aa07253abc1a4cf90fefd6985521472a.ppt

- Количество слайдов: 27

S&R Best Practice Test Track: Generic Layout – Surface Details Mark Shkoukani VO -FAE Squeak & Rattle 8/26/2003 1 1

Background The test track is designed to provide the desired input energy (frequency range and amplitude) to excite specific squeak & rattle concerns (based on benchmarking Volvo, NA Plants, and DPG). Ø Ø Interior squeaks & rattles Body Creaks Chassis Clunk / pop / other noise Loose stock The surface lengths are optimized to allow sufficient time for the track to excite concerns and for the driver to recognize and locate the source. The S&R test track should be covered to eliminate effect of snow, rain, ice (provides a consistent environment) 2 2

Current Status The Best Practice S&R test track has been installed at the following plants (enclosure is not included) Ø OAP in July, 2001 (funded by facility/new launch f Ø KTP in July, 2001/May, 2002 (funded by PVT / 2002 FAE Quality Budget) Ø DTP in June, 2003 (funded by facility/new launch) Requested funding to implement the Best Practices S&R test track for the following plants (request was rejected): Ø LVL & KCAP-SUV (2002 & 2003 Quality Budget) Ø LVL (U 251 program) Ø Strategy to implement 2 plants per year (5 year migration plan) 3 3

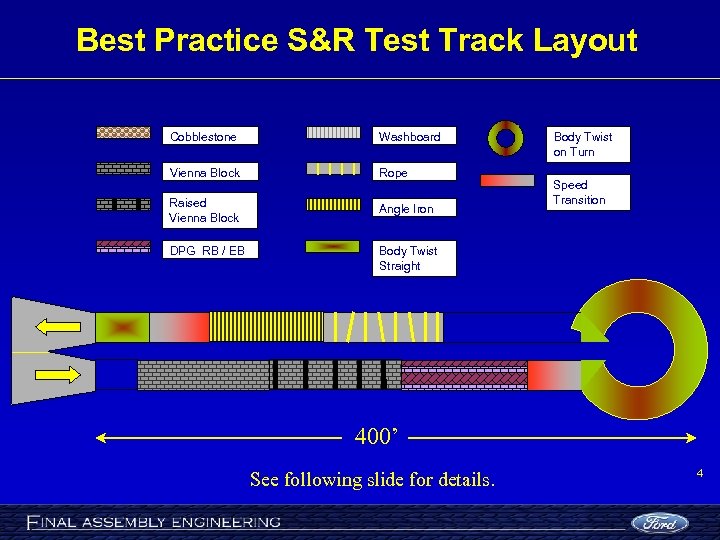

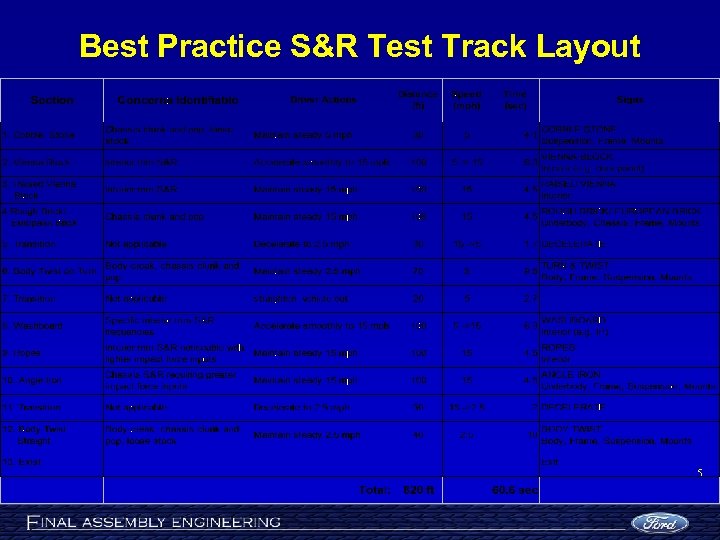

Best Practice S&R Test Track Layout Cobblestone Washboard Vienna Block Rope Raised Vienna Block Angle Iron DPG RB / EB Body Twist on Turn Body Twist Straight Speed Transition 400’ See following slide for details. 4 4

Best Practice S&R Test Track Layout 5 5

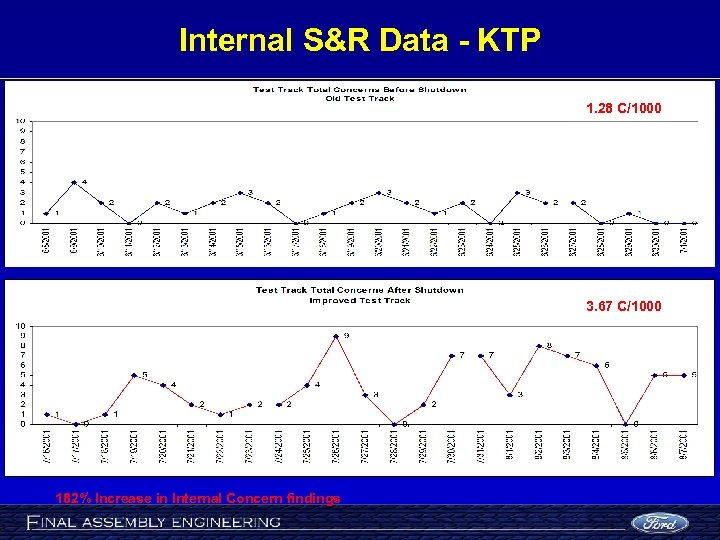

Internal S&R Data - KTP 1. 28 C/1000 3. 67 C/1000 6 182% Increase in Internal Concern findings 6

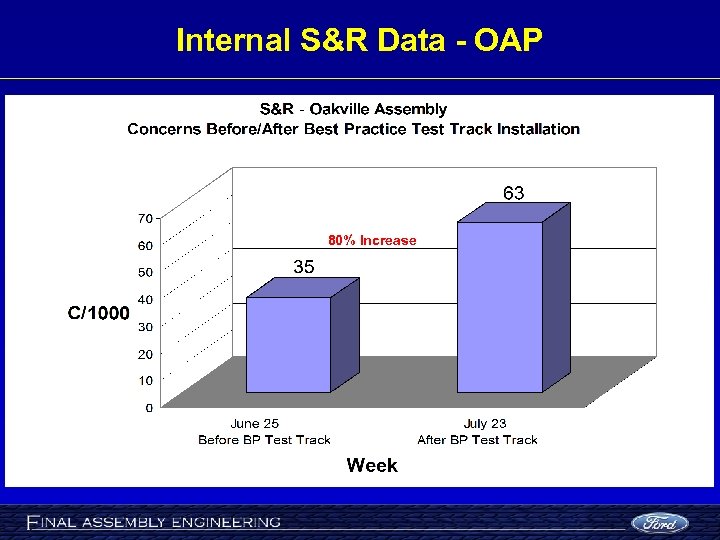

Internal S&R Data - OAP 80% Increase 7 7

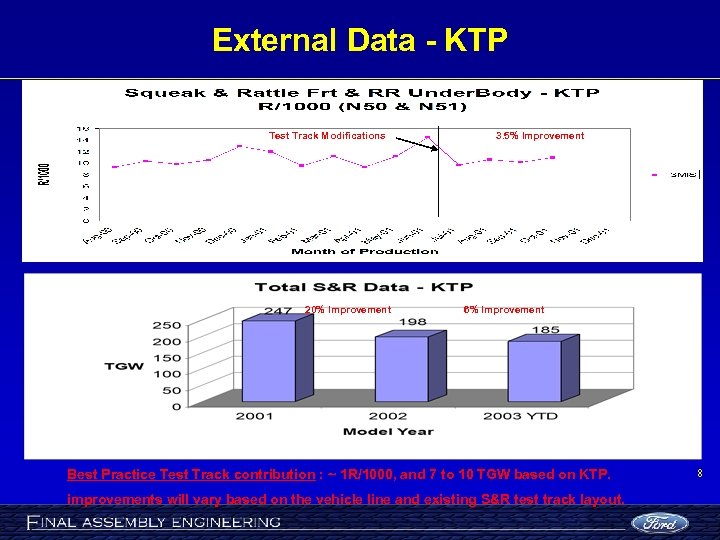

External Data - KTP Test Track Modifications 20% Improvement 3. 5% Improvement 6% Improvement Best Practice Test Track contribution : ~ 1 R/1000, and 7 to 10 TGW based on KTP. 8 improvements will vary based on the vehicle line and existing S&R test track layout. 8

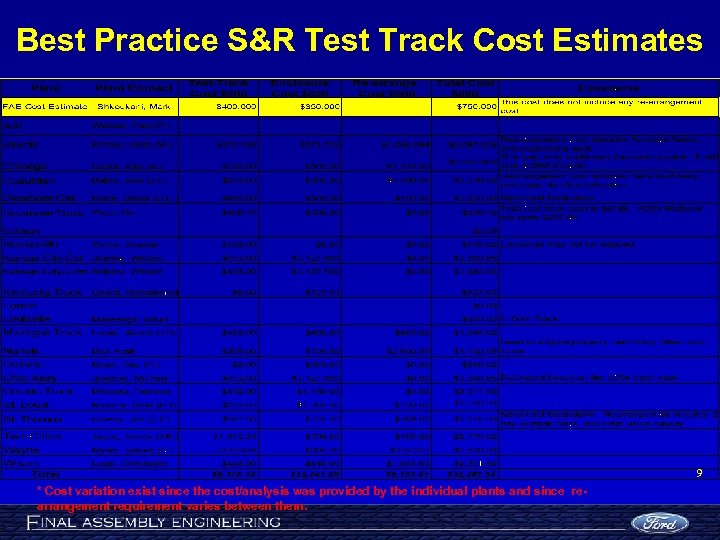

Best Practice S&R Test Track Cost Estimates 9 * Cost variation exist since the cost/analysis was provided by the individual plants and since rearrangement requirement varies between them. 9

Other steps to Improve S&R Process • S&R QOS • NOMAD (S&R objective measurement to validate product/process changes) • Formal training (includes a training video tape) • Provide a reflective sound walls • S&R test track minor Modifications and continuous coaching as required. • Speed signs / Visual Aids as required. 10 10

Appendix 11 11

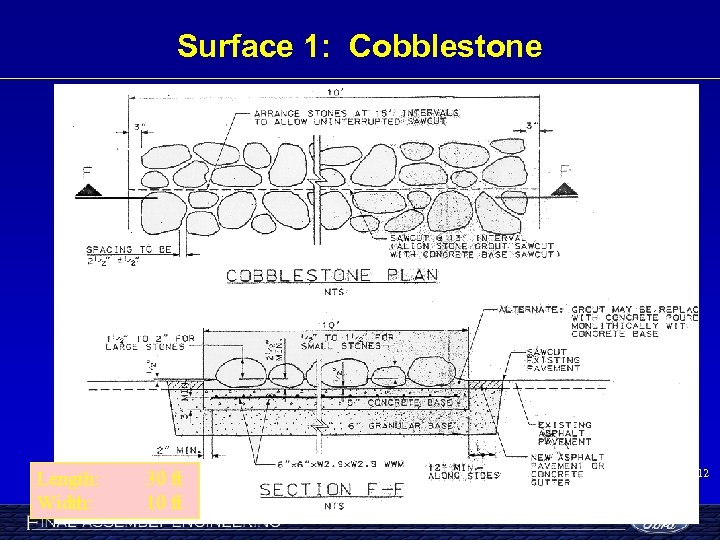

Surface 1: Cobblestone Length: 30 ft Width: 10 and Test Track Layoutft Operator Training 12 12

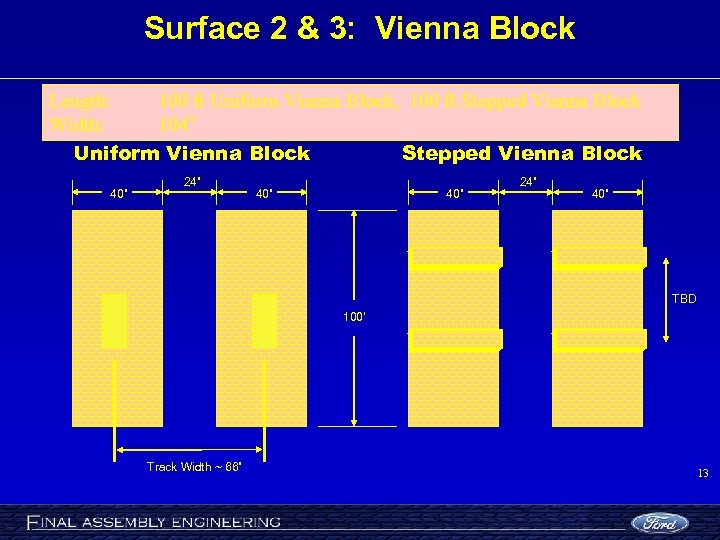

Surface 2 & 3: Vienna Block Length: 100 ft Uniform Vienna Block, 100 ft Stepped Vienna Block Width: 104” Uniform Vienna Block Stepped Vienna Block 40” 24” 40” TBD 100’ Track Width ~ 66” 13 13

Surface 2 & 3: Vienna Block Uniform Vienna Block Stepped Vienna Block (~1” Step in Height) 14 14

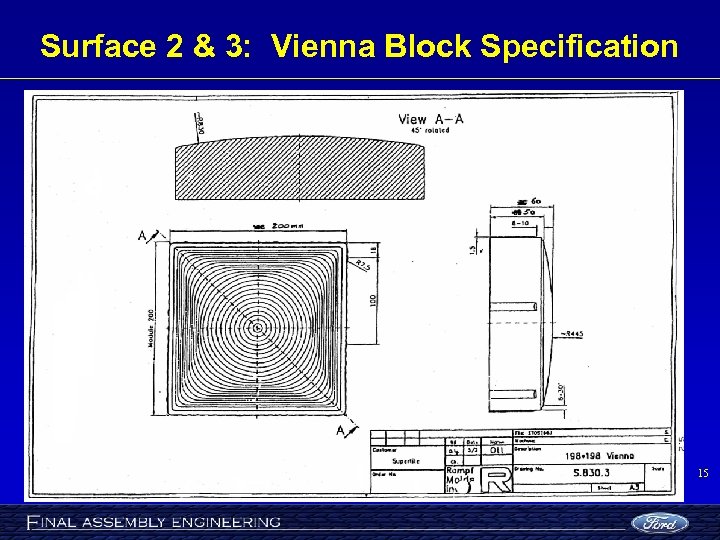

Surface 2 & 3: Vienna Block Specification 15 15

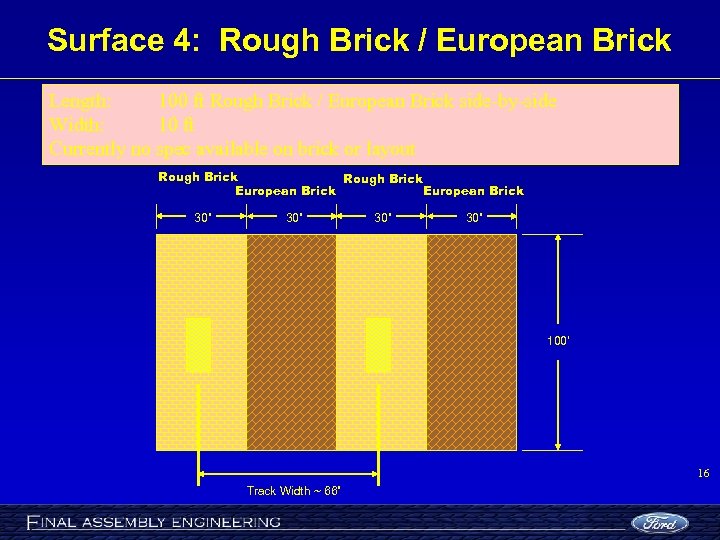

Surface 4: Rough Brick / European Brick Length: 100 ft Rough Brick / European Brick side-by-side Width: 10 ft Currently no spec available on brick or layout Rough Brick European Brick 30” 30” 100’ 16 Track Width ~ 66” 16

Surface 5: Transition Length: Width: 30 ft 10 ft Brushed concrete surface used to brake from 15 mph to 5 mph. 17 17

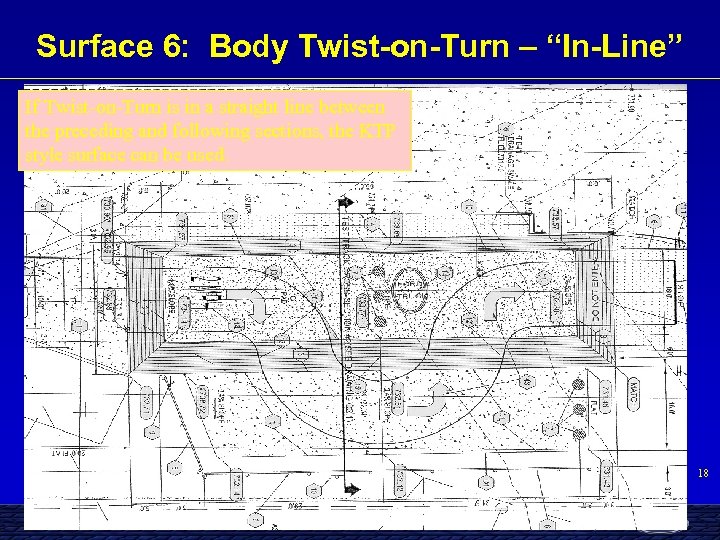

Surface 6: Body Twist-on-Turn – “In-Line” If Twist-on-Turn is in a straight line between the preceding and following sections, the KTP style surface can be used. 18 18

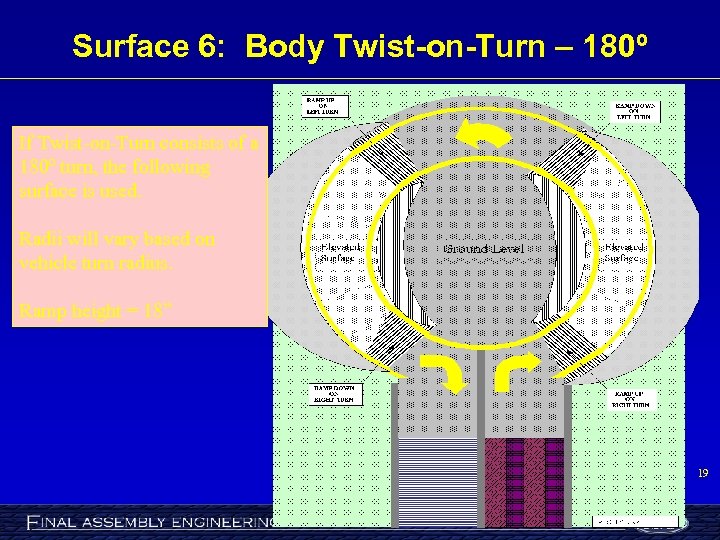

Surface 6: Body Twist-on-Turn – 180º If Twist-on-Turn consists of a 180º turn, the following surface is used. Radii will vary based on vehicle turn radius. Ramp height = 18” 19 19

Surface 7: Transition Length: Width: 20 ft 10 ft Brushed concrete section used to straighten the vehicle out from the turn. 20 20

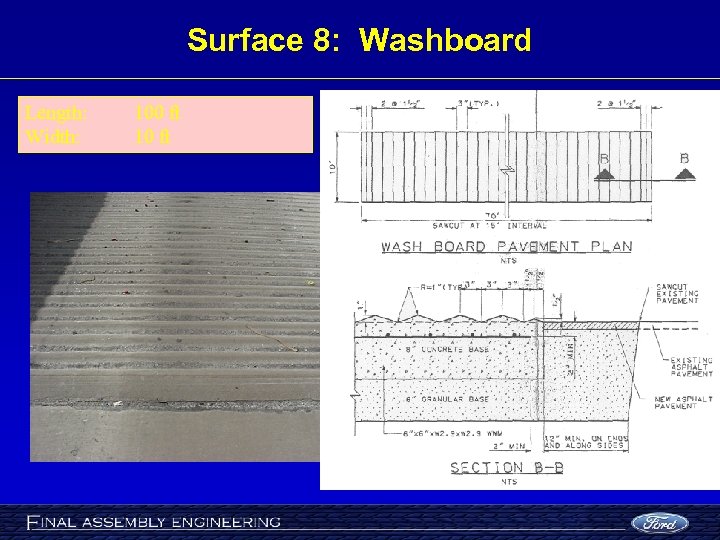

Surface 8: Washboard Length: Width: 100 ft 10 ft 21 21

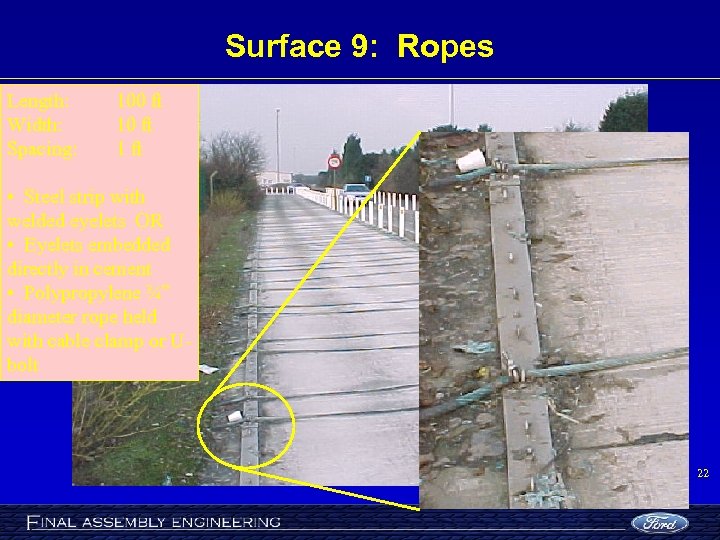

Surface 9: Ropes Length: Width: Spacing: 100 ft 1 ft • Steel strip with welded eyelets OR • Eyelets embedded directly in cement • Polypropylene ¾” diameter rope held with cable clamp or Ubolt 22 22

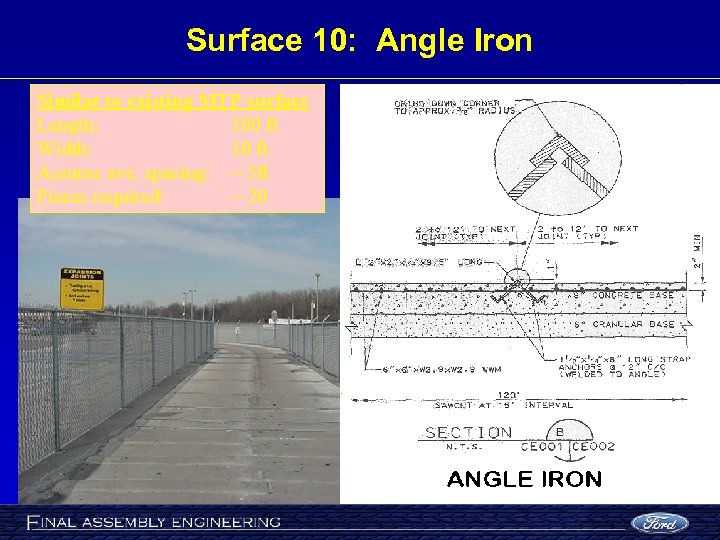

Surface 10: Angle Iron Similar to existing MTP surface Length: 100 ft Width: 10 ft Assume ave. spacing: ~ 5 ft Pieces required: ~ 20 23 23

Surface 11: Transition Length: Width: 30 ft 10 ft Brushed concrete surface used to brake from 15 mph to 2. 5 mph. 24 24

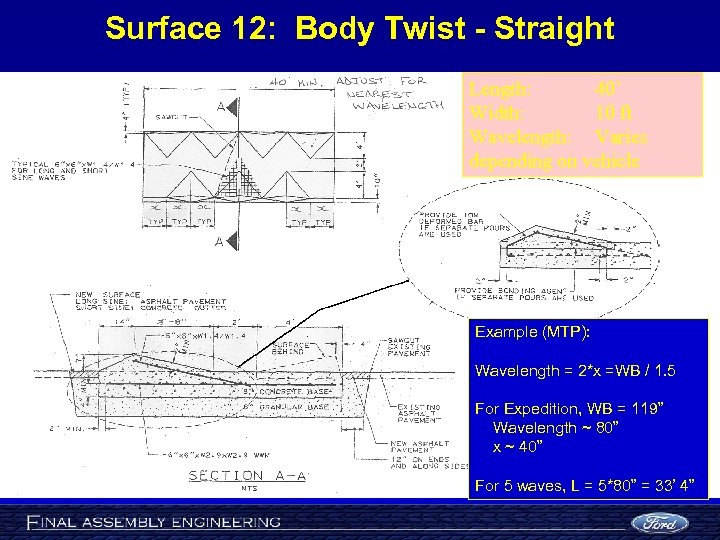

Surface 12: Body Twist - Straight Length: 40’ Width: 10 ft Wavelength: Varies depending on vehicle Example (MTP): Wavelength = 2*x =WB / 1. 5 For Expedition, WB = 119” Wavelength ~ 80” x ~ 40” For 5 waves, L = 5*80” = 33’ 4” 25 25

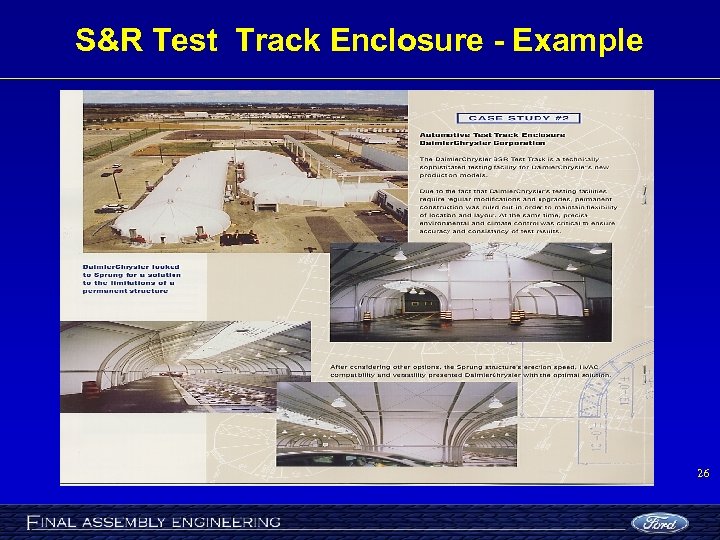

S&R Test Track Enclosure - Example 26 26

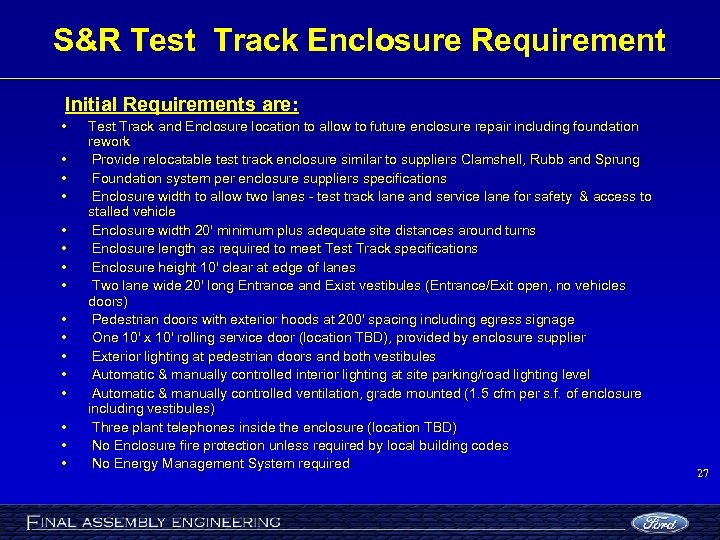

S&R Test Track Enclosure Requirement Initial Requirements are: • • • • Test Track and Enclosure location to allow to future enclosure repair including foundation rework Provide relocatable test track enclosure similar to suppliers Clamshell, Rubb and Sprung Foundation system per enclosure suppliers specifications Enclosure width to allow two lanes - test track lane and service lane for safety & access to stalled vehicle Enclosure width 20' minimum plus adequate site distances around turns Enclosure length as required to meet Test Track specifications Enclosure height 10' clear at edge of lanes Two lane wide 20' long Entrance and Exist vestibules (Entrance/Exit open, no vehicles doors) Pedestrian doors with exterior hoods at 200' spacing including egress signage One 10' x 10' rolling service door (location TBD), provided by enclosure supplier Exterior lighting at pedestrian doors and both vestibules Automatic & manually controlled interior lighting at site parking/road lighting level Automatic & manually controlled ventilation, grade mounted (1. 5 cfm per s. f. of enclosure including vestibules) Three plant telephones inside the enclosure (location TBD) No Enclosure fire protection unless required by local building codes No Energy Management System required 27 27

aa07253abc1a4cf90fefd6985521472a.ppt