f811080fb0fb547dc88ab101c8d1238c.ppt

- Количество слайдов: 30

Sample-Handling and Conditioning Systems Basics Dr. Achim Zajc

Sample-Handling / Conditioning Systems Design Objectives à The sample-handling and conditioning system must: – Obtain a sample that is representative – Transport of the sample to analyzer – Condition the sample (i. e. clean, vaporize, condense adjust pressure, dilute etc. ) to the analyzer requirements – Return the unused sample either to the process or to a waste disposal system

Sample-Handling / Conditioning Systems Representative Sampling à Sample Point – Locate in a flowing stream where the composition is more likely to give up-to-date information – Locate as close as possible to the point where corrective action is to be applied to control the process – Locate a point with moderate pressure and temperature – Locate the sample point where the process is intimately mixed, where the reaction is complete and where composition is stable – The sample point should be located so that it can be readily accessed

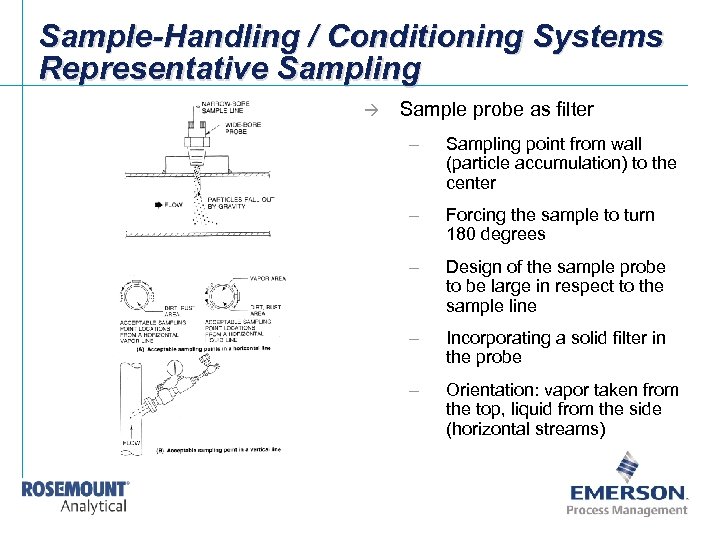

Sample-Handling / Conditioning Systems Representative Sampling à Sample Probes – Purpose • Deliver a representative sample • Taking the sample near the center of the stream (turbulent mixing, changes in the process can be quickly sensed) • Serves as a preliminary stage of the conditioning by acting as a primary filter

Sample-Handling / Conditioning Systems Representative Sampling à Sample probe as filter – Sampling point from wall (particle accumulation) to the center – Forcing the sample to turn 180 degrees – Design of the sample probe to be large in respect to the sample line – Incorporating a solid filter in the probe – Orientation: vapor taken from the top, liquid from the side (horizontal streams)

Sample-Handling / Conditioning Systems Sample Transport à Overall system dead time à Turnaround time – Mounting the analyzer closer to the sample point – Increasing the flow of the sample (fast loop) • Turbulent mixing • Representative sampling

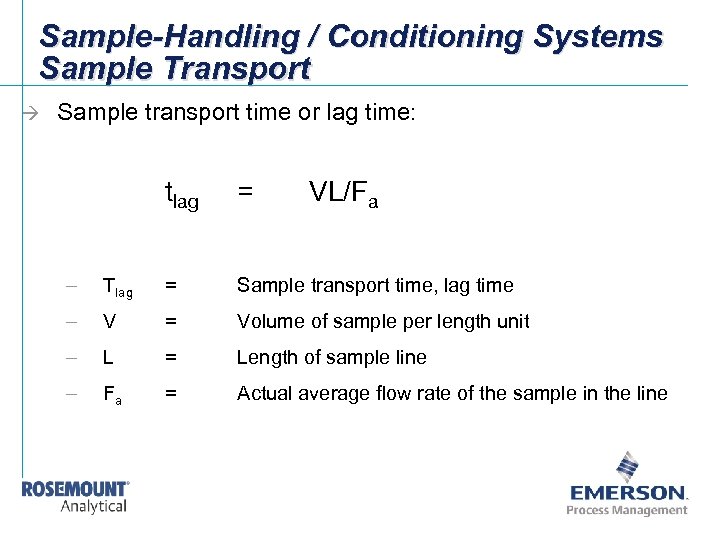

Sample-Handling / Conditioning Systems Sample Transport à Sample transport time or lag time: tlag = VL/Fa – Tlag = Sample transport time, lag time – V = Volume of sample per length unit – L = Length of sample line – Fa = Actual average flow rate of the sample in the line

Sample-Handling / Conditioning Systems Sample Transport

Sample-Handling / Conditioning Systems Sizing of Sample Transport Lines à General Considerations – Requirements of the analyzer • In a case of a multistream analyzer to avoid cross contamination the sample line have to should be flashed at least five times by new sample – The presence of various SCS elements will also contribute to the lag time

Sample-Handling / Conditioning Systems Dew Point Calculation à The calculation of the dew point relies on the use of distribution coefficients Ki: Ki = Yi/Xi – Ki = Distribution coefficient of component i – Yi = Mole fraction of component i in the vapor phase – Xi = Mole fraction of component i in the liquid phase

Sample-Handling / Conditioning Systems Dew Point Calculation

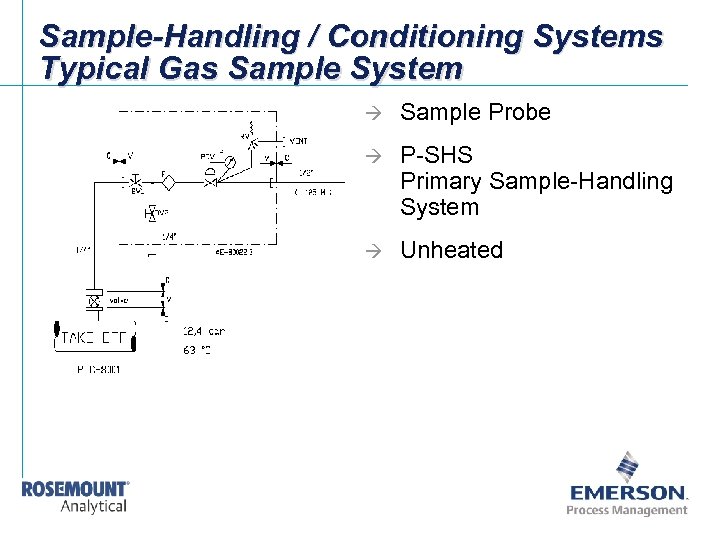

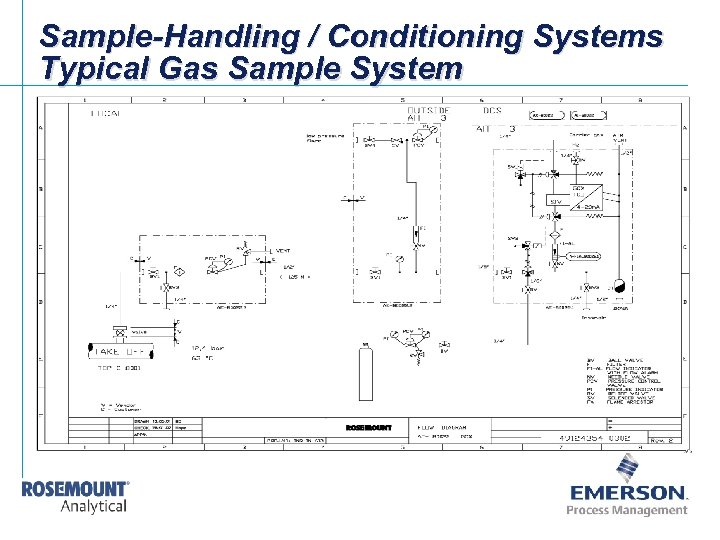

Sample-Handling / Conditioning Systems Typical Gas Sample System à Sample Probe à P-SHS Primary Sample-Handling System à Unheated

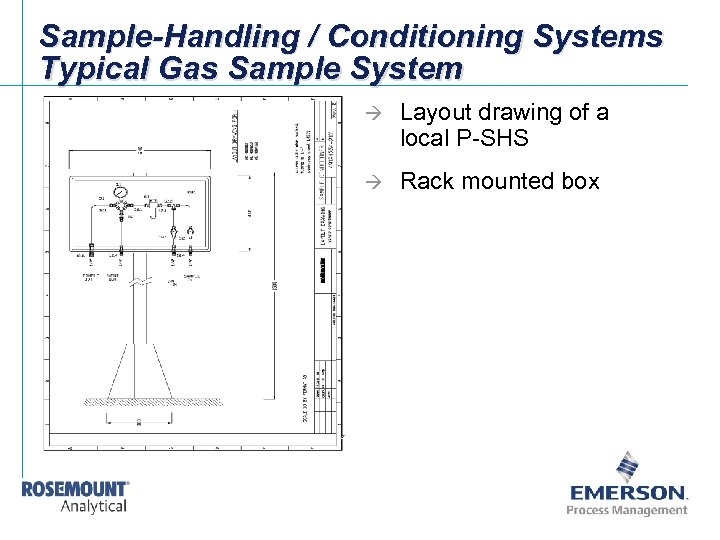

Sample-Handling / Conditioning Systems Typical Gas Sample System à Layout drawing of a local P-SHS à Rack mounted box

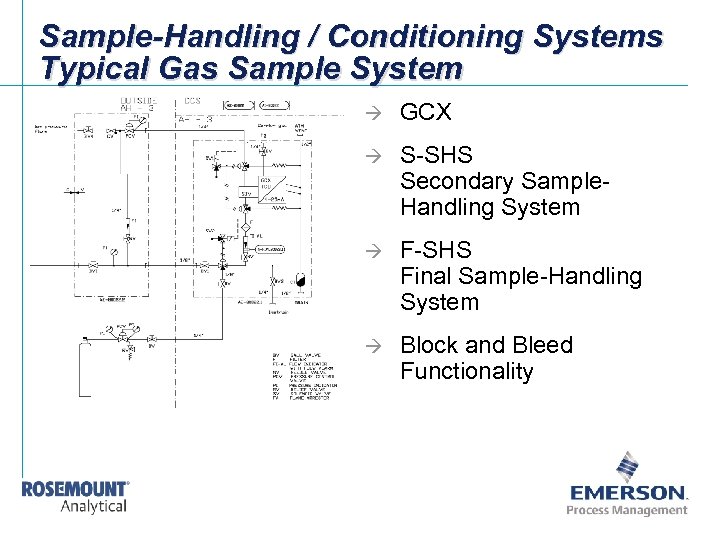

Sample-Handling / Conditioning Systems Typical Gas Sample System à GCX à S-SHS Secondary Sample. Handling System à F-SHS Final Sample-Handling System à Block and Bleed Functionality

Sample-Handling / Conditioning Systems Typical Gas Sample System

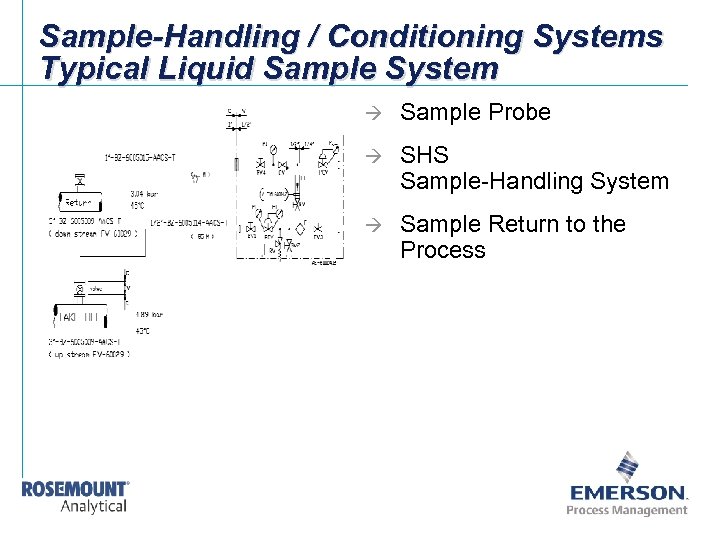

Sample-Handling / Conditioning Systems Typical Liquid Sample System à Sample Probe à SHS Sample-Handling System à Sample Return to the Process

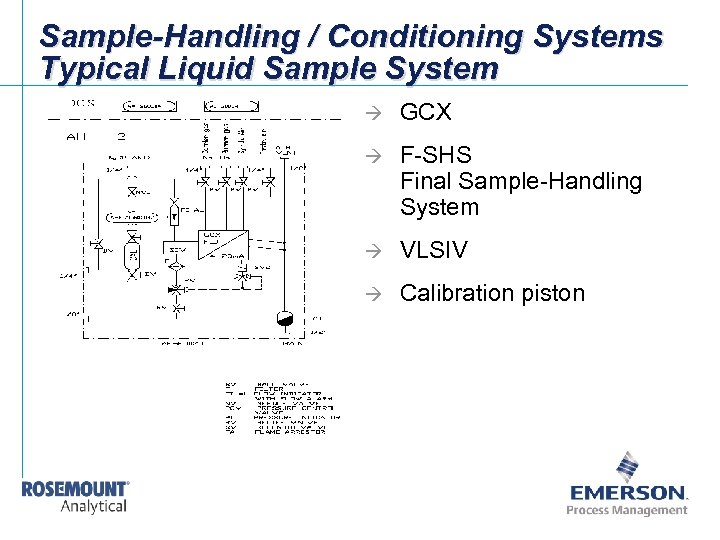

Sample-Handling / Conditioning Systems Typical Liquid Sample System à GCX à F-SHS Final Sample-Handling System à VLSIV à Calibration piston

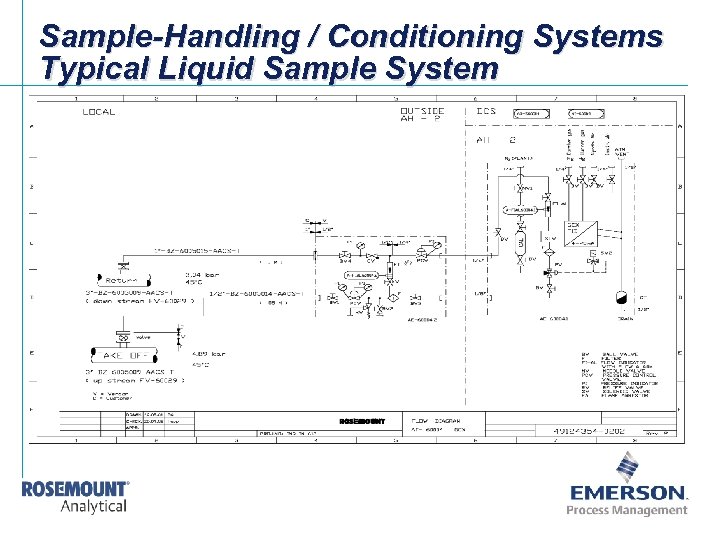

Sample-Handling / Conditioning Systems Typical Liquid Sample System

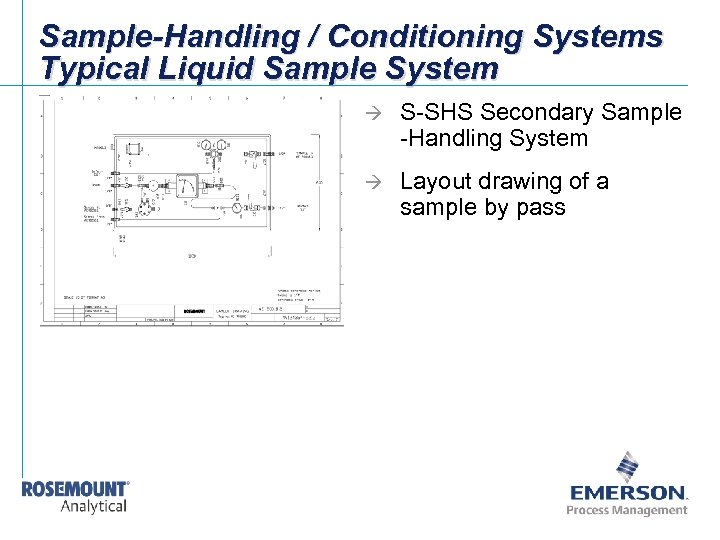

Sample-Handling / Conditioning Systems Typical Liquid Sample System à S-SHS Secondary Sample -Handling System à Layout drawing of a sample by pass

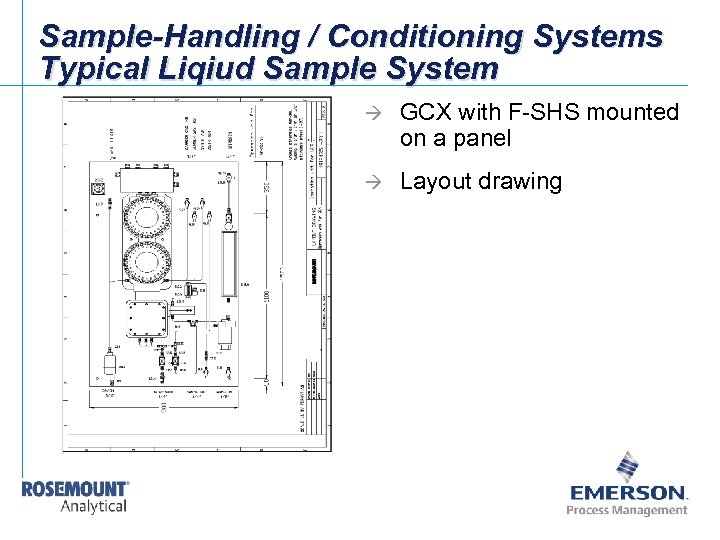

Sample-Handling / Conditioning Systems Typical Liqiud Sample System à GCX with F-SHS mounted on a panel à Layout drawing

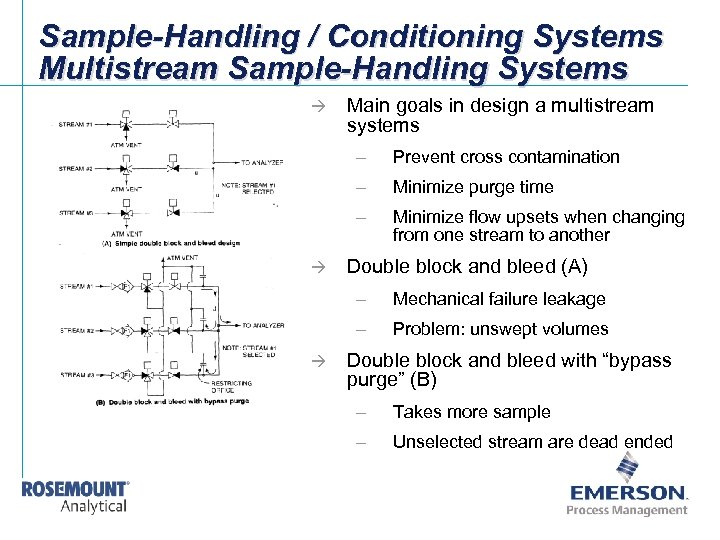

Sample-Handling / Conditioning Systems Multistream Sample-Handling Systems à Main goals in design a multistream systems – – Minimize purge time – à Prevent cross contamination Minimize flow upsets when changing from one stream to another Double block and bleed (A) – – à Mechanical failure leakage Problem: unswept volumes Double block and bleed with “bypass purge” (B) – Takes more sample – Unselected stream are dead ended

Sample-Handling / Conditioning Systems Multistream Sample-Handling Systems à Double block and bleed – Bypass purge – Continous sample flow in unselected lines

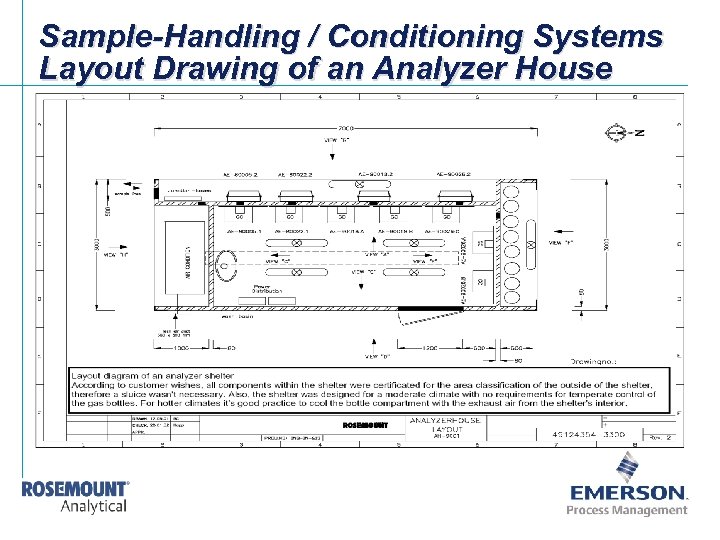

Sample-Handling / Conditioning Systems Layout Drawing of an Analyzer House

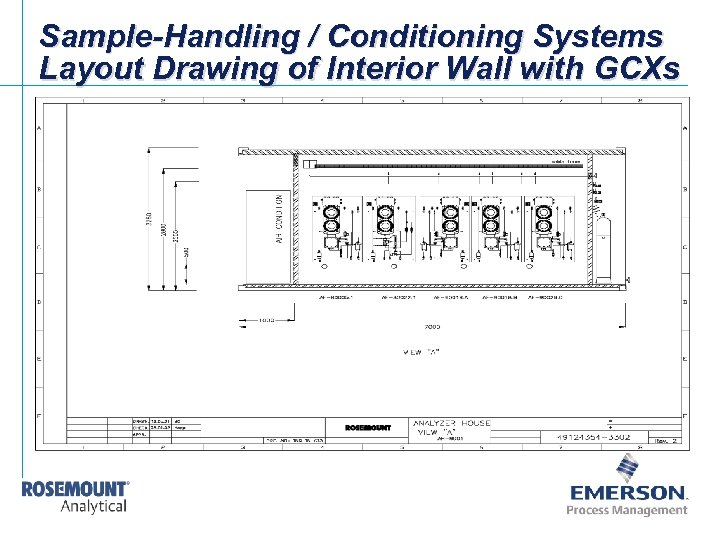

Sample-Handling / Conditioning Systems Layout Drawing of Interior Wall with GCXs

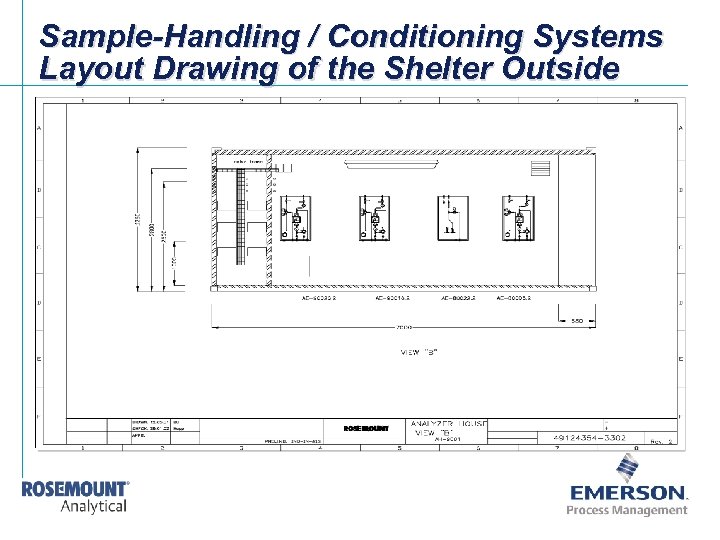

Sample-Handling / Conditioning Systems Layout Drawing of the Shelter Outside

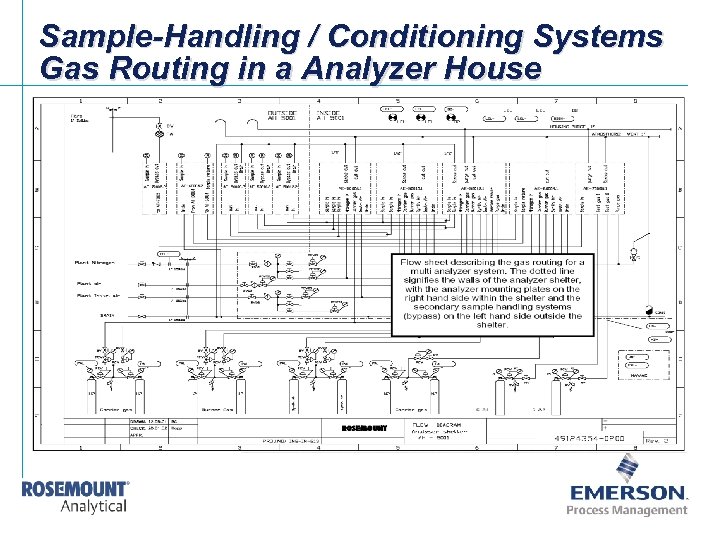

Sample-Handling / Conditioning Systems Gas Routing in a Analyzer House

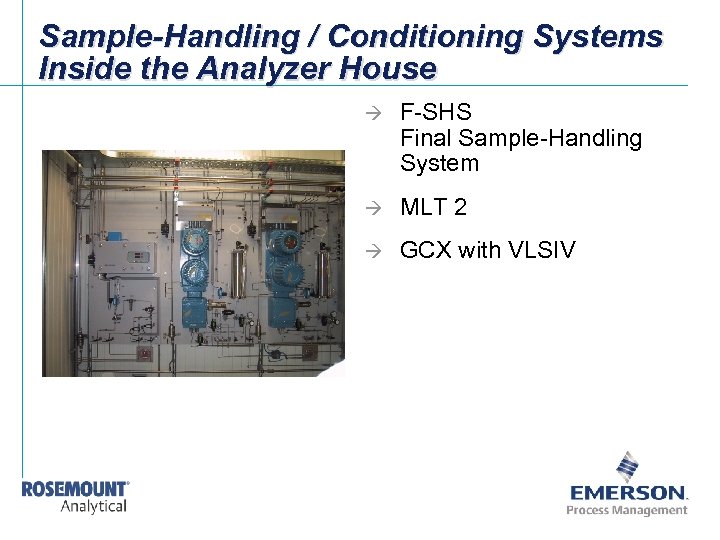

Sample-Handling / Conditioning Systems Inside the Analyzer House à F-SHS Final Sample-Handling System à MLT 2 à GCX with VLSIV

Sample-Handling / Conditioning Systems Maintenance Considerations I à Locate the system components for effective maintenance à Systems that handle corrosive streams should have purge capabilities for cleaning à If elevated temperature mount components within a heated box rather than just insulating and packing à Provide valving for venting system pressure à Provide valving for the introduction of calibration standard

Sample-Handling / Conditioning Systems Maintenance Considerations II à Provide that any malfunctioning part can be replaced easily and quickly à Provide isolation valving so that sample can continue flowing in the long sample lines while maintenance work is being performed (routine or preventive maintenance) à Keep volumes as small as possible

Sample-Handling / Conditioning Systems Summary à Requested informations to design a SHS/SCS: – Temperature of the sample – Pressure of the sample – Complete stream composition – Components to be analyzed – Ambient air conditions – Area classification

f811080fb0fb547dc88ab101c8d1238c.ppt