d69718bc34af8e1aff8dcd03152f2a72.ppt

- Количество слайдов: 29

Scaling II Mohammad Sharifkhani

Reading • Textbook I, Chapter 2 • Textbook II, Section 3. 5, Section 4. 5. 3, Section 5. 6

CMOS Scaling • Basic MOS rule: L↓ gm↑, C ↓ • Short channel effect + Lithography limits L • The worst SCE: reduction in gate Vt where MOS turns on, especially at high VDS • Process needs to keep SCE under control

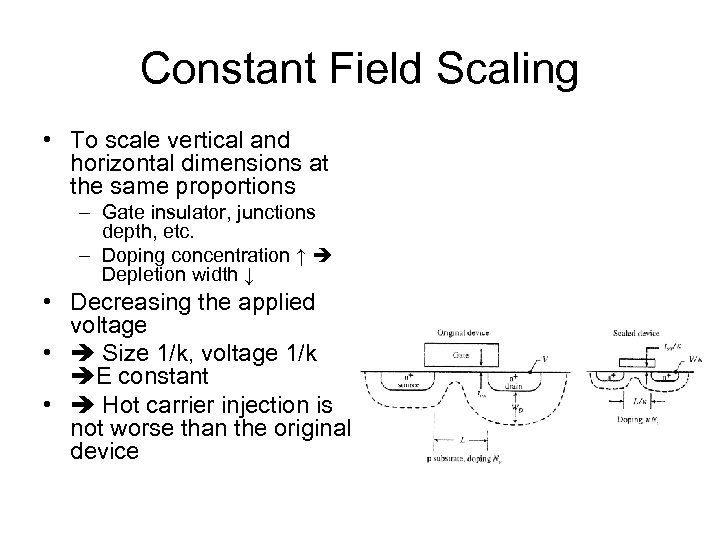

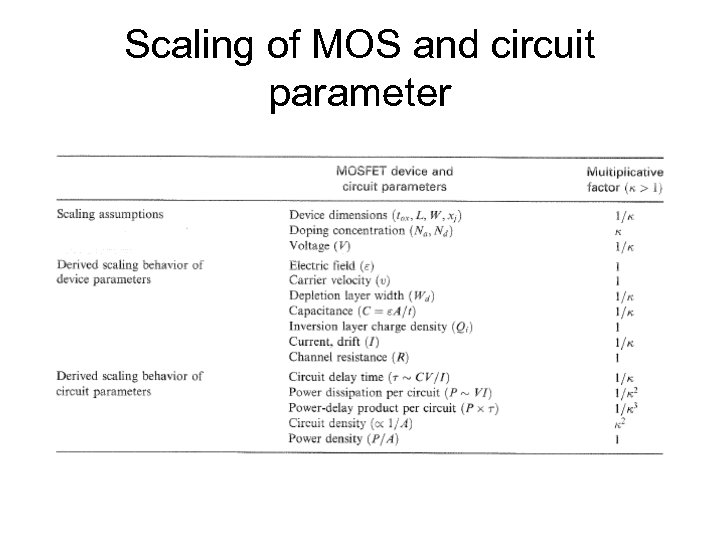

Constant Field Scaling • To scale vertical and horizontal dimensions at the same proportions – Gate insulator, junctions depth, etc. – Doping concentration ↑ Depletion width ↓ • Decreasing the applied voltage • Size 1/k, voltage 1/k E constant • Hot carrier injection is not worse than the original device

Scaling of MOS and circuit parameter

Scaling of MOS and circuit parameter • R of the MOS remains unchanged (I and V scale together) • Delay ~ R x C 1/K • Power ~ V x I 1/K^2 • Power x Delay 1/K^3 • Power density ~ Power / Area 1

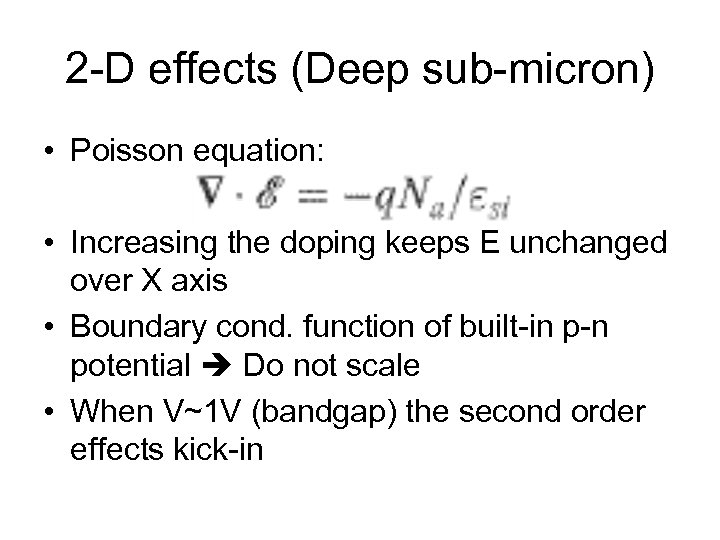

2 -D effects (Deep sub-micron) • Poisson equation: • Increasing the doping keeps E unchanged over X axis • Boundary cond. function of built-in p-n potential Do not scale • When V~1 V (bandgap) the second order effects kick-in

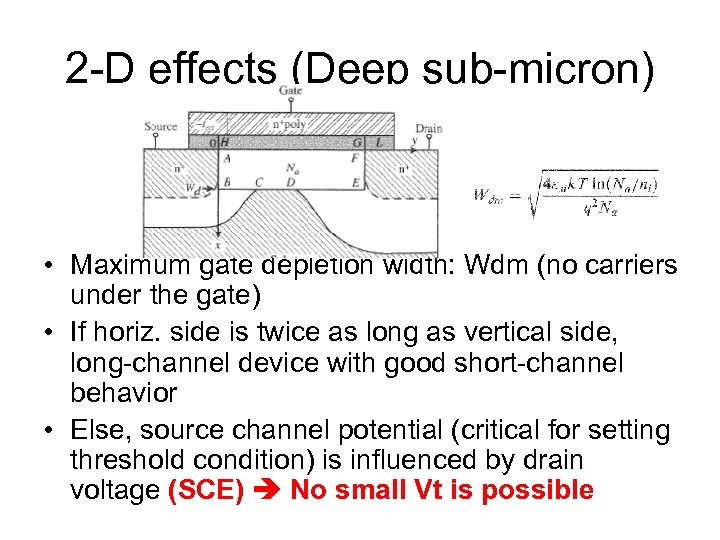

2 -D effects (Deep sub-micron) • Maximum gate depletion width: Wdm (no carriers under the gate) • If horiz. side is twice as long as vertical side, long-channel device with good short-channel behavior • Else, source channel potential (critical for setting threshold condition) is influenced by drain voltage (SCE) No small Vt is possible

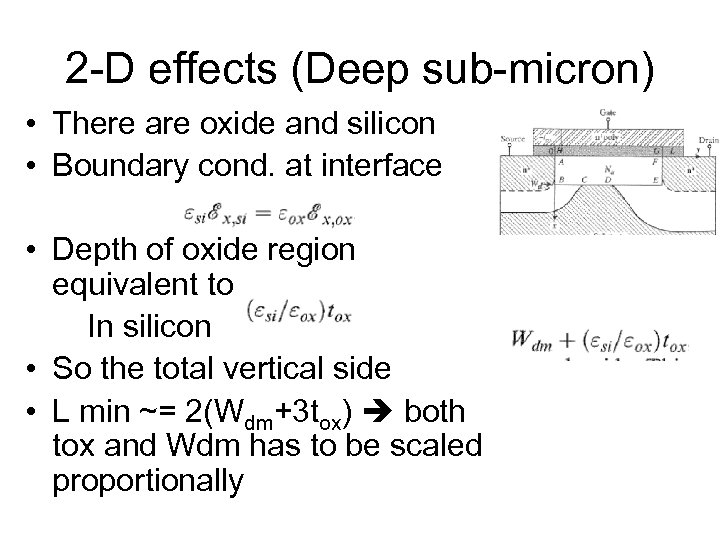

2 -D effects (Deep sub-micron) • There are oxide and silicon • Boundary cond. at interface • Depth of oxide region equivalent to In silicon • So the total vertical side • L min ~= 2(Wdm+3 tox) both tox and Wdm has to be scaled proportionally

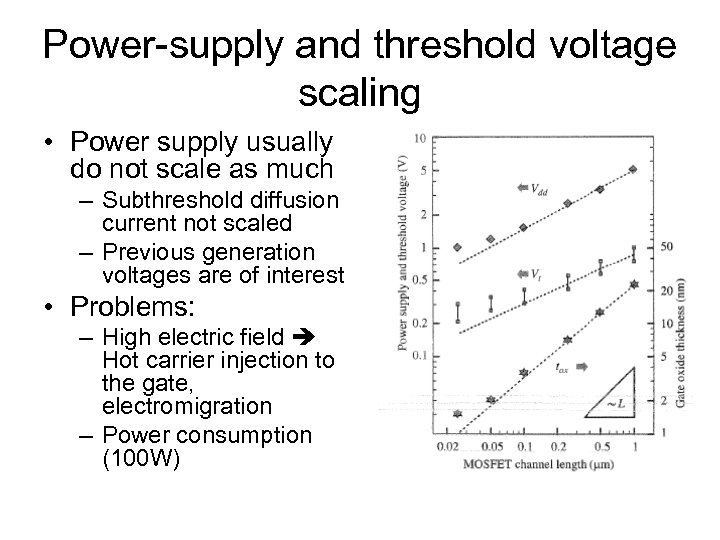

Power-supply and threshold voltage scaling • Power supply usually do not scale as much – Subthreshold diffusion current not scaled – Previous generation voltages are of interest • Problems: – High electric field Hot carrier injection to the gate, electromigration – Power consumption (100 W)

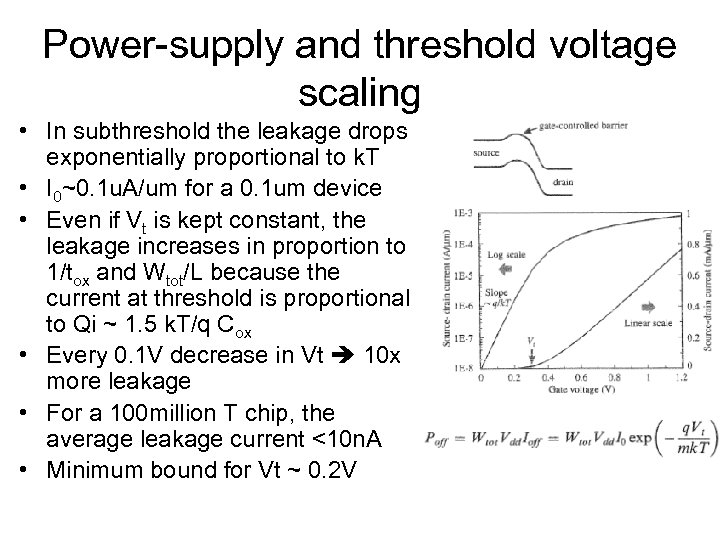

Power-supply and threshold voltage scaling • In subthreshold the leakage drops exponentially proportional to k. T • I 0~0. 1 u. A/um for a 0. 1 um device • Even if Vt is kept constant, the leakage increases in proportion to 1/tox and Wtot/L because the current at threshold is proportional to Qi ~ 1. 5 k. T/q Cox • Every 0. 1 V decrease in Vt 10 x more leakage • For a 100 million T chip, the average leakage current <10 n. A • Minimum bound for Vt ~ 0. 2 V

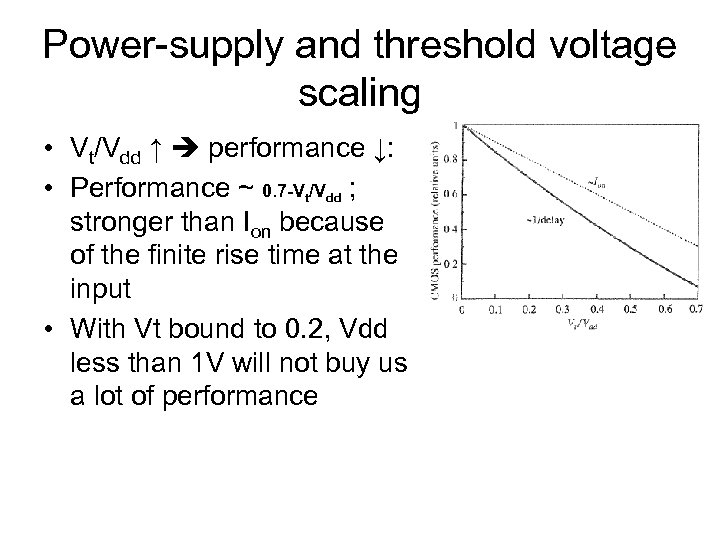

Power-supply and threshold voltage scaling • Vt/Vdd ↑ performance ↓: • Performance ~ 0. 7 -Vt/Vdd ; stronger than Ion because of the finite rise time at the input • With Vt bound to 0. 2, Vdd less than 1 V will not buy us a lot of performance

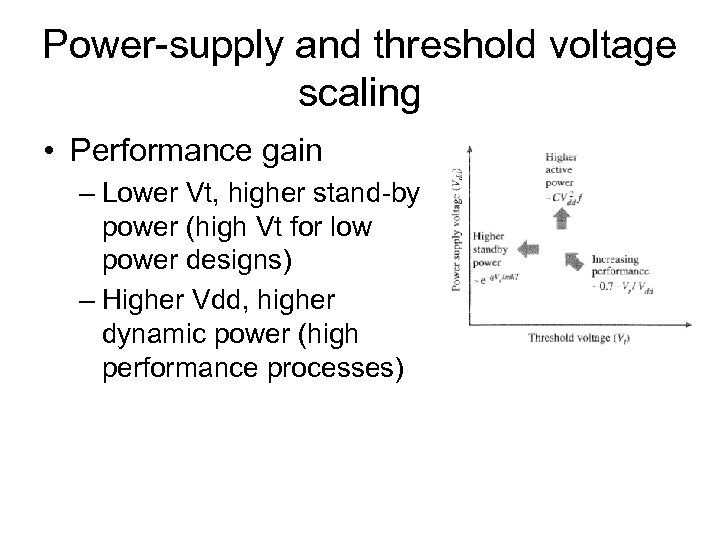

Power-supply and threshold voltage scaling • Performance gain – Lower Vt, higher stand-by power (high Vt for low power designs) – Higher Vdd, higher dynamic power (high performance processes)

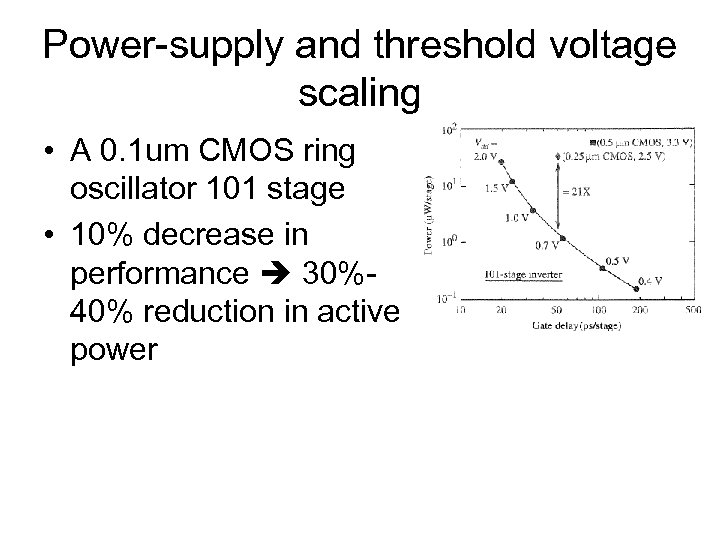

Power-supply and threshold voltage scaling • A 0. 1 um CMOS ring oscillator 101 stage • 10% decrease in performance 30%40% reduction in active power

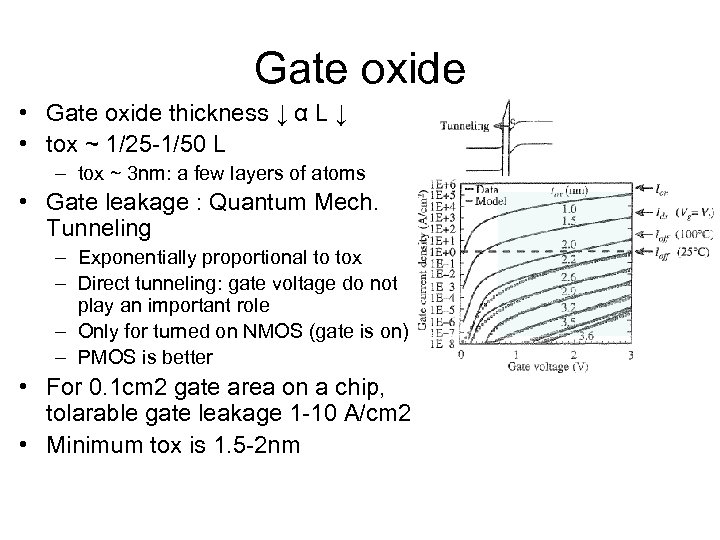

Gate oxide • Gate oxide thickness ↓ α L ↓ • tox ~ 1/25 -1/50 L – tox ~ 3 nm: a few layers of atoms • Gate leakage : Quantum Mech. Tunneling – Exponentially proportional to tox – Direct tunneling: gate voltage do not play an important role – Only for turned on NMOS (gate is on) – PMOS is better • For 0. 1 cm 2 gate area on a chip, tolarable gate leakage 1 -10 A/cm 2 • Minimum tox is 1. 5 -2 nm

Gate oxide • Two other phenomena: – Inversion layer quantization: • Density of inversion electrons 1 nm below the Si surface effectively 0. 3 -0. 4 nm thicker tox (Si. O 2) – Polysilicon gate depletion effect: • Thin space charge layer within the poly reduces the effectiveness of the gate • At tox = 2 nm; 20% loss in inversion charge

Gate • Poly: – Resistive (silicide) – Depletion effect • Why poly and not metal? – Metal : mid-gap bands – Compensating doping poor short channel effect

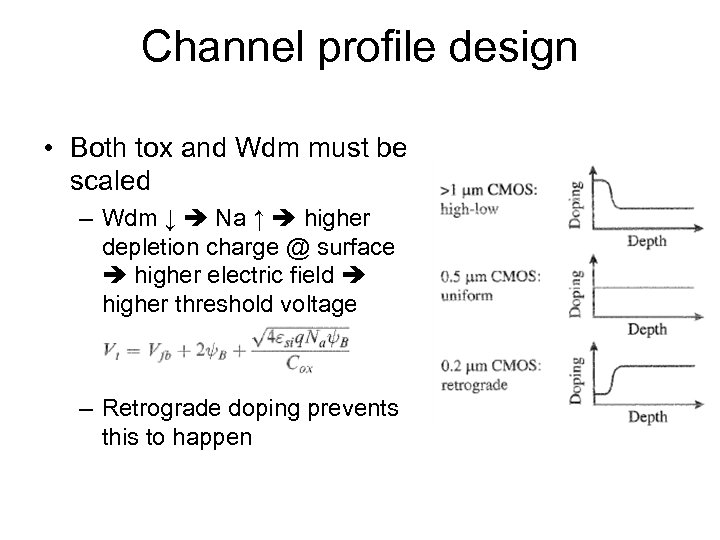

Channel profile design • Both tox and Wdm must be scaled – Wdm ↓ Na ↑ higher depletion charge @ surface higher electric field higher threshold voltage – Retrograde doping prevents this to happen

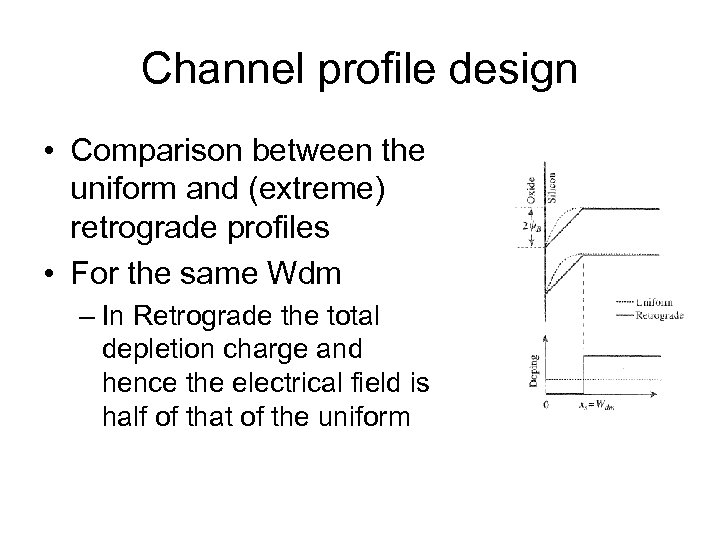

Channel profile design • Comparison between the uniform and (extreme) retrograde profiles • For the same Wdm – In Retrograde the total depletion charge and hence the electrical field is half of that of the uniform

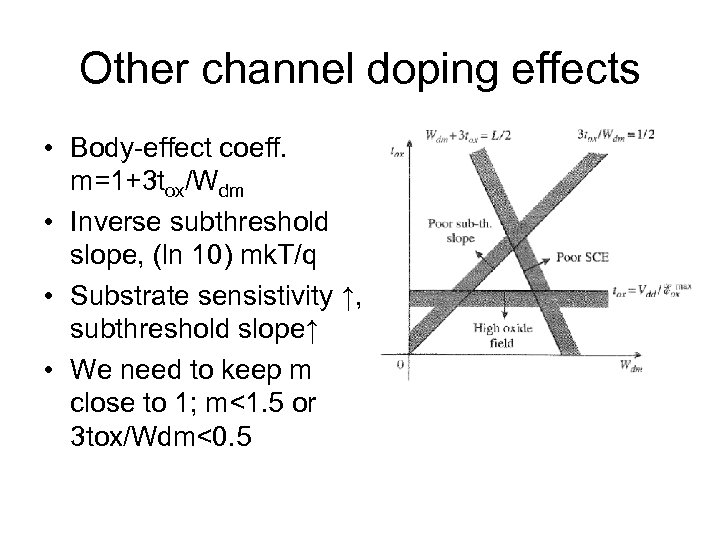

Other channel doping effects • Body-effect coeff. m=1+3 tox/Wdm • Inverse subthreshold slope, (ln 10) mk. T/q • Substrate sensistivity ↑, subthreshold slope↑ • We need to keep m close to 1; m<1. 5 or 3 tox/Wdm<0. 5

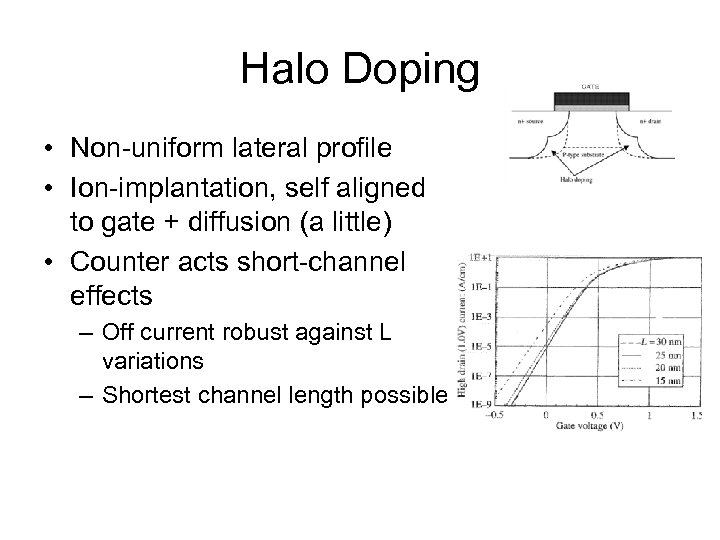

Halo Doping • Non-uniform lateral profile • Ion-implantation, self aligned to gate + diffusion (a little) • Counter acts short-channel effects – Off current robust against L variations – Shortest channel length possible

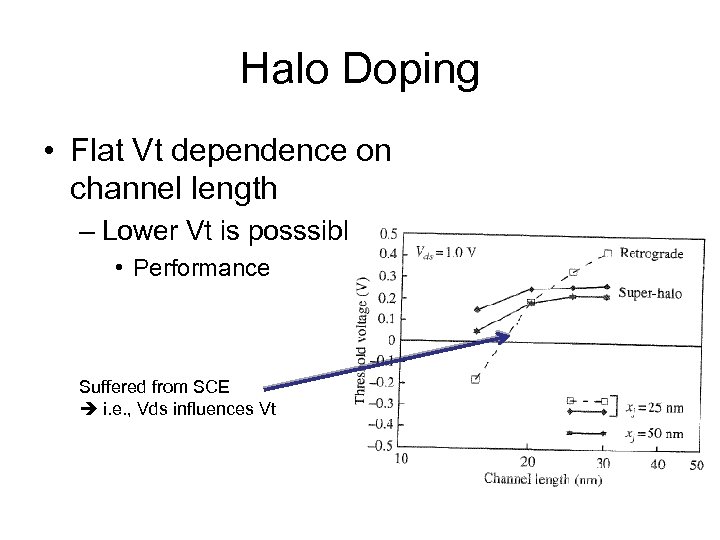

Halo Doping • Flat Vt dependence on channel length – Lower Vt is posssible • Performance Suffered from SCE i. e. , Vds influences Vt

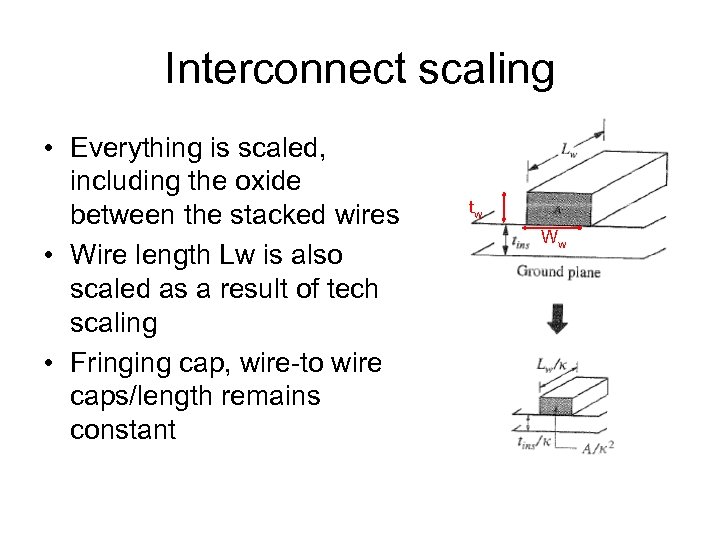

Interconnect scaling • Everything is scaled, including the oxide between the stacked wires • Wire length Lw is also scaled as a result of tech scaling • Fringing cap, wire-to wire caps/length remains constant tw Ww

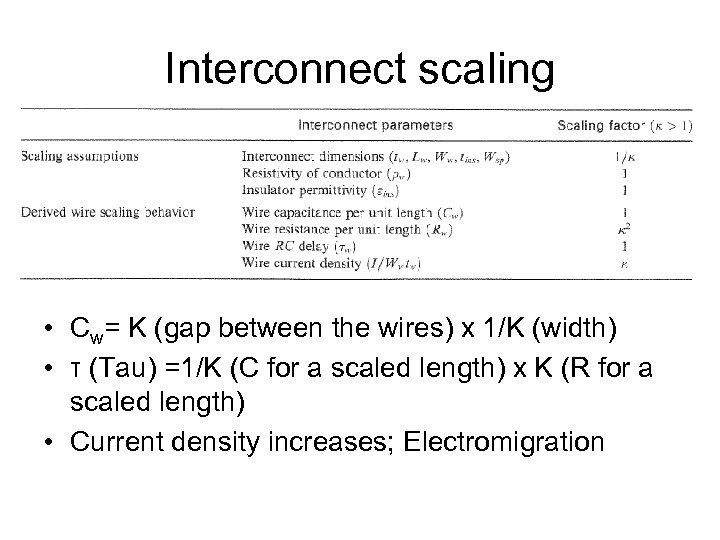

Interconnect scaling • Cw= K (gap between the wires) x 1/K (width) • τ (Tau) =1/K (C for a scaled length) x K (R for a scaled length) • Current density increases; Electromigration

Interconnect scaling • Some typical values: – @0. 25 um ; Cw = 2 p. F/cm – For aluminum • Tau = 3 x 10 -18 (sec) x L 2/(Ww x tw) • For a 0. 25 u x 0. 25 u size wire x 100 um long; delay = 0. 5 p. Sec; comparable to a cmos inverter in 0. 1 u tech (20 p. Sec). • Conclusion: local wires is not a big issue

Global wire issues • Global block to block cross-chip wires • The chip size usually do not scale; it may even increase – When remains the same; Tau increases by K 2(see last page L cte) – The cross-chip wires can create up to 1 ns delay

Global interconnects • Solutions: – Use of copper: 40% faster – Minimizing the number of corss-chip interconnects (Brain, CAD tools, etc. ) – Repeaters • Fundamental solution – Thicker wires (lower resistance, higher cap) – wider dielectric spacing (lower cap)

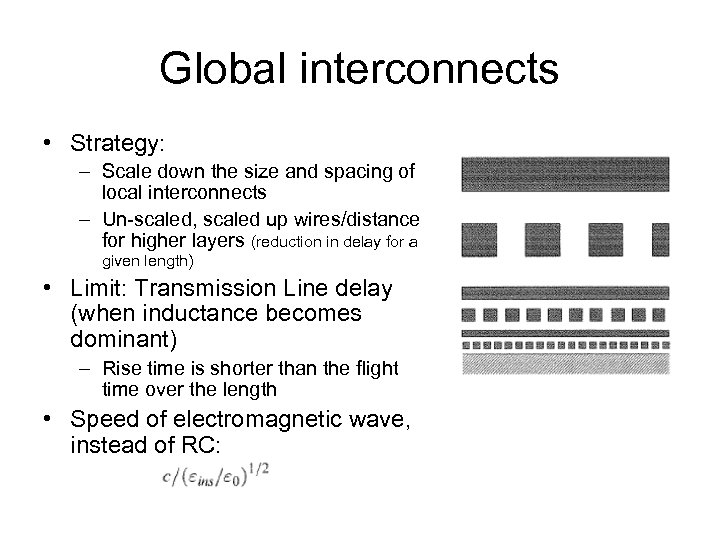

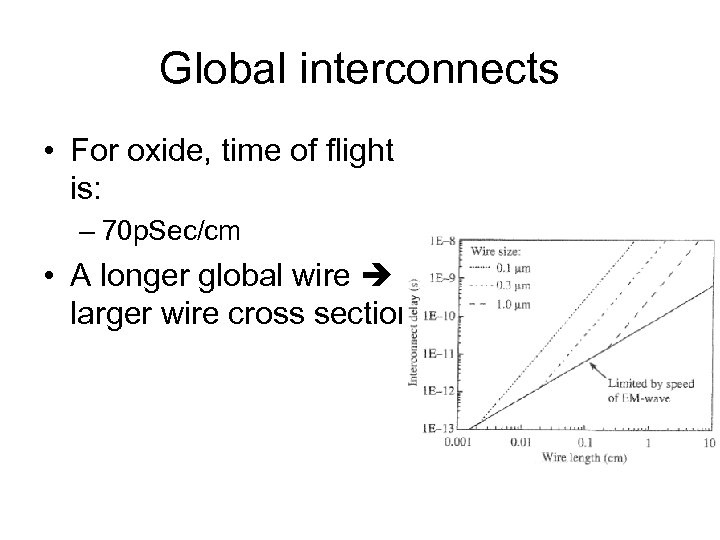

Global interconnects • Strategy: – Scale down the size and spacing of local interconnects – Un-scaled, scaled up wires/distance for higher layers (reduction in delay for a given length) • Limit: Transmission Line delay (when inductance becomes dominant) – Rise time is shorter than the flight time over the length • Speed of electromagnetic wave, instead of RC:

Global interconnects • For oxide, time of flight is: – 70 p. Sec/cm • A longer global wire larger wire cross section

d69718bc34af8e1aff8dcd03152f2a72.ppt