cc7067a6a532fdb7245924b41e66903d.ppt

- Количество слайдов: 31

ROADS Services Training Group LOCAL AUTHORITY ROADS CONFERENCE 2015 Reforms, Challenges and Safety Treacys West County Hotel, Ennis, May 2015. 1

ROADS Services Training Group LOCAL AUTHORITY ROADS CONFERENCE 2015 Reforms, Challenges and Safety Treacys West County Hotel, Ennis, May 2015. 1

Reforms, Challenges and Safety Development of NRA MCDRW Series 900 Tom Casey & Edward Winterlich National Roads Authority

Reforms, Challenges and Safety Development of NRA MCDRW Series 900 Tom Casey & Edward Winterlich National Roads Authority

Why Change § Retrofitting EN to BS derived format § Terminology and format differences Updating EN § standards § v CE Marking v Understanding § Do. P v § CE Marking introduced to regulate mixtures (but not the Works) Making a declaration and compliance sits with the manufacturer Legal requirement with penalties for non compliance Families of Products / Processes

Why Change § Retrofitting EN to BS derived format § Terminology and format differences Updating EN § standards § v CE Marking v Understanding § Do. P v § CE Marking introduced to regulate mixtures (but not the Works) Making a declaration and compliance sits with the manufacturer Legal requirement with penalties for non compliance Families of Products / Processes

Why Change n n v Contract Perspective Lack of transparency in test results Difficulty in resolving failures in timely manner n Lack of understanding between “asphalt as a product” and “finished works incorporating an asphalt product” n Discontinuity between production and site n Investigation procedures disproportionate to majority of discrepancies

Why Change n n v Contract Perspective Lack of transparency in test results Difficulty in resolving failures in timely manner n Lack of understanding between “asphalt as a product” and “finished works incorporating an asphalt product” n Discontinuity between production and site n Investigation procedures disproportionate to majority of discrepancies

Why Change § § v Design Perspective Ability of site specific design Suite of materials with common approach § Better demonstration of value for money in chosen material § Analytical vs empirical basis § Easier to exploit material properties

Why Change § § v Design Perspective Ability of site specific design Suite of materials with common approach § Better demonstration of value for money in chosen material § Analytical vs empirical basis § Easier to exploit material properties

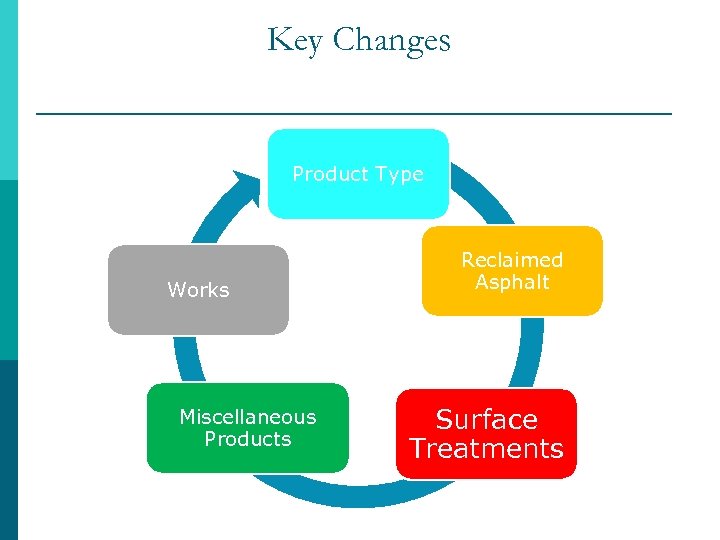

Key Changes Product Type Works Miscellaneous Products Reclaimed Asphalt Surface Treatments

Key Changes Product Type Works Miscellaneous Products Reclaimed Asphalt Surface Treatments

Objective v Make the Series easier to negotiate. v Make a clear distinction between products and the works v ‘As laid’ performance testing needed to confirm that the products supplied are consistent with the declared performance v The revision is part 1 of a 2 stage process

Objective v Make the Series easier to negotiate. v Make a clear distinction between products and the works v ‘As laid’ performance testing needed to confirm that the products supplied are consistent with the declared performance v The revision is part 1 of a 2 stage process

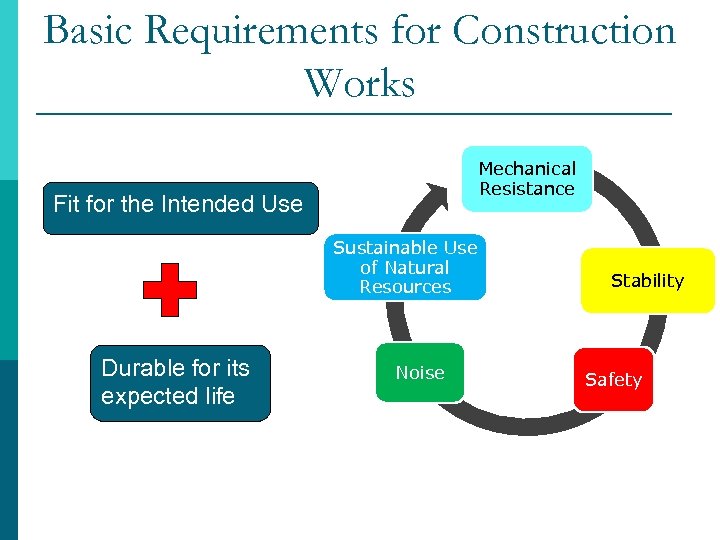

Objective (Stage 2) v v Assess the data gathered from the works to determine and set future achievable performance criteria v Testing information gathered from the works Also to ensure the products will perform to meet the CPR Basic Requirements for Construction Works which include,

Objective (Stage 2) v v Assess the data gathered from the works to determine and set future achievable performance criteria v Testing information gathered from the works Also to ensure the products will perform to meet the CPR Basic Requirements for Construction Works which include,

Basic Requirements for Construction Works Mechanical Resistance Fit for the Intended Use Sustainable Use of Natural Resources Durable for its expected life Noise Stability Safety

Basic Requirements for Construction Works Mechanical Resistance Fit for the Intended Use Sustainable Use of Natural Resources Durable for its expected life Noise Stability Safety

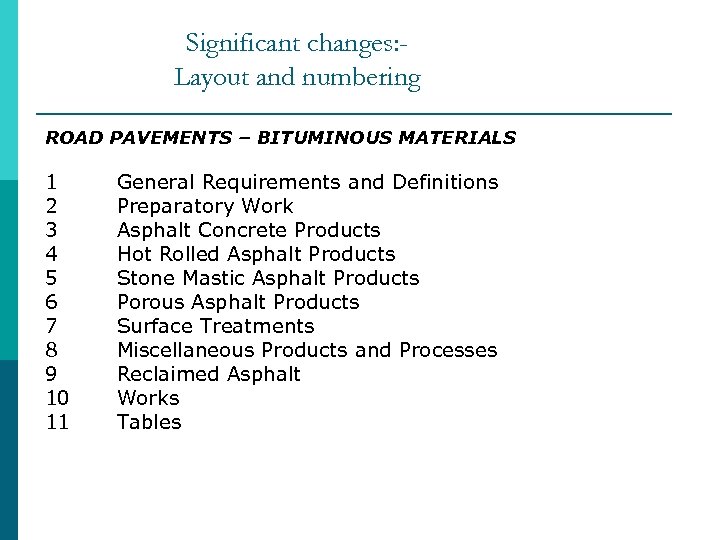

Significant changes: Layout and numbering ROAD PAVEMENTS – BITUMINOUS MATERIALS 1 2 3 4 5 6 7 8 9 10 11 General Requirements and Definitions Preparatory Work Asphalt Concrete Products Hot Rolled Asphalt Products Stone Mastic Asphalt Products Porous Asphalt Products Surface Treatments Miscellaneous Products and Processes Reclaimed Asphalt Works Tables

Significant changes: Layout and numbering ROAD PAVEMENTS – BITUMINOUS MATERIALS 1 2 3 4 5 6 7 8 9 10 11 General Requirements and Definitions Preparatory Work Asphalt Concrete Products Hot Rolled Asphalt Products Stone Mastic Asphalt Products Porous Asphalt Products Surface Treatments Miscellaneous Products and Processes Reclaimed Asphalt Works Tables

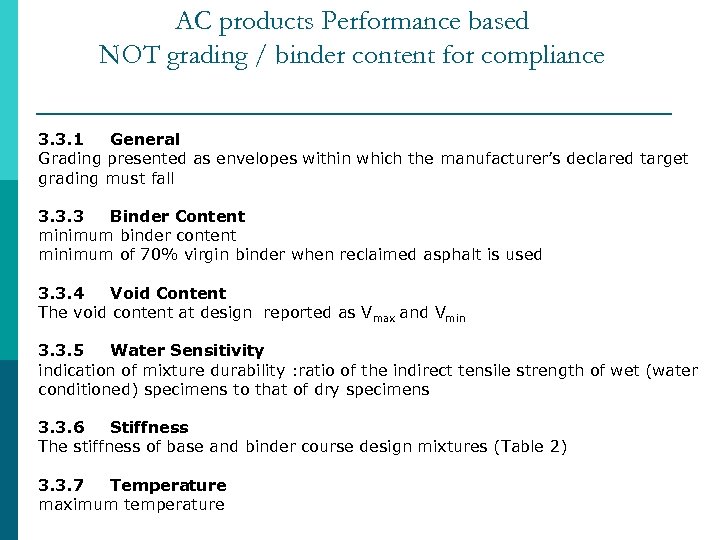

AC products Performance based NOT grading / binder content for compliance 3. 3. 1 General Grading presented as envelopes within which the manufacturer’s declared target grading must fall 3. 3. 3 Binder Content minimum binder content minimum of 70% virgin binder when reclaimed asphalt is used 3. 3. 4 Void Content The void content at design reported as Vmax and Vmin 3. 3. 5 Water Sensitivity indication of mixture durability : ratio of the indirect tensile strength of wet (water conditioned) specimens to that of dry specimens 3. 3. 6 Stiffness The stiffness of base and binder course design mixtures (Table 2) 3. 3. 7 Temperature maximum temperature

AC products Performance based NOT grading / binder content for compliance 3. 3. 1 General Grading presented as envelopes within which the manufacturer’s declared target grading must fall 3. 3. 3 Binder Content minimum binder content minimum of 70% virgin binder when reclaimed asphalt is used 3. 3. 4 Void Content The void content at design reported as Vmax and Vmin 3. 3. 5 Water Sensitivity indication of mixture durability : ratio of the indirect tensile strength of wet (water conditioned) specimens to that of dry specimens 3. 3. 6 Stiffness The stiffness of base and binder course design mixtures (Table 2) 3. 3. 7 Temperature maximum temperature

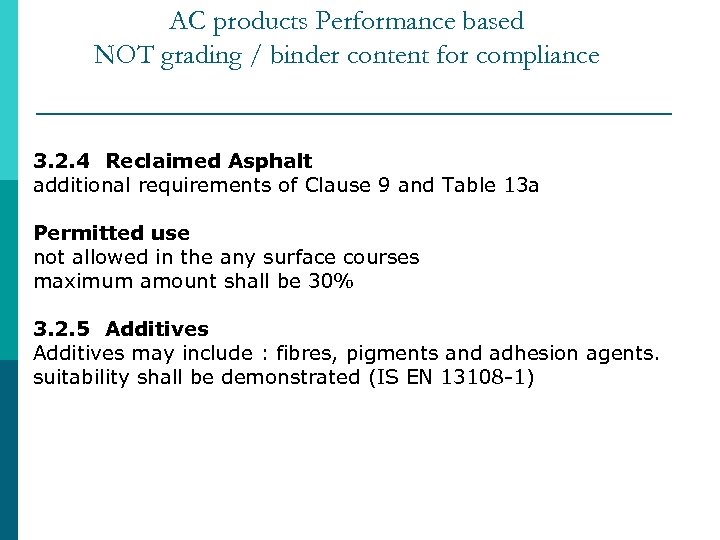

AC products Performance based NOT grading / binder content for compliance 3. 2. 4 Reclaimed Asphalt additional requirements of Clause 9 and Table 13 a Permitted use not allowed in the any surface courses maximum amount shall be 30% 3. 2. 5 Additives may include : fibres, pigments and adhesion agents. suitability shall be demonstrated (IS EN 13108 -1)

AC products Performance based NOT grading / binder content for compliance 3. 2. 4 Reclaimed Asphalt additional requirements of Clause 9 and Table 13 a Permitted use not allowed in the any surface courses maximum amount shall be 30% 3. 2. 5 Additives may include : fibres, pigments and adhesion agents. suitability shall be demonstrated (IS EN 13108 -1)

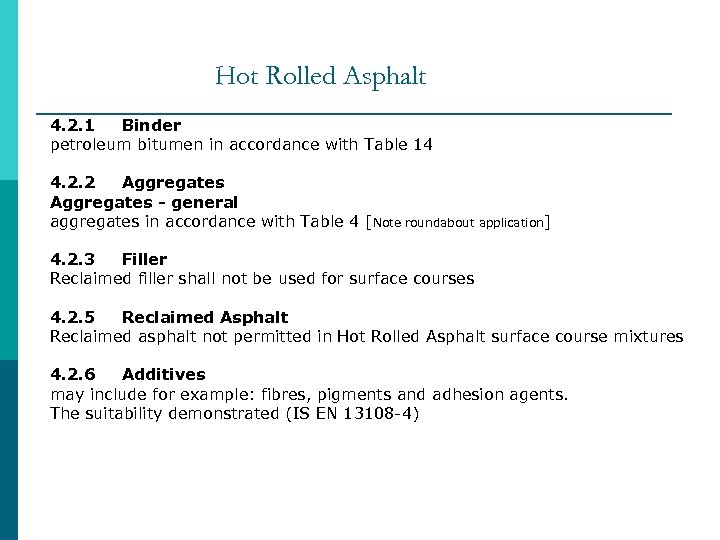

Hot Rolled Asphalt 4. 2. 1 Binder petroleum bitumen in accordance with Table 14 4. 2. 2 Aggregates - general aggregates in accordance with Table 4 [Note roundabout application] 4. 2. 3 Filler Reclaimed filler shall not be used for surface courses 4. 2. 5 Reclaimed Asphalt Reclaimed asphalt not permitted in Hot Rolled Asphalt surface course mixtures 4. 2. 6 Additives may include for example: fibres, pigments and adhesion agents. The suitability demonstrated (IS EN 13108 -4)

Hot Rolled Asphalt 4. 2. 1 Binder petroleum bitumen in accordance with Table 14 4. 2. 2 Aggregates - general aggregates in accordance with Table 4 [Note roundabout application] 4. 2. 3 Filler Reclaimed filler shall not be used for surface courses 4. 2. 5 Reclaimed Asphalt Reclaimed asphalt not permitted in Hot Rolled Asphalt surface course mixtures 4. 2. 6 Additives may include for example: fibres, pigments and adhesion agents. The suitability demonstrated (IS EN 13108 -4)

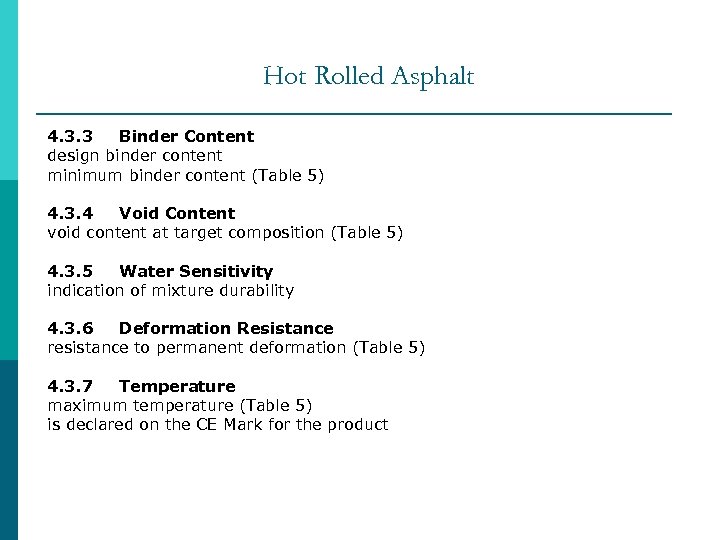

Hot Rolled Asphalt 4. 3. 3 Binder Content design binder content minimum binder content (Table 5) 4. 3. 4 Void Content void content at target composition (Table 5) 4. 3. 5 Water Sensitivity indication of mixture durability 4. 3. 6 Deformation Resistance resistance to permanent deformation (Table 5) 4. 3. 7 Temperature maximum temperature (Table 5) is declared on the CE Mark for the product

Hot Rolled Asphalt 4. 3. 3 Binder Content design binder content minimum binder content (Table 5) 4. 3. 4 Void Content void content at target composition (Table 5) 4. 3. 5 Water Sensitivity indication of mixture durability 4. 3. 6 Deformation Resistance resistance to permanent deformation (Table 5) 4. 3. 7 Temperature maximum temperature (Table 5) is declared on the CE Mark for the product

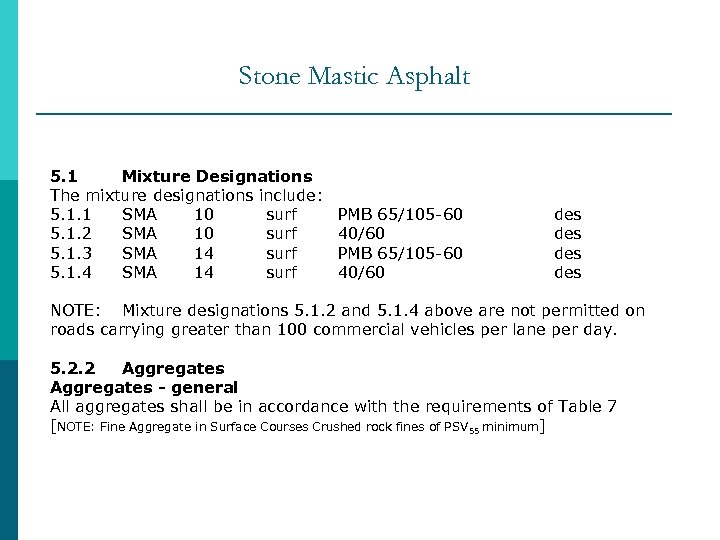

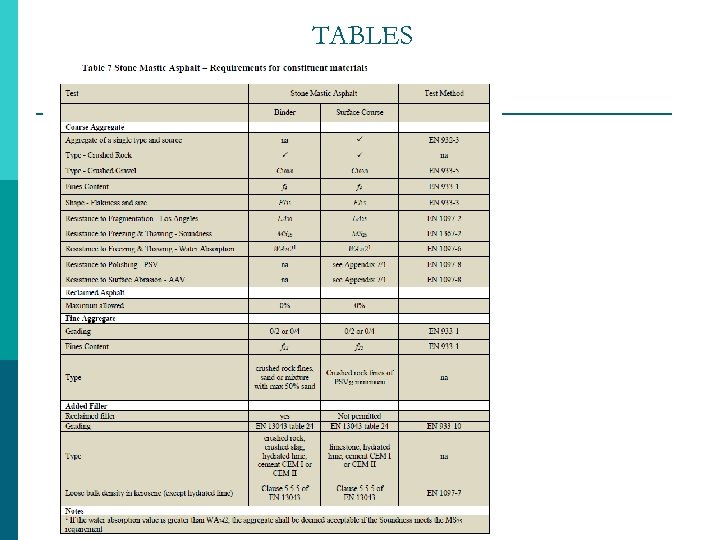

Stone Mastic Asphalt 5. 1 Mixture Designations The mixture designations include: 5. 1. 1 SMA 10 surf 5. 1. 2 SMA 10 surf 5. 1. 3 SMA 14 surf 5. 1. 4 SMA 14 surf PMB 65/105 -60 40/60 des des NOTE: Mixture designations 5. 1. 2 and 5. 1. 4 above are not permitted on roads carrying greater than 100 commercial vehicles per lane per day. 5. 2. 2 Aggregates - general All aggregates shall be in accordance with the requirements of Table 7 [NOTE: Fine Aggregate in Surface Courses Crushed rock fines of PSV 55 minimum]

Stone Mastic Asphalt 5. 1 Mixture Designations The mixture designations include: 5. 1. 1 SMA 10 surf 5. 1. 2 SMA 10 surf 5. 1. 3 SMA 14 surf 5. 1. 4 SMA 14 surf PMB 65/105 -60 40/60 des des NOTE: Mixture designations 5. 1. 2 and 5. 1. 4 above are not permitted on roads carrying greater than 100 commercial vehicles per lane per day. 5. 2. 2 Aggregates - general All aggregates shall be in accordance with the requirements of Table 7 [NOTE: Fine Aggregate in Surface Courses Crushed rock fines of PSV 55 minimum]

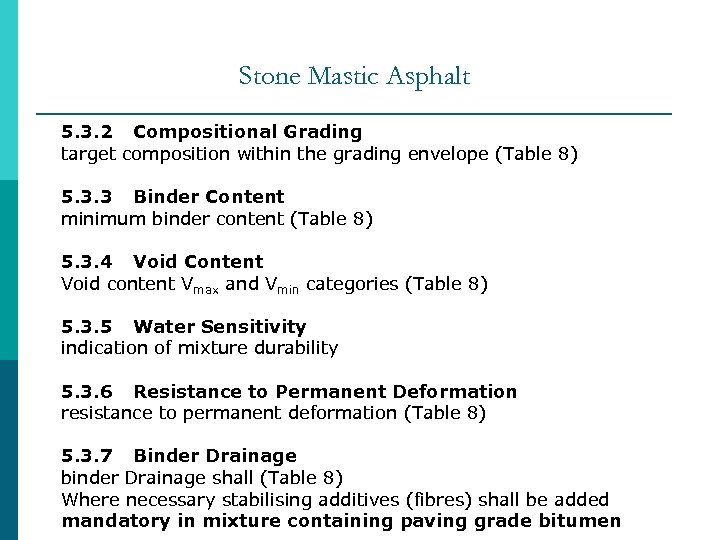

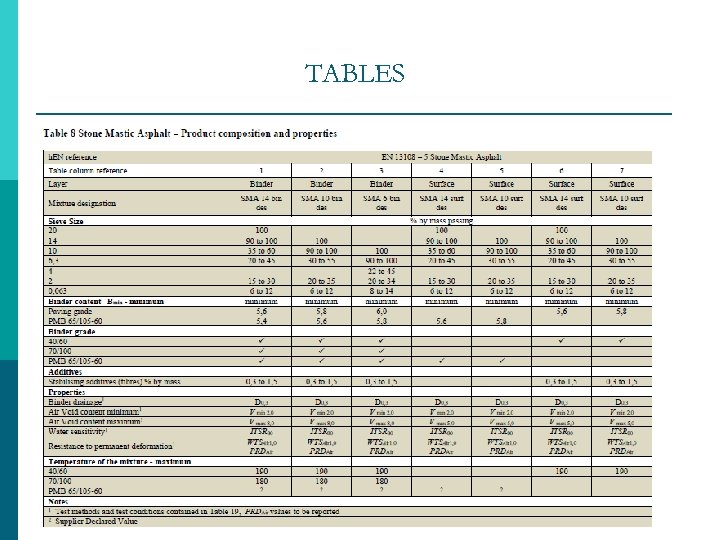

Stone Mastic Asphalt 5. 3. 2 Compositional Grading target composition within the grading envelope (Table 8) 5. 3. 3 Binder Content minimum binder content (Table 8) 5. 3. 4 Void Content Void content Vmax and Vmin categories (Table 8) 5. 3. 5 Water Sensitivity indication of mixture durability 5. 3. 6 Resistance to Permanent Deformation resistance to permanent deformation (Table 8) 5. 3. 7 Binder Drainage binder Drainage shall (Table 8) Where necessary stabilising additives (fibres) shall be added mandatory in mixture containing paving grade bitumen

Stone Mastic Asphalt 5. 3. 2 Compositional Grading target composition within the grading envelope (Table 8) 5. 3. 3 Binder Content minimum binder content (Table 8) 5. 3. 4 Void Content Void content Vmax and Vmin categories (Table 8) 5. 3. 5 Water Sensitivity indication of mixture durability 5. 3. 6 Resistance to Permanent Deformation resistance to permanent deformation (Table 8) 5. 3. 7 Binder Drainage binder Drainage shall (Table 8) Where necessary stabilising additives (fibres) shall be added mandatory in mixture containing paving grade bitumen

Surface Treatments - Microsurfacing 7. 1. 3. 1 Defects determined by visual inspection Producer assesses site and measures defects, by visual assessment, after one year of completion of the installation and at one year intervals thereafter for the five year ‘Design Working Life’ period, or period specified in Appendix 7/10 7. 1. 3. 2 Macrotexture The Purchaser l monitor the performance levels of the microsurfacing during ‘Design Working Life’, and bring any defects to the attention of the Producer 7. 1. 3. 3 Surface Shear Strength Unless otherwise specified in Appendix 7/10, the performance of the product’s bond to the substrate evaluated (surface shear strength test : pr. CEN/TS 1269751)

Surface Treatments - Microsurfacing 7. 1. 3. 1 Defects determined by visual inspection Producer assesses site and measures defects, by visual assessment, after one year of completion of the installation and at one year intervals thereafter for the five year ‘Design Working Life’ period, or period specified in Appendix 7/10 7. 1. 3. 2 Macrotexture The Purchaser l monitor the performance levels of the microsurfacing during ‘Design Working Life’, and bring any defects to the attention of the Producer 7. 1. 3. 3 Surface Shear Strength Unless otherwise specified in Appendix 7/10, the performance of the product’s bond to the substrate evaluated (surface shear strength test : pr. CEN/TS 1269751)

Surface Treatments - Microsurfacing 7. 1. 4 Construction Products Regulation Do. P, CE Mark, Type Approval Installation Trial and FPC information. . . shall be provided 7. 1. 4. 1 Factory Production Control (FPC) Notified Body shall certify the FPC system 7. 1. 4. 2 Determination of Product Type - Type Approval Installation Trial (TAIT) TAIT carried out on a site with similar characteristics and traffic category to that to be treated in the Contract. TAIT shall have been installed in accordance with the Producer’s certified Factory Production Control system 7. 1. 4. 3 Declaration of Performance (Do. P) Producer shall provide the Do. P Producer shall monitor the TAIT site and declare the period that the performance characteristics have been retained 7. 1. 4. 4 CE Marking Producer shall provide the CE Marking

Surface Treatments - Microsurfacing 7. 1. 4 Construction Products Regulation Do. P, CE Mark, Type Approval Installation Trial and FPC information. . . shall be provided 7. 1. 4. 1 Factory Production Control (FPC) Notified Body shall certify the FPC system 7. 1. 4. 2 Determination of Product Type - Type Approval Installation Trial (TAIT) TAIT carried out on a site with similar characteristics and traffic category to that to be treated in the Contract. TAIT shall have been installed in accordance with the Producer’s certified Factory Production Control system 7. 1. 4. 3 Declaration of Performance (Do. P) Producer shall provide the Do. P Producer shall monitor the TAIT site and declare the period that the performance characteristics have been retained 7. 1. 4. 4 CE Marking Producer shall provide the CE Marking

Surface Treatments – Surface Dressing 7. 2. 2. 1. 1 Binder shall be in accordance Table 15 (minimum peak cohesion for Pm. B) 7. 2. 1 General Recipe Surface Dressing (RSD) designed by the Employer [NRA HD 300 ; Clause 7. 2. 2 and Appendix 7/21] Surface Dressing Product (End Performance) designed and installed by the Producer CE marked and comply with Clause 7. 2. 3 and Appendix 7/3 7. 2. 2. 2 Composition RSD Employer design information including the product type shall be provided in Appendix 7/21 Additional requirements for the accuracy of distribution of both binder and aggregates tolerances on rates of spread (Clauses 10. 2. 3. 1. 3 and 10. 2. 3. 1. 4)

Surface Treatments – Surface Dressing 7. 2. 2. 1. 1 Binder shall be in accordance Table 15 (minimum peak cohesion for Pm. B) 7. 2. 1 General Recipe Surface Dressing (RSD) designed by the Employer [NRA HD 300 ; Clause 7. 2. 2 and Appendix 7/21] Surface Dressing Product (End Performance) designed and installed by the Producer CE marked and comply with Clause 7. 2. 3 and Appendix 7/3 7. 2. 2. 2 Composition RSD Employer design information including the product type shall be provided in Appendix 7/21 Additional requirements for the accuracy of distribution of both binder and aggregates tolerances on rates of spread (Clauses 10. 2. 3. 1. 3 and 10. 2. 3. 1. 4)

Surface Treatments – Surface Dressing 7. 2. 3 Surface Dressing Product (End Performance) Requirements for constituents and composition Additional requirements for Works (Clause 10. 2. 3. 2) Designer responsible for the intended use as set out in this Clause and contained in Appendix 7/3 Producer responsible for : the surface dressing product (CE Marked) the performance - macrotexture and maximum levels of defects initial stability -capable of withstanding the normal traffic for the site when first opened TAIT documentation & evidence the period for which the performance characteristics have been retained surface dressing in accordance with IS EN 12271 and the requirements specified in Appendix 7/3. The performance of the design, materials and workmanship shall be maintained for a minimum period of five years, or the period specified in Appendix 7/3, from the date of completion of the Works. (‘Design Working Life’)

Surface Treatments – Surface Dressing 7. 2. 3 Surface Dressing Product (End Performance) Requirements for constituents and composition Additional requirements for Works (Clause 10. 2. 3. 2) Designer responsible for the intended use as set out in this Clause and contained in Appendix 7/3 Producer responsible for : the surface dressing product (CE Marked) the performance - macrotexture and maximum levels of defects initial stability -capable of withstanding the normal traffic for the site when first opened TAIT documentation & evidence the period for which the performance characteristics have been retained surface dressing in accordance with IS EN 12271 and the requirements specified in Appendix 7/3. The performance of the design, materials and workmanship shall be maintained for a minimum period of five years, or the period specified in Appendix 7/3, from the date of completion of the Works. (‘Design Working Life’)

Surface Treatments – High Friction Surfacing 7. 3 High Friction Surfacing Rrequirements for Works are contained in Clause 10. 2. 4. Performance of the design, materials and workmanship maintained for a minimum period of five years, or the period specified in Appendix 7/10 The ‘Design Working Life’ 7. 3. 1. 1 Binder Unless otherwise specified in Appendix 7/11, shall be one of the following: Cold binders (principally thermosetting products): Epoxy resin; Bitumen extended epoxy resin; Polyurethane; Polyurea; and Methyl methacrylate. Hot binders (thermoplastic products): Rosin ester; and Hydrocarbon resin. The binder shall comply with the requirements of Table 23 a 7. 3. 1. 2 Aggregates Manufactured or natural from a single source and free from foreign matter PSV and AAV requirements stated in Table 23 b and Table 23 c unless otherwise specified in Appendix 7/11.

Surface Treatments – High Friction Surfacing 7. 3 High Friction Surfacing Rrequirements for Works are contained in Clause 10. 2. 4. Performance of the design, materials and workmanship maintained for a minimum period of five years, or the period specified in Appendix 7/10 The ‘Design Working Life’ 7. 3. 1. 1 Binder Unless otherwise specified in Appendix 7/11, shall be one of the following: Cold binders (principally thermosetting products): Epoxy resin; Bitumen extended epoxy resin; Polyurethane; Polyurea; and Methyl methacrylate. Hot binders (thermoplastic products): Rosin ester; and Hydrocarbon resin. The binder shall comply with the requirements of Table 23 a 7. 3. 1. 2 Aggregates Manufactured or natural from a single source and free from foreign matter PSV and AAV requirements stated in Table 23 b and Table 23 c unless otherwise specified in Appendix 7/11.

Surface Treatments – High Friction Surfacing 7. 3. 3 Performance Requirements provisional Type Approval Installation Trial (pr. TAIT) [Clause 1. 6 and NRA HD 301] 7. 3. 3. 1 Defects determined by visual inspection assessment over five year ‘Design Working Life( or period in Appendix 7/11) level of defects - Appendix 7/11 7. 3. 3. 2 Macrotexture assessment over the ‘Design Working Life’ Contractor to ensure initial macrotexture depth sufficient to enable performance levels to be achieved 10. 2. 4. 5 Laying bond to the substrate : pull-off test in accordance with ASTM 1583 and the requirements of Table 23 e broadcast systems- at the time of installation prior to application of aggregate screeded systems, - on site on the system.

Surface Treatments – High Friction Surfacing 7. 3. 3 Performance Requirements provisional Type Approval Installation Trial (pr. TAIT) [Clause 1. 6 and NRA HD 301] 7. 3. 3. 1 Defects determined by visual inspection assessment over five year ‘Design Working Life( or period in Appendix 7/11) level of defects - Appendix 7/11 7. 3. 3. 2 Macrotexture assessment over the ‘Design Working Life’ Contractor to ensure initial macrotexture depth sufficient to enable performance levels to be achieved 10. 2. 4. 5 Laying bond to the substrate : pull-off test in accordance with ASTM 1583 and the requirements of Table 23 e broadcast systems- at the time of installation prior to application of aggregate screeded systems, - on site on the system.

Reclaimed Asphalt 9. RECLAIMED ASPHALT Only where asphalt plant has capability to add RA accurately procedures to record the quantity 9. 1 Source RA only contain mineral aggregate, filler and paving grade bitumen 9. 2 Classification and Description Suitability tests (Table 13 a) Recovered binder content tests for penetration and softening point Inert if < 15 9. 3 Storage Labelled stockpiles; protected from rain, snow and direct sunshine Feedstock from different stockpiles treated separately (no cross-contamination) Requirements for bituminous mixtures same with / without RA Homogeneity of bituminous mixture determines the maximum RA amount

Reclaimed Asphalt 9. RECLAIMED ASPHALT Only where asphalt plant has capability to add RA accurately procedures to record the quantity 9. 1 Source RA only contain mineral aggregate, filler and paving grade bitumen 9. 2 Classification and Description Suitability tests (Table 13 a) Recovered binder content tests for penetration and softening point Inert if < 15 9. 3 Storage Labelled stockpiles; protected from rain, snow and direct sunshine Feedstock from different stockpiles treated separately (no cross-contamination) Requirements for bituminous mixtures same with / without RA Homogeneity of bituminous mixture determines the maximum RA amount

Reclaimed Asphalt 9. 4 Mixture Design mixtures with up to 10% Reclaimed Asphalt (Table 2) > 10% Reclaimed Asphalt (Table 13 b) fresh binder added shall be a single designated paving combinations of grades shall not be permitted penetration and softening point of the combined fresh and active binder shall fall within the permitted range for the mixture designation 9. 5 Type Test report Individual Type Test reports for each mixture: percentage of RA proposed active binder content grade of fresh binder added 9. 6 Testing In addition to routine testing requirements (Table 13 c) 9. 7 Traceability RA to be traceable through the production process Testing documentation from initial stockpile final products

Reclaimed Asphalt 9. 4 Mixture Design mixtures with up to 10% Reclaimed Asphalt (Table 2) > 10% Reclaimed Asphalt (Table 13 b) fresh binder added shall be a single designated paving combinations of grades shall not be permitted penetration and softening point of the combined fresh and active binder shall fall within the permitted range for the mixture designation 9. 5 Type Test report Individual Type Test reports for each mixture: percentage of RA proposed active binder content grade of fresh binder added 9. 6 Testing In addition to routine testing requirements (Table 13 c) 9. 7 Traceability RA to be traceable through the production process Testing documentation from initial stockpile final products

WORKS 10. 1. 7. 1 Laying conditions specific to Hot Rolled Asphalt mixtures positive macrotexture shoulder-to-shoulder cover 10. 1. 9 Compaction Control Compaction controlled and monitored (Table 3, Table 6, Table 9 and Table 12) ‘to be recorded’ two pairs of cores for every 1, 000 linear metres laid per lane schemes less than 1, 000 m in length, a minimum of one pair of cores Air void content Resistance to permanent deformation Water Sensitivity 10. 1. 9. 1 Compaction Control specific to Asphalt Concrete mixtures - Base and Binder Course Air void content : In situ laid material Within 100 mm of joints In situ at refusal Resistance to permanent deformation Water Sensitivity Stiffness

WORKS 10. 1. 7. 1 Laying conditions specific to Hot Rolled Asphalt mixtures positive macrotexture shoulder-to-shoulder cover 10. 1. 9 Compaction Control Compaction controlled and monitored (Table 3, Table 6, Table 9 and Table 12) ‘to be recorded’ two pairs of cores for every 1, 000 linear metres laid per lane schemes less than 1, 000 m in length, a minimum of one pair of cores Air void content Resistance to permanent deformation Water Sensitivity 10. 1. 9. 1 Compaction Control specific to Asphalt Concrete mixtures - Base and Binder Course Air void content : In situ laid material Within 100 mm of joints In situ at refusal Resistance to permanent deformation Water Sensitivity Stiffness

WORKS 10. 3. 1. 1 General Low Energy Bound Mixtures (LEBM) : Type Test ( HD 301 and Table 24 g) 10. 3. 1. 11 Performance Insitu density Moisture content Indirect tensilt stiffness modulus Percentage air voids LEBM shall meet the requirement of one of the performance classes in Table 24 h. 10. 3. 2 Geotextiles and Geotextile-related Products The installation shall be in accordance with the requirements of NRA HD 300.

WORKS 10. 3. 1. 1 General Low Energy Bound Mixtures (LEBM) : Type Test ( HD 301 and Table 24 g) 10. 3. 1. 11 Performance Insitu density Moisture content Indirect tensilt stiffness modulus Percentage air voids LEBM shall meet the requirement of one of the performance classes in Table 24 h. 10. 3. 2 Geotextiles and Geotextile-related Products The installation shall be in accordance with the requirements of NRA HD 300.

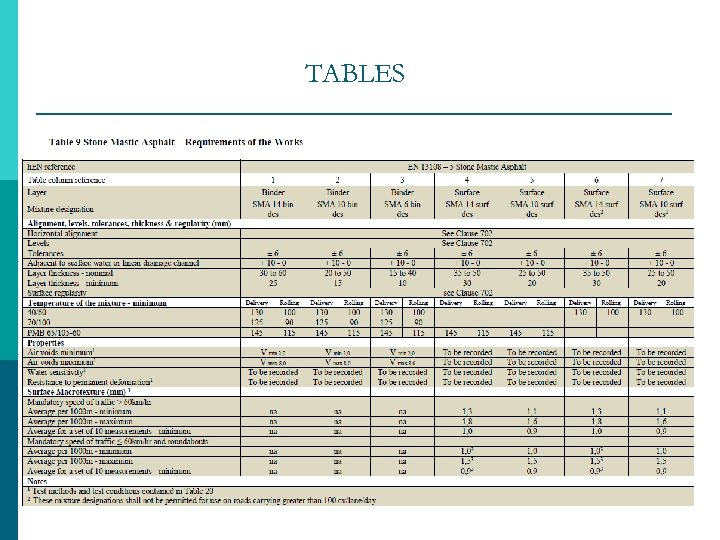

TABLES

TABLES

TABLES

TABLES

TABLES

TABLES

Other Documents p p p HD 23 Pavement Design and Maintenance General Information HD 24 Traffic Assessment HD 25 /26 Pavement and Foundation Design HD 300 Design of Bituminous Mixtures, Surface Treatments, and Misc Products / Processes HD 28 Management of Skid Resistance p p p HD 30 Pavement Asset Repair and Renewal – Scheme Approval HD 31 Pavement Asset Repair and Renewal Principles HD 36 Surface Materials for New and Maintenance Construction HD 37 Bituminous Mixtures, Surface Treatments Materials and Techniques HD 301 Approval of Specific Products Manual

Other Documents p p p HD 23 Pavement Design and Maintenance General Information HD 24 Traffic Assessment HD 25 /26 Pavement and Foundation Design HD 300 Design of Bituminous Mixtures, Surface Treatments, and Misc Products / Processes HD 28 Management of Skid Resistance p p p HD 30 Pavement Asset Repair and Renewal – Scheme Approval HD 31 Pavement Asset Repair and Renewal Principles HD 36 Surface Materials for New and Maintenance Construction HD 37 Bituminous Mixtures, Surface Treatments Materials and Techniques HD 301 Approval of Specific Products Manual

Other Documents p p p Series 000, and Series 100 incl Notes for Guidance Series 700 and NG Series 700 Notes for Guidance NG Series 900 Notes for Guidance Method of Measurement Series 700, RCD’s / 700 /1 and 6

Other Documents p p p Series 000, and Series 100 incl Notes for Guidance Series 700 and NG Series 700 Notes for Guidance NG Series 900 Notes for Guidance Method of Measurement Series 700, RCD’s / 700 /1 and 6