f2a27286d4dacf46da813287b0a41eeb.ppt

- Количество слайдов: 30

Samegoal Precision machining Co. , Ltd Company Introduction Nov-14 th-2008

Samegoal Precision machining Co. , Ltd Company Introduction Nov-14 th-2008

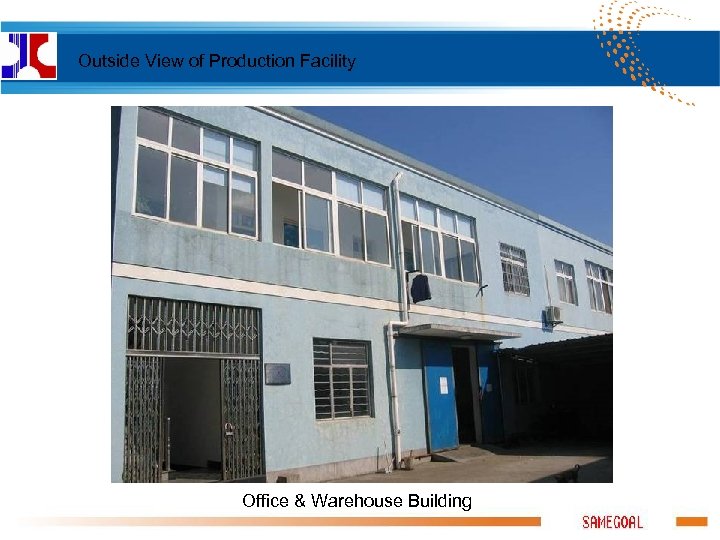

Outside View of Production Facility Office & Warehouse Building

Outside View of Production Facility Office & Warehouse Building

Overall Introduction Samegoal Precision Machining Co. , Ltd was established in 2004 as a trading company. Seeing the need to guarantee our customers increased quality and service, we opened our own production facility in the Ningbo City area in March, 2008. From the beginning our company policy has always been: “Quality first, on-time delivery, and continuous improvement are Samegoal’s core values. ” To provide the quality our customers expect, we modeled our quality system after the ISO 9001 system. Based on our customers requirements, we will prepare PPAPs, Implement FMEAs, Provide control plans, Provide SPC control plans, First Article Inspections and Outgoing Inspection Report.

Overall Introduction Samegoal Precision Machining Co. , Ltd was established in 2004 as a trading company. Seeing the need to guarantee our customers increased quality and service, we opened our own production facility in the Ningbo City area in March, 2008. From the beginning our company policy has always been: “Quality first, on-time delivery, and continuous improvement are Samegoal’s core values. ” To provide the quality our customers expect, we modeled our quality system after the ISO 9001 system. Based on our customers requirements, we will prepare PPAPs, Implement FMEAs, Provide control plans, Provide SPC control plans, First Article Inspections and Outgoing Inspection Report.

Overall Introduction Business Focus: Machined parts (CNC Turning and Milling, etc. ) Plastic molding and injection Customers: Our customers are mainly from USA, Canada, Norway, Denmark; United Kingdom, Germany, France, and Hong Kong Engineering and CAD Capabilities: We accept and use all file types: Auto-CAD, Pro-E, Solidworks, etc. Work Force: 20 skilled operators and 2 Quality Assurance Inspectors Facility: 8 sets of CNC lathe and other machining equipment 600 Square Meters (6, 500 Square Feet)

Overall Introduction Business Focus: Machined parts (CNC Turning and Milling, etc. ) Plastic molding and injection Customers: Our customers are mainly from USA, Canada, Norway, Denmark; United Kingdom, Germany, France, and Hong Kong Engineering and CAD Capabilities: We accept and use all file types: Auto-CAD, Pro-E, Solidworks, etc. Work Force: 20 skilled operators and 2 Quality Assurance Inspectors Facility: 8 sets of CNC lathe and other machining equipment 600 Square Meters (6, 500 Square Feet)

Management Team Longman Long---Operation manager, worked for TDK, Emerson, Nilfisk. ALTO as quality engineer and purchasing manager more than 10 years. Sunny Wong----Project and Quality Manager. Previous experience includes 11+ years of engineering and quality management for: Philips Electric, Pulse, Wagner. Mr. Zhang----Engineering manager. He has more than 20 years mechanical machining experience. Mr. Chen-----Factory manager. He has more than 30 years experience in machining industry. Craig Peterson----as North American Sales Manager.

Management Team Longman Long---Operation manager, worked for TDK, Emerson, Nilfisk. ALTO as quality engineer and purchasing manager more than 10 years. Sunny Wong----Project and Quality Manager. Previous experience includes 11+ years of engineering and quality management for: Philips Electric, Pulse, Wagner. Mr. Zhang----Engineering manager. He has more than 20 years mechanical machining experience. Mr. Chen-----Factory manager. He has more than 30 years experience in machining industry. Craig Peterson----as North American Sales Manager.

Main Equipment

Main Equipment

Main Equipment

Main Equipment

Workshop

Workshop

Machining Capability Stainless / Steel: length up to 300 mm, diameter up to 60 mm Aluminum / Brass: length up to 300 mm, diameter up to 120 mm Turning Professional CNC lathe, working ranges: Milling Plain milling machines & CNC milling machine Finishing Anodized, plating (zinc, tin, nickel, etc), polishing (manual electro-polishing), Surtec 650 etc. Heat treatment Annealing, Normalizing, Tempering, Nitriding, Carbonitriding, Carburizing, Induction hardening Outsourcing process Cold forming, forging, die casting, investment casting

Machining Capability Stainless / Steel: length up to 300 mm, diameter up to 60 mm Aluminum / Brass: length up to 300 mm, diameter up to 120 mm Turning Professional CNC lathe, working ranges: Milling Plain milling machines & CNC milling machine Finishing Anodized, plating (zinc, tin, nickel, etc), polishing (manual electro-polishing), Surtec 650 etc. Heat treatment Annealing, Normalizing, Tempering, Nitriding, Carbonitriding, Carburizing, Induction hardening Outsourcing process Cold forming, forging, die casting, investment casting

Machining Capability Available Materials : Stainless steel: SUS 430, 303, 304, 316 L, 321, etc. Carbon steel: AISI 1010, 1015, 1020, 1045, 16 Mn, Q 235 B, Q 345 B, 20 Cr 40 Cr. Mo. etc. Free cutting steel: AISI 1213, 12 L 14, 9 SMn. Pb 28, 9 SMn. Pb 36, 9 SMn 28, etc. Aluminum alloy: 6061 -T 6, 6063, 7075, 5052 etc. Copper and Brass: C 38000, C 37800, C 37700, C 36000, C 28000 etc Supper alloy: Inconel 600

Machining Capability Available Materials : Stainless steel: SUS 430, 303, 304, 316 L, 321, etc. Carbon steel: AISI 1010, 1015, 1020, 1045, 16 Mn, Q 235 B, Q 345 B, 20 Cr 40 Cr. Mo. etc. Free cutting steel: AISI 1213, 12 L 14, 9 SMn. Pb 28, 9 SMn. Pb 36, 9 SMn 28, etc. Aluminum alloy: 6061 -T 6, 6063, 7075, 5052 etc. Copper and Brass: C 38000, C 37800, C 37700, C 36000, C 28000 etc Supper alloy: Inconel 600

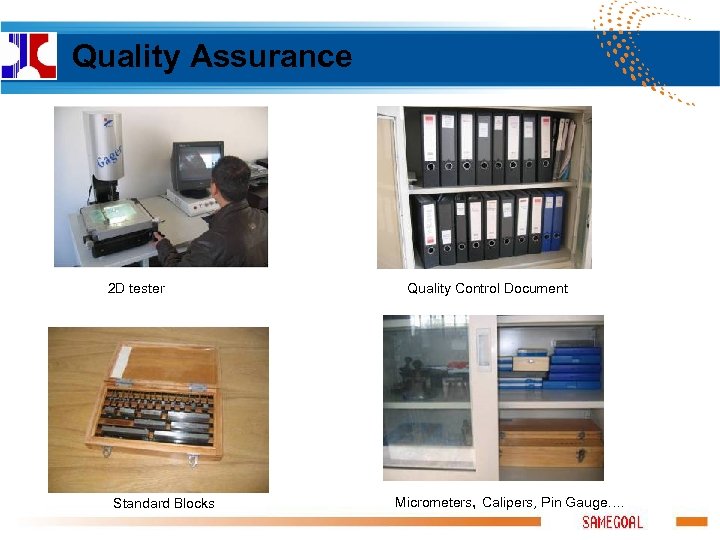

Quality Assurance 2 D tester Standard Blocks Quality Control Document Micrometers, Calipers, Pin Gauge….

Quality Assurance 2 D tester Standard Blocks Quality Control Document Micrometers, Calipers, Pin Gauge….

Quality Assurance Spectrometer (outsourcing) Roundness tester (outsourcing) Roughness tester (outsourcing) 3 D tester (outsourcing)

Quality Assurance Spectrometer (outsourcing) Roundness tester (outsourcing) Roughness tester (outsourcing) 3 D tester (outsourcing)

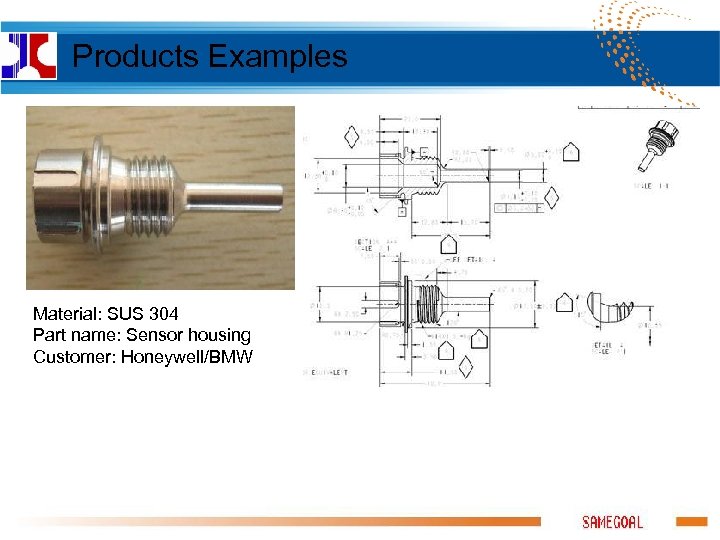

Products Examples Material: SUS 304 Part name: Sensor housing Customer: Honeywell/BMW

Products Examples Material: SUS 304 Part name: Sensor housing Customer: Honeywell/BMW

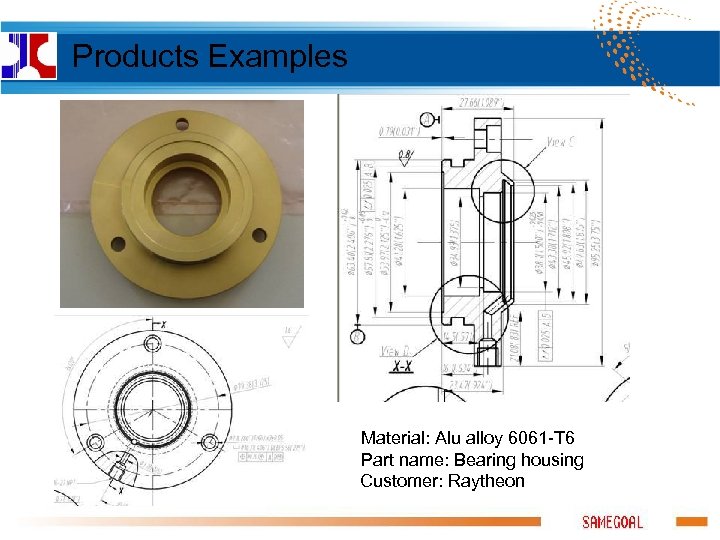

Products Examples Material: Alu alloy 6061 -T 6 Part name: Bearing housing Customer: Raytheon

Products Examples Material: Alu alloy 6061 -T 6 Part name: Bearing housing Customer: Raytheon

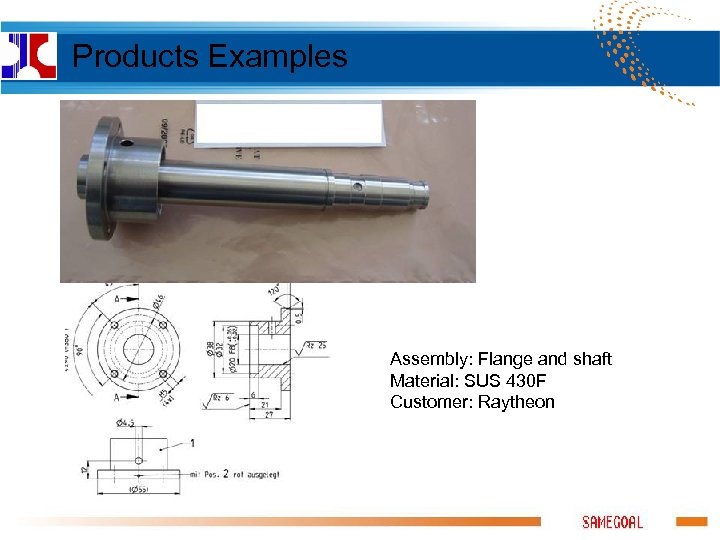

Products Examples Assembly: Flange and shaft Material: SUS 430 F Customer: Raytheon

Products Examples Assembly: Flange and shaft Material: SUS 430 F Customer: Raytheon

Products Examples Name: Hygiene head/Drive shaft Material: 316 L Customer: Endress+Hauser Wetzer Gmb. H+Co. KG Name: Valve body/Cylinder Material: Brass/12 L 14 Customer: BRIDON industry

Products Examples Name: Hygiene head/Drive shaft Material: 316 L Customer: Endress+Hauser Wetzer Gmb. H+Co. KG Name: Valve body/Cylinder Material: Brass/12 L 14 Customer: BRIDON industry

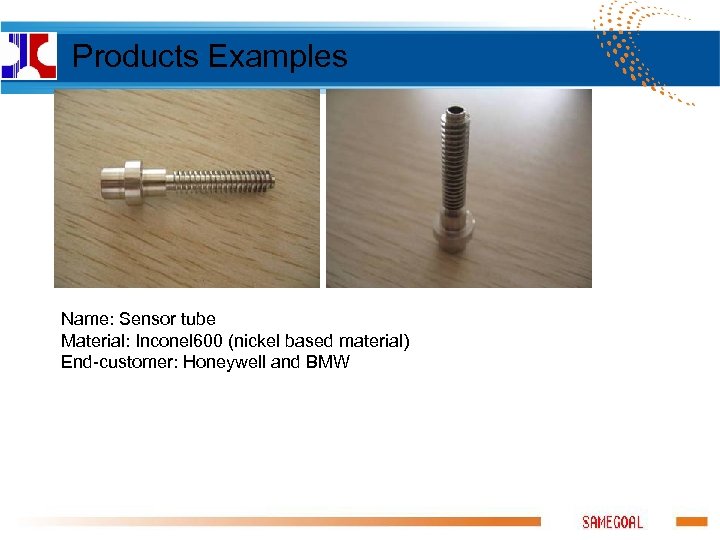

Products Examples Name: Sensor tube Material: Inconel 600 (nickel based material) End-customer: Honeywell and BMW

Products Examples Name: Sensor tube Material: Inconel 600 (nickel based material) End-customer: Honeywell and BMW

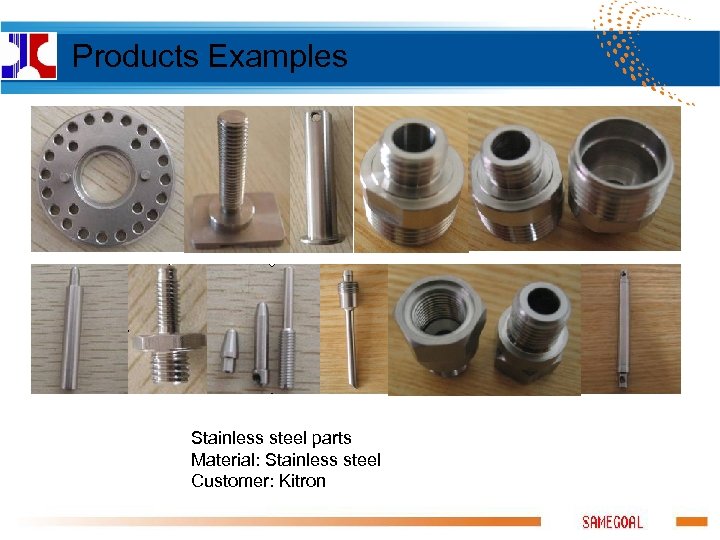

Products Examples Stainless steel parts Material: Stainless steel Customer: Kitron

Products Examples Stainless steel parts Material: Stainless steel Customer: Kitron

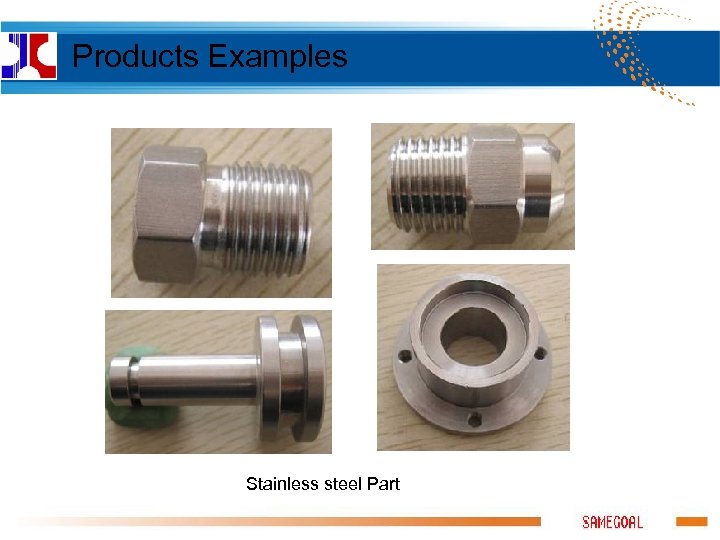

Products Examples Stainless steel Part

Products Examples Stainless steel Part

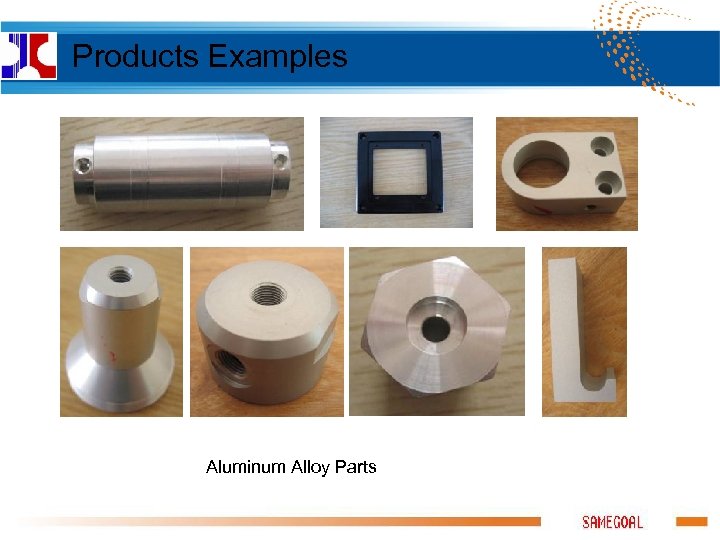

Products Examples Aluminum Alloy Parts

Products Examples Aluminum Alloy Parts

Products Examples Brass Parts

Products Examples Brass Parts

Products Examples Milling Parts

Products Examples Milling Parts

Products Examples Machined Plastic Parts (POM)

Products Examples Machined Plastic Parts (POM)

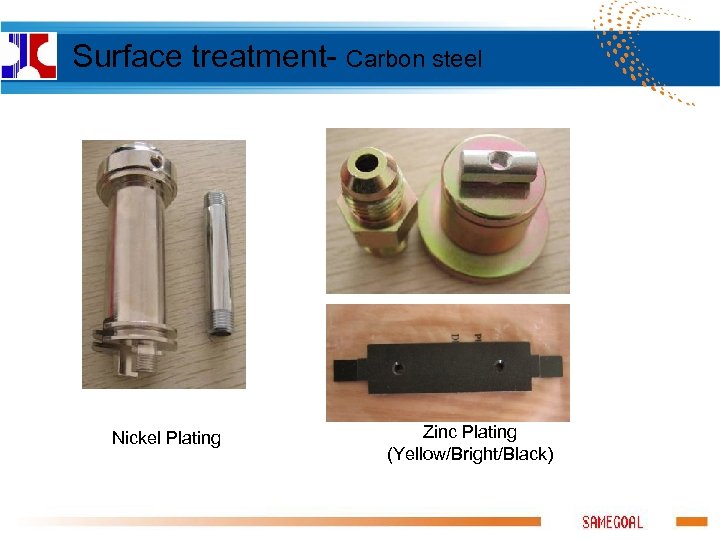

Surface treatment- Carbon steel Nickel Plating Zinc Plating (Yellow/Bright/Black)

Surface treatment- Carbon steel Nickel Plating Zinc Plating (Yellow/Bright/Black)

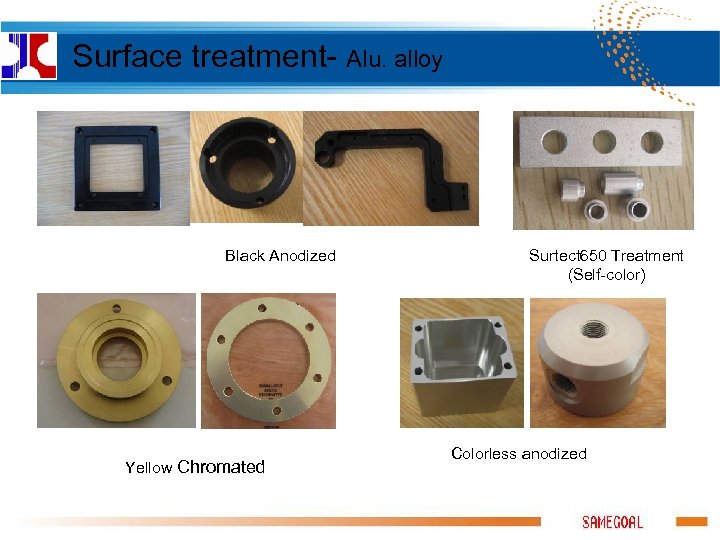

Surface treatment- Alu. alloy Black Anodized Yellow Chromated Surtect 650 Treatment (Self-color) Colorless anodized

Surface treatment- Alu. alloy Black Anodized Yellow Chromated Surtect 650 Treatment (Self-color) Colorless anodized

Products Examples Injection Molding Parts (PA 66, PP, PE, PVC)

Products Examples Injection Molding Parts (PA 66, PP, PE, PVC)

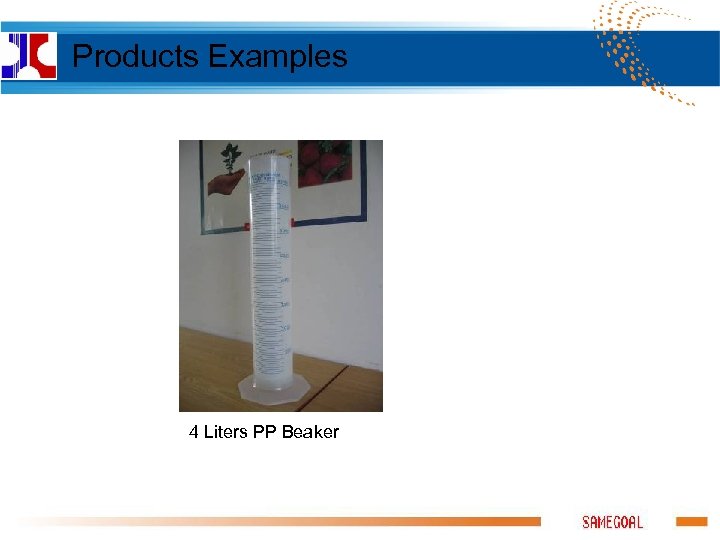

Products Examples 4 Liters PP Beaker

Products Examples 4 Liters PP Beaker

Quality Certificate

Quality Certificate

Our Vision Quality System • TS 16949 certificate in 2010 Facility: 1500 -2000 Square meters within 2~3 years 20 -30 sets of CNC lathe within 3~4 years 2 -3 sets of CNC machining centre within 3~4 years 1 set of 3 D tester within 3~4 years Human Resource: 30 -50 people in 2~3 years

Our Vision Quality System • TS 16949 certificate in 2010 Facility: 1500 -2000 Square meters within 2~3 years 20 -30 sets of CNC lathe within 3~4 years 2 -3 sets of CNC machining centre within 3~4 years 1 set of 3 D tester within 3~4 years Human Resource: 30 -50 people in 2~3 years