3. Medium-term 4. Long-term

Time Horizon Identify the time horizon for the following planning: Planning type in SCM: Sales (2) Demand planning (4) Transportation planning (1) Distribution planning (3) Replenishment (2) Production planning (3) Detail scheduling (2) Production execution (1) Purchasing (3) Horizon type: 1. Execution 2. Short-term 3. Medium-term 4. Long-term

Master Data and Application in Distribution Planning and PP • Master Data for Distribution Planning: Location, Product, Resource, Transportation lane, Quota arrangement. • Master data for Production Planning: Location, Product, Resource, PPM/PDS , Quota arrangement.

Master Data and Application in Distribution Planning and PP • Master Data for Distribution Planning: Location, Product, Resource, Transportation lane, Quota arrangement. • Master data for Production Planning: Location, Product, Resource, PPM/PDS , Quota arrangement.

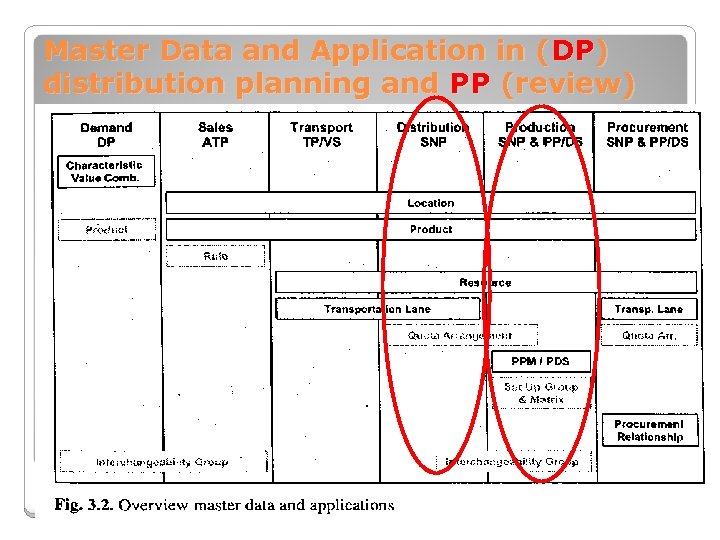

Master Data and Application in (DP) distribution planning and PP (review)

Master Data and Application in (DP) distribution planning and PP (review)

Master Data and Application in Distribution Planning and PP (Overview) • Transportation lanes: • Transportation lanes are required to link locations in SCM, such as from plant to distribution centers (DCs), from vendors to plants, and from plants or DCs to customers. • Quota arrangement (vendor’s quota): • Quota arrangement must be used, if it is intended to source from multiple locations on a regular basis. • Concerned products are assigned to the quota arrangement, and the ratio of the resources is defined per product.

Master Data and Application in Distribution Planning and PP (Overview) • Transportation lanes: • Transportation lanes are required to link locations in SCM, such as from plant to distribution centers (DCs), from vendors to plants, and from plants or DCs to customers. • Quota arrangement (vendor’s quota): • Quota arrangement must be used, if it is intended to source from multiple locations on a regular basis. • Concerned products are assigned to the quota arrangement, and the ratio of the resources is defined per product.

SCM Master Data - 2 Master Data for Distribution Planning

SCM Master Data - 2 Master Data for Distribution Planning

Distribution (and Supply Chain) Planning • Distribution planning between the manufacturing plants and warehouses (DCs) is important, as companies reduce inventory by changing their logistics processes to global inventory management from non-coordinated local inventory management. • Distribution (and supply chain) planning focuses on make-to-stock production.

Distribution (and Supply Chain) Planning • Distribution planning between the manufacturing plants and warehouses (DCs) is important, as companies reduce inventory by changing their logistics processes to global inventory management from non-coordinated local inventory management. • Distribution (and supply chain) planning focuses on make-to-stock production.

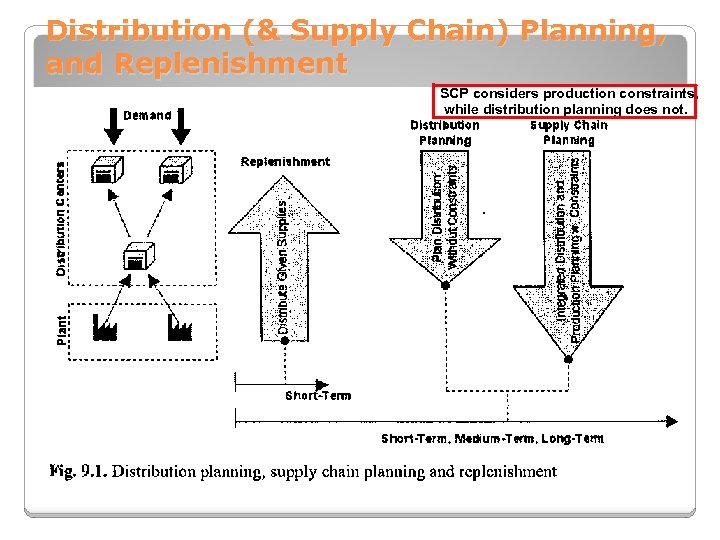

Distribution (& Supply Chain) Planning, and Replenishment SCP considers production constraints, while distribution planning does not.

Distribution (& Supply Chain) Planning, and Replenishment SCP considers production constraints, while distribution planning does not.

Distribution and Supply Chain Planning 1. Distribution planning is performed based on demand supply information with the result of planned stock transfers. 2. The most important issues are usually the netting of the local stocks, safety stock levels, sourcing options, transportation times and lot sizes for the planned stock transfers. 3. If required, restrictions are considered regarding storage capacity and handling capacity for goods issue and goods receipt.

Distribution and Supply Chain Planning 1. Distribution planning is performed based on demand supply information with the result of planned stock transfers. 2. The most important issues are usually the netting of the local stocks, safety stock levels, sourcing options, transportation times and lot sizes for the planned stock transfers. 3. If required, restrictions are considered regarding storage capacity and handling capacity for goods issue and goods receipt.

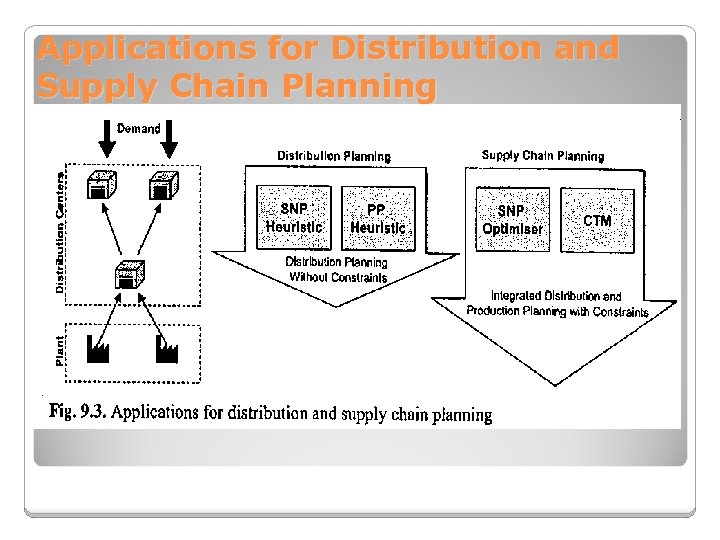

Distribution and Supply Chain Planning SAP APO supports distribution and production planning, with the following 4 applications: For distribution: • SNP heuristic • PP/DS heuristics For SCP (Supply Chain Planning) • SNP optimizer • CTM (with SNP or PP/DS master data) CTM: Capable-to-Match PP: Production Planning DS: Detailed scheduling

Distribution and Supply Chain Planning SAP APO supports distribution and production planning, with the following 4 applications: For distribution: • SNP heuristic • PP/DS heuristics For SCP (Supply Chain Planning) • SNP optimizer • CTM (with SNP or PP/DS master data) CTM: Capable-to-Match PP: Production Planning DS: Detailed scheduling

Applications for Distribution and Supply Chain Planning

Applications for Distribution and Supply Chain Planning

• Distribution and Supply Chain Planning Distribution planning with SNP heuristic is often used in the environments where multiple sourcing is not an issue and production is usually able to meet the demands, so that the main task for SNP heuristic is to calculate the demands for production planning based on local inventories, transportation times, safety stocks and lot sizes • SNP optimization allows a complete consideration of the supply chain determinants (i. e. , sources and cost, production capacity, transport, storage and handling). The aim of SNP optimizer is to find a global optimum for supply chain based on cost and penalty cost. • CTM pursues a priority based simple rules such as FIFS.

• Distribution and Supply Chain Planning Distribution planning with SNP heuristic is often used in the environments where multiple sourcing is not an issue and production is usually able to meet the demands, so that the main task for SNP heuristic is to calculate the demands for production planning based on local inventories, transportation times, safety stocks and lot sizes • SNP optimization allows a complete consideration of the supply chain determinants (i. e. , sources and cost, production capacity, transport, storage and handling). The aim of SNP optimizer is to find a global optimum for supply chain based on cost and penalty cost. • CTM pursues a priority based simple rules such as FIFS.

Order Cycle for Stock Transfers The stock transfer order has two aspects – as a demand in the source location and as a supply in the target location. The creation of the planned stock transfer, deployment and transport load building (TLB) is performed in SAP APO. Transport Load Building (TLB). • creation of truck loads in order to adjust the planned stock transports to the available trucks/transport means and take their capacity restrictions into account.

Order Cycle for Stock Transfers The stock transfer order has two aspects – as a demand in the source location and as a supply in the target location. The creation of the planned stock transfer, deployment and transport load building (TLB) is performed in SAP APO. Transport Load Building (TLB). • creation of truck loads in order to adjust the planned stock transports to the available trucks/transport means and take their capacity restrictions into account.

Stock Transfer Order Stock transfer order is first scheduled in SAP APO, then transferred to SAP ERP and scheduled again in SAP ERP according to the delivery date. Stock transfers are executed according to the order dates in SAP ERP, therefore it is important to keep the scheduling in SAP APO and SAP ERP consistent. Transport duration in SAP APO is calculated using the entry from the transportation lane, whereas SAP ERP uses the planned delivery time of the material master of the target location.

Stock Transfer Order Stock transfer order is first scheduled in SAP APO, then transferred to SAP ERP and scheduled again in SAP ERP according to the delivery date. Stock transfers are executed according to the order dates in SAP ERP, therefore it is important to keep the scheduling in SAP APO and SAP ERP consistent. Transport duration in SAP APO is calculated using the entry from the transportation lane, whereas SAP ERP uses the planned delivery time of the material master of the target location.

Setting for Stock Transfer within and across Company Codes in SAP ERP Since SAP APO does not know any company codes, there is no difference in SAP APO whether stock transfers are planned within one company code or across company codes. On SAP ERP side, cross-company stock transfers require the additional settings. Stock transfer across two SAP ERP systems is modelled by a purchase order in the target plant and a sales order in the source plant.

Setting for Stock Transfer within and across Company Codes in SAP ERP Since SAP APO does not know any company codes, there is no difference in SAP APO whether stock transfers are planned within one company code or across company codes. On SAP ERP side, cross-company stock transfers require the additional settings. Stock transfer across two SAP ERP systems is modelled by a purchase order in the target plant and a sales order in the source plant.

SCM Master Data - 2 Master Data for Production Planning Process

SCM Master Data - 2 Master Data for Production Planning Process

Production Master Data Overview The relevant master data for production planning: • Location • Product • Resources • PPM and PDS • Quota arrangement, Note on resources: • SNP and PP/DS have a different view of the capacity. • SNP – in buckets • PP/DS – time-continuous capacity

Production Master Data Overview The relevant master data for production planning: • Location • Product • Resources • PPM and PDS • Quota arrangement, Note on resources: • SNP and PP/DS have a different view of the capacity. • SNP – in buckets • PP/DS – time-continuous capacity

Resources for SNP is to perform an aggregated planning. Since SNP is an application for bucket-oriented planning, the resources for SNP offer a certain capacity per time bucket – usually per day. The bucket resources provide the capacity – e. g. the amount of working hours per day. For the scheduling of the production orders, the factory calendar is assigned to the resources. The standard capacity is defined in the resource master.

Resources for SNP is to perform an aggregated planning. Since SNP is an application for bucket-oriented planning, the resources for SNP offer a certain capacity per time bucket – usually per day. The bucket resources provide the capacity – e. g. the amount of working hours per day. For the scheduling of the production orders, the factory calendar is assigned to the resources. The standard capacity is defined in the resource master.

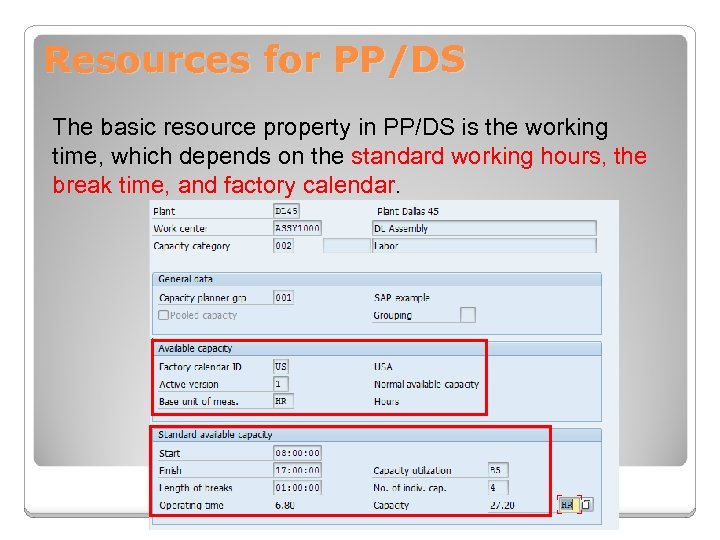

Resources for PP/DS The basic resource property in PP/DS is the working time, which depends on the standard working hours, the break time, and factory calendar.

Resources for PP/DS The basic resource property in PP/DS is the working time, which depends on the standard working hours, the break time, and factory calendar.

Production Master Data Overview PPM Production Process Model (PPM) defines the detailed information required for manufacturing a product. PPM combines routing and the bill of materials (BOM) into one master data object. Each PPM includes one or more operations. Each operation, in turn, includes one or more activities, for which materials, relationships and resources are maintained. Activities and resources defined in the PPM are assigned to costs used by the SNP Optimizer and by Production Planning and Detailed Scheduling (PP/DS) for finite scheduling.

Production Master Data Overview PPM Production Process Model (PPM) defines the detailed information required for manufacturing a product. PPM combines routing and the bill of materials (BOM) into one master data object. Each PPM includes one or more operations. Each operation, in turn, includes one or more activities, for which materials, relationships and resources are maintained. Activities and resources defined in the PPM are assigned to costs used by the SNP Optimizer and by Production Planning and Detailed Scheduling (PP/DS) for finite scheduling.

Production Master Data Overview Supply Network Planning (SNP) is a long term, rough cut planning tool. SNP requires a PPM with less information than the one used for production planning and detailed scheduling (PP/DS). During a planning run, SNP can schedule resources down to the day. When using optimization technologies, it is important to limit the number of inputs (materials) to find a proper solution in a reasonable runtime. SAP SCM allows to generate SNP production process models (PPMs) based on existing PP/DS PPMs. Restriction to a specific lot size is required to determine the exact production consumption or mode duration.

Production Master Data Overview Supply Network Planning (SNP) is a long term, rough cut planning tool. SNP requires a PPM with less information than the one used for production planning and detailed scheduling (PP/DS). During a planning run, SNP can schedule resources down to the day. When using optimization technologies, it is important to limit the number of inputs (materials) to find a proper solution in a reasonable runtime. SAP SCM allows to generate SNP production process models (PPMs) based on existing PP/DS PPMs. Restriction to a specific lot size is required to determine the exact production consumption or mode duration.

Production Master Data Overview PDS (production data structure) SAP initially developed the Production Process Model (PPM) to model manufacturing master data. It was replaced in SCM 4. 1 by PDS. However PPMs are still supported. In some industries modeling the production and evolution of a certain product can be very complicated. When a product has many variations due to customers choosing a combination of features and options they typically used the variant configuration solution in standard SAP ERP.

Production Master Data Overview PDS (production data structure) SAP initially developed the Production Process Model (PPM) to model manufacturing master data. It was replaced in SCM 4. 1 by PDS. However PPMs are still supported. In some industries modeling the production and evolution of a certain product can be very complicated. When a product has many variations due to customers choosing a combination of features and options they typically used the variant configuration solution in standard SAP ERP.

Production Master Data Overview PDS is used to integrate Engineering Change Management (ECM) and Variant Configuration between SAP ERP and APO. From SCM 4. 1 on, the Production Data Structure (PDS) is the key master data for all kinds of production planning related processes. The PDS is supported by the applications of PP/DS, SNP, CTM and DP. Like PPM, PDS corresponds to the production version on SAP ERP system. Though both PPM and PDS are still available as alternatives, there is no further development for the PPM since SCM 4. 0.

Production Master Data Overview PDS is used to integrate Engineering Change Management (ECM) and Variant Configuration between SAP ERP and APO. From SCM 4. 1 on, the Production Data Structure (PDS) is the key master data for all kinds of production planning related processes. The PDS is supported by the applications of PP/DS, SNP, CTM and DP. Like PPM, PDS corresponds to the production version on SAP ERP system. Though both PPM and PDS are still available as alternatives, there is no further development for the PPM since SCM 4. 0.

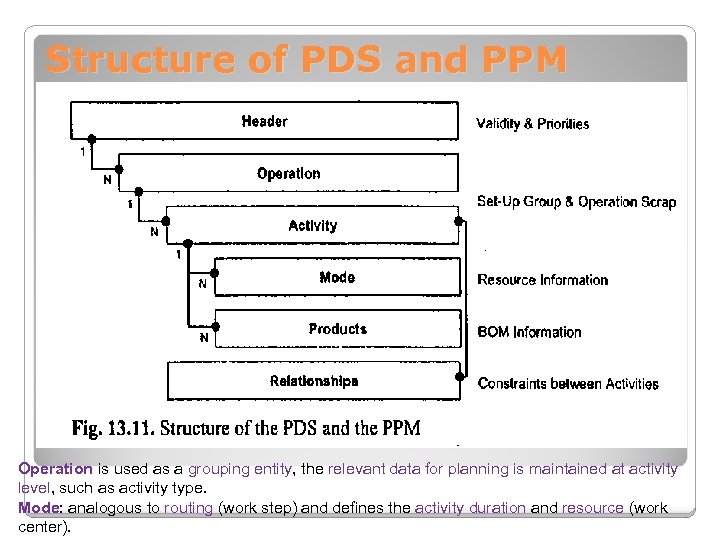

Structure of PDS and PPM Operation is used as a grouping entity, the relevant data for planning is maintained at activity level, such as activity type. Mode: analogous to routing (work step) and defines the activity duration and resource (work center).

Structure of PDS and PPM Operation is used as a grouping entity, the relevant data for planning is maintained at activity level, such as activity type. Mode: analogous to routing (work step) and defines the activity duration and resource (work center).

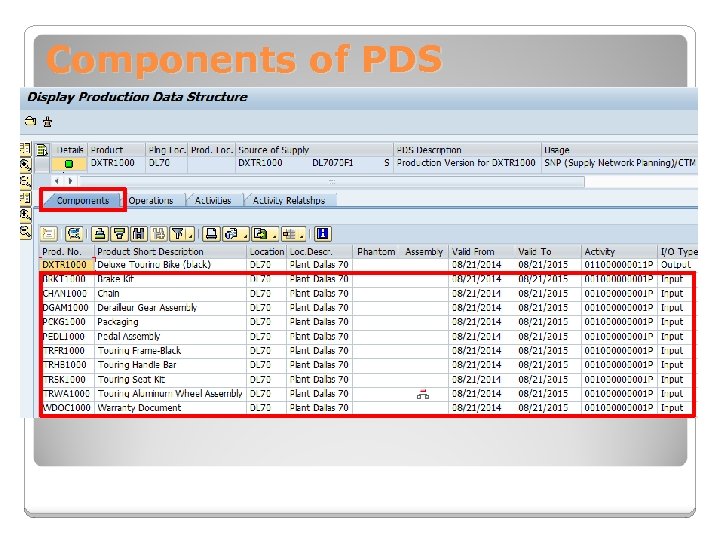

Components of PDS

Components of PDS

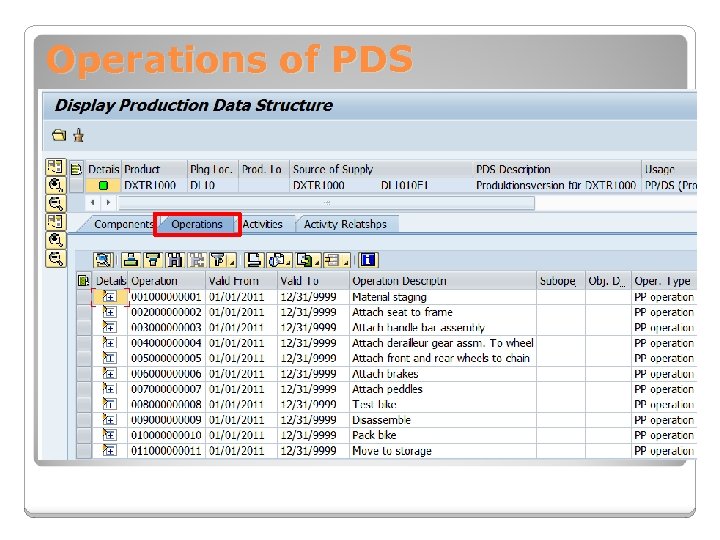

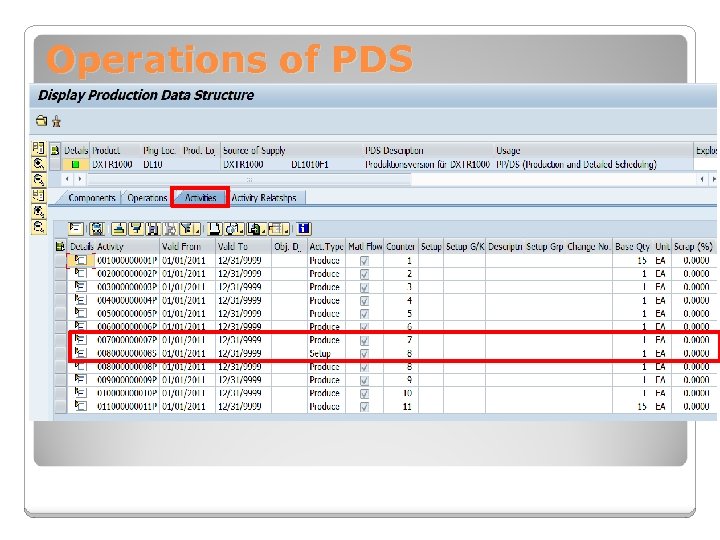

Operations of PDS

Operations of PDS

Operations of PDS

Operations of PDS

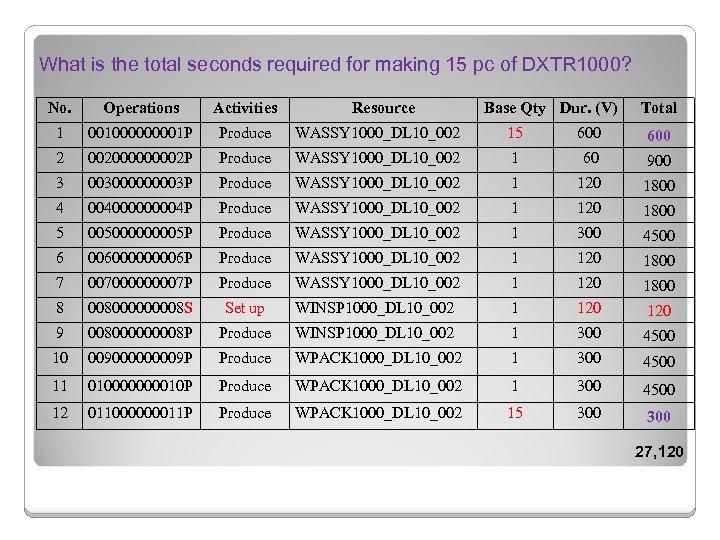

What is the total seconds required for making 15 pc of DXTR 1000? No. Operations Activities Resource Base Qty Dur. (V) Total 1 00100001 P Produce WASSY 1000_DL 10_002 15 600 2 00200002 P Produce WASSY 1000_DL 10_002 1 60 900 3 00300003 P Produce WASSY 1000_DL 10_002 1 120 1800 4 00400004 P Produce WASSY 1000_DL 10_002 1 120 1800 5 00500005 P Produce WASSY 1000_DL 10_002 1 300 4500 6 00600006 P Produce WASSY 1000_DL 10_002 1 120 1800 7 00700007 P Produce WASSY 1000_DL 10_002 1 120 1800 8 00800008 S Set up WINSP 1000_DL 10_002 1 120 9 00800008 P Produce WINSP 1000_DL 10_002 1 300 4500 10 00900009 P Produce WPACK 1000_DL 10_002 1 300 4500 11 01000010 P Produce WPACK 1000_DL 10_002 1 300 4500 12 011000000011 P Produce WPACK 1000_DL 10_002 15 300 27, 120

What is the total seconds required for making 15 pc of DXTR 1000? No. Operations Activities Resource Base Qty Dur. (V) Total 1 00100001 P Produce WASSY 1000_DL 10_002 15 600 2 00200002 P Produce WASSY 1000_DL 10_002 1 60 900 3 00300003 P Produce WASSY 1000_DL 10_002 1 120 1800 4 00400004 P Produce WASSY 1000_DL 10_002 1 120 1800 5 00500005 P Produce WASSY 1000_DL 10_002 1 300 4500 6 00600006 P Produce WASSY 1000_DL 10_002 1 120 1800 7 00700007 P Produce WASSY 1000_DL 10_002 1 120 1800 8 00800008 S Set up WINSP 1000_DL 10_002 1 120 9 00800008 P Produce WINSP 1000_DL 10_002 1 300 4500 10 00900009 P Produce WPACK 1000_DL 10_002 1 300 4500 11 01000010 P Produce WPACK 1000_DL 10_002 1 300 4500 12 011000000011 P Produce WPACK 1000_DL 10_002 15 300 27, 120

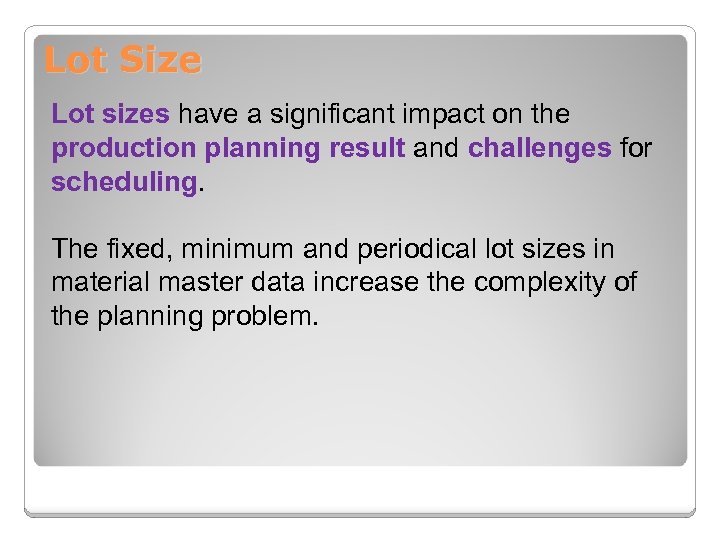

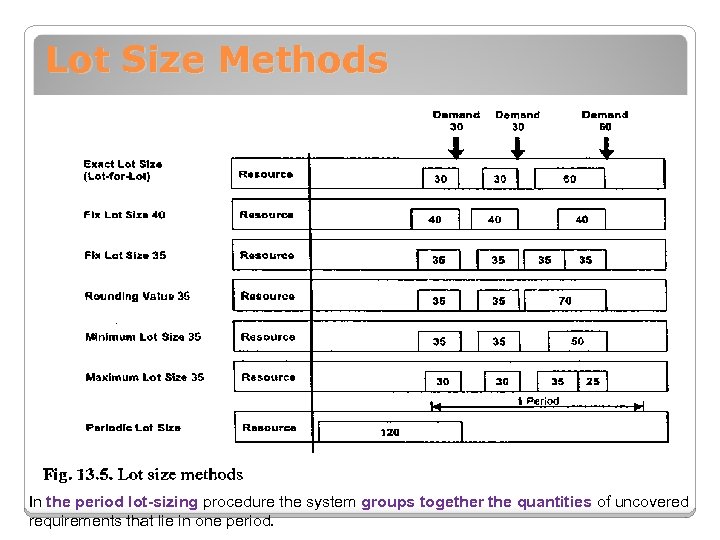

Lot Size Lot sizes have a significant impact on the production planning result and challenges for scheduling. The fixed, minimum and periodical lot sizes in material master data increase the complexity of the planning problem.

Lot Size Lot sizes have a significant impact on the production planning result and challenges for scheduling. The fixed, minimum and periodical lot sizes in material master data increase the complexity of the planning problem.

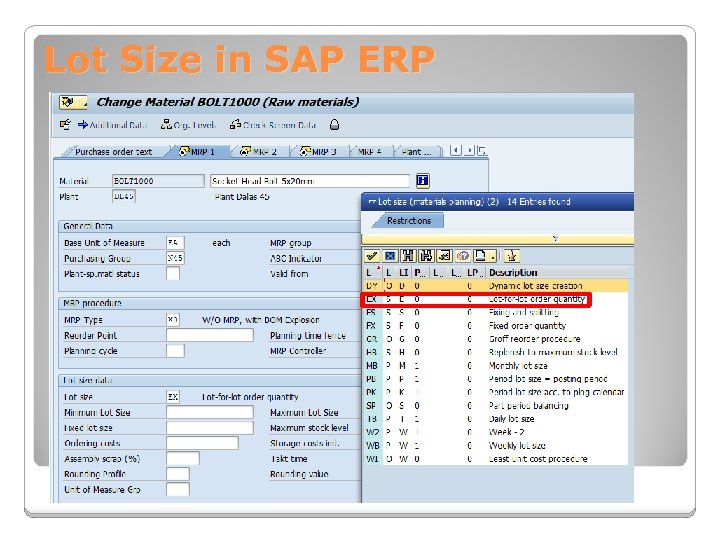

Lot Size in SAP ERP

Lot Size in SAP ERP

Lot Size Methods In the period lot-sizing procedure the system groups together the quantities of uncovered requirements that lie in one period.

Lot Size Methods In the period lot-sizing procedure the system groups together the quantities of uncovered requirements that lie in one period.

Lot Size Methods 32 32

Lot Size Methods 32 32

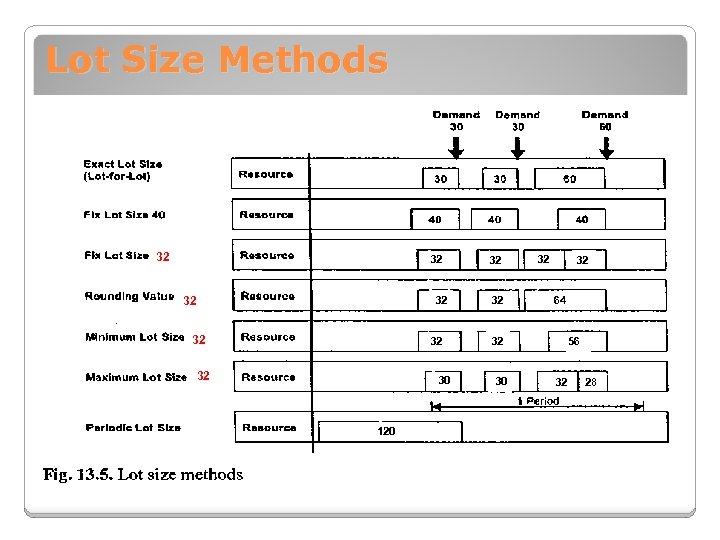

Lot Size Methods 32 32 30 120 32 32 64 32 30 56 32 28

Lot Size Methods 32 32 30 120 32 32 64 32 30 56 32 28