6a427ec64af0dd3942fff9dc25666ce9.ppt

- Количество слайдов: 32

Sampling Plan Feed Industry MUTUALISED APPROACH Yvan Dejaegher Director BEMEFA Presentation for : AIC Presentation by : BEMEFA 2011

Sampling Plan Feed Industry MUTUALISED APPROACH Yvan Dejaegher Director BEMEFA Presentation for : AIC Presentation by : BEMEFA 2011

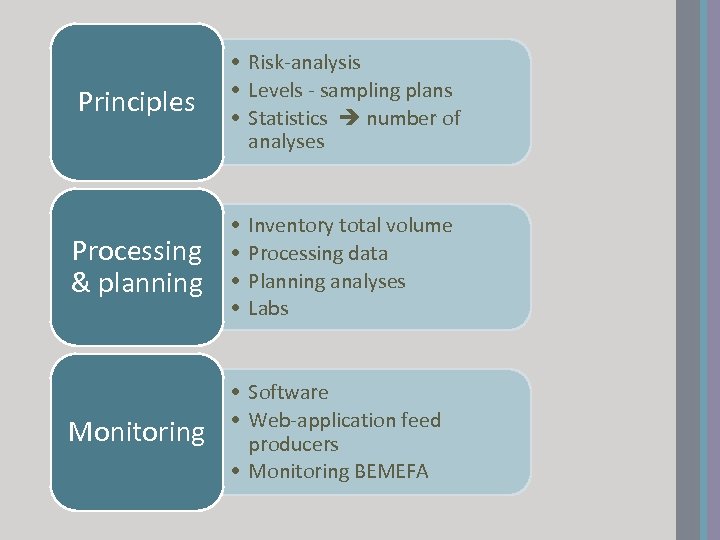

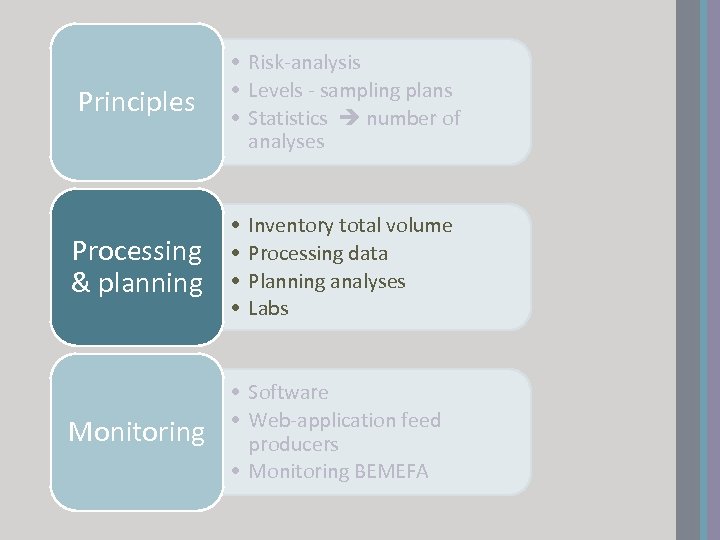

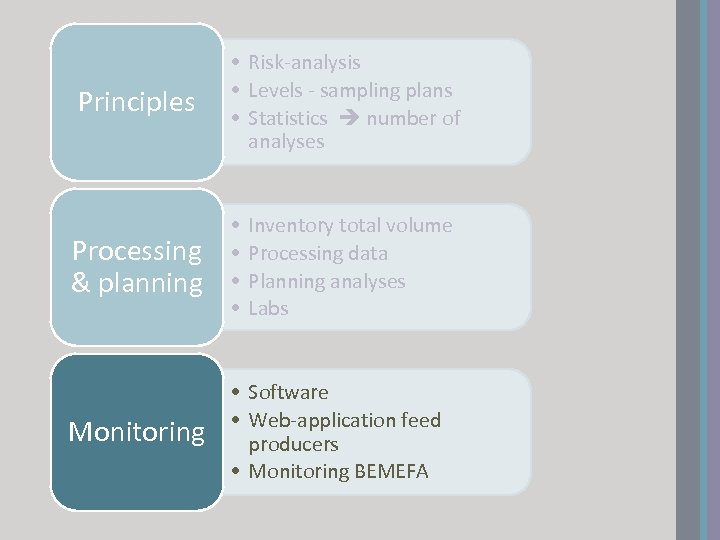

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

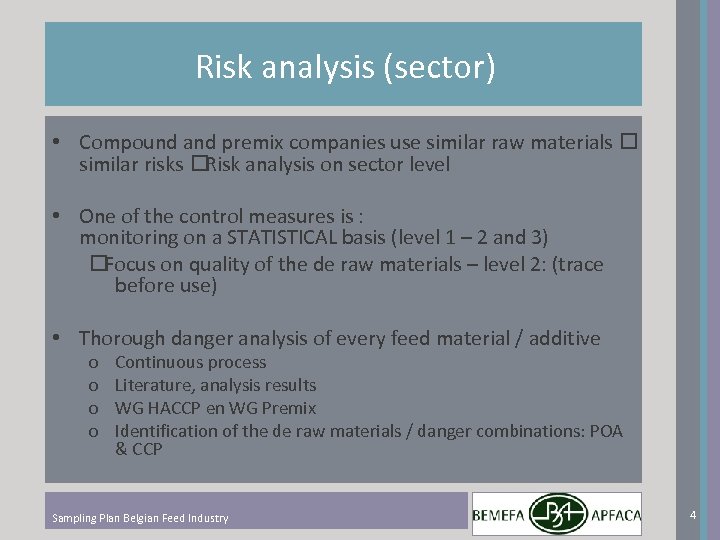

Risk analysis (sector) • Compound and premix companies use similar raw materials similar risks Risk analysis on sector level • One of the control measures is : monitoring on a STATISTICAL basis (level 1 – 2 and 3) Focus on quality of the de raw materials – level 2: (trace before use) • Thorough danger analysis of every feed material / additive o o Continuous process Literature, analysis results WG HACCP en WG Premix Identification of the de raw materials / danger combinations: POA & CCP Sampling Plan Belgian Feed Industry 4

Risk analysis (sector) • Compound and premix companies use similar raw materials similar risks Risk analysis on sector level • One of the control measures is : monitoring on a STATISTICAL basis (level 1 – 2 and 3) Focus on quality of the de raw materials – level 2: (trace before use) • Thorough danger analysis of every feed material / additive o o Continuous process Literature, analysis results WG HACCP en WG Premix Identification of the de raw materials / danger combinations: POA & CCP Sampling Plan Belgian Feed Industry 4

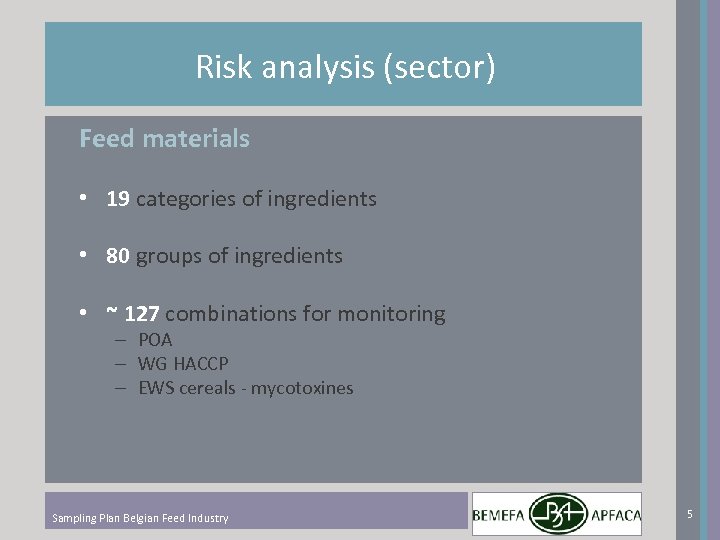

Risk analysis (sector) Feed materials • 19 categories of ingredients • 80 groups of ingredients • ~ 127 combinations for monitoring – POA – WG HACCP – EWS cereals - mycotoxines Sampling Plan Belgian Feed Industry 5

Risk analysis (sector) Feed materials • 19 categories of ingredients • 80 groups of ingredients • ~ 127 combinations for monitoring – POA – WG HACCP – EWS cereals - mycotoxines Sampling Plan Belgian Feed Industry 5

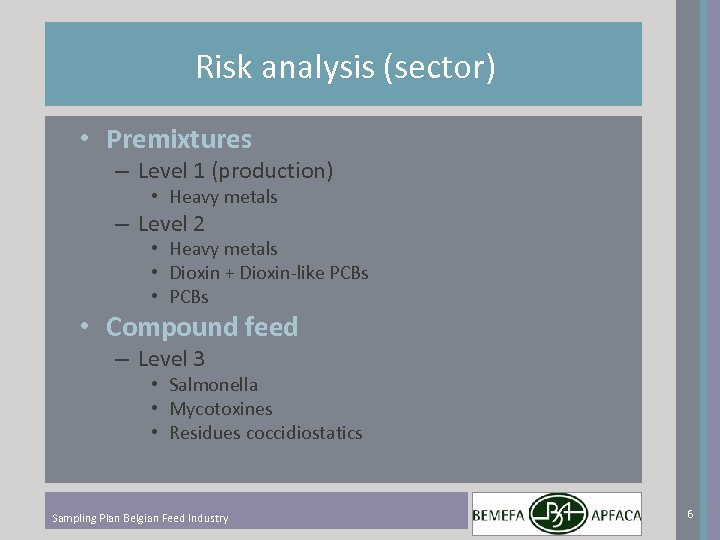

Risk analysis (sector) • Premixtures – Level 1 (production) • Heavy metals – Level 2 • Heavy metals • Dioxin + Dioxin-like PCBs • PCBs • Compound feed – Level 3 • Salmonella • Mycotoxines • Residues coccidiostatics Sampling Plan Belgian Feed Industry 6

Risk analysis (sector) • Premixtures – Level 1 (production) • Heavy metals – Level 2 • Heavy metals • Dioxin + Dioxin-like PCBs • PCBs • Compound feed – Level 3 • Salmonella • Mycotoxines • Residues coccidiostatics Sampling Plan Belgian Feed Industry 6

19 categories cereals Cereal products and by-products Products and by-products of seed and pulses Products and by-products of the sugarpreparation Products and by-products of the assimilation of fruit Products and by-products of tubers and carrots Oil-bearing seeds Products and by-products of oil-bearing seeds Dehydrated fodder Products with a high fibre content Fish products Oils & fats Dairy products Bakery products and products of food pasts Macro-minerals Special nitrogen compounds additives By-products of biofuel others Sampling Plan Belgian Feed Industry 7

19 categories cereals Cereal products and by-products Products and by-products of seed and pulses Products and by-products of the sugarpreparation Products and by-products of the assimilation of fruit Products and by-products of tubers and carrots Oil-bearing seeds Products and by-products of oil-bearing seeds Dehydrated fodder Products with a high fibre content Fish products Oils & fats Dairy products Bakery products and products of food pasts Macro-minerals Special nitrogen compounds additives By-products of biofuel others Sampling Plan Belgian Feed Industry 7

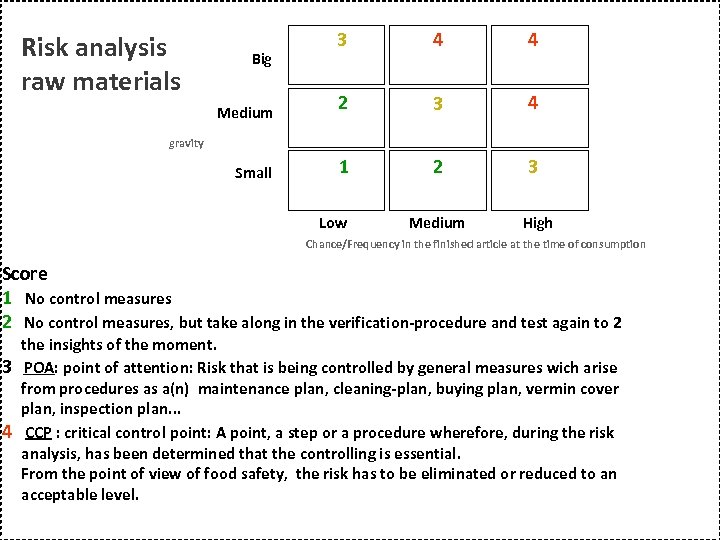

Risk analysis raw materials Big Medium 3 4 4 2 3 4 1 2 3 gravity Small Low Medium High Chance/Frequency in the finished article at the time of consumption Score 1 No control measures 2 No control measures, but take along in the verification-procedure and test again to 2 the insights of the moment. 3 POA: point of attention: Risk that is being controlled by general measures wich arise from procedures as a(n) maintenance plan, cleaning-plan, buying plan, vermin cover plan, inspection plan. . . 4 CCP : critical control point: A point, a step or a procedure wherefore, during the risk analysis, has been determined that the controlling is essential. From the point of view of food safety, the risk has to be eliminated or reduced to an acceptable level. 8

Risk analysis raw materials Big Medium 3 4 4 2 3 4 1 2 3 gravity Small Low Medium High Chance/Frequency in the finished article at the time of consumption Score 1 No control measures 2 No control measures, but take along in the verification-procedure and test again to 2 the insights of the moment. 3 POA: point of attention: Risk that is being controlled by general measures wich arise from procedures as a(n) maintenance plan, cleaning-plan, buying plan, vermin cover plan, inspection plan. . . 4 CCP : critical control point: A point, a step or a procedure wherefore, during the risk analysis, has been determined that the controlling is essential. From the point of view of food safety, the risk has to be eliminated or reduced to an acceptable level. 8

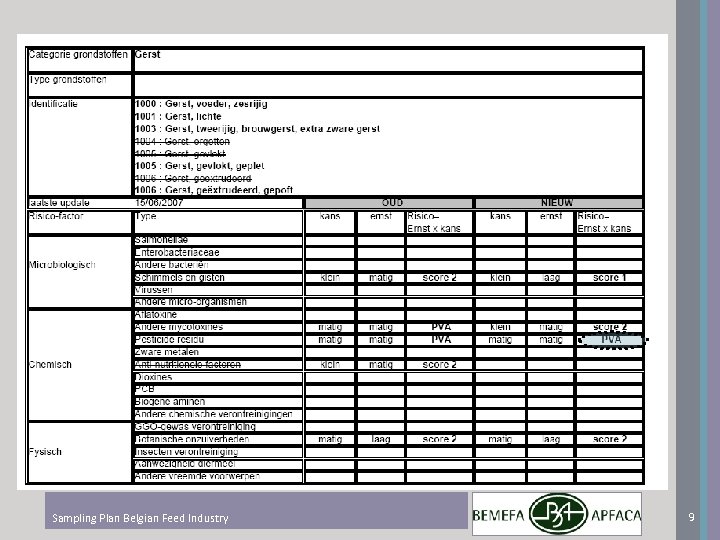

Sampling Plan Belgian Feed Industry 9

Sampling Plan Belgian Feed Industry 9

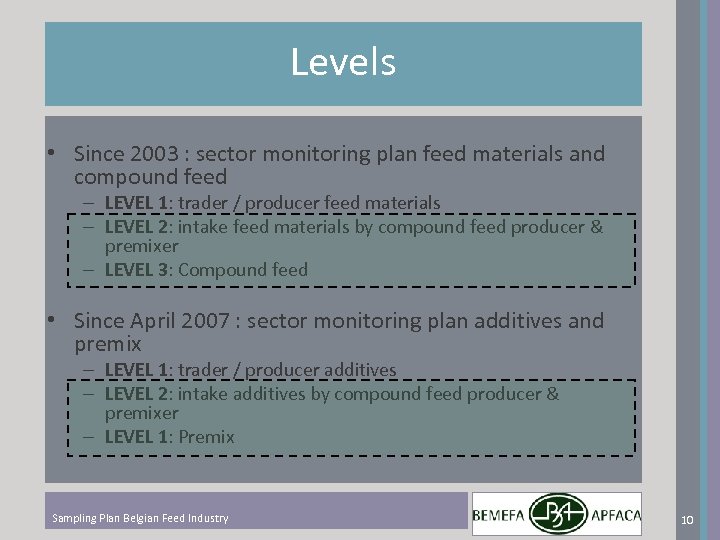

Levels • Since 2003 : sector monitoring plan feed materials and compound feed – LEVEL 1: trader / producer feed materials – LEVEL 2: intake feed materials by compound feed producer & premixer – LEVEL 3: Compound feed • Since April 2007 : sector monitoring plan additives and premix – LEVEL 1: trader / producer additives – LEVEL 2: intake additives by compound feed producer & premixer – LEVEL 1: Premix Sampling Plan Belgian Feed Industry 10

Levels • Since 2003 : sector monitoring plan feed materials and compound feed – LEVEL 1: trader / producer feed materials – LEVEL 2: intake feed materials by compound feed producer & premixer – LEVEL 3: Compound feed • Since April 2007 : sector monitoring plan additives and premix – LEVEL 1: trader / producer additives – LEVEL 2: intake additives by compound feed producer & premixer – LEVEL 1: Premix Sampling Plan Belgian Feed Industry 10

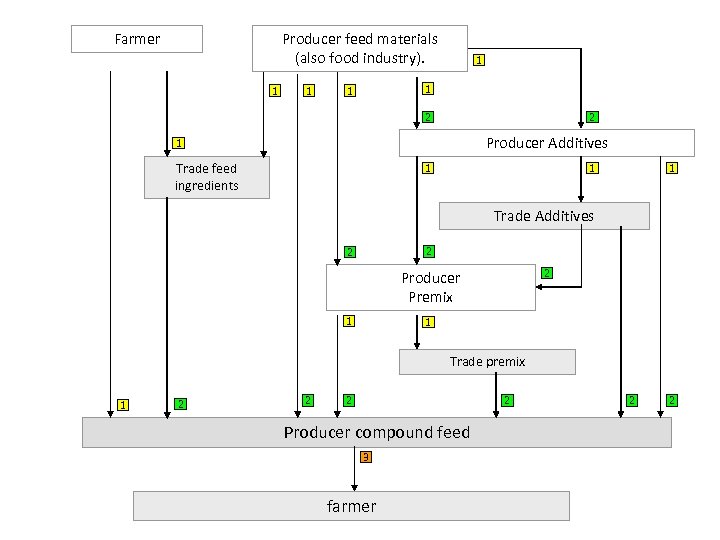

Farmer Producer feed materials (also food industry). 1 1 1 2 2 Producer Additives 1 Trade feed ingredients 1 1 1 Trade Additives 2 2 2 Producer Premix 1 1 Trade premix 1 2 2 2 Producer compound feed 3 11 farmer

Farmer Producer feed materials (also food industry). 1 1 1 2 2 Producer Additives 1 Trade feed ingredients 1 1 1 Trade Additives 2 2 2 Producer Premix 1 1 Trade premix 1 2 2 2 Producer compound feed 3 11 farmer

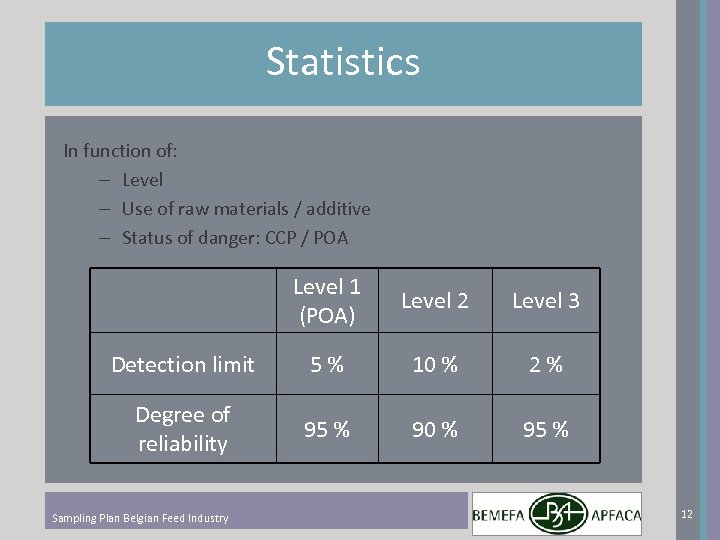

Statistics In function of: – Level – Use of raw materials / additive – Status of danger: CCP / POA Level 1 (POA) Level 2 Level 3 Detection limit 5% 10 % 2% Degree of reliability 95 % 90 % 95 % Sampling Plan Belgian Feed Industry 12

Statistics In function of: – Level – Use of raw materials / additive – Status of danger: CCP / POA Level 1 (POA) Level 2 Level 3 Detection limit 5% 10 % 2% Degree of reliability 95 % 90 % 95 % Sampling Plan Belgian Feed Industry 12

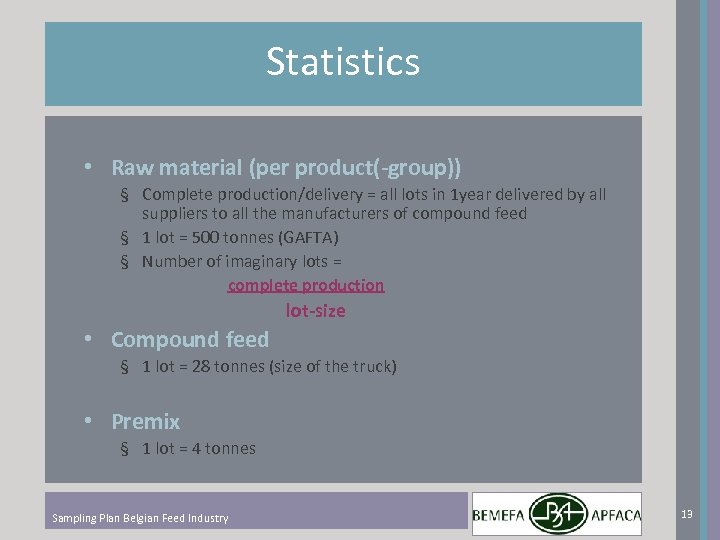

Statistics • Raw material (per product(-group)) § Complete production/delivery = all lots in 1 year delivered by all suppliers to all the manufacturers of compound feed § 1 lot = 500 tonnes (GAFTA) § Number of imaginary lots = complete production lot-size • Compound feed § 1 lot = 28 tonnes (size of the truck) • Premix § 1 lot = 4 tonnes Sampling Plan Belgian Feed Industry 13

Statistics • Raw material (per product(-group)) § Complete production/delivery = all lots in 1 year delivered by all suppliers to all the manufacturers of compound feed § 1 lot = 500 tonnes (GAFTA) § Number of imaginary lots = complete production lot-size • Compound feed § 1 lot = 28 tonnes (size of the truck) • Premix § 1 lot = 4 tonnes Sampling Plan Belgian Feed Industry 13

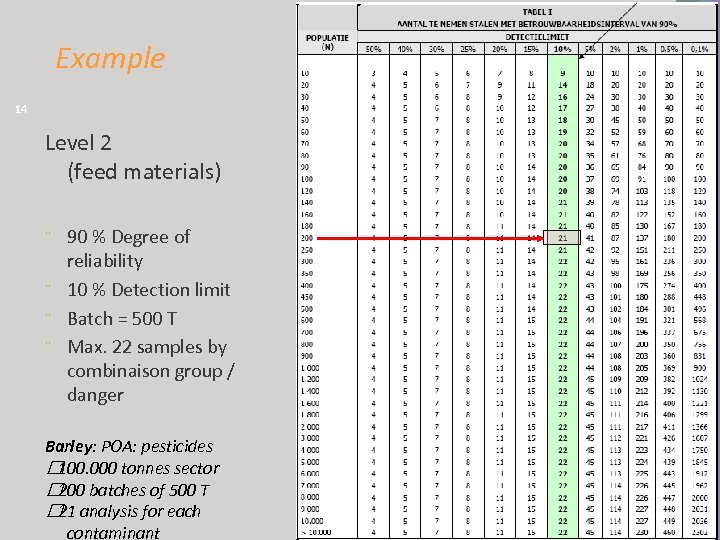

Example 14 Level 2 (feed materials) 90 % Degree of reliability ¨ 10 % Detection limit ¨ Batch = 500 T ¨ Max. 22 samples by combinaison group / danger ¨ Barley: POA: pesticides 100. 000 tonnes sector batches of 500 T 200 analysis for each 21 contaminant

Example 14 Level 2 (feed materials) 90 % Degree of reliability ¨ 10 % Detection limit ¨ Batch = 500 T ¨ Max. 22 samples by combinaison group / danger ¨ Barley: POA: pesticides 100. 000 tonnes sector batches of 500 T 200 analysis for each 21 contaminant

BEMEFA Sampling plans • • Start : 2003 on feed materials 2006 : premixtures & additives 2008 : coccidio 2010 : export petfood ü Validated by Food Safety Agency : less control on participants ü Samples (part) taken by certification bodies & total control by certification bodies Sampling Plan Belgian Feed Industry 15

BEMEFA Sampling plans • • Start : 2003 on feed materials 2006 : premixtures & additives 2008 : coccidio 2010 : export petfood ü Validated by Food Safety Agency : less control on participants ü Samples (part) taken by certification bodies & total control by certification bodies Sampling Plan Belgian Feed Industry 15

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

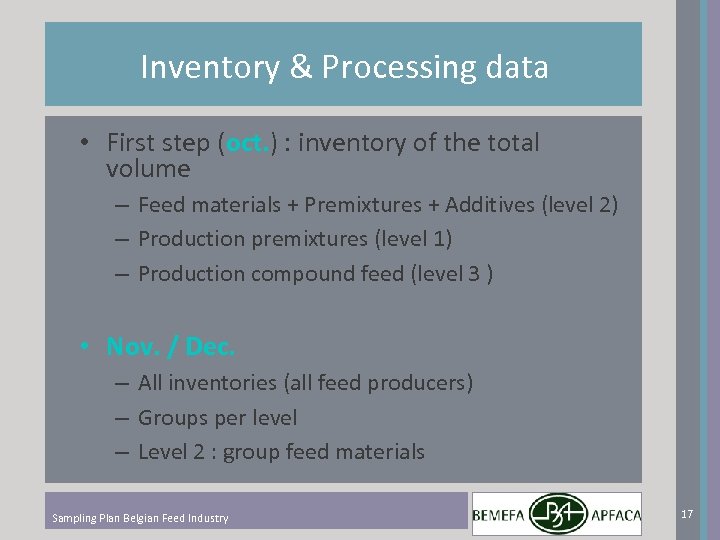

Inventory & Processing data • First step (oct. ) : inventory of the total volume – Feed materials + Premixtures + Additives (level 2) – Production premixtures (level 1) – Production compound feed (level 3 ) • Nov. / Dec. – All inventories (all feed producers) – Groups per level – Level 2 : group feed materials Sampling Plan Belgian Feed Industry 17

Inventory & Processing data • First step (oct. ) : inventory of the total volume – Feed materials + Premixtures + Additives (level 2) – Production premixtures (level 1) – Production compound feed (level 3 ) • Nov. / Dec. – All inventories (all feed producers) – Groups per level – Level 2 : group feed materials Sampling Plan Belgian Feed Industry 17

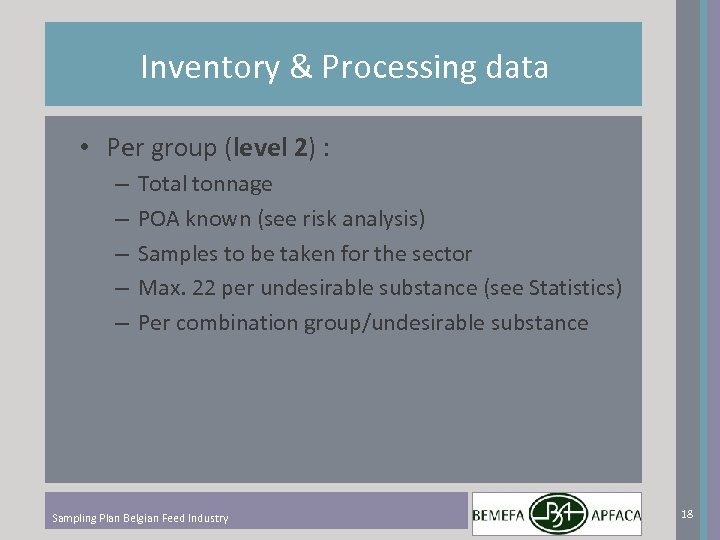

Inventory & Processing data • Per group (level 2) : – – – Total tonnage POA known (see risk analysis) Samples to be taken for the sector Max. 22 per undesirable substance (see Statistics) Per combination group/undesirable substance Sampling Plan Belgian Feed Industry 18

Inventory & Processing data • Per group (level 2) : – – – Total tonnage POA known (see risk analysis) Samples to be taken for the sector Max. 22 per undesirable substance (see Statistics) Per combination group/undesirable substance Sampling Plan Belgian Feed Industry 18

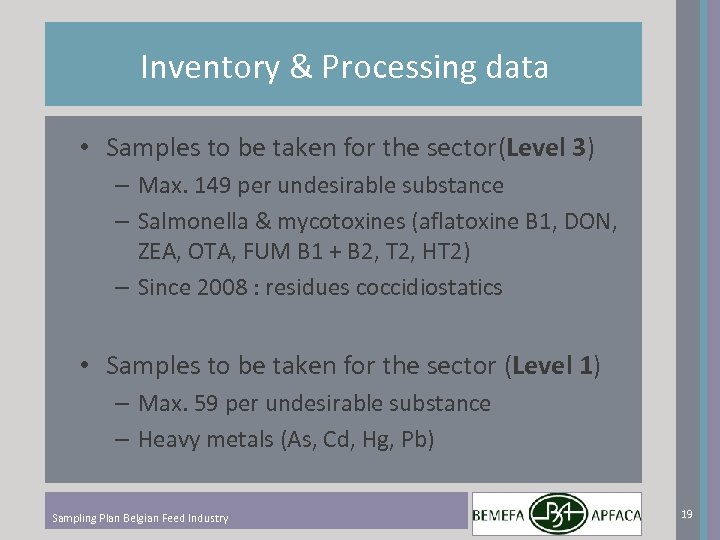

Inventory & Processing data • Samples to be taken for the sector(Level 3) – Max. 149 per undesirable substance – Salmonella & mycotoxines (aflatoxine B 1, DON, ZEA, OTA, FUM B 1 + B 2, T 2, HT 2) – Since 2008 : residues coccidiostatics • Samples to be taken for the sector (Level 1) – Max. 59 per undesirable substance – Heavy metals (As, Cd, Hg, Pb) Sampling Plan Belgian Feed Industry 19

Inventory & Processing data • Samples to be taken for the sector(Level 3) – Max. 149 per undesirable substance – Salmonella & mycotoxines (aflatoxine B 1, DON, ZEA, OTA, FUM B 1 + B 2, T 2, HT 2) – Since 2008 : residues coccidiostatics • Samples to be taken for the sector (Level 1) – Max. 59 per undesirable substance – Heavy metals (As, Cd, Hg, Pb) Sampling Plan Belgian Feed Industry 19

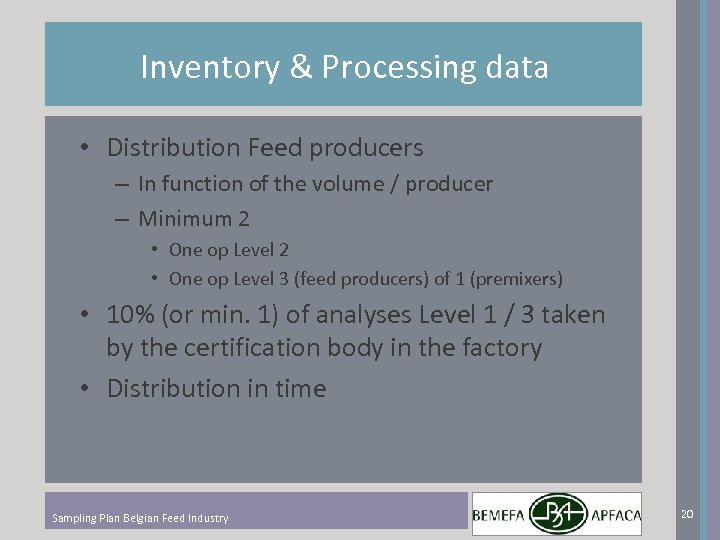

Inventory & Processing data • Distribution Feed producers – In function of the volume / producer – Minimum 2 • One op Level 3 (feed producers) of 1 (premixers) • 10% (or min. 1) of analyses Level 1 / 3 taken by the certification body in the factory • Distribution in time Sampling Plan Belgian Feed Industry 20

Inventory & Processing data • Distribution Feed producers – In function of the volume / producer – Minimum 2 • One op Level 3 (feed producers) of 1 (premixers) • 10% (or min. 1) of analyses Level 1 / 3 taken by the certification body in the factory • Distribution in time Sampling Plan Belgian Feed Industry 20

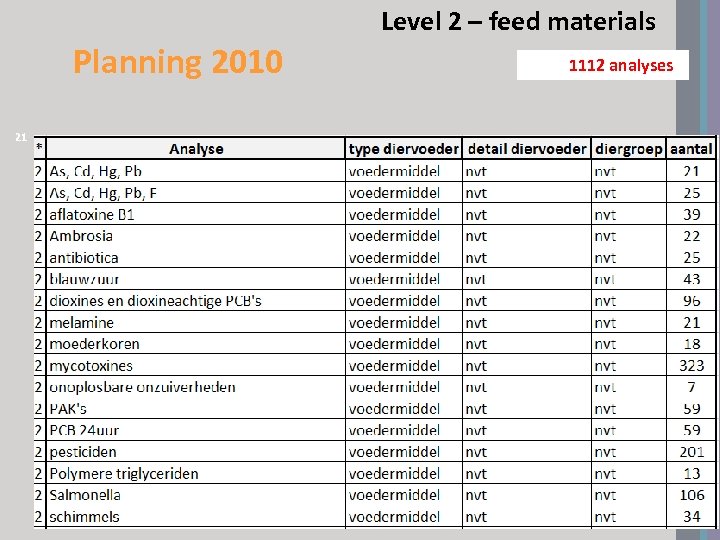

Level 2 – feed materials Planning 2010 21 1112 analyses

Level 2 – feed materials Planning 2010 21 1112 analyses

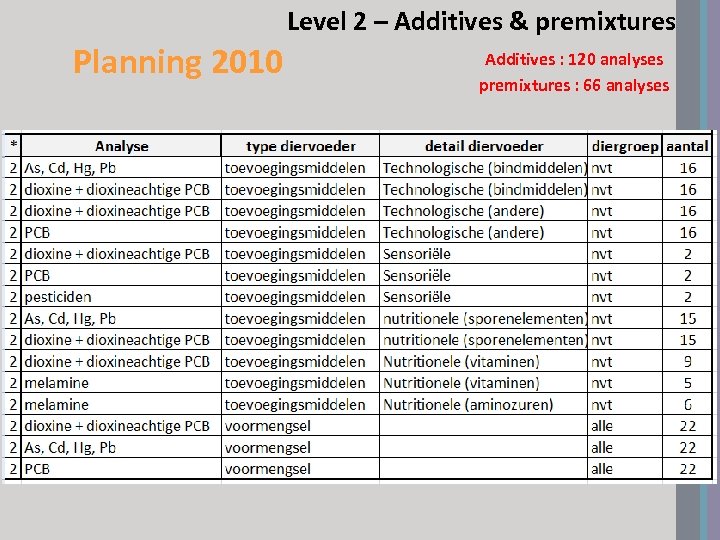

Level 2 – Additives & premixtures Planning 2010 Additives : 120 analyses premixtures : 66 analyses

Level 2 – Additives & premixtures Planning 2010 Additives : 120 analyses premixtures : 66 analyses

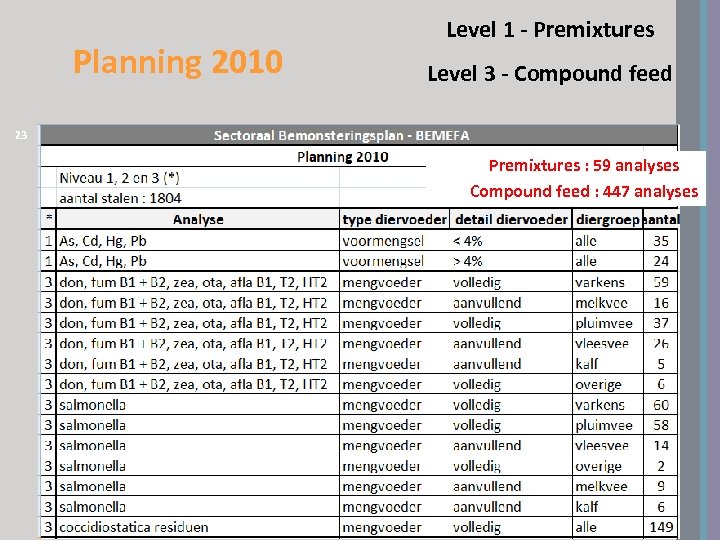

Planning 2010 Level 1 - Premixtures Level 3 - Compound feed 23 Planning 2010 Premixtures : 59 analyses Compound feed : 447 analyses

Planning 2010 Level 1 - Premixtures Level 3 - Compound feed 23 Planning 2010 Premixtures : 59 analyses Compound feed : 447 analyses

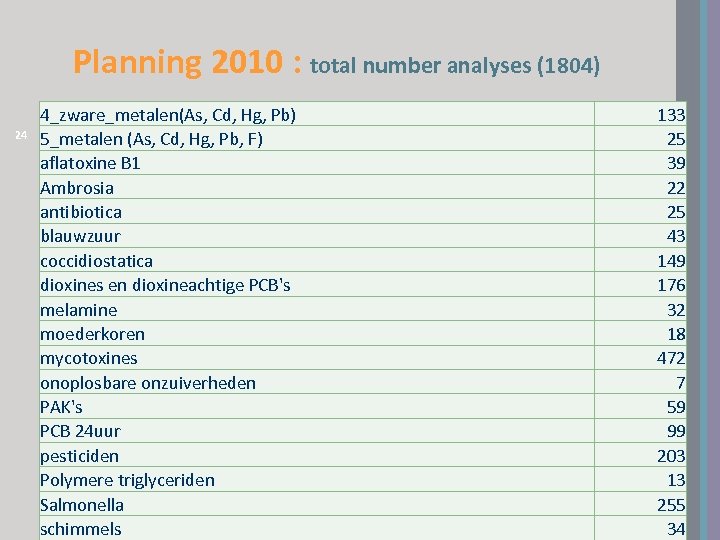

Planning 2010 : total number analyses (1804) 24 4_zware_metalen(As, Cd, Hg, Pb) 5_metalen (As, Cd, Hg, Pb, F) aflatoxine B 1 Ambrosia antibiotica blauwzuur coccidiostatica dioxines en dioxineachtige PCB's melamine moederkoren mycotoxines onoplosbare onzuiverheden PAK's PCB 24 uur pesticiden Polymere triglyceriden Salmonella schimmels 133 25 39 22 25 43 149 176 32 18 472 7 59 99 203 13 255 34

Planning 2010 : total number analyses (1804) 24 4_zware_metalen(As, Cd, Hg, Pb) 5_metalen (As, Cd, Hg, Pb, F) aflatoxine B 1 Ambrosia antibiotica blauwzuur coccidiostatica dioxines en dioxineachtige PCB's melamine moederkoren mycotoxines onoplosbare onzuiverheden PAK's PCB 24 uur pesticiden Polymere triglyceriden Salmonella schimmels 133 25 39 22 25 43 149 176 32 18 472 7 59 99 203 13 255 34

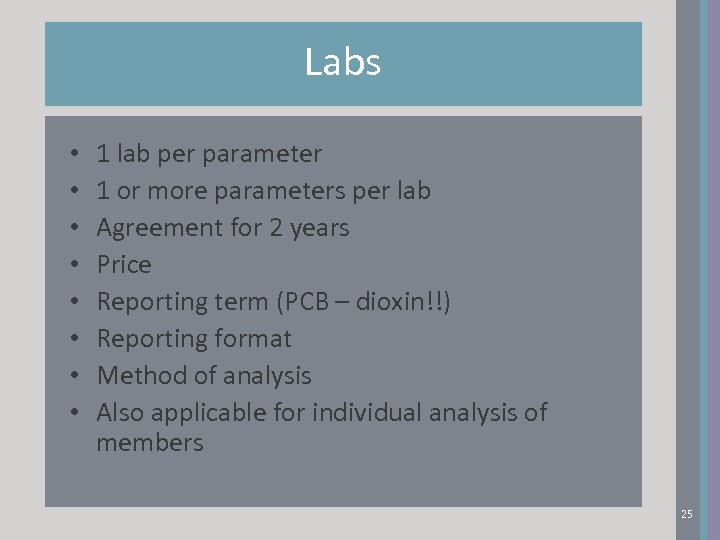

Labs • • 1 lab per parameter 1 or more parameters per lab Agreement for 2 years Price Reporting term (PCB – dioxin!!) Reporting format Method of analysis Also applicable for individual analysis of members 25

Labs • • 1 lab per parameter 1 or more parameters per lab Agreement for 2 years Price Reporting term (PCB – dioxin!!) Reporting format Method of analysis Also applicable for individual analysis of members 25

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

Principles • Risk-analysis • Levels - sampling plans • Statistics number of analyses Processing & planning • • Monitoring • Software • Web-application feed producers • Monitoring BEMEFA Inventory total volume Processing data Planning analyses Labs

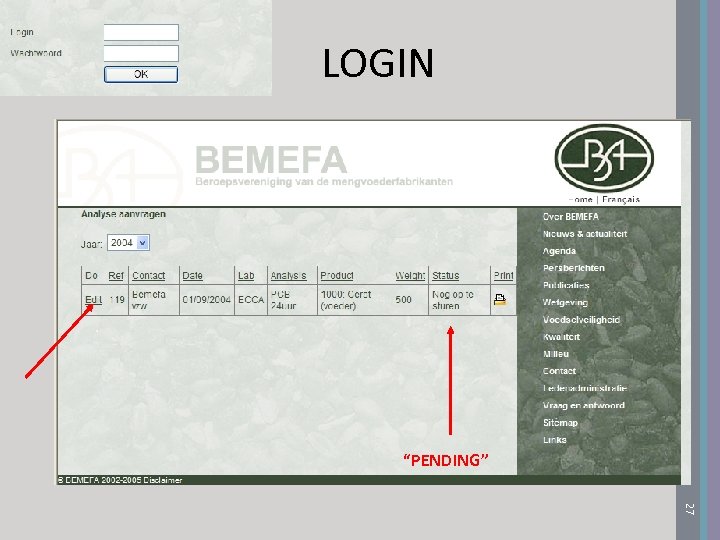

LOGIN “PENDING” 27

LOGIN “PENDING” 27

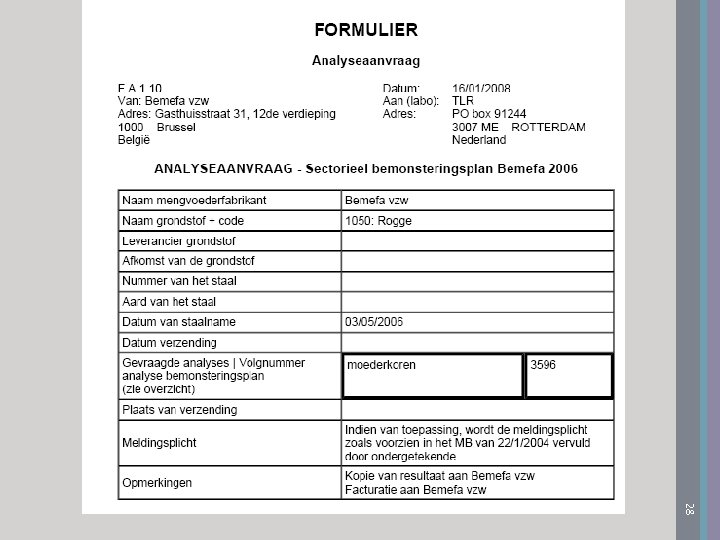

28

28

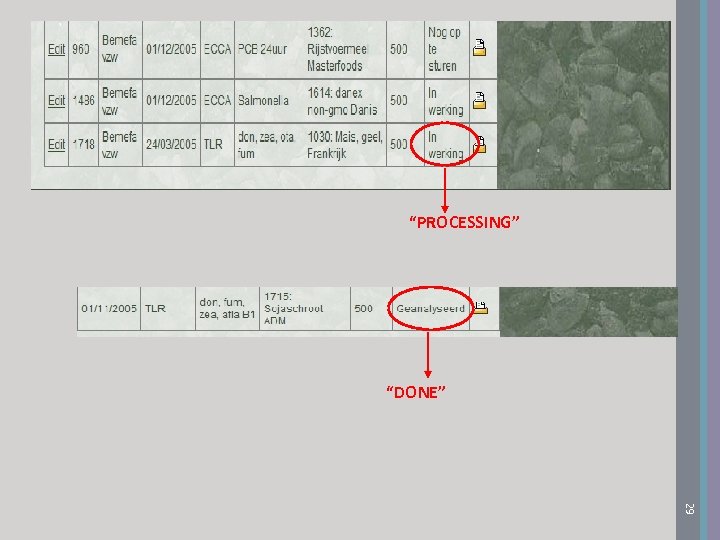

“PROCESSING” “DONE” 29

“PROCESSING” “DONE” 29

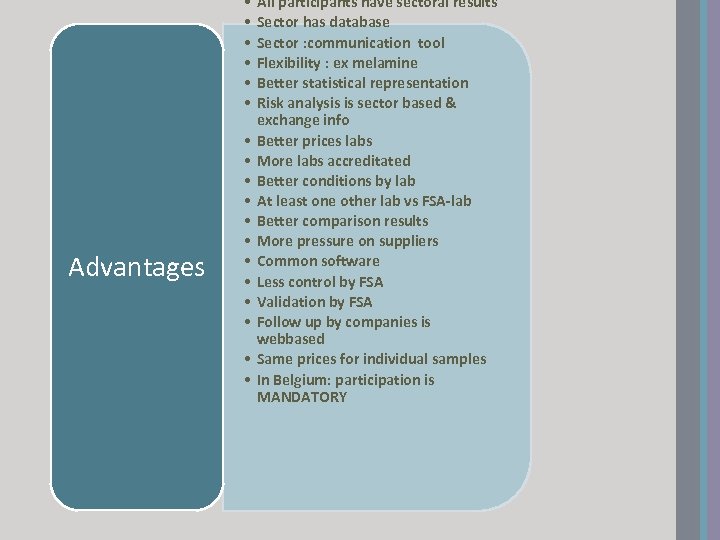

• • • Advantages • • • All participants have sectoral results Sector has database Sector : communication tool Flexibility : ex melamine Better statistical representation Risk analysis is sector based & exchange info Better prices labs More labs accreditated Better conditions by lab At least one other lab vs FSA-lab Better comparison results More pressure on suppliers Common software Less control by FSA Validation by FSA Follow up by companies is webbased Same prices for individual samples In Belgium: participation is MANDATORY

• • • Advantages • • • All participants have sectoral results Sector has database Sector : communication tool Flexibility : ex melamine Better statistical representation Risk analysis is sector based & exchange info Better prices labs More labs accreditated Better conditions by lab At least one other lab vs FSA-lab Better comparison results More pressure on suppliers Common software Less control by FSA Validation by FSA Follow up by companies is webbased Same prices for individual samples In Belgium: participation is MANDATORY

CONCLUSIONS • • COMMUNICATION Transparancy (for example : to retail) Attractivity Harmonization: national & international Credibility : takes time Continuous effort : take care for routine ! Financial : input but also important output

CONCLUSIONS • • COMMUNICATION Transparancy (for example : to retail) Attractivity Harmonization: national & international Credibility : takes time Continuous effort : take care for routine ! Financial : input but also important output

THANK YOU FOR YOUR ATTENTION! BEMEFA v. z. w. – APFACA a. s. b. l. Beroepsvereniging van de Mengvoeder. Fabrikanten Association Professionnelle des Fabricants d’Aliments Composés pour Animaux Gasthuisstraat 31 Rue de l'Hôpital Brussel 1000 Bruxelles (0)2/512. 09. 55 (0)2/514. 03. 51 +32 : www. bemefa. be info@bemefa. be : www. eufetec. eu Sampling Plan Belgian Feed Industry 34

THANK YOU FOR YOUR ATTENTION! BEMEFA v. z. w. – APFACA a. s. b. l. Beroepsvereniging van de Mengvoeder. Fabrikanten Association Professionnelle des Fabricants d’Aliments Composés pour Animaux Gasthuisstraat 31 Rue de l'Hôpital Brussel 1000 Bruxelles (0)2/512. 09. 55 (0)2/514. 03. 51 +32 : www. bemefa. be info@bemefa. be : www. eufetec. eu Sampling Plan Belgian Feed Industry 34