ac15f63312d212dc4c273ae636d049ed.ppt

- Количество слайдов: 12

SAND SAMPLING APPARATUS Eglin Air Force Base Gina Teofilak Richard Klimas Dan Mortensen Ruben De Sousa

Sand Fracture Mechanisms During High-Speed Sand Impacts William “Bill” Cooper, MSgt Wes Schuler, LT Brad Breaux, Lalit Chhabildas AFRL/RW Munitions Directorate Air Force Research Laboratory Phil Metzger Granular Mechanics & Surface Systems Lab NASA, Kennedy Space Center Victor Giurgiutiu Air Force Office of Scientific Research 2

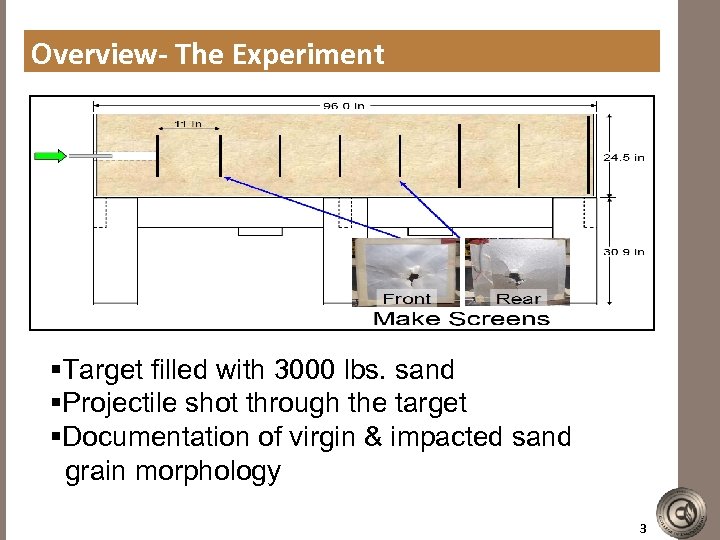

Overview- The Experiment §Target filled with 3000 lbs. sand §Projectile shot through the target §Documentation of virgin & impacted sand grain morphology 3

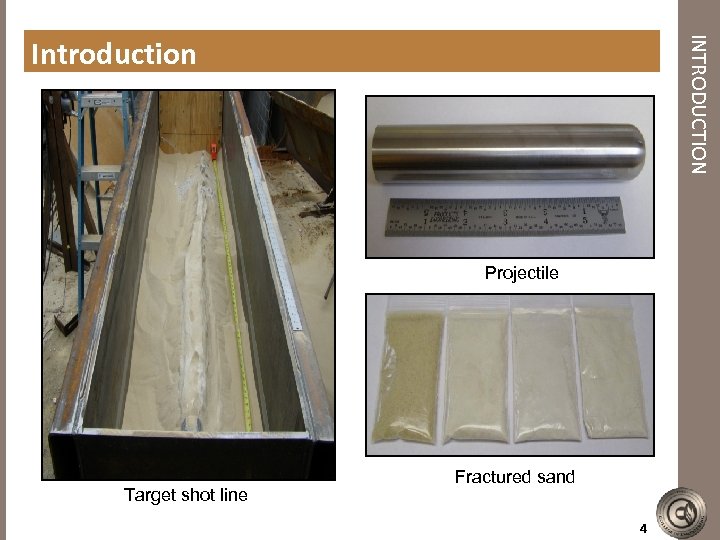

INTRODUCTION Introduction Projectile Target shot line Fractured sand 4

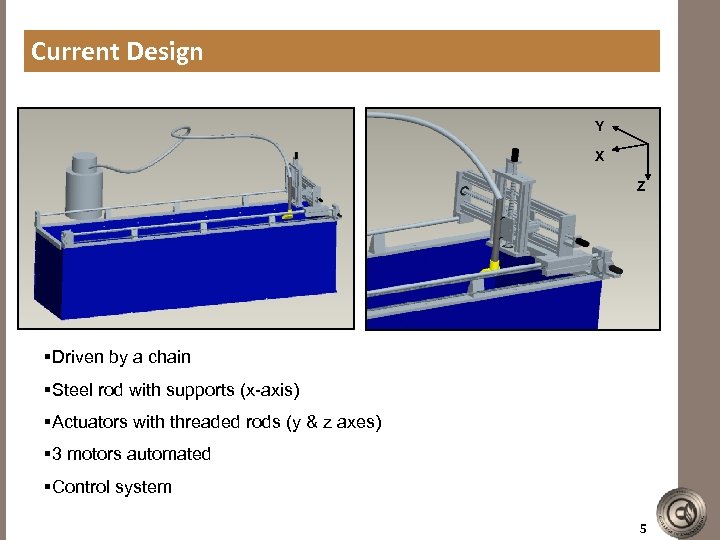

Current Design Y X Z §Driven by a chain §Steel rod with supports (x-axis) §Actuators with threaded rods (y & z axes) § 3 motors automated §Control system 5

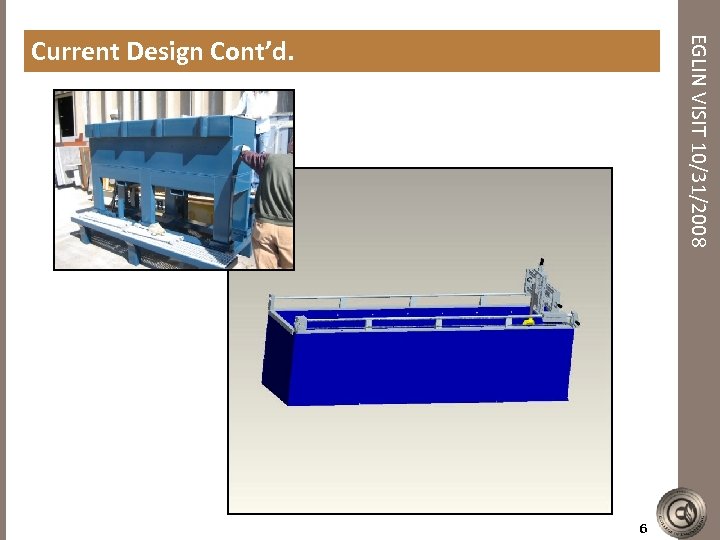

EGLIN VISIT 10/31/2008 Current Design Cont’d. 6

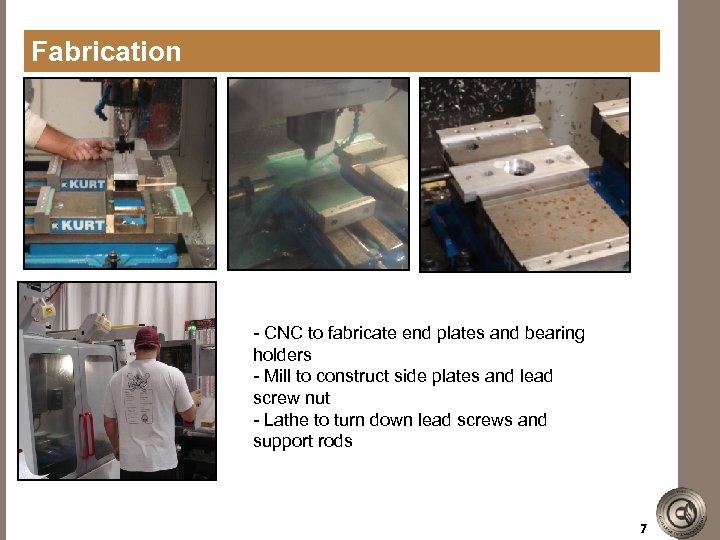

Fabrication - CNC to fabricate end plates and bearing holders - Mill to construct side plates and lead screw nut - Lathe to turn down lead screws and support rods 7

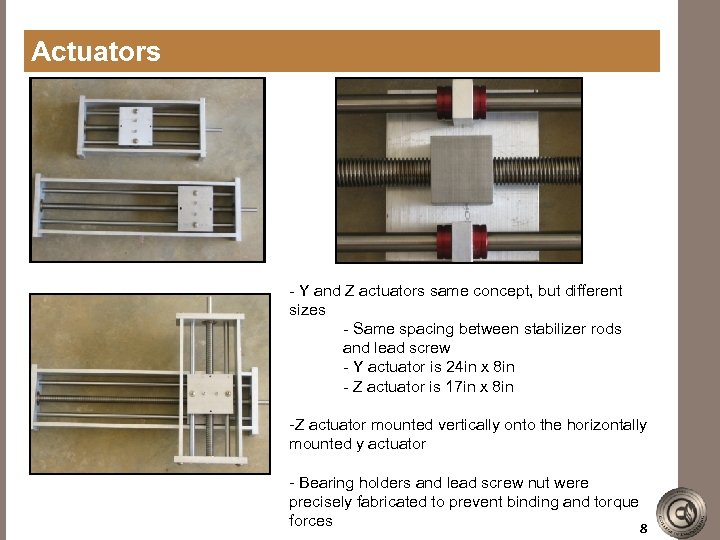

Actuators - Y and Z actuators same concept, but different sizes - Same spacing between stabilizer rods and lead screw - Y actuator is 24 in x 8 in - Z actuator is 17 in x 8 in -Z actuator mounted vertically onto the horizontally mounted y actuator - Bearing holders and lead screw nut were precisely fabricated to prevent binding and torque forces 8

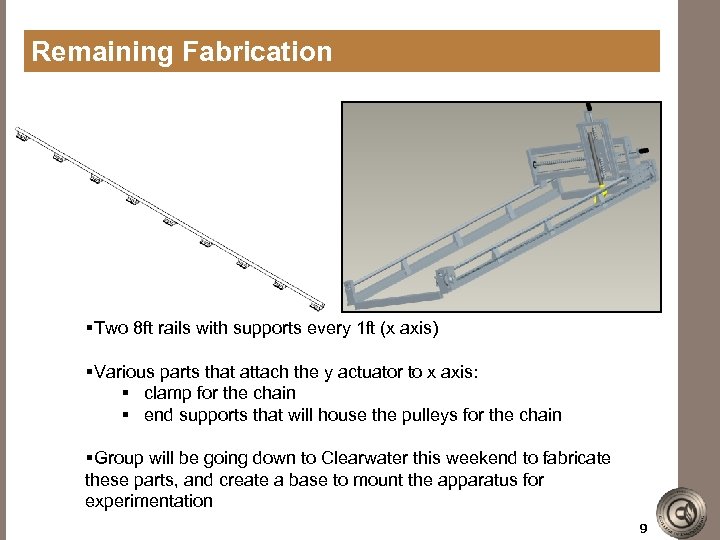

Remaining Fabrication §Two 8 ft rails with supports every 1 ft (x axis) §Various parts that attach the y actuator to x axis: § clamp for the chain § end supports that will house the pulleys for the chain §Group will be going down to Clearwater this weekend to fabricate these parts, and create a base to mount the apparatus for experimentation 9

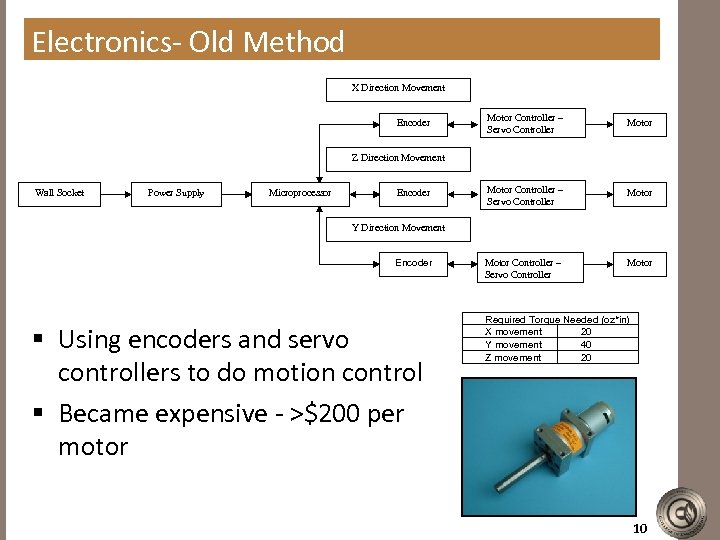

Electronics- Old Method X Direction Movement Encoder Motor Controller – Servo Controller Motor Z Direction Movement Wall Socket Power Supply Microprocessor Encoder Y Direction Movement Encoder § Using encoders and servo controllers to do motion control § Became expensive - >$200 per motor Required Torque Needed (oz*in) X movement 20 Y movement 40 Z movement 20 10

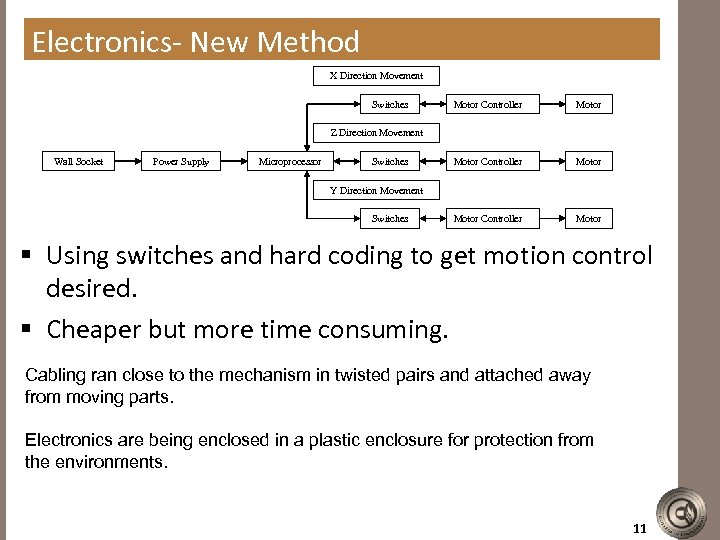

Electronics- New Method X Direction Movement Switches Motor Controller Motor Z Direction Movement Wall Socket Power Supply Microprocessor Switches Y Direction Movement Switches § Using switches and hard coding to get motion control desired. § Cheaper but more time consuming. Cabling ran close to the mechanism in twisted pairs and attached away from moving parts. Electronics are being enclosed in a plastic enclosure for protection from the environments. 11

REFERENCES 1. Cooper, William “Bill”, MSgt Wes Schuler, AFRL/RW Munitions Directorate Air Force Research Laboratory 2. Mortensen, Charles, Owner, Dynatech Associates 3. Dr. Chiang Shih, FAMU-FSU College of Engineering, Mechanical 4. Dr. Daudi Waryoba, FAMU-FSU College of Engineering, Mechanical 12

ac15f63312d212dc4c273ae636d049ed.ppt