05308fd36050d6a8b7e0e7e2befa7887.ppt

- Количество слайдов: 32

SANYO CO 2 Technologies at Ahlsell Seminar in Norway SANYO Airconditioners Europe. Kjell Lundén Nordic Branch Office 21 April, 2008

SANYO CO 2 Technologies at Ahlsell Seminar in Norway SANYO Airconditioners Europe. Kjell Lundén Nordic Branch Office 21 April, 2008

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

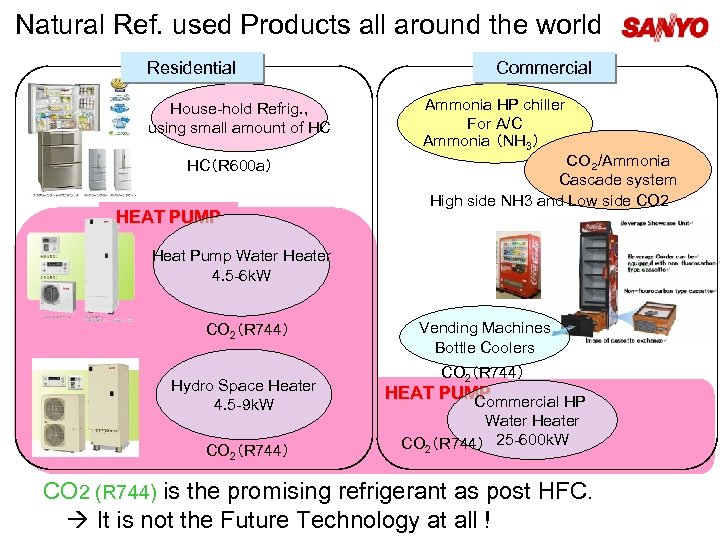

Natural Ref. used Products all around the world Residential House-hold Refrig. , using small amount of HC HC(R 600 a) HEAT PUMP Commercial Ammonia HP chiller For A/C Ammonia (NH 3) CO2/Ammonia Cascade system High side NH 3 and Low side CO 2 Heat Pump Water Heater 4. 5 -6 k. W CO 2(R 744) Hydro Space Heater 4. 5 -9 k. W CO 2(R 744) Vending Machines Bottle Coolers CO 2(R 744) HEAT PUMP Commercial HP Water Heater CO 2(R 744) 25 -600 k. W CO 2 (R 744) is the promising refrigerant as post HFC. It is not the Future Technology at all !

Natural Ref. used Products all around the world Residential House-hold Refrig. , using small amount of HC HC(R 600 a) HEAT PUMP Commercial Ammonia HP chiller For A/C Ammonia (NH 3) CO2/Ammonia Cascade system High side NH 3 and Low side CO 2 Heat Pump Water Heater 4. 5 -6 k. W CO 2(R 744) Hydro Space Heater 4. 5 -9 k. W CO 2(R 744) Vending Machines Bottle Coolers CO 2(R 744) HEAT PUMP Commercial HP Water Heater CO 2(R 744) 25 -600 k. W CO 2 (R 744) is the promising refrigerant as post HFC. It is not the Future Technology at all !

CO 2 Heat Pump Water Heater Market in Japan ■the number of units sold in Thousands (Sanyo estimate) (Thousands) 800 460 L ~ 370 L 650 ~ 300 L Small self contained type 550 450 350 225 81 03 130 04 05 06 07 (08) (09) (10) In Japan, most of HPWH uses CO 2 instead of HFC, simply because CO 2 is more suitable than HFC for heating application. . … WHY ? ?

CO 2 Heat Pump Water Heater Market in Japan ■the number of units sold in Thousands (Sanyo estimate) (Thousands) 800 460 L ~ 370 L 650 ~ 300 L Small self contained type 550 450 350 225 81 03 130 04 05 06 07 (08) (09) (10) In Japan, most of HPWH uses CO 2 instead of HFC, simply because CO 2 is more suitable than HFC for heating application. . … WHY ? ?

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

Reason #1. CO 2 is Natural Montreal Protocol. Kyoto Protocol → Natural refrigerant with Energy savings ■ Characteristics of natural refrigerants ODP Natural Substance CO 2 0 1 - - Yes HC 0 3 ++ - Yes 0 ≒ 0 + + Yes 0 1300 - - No R 410 A 0 1900 - - No R 407 C HCFC Toxicity R 134 a HFC Flammability NH 3 Natural Refrigerant GWP 0 1600 - - No R 22 0. 055 1700 - - No CO 2 is Environmentally Friendly: No ODP, negligible GWP CO 2 is Safe: Nonflammable, Nontoxic, no recovery required,

Reason #1. CO 2 is Natural Montreal Protocol. Kyoto Protocol → Natural refrigerant with Energy savings ■ Characteristics of natural refrigerants ODP Natural Substance CO 2 0 1 - - Yes HC 0 3 ++ - Yes 0 ≒ 0 + + Yes 0 1300 - - No R 410 A 0 1900 - - No R 407 C HCFC Toxicity R 134 a HFC Flammability NH 3 Natural Refrigerant GWP 0 1600 - - No R 22 0. 055 1700 - - No CO 2 is Environmentally Friendly: No ODP, negligible GWP CO 2 is Safe: Nonflammable, Nontoxic, no recovery required,

Reason #2. CO 2 is Good for Heat Pump Point 1 CO 2 (R 744) do not condense at high side of Heat Pump cycle because the critical point is lower than working pressure. (Transcritical Cycle) High Volumetric Capacity, Small Pressure Drop. Temperature curve Pressure [MPa] Critical Point(31℃) CO 2 ● ● HFCs Critical Point R 410 A 72℃ R 407 C 86℃ R 134 a 101℃ R 404 A 72℃ Enthalpy (k. J/kg) Point 2 CO 2 (R 744) has high pressure and high density even at low ambient such as -20℃. High Heat Pump Performance even at Nordic Area.

Reason #2. CO 2 is Good for Heat Pump Point 1 CO 2 (R 744) do not condense at high side of Heat Pump cycle because the critical point is lower than working pressure. (Transcritical Cycle) High Volumetric Capacity, Small Pressure Drop. Temperature curve Pressure [MPa] Critical Point(31℃) CO 2 ● ● HFCs Critical Point R 410 A 72℃ R 407 C 86℃ R 134 a 101℃ R 404 A 72℃ Enthalpy (k. J/kg) Point 2 CO 2 (R 744) has high pressure and high density even at low ambient such as -20℃. High Heat Pump Performance even at Nordic Area.

Reason #2. CO 2 is Good for Heat Pump Point 3 Because it is Transcritical cycle, efficiently heat up the water. HFC Temp. condensation of refrigerant CO 2 Ref. IN 90℃ Temp. Ref. IN Water OUT 65℃ Water OUT Water Ref. OUT The larger the temp. difference, the better the efficiency. Ref. OUT Water IN Inlet temp also affect the system efficiency a lot. Point 4 In addition to the non-condensation property, CO 2 has high heat transference ratio. → better Heat Pump efficiency, and Hot Water(90℃) can be obtained.

Reason #2. CO 2 is Good for Heat Pump Point 3 Because it is Transcritical cycle, efficiently heat up the water. HFC Temp. condensation of refrigerant CO 2 Ref. IN 90℃ Temp. Ref. IN Water OUT 65℃ Water OUT Water Ref. OUT The larger the temp. difference, the better the efficiency. Ref. OUT Water IN Inlet temp also affect the system efficiency a lot. Point 4 In addition to the non-condensation property, CO 2 has high heat transference ratio. → better Heat Pump efficiency, and Hot Water(90℃) can be obtained.

Summary: Characteristics of CO 2 as refrigerant Advantages: Green 1. Environmentally friendly (ODP=0, GWP=1) Refrigerant 2. Nonflammable, Nontoxic CO 2 3. No recovery or recycling required 4. Worldwide availability 5. High volumetric capacity and Heat transfer 6. Heat pump ability at low temperature ambient Best Refrigerant for Heat Pump! Especially in the Cold Climate (-20℃) Challenge: High pressure (12 MPa or more) & Large pressure difference Advanced technologies were required, especially for Compressor and Refrigeration system. Technology Break-through by Sanyo

Summary: Characteristics of CO 2 as refrigerant Advantages: Green 1. Environmentally friendly (ODP=0, GWP=1) Refrigerant 2. Nonflammable, Nontoxic CO 2 3. No recovery or recycling required 4. Worldwide availability 5. High volumetric capacity and Heat transfer 6. Heat pump ability at low temperature ambient Best Refrigerant for Heat Pump! Especially in the Cold Climate (-20℃) Challenge: High pressure (12 MPa or more) & Large pressure difference Advanced technologies were required, especially for Compressor and Refrigeration system. Technology Break-through by Sanyo

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

Feature of Sanyo CO 2 Compressor Since Y 2001, The World’s First Rotary 2 -Stage CO 2 Compressor ・ 2 -Stage Compression Mechanism in One Compressor against large pressure difference ・Internal Intermediate Pressure Structure against high working pressure ・Very efficient DC Brushless Inverter Motor comply with varied Heating Load ・SANYO’s Unique Technologies Excellent Processing & Assembly Technology Optimized Pump Dimension System Advantages belong to only 2 -Stage Compressor High Performance High Reliability Low-Vibration Low-Noise Compact Design

Feature of Sanyo CO 2 Compressor Since Y 2001, The World’s First Rotary 2 -Stage CO 2 Compressor ・ 2 -Stage Compression Mechanism in One Compressor against large pressure difference ・Internal Intermediate Pressure Structure against high working pressure ・Very efficient DC Brushless Inverter Motor comply with varied Heating Load ・SANYO’s Unique Technologies Excellent Processing & Assembly Technology Optimized Pump Dimension System Advantages belong to only 2 -Stage Compressor High Performance High Reliability Low-Vibration Low-Noise Compact Design

Feature of Sanyo CO 2 Compressor Working for Heating Applications. High Pressure Motor Low Shell Pressure 2 nd Stage Internal Intermediate Pressure 1 st Stage

Feature of Sanyo CO 2 Compressor Working for Heating Applications. High Pressure Motor Low Shell Pressure 2 nd Stage Internal Intermediate Pressure 1 st Stage

Feature of Sanyo CO 2 Compressor Working for Heating Applications. Heat the Water without condensation Pressure (MPa) 2 -stage Compression realizes the high isentropic efficiency and high reliability Enthalpy (k. J/kg)

Feature of Sanyo CO 2 Compressor Working for Heating Applications. Heat the Water without condensation Pressure (MPa) 2 -stage Compression realizes the high isentropic efficiency and high reliability Enthalpy (k. J/kg)

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CONTENTS 1. Introduction of CO 2 Products 2. Why CO 2 as refrigerant for Heat Pump ? 3. Technology of Sanyo CO 2 ECO 3 -1. Compressor Design 3 -2. Introduction of CO 2 ECO 4. Summary

CO 2 ECO System Features Heater (radiator) For Shower Hot Water Cold Water Gas Cooler Expansion Device(No. 1) (Main) W-W HX Heater 9 k. W Inter. Heat Excha ng er Second St. First St. Heater 6 k. W Expansion Device(No. 2) (Bypass ) Compressor Mixing Valve Accumlator Water Pump Evaporator For HP P

CO 2 ECO System Features Heater (radiator) For Shower Hot Water Cold Water Gas Cooler Expansion Device(No. 1) (Main) W-W HX Heater 9 k. W Inter. Heat Excha ng er Second St. First St. Heater 6 k. W Expansion Device(No. 2) (Bypass ) Compressor Mixing Valve Accumlator Water Pump Evaporator For HP P

Sanyo Original CO 2 Technology Only Available for Sanyo Original 2 -stage CO 2 Cycle ! This Technology was applied to new 9 k. W CO 2 ECO! Hot Water Cold Water Gas Cooler Second St. Expansion Device(No. 1)(Main) Inter. Heat Excha nger First St. Expansion Device(No. 2) (Bypass ) Compressor Evaporator Accumulator State of the Art Technology !

Sanyo Original CO 2 Technology Only Available for Sanyo Original 2 -stage CO 2 Cycle ! This Technology was applied to new 9 k. W CO 2 ECO! Hot Water Cold Water Gas Cooler Second St. Expansion Device(No. 1)(Main) Inter. Heat Excha nger First St. Expansion Device(No. 2) (Bypass ) Compressor Evaporator Accumulator State of the Art Technology !

New Refrigerant Circuit “Split Cycle” Only Available for Sanyo Original 2 -stage CO 2 Cycle !

New Refrigerant Circuit “Split Cycle” Only Available for Sanyo Original 2 -stage CO 2 Cycle !

(Data) New Refrigerant Circuit “Split Cycle” Addition of split cycle Adjustment of COMP Hz - Heat Pump Unit COP is increased by 17% at -20℃, by 16% at -10℃. - Heating Capacity is increased by 50% at -20℃. (Return Temp. ; 40℃ , Output Temp. ; 55℃) - Heating System Ave. COP is increased by 8%. ※Data source: Sanyo test data

(Data) New Refrigerant Circuit “Split Cycle” Addition of split cycle Adjustment of COMP Hz - Heat Pump Unit COP is increased by 17% at -20℃, by 16% at -10℃. - Heating Capacity is increased by 50% at -20℃. (Return Temp. ; 40℃ , Output Temp. ; 55℃) - Heating System Ave. COP is increased by 8%. ※Data source: Sanyo test data

Strength of CO 2 ECO for Northern Europe Tank Unit Outlet Water Sanyo Original Freeze Prevention Coil Inlet Water Expansion Valve Air Flow Air – Gas Heat Exchanger Heat Pump Unit Gas – Water Heat Exchanger Air Low Pressure Gas Air Compressor High Pressure Hot Gas Accumulator *Cross-section Diagram at the bottom of the Evaporator Actual Effect of Evaporator Special Refrigerant flow was adopted to prevent heat exchanger coil from freezing without stopping the operation. (No Heater, No reverse cycle required)

Strength of CO 2 ECO for Northern Europe Tank Unit Outlet Water Sanyo Original Freeze Prevention Coil Inlet Water Expansion Valve Air Flow Air – Gas Heat Exchanger Heat Pump Unit Gas – Water Heat Exchanger Air Low Pressure Gas Air Compressor High Pressure Hot Gas Accumulator *Cross-section Diagram at the bottom of the Evaporator Actual Effect of Evaporator Special Refrigerant flow was adopted to prevent heat exchanger coil from freezing without stopping the operation. (No Heater, No reverse cycle required)

Strength of CO 2 ECO for Northern Europe Heat Pump Capacity Comparison Actual Test Results by Sanyo Labo. Heat Pump Capacity (k. W) Co. A Co. B Co. C SANYO SHPC 90 GDN Dimension H 1045 W 1200 D 500 H 1040 W 1280 D 407 H 952 W 1086 D 600 H 1230 W 930 D 340 Weight 132 kg 135 kg 150 kg 105 kg Refrigerant Sanyo 9 k. W R 404 A 2. 0 kg R 407 C 2. 2 kg R 407 C 2. 6 kg CO 2 1. 6 kg STOP at -20℃ STOP at -11℃ 5. 0 8. 0 ― ― 1. 6 1. 8 10. 4 9. 0 3. 2 3. 0 3. 2 Model A C Outlook Co. B Co. A Co. B Co. C SANYO 9 k. W Ambient Temp (℃) COP Comparison COP (W/W) Heating Capacity[ Amb. Temp. k. W] -20 ℃ COP Co. A Co. B Co. C SANYO 9 k. W Ambient Temp (℃) Heating Capacity Amb. Temp. [k. W] 7℃ COP

Strength of CO 2 ECO for Northern Europe Heat Pump Capacity Comparison Actual Test Results by Sanyo Labo. Heat Pump Capacity (k. W) Co. A Co. B Co. C SANYO SHPC 90 GDN Dimension H 1045 W 1200 D 500 H 1040 W 1280 D 407 H 952 W 1086 D 600 H 1230 W 930 D 340 Weight 132 kg 135 kg 150 kg 105 kg Refrigerant Sanyo 9 k. W R 404 A 2. 0 kg R 407 C 2. 2 kg R 407 C 2. 6 kg CO 2 1. 6 kg STOP at -20℃ STOP at -11℃ 5. 0 8. 0 ― ― 1. 6 1. 8 10. 4 9. 0 3. 2 3. 0 3. 2 Model A C Outlook Co. B Co. A Co. B Co. C SANYO 9 k. W Ambient Temp (℃) COP Comparison COP (W/W) Heating Capacity[ Amb. Temp. k. W] -20 ℃ COP Co. A Co. B Co. C SANYO 9 k. W Ambient Temp (℃) Heating Capacity Amb. Temp. [k. W] 7℃ COP

Correlations between Outdoor Temp. and HP Performance Demanded Heat Level for a house al 9 NEW 1 phase-230 V 9 k. W 10 k. W NEW 3 phase-400 V 9 k. W FC WH. 0 k n ntio ve Con k. W al 6. 0 tion nven HFC Co 5 k. W -25℃ 4. 5 k. W CO 2 -20℃ -10℃ 0℃ 10℃

Correlations between Outdoor Temp. and HP Performance Demanded Heat Level for a house al 9 NEW 1 phase-230 V 9 k. W 10 k. W NEW 3 phase-400 V 9 k. W FC WH. 0 k n ntio ve Con k. W al 6. 0 tion nven HFC Co 5 k. W -25℃ 4. 5 k. W CO 2 -20℃ -10℃ 0℃ 10℃

SUMMARY 1. CO 2 HP is widely used in Japan and best matches the use in cold climate. (works even at -25℃) Big Energy Saving compared to HFCs. 2. Easy Installation. (No Drilling, No connection kit) 3. Sanyo 2 -stage compression enabled the very reliable CO 2 cycle and cutting edge technology, “Split Cycle”. 4. CO 2 ECO is the best and only product for Nordic!

SUMMARY 1. CO 2 HP is widely used in Japan and best matches the use in cold climate. (works even at -25℃) Big Energy Saving compared to HFCs. 2. Easy Installation. (No Drilling, No connection kit) 3. Sanyo 2 -stage compression enabled the very reliable CO 2 cycle and cutting edge technology, “Split Cycle”. 4. CO 2 ECO is the best and only product for Nordic!

How CO 2 can be applied to Cooling ?

How CO 2 can be applied to Cooling ?

Feature of Sanyo CO 2 Compressor Internal Intermediate Pressure Structure High Pressure Structure Pressure in Chamber [MPa] High Pressure Structure ON OFF Intermediate Pressure Structure ON △F h △F i Intermediate Pressure Structure The fluctuation of Inner Pressure is below 25% compared with high Pressure Structure. 100% 65% Thickness : 65% Weight of the vessel : 50% Internal intermediate pressure structure gives high reliability and light weight design.

Feature of Sanyo CO 2 Compressor Internal Intermediate Pressure Structure High Pressure Structure Pressure in Chamber [MPa] High Pressure Structure ON OFF Intermediate Pressure Structure ON △F h △F i Intermediate Pressure Structure The fluctuation of Inner Pressure is below 25% compared with high Pressure Structure. 100% 65% Thickness : 65% Weight of the vessel : 50% Internal intermediate pressure structure gives high reliability and light weight design.

Feature of Sanyo CO 2 Compressor Torque Fluctuation Lower Vibration & Noise Comparison of compression torque fluctuation 100 2 -Stage Compression 25 0 -25 1 -Stage Compression -100 0 90 180 270 360 Crankshaft Angle [deg] 2 -Stage Compression Mechanism by 2 -Rolling Pistons can achieve high discharge pressure while suppressing both vibration and noise.

Feature of Sanyo CO 2 Compressor Torque Fluctuation Lower Vibration & Noise Comparison of compression torque fluctuation 100 2 -Stage Compression 25 0 -25 1 -Stage Compression -100 0 90 180 270 360 Crankshaft Angle [deg] 2 -Stage Compression Mechanism by 2 -Rolling Pistons can achieve high discharge pressure while suppressing both vibration and noise.

Feature of Sanyo CO 2 Compressor Working for Cooling Applications. High Pressure Motor Low Shell Pressure Intermediate Pressure 2 nd Stage Inter Cooler 1 st Stage

Feature of Sanyo CO 2 Compressor Working for Cooling Applications. High Pressure Motor Low Shell Pressure Intermediate Pressure 2 nd Stage Inter Cooler 1 st Stage

Feature of Sanyo CO 2 Compressor Only belongs to Sanyo’s 2 stage compressor! Animation AT: 32℃ RH: 65%

Feature of Sanyo CO 2 Compressor Only belongs to Sanyo’s 2 stage compressor! Animation AT: 32℃ RH: 65%

Feature of Sanyo CO 2 Compressor Conventional Rotary Compressor for AC Motor Cylinder Oil Parts and materials used for CO 2 compressor are almost same as those for conventional HFC or HCFC rotary compressor for AC. If the production quantity of CO 2 compressors is closer to that of the conventional rotary compressors for AC, the incremental cost of CO 2 compressor will ultimately become the difference of material usage.

Feature of Sanyo CO 2 Compressor Conventional Rotary Compressor for AC Motor Cylinder Oil Parts and materials used for CO 2 compressor are almost same as those for conventional HFC or HCFC rotary compressor for AC. If the production quantity of CO 2 compressors is closer to that of the conventional rotary compressors for AC, the incremental cost of CO 2 compressor will ultimately become the difference of material usage.

Feature of Sanyo CO 2 Compressor Comparison of various CO 2 Compressors for 4. 5 k. W~ 6. 0 k. W Same Heating Capacity, Half size. ▲ 146 mm Smallest and Lightest Co. A Swing-Rotary 20 kg Co. B Scroll 18 kg Co. C Scroll 15 kg Sanyo 2 -stage Rotary 9 kg

Feature of Sanyo CO 2 Compressor Comparison of various CO 2 Compressors for 4. 5 k. W~ 6. 0 k. W Same Heating Capacity, Half size. ▲ 146 mm Smallest and Lightest Co. A Swing-Rotary 20 kg Co. B Scroll 18 kg Co. C Scroll 15 kg Sanyo 2 -stage Rotary 9 kg

Let’s go with the natural choice!

Let’s go with the natural choice!

32 SANYO New VISION Think GAIA 未 来 の子 供 た ち に 美 し い 地 球 を 還 そう

32 SANYO New VISION Think GAIA 未 来 の子 供 た ち に 美 し い 地 球 を 還 そう