6ca21113df145a4574dce3a30feba5c7.ppt

- Количество слайдов: 101

SAF 130 B PRESSURE AND VACUUM SYSTEMS DESIGN AUTHORITY TRAINING This training was conducted on March 9, 2016. It is meant as a summary of the Design Authority’s responsibilities in ES&H Manual Chapter 6151, the new Pressure and Vacuum Systems Safety Supplement and the revised Welding and Brazing Program Supplement. In all cases, the actual language in the Chapter and the Supplements supersedes the information provided herein. 1

Course Overview Why Are We Here? JLab and other DOE Lab Performance 10 CFR 851 Requirements Hazard Avoidance Techniques Revised ES&H Manual Chapter 6151 Overview / Major differences The New Pressure and Vacuum Systems Safety Supplement Overview / Major differences Revised Welding and Brazing Program Supplement Overview / Major differences Future Plans 2

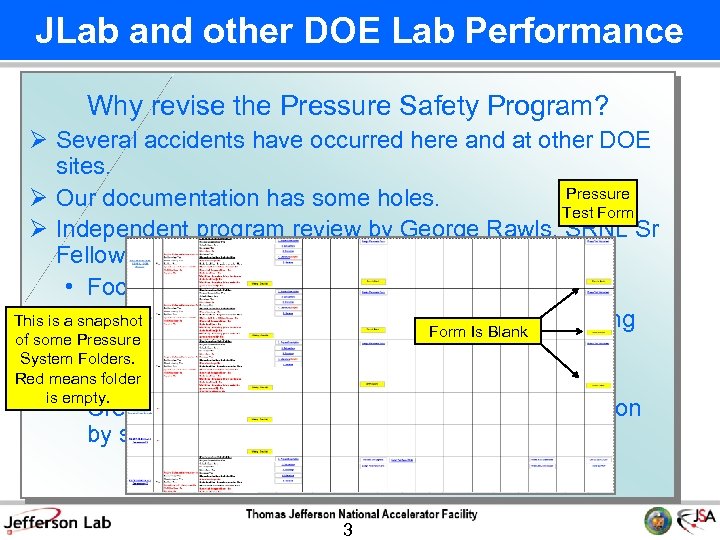

JLab and other DOE Lab Performance Why revise the Pressure Safety Program? Ø Several accidents have occurred here and at other DOE sites. Pressure Ø Our documentation has some holes. Test Form Ø Independent program review by George Rawls, SRNL Sr Fellow Engineer: • Focus on ASME Code requirements This is a snapshot • Clearly identify required examinations, both welding Form Is Blank of some Pressure and mechanical System Folders. Red means folder Owner’s Inspection function • Clarify is empty. • Create approval process for overpressure protection by system design 3

“Contractors must establish safety policies and procedures to ensure that pressure systems are designed, fabricated, tested, inspected, maintained, repaired, and operated by trained and qualified personnel in accordance with applicable and sound engineering principles. ” “Contractors must ensure that all pressure vessels … and supporting piping systems conform to: (1) The applicable ASME Boiler and Pressure Vessel Code (2) The applicable ASME B 31 Code for Pressure Piping (3) The strictest applicable state and local codes” “When national consensus codes are not applicable (because of pressure range, vessel geometry, use of special material, etc. ), contractors must implement measures to provide equivalent protection…” 4

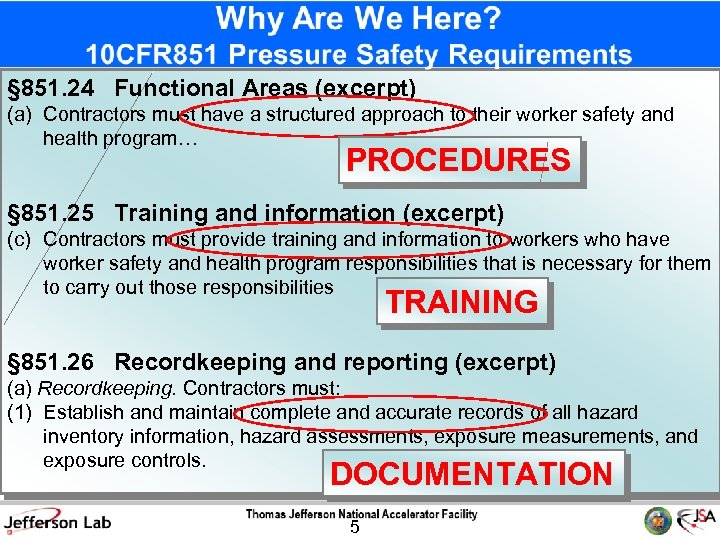

§ 851. 24 Functional Areas (excerpt) (a) Contractors must have a structured approach to their worker safety and health program… PROCEDURES § 851. 25 Training and information (excerpt) (c) Contractors must provide training and information to workers who have worker safety and health program responsibilities that is necessary for them to carry out those responsibilities TRAINING § 851. 26 Recordkeeping and reporting (excerpt) (a) Recordkeeping. Contractors must: (1) Establish and maintain complete and accurate records of all hazard inventory information, hazard assessments, exposure measurements, and exposure controls. DOCUMENTATION 5

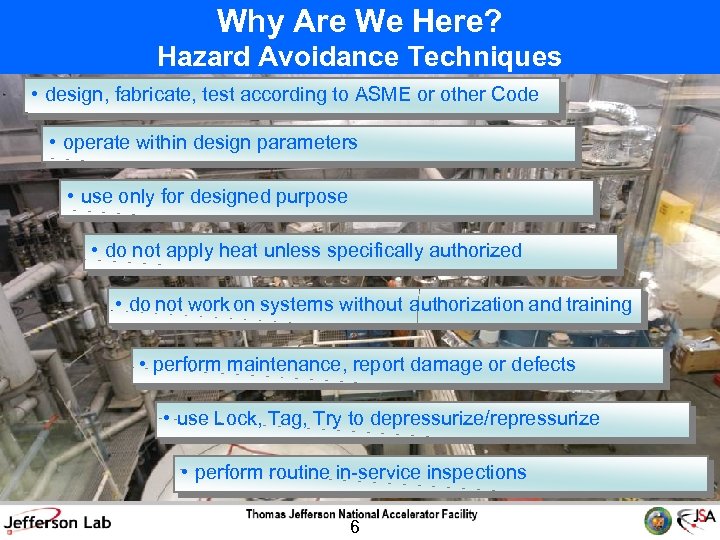

Why Are We Here? Hazard Avoidance Techniques • design, fabricate, test according to ASME or other Code • operate within design parameters • use only for designed purpose • do not apply heat unless specifically authorized • do not work on systems without authorization and training • perform maintenance, report damage or defects • use Lock, Tag, Try to depressurize/repressurize • perform routine in-service inspections 6

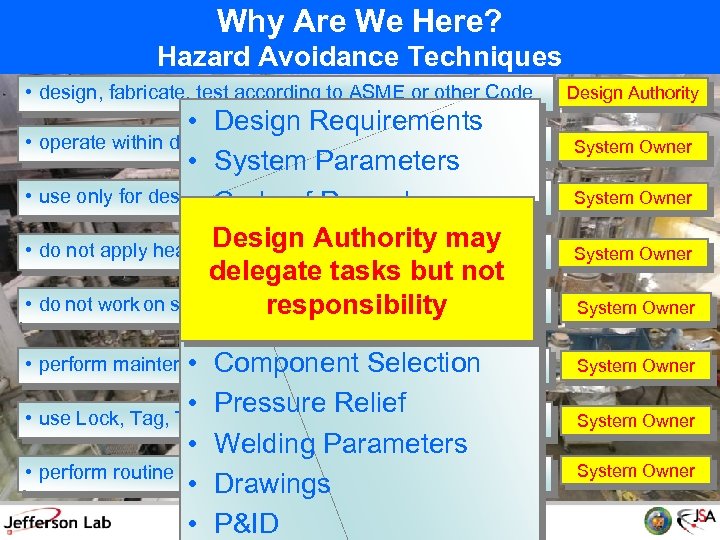

Why Are We Here? Hazard Avoidance Techniques • design, fabricate, test according to ASME or other Code • Design Requirements • operate within design parameters • System Parameters • use only for designed purpose Record • Code of • Design Authority may Operating Conditions • do not apply heat unless specifically authorized • delegate tasks but not Calculations • do not work on systems without authorization and training responsibility • Material Selection • perform maintenance, report damage. Selection • Component or defects • Pressure Relief • use Lock, Tag, Try to depressurize/repressurize • Welding Parameters • perform routine in-service inspections • Drawings 7 • P&ID Design Authority System Owner System Owner

Course Overview Why Are We Here? JLab and other DOE Lab Performance 10 CFR 851 Requirements Hazard Avoidance Techniques Revised ES&H Manual Chapter 6151 Overview / Major differences The New Pressure and Vacuum Systems Safety Supplement Overview / Major differences Revised Welding and Brazing Program Supplement Overview / Major differences Future Plans 8

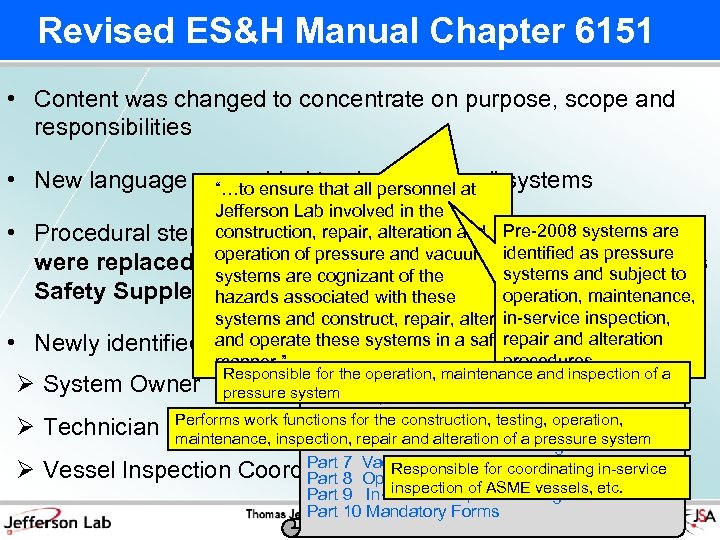

Revised ES&H Manual Chapter 6151 • Content was changed to concentrate on purpose, scope and responsibilities • New language was added to clarify “legacy” systems “…to ensure that all personnel at • • Jefferson Lab involved in the Procedural steps construction, repair, alteration and Pre-2008 systems are were removed and all technical appendices operation of pressure and vacuum identified as pressure were replaced with the new Pressure and Vacuum Systems systems and subject to systems are cognizant of the Safety Supplement associated with these operation, maintenance, hazards systems and construct, repair, alter in-service Safety Pressure & Vacuum Systems inspection, and operate a saferepair Newly identified functions: these systems in. Supplement and alteration procedures manner. ” Part 1 General Program Information Ø System Owner Ø Technician Responsible for the Pressure System Construction Part 2 operation, maintenance and inspection of a pressure system 3 Equivalent Measures Part 4 Overpressure Protection Performs work functions for the construction, testing, operation, Part 5 Repair and Alteration maintenance, inspection, repair and alteration of a pressure system Part 6 Pressure and Leak Testing Part 7 Responsible for Ø Vessel Inspection Coordinator. Vacuum Systems coordinating in-service Part 8 Operation and Maintenance inspection of ASME vessels, Part 9 In-service Inspection Program etc. Part 10 Mandatory Forms 9

JLab Definition of Pressure System: (OLD) Pressure System: (NEW) A connected set of piping, piping components and/or pressure vessel(s) used to either convey or contain a Any combination of vessels, piping, instrumentation fluid under pressure above 0 psig. (e. g. gauges), and/or equipment (e. g. pumps or compressors) either containing a fluid under internal Pressure or exposed to external fluid pressure. and pressure sources, fittings, pressure relief devices associated hardware such as gages and regulators are also integral parts of the pressure system. Note that vacuum systems are a subclass of pressure systems. Vacuum systems which cannot be protected against Vacuum systems can be especially hazardous when backfilling or purging. pressurization exceeding 15 psig from all credible pressure sources are considered pressure systems. 10

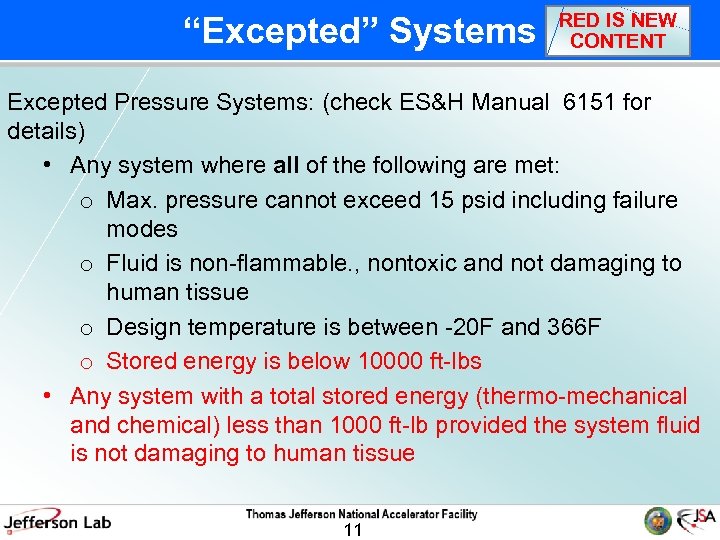

“Excepted” Systems RED IS NEW CONTENT Excepted Pressure Systems: (check ES&H Manual 6151 for details) • Any system where all of the following are met: all of o Max. pressure cannot exceed 15 psid including failure modes o Fluid is non-flammable. , nontoxic and not damaging to human tissue o Design temperature is between -20 F and 366 F o Stored energy is below 10000 ft-lbs • Any system with a total stored energy (thermo-mechanical and chemical) less than 1000 ft-lb provided the system fluid is not damaging to human tissue 11

“Excepted” Systems • • • RED IS NEW CONTENT Gas/liquified gas cylinders (covered by ES&H Manual 6150) USDOT covered vehicle pneumatic and hydraulic systems SCBA air cylinders Domestic water heaters with a capacity less than 120 gal, “Excepted” less than 210 F and heat input below 200000 BTU/hr doesn’t mean Domestic appliances covered by national standards hazards aren’t real ASHRAE compliant systems and devices for those systems! Roof and floor drains, plumbing and sewers Hazard avoidance Domestic hot, cold and grey water piping must always be Piping for handconsidered for any valve tools downstream of stop Instruments (not instrument piping/tubing) pressurized system! Fire protection systems (covered by ES&H Manual 6900) 12

Course Overview Why Are We Here? JLab and other DOE Lab Performance 10 CFR 851 Requirements Hazard Avoidance Techniques Revised ES&H Manual Chapter 6151 Overview / Major differences The New Pressure and Vacuum Systems Safety Supplement Overview / Major differences Revised Welding and Brazing Program Supplement Overview / Major differences Future Plans 13

New Pressure & Vacuum Systems Safety Supplement The Supplement should be considered a “living” document. Table of Contents The we chose Part understand. Program program will evolve and first section We 1 General that this Information Part 1 General Program Information includes general Code Part 2 Pressure System Constructionthe revision process. this “Supplement” format to simplify discussion, Part 2 Pressure System Construction Part 3 Equivalent Measures responsibilities, Part 3 Equivalent Measures all Open communication Protection parties involved is vital for between Part 4 Overpressure Protection program. qualifications and the success documentation Part 5 Repair and Alterationof this Part 5 Repair and Alteration requirements Part 6 Pressure and Leak Testing If you have Part 6 Pressure and Leak Testing questions or comments Part 7 Vacuum Systems please bring them to the Part 7 Vacuum Systems Part 8 Operation and Maintenance Pressure Systems Committee. Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms Use the Website as a resource. 14

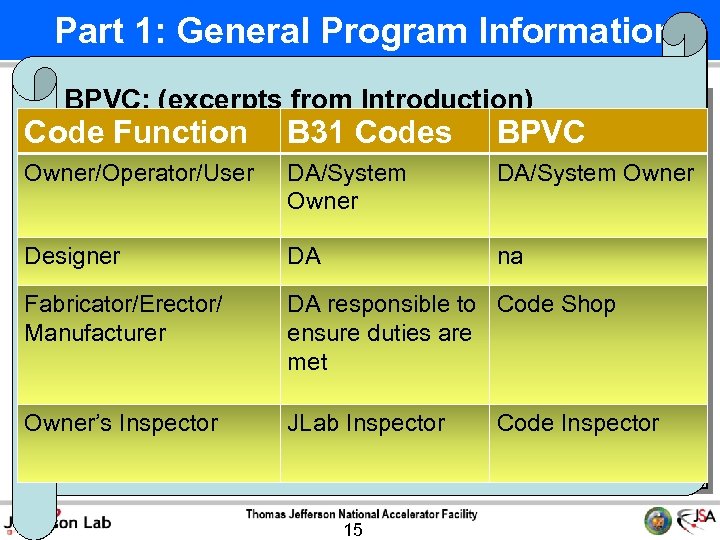

Part 1: General Program Information B 31: (excerpts from Introduction) BPVC: (excerpts from Introduction) Code Function mandatory requirements, specific BPVC This Code contains B 31 Codes The Code sets forth engineering requirements deemed • prohibitions, and nonmandatory guidance for construction PS Committee. DA/System duties of assumes Owner/Operator/User DA/System Owner necessary for inservice inspection and testing activities. safe authority construction of pressure design and jurisdictional Owner activities and piping. o Arbitration and interpretation of Code/policy issues The Code is guidance when requested replace Designer. Providenot a handbook and cannot na DA o All applicable requirements the use of engineering of the selected Code Section education, experience, and in-service inspection issues o Arbitrate and oversee shall be met. Fabricator/Erector/ judgment. Code DA responsible to Code Shop • ASME Manufacturer ensure duties are o Code ofnot a design handbook; it does not do away Record met be identified (CODE + EDITION) shall The Code is judgments must be consistent with Code Engineering o What does “Code is not a handbook” mean? with the need forsuchdesigner or must never be used to philosophy, and the Code functionscompetent judgments for o Interpretation of engineering judgment. Owner’s Inspector JLab Inspector Code Inspector overrule mandatory requirements or specific prohibitions of the Code. 15

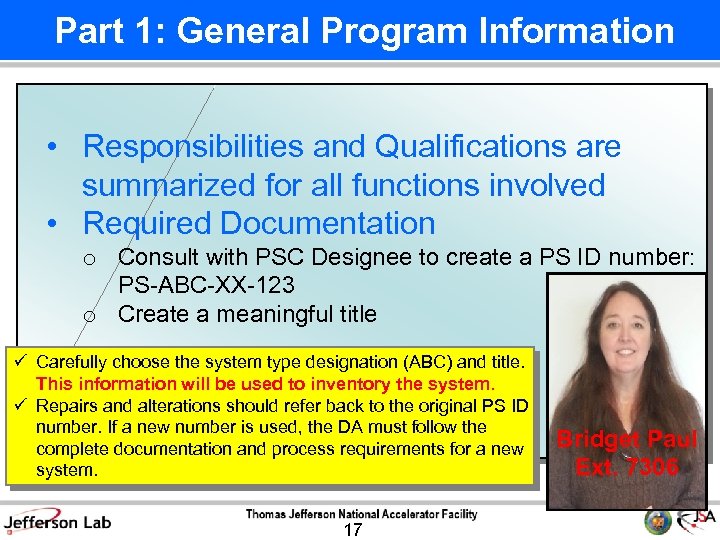

Part 1: General Program Information Design Authority Responsibilities: • Ensure safety of the public, personnel and the environment are primary considerations. • Responsibilities and Qualifications are • Ensure construction, alteration, repair and documentation meet the summarized for all functions involved Supplement • Employ, as required, the expertise available through other DAs, the QA/CI Inspector, Welding Committee and the Pressure Systems Committee … • • The list continues to summarize tasks involved with meeting Supplement requirements. Note the final 3 are not • new but are now given a structured approach: • • • Define the in-service inspection requirements • Define the operational requirements • Define special maintenance requirements 16

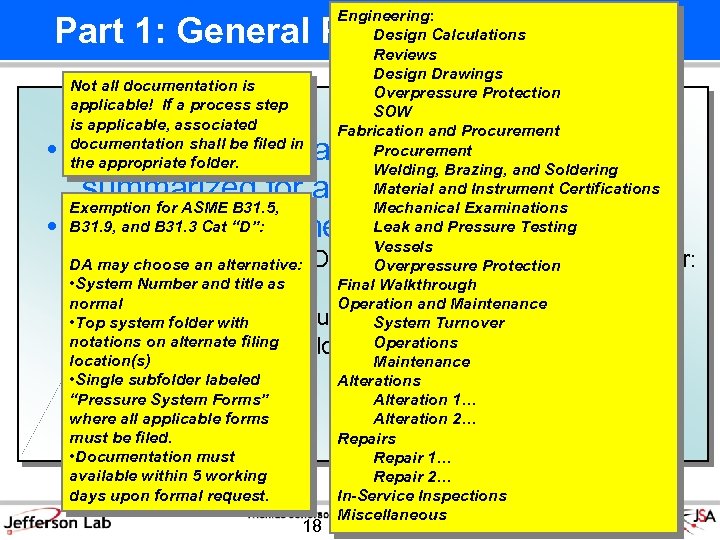

Part 1: General Program Information • Responsibilities and Qualifications are summarized for all functions involved • Required Documentation o Consult with PSC Designee to create a PS ID number: PS-ABC-XX-123 o Create a meaningful title ü Carefully choose the system type designation (ABC) and title. This information will be used to inventory the system. ü Repairs and alterations should refer back to the original PS ID number. If a new number is used, the DA must follow the complete documentation and process requirements for a new system. 17 Bridget Paul Ext. 7306

Engineering: Design Calculations Reviews Design Drawings Not all documentation is Overpressure Protection applicable! If a process step SOW is applicable, associated Fabrication and Procurement documentation shall be filed in Procurement the appropriate folder. Welding, Brazing, and Soldering Material and Instrument Certifications Exemption for ASME B 31. 5, Mechanical Examinations B 31. 9, and B 31. 3 Cat “D”: Leak and Pressure Testing Vessels o Consult with PSC DA may choose an alternative: Designee to create a PS ID number: Overpressure Protection • System Number and title as Final Walkthrough PS-ABC-XX-123 normal Operation and Maintenance o Create a with • Top system folder meaningful title System Turnover notations on alternate filing folder with subfolders Operations o Create a project location(s) Maintenance • Single subfolder labeled Alterations “Pressure System Forms” Alteration 1… where all applicable forms Alteration 2… must be filed. Repairs • Documentation must Repair 1… available within 5 working Repair 2… days upon formal request. In-Service Inspections Miscellaneous Part 1: General Program Information • Responsibilities and Qualifications are summarized for all functions involved • Required Documentation 18

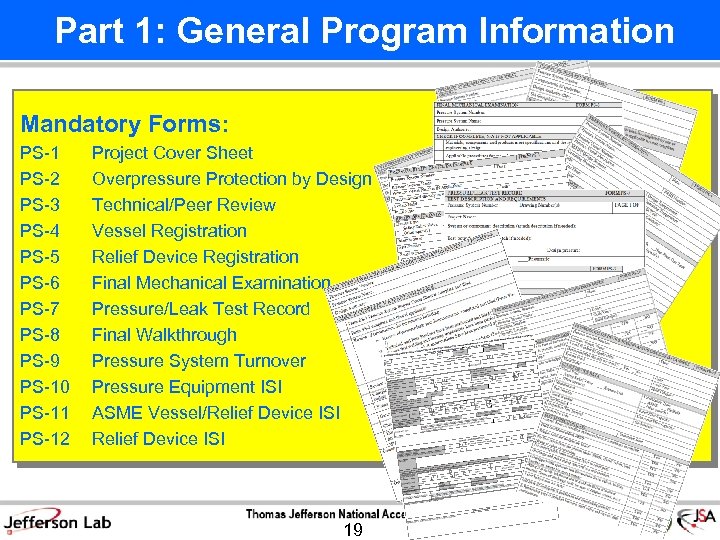

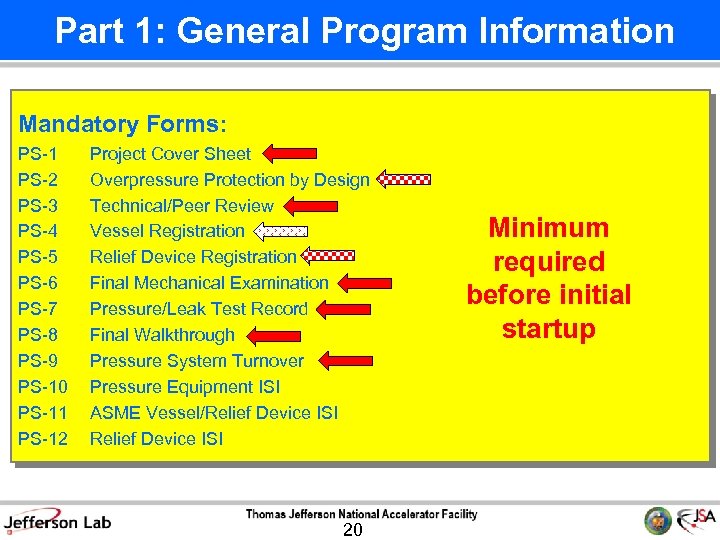

Part 1: General Program Information Mandatory Forms: PS-1 PS-2 PS-3 PS-4 PS-5 PS-6 PS-7 PS-8 PS-9 PS-10 PS-11 PS-12 Project Cover Sheet Overpressure Protection by Design Technical/Peer Review Vessel Registration Relief Device Registration Final Mechanical Examination Pressure/Leak Test Record Final Walkthrough Pressure System Turnover Pressure Equipment ISI ASME Vessel/Relief Device ISI 19

Part 1: General Program Information Mandatory Forms: PS-1 PS-2 PS-3 PS-4 PS-5 PS-6 PS-7 PS-8 PS-9 PS-10 PS-11 PS-12 Project Cover Sheet Overpressure Protection by Design Technical/Peer Review Vessel Registration Relief Device Registration Final Mechanical Examination Pressure/Leak Test Record Final Walkthrough Pressure System Turnover Pressure Equipment ISI ASME Vessel/Relief Device ISI 20 Minimum required before initial startup

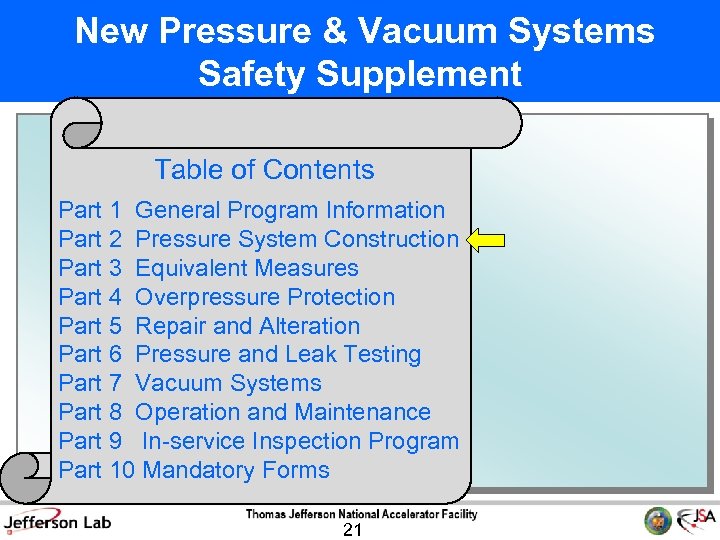

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 21

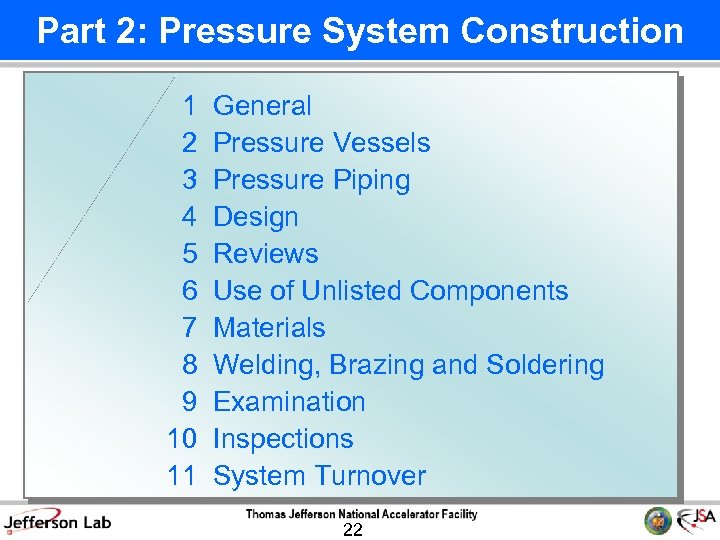

Part 2: Pressure System Construction 1 2 3 4 5 6 7 8 9 10 11 General Pressure Vessels Pressure Piping Design Reviews Use of Unlisted Components Materials Welding, Brazing and Soldering Examination Inspections System Turnover 22

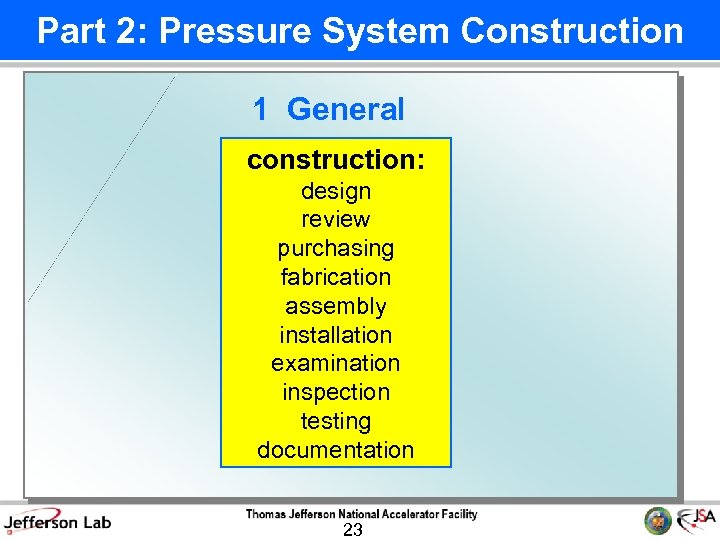

Part 2: Pressure System Construction 1 General construction: design review purchasing fabrication assembly installation examination inspection testing documentation 23

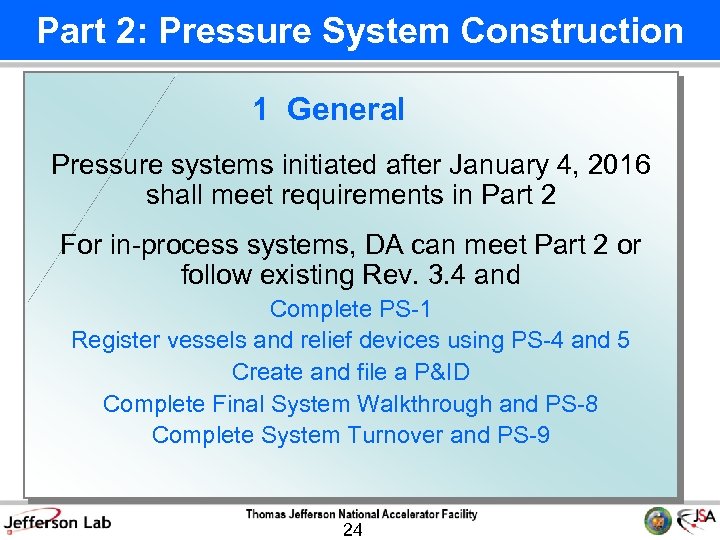

Part 2: Pressure System Construction 1 General Pressure systems initiated after January 4, 2016 shall meet requirements in Part 2 For in-process systems, DA can meet Part 2 or follow existing Rev. 3. 4 and Complete PS-1 Register vessels and relief devices using PS-4 and 5 Create and file a P&ID Complete Final System Walkthrough and PS-8 Complete System Turnover and PS-9 24

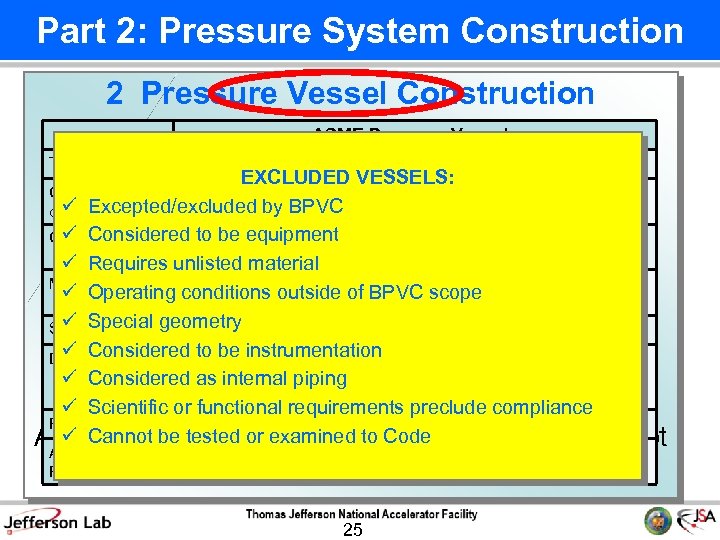

Part 2: Pressure System Construction 2 Pressure Vessel Construction ASME Pressure Vessels Pressure. Unique vessels shall be constructed, to the Off the Shelf Repurposed EXCLUDED VESSELS: Code greatest extent reasonably possible, in full BPVC compliant Original BPVC ü Excepted/excluded compliance with by BPVC the ASME Boiler and Pressure ü of Record BPVC Section VIII, Original Code of Code. Considered to be equipment Vessel # and Edition Record Code Div # and Edition Div Type ü Requires unlisted material Manufacturer shop Built shop ü Operating Built by Code outside of by Code scope Built/repaired by Code conditions BPVC shop 2 categories: ü Special geometry Stamp U stamp U and/or R stamp ASME Pressure ü Considered to be instrumentation Vessels U-1, U-1 A, etc Documentation Form U-1, U-1 A, Form etc. plus. Excluded full etc ü Considered as internal piping Vessels and Form R-1, R-1 A documentation ü Scientific or functional requirements preclude compliance Review Technical Review na na ü Cannot be tested or shall beto Code examined identified whether or not A Code of Record Additional Req’ts Registration/ID Tag the Code can be fully applied 25

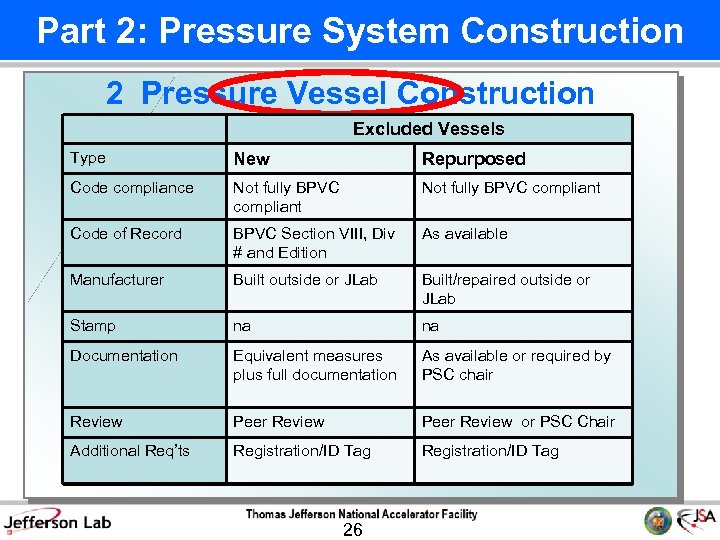

Part 2: Pressure System Construction 2 Pressure Vessel Construction Excluded Vessels Type New Repurposed Code compliance Not fully BPVC compliant Code of Record BPVC Section VIII, Div # VII, Div # and Edition As available Manufacturer Built outside or JLab Built/repaired outside or JLab Stamp na na Documentation Equivalent measures plus full documentation As available or required by PSC chair Review Peer Review or PSC Chair Additional Req’ts Registration/ID Tag 26

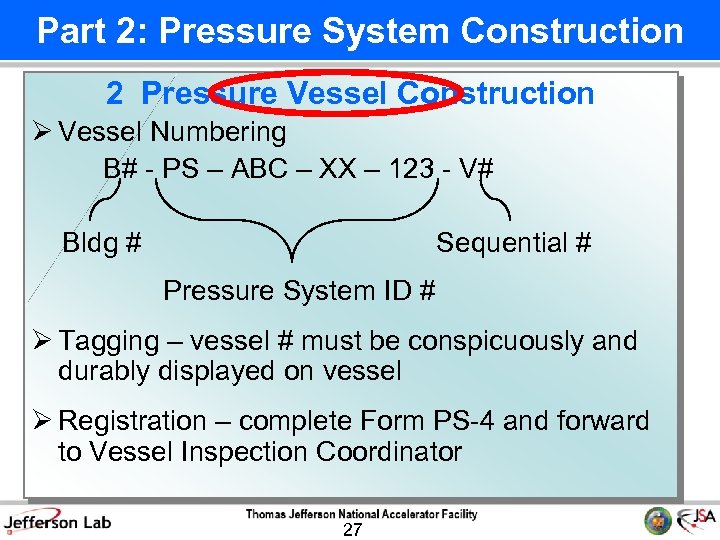

Part 2: Pressure System Construction 2 Pressure Vessel Construction Ø Vessel Numbering B# - PS – ABC – XX – 123 - V# Bldg # Sequential # Pressure System ID # Ø Tagging – vessel # must be conspicuously and durably displayed on vessel Ø Registration – complete Form PS-4 and forward to Vessel Inspection Coordinator 27

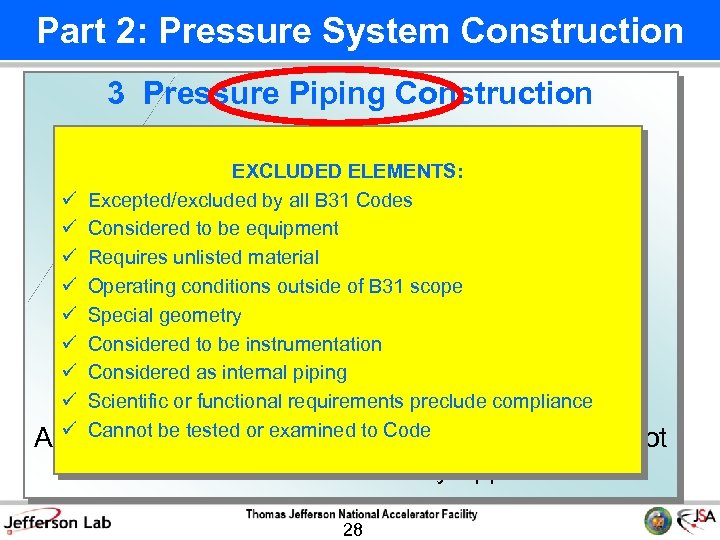

Part 2: Pressure System Construction 3 Pressure Piping Construction Pressure piping shall be constructed, to the EXCLUDED ELEMENTS: greatest extent possible, Codes in compliance with the ü Excepted/excluded by all B 31 ASME be equipment ü Considered to. B 31 Code for Pressure Piping ü ü ü ü Requires unlisted material Operating conditions 2 categories: outside of B 31 scope Special geometry ASME B 31 Pressure Piping Considered to be instrumentation Excluded Considered as internal piping Elements Scientific or functional requirements preclude compliance Cannot be tested or examined to Code A Code of Record shall be identified whether or not a B 31 Code can be fully applied 28

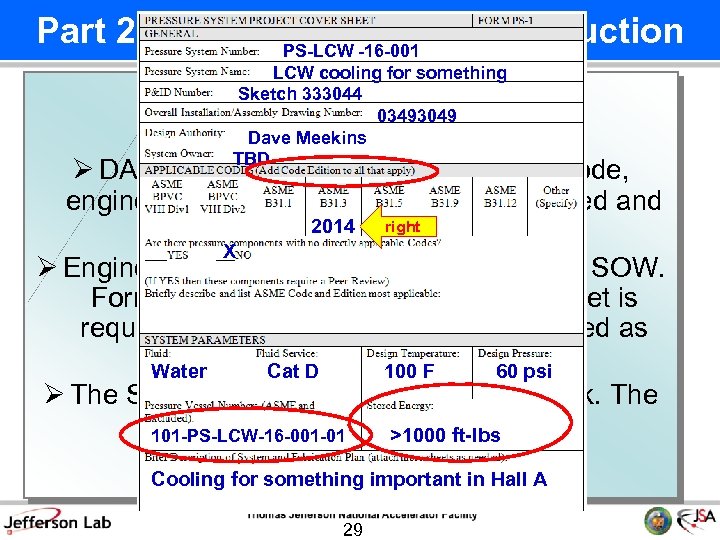

Part 2: Pressure System Construction PS-LCW -16 -001 LCW cooling for something Sketch 333044 03493049 Dave Meekins TBD 4 Vessel and Piping Design: Ø DA ensures calculations required by Code, engineering design and JLab are performed and right x reviewed 2014 wrong X Ø Engineering design must be formalized by SOW. Form PS-1 Pressure System Cover Sheet is required for each system and may be used as the SOW. Water Cat D 100 F 60 psi Ø The Supplement is not a design handbook. The DA must consider many elements… 101 -PS-LCW-16 -001 -01 >1000 ft-lbs Cooling for something important in Hall A 29

Part 2: Pressure System Construction • • Design Considerations Design life of the system Properties of the confined fluid All operating conditions – start-up, normal, shutdown, stand-by and emergency Need for maintenance and in-service inspection Future changes to design conditions Protection against system failure Suitable material selection External forces including thermal, seismic and wind (if applicable) 30

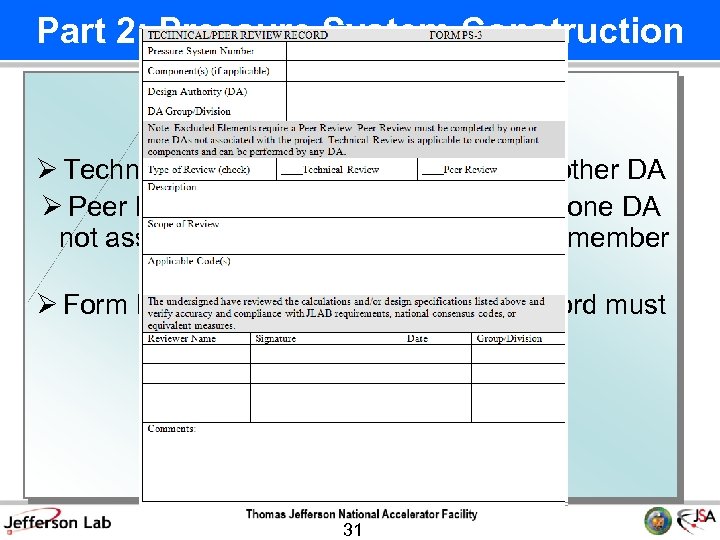

Part 2: Pressure System Construction 5 Reviews: Ø Technical Review – formal review by another DA Ø Peer Review – formal review by at least one DA not associated with the project and not a member of the same group Ø Form PS-3, Technical/Peer Review Record must be completed 31

Part 2: Pressure System Construction 6 Unlisted Components: Ø B 31 allows use of unlisted components with consent of the Owner. DA assumes this role. Ø DA shall ensure that all calculations are performed, reviewed and documented. Ø Qualify unlisted components according to Code. (Note that equivalent measures may not be required) Ø Unlisted piping components must meet B 31. 3 304. 7. 2 32

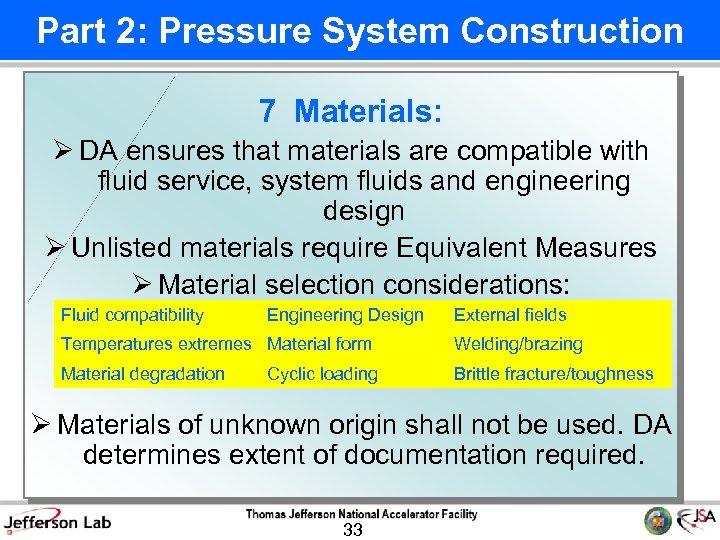

Part 2: Pressure System Construction 7 Materials: Ø DA ensures that materials are compatible with fluid service, system fluids and engineering design Ø Unlisted materials require Equivalent Measures Ø Material selection considerations: Fluid compatibility Engineering Design External fields Temperatures extremes Material form Welding/brazing Material degradation Brittle fracture/toughness Cyclic loading Ø Materials of unknown origin shall not be used. DA determines extent of documentation required. 33

Part 2: Pressure System Construction 8 Welding, Brazing and Soldering: Ø Pressure Boundary – Joint design, personnel and procedures must meet JLab Welding & Brazing Supplement and the applicable ASME or NB Code Ø Support Elements – Joint design, personnel and procedures shall meet JLab Welding & Brazing Supplement and the applicable ASME or AWS Structural Welding Code Ø DA completes Design Parameter Form or equivalent Ø Examinations and Inspections must follow Code and reports must be filed with system documentation 34

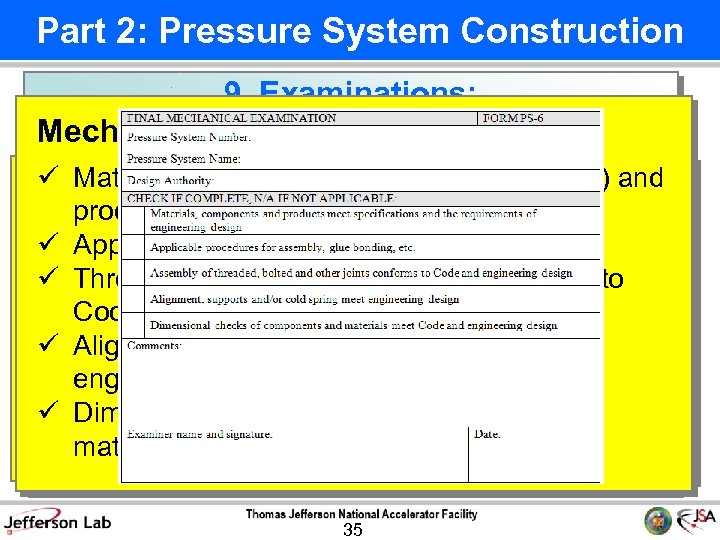

Part 2: Pressure System Construction 9 Examinations: Ø Examinations are not Mechanical Examination: Inspections! üØ DA ensures that all examinations required by Materials, components (fittings, valves, etc) and Examination - observation, by suitabledesign are of Code, JLab policyto specifications technique, products conform and engineering components, joints, and other elements either before, completed and documented ü Applicable procedures It may include during or after construction. for assembly verification Ø components, other joints conform ü materials, 2 Categoriesdimensions, joint prep, to Threaded, bolted and of Examinations: of Welding/Brazing – method (RT, UT, alignment, welding, supports or assembly. VT, etc. ) Code and engineering design chosen by DA, must meet Code ü Alignment, supports and cold spring meet Inspection – verification that all required Mechanical – in-process and final engineering designhave been completed and that examinations and tests Ø Final mechanical examination is required ü Dimensional checks of components and after documentation conforms to Code, JLab policy and installation is complete. Document and file using materials engineering design. Form PS-6 35

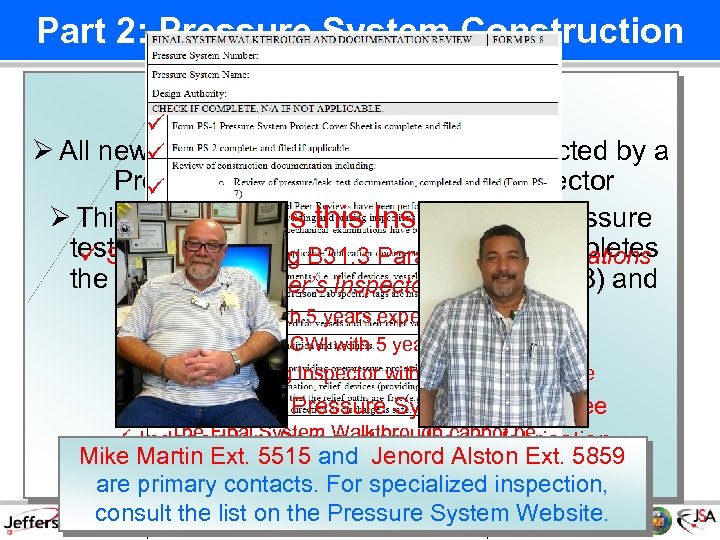

Part 2: Pressure System Construction 10 Inspections: ü Ø All newü pressure systems shall be inspected by a Pressure System Construction Inspector ü Ø This inspector witnesses final system pressure Who is this Inspector? test (unless meeting B 31. 3 Para. 340. 4 Qualifications ü Someone otherwise arranged) and completes ü System Walkthrough (Form PS-8) the Finalof the Owner’s Inspector requirements: and ü signs with 5 years experience or DA as Owner’s Inspector ü üCWI or senior CWI with 5 years experience or Authorized Piping Inspector with 5 years experience ü üü Approved by Pressure Systems Committee The Final System system design, fabrication, ü Independent are for. Walkthrough cannot be from documentation control. These items performed 5515 and Jenord Alston the Mike Martin Ext. without actually “walking down” Ext. 5859 installation, testing and examination system, contacts. pressure relief valves, etc. are primary checking For specialized inspection, consult the list on the Pressure System Website. 36

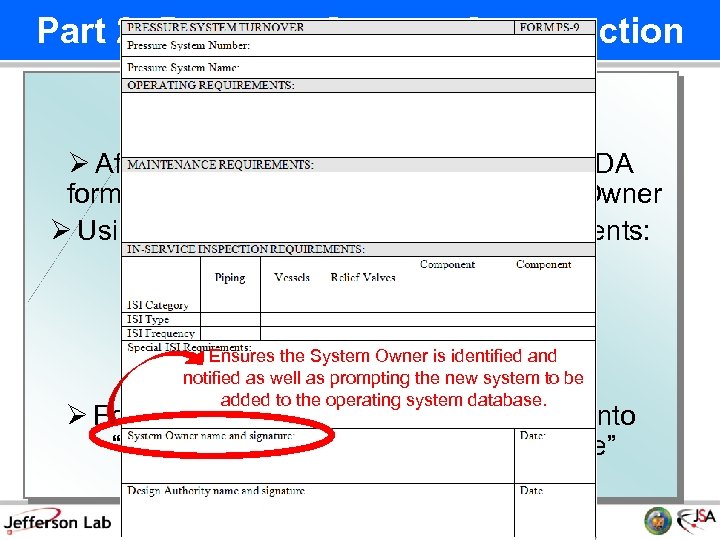

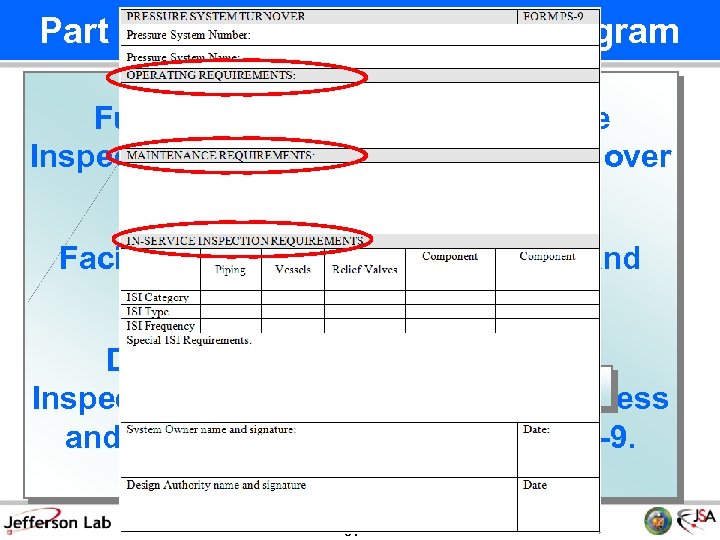

Part 2: Pressure System Construction 11 System Turnover: Ø After walkthrough and before operation, DA formally turns system over to the System Owner Ø Using Form PS-9, DA defines and documents: operating requirements special maintenance requirements in-service inspection requirements Ensures the System Owner is identified and notified as well as prompting and system Ø Both parties sign the newdate to be added to the operating system database. Ø Forward to Bridget Paul to prompt entry into “Operating Pressure Systems Database” 37

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 38

Part 3: Equivalent Measures • Equivalent measures shall be used to ensure a level of safety equal to or greater than that required by ASME Pressure Codes FOR EACH EXCLUDED ELEMENT. • Documentation shall include all of the following in addition to The most applicable Code of Record the standard: must always be identified – Reason why the Excluded Element cannot fully comply with selected Code of Record – Specific Code requirements that cannot be met – Calculations required by Code, sound engineering principles, and the engineering design – Specifications for special examinations or inspections if applicable – Specific measures taken 39

Part 3: Equivalent Measures • Measures taken to ensure a level of safety equal to or greater than ASME Pressure Code can include: v Extensive detailed analysis v Protective barriers v Secondary containment v Specialized testing v Protection of thin sections from accidental damage v Administration controls 40

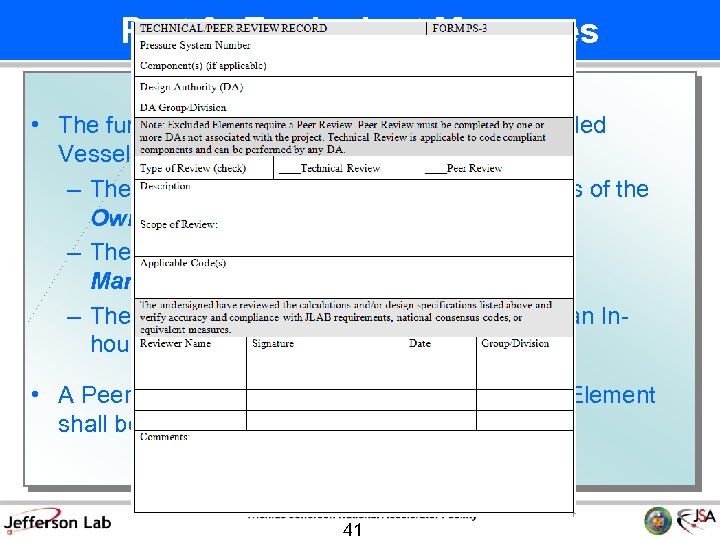

Part 3: Equivalent Measures • The functions defined by ASME BPVC for Excluded Vessels shall be as follows: – The DA and System Owner assume the duties of the Owner/User – The DA assumes the responsibilities of the Manufacturer – The duties of the Inspector are assumed by an Inhouse Inspector • A Peer Review of each Excluded Vessel and/or Element shall be performed. 41

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 42

Part 4: Overpressure Protection 1 2 3 4 5 6 7 8 General Requirements Potential Causes of Overpressure Relief Devices Exposed to Weather Pressure Relieving Requirements Overpressure Protection by Relief Device Installation Relief Device Registration Overpressure Protection by System Design 43

Part 4: Overpressure Protection 1 General Requirements Ø Design must account for all reasonable sources of overpressure and mitigate them through relief devices, design or other method Ø For systems >15 psi, DA shall • Analyze possible failure modes and effects (simple or formalized) • Calculate relief capacity • Consider discharge effects (reaction forces, venting, environmental factors) Ø For Excluded Elements and Vessels (MAWP>15 psi) use BPVC VIII D 1 Ø Overpressure protection analysis requires a technical review 44

Part 4: Overpressure Protection 2 Potential Causes of Overpressure results from disruption or unbalance of fluid flow or energy. Some causes include: 45

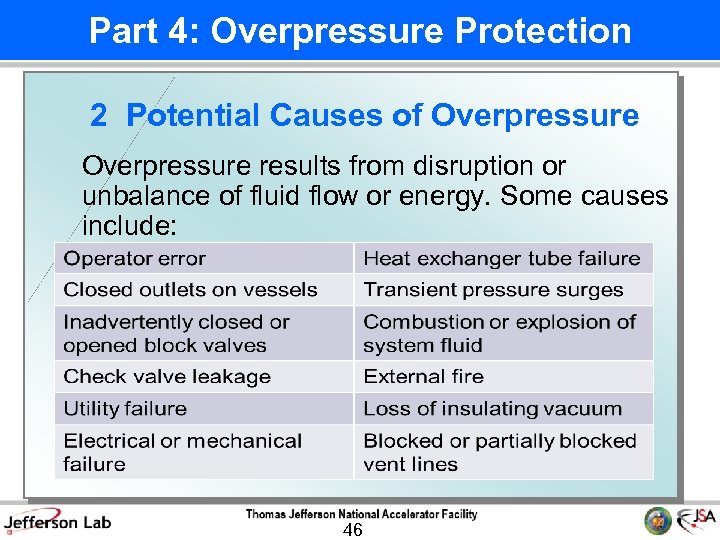

Part 4: Overpressure Protection 2 Potential Causes of Overpressure results from disruption or unbalance of fluid flow or energy. Some causes include: 46

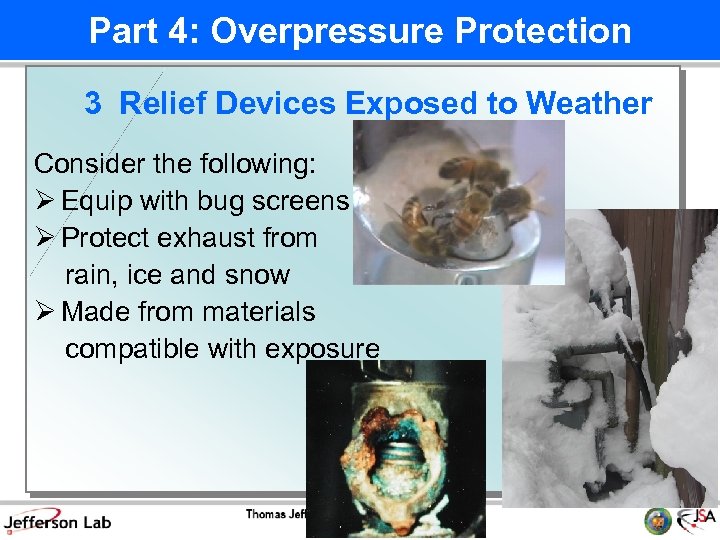

Part 4: Overpressure Protection 3 Relief Devices Exposed to Weather Consider the following: Ø Equip with bug screens Ø Protect exhaust from rain, ice and snow Ø Made from materials compatible with exposure 47

Part 4: Overpressure Protection 4 Pressure Relieving Requirements Ø DA shall determine largest credible relief capacity required and size relief devices appropriately Ø Max. allowable accumulation shall be in accordance with Code of Record (BPVC VIII D 1 for Excluded) Ø Devices shall be sized such that total capacity is sufficient for calculated mass flow Ø Relief path shall be analyzed for capacity and pressure drop 48

Part 4: Overpressure Protection 4 Pressure Relieving Requirements (cont. ) Ø Considerations for Overpressure from Exposure to Prolonged External Fire v Ø Considerations fire can result in verydue to the loads Exposure to external for Overpressure large relief Loss of Insulating Vacuum v Excellent guidance for liquid hydrocarbon pool fire is in API 521 Section 5. 15 v Cryogenic Vacuum Insulation relief depends on many factors: v JLab Fire Protection Engineer can provide guidance is critical in • Fluid properties and chemistry The heat transfer rate v Fire mitigation may be provided by preventative measures: calculating required relief capacity. • Geometry Adequate drainage, dykes to DA is encouraged • Insulation type and thickness prevent pooling to collaborate with other experienced DAs Removal of brush, debris • Temperature gradient • Elimination or vacuum of high flammable surfaces v Loss of insulating limitationon closetemperaturematerial may • Fire catastrophic failure, result insuppression system OSP or TOSP is required • Insulation and fireproofing 49

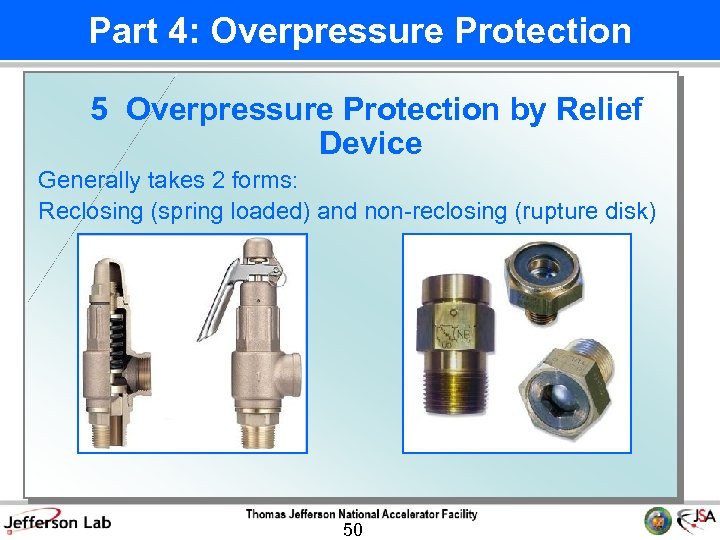

Part 4: Overpressure Protection 5 Overpressure Protection by Relief Device Generally takes 2 forms: Reclosing (spring loaded) and non-reclosing (rupture disk) 50

Part 4: Overpressure Protection 5 Overpressure Protection by Relief Device Ø Relief Devices with Set Pressure ≥ 15 psig Installed after March 1, 2008 • ASME stamped devices only • Registered if protecting a vessel, Cat. M system or piping larger than 6 NPS Installed before March 1, 2008 • Devices may be ASME, CE/PED or non-certified. • At replacement, only ASME stamped devices shall be used • Registered if protecting a vessel, Cat. M system or piping larger than 6 NPS 51

Part 4: Overpressure Protection 5 Overpressure Protection by Relief Device (cont. ) Ø Relief Devices with Set Pressure < 15 psig* • Not required to meet ASME BPVC • Devices may be procured or manufactured, whole or in part, on or off site. * Devices with set pressures < 30 psi, protecting vacuum jackets for cryo piping ≤ 6 NPS are also not required to meet ASME BPVC. Ø Procure from reputable manufacturers. Capacity shall be determined through calculation or test. Set pressure for reclosing devices shall be verified by test. Ø JLab made devices shall comply with Supplement Ø Parallel Plate devices, use max. coefficient of discharge no greater than Kd = 0. 62 52

Part 4: Overpressure Protection 6 Installation Ø Installed by qualified technicians Ø Block or stop valves may be installed upstream if ASME BPVC VIII Div 1 App M requirements are met Ø Direction of discharge is safe 53

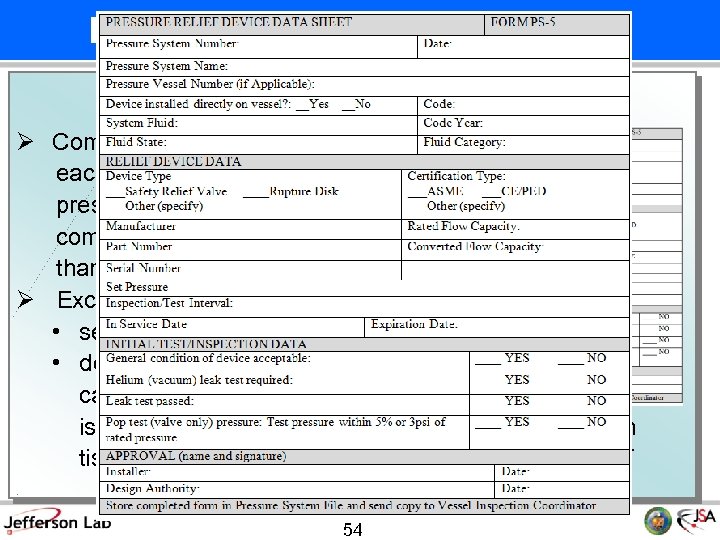

Part 4: Overpressure Protection 7 Relief Device Registration Ø Complete Form PS-5 for each relief device protecting pressure vessels, Cat. M components or piping larger than NPS 6 Ø Exceptions: • set points < 15 psig • devices where max pressure cannot exceed 15 psid; fluid is nonflammable, nontoxic and not harmful to human tissue; and temperature is between -20°F and 366°F 54

Part 4: Overpressure Protection 8 Overpressure Protection by System Design Ø If fluid is water <130°F and system does not have a vessel, no further requirements Ø For all others, DA writes a report addressing: Ø Reason Ø Detailed failure analysis (FMECA, etc. ) Ø Detailed analysis of maximum credible pressure Ø Requirements for periodic inspections and testing of controls 55

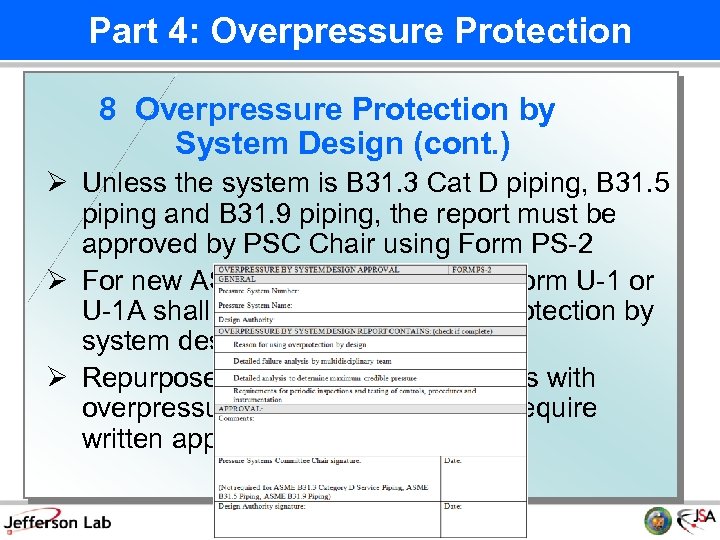

Part 4: Overpressure Protection 8 Overpressure Protection by System Design (cont. ) Ø Unless the system is B 31. 3 Cat D piping, B 31. 5 piping and B 31. 9 piping, the report must be approved by PSC Chair using Form PS-2 Ø For new ASME pressure vessels, Form U-1 or U-1 A shall indicate overpressure protection by system design Ø Repurposed ASME pressure vessels with overpressure protection by design require written approval by PSC Chair. 56

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 57

Part 5: Repair and Alteration 1 2 3 4 5 6 General Repair or Alteration of Pressure Vessels Repair or Alteration of Relief Devices Repair and Alteration Procedures Design Calculations Repairs and Alterations Requiring Welding, Brazing or Hot Work 7 Examinations and Testing 8 Inspections 9 Documentation 58

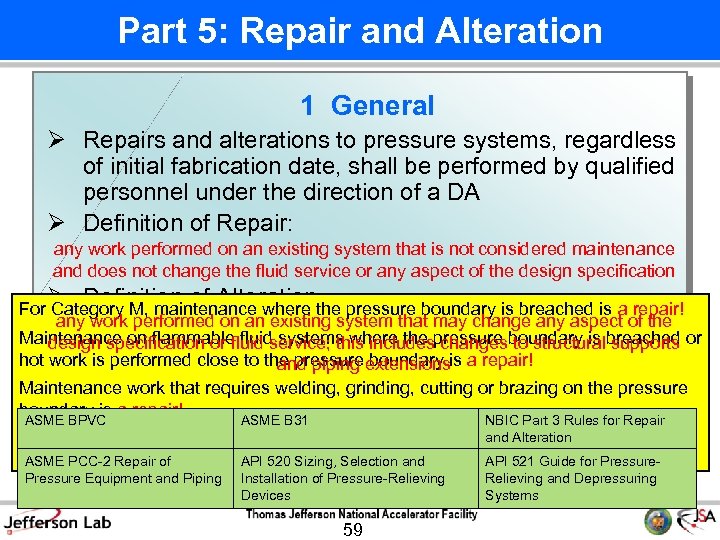

Part 5: Repair and Alteration 1 General Ø Repairs and alterations to pressure systems, regardless of initial fabrication date, shall be performed by qualified personnel under the direction of a DA Ø Definition of Repair: any work performed on an existing system that is not considered maintenance and does not change the fluid service or any aspect of the design specification Ø Definition of Alteration: For Category M, maintenance where the pressure boundary is breached is a repair! any work performed on an existing system that may change any aspect of the Maintenance on flammable fluid systems where the pressure boundary is breached or design specification or fluid service; this includes changes to structural supports hot work is performed close to the pressure extensionsis a repair! and piping boundary Maintenance work that. Codes: welding, grinding, cutting or brazing on the pressure Ø Applicable requires boundary is a repair! ASME BPVC ASME B 31 NBIC Part 3 Rules for Repairs on components NPS 5 or smaller that do not require welding are considered and Alteration maintenance. ASME PCC-2 Repair of API 520 Sizing, Selection and API 521 Guide for Pressure Equipment and Piping Installation of Pressure-Relieving Devices 59 Relieving and Depressuring Systems

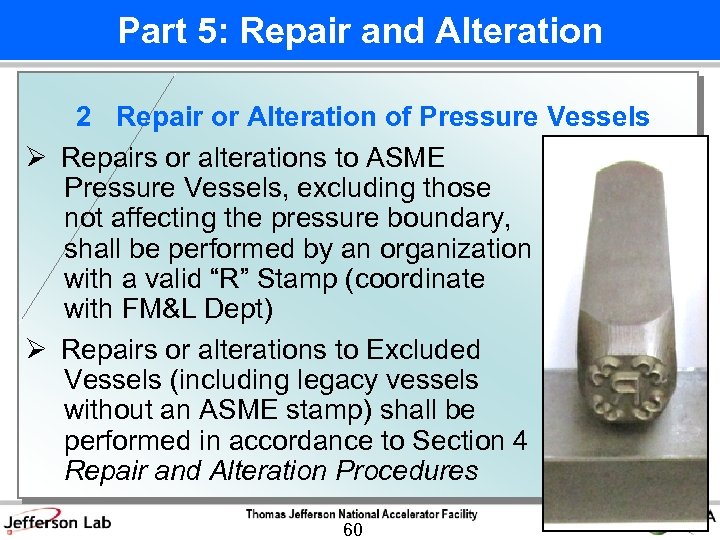

Part 5: Repair and Alteration 2 Repair or Alteration of Pressure Vessels Ø Repairs or alterations to ASME Pressure Vessels, excluding those not affecting the pressure boundary, shall be performed by an organization with a valid “R” Stamp (coordinate with FM&L Dept) Ø Repairs or alterations to Excluded Vessels (including legacy vessels without an ASME stamp) shall be performed in accordance to Section 4 Repair and Alteration Procedures 60

Part 5: Repair and Alteration 3 Repair or Alteration of Relief Devices Ø Repairs or alterations to “ASME”, “V”, “UV”, “HV”, “UV 3”, “TV”, or NBIC “VR” stamped relief devices shall be performed by an organization with a valid “VR” Stamp Ø Relief devices with set pressures greater than 15 psig requiring repair shall be replaced with Code devices 61

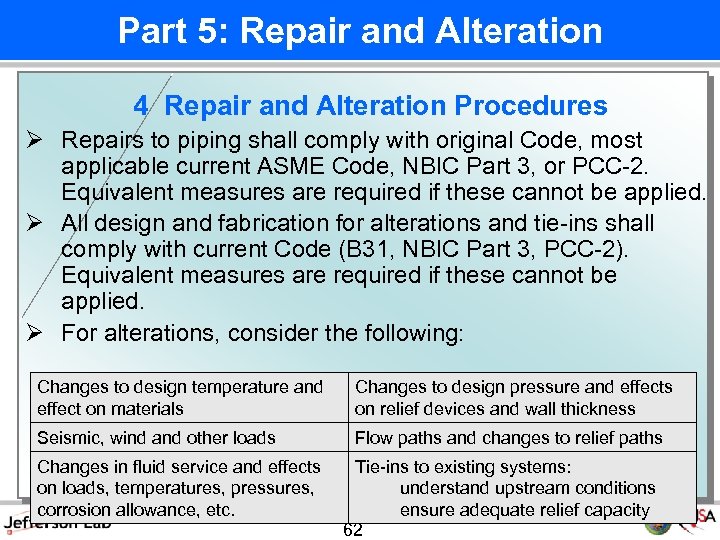

Part 5: Repair and Alteration 4 Repair and Alteration Procedures Ø Repairs to piping shall comply with original Code, most applicable current ASME Code, NBIC Part 3, or PCC-2. Equivalent measures are required if these cannot be applied. Ø All design and fabrication for alterations and tie-ins shall comply with current Code (B 31, NBIC Part 3, PCC-2). Equivalent measures are required if these cannot be applied. Ø For alterations, consider the following: Changes to design temperature and effect on materials Changes to design pressure and effects on relief devices and wall thickness Seismic, wind and other loads Flow paths and changes to relief paths Changes in fluid service and effects on loads, temperatures, pressures, corrosion allowance, etc. Tie-ins to existing systems: understand upstream conditions ensure adequate relief capacity 62

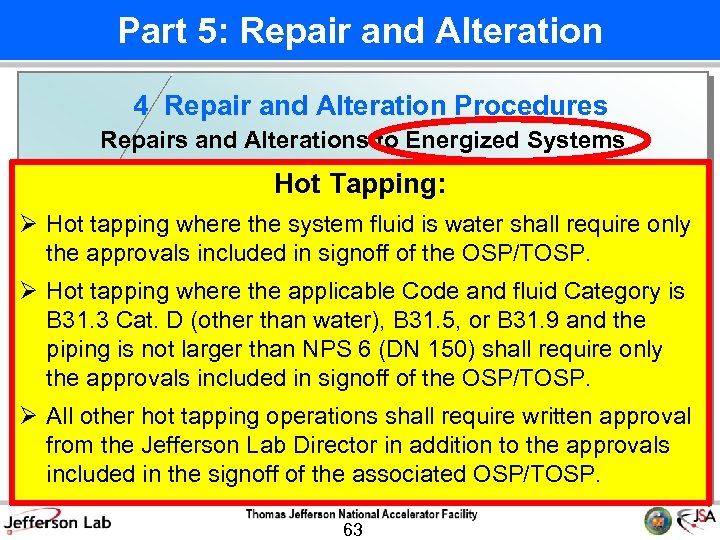

Part 5: Repair and Alteration 4 Repair and Alteration Procedures Repairs and Alterations to Energized Systems Case 1: Work on a component/branch that is isolated by valve Hot Tapping: CASE 2 (Fully or Partially Energized) CASE 1 (Locally Deenergized) lineup or system configuration and locally deenergized Ø Hot tapping where the system fluid is water shall require prior Ø An OSP or TOSP detailing the system configuration and preparation only (parts unaffected by the work remain energized) to and following the work as in signoff repair/alteration procedure itself the approvals included well as the of the OSP/TOSP. Case 2: Work on or componentthe DA in addition to normal procedural shall be written by a approved by or branch that is fully or partially Ø signoffs. energized the applicable Code and fluid Category is Hot tapping where B 31. 3 Cat. D (other than water), B 31. 5, or B 31. 9 and the The system provide detailed procedures in considered be isolated Ø If the. DA shallfluid or flammable, Category M, orthe OSP or TOSP to ensure The component is branch NPS 6 (DN 150) shall require only by to repaired/altered shall hazardous piping is and equipment isolated not larger than personnel the ES&H manual then thesafety. component orserviceof the system (Caseapprovals provided in signoff of the OSP/TOSP. 1 above) included no unacceptable branch interruption the shall be purged bywhere the system fluid is Categoryalteration. The Ø Work on systems an is created. to any repair or M shall require or unsafe condition inert fluid prior Ø procedure for purging theoperations shall require TOSP. approval All other hot tapping Jefferson Lab Director. written approval from shall be included in the OSP or written Work to non-pressure containing components may approvals from the Jefferson Lab Director requiring “Hotto the be Ø Special considerations for alterations in addition Tapping”. performed with safety assured associated OSP/TOSP. by DA included in the signoff of the by procedures reviewed 63

Part 5: Repair and Alteration 4 Repair and Alteration Procedures Repairs and Alterations to Deenergized Systems Ø Standard work planning tools (i. e. THA, Atlis, TOSP, AHA, etc. ) shall be written to ensure personnel and equipment safety. These documents shall describe any required system configuration and preparation prior to and following the work as well as the repair/alteration procedure itself (if required). Ø If the system fluid is flammable, Category M, or considered hazardous by the ES&H Manual, then the system must be purged by an inert fluid prior to any repair or alteration of any pressure retaining components. 64

Part 5: Repair and Alteration 5 Design Calculations Ø DA determines nature and extent of calculations required. Tech Review required where design meets ASME or NBIC; Peer Review required otherwise Ø Calculations are required for all repairs and alterations involving welding or brazing Ø Where piping or Excluded Vessels are affected, calculations showing that the repair meets or exceeds the original design requirements are required Ø Calculations for alterations and tie-ins shall be the same as those for new construction 65

Part 5: Repair and Alteration 6 Repairs and Alterations Requiring Welding, Brazing or Hot Work Ø Where welding or brazing is required, additional requirements are in Welding and Brazing supplement Ø If the system fluid is flammable, considered hazardous or Cat M, the system shall be purged with an inert fluid and the purged condition verified prior to performance of hot work (Exclusions for “Hot Tapping”) 66

Part 5: Repair and Alteration 7 Examinations and Testing Ø Welding and brazing shall meet the examination requirements of the applicable code Ø DA ensures one or more of the following are performed: Hydrostatic Pressure Test per B 31, PCC-2 or NBIC Part 3 Pneumatic Pressure Test per B 31, PCC-2 or NBIC Part 3 (PVC, CPVC, PVDF, etc. shall not be pneumatically tested) Initial Service Leak Test if fluid service is Cat. D or Normal, not flammable, toxic or harmful; exclusive use is prohibited unless allowed by original code of construction Sensitive Vacuum Leak Test, exclusive use is prohibited if design pressure is greater than 15 psi Nondestructive Examination per BPVC Section V, exclusive use of VT is prohibited if greater then NPS 5 Ø Cat. M Fluid Systems and High Pressure Piping must meet requirements in the most recent edition of B 31. 3 67

Part 5: Repair and Alteration 8 Inspections Repairs and alterations requiring welding or brazing shall meet the requirements defined in the Welding and Brazing Supplement 68

Part 5: Repair and Alteration 9 Documentation for repair or alteration shall be filed in the ORIGINAL PRESSURE SYSTEM FOLDER! Pressure System ID numbers and new folders are for discreet systems, not repairs or alterations of existing ones! 69

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 70

Part 6: Pressure and Leak Testing Ø ASME and NBIC require pressure/leak testing for new construction, alterations and repairs Ø All personnel directly involved in the testing shall be qualified Ø Test witnessed by inspector unless waived by DA, System Owner and inspector Ø DA or pressure test engineer must determine stored energy of system Ø 3 types of tests: hydrostatic, pneumatic or hydropneumatic 71

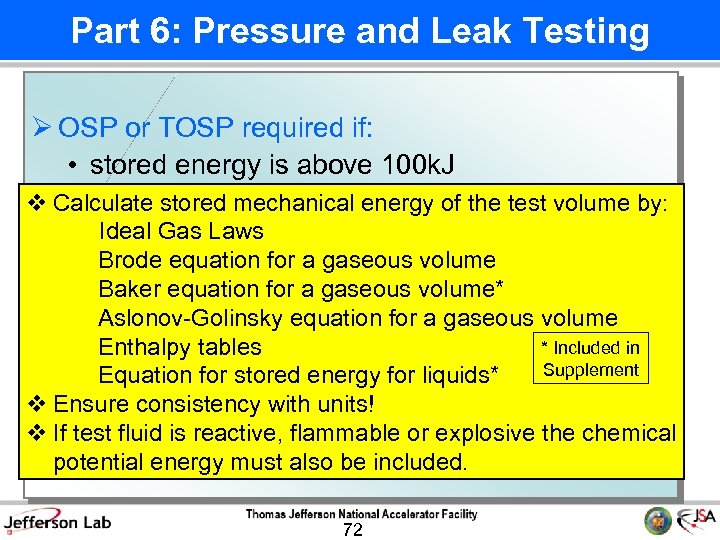

Part 6: Pressure and Leak Testing Ø OSP or TOSP required if: • stored energy is above 100 k. J v Calculate stored mechanical energy of the testor • exposure to Cat. M fluid and system volume by: Ideal Gas Laws component has not been fully cleaned and Brode equation for a gaseous volume released Baker equation inert • test fluid is notfor a gaseous volume* Aslonov-Golinsky equation for a gaseous volume • test fluid tables at > 250 psi * Included in Enthalpy is air Supplement • test mustfor stored energy on liquids* Equation be performed for a radioactively v Ensure consistency system contaminated with units! v If test fluid is reactive, flammable or explosive the chemical potential energy must also be included. 72

Part 6: Pressure and Leak Testing Ø OSP or TOSP must include: • • • Roles and responsibilities Rational for selection of test type Stored energy of test Qualification of personnel Protection for personnel performing test; personnel near or potentially exposed; and equipment Test rig or pressure manifold Schematic of test set-up ODH hazards Detailed procedure for performing test Inspection requirements before, during and after test Recovery procedure if applicable 73

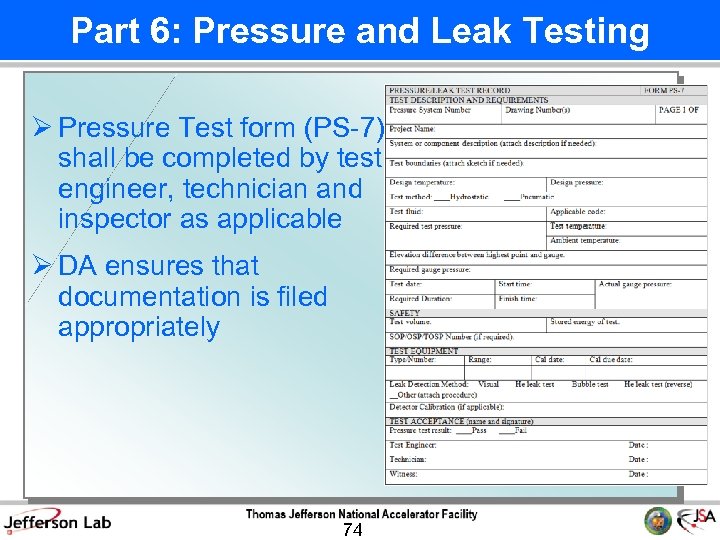

Part 6: Pressure and Leak Testing Ø Pressure Test form (PS-7) shall be completed by test engineer, technician and inspector as applicable Ø DA ensures that documentation is filed appropriately 74

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 75 4 Categories of Vacuum Systems based on risk

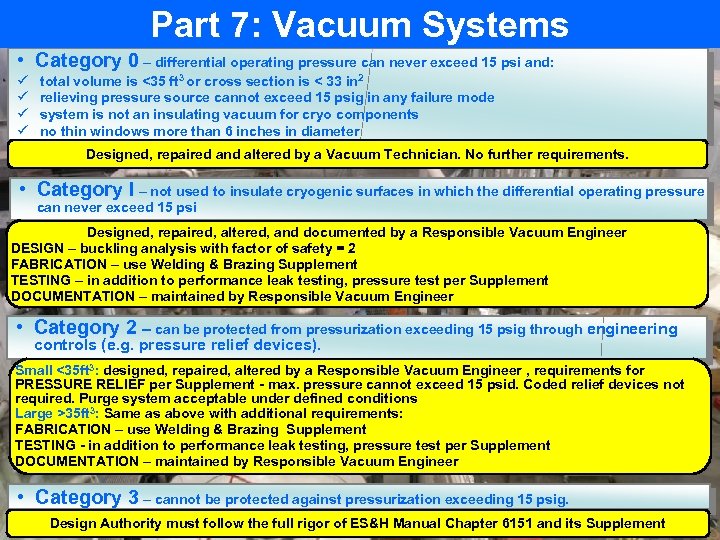

Part 7: Vacuum Systems • Category 0 – differential operating pressure can never exceed 15 psi and: ü ü total volume is <35 ft 3 or cross section is < 33 in 2 relieving pressure source cannot exceed 15 psig in any failure mode system is not an insulating vacuum for cryo components no thin windows more than 6 inches in diameter Designed, repaired and altered by a Vacuum Technician. No further requirements. • Category I – not used to insulate cryogenic surfaces in which the differential operating pressure can never exceed 15 psi Designed, repaired, altered, and documented by a Responsible Vacuum Engineer DESIGN – buckling analysis with factor of safety = 2 FABRICATION – use Welding & Brazing Supplement TESTING – in addition to performance leak testing, pressure test per Supplement DOCUMENTATION – maintained by Responsible Vacuum Engineer • Category 2 – can be protected from pressurization exceeding 15 psig through engineering controls (e. g. pressure relief devices). Small <35 ft 3: designed, repaired, altered by a Responsible Vacuum Engineer , requirements for PRESSURE RELIEF per Supplement - max. pressure cannot exceed 15 psid. Coded relief devices not required. Purge system acceptable under defined conditions Large >35 ft 3: Same as above with additional requirements: FABRICATION – use Welding & Brazing Supplement TESTING - in addition to performance leak testing, pressure test per Supplement DOCUMENTATION – maintained by Responsible Vacuum Engineer • Category 3 – cannot be protected against pressurization exceeding 15 psig. Design Authority must follow the full rigor of ES&H Manual Chapter 6151 and its Supplement 76

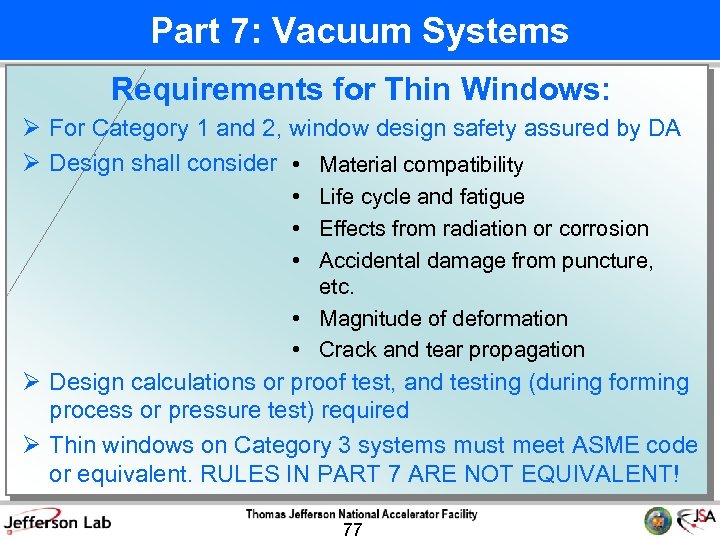

Part 7: Vacuum Systems Requirements for Thin Windows: Ø For Category 1 and 2, window design safety assured by DA Ø Design shall consider • Material compatibility • Life cycle and fatigue • Effects from radiation or corrosion • Accidental damage from puncture, etc. • Magnitude of deformation • Crack and tear propagation Ø Design calculations or proof test, and testing (during forming process or pressure test) required Ø Thin windows on Category 3 systems must meet ASME code or equivalent. RULES IN PART 7 ARE NOT EQUIVALENT! 77

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 78

Part 8: Operation and Maintenance Operation Ø System Owner is responsible for safe operation Ø DA must identify operating requirements on Form PS-9 for new or in-process systems 79

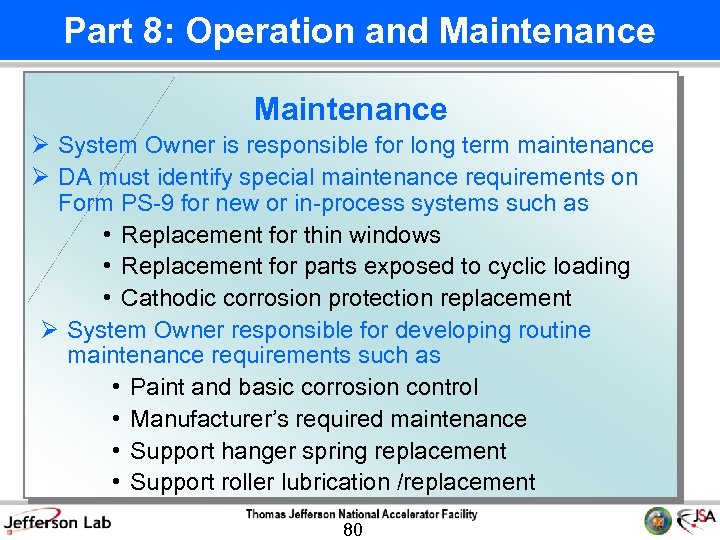

Part 8: Operation and Maintenance Ø System Owner is responsible for long term maintenance Ø DA must identify special maintenance requirements on Form PS-9 for new or in-process systems such as • Replacement for thin windows • Replacement for parts exposed to cyclic loading • Cathodic corrosion protection replacement Ø System Owner responsible for developing routine maintenance requirements such as • Paint and basic corrosion control • Manufacturer’s required maintenance • Support hanger spring replacement • Support roller lubrication /replacement 80

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 81

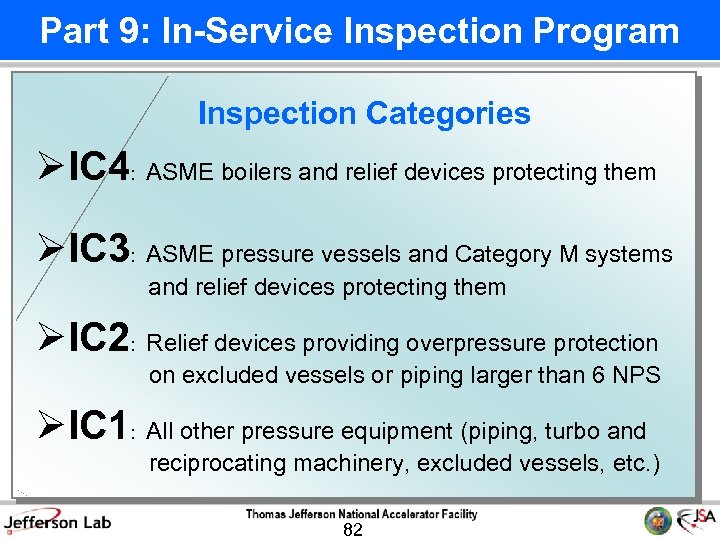

Part 9: In-Service Inspection Program Inspection Categories ØIC 4: ASME boilers and relief devices protecting them ØIC 3: ASME pressure vessels and Category M systems and relief devices protecting them ØIC 2: Relief devices providing overpressure protection on excluded vessels or piping larger than 6 NPS ØIC 1: All other pressure equipment (piping, turbo and reciprocating machinery, excluded vessels, etc. ) 82

Part 9: In-Service Inspection Program Inspection Type The inspector shall perform a visual inspection of vessels, piping, and ancillary equipment. The inspector shall use sound engineering principles to determine if further inspection and examination techniques are required. 83

Part 9: In-Service Inspection Program Inspection and Testing Intervals DA shall determine the required inspection interval by considering the following: • • • Fatigue, vibration, and pressure pulsing System fluid Component materials Environment in which the component is installed The potential for rust, scale, or build-up Other relevant factors determined by the System Owner/user or DA 84

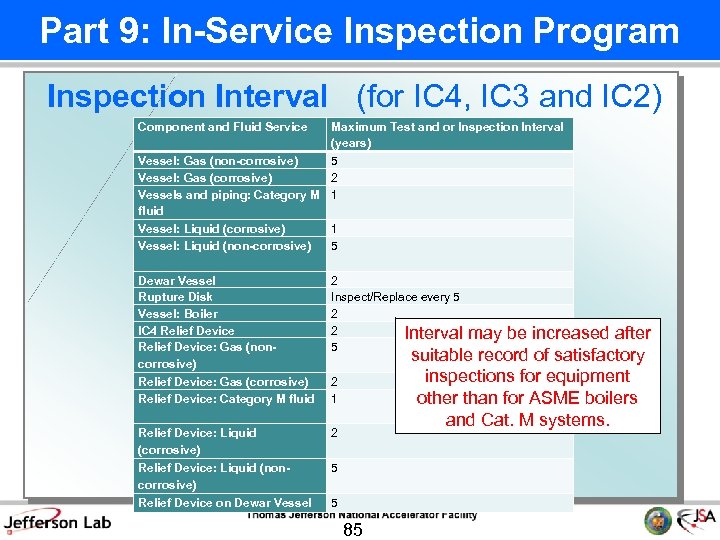

Part 9: In-Service Inspection Program Inspection Interval (for IC 4, IC 3 and IC 2) Component and Fluid Service Maximum Test and or Inspection Interval (years) Vessel: Gas (non-corrosive) 5 Vessel: Gas (corrosive) 2 Vessels and piping: Category M 1 fluid Vessel: Liquid (corrosive) Vessel: Liquid (non-corrosive) 1 5 Dewar Vessel Rupture Disk Vessel: Boiler IC 4 Relief Device: Gas (noncorrosive) 2 Inspect/Replace every 5 2 2 Interval 5 Relief Device: Gas (corrosive) Relief Device: Category M fluid 2 1 Relief Device: Liquid (corrosive) 2 Relief Device: Liquid (noncorrosive) 5 Relief Device on Dewar Vessel 5 may be increased after suitable record of satisfactory inspections for equipment other than for ASME boilers and Cat. M systems. 85

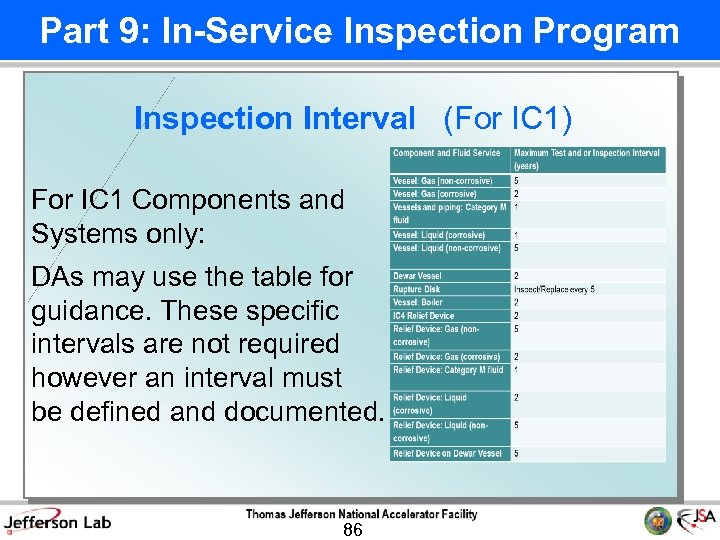

Part 9: In-Service Inspection Program Inspection Interval (For IC 1) For IC 1 Components and Systems only: DAs may use the table for guidance. These specific intervals are not required however an interval must be defined and documented. 86

Part 9: In-Service Inspection Program Full performance of the In-Service Inspection Program will be phased in over the next year or so. Facilities will continue their Boiler and Vessel Inspection Program. DAs must identify the In-Service Ron Bartek x 7671 Inspection requirements for all in-process and new systems through Form PS-9. 87

New Pressure & Vacuum Systems Safety Supplement Table of Contents Part 1 General Program Information Part 2 Pressure System Construction Part 3 Equivalent Measures Part 4 Overpressure Protection Part 5 Repair and Alteration Part 6 Pressure and Leak Testing Part 7 Vacuum Systems Part 8 Operation and Maintenance Part 9 In-service Inspection Program Part 10 Mandatory Forms 88

Part 10: Mandatory Forms: PS-1 PS-2 PS-3 PS-4 PS-5 PS-6 PS-7 PS-8 PS-9 PS-10 PS-11 PS-12 Project Cover Sheet Overpressure Protection by Design Technical/Peer Review Vessel Registration Relief Device Registration Final Mechanical Examination Pressure/Leak Test Record Final Walkthrough Pressure System Turnover Pressure Equipment ISI ASME Vessel/Relief Device ISI 89

Course Overview Why Are We Here? JLab and other DOE Lab Performance 10 CFR 851 Requirements Hazard Avoidance Techniques Revised ES&H Manual Chapter 6151 Overview / Major differences The New Pressure and Vacuum Systems Safety Supplement Overview / Major differences Revised Welding and Brazing Program Supplement Overview / Major differences Future Plans 90

Revised Welding and Brazing Program Supplement ES&H Manual Chapter 6122 defines Ch. 6122 covers safety of hot work safety requirements performing the weld Welding & Brazing Supplement The WBS covers the provides the quality requirements for quality of the weld itself welding and brazing operations including design, examination and inspection Supplement Covers: design and classification of joints; qualifications of procedures, welders, examiners and inspectors; material control; documentation 91

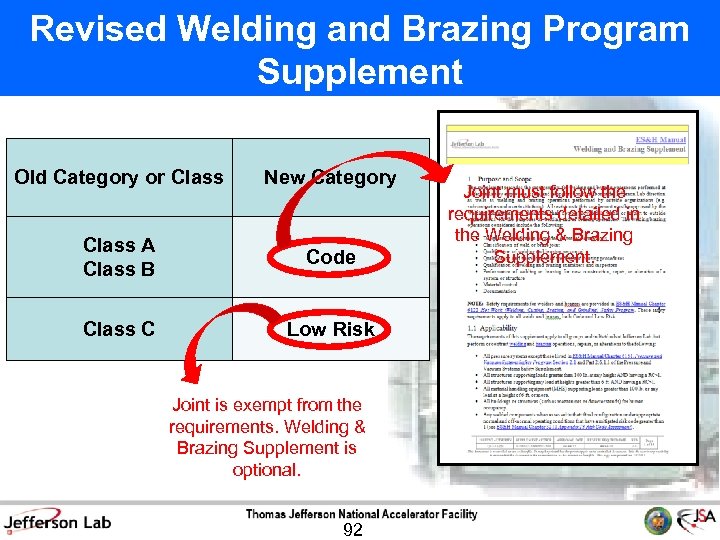

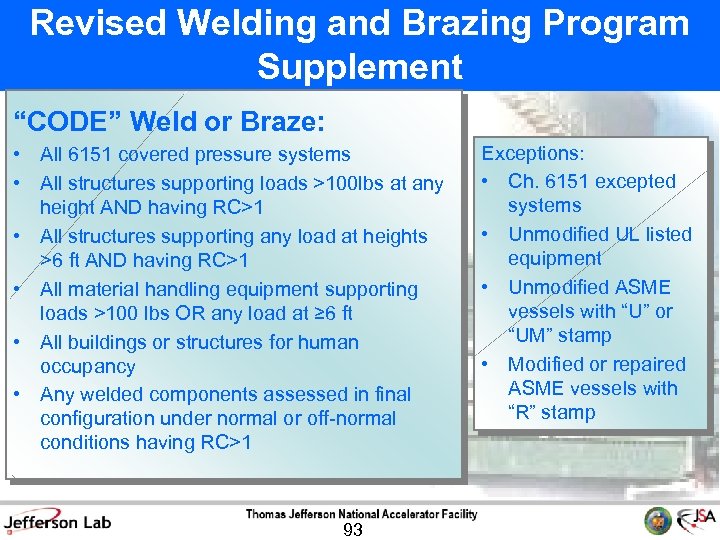

Revised Welding and Brazing Program Supplement Old Category or Class New Category Class A Class B Code Class C Low Risk Joint is exempt from the requirements. Welding & Brazing Supplement is optional. 92 Joint must follow the requirements detailed in the Welding & Brazing Supplement.

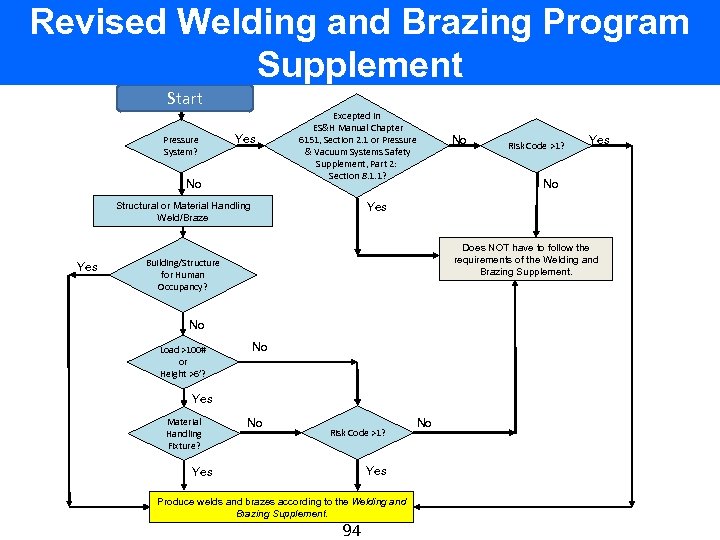

Revised Welding and Brazing Program Supplement “CODE” Weld or Braze: • All 6151 covered pressure systems • All structures supporting loads >100 lbs at any height AND having RC>1 • All structures supporting any load at heights >6 ft AND having RC>1 • All material handling equipment supporting loads >100 lbs OR any load at ≥ 6 ft • All buildings or structures for human occupancy • Any welded components assessed in final configuration under normal or off-normal conditions having RC>1 93 Exceptions: • Ch. 6151 excepted systems • Unmodified UL listed equipment • Unmodified ASME vessels with “U” or “UM” stamp • Modified or repaired ASME vessels with “R” stamp

Revised Welding and Brazing Program Supplement Start Pressure System? Yes No Excepted in ES&H Manual Chapter 6151, Section 2. 1 or Pressure & Vacuum Systems Safety Supplement, Part 2: Section 8. 1. 1? Structural or Material Handling Weld/Braze Yes No Does NOT have to follow the requirements of the Welding and Brazing Supplement. No No Yes Material Handling Fixture? Risk Code >1? Yes Building/Structure for Human Occupancy? Load >100# or Height >6’? No No Risk Code >1? Yes Produce welds and brazes according to the Welding and Brazing Supplement. 94 No

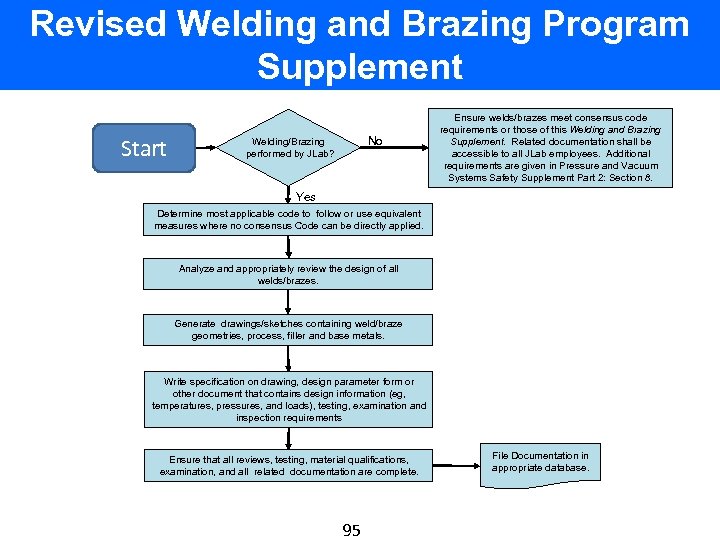

Revised Welding and Brazing Program Supplement Start No Welding/Brazing performed by JLab? Ensure welds/brazes meet consensus code requirements or those of this Welding and Brazing Supplement. Related documentation shall be accessible to all JLab employees. Additional requirements are given in Pressure and Vacuum Systems Safety Supplement Part 2: Section 8. Yes Determine most applicable code to follow or use equivalent measures where no consensus Code can be directly applied. Analyze and appropriately review the design of all welds/brazes. Generate drawings/sketches containing weld/braze geometries, process, filler and base metals. Write specification on drawing, design parameter form or other document that contains design information (eg, temperatures, pressures, and loads), testing, examination and inspection requirements Ensure that all reviews, testing, material qualifications, examination, and all related documentation are complete. 95 File Documentation in appropriate database.

Revised Welding and Brazing Program Supplement Key points to remember: Ø New classification for welds – Code and Low Risk Ø Welding Technical Committee is available as a resource Ø Inspection requirements are provided in WBS, involve the QA/CI Inspector Mike Martin Ext. 5515 Ed Daly Tim Whitlatch Steve Smith Kelly Dixon Mike Martin Dave Meekins Not pictured: Ron Bartek 96

Course Overview Why Are We Here? JLab and other DOE Lab Performance 10 CFR 851 Requirements Hazard Avoidance Techniques Revised ES&H Manual Chapter 6151 Overview / Major differences The New Pressure and Vacuum Systems Safety Supplement Overview / Major differences Revised Welding and Brazing Program Supplement Overview / Major differences Future Plans 97

Future Plans Create a database of Operating Pressure Systems Review existing Docushare database Interview associated DAs or System Owners Compile data and develop methods for real time updating 98

Future Plans Create a database of Operating Pressure Systems Review existing Docushare database Interview associated DAs or System Owners Compile data and develop methods for real time updating Incorporate AIMS Software Replace Docu. Share with tool that has intuitive UI that is easier to use Provide asset integrity management (AIMS) database Manage all inspection data 99

Future Plans Create a database of Operating Pressure Systems Review existing Docushare database Interview associated DAs or System Owners Compile data and develop methods for real time updating Incorporate AIMS Software Replace Docu. Share with tool that has intuitive UI that is easier to use Provide asset integrity management (AIMS) database Manage all inspection data ASME Training Specific to JLab Reinstate Sharing Lessons Learned Implement ISI Program Facilities and Ron Bartek will continue current program Projected 12 to 18 months until full implementation 100

What We Want You To Remember We’re Here to Help Pressure Systems Committee Will Oren (Chair), Ed Daly, Tim Whitlatch, Steve Smith, Kelly Dixon, Dave Meekins, George Perry (not pictured) Ron Bartek 101

6ca21113df145a4574dce3a30feba5c7.ppt