1951de9c1b0ad707766f77a055490fc4.ppt

- Количество слайдов: 71

SAFE OPERATION OF FORKLIFT A TRAINING FOR THE METALWORKING INDUSTRIES Ø Updated on June 2015

SAFE OPERATION OF FORKLIFT A TRAINING FOR THE METALWORKING INDUSTRIES Ø Updated on June 2015

Table of Contents q Introduction q Risk management on forklift q Common forklift hazards q Route plan q Training forklift operators q Pre-operation checks q Load assessments q Common safe practices q Forklift traffic control

Table of Contents q Introduction q Risk management on forklift q Common forklift hazards q Route plan q Training forklift operators q Pre-operation checks q Load assessments q Common safe practices q Forklift traffic control

Introduction q Forklift can be hazardous if not handled properly q Forklift accidents can cause serious injury, death, property and product damage q This poses a serious problem for everyone q Accidents can be prevented if risk assessment and safe work procedures (SWP) are followed. Picture source: http: //www. thompsonandjohnson. com/images/accident 1. jpg

Introduction q Forklift can be hazardous if not handled properly q Forklift accidents can cause serious injury, death, property and product damage q This poses a serious problem for everyone q Accidents can be prevented if risk assessment and safe work procedures (SWP) are followed. Picture source: http: //www. thompsonandjohnson. com/images/accident 1. jpg

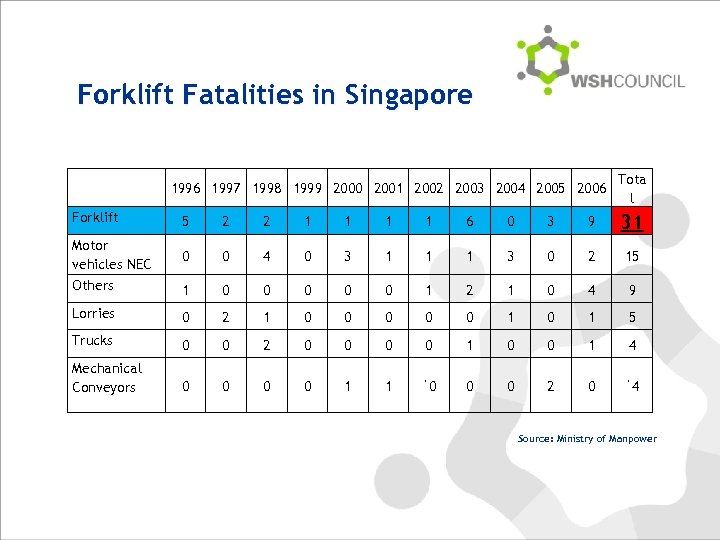

Forklift Fatalities in Singapore 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 Tota l Forklift 5 2 2 1 1 6 0 3 9 31 Motor vehicles NEC 0 0 4 0 3 1 1 1 3 0 2 15 Others 1 0 0 0 1 2 1 0 4 9 Lorries 0 2 1 0 0 0 1 5 Trucks 0 0 2 0 0 1 4 Mechanical Conveyors 0 0 1 1 `0 0 0 2 0 `4 Source: Ministry of Manpower

Forklift Fatalities in Singapore 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 Tota l Forklift 5 2 2 1 1 6 0 3 9 31 Motor vehicles NEC 0 0 4 0 3 1 1 1 3 0 2 15 Others 1 0 0 0 1 2 1 0 4 9 Lorries 0 2 1 0 0 0 1 5 Trucks 0 0 2 0 0 1 4 Mechanical Conveyors 0 0 1 1 `0 0 0 2 0 `4 Source: Ministry of Manpower

Potential Forklift Accidents Picture source: http: //marbella. to/humour/sep 00/forklift. jpg

Potential Forklift Accidents Picture source: http: //marbella. to/humour/sep 00/forklift. jpg

Potential Forklift Accidents Picture source: http: //www. facelift. co. uk/images/roguesgallery/forklift_no-no 1. jpg

Potential Forklift Accidents Picture source: http: //www. facelift. co. uk/images/roguesgallery/forklift_no-no 1. jpg

Forklift Accidents Picture source: http: //siri. uvm. edu/graphics/Industrial_Operations/Forklift_accident. gif

Forklift Accidents Picture source: http: //siri. uvm. edu/graphics/Industrial_Operations/Forklift_accident. gif

Forklift Accidents Picture source: http: //www. jicosh. gr. jp/english/cases/case 105. gif

Forklift Accidents Picture source: http: //www. jicosh. gr. jp/english/cases/case 105. gif

Forklift Accidents Picture source: European Industrial Gases Association

Forklift Accidents Picture source: European Industrial Gases Association

Risk Management on Operation of Forklift q Required to manage risks under WSH (risk management) regulations q Assess the risk q Take all reasonably practical steps q Eliminate any risks

Risk Management on Operation of Forklift q Required to manage risks under WSH (risk management) regulations q Assess the risk q Take all reasonably practical steps q Eliminate any risks

Risk Management on Operation of Forklift q Step 1: Identification of hazard Picture source: http: //www. safetyworld. com/images/101. gif

Risk Management on Operation of Forklift q Step 1: Identification of hazard Picture source: http: //www. safetyworld. com/images/101. gif

Common Forklift Hazards q Overloading q Unsafe stacking q Speeding q Raised forks q Unauthorized operation of forklift q Untrained forklift operators Picture source: http: //www. iqsdirectory. com/info/fork-lift-trucks/images/fork 2. jpg

Common Forklift Hazards q Overloading q Unsafe stacking q Speeding q Raised forks q Unauthorized operation of forklift q Untrained forklift operators Picture source: http: //www. iqsdirectory. com/info/fork-lift-trucks/images/fork 2. jpg

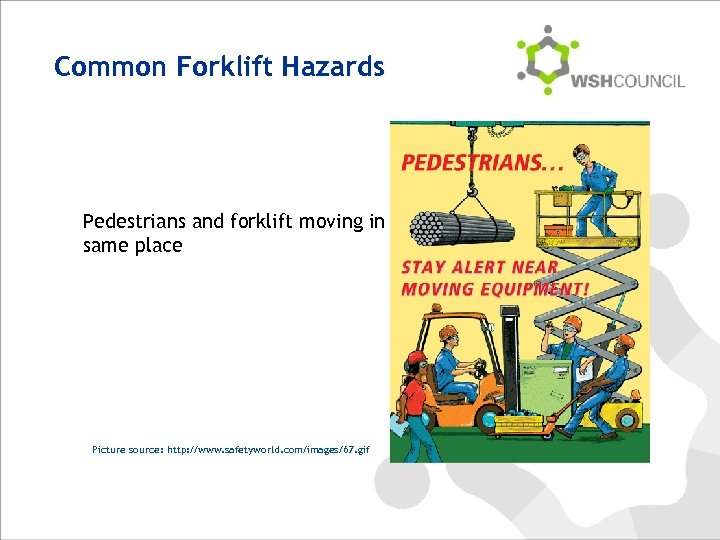

Common Forklift Hazards q Lifting of persons on forks q Pedestrians and forklifts moving in the same place q Travelling on slope q Obstruction in the path e. g. overhead, blind corners q Poor ground conditions e. g. slippery, uneven, potholes

Common Forklift Hazards q Lifting of persons on forks q Pedestrians and forklifts moving in the same place q Travelling on slope q Obstruction in the path e. g. overhead, blind corners q Poor ground conditions e. g. slippery, uneven, potholes

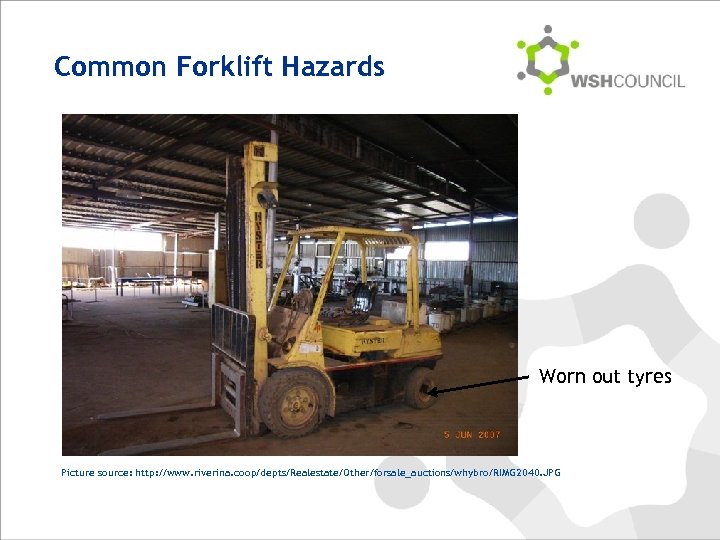

Common Forklift Hazards Source: Ministry of Manpower q Body/limbs caught in moving parts of the forklift q Falling loads q Poor condition tyres e. g. without thread markings q Electric Shock (Battery operated forklift) Picture source: http: //www. cdc. gov/niosh/face/images/96 nj 062. jpg

Common Forklift Hazards Source: Ministry of Manpower q Body/limbs caught in moving parts of the forklift q Falling loads q Poor condition tyres e. g. without thread markings q Electric Shock (Battery operated forklift) Picture source: http: //www. cdc. gov/niosh/face/images/96 nj 062. jpg

Common Forklift Hazards Pedestrians and forklift moving in same place Picture source: http: //www. safetyworld. com/images/67. gif

Common Forklift Hazards Pedestrians and forklift moving in same place Picture source: http: //www. safetyworld. com/images/67. gif

Common Forklift Hazards Forklift traveling on slope Picture source: http: //www. sandhillquilting. com/images/M-16 -SYS-8436 -L. jpg

Common Forklift Hazards Forklift traveling on slope Picture source: http: //www. sandhillquilting. com/images/M-16 -SYS-8436 -L. jpg

Common Forklift Hazards Poor ground conditions Picture source: http: //eternitycaptured. com/blog/wpcontent/uploads/2007/04/bigstockphoto_Road_Cracks_And_Potholes_606173. jpg

Common Forklift Hazards Poor ground conditions Picture source: http: //eternitycaptured. com/blog/wpcontent/uploads/2007/04/bigstockphoto_Road_Cracks_And_Potholes_606173. jpg

Common Forklift Hazards Worn out tyres Picture source: http: //www. riverina. coop/depts/Realestate/Other/forsale_auctions/whybro/RIMG 2040. JPG

Common Forklift Hazards Worn out tyres Picture source: http: //www. riverina. coop/depts/Realestate/Other/forsale_auctions/whybro/RIMG 2040. JPG

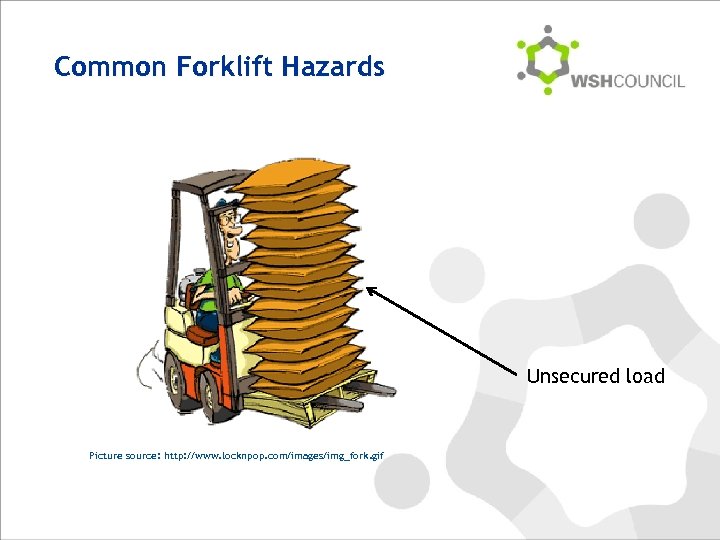

Common Forklift Hazards Unsecured load Picture source: http: //www. locknpop. com/images/img_fork. gif

Common Forklift Hazards Unsecured load Picture source: http: //www. locknpop. com/images/img_fork. gif

Common Forklift Hazards Picture source: http: //www. ubuyme. com/img_prod/679/pic 1. jpg Electric shock from battery

Common Forklift Hazards Picture source: http: //www. ubuyme. com/img_prod/679/pic 1. jpg Electric shock from battery

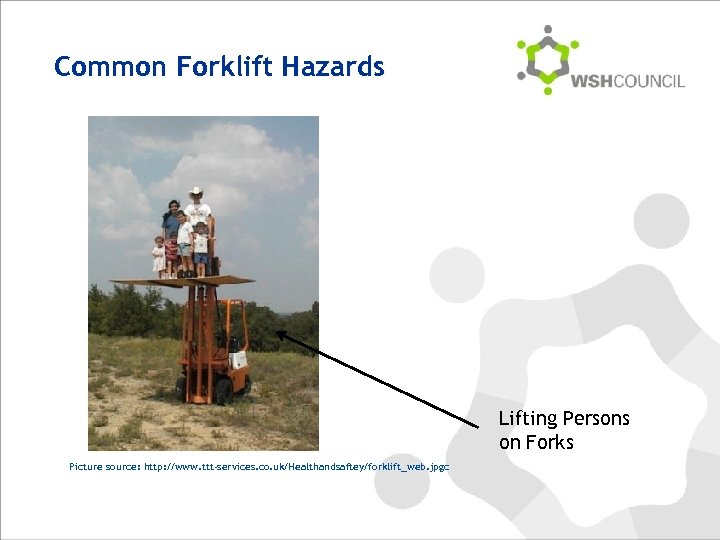

Common Forklift Hazards Lifting Persons on Forks Picture source: http: //www. ttt-services. co. uk/Healthandsaftey/forklift_web. jpgc

Common Forklift Hazards Lifting Persons on Forks Picture source: http: //www. ttt-services. co. uk/Healthandsaftey/forklift_web. jpgc

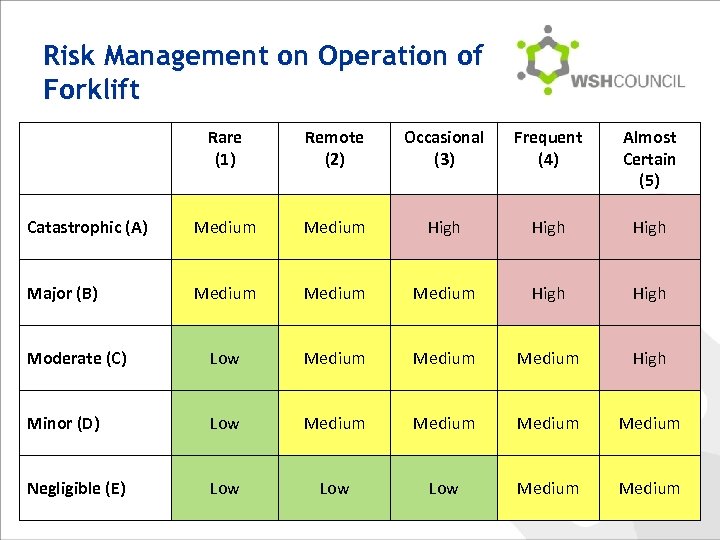

Risk Management on Operation of Forklift q Step 2: Assess the risk v Dependent on severity of risk and likelihood of hazards occurring v severity X likelihood = risk level v Risk Level = Low, Moderate or High

Risk Management on Operation of Forklift q Step 2: Assess the risk v Dependent on severity of risk and likelihood of hazards occurring v severity X likelihood = risk level v Risk Level = Low, Moderate or High

Risk Management on Operation of Forklift Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) Catastrophic (A) Medium High Major (B) Medium High Moderate (C) Low Medium High Minor (D) Low Medium Negligible (E) Low Low Medium

Risk Management on Operation of Forklift Rare (1) Remote (2) Occasional (3) Frequent (4) Almost Certain (5) Catastrophic (A) Medium High Major (B) Medium High Moderate (C) Low Medium High Minor (D) Low Medium Negligible (E) Low Low Medium

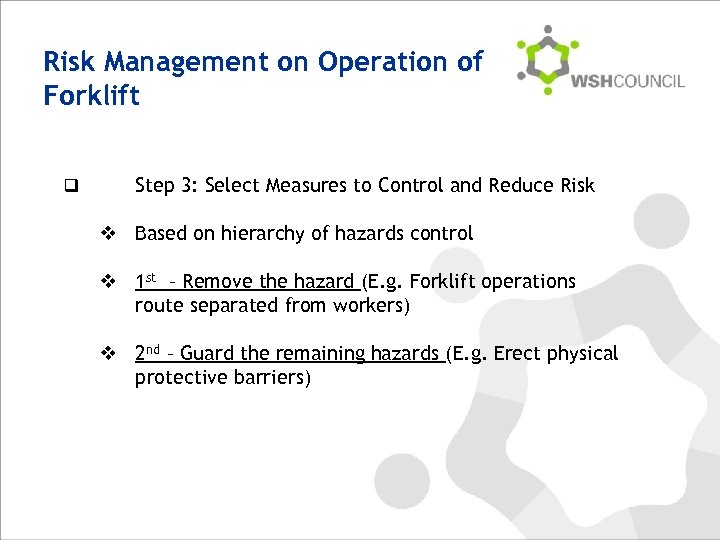

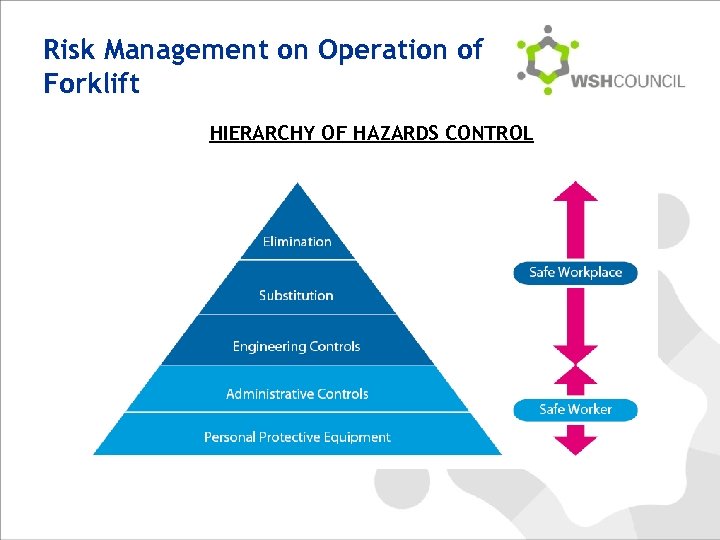

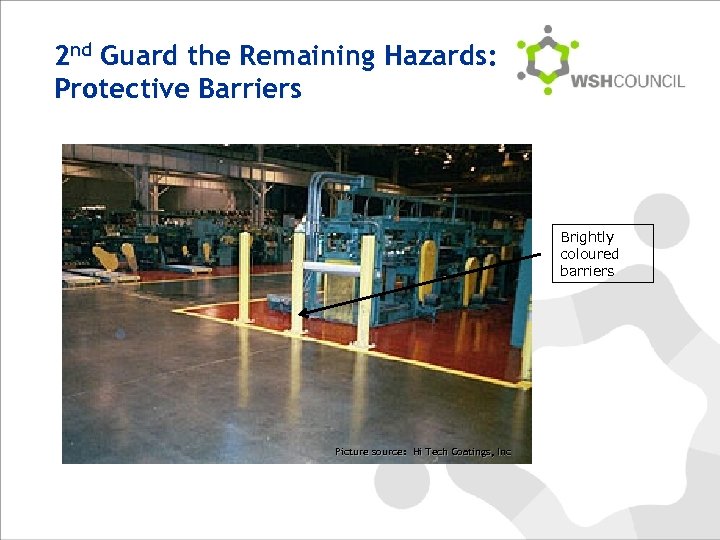

Risk Management on Operation of Forklift q Step 3: Select Measures to Control and Reduce Risk v Based on hierarchy of hazards control v 1 st – Remove the hazard (E. g. Forklift operations route separated from workers) v 2 nd – Guard the remaining hazards (E. g. Erect physical protective barriers)

Risk Management on Operation of Forklift q Step 3: Select Measures to Control and Reduce Risk v Based on hierarchy of hazards control v 1 st – Remove the hazard (E. g. Forklift operations route separated from workers) v 2 nd – Guard the remaining hazards (E. g. Erect physical protective barriers)

Risk Management on Operation of Forklift HIERARCHY OF HAZARDS CONTROL

Risk Management on Operation of Forklift HIERARCHY OF HAZARDS CONTROL

1 st Remove the Hazards – Forklift Route Planning Picture source: http: //maaw. info/images/Figure 8 -10. gif

1 st Remove the Hazards – Forklift Route Planning Picture source: http: //maaw. info/images/Figure 8 -10. gif

Route Plan • Efficient workplace layout/plan • Floors and surfaces in good condition • Fixtures which are clearly visible • Forklift operating and pedestrian paths identified and clearly marked • Designated maintenance, parking and battery charging areas

Route Plan • Efficient workplace layout/plan • Floors and surfaces in good condition • Fixtures which are clearly visible • Forklift operating and pedestrian paths identified and clearly marked • Designated maintenance, parking and battery charging areas

Forklift Operation Separated from Worker Area Forklift operation area Picture source: Hi Tech Coatings, Inc

Forklift Operation Separated from Worker Area Forklift operation area Picture source: Hi Tech Coatings, Inc

Allocated Goods Area Goods sitting area Picture source: Hi Tech Coatings, Inc

Allocated Goods Area Goods sitting area Picture source: Hi Tech Coatings, Inc

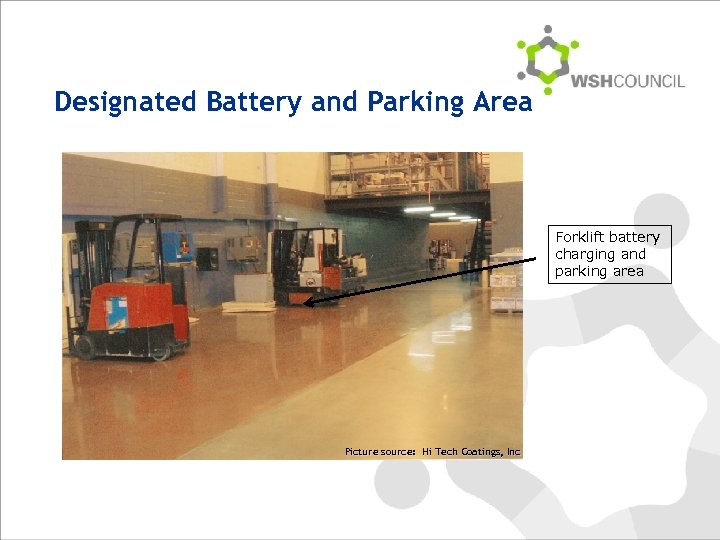

Designated Battery and Parking Area Forklift battery charging and parking area Picture source: Hi Tech Coatings, Inc

Designated Battery and Parking Area Forklift battery charging and parking area Picture source: Hi Tech Coatings, Inc

2 nd Guard the Remaining Hazards: Protective Barriers Brightly coloured barriers Picture source: Hi Tech Coatings, Inc

2 nd Guard the Remaining Hazards: Protective Barriers Brightly coloured barriers Picture source: Hi Tech Coatings, Inc

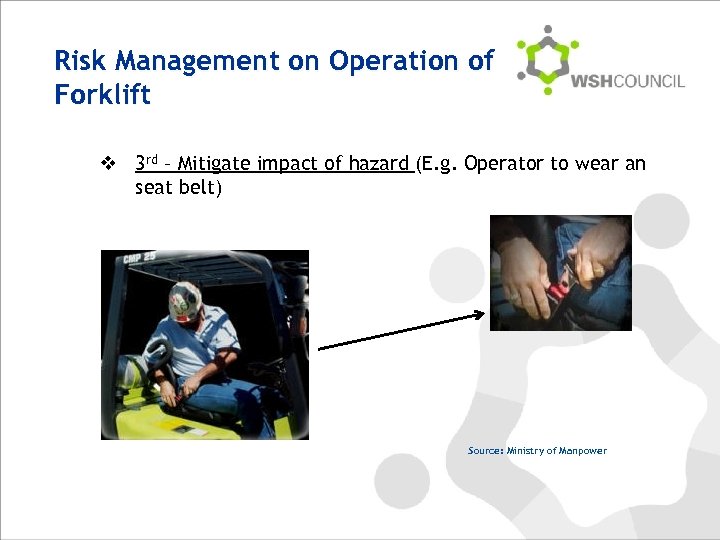

Risk Management on Operation of Forklift v 3 rd – Mitigate impact of hazard (E. g. Operator to wear an seat belt) Source: Ministry of Manpower

Risk Management on Operation of Forklift v 3 rd – Mitigate impact of hazard (E. g. Operator to wear an seat belt) Source: Ministry of Manpower

Risk Management on Operation of Forklift q Risk assessment to be done for every forklift tasks q To identify the risk and control measures q Establish safe work procedures (SWP) q Inform staff of SWP q Staff to follow SWP Source: Ministry of Manpower

Risk Management on Operation of Forklift q Risk assessment to be done for every forklift tasks q To identify the risk and control measures q Establish safe work procedures (SWP) q Inform staff of SWP q Staff to follow SWP Source: Ministry of Manpower

Risk Management on Operation of Forklift q Forklift Safe Work Procedures (SWP) Ø Forklift Training Ø Pre-Operation Check Ø Load Assessment Ø Common Safe Practice Ø Traffic Control Source: Ministry of Manpower

Risk Management on Operation of Forklift q Forklift Safe Work Procedures (SWP) Ø Forklift Training Ø Pre-Operation Check Ø Load Assessment Ø Common Safe Practice Ø Traffic Control Source: Ministry of Manpower

Forklift Training v Under Factories (Safety Training Courses) Order, all forklift operators shall undergo a Forklift Drivers’ Training Course v Conducted by a MOM Accredited Training Provider v Consists of 1 -day theory course v And 4 or 2 days practical course

Forklift Training v Under Factories (Safety Training Courses) Order, all forklift operators shall undergo a Forklift Drivers’ Training Course v Conducted by a MOM Accredited Training Provider v Consists of 1 -day theory course v And 4 or 2 days practical course

Why Conduct Forklift Training v Ensure forklift drivers are competent v To train driver in basic forklift operation v To provide knowledge of safe operating practices forklift Picture source: http: //www. crowndfw. com/training. html

Why Conduct Forklift Training v Ensure forklift drivers are competent v To train driver in basic forklift operation v To provide knowledge of safe operating practices forklift Picture source: http: //www. crowndfw. com/training. html

Why Conduct Pre-operation Checks? v Ensure efficient and safe operation of forklifts v Prevent workplace injuries v To remove inefficient forklift practices

Why Conduct Pre-operation Checks? v Ensure efficient and safe operation of forklifts v Prevent workplace injuries v To remove inefficient forklift practices

Under WSHAC Forklift Checklist, Preoperation Checks Includes: q q q q q Tyres and wheels Forks/attachments Chains, cables and hoses Safety devices (e. g. seat belts, warning devices, rear mirror and etc. ) Leaks Hour meter Battery/LPG system Battery connector Guards Structural damage

Under WSHAC Forklift Checklist, Preoperation Checks Includes: q q q q q Tyres and wheels Forks/attachments Chains, cables and hoses Safety devices (e. g. seat belts, warning devices, rear mirror and etc. ) Leaks Hour meter Battery/LPG system Battery connector Guards Structural damage

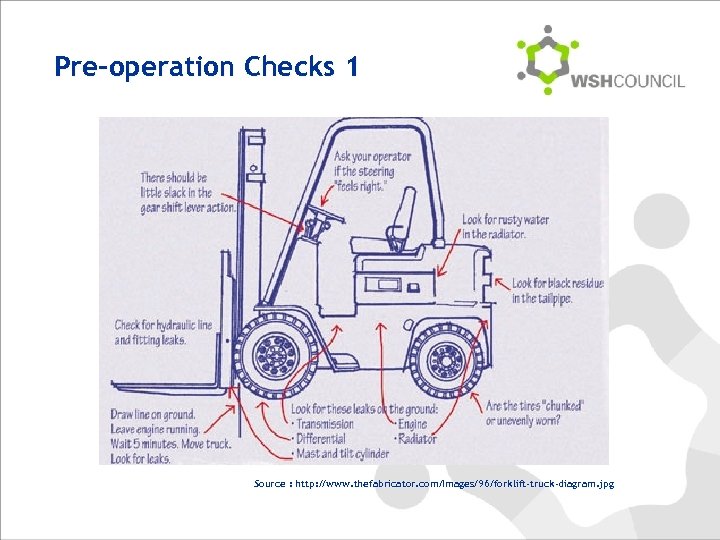

Pre-operation Checks 1 Source : http: //www. thefabricator. com/Images/96/forklift-truck-diagram. jpg

Pre-operation Checks 1 Source : http: //www. thefabricator. com/Images/96/forklift-truck-diagram. jpg

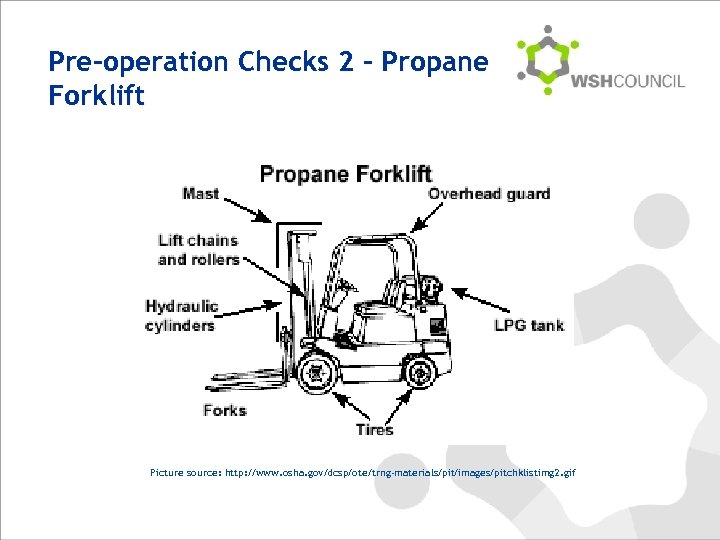

Pre-operation Checks 2 – Propane Forklift Picture source: http: //www. osha. gov/dcsp/ote/trng-materials/pit/images/pitchklistimg 2. gif

Pre-operation Checks 2 – Propane Forklift Picture source: http: //www. osha. gov/dcsp/ote/trng-materials/pit/images/pitchklistimg 2. gif

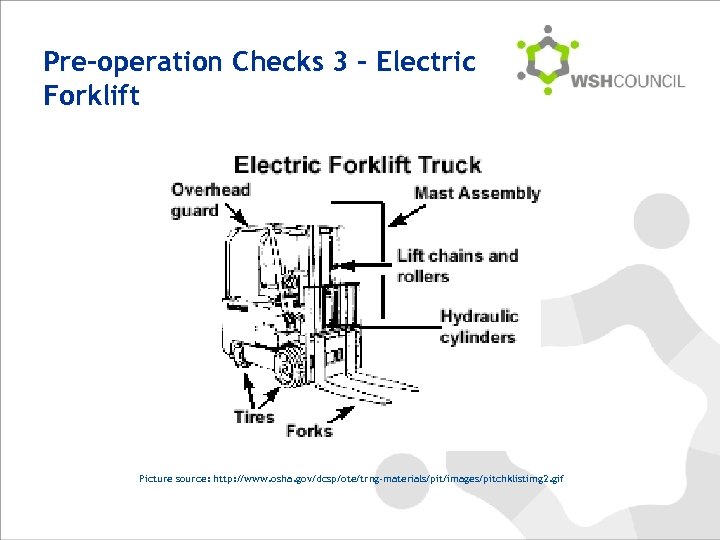

Pre-operation Checks 3 – Electric Forklift Picture source: http: //www. osha. gov/dcsp/ote/trng-materials/pit/images/pitchklistimg 2. gif

Pre-operation Checks 3 – Electric Forklift Picture source: http: //www. osha. gov/dcsp/ote/trng-materials/pit/images/pitchklistimg 2. gif

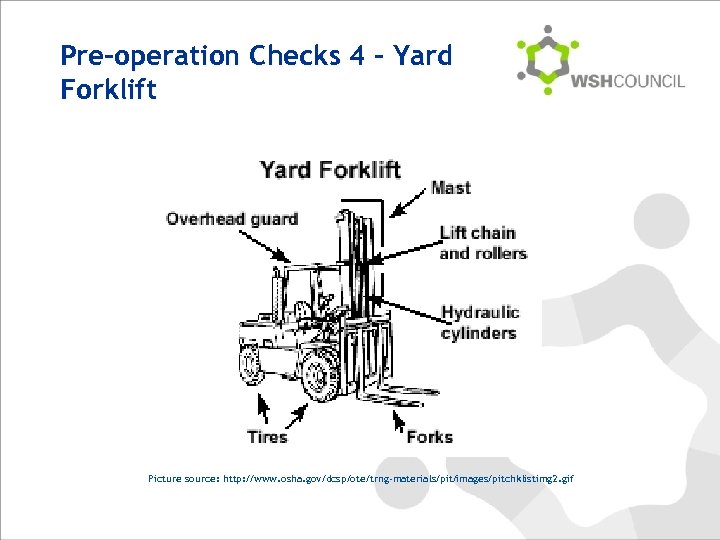

Pre-operation Checks 4 – Yard Forklift Picture source: http: //www. osha. gov/dcsp/ote/trng-materials/pit/images/pitchklistimg 2. gif

Pre-operation Checks 4 – Yard Forklift Picture source: http: //www. osha. gov/dcsp/ote/trng-materials/pit/images/pitchklistimg 2. gif

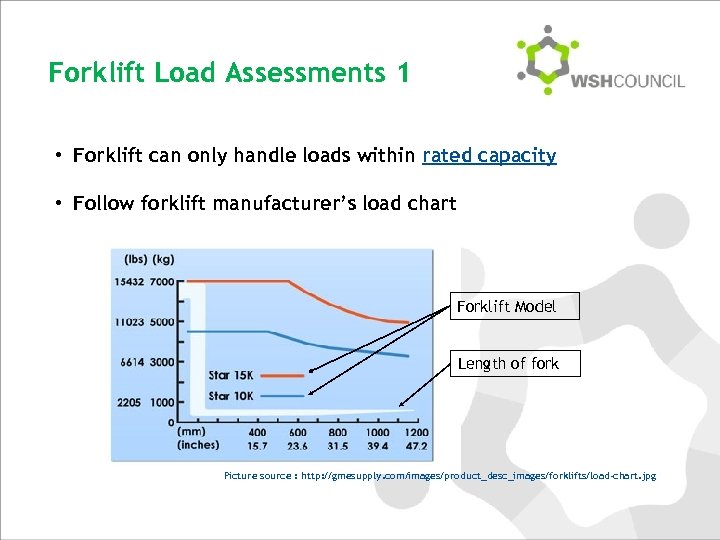

Forklift Load Assessments 1 • Forklift can only handle loads within rated capacity • Follow forklift manufacturer’s load chart Forklift Model Length of fork Picture source : http: //gmesupply. com/images/product_desc_images/forklifts/load-chart. jpg

Forklift Load Assessments 1 • Forklift can only handle loads within rated capacity • Follow forklift manufacturer’s load chart Forklift Model Length of fork Picture source : http: //gmesupply. com/images/product_desc_images/forklifts/load-chart. jpg

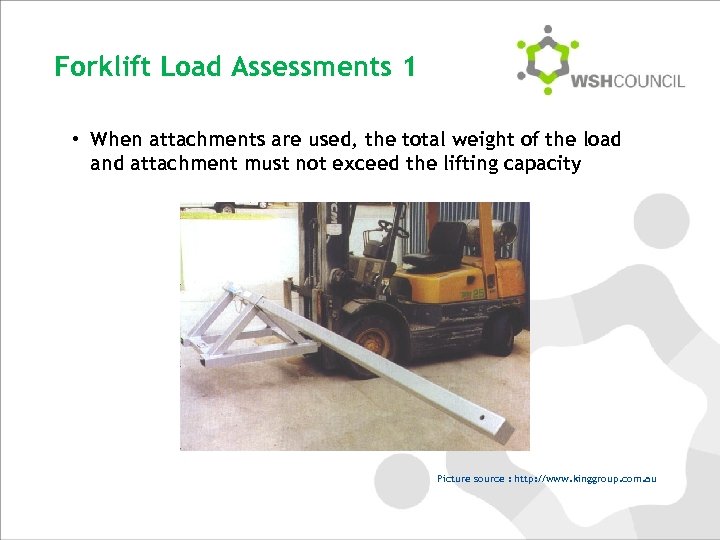

Forklift Load Assessments 1 • When attachments are used, the total weight of the load and attachment must not exceed the lifting capacity Picture source : http: //www. kinggroup. com. au

Forklift Load Assessments 1 • When attachments are used, the total weight of the load and attachment must not exceed the lifting capacity Picture source : http: //www. kinggroup. com. au

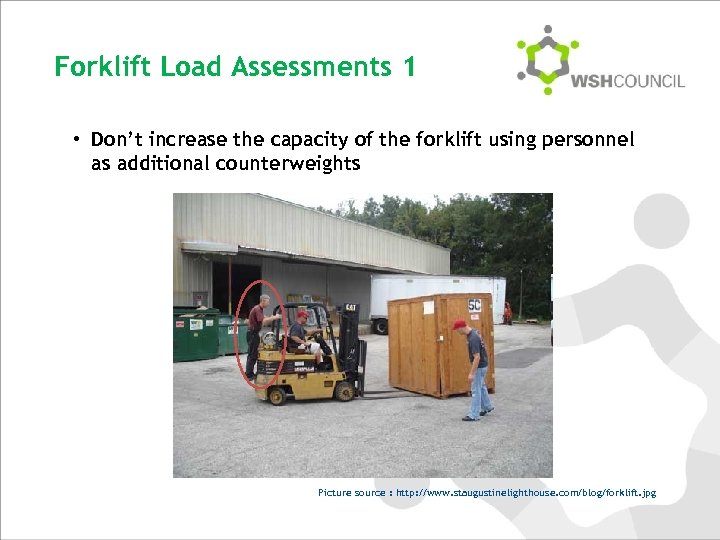

Forklift Load Assessments 1 • Don’t increase the capacity of the forklift using personnel as additional counterweights Picture source : http: //www. staugustinelighthouse. com/blog/forklift. jpg

Forklift Load Assessments 1 • Don’t increase the capacity of the forklift using personnel as additional counterweights Picture source : http: //www. staugustinelighthouse. com/blog/forklift. jpg

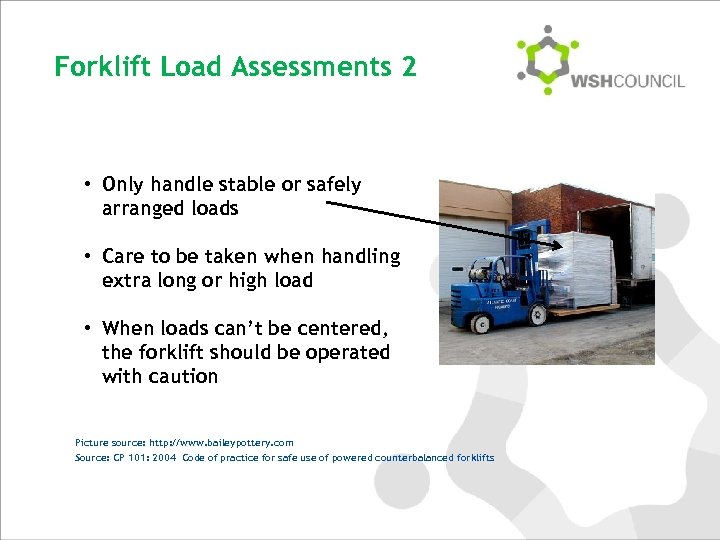

Forklift Load Assessments 2 • Only handle stable or safely arranged loads • Care to be taken when handling extra long or high load • When loads can’t be centered, the forklift should be operated with caution Picture source: http: //www. baileypottery. com Source: CP 101: 2004 Code of practice for safe use of powered counterbalanced forklifts

Forklift Load Assessments 2 • Only handle stable or safely arranged loads • Care to be taken when handling extra long or high load • When loads can’t be centered, the forklift should be operated with caution Picture source: http: //www. baileypottery. com Source: CP 101: 2004 Code of practice for safe use of powered counterbalanced forklifts

Load Assessments – Weighing the Load Picture source: http: //www. weighing-systems. com/Technology. Centre/forkliftweigh. html

Load Assessments – Weighing the Load Picture source: http: //www. weighing-systems. com/Technology. Centre/forkliftweigh. html

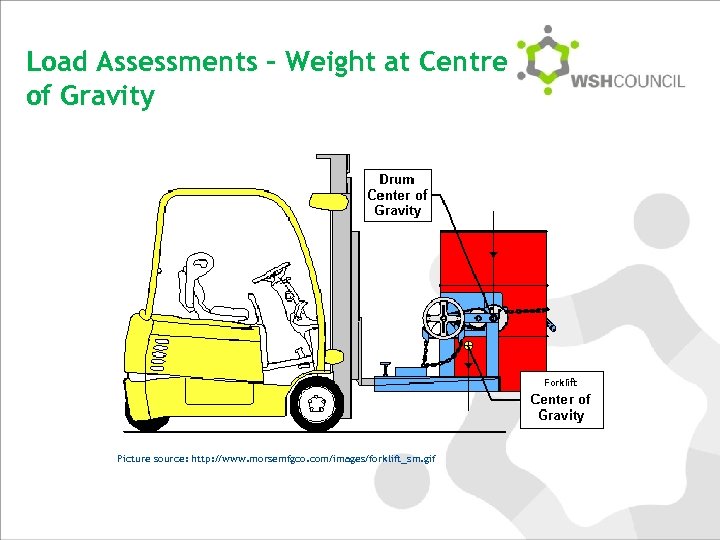

Load Assessments – Weight at Centre of Gravity Forklift Picture source: http: //www. morsemfgco. com/images/forklift_sm. gif

Load Assessments – Weight at Centre of Gravity Forklift Picture source: http: //www. morsemfgco. com/images/forklift_sm. gif

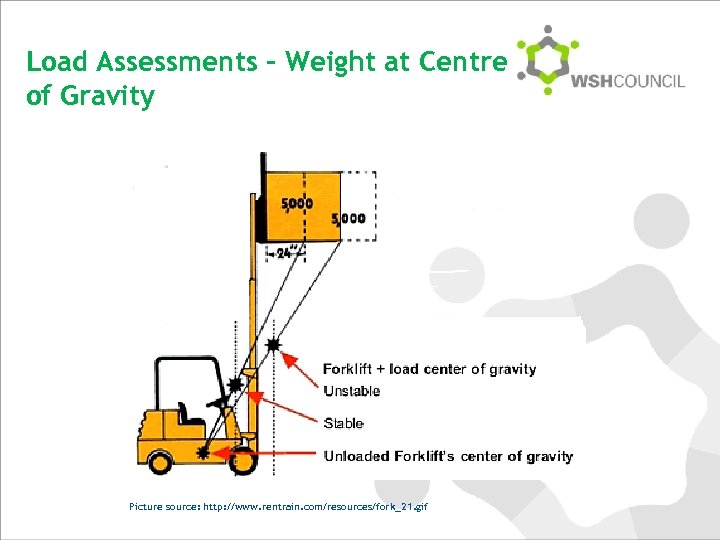

Load Assessments – Weight at Centre of Gravity Picture source: http: //www. rentrain. com/resources/fork_21. gif

Load Assessments – Weight at Centre of Gravity Picture source: http: //www. rentrain. com/resources/fork_21. gif

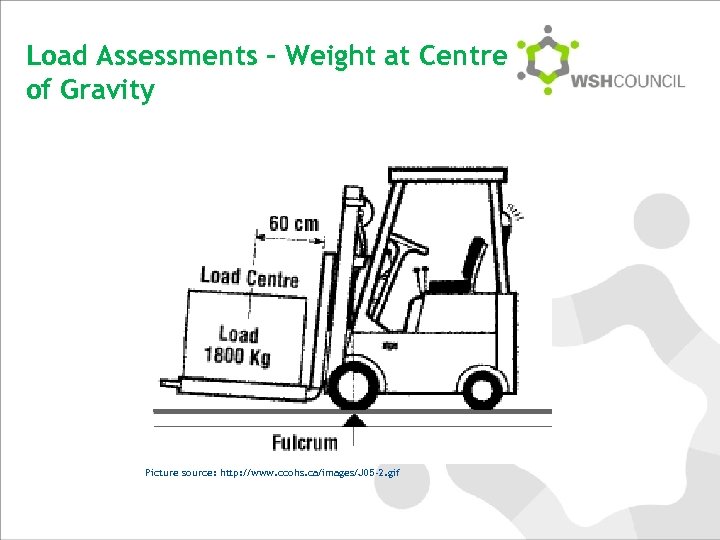

Load Assessments – Weight at Centre of Gravity Picture source: http: //www. ccohs. ca/images/J 05 -2. gif

Load Assessments – Weight at Centre of Gravity Picture source: http: //www. ccohs. ca/images/J 05 -2. gif

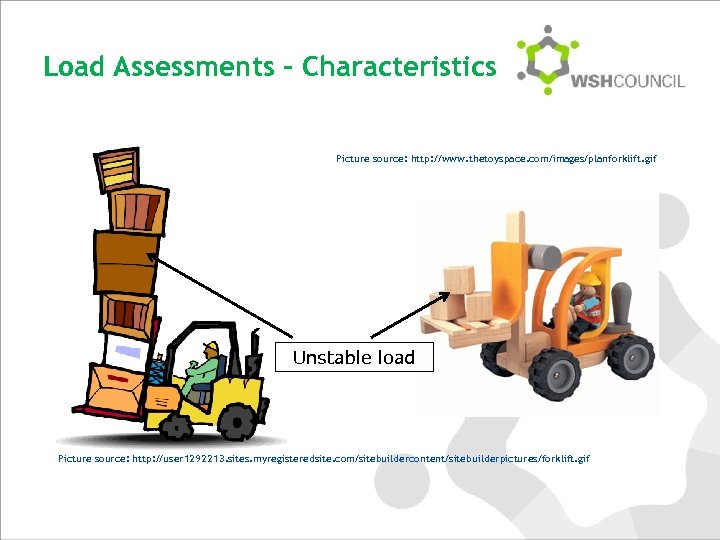

Load Assessments – Characteristics Picture source: http: //www. thetoyspace. com/images/planforklift. gif Unstable load Picture source: http: //user 1292213. sites. myregisteredsite. com/sitebuildercontent/sitebuilderpictures/forklift. gif

Load Assessments – Characteristics Picture source: http: //www. thetoyspace. com/images/planforklift. gif Unstable load Picture source: http: //user 1292213. sites. myregisteredsite. com/sitebuildercontent/sitebuilderpictures/forklift. gif

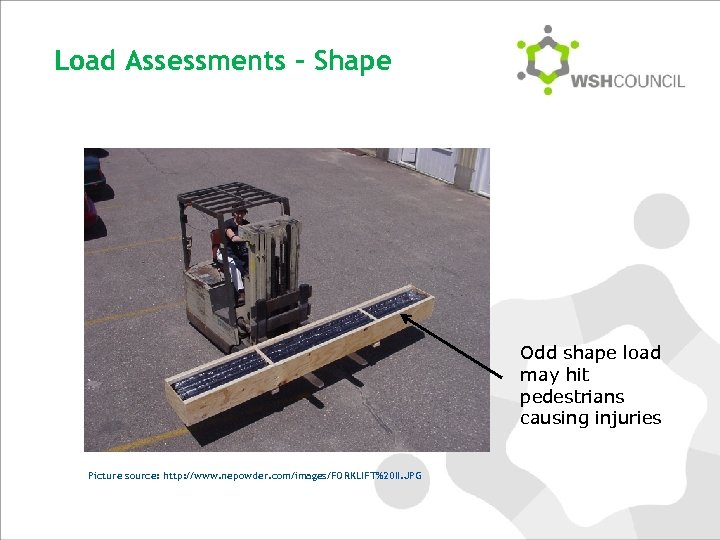

Load Assessments – Shape Odd shape load may hit pedestrians causing injuries Picture source: http: //www. nepowder. com/images/FORKLIFT%20 II. JPG

Load Assessments – Shape Odd shape load may hit pedestrians causing injuries Picture source: http: //www. nepowder. com/images/FORKLIFT%20 II. JPG

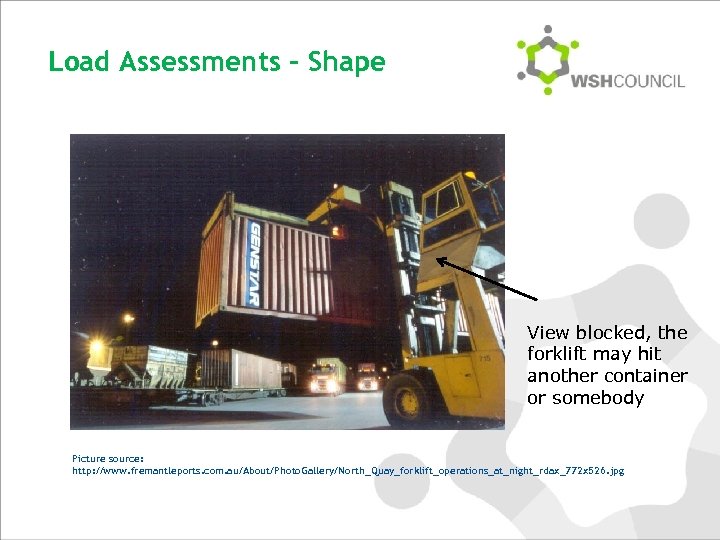

Load Assessments – Shape View blocked, the forklift may hit another container or somebody Picture source: http: //www. fremantleports. com. au/About/Photo. Gallery/North_Quay_forklift_operations_at_night_rdax_772 x 526. jpg

Load Assessments – Shape View blocked, the forklift may hit another container or somebody Picture source: http: //www. fremantleports. com. au/About/Photo. Gallery/North_Quay_forklift_operations_at_night_rdax_772 x 526. jpg

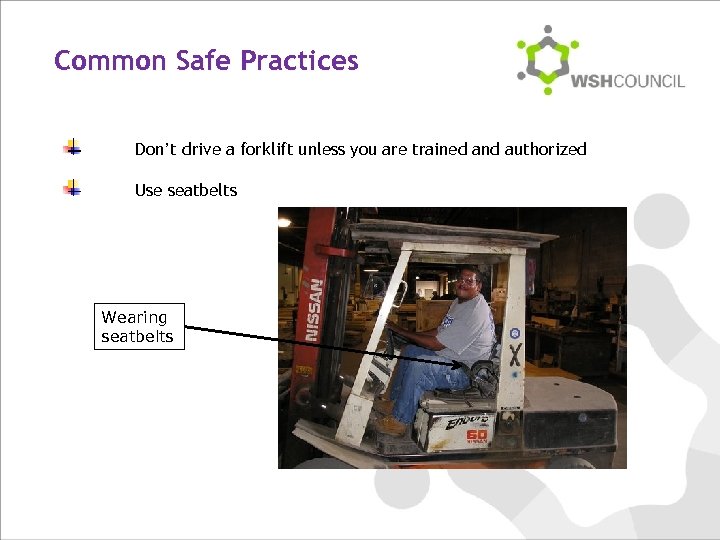

Common Safe Practices Don’t drive a forklift unless you are trained and authorized Use seatbelts Wearing seatbelts

Common Safe Practices Don’t drive a forklift unless you are trained and authorized Use seatbelts Wearing seatbelts

Common Safe Practices Report to your supervisor on any forklift damage or problems Don’t use a forklift to lift worker Use caution on slopes or ramps Picture source: http: //www. liftomatic. com

Common Safe Practices Report to your supervisor on any forklift damage or problems Don’t use a forklift to lift worker Use caution on slopes or ramps Picture source: http: //www. liftomatic. com

Common Safe Practices While on slopes, tilt the load back and raise it above road surface Don’t raise or lower the forks while the forklift is moving Don’t handle loads that are above the weight capacity of the forklift Follow the speed limit

Common Safe Practices While on slopes, tilt the load back and raise it above road surface Don’t raise or lower the forks while the forklift is moving Don’t handle loads that are above the weight capacity of the forklift Follow the speed limit

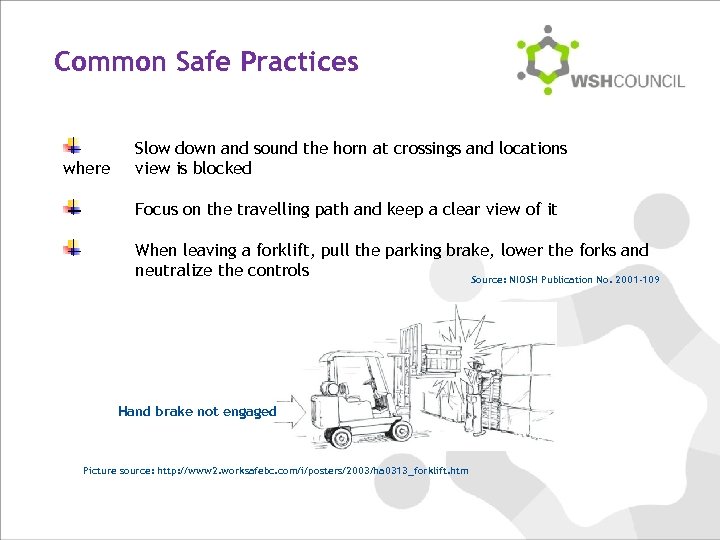

Common Safe Practices where Slow down and sound the horn at crossings and locations view is blocked Focus on the travelling path and keep a clear view of it When leaving a forklift, pull the parking brake, lower the forks and neutralize the controls Source: NIOSH Publication No. 2001 -109 Hand brake not engaged Picture source: http: //www 2. worksafebc. com/i/posters/2003/ha 0313_forklift. htm

Common Safe Practices where Slow down and sound the horn at crossings and locations view is blocked Focus on the travelling path and keep a clear view of it When leaving a forklift, pull the parking brake, lower the forks and neutralize the controls Source: NIOSH Publication No. 2001 -109 Hand brake not engaged Picture source: http: //www 2. worksafebc. com/i/posters/2003/ha 0313_forklift. htm

Common Safe Practices Attend briefing on forklift operations Follow traffic management Carry out daily forklift pre-operation checks using checklist Ensure that the forklifts are well maintained Use rear view mirrors while reversing Give way to pedestrians Park forklift at approved locations. Picture source: http: //www. safety-mirrors. co. uk/cabfront. jpg

Common Safe Practices Attend briefing on forklift operations Follow traffic management Carry out daily forklift pre-operation checks using checklist Ensure that the forklifts are well maintained Use rear view mirrors while reversing Give way to pedestrians Park forklift at approved locations. Picture source: http: //www. safety-mirrors. co. uk/cabfront. jpg

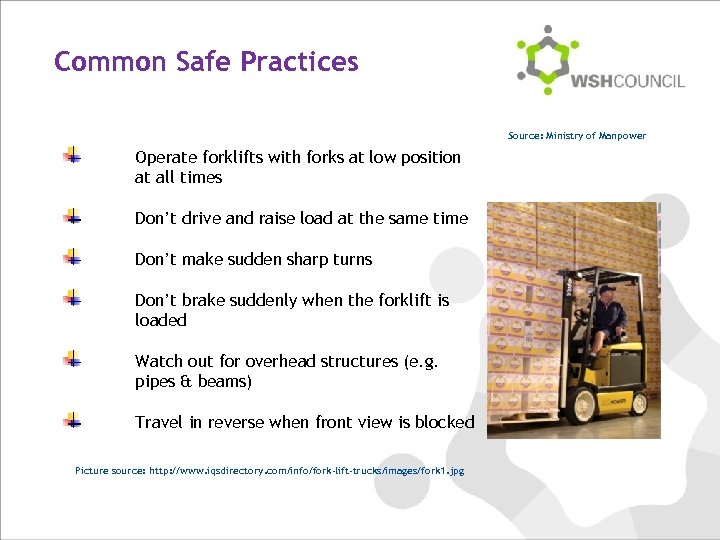

Common Safe Practices Source: Ministry of Manpower Operate forklifts with forks at low position at all times Don’t drive and raise load at the same time Don’t make sudden sharp turns Don’t brake suddenly when the forklift is loaded Watch out for overhead structures (e. g. pipes & beams) Travel in reverse when front view is blocked Picture source: http: //www. iqsdirectory. com/info/fork-lift-trucks/images/fork 1. jpg

Common Safe Practices Source: Ministry of Manpower Operate forklifts with forks at low position at all times Don’t drive and raise load at the same time Don’t make sudden sharp turns Don’t brake suddenly when the forklift is loaded Watch out for overhead structures (e. g. pipes & beams) Travel in reverse when front view is blocked Picture source: http: //www. iqsdirectory. com/info/fork-lift-trucks/images/fork 1. jpg

Traffic Controls • Follow the forklift route plan and pedestrian path • Obey the speed limits, pedestrian crossings and one way signs etc.

Traffic Controls • Follow the forklift route plan and pedestrian path • Obey the speed limits, pedestrian crossings and one way signs etc.

Traffic Controls • Follow site rules and inform all staff and visitors • Operate forklift only in clearly marked areas • Lookout for people opening doors • Check back when reversing • Give way to pedestrians Picture source: http: //www. derrycity. gov. uk/Site_Images/forklift. jpg

Traffic Controls • Follow site rules and inform all staff and visitors • Operate forklift only in clearly marked areas • Lookout for people opening doors • Check back when reversing • Give way to pedestrians Picture source: http: //www. derrycity. gov. uk/Site_Images/forklift. jpg

Traffic Controls • Wear high visibility clothing • Be cautious on road slopes • Park on flat surfaces • Avoid driving over objects on the road surface • When making turns, reduce speed to safe level Picture source: http: //www. thompsonandjohnson. com/newsletter/images/tip 70509. jpg

Traffic Controls • Wear high visibility clothing • Be cautious on road slopes • Park on flat surfaces • Avoid driving over objects on the road surface • When making turns, reduce speed to safe level Picture source: http: //www. thompsonandjohnson. com/newsletter/images/tip 70509. jpg

Summary of Key Points Training forklift operators Pre-operation checks Load assessments Route plan Common forklift hazards Forklift common safe practices Forklift traffic control Risk management on operation of forklift

Summary of Key Points Training forklift operators Pre-operation checks Load assessments Route plan Common forklift hazards Forklift common safe practices Forklift traffic control Risk management on operation of forklift

All accidents are preventable Be proactive: it is up to US to prevent it

All accidents are preventable Be proactive: it is up to US to prevent it

Thank You

Thank You

References: 1. WSHAC Occupational Safety & Health Technical Advisory – Safe Operation of Forklift Truck 2. WSHAC Forklift Safety Checklist 3. CP: 101: 2004 Code of Practice for Safe Use of Powered Counterbalanced Forklifts 4. MOM Case Studies on Forklift Accidents 5. NIOSH Publication No. 2001 -109 NIOSH Alert: Preventing Injuries and Deaths of Workers Who Operate or Work Near Forklifts 6. Chisholm Institute (Warehouse Task – Drive a forklift) (http: //olvc. chisholm. vic. edu. au/warehouse/D 10/Virtualwa rehouse/D 10 Tasks/D 10 tasks. htm)

References: 1. WSHAC Occupational Safety & Health Technical Advisory – Safe Operation of Forklift Truck 2. WSHAC Forklift Safety Checklist 3. CP: 101: 2004 Code of Practice for Safe Use of Powered Counterbalanced Forklifts 4. MOM Case Studies on Forklift Accidents 5. NIOSH Publication No. 2001 -109 NIOSH Alert: Preventing Injuries and Deaths of Workers Who Operate or Work Near Forklifts 6. Chisholm Institute (Warehouse Task – Drive a forklift) (http: //olvc. chisholm. vic. edu. au/warehouse/D 10/Virtualwa rehouse/D 10 Tasks/D 10 tasks. htm)

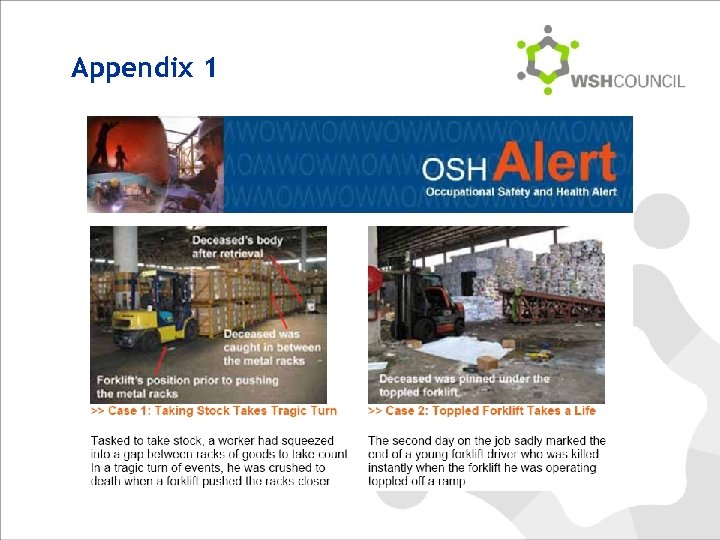

Appendix 1

Appendix 1

Appendix 1

Appendix 1

Appendix 1

Appendix 1

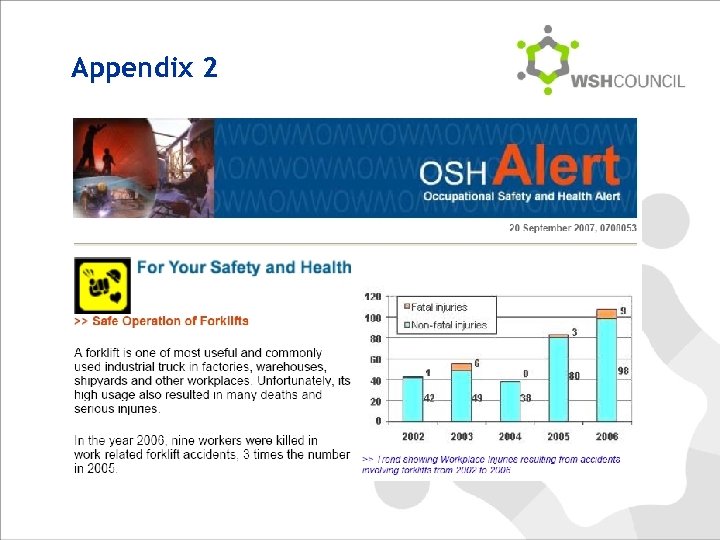

Appendix 2

Appendix 2

Appendix

Appendix