a09e4e3c0ea43fd80a613c3b6047b5fa.ppt

- Количество слайдов: 36

Safety of WWER Reactors Wolfgang Kromp Institute of Risk Research University of Vienna Budapest, 23. 04. 2007

Safety of WWER Reactors Wolfgang Kromp Institute of Risk Research University of Vienna Budapest, 23. 04. 2007

Tschernobyl September 1999

Tschernobyl September 1999

Nuclear revisited PLUS • TMI-Upgradings • PSA • SAMGs MINUS • Timeliness • Liberalized market • Aging • Lack of nuclear grade spare parts • Lack of personnel • Human factor & societal instability

Nuclear revisited PLUS • TMI-Upgradings • PSA • SAMGs MINUS • Timeliness • Liberalized market • Aging • Lack of nuclear grade spare parts • Lack of personnel • Human factor & societal instability

Nuclear revisited Further Questions • Life Extension • Power Uprating • Fissile Uranium

Nuclear revisited Further Questions • Life Extension • Power Uprating • Fissile Uranium

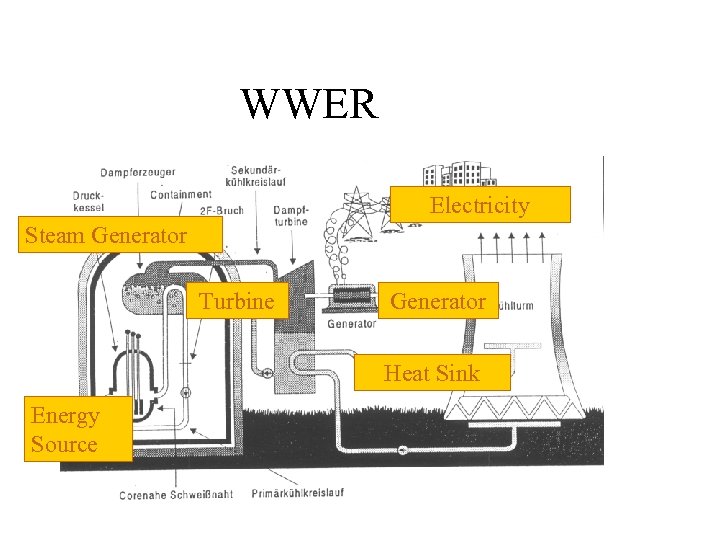

WWER Electricity Steam Generator Turbine Generator Heat Sink Energy Source

WWER Electricity Steam Generator Turbine Generator Heat Sink Energy Source

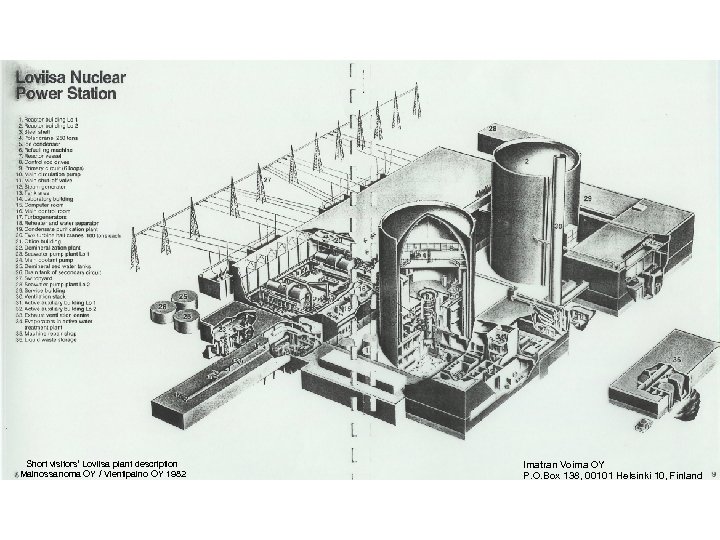

Short visitors’ Loviisa plant description Mainossanoma OY / Vientipaino OY 1982 Imatran Voima OY P. O. Box 138, 00101 Helsinki 10, Finland

Short visitors’ Loviisa plant description Mainossanoma OY / Vientipaino OY 1982 Imatran Voima OY P. O. Box 138, 00101 Helsinki 10, Finland

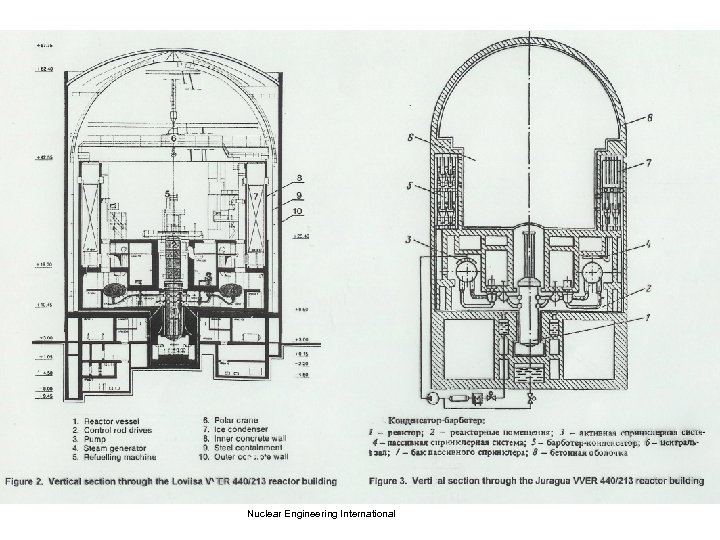

Nuclear Engineering International

Nuclear Engineering International

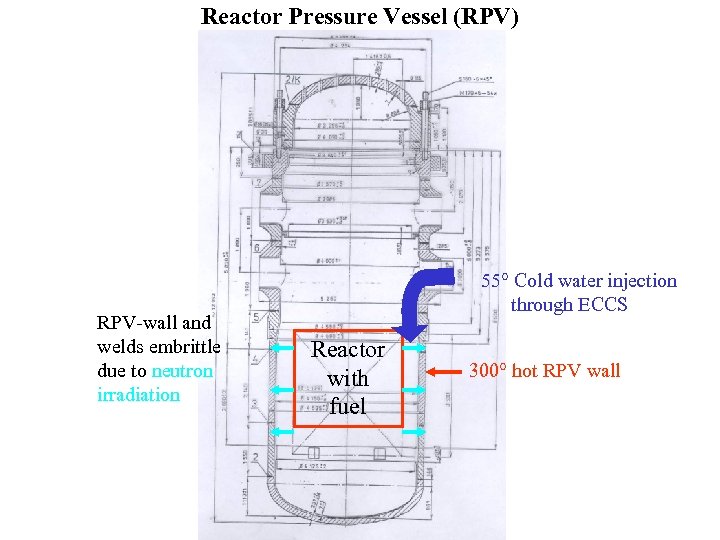

Reactor Pressure Vessel (RPV) RPV-wall and welds embrittle due to neutron irradiation 55° Cold water injection through ECCS Reactor with fuel 300° hot RPV wall

Reactor Pressure Vessel (RPV) RPV-wall and welds embrittle due to neutron irradiation 55° Cold water injection through ECCS Reactor with fuel 300° hot RPV wall

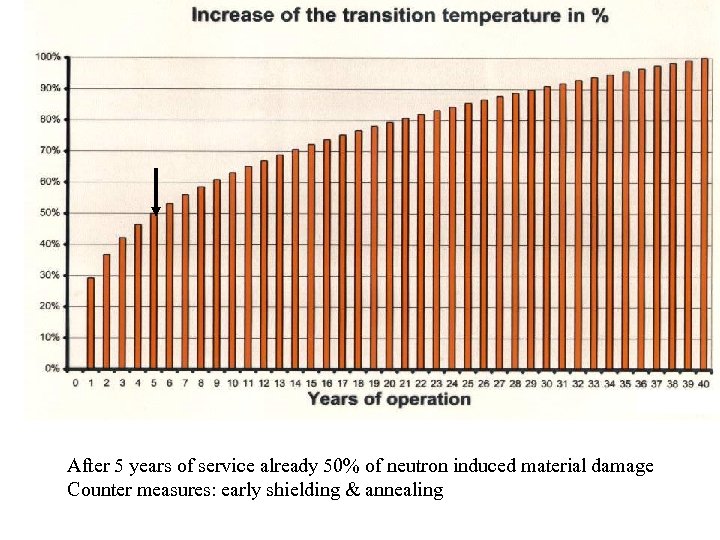

After 5 years of service already 50% of neutron induced material damage Counter measures: early shielding & annealing

After 5 years of service already 50% of neutron induced material damage Counter measures: early shielding & annealing

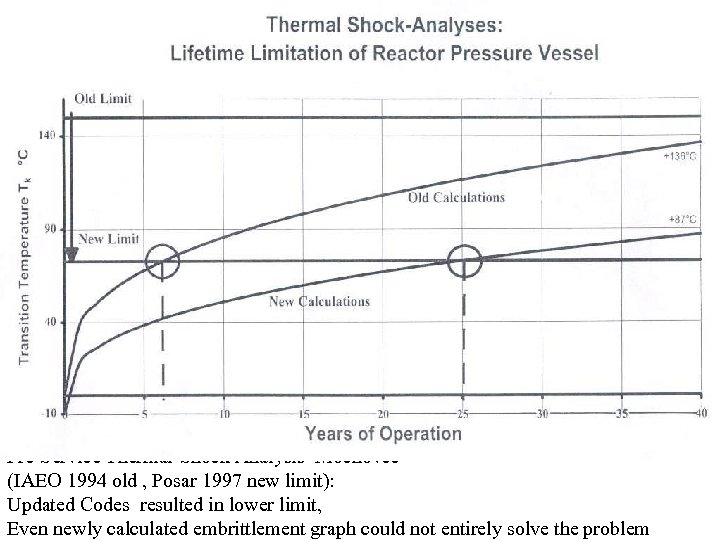

Pre-Service Thermal-Shock Analysis Mochovce (IAEO 1994 old , Posar 1997 new limit): Updated Codes resulted in lower limit, Even newly calculated embrittlement graph could not entirely solve the problem

Pre-Service Thermal-Shock Analysis Mochovce (IAEO 1994 old , Posar 1997 new limit): Updated Codes resulted in lower limit, Even newly calculated embrittlement graph could not entirely solve the problem

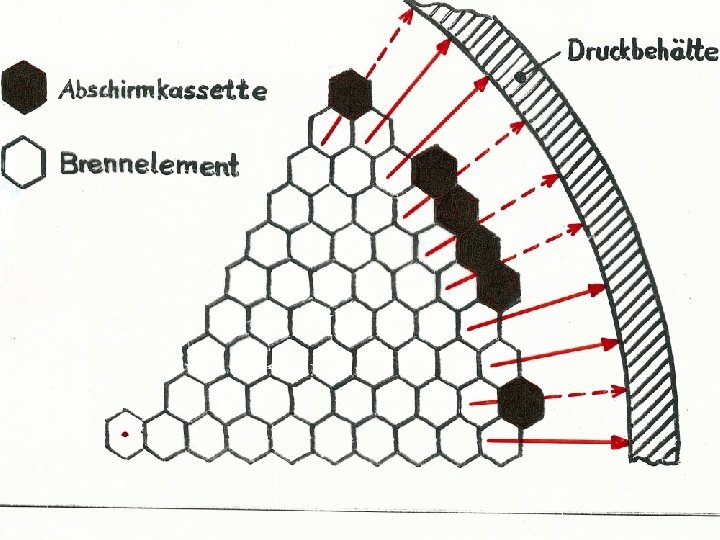

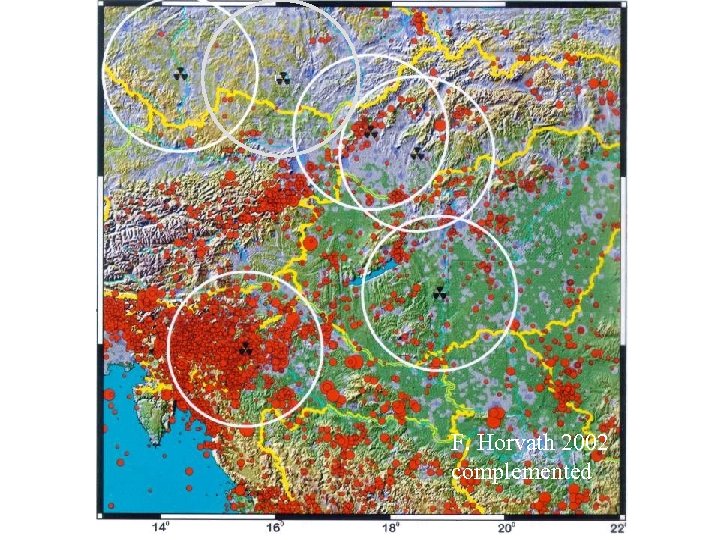

F. Horvath 2002 complemented

F. Horvath 2002 complemented

„Events“ since 2000 • • • Brunsbüttel (00) – tube line leakage Japan (02) – data falsification Davis-Besse (90 -02) – vessel lid corrosion Koslodui (03) - LOCA Paks (03) – fuel damage Repro plant Sellafield (04 -05) – Leekage Kosloduy (06) – control rod jamming Forsmark (06) – loss of off-site power etc. …

„Events“ since 2000 • • • Brunsbüttel (00) – tube line leakage Japan (02) – data falsification Davis-Besse (90 -02) – vessel lid corrosion Koslodui (03) - LOCA Paks (03) – fuel damage Repro plant Sellafield (04 -05) – Leekage Kosloduy (06) – control rod jamming Forsmark (06) – loss of off-site power etc. …

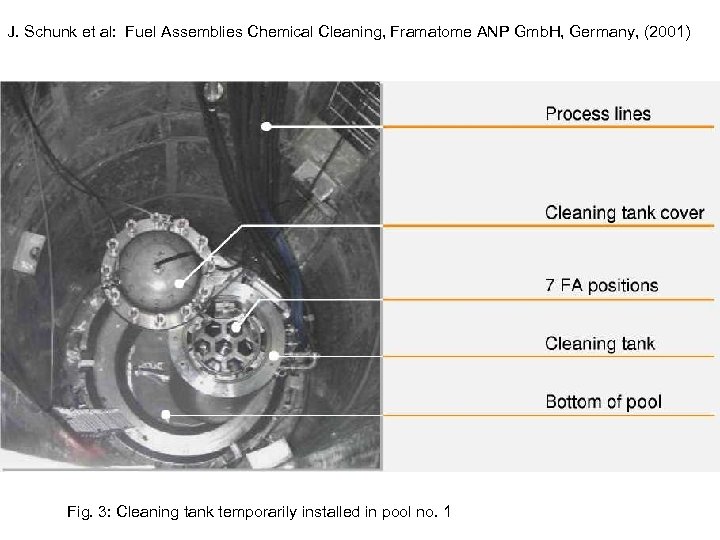

J. Schunk et al: Fuel Assemblies Chemical Cleaning, Framatome ANP Gmb. H, Germany, (2001) Fig. 3: Cleaning tank temporarily installed in pool no. 1

J. Schunk et al: Fuel Assemblies Chemical Cleaning, Framatome ANP Gmb. H, Germany, (2001) Fig. 3: Cleaning tank temporarily installed in pool no. 1

Warnings • IAEO-Generaldirektor El Baradei, New Orleans , Nov. 03: – „We cannot afford another accident“ • WANO Chair Hajimu Maeda, Okt. 03: – “a terrible disease that originates within the organization” – “a major accident” … “destroy the whole organization“

Warnings • IAEO-Generaldirektor El Baradei, New Orleans , Nov. 03: – „We cannot afford another accident“ • WANO Chair Hajimu Maeda, Okt. 03: – “a terrible disease that originates within the organization” – “a major accident” … “destroy the whole organization“

Extension of Operational Life-Time: WWER-Related Aspects Main focus on ageing at VVER–plants: • Reactor vessel [1] • Ageing of components • Confinement tightness • Internals, Piping • Concrete RPV Embrittlement • VVER 440/ 213 End of Life depends on weld Radiation Embrittlement • Radiation Embrittlement depends on P and Cu contents [1] Control of permanent set structures state at definition of nuclear power plants lifetime Ya. I. Shtrombakh

Extension of Operational Life-Time: WWER-Related Aspects Main focus on ageing at VVER–plants: • Reactor vessel [1] • Ageing of components • Confinement tightness • Internals, Piping • Concrete RPV Embrittlement • VVER 440/ 213 End of Life depends on weld Radiation Embrittlement • Radiation Embrittlement depends on P and Cu contents [1] Control of permanent set structures state at definition of nuclear power plants lifetime Ya. I. Shtrombakh

Extension of Operational Life-Time: Paks-Related Aspects Systematic preparatory work for long-term operation of Paks NPP WWER-440/213 units had started in 2000 and is on going [2] Ageing Management (AM) measures concentrated for Paks NPP on: - RPV embrittlement - Leaking of confinement due to liner degradation, - Seismic resistance of bubbler condenser ) - Corrosion of SG heat exchange tubes (magnetite problem) - etc. [2] KEY ELEMENTS OF LONG TE M OPE ATION OF WWE -440/213 UNITS AT PAKS NPP T. Katona, S Rátkai Nuclear Power Plant Pak, Hungary

Extension of Operational Life-Time: Paks-Related Aspects Systematic preparatory work for long-term operation of Paks NPP WWER-440/213 units had started in 2000 and is on going [2] Ageing Management (AM) measures concentrated for Paks NPP on: - RPV embrittlement - Leaking of confinement due to liner degradation, - Seismic resistance of bubbler condenser ) - Corrosion of SG heat exchange tubes (magnetite problem) - etc. [2] KEY ELEMENTS OF LONG TE M OPE ATION OF WWE -440/213 UNITS AT PAKS NPP T. Katona, S Rátkai Nuclear Power Plant Pak, Hungary

Extension of Operational Life-Time: Paks-Related Aspects Additional Questions: • International programms & experiences from RPV embrittlement studies e. g. Rovno 1 and 2, Kola NPP sufficietly considered? • Different studies are focused on the RPV base materials and weldings: The condition of metal of the RPV is known as essential for VVER-440 life time [3] THE EXPERIENCE OF ERVICE LIFE PROLONGATION OF NPP UNIT OF THE FIRST GENERATION, M. Kakirov, V. Potapov, A. Kann, A. Dementev, V. Levchuk, E. akhus, S. C ubarov, V. Ilyn, E. Mamaeva, A. Mazepa, Centre of Materials Researches and Lifetime Management, Moscow, Russia, Rostechnadzor, Novovoronezh, Russia Concern “Rosenergoatom”, CNIITMASH, Moscow, Russia

Extension of Operational Life-Time: Paks-Related Aspects Additional Questions: • International programms & experiences from RPV embrittlement studies e. g. Rovno 1 and 2, Kola NPP sufficietly considered? • Different studies are focused on the RPV base materials and weldings: The condition of metal of the RPV is known as essential for VVER-440 life time [3] THE EXPERIENCE OF ERVICE LIFE PROLONGATION OF NPP UNIT OF THE FIRST GENERATION, M. Kakirov, V. Potapov, A. Kann, A. Dementev, V. Levchuk, E. akhus, S. C ubarov, V. Ilyn, E. Mamaeva, A. Mazepa, Centre of Materials Researches and Lifetime Management, Moscow, Russia, Rostechnadzor, Novovoronezh, Russia Concern “Rosenergoatom”, CNIITMASH, Moscow, Russia

Timeliness Limits: • Construction capacity • Availabilty of financial resources • Availability of trained personnel

Timeliness Limits: • Construction capacity • Availabilty of financial resources • Availability of trained personnel

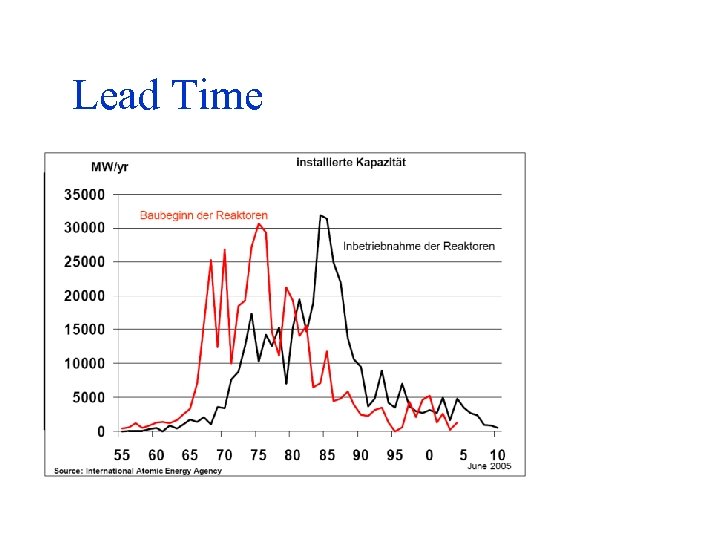

Lead Time

Lead Time

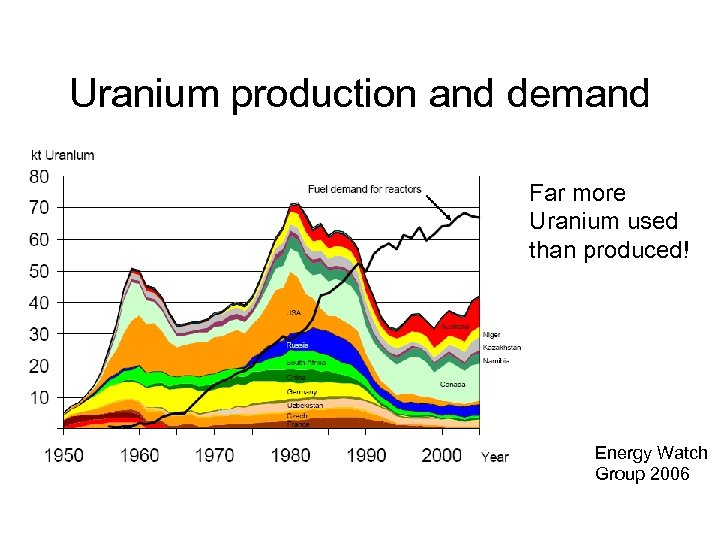

Uranium production and demand Far more Uranium used than produced! Energy Watch Group 2006

Uranium production and demand Far more Uranium used than produced! Energy Watch Group 2006

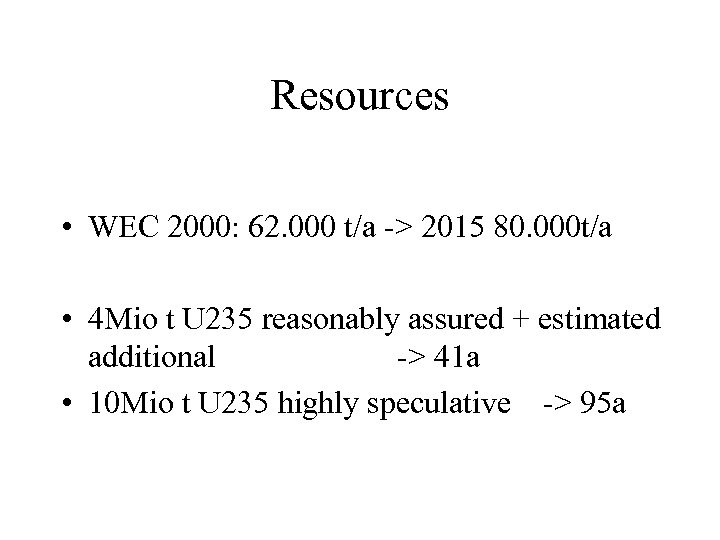

Resources • WEC 2000: 62. 000 t/a -> 2015 80. 000 t/a • 4 Mio t U 235 reasonably assured + estimated additional -> 41 a • 10 Mio t U 235 highly speculative -> 95 a

Resources • WEC 2000: 62. 000 t/a -> 2015 80. 000 t/a • 4 Mio t U 235 reasonably assured + estimated additional -> 41 a • 10 Mio t U 235 highly speculative -> 95 a

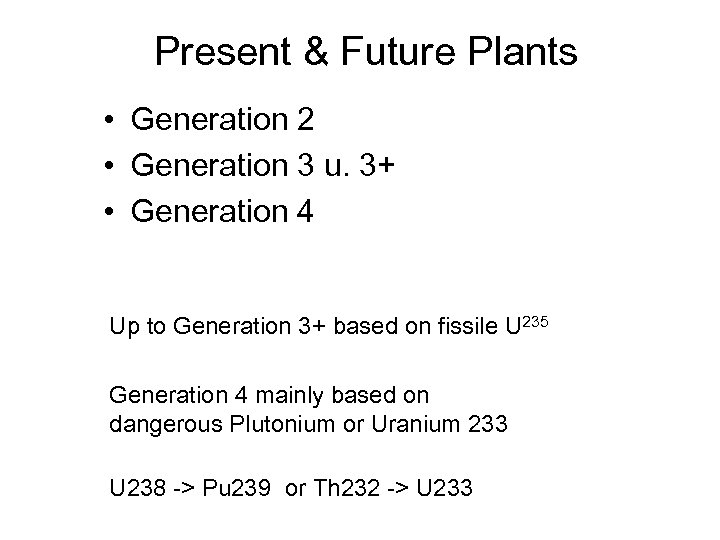

Present & Future Plants • Generation 2 • Generation 3 u. 3+ • Generation 4 Up to Generation 3+ based on fissile U 235 Generation 4 mainly based on dangerous Plutonium or Uranium 233 U 238 -> Pu 239 or Th 232 -> U 233

Present & Future Plants • Generation 2 • Generation 3 u. 3+ • Generation 4 Up to Generation 3+ based on fissile U 235 Generation 4 mainly based on dangerous Plutonium or Uranium 233 U 238 -> Pu 239 or Th 232 -> U 233

Generation 4 • • No severe accident No long lived waste No matter for proliferation Cheap Ordinary fast breeder! „Pu economy“

Generation 4 • • No severe accident No long lived waste No matter for proliferation Cheap Ordinary fast breeder! „Pu economy“

Generation 4 • “We have not found and, based on current knowledge, do not believe it is realistic to expect that there are new reactor and fuel cycle technologies that simultaneously overcome the problems of cost, safety, waste, and proliferation” MIT (2003), op. cit. , p. 76 .

Generation 4 • “We have not found and, based on current knowledge, do not believe it is realistic to expect that there are new reactor and fuel cycle technologies that simultaneously overcome the problems of cost, safety, waste, and proliferation” MIT (2003), op. cit. , p. 76 .

NPP – attractive target • Radioactivity & energy inventory • Key components of electricity networks • Structures visible at large distance

NPP – attractive target • Radioactivity & energy inventory • Key components of electricity networks • Structures visible at large distance

Example of insuccessful terror defence at RBMK Smolensk • • Simulated terror attack early eighties 14 days pre-warning Security guards prepared Safety barriers overcome by intrudor Alarm went on Intrudor disappeared among personnel Intrudor communicated with personnel of main circulation pump control room

Example of insuccessful terror defence at RBMK Smolensk • • Simulated terror attack early eighties 14 days pre-warning Security guards prepared Safety barriers overcome by intrudor Alarm went on Intrudor disappeared among personnel Intrudor communicated with personnel of main circulation pump control room

Radiant Inheritance • Plutonium 239, Technetium 99 HLT 24. 000 and 211. 000 ys 9 kg per t spent fuel • Neptunium 237, Cerium 93, Cesium 135, Palladium 107, Iodine 129 HLT 1, 5 to 15 million ys 3, 5 kg per t spent fuel • Globally 436 NPPs 10. 500 t heavy metal / a 265 000 t spent fuel up to date > 3 300 t long time radio nuclids up to date

Radiant Inheritance • Plutonium 239, Technetium 99 HLT 24. 000 and 211. 000 ys 9 kg per t spent fuel • Neptunium 237, Cerium 93, Cesium 135, Palladium 107, Iodine 129 HLT 1, 5 to 15 million ys 3, 5 kg per t spent fuel • Globally 436 NPPs 10. 500 t heavy metal / a 265 000 t spent fuel up to date > 3 300 t long time radio nuclids up to date

Interim storage – anthropogenic threat • Attacke on spent fuel pit Circonia fire • Could be „well beyond Chernobyl“(Sensintaffar 2005) „Main stream“ deep geological structures?

Interim storage – anthropogenic threat • Attacke on spent fuel pit Circonia fire • Could be „well beyond Chernobyl“(Sensintaffar 2005) „Main stream“ deep geological structures?

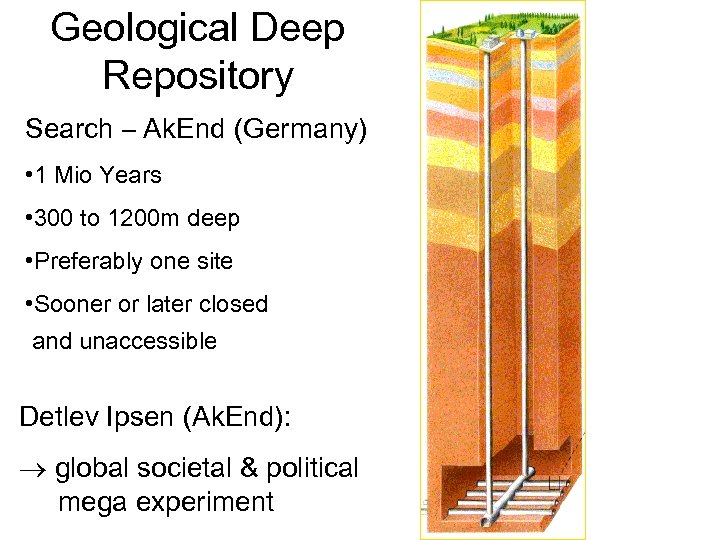

Geological Deep Repository Search – Ak. End (Germany) • 1 Mio Years • 300 to 1200 m deep • Preferably one site • Sooner or later closed and unaccessible Detlev Ipsen (Ak. End): global societal & political mega experiment

Geological Deep Repository Search – Ak. End (Germany) • 1 Mio Years • 300 to 1200 m deep • Preferably one site • Sooner or later closed and unaccessible Detlev Ipsen (Ak. End): global societal & political mega experiment

Summary • • Remarkable Efforts to be Acknowledged Old and New Constraints Persistent „Near Misses“ Threat of Severe Accident Unresolved Waste Issue Daughtful Future Developments To Small & Late for Climate Change and Fossiles‘ Shortage

Summary • • Remarkable Efforts to be Acknowledged Old and New Constraints Persistent „Near Misses“ Threat of Severe Accident Unresolved Waste Issue Daughtful Future Developments To Small & Late for Climate Change and Fossiles‘ Shortage