Road construction machines.pptx

- Количество слайдов: 12

Road construction machines. Выполнил: Галиев Д. группа: НТКб-12 Т 2 Омск 2013

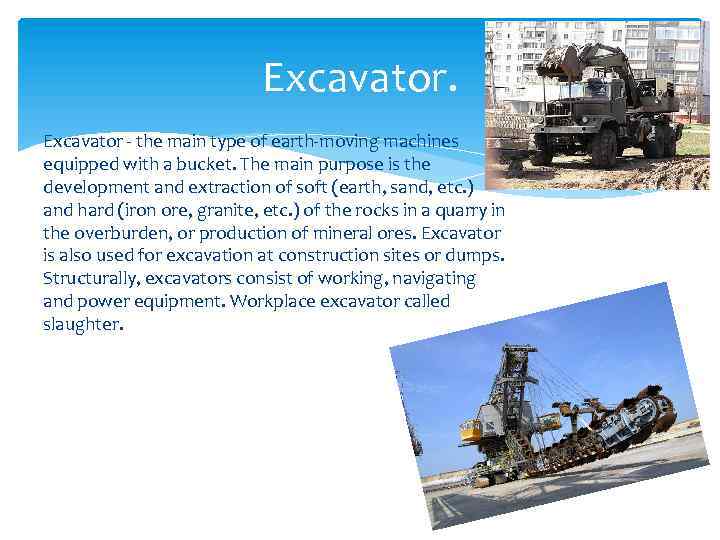

Excavator - the main type of earth-moving machines equipped with a bucket. The main purpose is the development and extraction of soft (earth, sand, etc. ) and hard (iron ore, granite, etc. ) of the rocks in a quarry in the overburden, or production of mineral ores. Excavator is also used for excavation at construction sites or dumps. Structurally, excavators consist of working, navigating and power equipment. Workplace excavator called slaughter.

ory. Hist Officially the idea of a digger belongs to Leonardo da Vinci, he is still in the early XVI century, has developed a prototype of the modern scheme of dragline excavators. Known sketch drawing for grabs, excavator da Vinci created in 1500, and later Leonardo participated in the laying of canals in Milan Valley with his invention. But there is evidence that earlier, in 1420, in the Venetian edition of the "Code of Giovanni Fontana" was published the text with reference to earth-moving machine that was used for the dredging of channels and harbors expansion. Italy for some time, namely Venice, actively developed excavating business - machines were needed to clear the canals of Venice. The invention is further developed in France and America. Active construction of railway beds in the 30 -ies of the XIX century and the lack of employment spodvigla American Otis in the years 1832 -1836 to invent the first shovel. Later, the multi-bucket excavators, abzettsery or who have had enormous size and moved on rails, digging troughs breed. To work with them a lot of special vehicles, including prominent puteperedvigatel, moves many tracks excavator. In the Soviet Union since the early 1960 s in mining phosphate rock mine in Lopatinsky worked abzettsera three, two of which are produced in Germany (Bukau ES-400 -20/8, Takraf Ers 710). At this point, all three machines are not functioning and sold for recycling, in the mine operates only one small abzettser (ESh-11/70), phosphate rock mining in limited quantities.

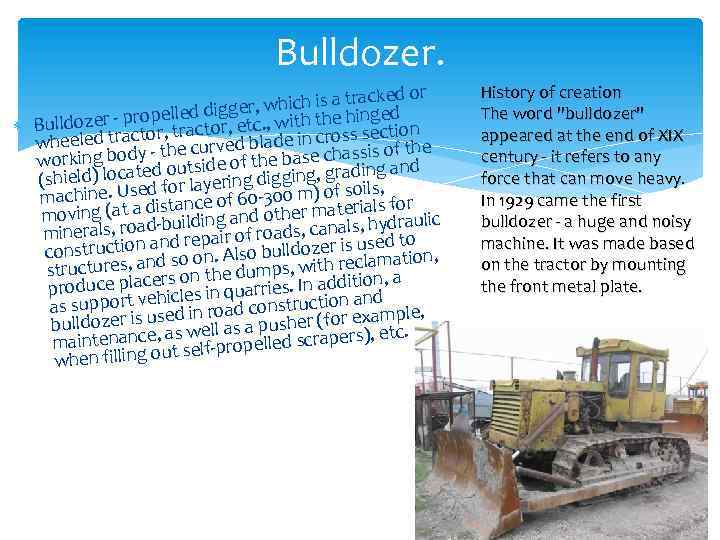

Bulldozer. cked or , which is a tra ged ed digger ozer - propellractor, etc. , with the hin tion Bulld sec tor, t wheeled tracy - the curved blade in cross sis of the s working bod ed outside of the base chading and (shield) locat d for layering digging, gra oils, machine. Use istance of 60 -300 m) of s ials for moving (at a d -building and other mater, hydraulic d minerals, roa and repair of roads, canals sed to construction d so on. Also bulldozer is ulamation, structures, an rs on the dumps, with rec n, a produce place icles in quarries. In additiod h as support vesed in road construction anample, bulldozer is u, as well as a pusher (for ex, etc. maintenance ut self-propelled scrapers) when filling o History of creation The word "bulldozer" appeared at the end of XIX century - it refers to any force that can move heavy. In 1929 came the first bulldozer - a huge and noisy machine. It was made based on the tractor by mounting the front metal plate.

Greider. Greider (born grader, from the English. Grade - level, align) - trailed or self-propelled vehicle for planning and grading areas and slopes, leveling and earth moving, snow or loose building materials. All functions grader comes with a special working body - with a knife blade that is mounted on the machine frame. It can raise, lower, rotate in a horizontal and vertical plane. Motor graders are also called motor graders. Blade graders provided with mechanical or hydraulic control, driven by the engine. Sometimes, motor graders set a subsidiary body - scarifier, which consists of 7 -11 teeth, designed to destroy the pavements and coatings for the repair of roads. Graders are used in the construction and maintenance of roads, airfields and agriculture. Length of blade graders, produced in the USSR and later in Russia - 2. 5 -4. 5 m; productivity 45 m 3 / h Automatic leveling for motor grader Graders, with volume hydraulic adjustment of the blade, can be equipped with automatic leveling systems, the use of which makes the operator's job and allows you to achieve the required parameters profiled surfaces in fewer passes grader, increasing the technical and economic performance of the machine.

der. Grei

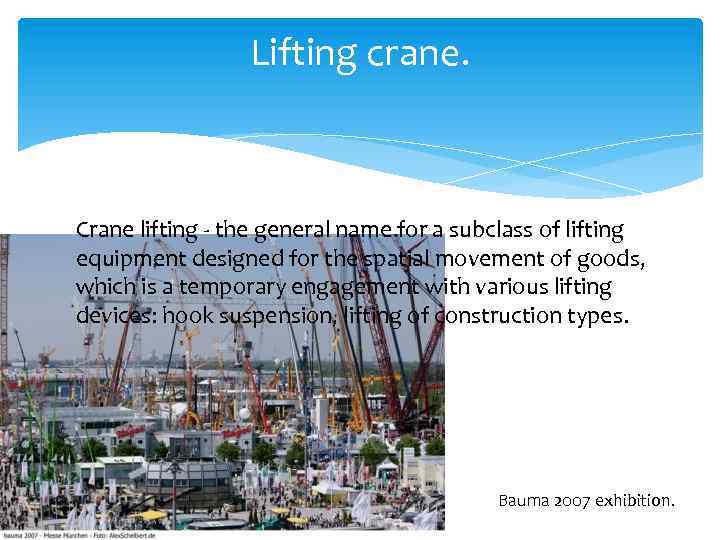

Lifting crane. Crane lifting - the general name for a subclass of lifting equipment designed for the spatial movement of goods, which is a temporary engagement with various lifting devices: hook suspension, lifting of construction types. Bauma 2007 exhibition.

History and Development. Reconstruction of the Roman crane vbonnskom Museum. Crane with manual drive XIX veka. Germaniya The simplest cranes, like most of the lifting equipment to the end of XVIII vekaizgotovlyalis of wood and had a manual transmission. In the XI-XII centuries, the development of trade and navigation, has seen first versions of modern cranes. They had a handoperated or driven topchakovyh wheels. Construction cranes initially performed from wood and the axis of the hooks and made of steel. Such a crane that has been preserved to the present day, has been designed and built in 1330. He had the ability to turn and set in motion the wheels of topchakovyh. In the XIV century in the construction of the cathedral in Cologne used a crane driven by a 2 topchakovyh wheels. This crane was lifting capacity of 5 tons and a height of 15 m. By the beginning of XIX century, responsible, wear parts (axles, wheels, clamps) have to do with metal. In the 20 -ies. XIX century, the first all-metal cranes at first hand, and in 1830 respectively - with a mechanical drive. The first steam crane set up in the UK in 1830, hydraulic - the same place in 1847. The internal combustion engine has been used in a crane, in 1895, and the electric motor to 1880 -1885 almost simultaneously in the USA and Germany. This bylimostovye cranes single-engine drive. In 1890 created cranes with a multiengine individual drive in the U. S. i. Germanii. The first prototype of the modern tower cranes appeared in 1913: the crane, established by Julius Wolff, had a rotating platform at the top of the tower. After another 15 years, there is a first tower crane beam with an arrow, and in 1952 - with a lift.

Brush Cutter. r a o cle chine designed t g a ma h Cutter - buildin om trees and shrubs. Brus e fr rk construction sit the preparatory wo d in the f machine is use This type o me on the site. based on the sa ere n made cutters are ofte dozers. For example, th Brush ll achine as the bu tractor T-100, T-130, etc. basic m ased s edge trimmers b are h Shrubs and tree ump. body scrub is a d he bottom of the pile. The working n t knives that are i of rotating discs, are cut with rm e made in the fo pplicable type. Blades can b o a ter blades are als milling, cut

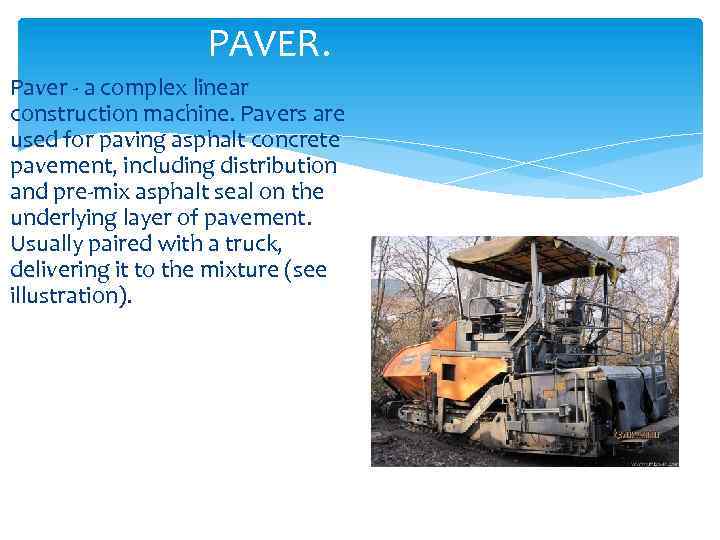

PAVER. Paver - a complex linear construction machine. Pavers are used for paving asphalt concrete pavement, including distribution and pre-mix asphalt seal on the underlying layer of pavement. Usually paired with a truck, delivering it to the mixture (see illustration).

AUTOMATION FOR leveling asphalt paver. The design of all modern asphalt can automatically process control supply, distribution and installation of pavement material. Quality construction coating can not be performed without the use of a working body to control the stacker automatic leveling, except that small area, scattered plots. In the construction of complex objects is not mounted on the stacker, as a minimum, the sensors monitoring the distribution of the material on the screw, the sensor bias controlling the angle to the horizontal plate, one or two of the height sensor, controlling the thickness of layer. On the important facilities, especially in laying a broad band of pavement, with telescoped the plate, use a more complex system of automatic leveling. ACS for asphalt and other SDM mode of transmission and processing of the control signal are divided into digital and analog. Digital instruments are created to account for the use of the latest advances in computer technology. Automatic leveling system, can be combined on the basis of universal, multi-functional, providing the possibility of using different combinations of sensors, such as the one set of ACS may include non-contact ultrasonic height sensor and transmitter-receiver laser planes.

ROCKER (of lifting devices). Manipulator (hydraulic crane, crane-manipulator) - lifting device used for loading and unloading and mounted (usually) to mobile platforms (truck or river small craft). CLASSIFICATION Manipulators are classified into: • carrying capacity • by the type of work equipment: • «Z» shaped design - the type of manipulators, a design feature which will enable the equipment manipulator behind the cab car in the transport position (across the frame of the car). • «L» shaped design - the type of manipulators, which in the transport position located above the driver's cab of the vehicle or the body (in the direction along the frame of the car). • the type of base for mounting: • An onboard vehicle - column manipulator located behind the cab (usually) or at the end of the airborne platform (rear-mounted) • tractor - column manipulator is located behind the cab • small-sized riverboat • caterpillar tractor • stationary technology platforms

Road construction machines.pptx