6a4f6a59c37d0165fc6d1fa167e3dab8.ppt

- Количество слайдов: 64

Romax. Designer Single Product Model for Transmission Design & Analysis

Romax. Designer Single Product Model for Transmission Design & Analysis

About this Presentation n Aims of the presentation n Modelling the components: • shafts • bearings • gears n Assembling the gearbox n Defining the loads and powers n Running the analysis n Review of the results and further Romax. Designer capabilities Copyright © Romax Technology Limited 2000 - 2005

About this Presentation n Aims of the presentation n Modelling the components: • shafts • bearings • gears n Assembling the gearbox n Defining the loads and powers n Running the analysis n Review of the results and further Romax. Designer capabilities Copyright © Romax Technology Limited 2000 - 2005

Introduction Aims of this presentation are to show how: n To model an existing transmission in just one day n To analyze the model for shaft, bearing and gear performance and life n To use the analysis results to optimize an existing design Copyright © Romax Technology Limited 2000 - 2005

Introduction Aims of this presentation are to show how: n To model an existing transmission in just one day n To analyze the model for shaft, bearing and gear performance and life n To use the analysis results to optimize an existing design Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Key Stages for Creating a Romax. Designer Model n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Key Stages for Creating a Romax. Designer Model n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling stages: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling stages: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

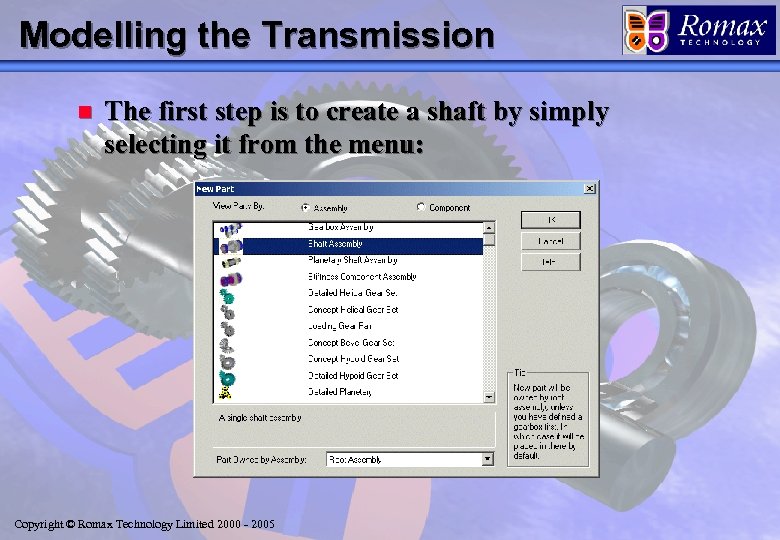

Modelling the Transmission n The first step is to create a shaft by simply selecting it from the menu: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n The first step is to create a shaft by simply selecting it from the menu: Copyright © Romax Technology Limited 2000 - 2005

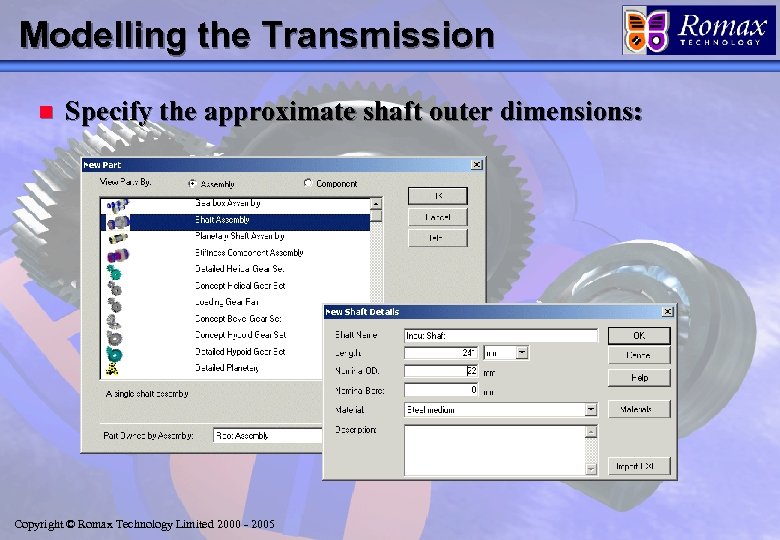

Modelling the Transmission n Specify the approximate shaft outer dimensions: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Specify the approximate shaft outer dimensions: Copyright © Romax Technology Limited 2000 - 2005

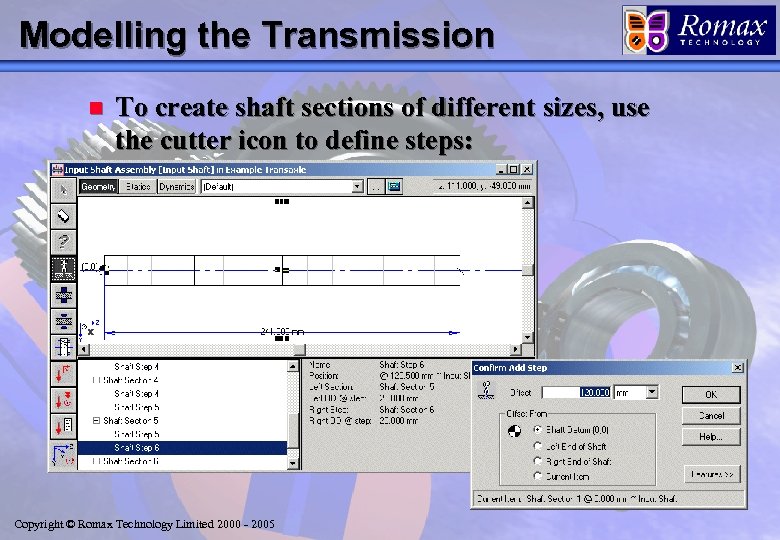

Modelling the Transmission n To create shaft sections of different sizes, use the cutter icon to define steps: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n To create shaft sections of different sizes, use the cutter icon to define steps: Copyright © Romax Technology Limited 2000 - 2005

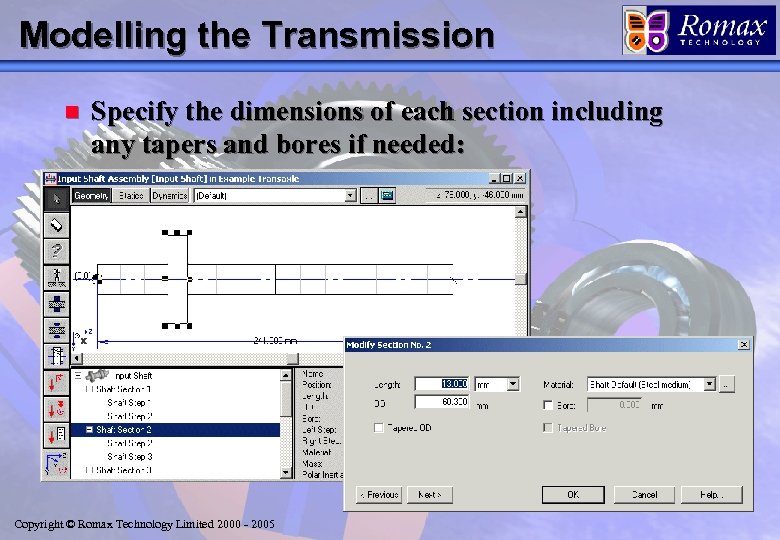

Modelling the Transmission n Specify the dimensions of each section including any tapers and bores if needed: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Specify the dimensions of each section including any tapers and bores if needed: Copyright © Romax Technology Limited 2000 - 2005

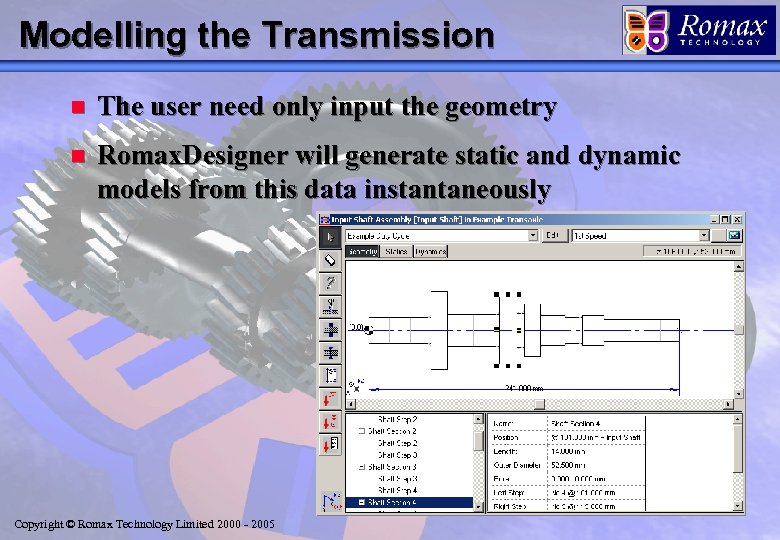

Modelling the Transmission n The user need only input the geometry n Romax. Designer will generate static and dynamic models from this data instantaneously Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n The user need only input the geometry n Romax. Designer will generate static and dynamic models from this data instantaneously Copyright © Romax Technology Limited 2000 - 2005

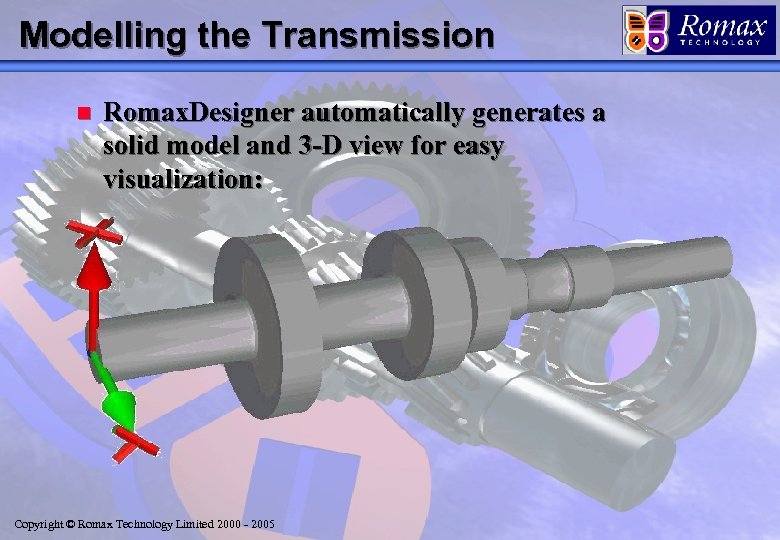

Modelling the Transmission n Romax. Designer automatically generates a solid model and 3 -D view for easy visualization: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Romax. Designer automatically generates a solid model and 3 -D view for easy visualization: Copyright © Romax Technology Limited 2000 - 2005

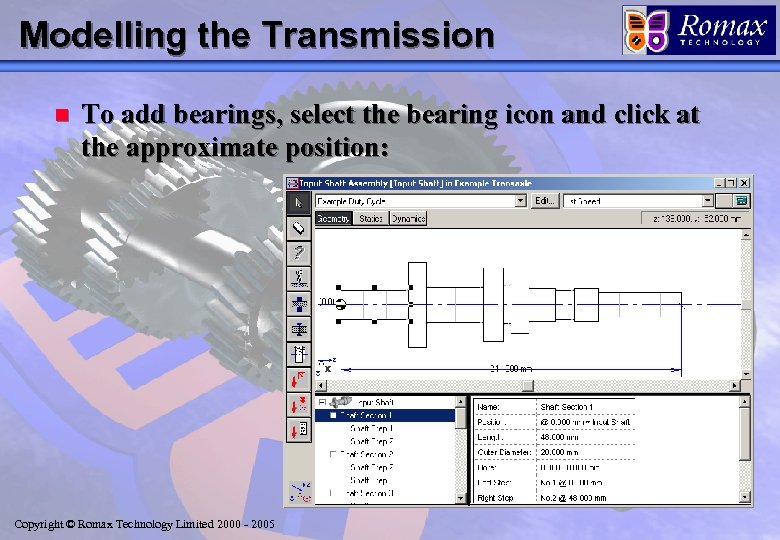

Modelling the Transmission n To add bearings, select the bearing icon and click at the approximate position: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n To add bearings, select the bearing icon and click at the approximate position: Copyright © Romax Technology Limited 2000 - 2005

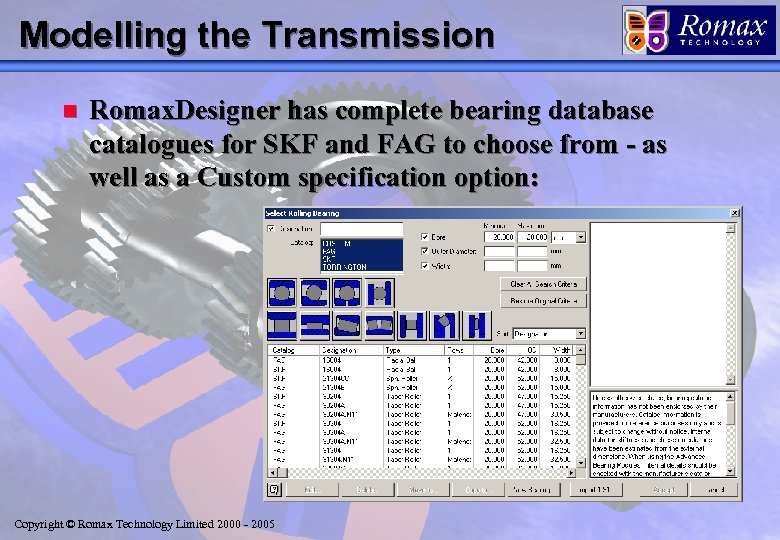

Modelling the Transmission n Romax. Designer has complete bearing database catalogues for SKF and FAG to choose from - as well as a Custom specification option: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Romax. Designer has complete bearing database catalogues for SKF and FAG to choose from - as well as a Custom specification option: Copyright © Romax Technology Limited 2000 - 2005

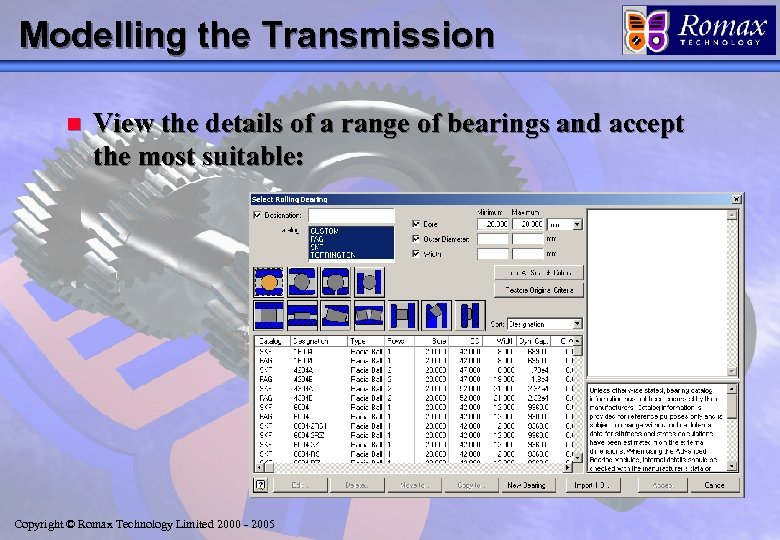

Modelling the Transmission n View the details of a range of bearings and accept the most suitable: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n View the details of a range of bearings and accept the most suitable: Copyright © Romax Technology Limited 2000 - 2005

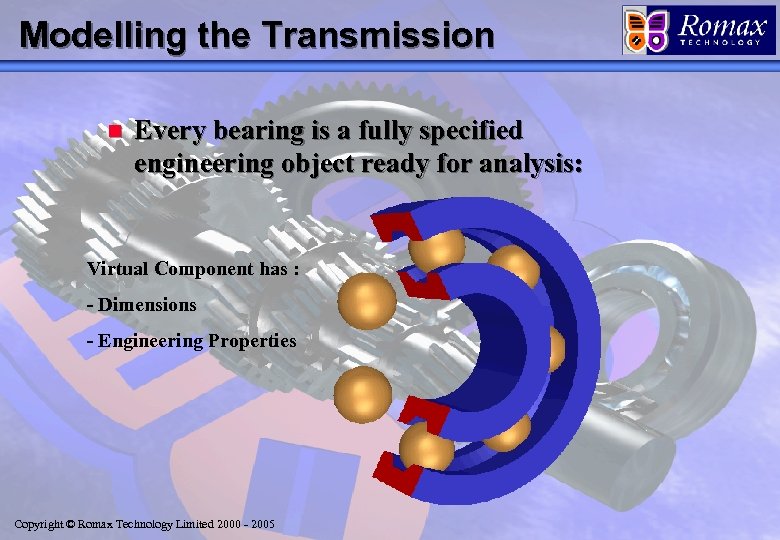

Modelling the Transmission n Every bearing is a fully specified engineering object ready for analysis: Virtual Component has : - Dimensions - Engineering Properties Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Every bearing is a fully specified engineering object ready for analysis: Virtual Component has : - Dimensions - Engineering Properties Copyright © Romax Technology Limited 2000 - 2005

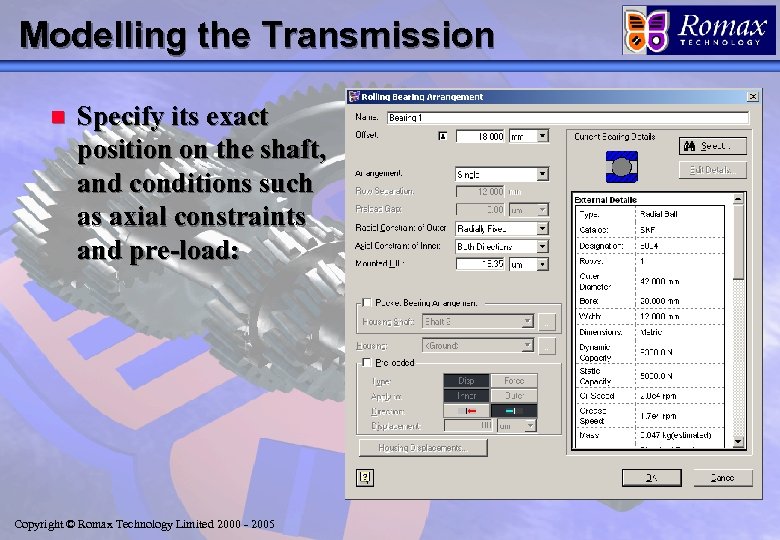

Modelling the Transmission n Specify its exact position on the shaft, and conditions such as axial constraints and pre-load: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Specify its exact position on the shaft, and conditions such as axial constraints and pre-load: Copyright © Romax Technology Limited 2000 - 2005

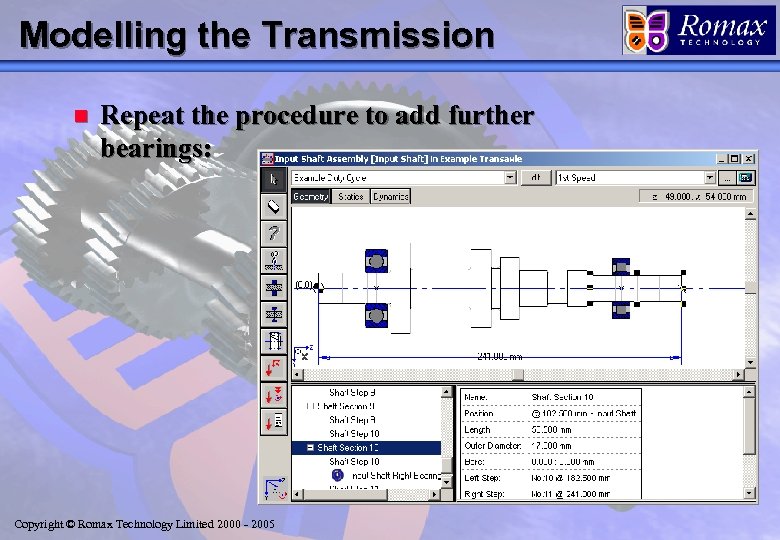

Modelling the Transmission n Repeat the procedure to add further bearings: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Repeat the procedure to add further bearings: Copyright © Romax Technology Limited 2000 - 2005

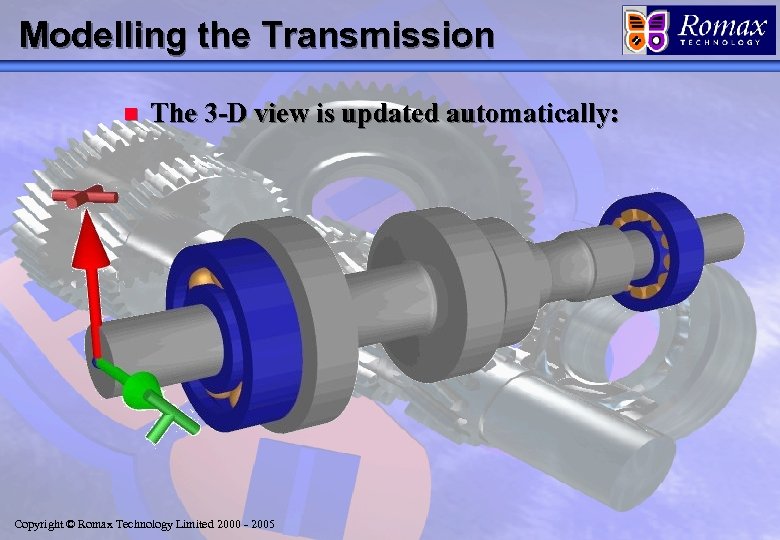

Modelling the Transmission n The 3 -D view is updated automatically: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n The 3 -D view is updated automatically: Copyright © Romax Technology Limited 2000 - 2005

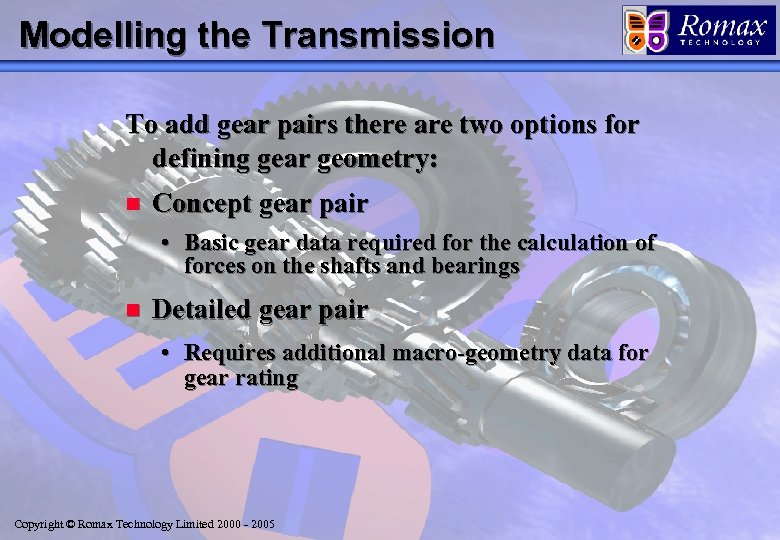

Modelling the Transmission To add gear pairs there are two options for defining gear geometry: n Concept gear pair • Basic gear data required for the calculation of forces on the shafts and bearings n Detailed gear pair • Requires additional macro-geometry data for gear rating Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission To add gear pairs there are two options for defining gear geometry: n Concept gear pair • Basic gear data required for the calculation of forces on the shafts and bearings n Detailed gear pair • Requires additional macro-geometry data for gear rating Copyright © Romax Technology Limited 2000 - 2005

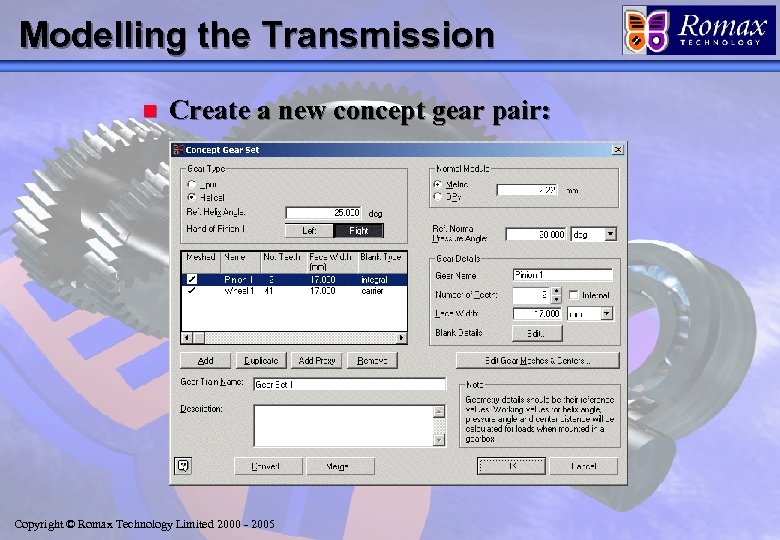

Modelling the Transmission n Create a new concept gear pair: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Create a new concept gear pair: Copyright © Romax Technology Limited 2000 - 2005

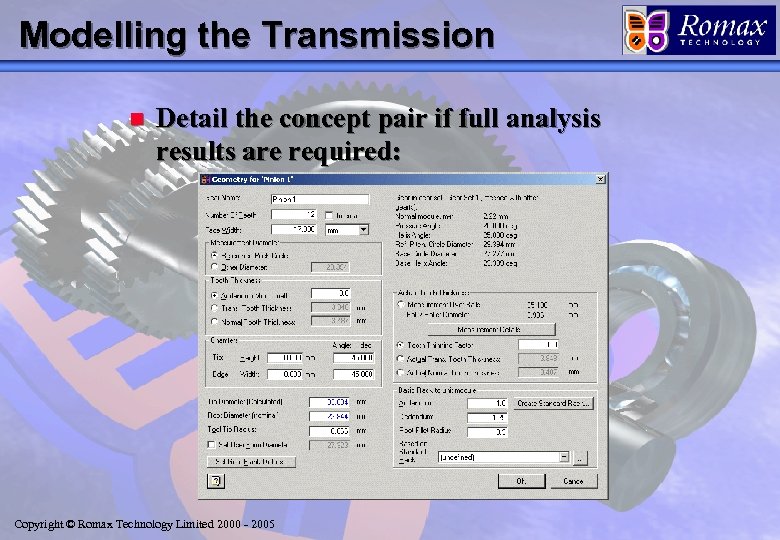

Modelling the Transmission n Detail the concept pair if full analysis results are required: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Detail the concept pair if full analysis results are required: Copyright © Romax Technology Limited 2000 - 2005

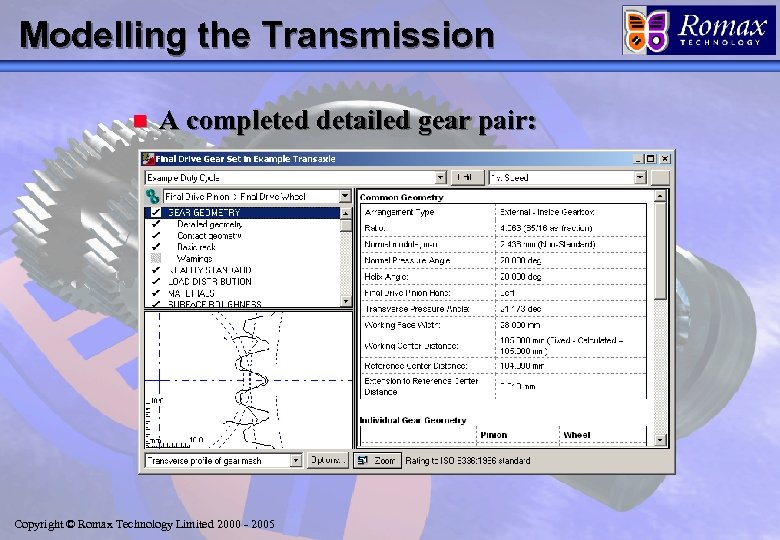

Modelling the Transmission n A completed detailed gear pair: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n A completed detailed gear pair: Copyright © Romax Technology Limited 2000 - 2005

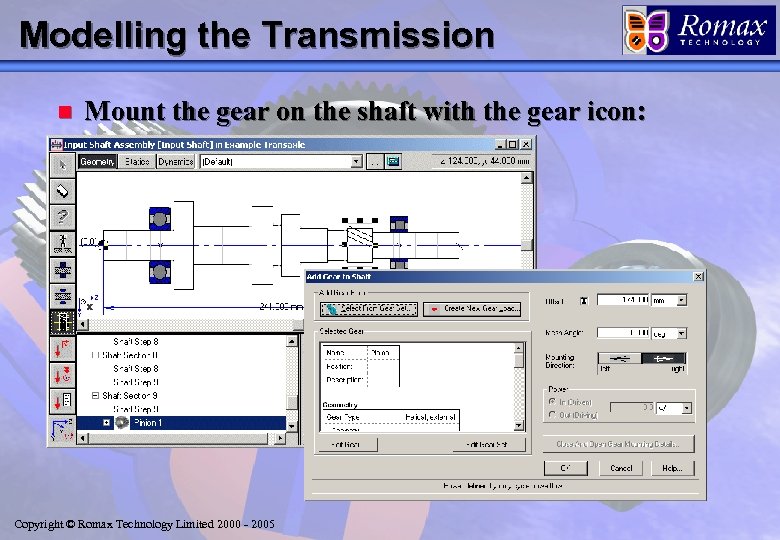

Modelling the Transmission n Mount the gear on the shaft with the gear icon: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Mount the gear on the shaft with the gear icon: Copyright © Romax Technology Limited 2000 - 2005

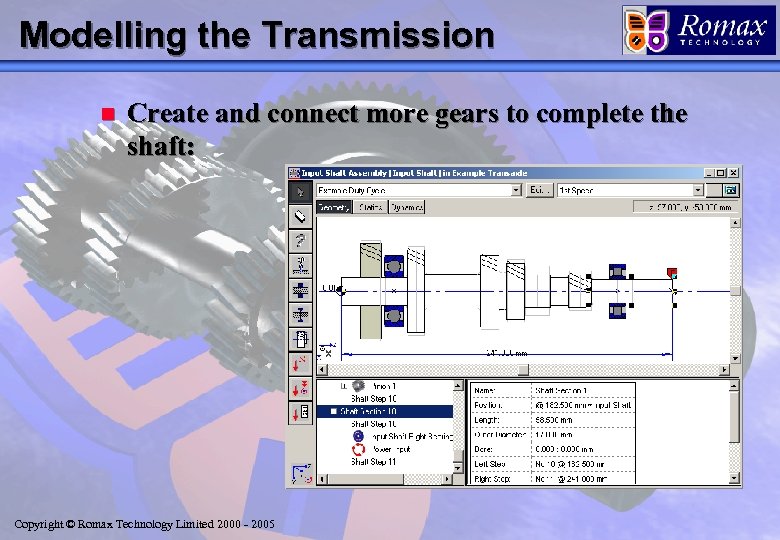

Modelling the Transmission n Create and connect more gears to complete the shaft: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Create and connect more gears to complete the shaft: Copyright © Romax Technology Limited 2000 - 2005

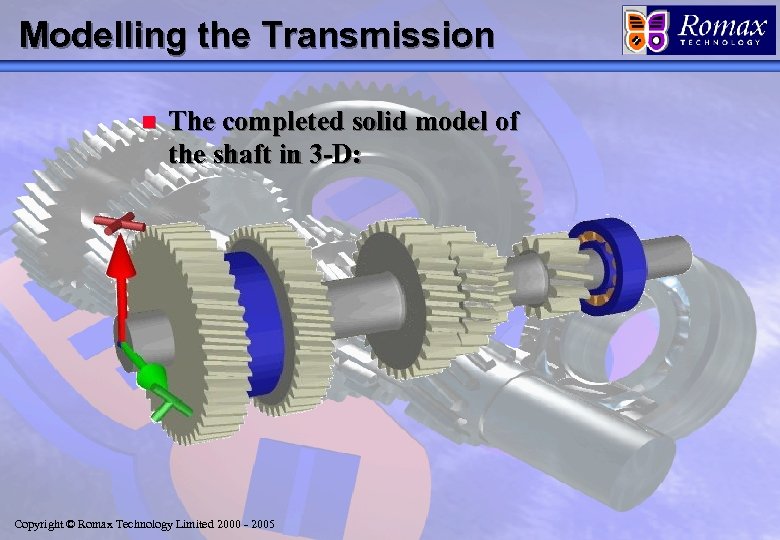

Modelling the Transmission n The completed solid model of the shaft in 3 -D: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n The completed solid model of the shaft in 3 -D: Copyright © Romax Technology Limited 2000 - 2005

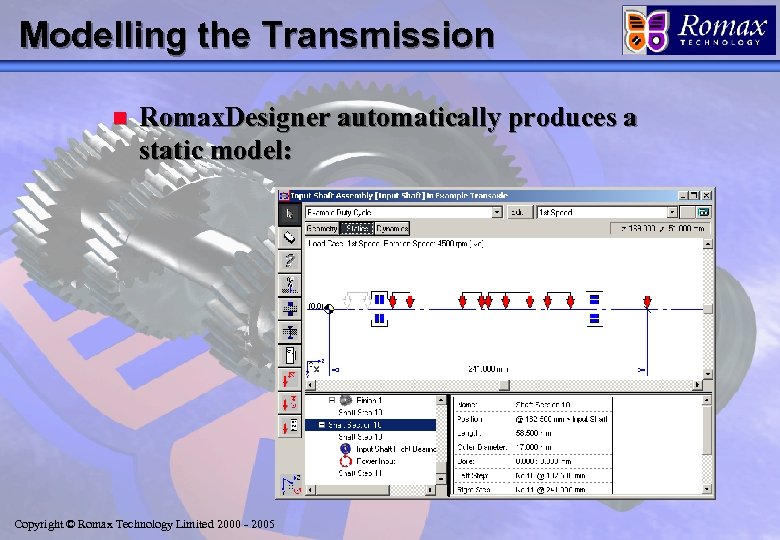

Modelling the Transmission n Romax. Designer automatically produces a static model: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Romax. Designer automatically produces a static model: Copyright © Romax Technology Limited 2000 - 2005

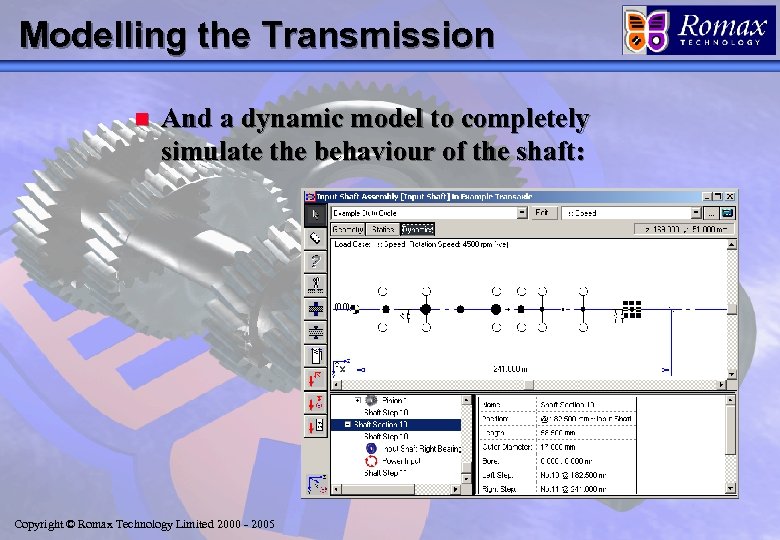

Modelling the Transmission n And a dynamic model to completely simulate the behaviour of the shaft: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n And a dynamic model to completely simulate the behaviour of the shaft: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

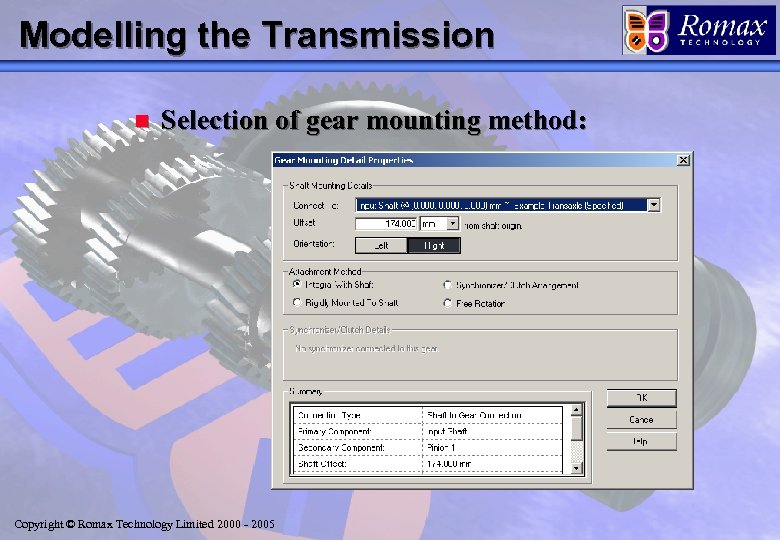

Modelling Overview Gear mounting definition There are four options for defining gear mounting in the model: n Integral with shaft • The gear is manufactured into the shaft n Rigidly mounted to shaft • The gear is permanently attached to the shaft n Synchronizer or clutch connection • The gear is free to rotate on the shaft unless the synchroniser/clutch is engaged n Free Rotation • The gear is free to rotate on the shaft Copyright © Romax Technology Limited 2000 - 2005

Modelling Overview Gear mounting definition There are four options for defining gear mounting in the model: n Integral with shaft • The gear is manufactured into the shaft n Rigidly mounted to shaft • The gear is permanently attached to the shaft n Synchronizer or clutch connection • The gear is free to rotate on the shaft unless the synchroniser/clutch is engaged n Free Rotation • The gear is free to rotate on the shaft Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Selection of gear mounting method: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Selection of gear mounting method: Copyright © Romax Technology Limited 2000 - 2005

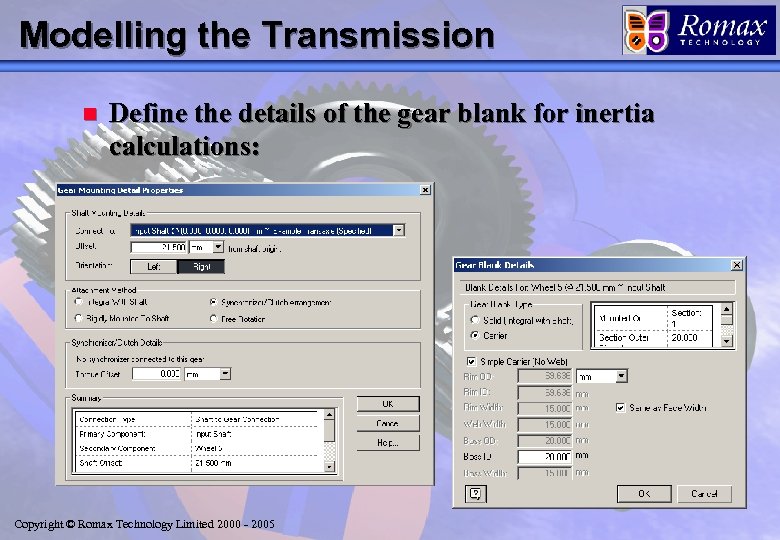

Modelling the Transmission n Define the details of the gear blank for inertia calculations: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Define the details of the gear blank for inertia calculations: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

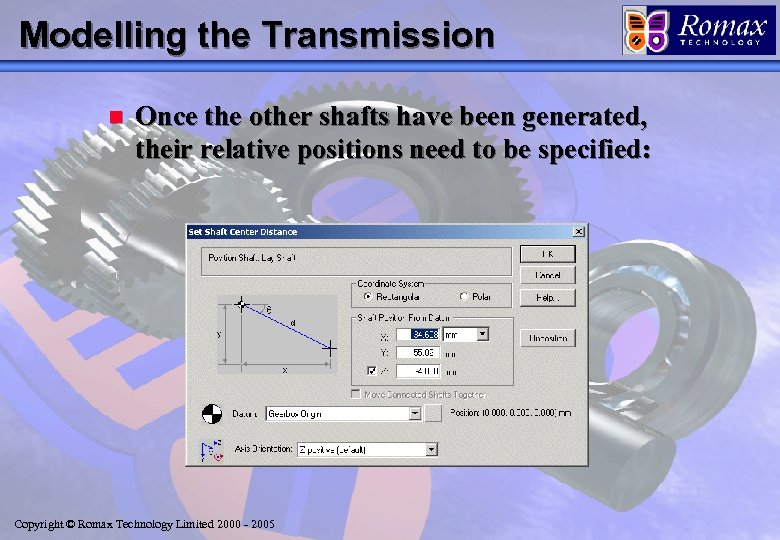

Modelling the Transmission n Once the other shafts have been generated, their relative positions need to be specified: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n Once the other shafts have been generated, their relative positions need to be specified: Copyright © Romax Technology Limited 2000 - 2005

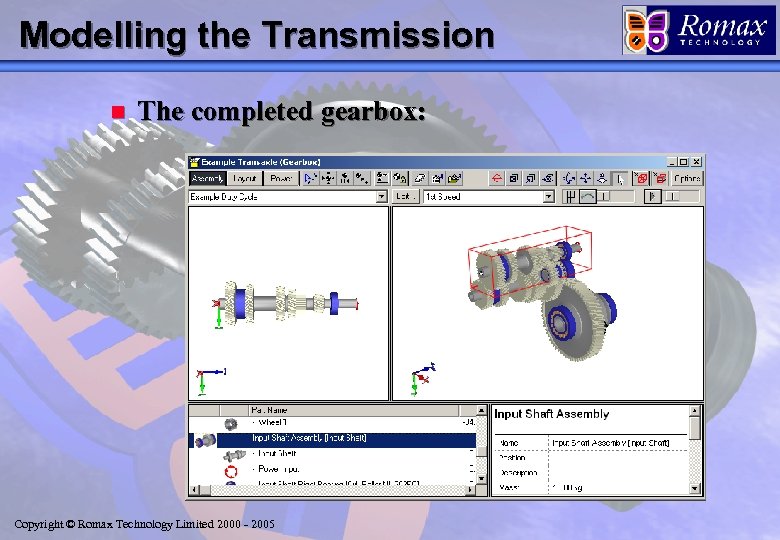

Modelling the Transmission n The completed gearbox: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n The completed gearbox: Copyright © Romax Technology Limited 2000 - 2005

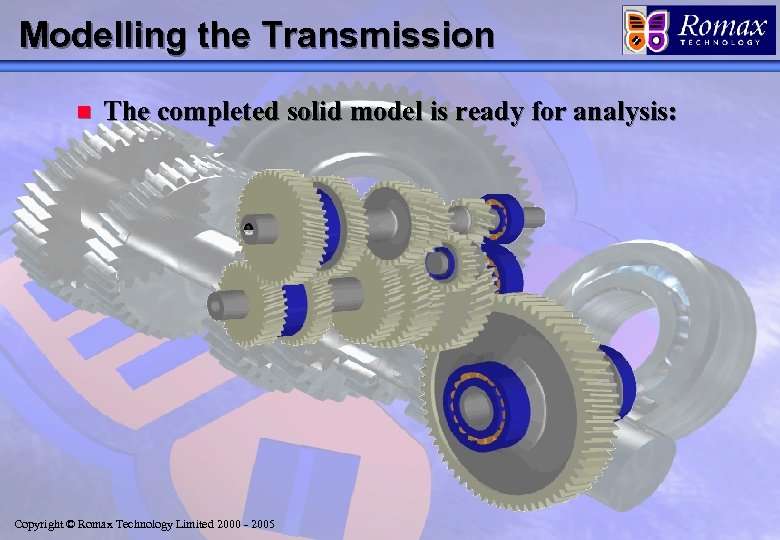

Modelling the Transmission n The completed solid model is ready for analysis: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission n The completed solid model is ready for analysis: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

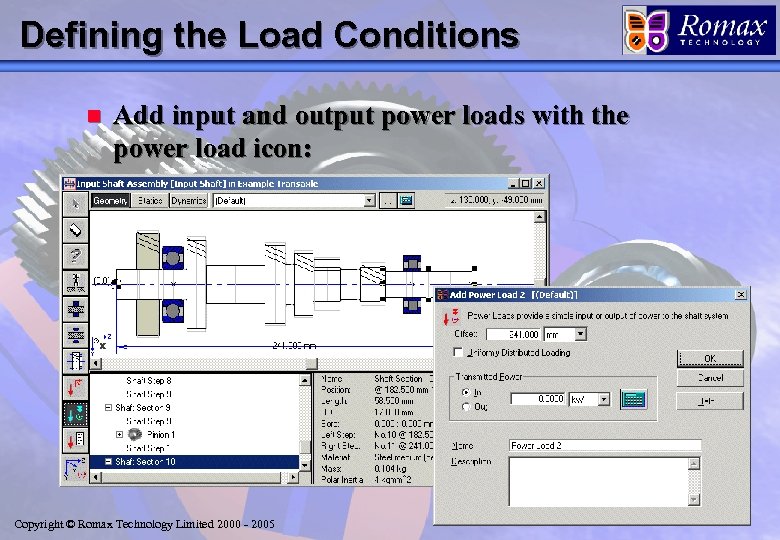

Defining the Load Conditions n Add input and output power loads with the power load icon: Copyright © Romax Technology Limited 2000 - 2005

Defining the Load Conditions n Add input and output power loads with the power load icon: Copyright © Romax Technology Limited 2000 - 2005

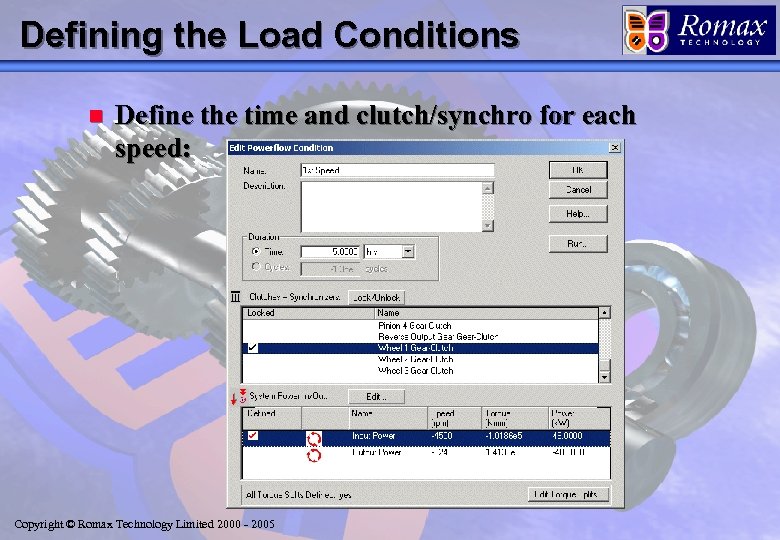

Defining the Load Conditions n Define the time and clutch/synchro for each speed: Copyright © Romax Technology Limited 2000 - 2005

Defining the Load Conditions n Define the time and clutch/synchro for each speed: Copyright © Romax Technology Limited 2000 - 2005

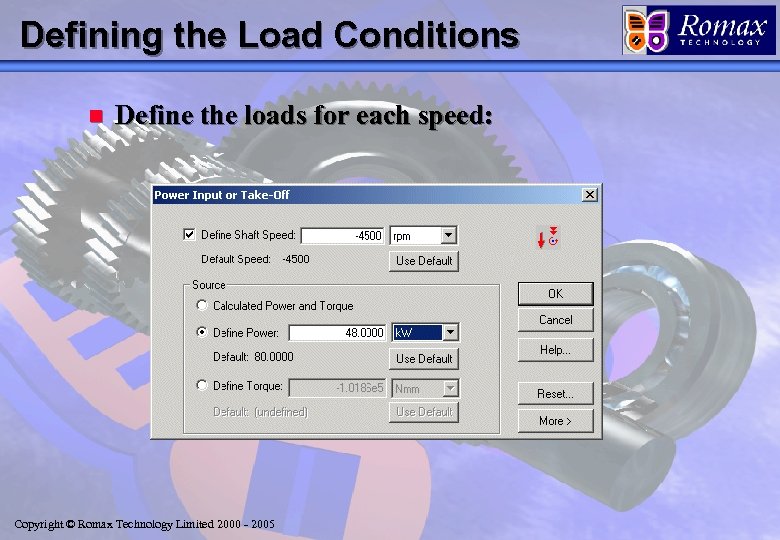

Defining the Load Conditions n Define the loads for each speed: Copyright © Romax Technology Limited 2000 - 2005

Defining the Load Conditions n Define the loads for each speed: Copyright © Romax Technology Limited 2000 - 2005

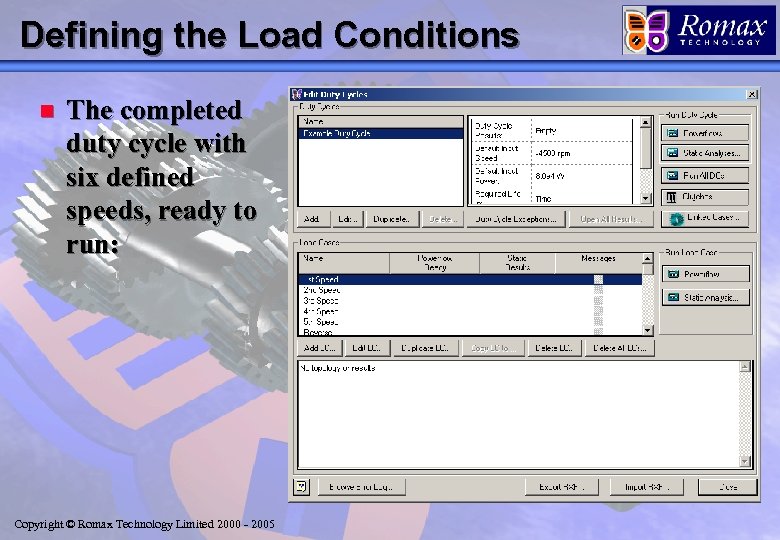

Defining the Load Conditions n The completed duty cycle with six defined speeds, ready to run: Copyright © Romax Technology Limited 2000 - 2005

Defining the Load Conditions n The completed duty cycle with six defined speeds, ready to run: Copyright © Romax Technology Limited 2000 - 2005

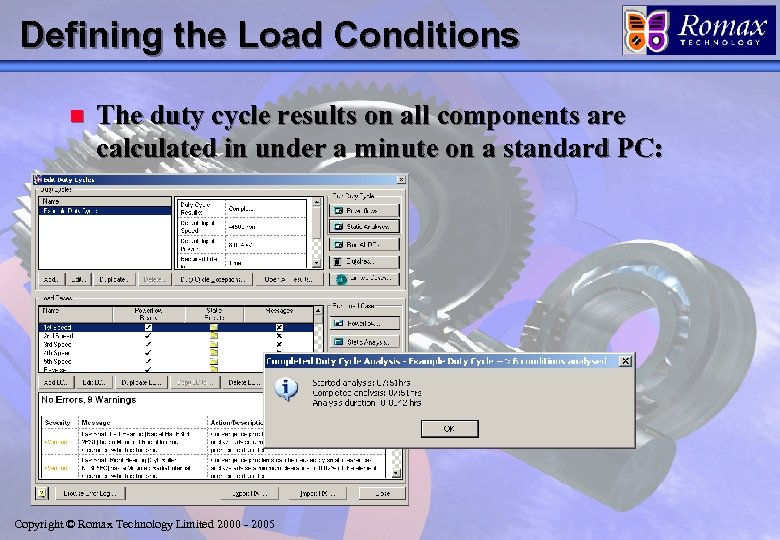

Defining the Load Conditions n The duty cycle results on all components are calculated in under a minute on a standard PC: Copyright © Romax Technology Limited 2000 - 2005

Defining the Load Conditions n The duty cycle results on all components are calculated in under a minute on a standard PC: Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Review of Results n Romax. Designer calculates complete duty cycle results, in under a minute, on a standard PC n The results for each load case include: • Forces, moments, displacements and stresses for all shafts • Deflections, tilts and displacements on all bearings • Mesh misalignment for all gear meshes • Life rating for all bearings and gears including misalignment effects Copyright © Romax Technology Limited 2000 - 2005

Review of Results n Romax. Designer calculates complete duty cycle results, in under a minute, on a standard PC n The results for each load case include: • Forces, moments, displacements and stresses for all shafts • Deflections, tilts and displacements on all bearings • Mesh misalignment for all gear meshes • Life rating for all bearings and gears including misalignment effects Copyright © Romax Technology Limited 2000 - 2005

Review of Results n The results for a single load case will be examined first: • Shaft loadings and deflections leading to bearing rating and gear mesh misalignment n Then the cumulative effect of the duty cycle will be shown n This gives a final assessment of gear and bearing performance for the specified duty cycle Copyright © Romax Technology Limited 2000 - 2005

Review of Results n The results for a single load case will be examined first: • Shaft loadings and deflections leading to bearing rating and gear mesh misalignment n Then the cumulative effect of the duty cycle will be shown n This gives a final assessment of gear and bearing performance for the specified duty cycle Copyright © Romax Technology Limited 2000 - 2005

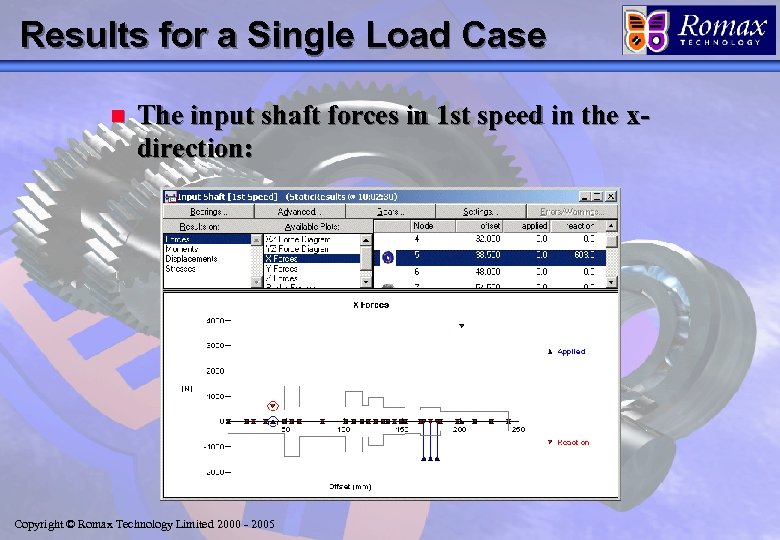

Results for a Single Load Case n The input shaft forces in 1 st speed in the xdirection: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n The input shaft forces in 1 st speed in the xdirection: Copyright © Romax Technology Limited 2000 - 2005

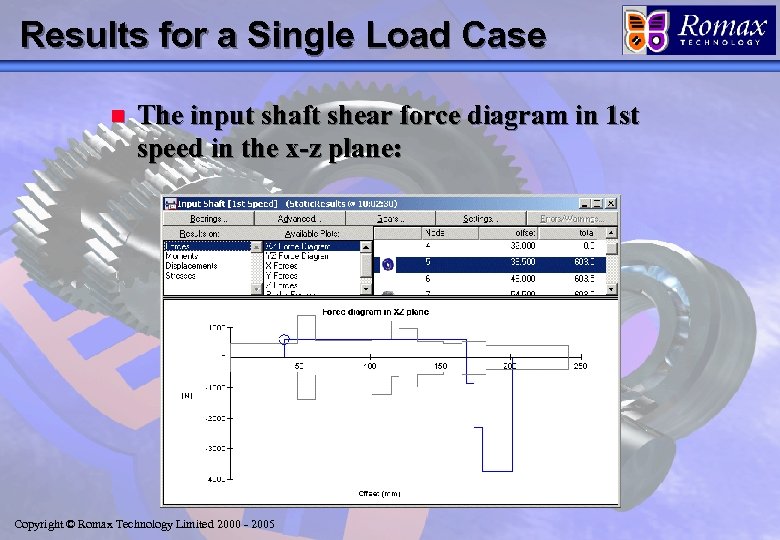

Results for a Single Load Case n The input shaft shear force diagram in 1 st speed in the x-z plane: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n The input shaft shear force diagram in 1 st speed in the x-z plane: Copyright © Romax Technology Limited 2000 - 2005

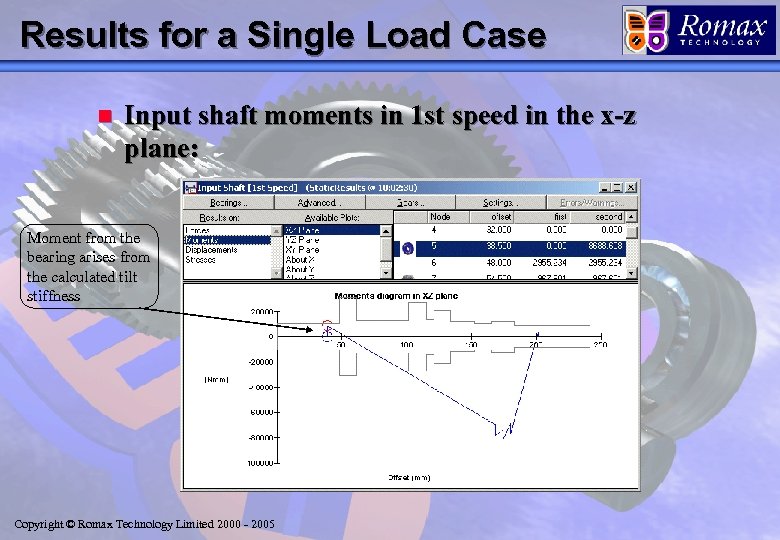

Results for a Single Load Case n Input shaft moments in 1 st speed in the x-z plane: Moment from the bearing arises from the calculated tilt stiffness Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n Input shaft moments in 1 st speed in the x-z plane: Moment from the bearing arises from the calculated tilt stiffness Copyright © Romax Technology Limited 2000 - 2005

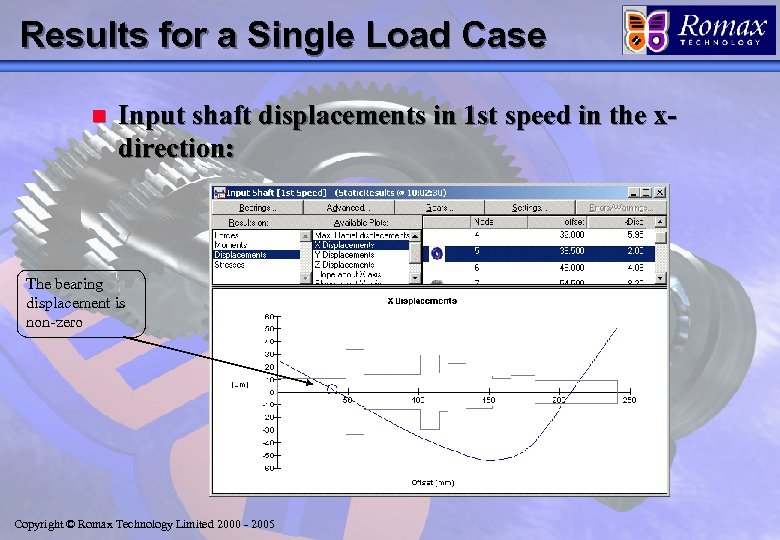

Results for a Single Load Case n Input shaft displacements in 1 st speed in the xdirection: The bearing displacement is non-zero Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n Input shaft displacements in 1 st speed in the xdirection: The bearing displacement is non-zero Copyright © Romax Technology Limited 2000 - 2005

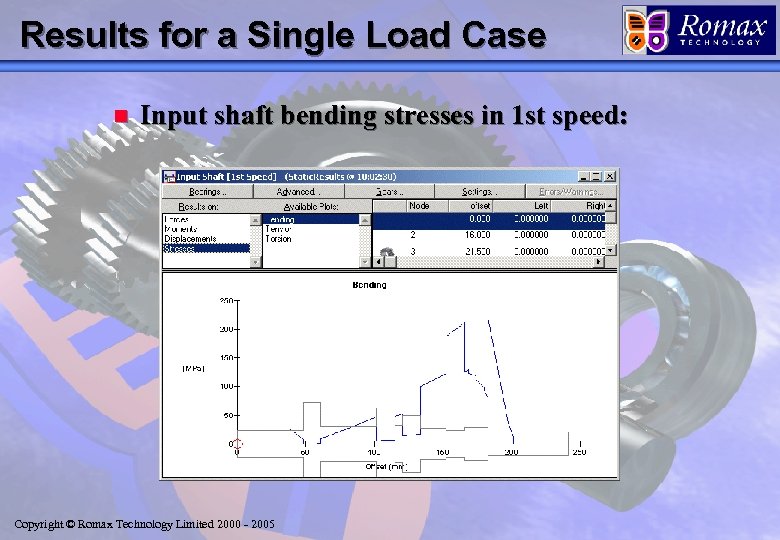

Results for a Single Load Case n Input shaft bending stresses in 1 st speed: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n Input shaft bending stresses in 1 st speed: Copyright © Romax Technology Limited 2000 - 2005

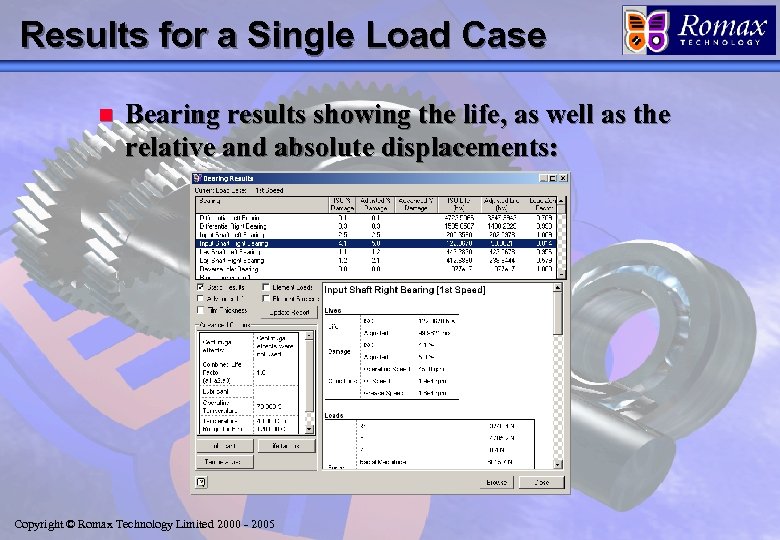

Results for a Single Load Case n Bearing results showing the life, as well as the relative and absolute displacements: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n Bearing results showing the life, as well as the relative and absolute displacements: Copyright © Romax Technology Limited 2000 - 2005

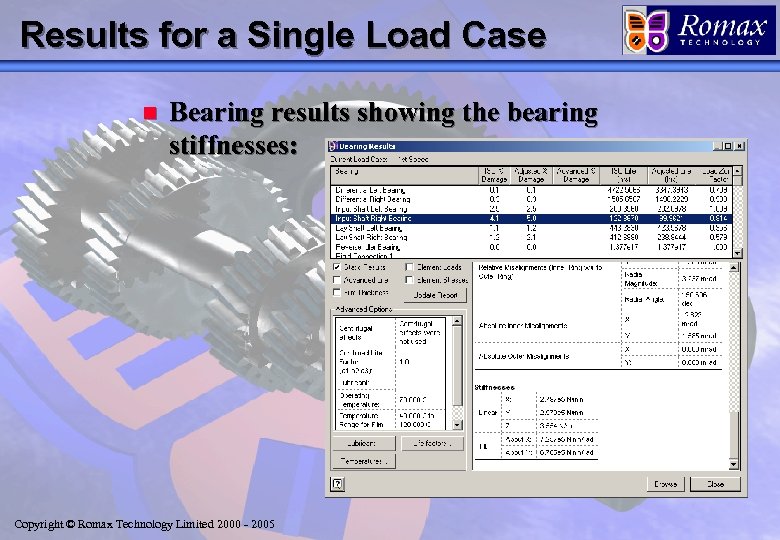

Results for a Single Load Case n Bearing results showing the bearing stiffnesses: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n Bearing results showing the bearing stiffnesses: Copyright © Romax Technology Limited 2000 - 2005

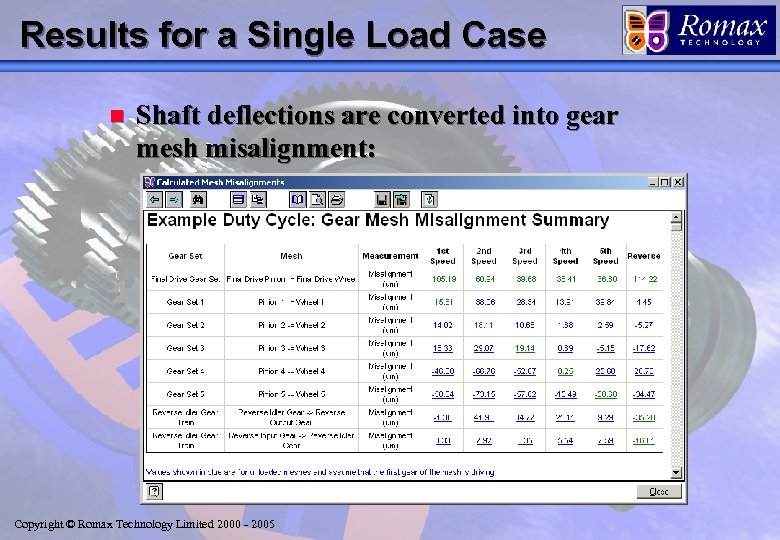

Results for a Single Load Case n Shaft deflections are converted into gear mesh misalignment: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n Shaft deflections are converted into gear mesh misalignment: Copyright © Romax Technology Limited 2000 - 2005

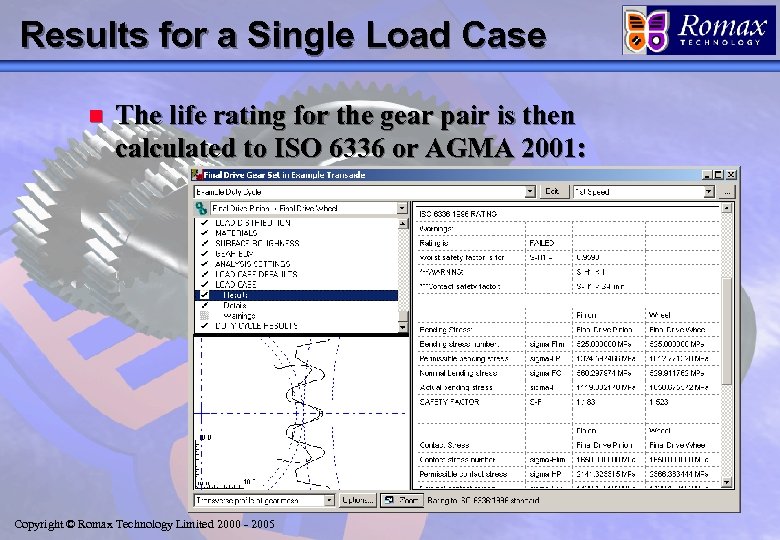

Results for a Single Load Case n The life rating for the gear pair is then calculated to ISO 6336 or AGMA 2001: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n The life rating for the gear pair is then calculated to ISO 6336 or AGMA 2001: Copyright © Romax Technology Limited 2000 - 2005

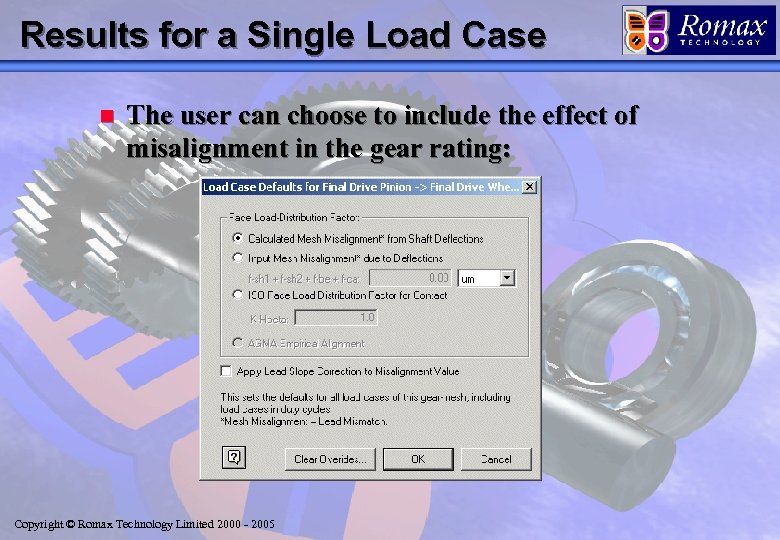

Results for a Single Load Case n The user can choose to include the effect of misalignment in the gear rating: Copyright © Romax Technology Limited 2000 - 2005

Results for a Single Load Case n The user can choose to include the effect of misalignment in the gear rating: Copyright © Romax Technology Limited 2000 - 2005

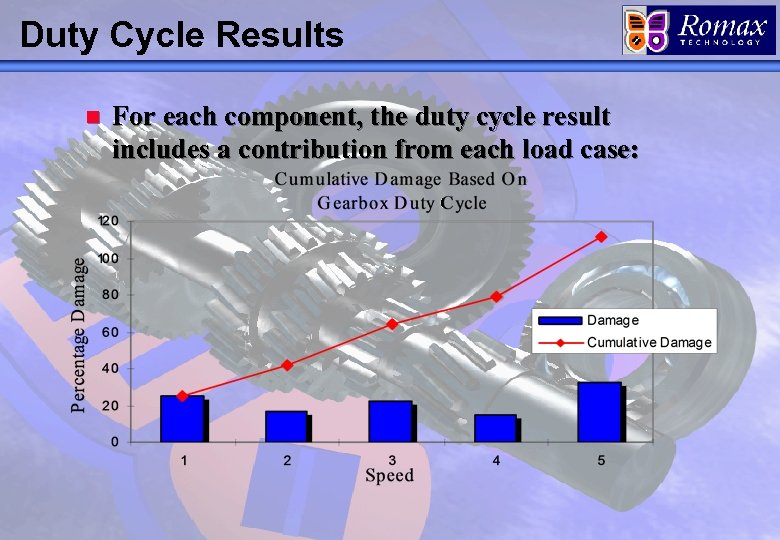

Duty Cycle Results n For each component, the duty cycle result includes a contribution from each load case:

Duty Cycle Results n For each component, the duty cycle result includes a contribution from each load case:

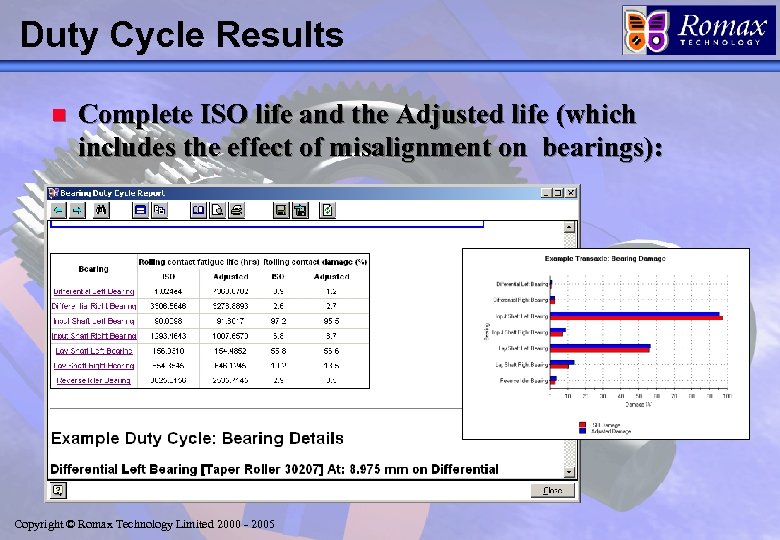

Duty Cycle Results n Complete ISO life and the Adjusted life (which includes the effect of misalignment on bearings): Copyright © Romax Technology Limited 2000 - 2005

Duty Cycle Results n Complete ISO life and the Adjusted life (which includes the effect of misalignment on bearings): Copyright © Romax Technology Limited 2000 - 2005

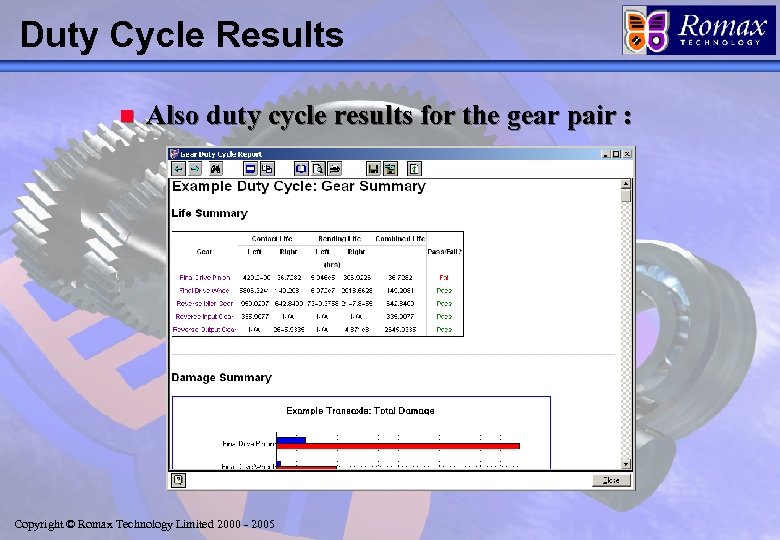

Duty Cycle Results n Also duty cycle results for the gear pair : Copyright © Romax Technology Limited 2000 - 2005

Duty Cycle Results n Also duty cycle results for the gear pair : Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Modelling the Transmission Romax. Designer Modelling Areas: n Definition of components n Mounting the gears on to shafts n Definition of gearbox internal geometry n Powerflow definition and analysis n Review of results n Options for further analysis and optimization Copyright © Romax Technology Limited 2000 - 2005

Further Analysis (i) Examples of additional work possible using the Romax. Designer software: n The influence of Housing Stiffness on the system deflections n The misalignment of synchronized gears mounted on needle roller bearings n Stress concentration factors and shaft fatigue analysis. Copyright © Romax Technology Limited 2000 - 2005

Further Analysis (i) Examples of additional work possible using the Romax. Designer software: n The influence of Housing Stiffness on the system deflections n The misalignment of synchronized gears mounted on needle roller bearings n Stress concentration factors and shaft fatigue analysis. Copyright © Romax Technology Limited 2000 - 2005

Further Analysis (ii) Examples of additional work possible using the Romax. Designer software: n A more detailed duty cycle, e. g. for different driving styles and conditions n Gear micro-geometry definition and transmission error calculation n Synchronizer sizing and simulation. Copyright © Romax Technology Limited 2000 - 2005

Further Analysis (ii) Examples of additional work possible using the Romax. Designer software: n A more detailed duty cycle, e. g. for different driving styles and conditions n Gear micro-geometry definition and transmission error calculation n Synchronizer sizing and simulation. Copyright © Romax Technology Limited 2000 - 2005

Further Analysis (iii) Examples of additional work possible using the Romax. Designer software: n Driveline dynamic analysis and NVH n Perpendicular shafts, hypoid, spiroid and bevel gears n In-depth analysis of bearings. Copyright © Romax Technology Limited 2000 - 2005

Further Analysis (iii) Examples of additional work possible using the Romax. Designer software: n Driveline dynamic analysis and NVH n Perpendicular shafts, hypoid, spiroid and bevel gears n In-depth analysis of bearings. Copyright © Romax Technology Limited 2000 - 2005

Conclusions Romax. Designer allows: n Modelling of a complete gearbox … in less than 1 day n Duty cycle analysis of a gearbox … in under 1 minute n World-leading analysis in an easy-to-use interface n This speed-of-use allows rapid iterative design optimization for the first time Copyright © Romax Technology Limited 2000 - 2005

Conclusions Romax. Designer allows: n Modelling of a complete gearbox … in less than 1 day n Duty cycle analysis of a gearbox … in under 1 minute n World-leading analysis in an easy-to-use interface n This speed-of-use allows rapid iterative design optimization for the first time Copyright © Romax Technology Limited 2000 - 2005

Your Next Step! Thank you for reviewing Romax. Designer. You may now wish to: Start using Romax. Designer Take one of the Romax in-depth training courses on transmissions, or gear design using Romax. Designer (email us - see next slide) Contact Romax for more details on Romax software solutions (see next slide) Copyright © Romax Technology Limited 2000 - 2005

Your Next Step! Thank you for reviewing Romax. Designer. You may now wish to: Start using Romax. Designer Take one of the Romax in-depth training courses on transmissions, or gear design using Romax. Designer (email us - see next slide) Contact Romax for more details on Romax software solutions (see next slide) Copyright © Romax Technology Limited 2000 - 2005

For more information contact: Romax Technology Limited Rutherford House Nottingham Science and Technology Park Nottingham England, NG 7 2 PZ Tel: +44 (0)115 951 8800 Fax: +44 (0)115 951 8801 e-mail: info@romaxtech. com http: //www. romaxtech. com

For more information contact: Romax Technology Limited Rutherford House Nottingham Science and Technology Park Nottingham England, NG 7 2 PZ Tel: +44 (0)115 951 8800 Fax: +44 (0)115 951 8801 e-mail: info@romaxtech. com http: //www. romaxtech. com